Abstract

A 350 MW cogeneration unit was selected as the research object to investigate a molten salt energy storage system. Key evaluation indicators, including peak shaving capacity, thermal efficiency, equivalent round-trip efficiency, and comprehensive coal consumption, were analyzed under heat storage-release strategies involving single-steam source and multi-steam source heating, combined with steam grade and steam split ratio. The thermoelectric characteristic curve of the unit during the heat storage-release phase was determined based on the storage-release characteristics of the molten salt system. The results indicate that under heat storage mode, similar peak shaving depths are achieved with both single-steam source and multi-steam source heating strategies. However, thermal efficiency is higher with the multi-steam source strategy, and peak shaving capacity improves with an increased steam split ratio. During heat release mode, higher peak shaving capacity is achieved when steam is matched with the grade of cold reheat steam.

Similar content being viewed by others

Introduction

Molten salt energy storage finds applications in photovoltaic power generation, heat treatment, and electrochemical treatment1. A series of studies and experiments involving molten salts have been conducted at Sandia Labs and various national research institutions across the EU. The primary components of molten salt include NaNO3, KNO3, Ca(NO3)2, and NaNO2. To achieve lower melting points, higher-cost additives such as LiNO3 and CsNO3 are incorporated into the formulation2. Research into the characteristics of molten salt has focused on improving the materials and proportions used3,4,5,6,7, elucidating the stability and corrosion mechanisms of molten salt under varying operational conditions8,9,10,11,12, simulating the heat transfer efficiency and energy storage effects during heat transfer and flow via hydrodynamics13,14, and studying the impact of pinch point temperature on energy storage efficiency during charging and exothermic processes15. Furthermore, molten salt energy storage is applied in grid control16 and battery energy storage17,18.

With the large-scale grid connection of wind power, photovoltaic, and other clean energy sources, the proportion of wind and solar energy in the overall power structure continues to rise. Simultaneously, the installed capacity of photovoltaic, solar thermal, and other clean energy technologies is steadily increasing. However, the inherent randomness and intermittent nature of clean energy lead to significant energy wastage. To address this, energy can be stored and released through heat storage and exothermic cycles when using molten salt as a heat transfer medium19. During the energy storage phase, heat is accumulated in the molten salt through steam heating or electric heating, which helps reduce the load of the unit. The steam, after heat exchange, can either flow into a cylinder to perform work, be directed toward heating feed water alongside the extraction steam, or discharge directly into the condenser following temperature and pressure reduction. In the energy release phase, the heat stored in the molten salt is utilized to generate superheated steam, which can be matched with the appropriate grade of live or reheat steam before entering the cylinder for work. This process may also replace some steam extraction for feedwater heating, consequently increasing electrical power output.

Current research on molten salt energy storage strategies primarily employs a single-steam source heating mode20,21,22,23,24. However, due to the impact of over-temperature conditions in the reheater and the minimum inlet steam flow requirement for the low-pressure cylinder, steam extraction and peak capacity are constrained, resulting in limited heat storage capacity. The multi-steam source energy storage mode, on the other hand, can enhance the stability and reliability of energy supply. In this setup, if one of the steam sources fails or is unstable, the remaining sources can still provide energy output, ensuring higher stability and reliability. Additionally, by optimizing the input share from each steam source under the multi-steam source energy storage mode, improved peak shaving capacity can be achieved. Therefore, it is essential to analyze the application of the multi-steam source heating storage mode in peak shaving for cogeneration units.

Under the condition of safe operation of the cogeneration unit, the multi-steam source heating storage mode utilizes a method that diverts a portion of the live steam and reheat steam to heat the molten salt. Conversely, the single steam source heating storage mode diverts only a portion of the live steam for the same purpose. EBSILON software was employed to calculate the thermal power storage and peak shaving capacity for both the single steam source and multi-steam source heating storage modes. The concept of the steam split ratio was introduced to evaluate the impact of the diversion flows of live steam and reheat steam on peak shaving increments. The analysis includes the peak promotion capacity and equivalent round-trip efficiency when steam is matched with the grades of live steam, reheat steam, and cold reheat steam during the heat release phase. Additionally, thermoelectric characteristic curves during both heat storage and heat release phase are plotted based on the peak shaving characteristics of the cogeneration unit under the multi-steam source heating storage mode.

The coupled system of cogeneration unit with molten salt

The research focuses on a 350 MW cogeneration unit, which operates under super-critical conditions with primary reheating and an indirect air-cooled turbine. The design parameters of the cogeneration unit under different working conditions are outlined in Table 1.

Steam enters the cylinder and drives the rotor to perform work. As the working process progresses, the steam pressure gradually decreases while the volume increases. The corresponding enthalpy-entropy diagram is illustrated in Fig. 1.

Molten salt serves as an effective medium for heat storage, offering stable chemical properties and a high specific heat capacity. Consequently, the integration of molten salt with cogeneration units can facilitate deep peak shaving and promote the use of clean energy. The most commonly utilized mediums for heat storage are solar salt and HITEC salt. The parameters of the molten salt are presented in Table 2.

30% of the energy carried by high-temperature steam is sensible heat, while 70% is latent heat. Utilizing the latent heat of steam necessitates the establishment of a substantial heat storage system. Consequently, steam heating storage strategies focus on employing steam sensible heat. In a cogeneration unit coupled with molten salt, high-temperature steam transfers heat to the molten salt through a molten salt heat exchanger. This heat exchange occurs without any phase transition, resulting in the high-temperature steam being converted to low-temperature steam for further consumption in the system. To enhance the storage of sensible heat, high-grade steam is typically utilized for heat exchange with molten salt. In a steam turbine, steam with a higher grade and work capacity is achieved when a greater amount of heat is transported per unit mass of steam. As illustrated in Fig. 1, live steam and reheat steam possess higher grades; thus, utilizing these in the heat exchange process can significantly increase the heat storage capacity and achieve more effective peak shaving.

When using steam sensible heat to heat molten salt, it is essential to consider the difference between the minimum working temperature of the molten salt and the saturation temperature of the steam under operational conditions. If these two parameters are very close to each other, it becomes challenging to store the steam sensible heat effectively25. Taking the 50% thermal heat absorption (THA) working condition as a reference for heat storage, the minimum working temperature of solar salt is 240 °C, which closely aligns with the saturation temperature of reheat steam (221 °C) in this benchmark scenario. The temperature difference between the minimum working temperature of HITEC salt and the saturation temperature of reheat steam is 71 °C, allowing for effective heat exchange and adequate storage of the steam’s sensible heat. Therefore, when incorporating reheat steam in heat storage, using HITEC salt with its lower operating temperature is preferable.

Heat storage-release strategy and evaluation index

Heat storage-release strategy

Live steam and reheat steam serve as heating sources to analyze and compare the heating storage strategies between a single steam source and multi-steam sources. Figure 2 presents a schematic diagram of the single steam source heat storage-release system. In the single steam source heating storage strategy, a portion of the live steam enters the preheater and heat exchanger, facilitating sensible heat exchange with cold molten salt. This process converts the cold molten salt into hot molten salt, which exhibits improved liquidity following heat exchange. The hot molten salt is then stored in a tank for heat storage. After the heat release, the steam is discharged into the condenser after undergoing temperature reduction and decompression. In the heat release strategy, feed water from the deaerator is converted into steam in the steam generator, which matches the grade of live steam and moves into the cylinder to perform work for grid power enhancement. Subsequently, the hot molten salt is transformed into cold molten salt after heat release, and the cold molten salt is stored in a tank for the next heat exchange cycle.

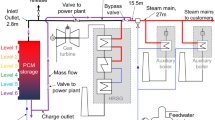

The schematic diagram of the multi-steam source heat storage-release system is illustrated in Fig. 3. Under the multi-steam source heating storage mode, a portion of live steam and reheat steam is extracted into a heat exchanger for sensible heat exchange with cold molten salt. Following this heat exchange, the cold molten salt is converted into hot molten salt with improved liquidity. The hot molten salt is then stored in a tank for heat storage. After the heat exchange with molten salt, the fractional flow of live steam is mixed into the cold reheat system for reheating, while the fractional flow of reheat steam subsequently enters the low-pressure cylinder to perform additional work. The heat release mode mirrors that of the single steam source mode.

Evaluation indices

The evaluation indices for molten salt energy storage include reliability and energy efficiency assessments. Reliability includes load increment and depth of peak shaving and promotion. Energy efficiency is evaluated based on thermal efficiency, equivalent round-trip efficiency, and comprehensive coal consumption for power generation.

Grid peak shaving and promotion increment

The increment of peak shaving is defined as the difference between the generation load under the reference condition for peak shaving and the heat storage condition. The increment of peak promotion represents the difference between the generation load during the heat release condition and the generation load during the reference condition for peak promotion.

\(\:{\Delta\:}{\text{P}}_{\text{c}},{\text{} \Delta \text{P}}_{\text{s}}\) are respectively the load increment in the process of heat storage and heat release, MW; \(\:{\text{P}}_{\text{0}}\),\(\:{\text{P}}_{\text{0}}^{{\prime\:}}\) are the power generation load of reference condition under the peak shaving and the peak promotion respectively, MW; \(\:{\text{P}}_{\text{c}}\),\(\:{\text{P}}_{\text{s}}\) are power generation load under heat storage and heat release condition, MW.

Depth of peak shaving

The depth of peak shaving is defined as the ratio of the increment of peak shaving capacity to the rated generation of the cogeneration unit.

\(\:{\text{P}}_{\text{w}}\) is the rated load of the unit, MW.

Thermal efficiency

Thermal efficiency refers to the energy conversion rate during the processes of heat storage-release.

\(\:{\eta}_{\text{c}}\),\(\:{\eta}_{\text{s}}\)are thermal efficiency under heat storage and heat release condition respectively, %. \(\:\text{Q}\text{}\),\(\:\:{\text{Q}}^{{\prime\:}}\) are the total heat under the heat storage and heat release base condition, MW. \(\:{\text{Q}}_{\text{c}}\),\(\:{\text{Q}}_{\text{s}}\) are heat of storage-release conditions respectively, MW.

Equivalent round-trip efficiency

Equivalent round-trip efficiency is defined as the ratio of the electric energy consumed by the heat storage system during the heat storage process to the increased output during the heat release process.

\(\:{\eta}_{\text{round}}\) is the equivalent round-trip efficiency, %; \(\:{\text{t}}_{\text{s}}\),\(\:{\text{t}}_{\text{c}}\) are times of heat release and heat storage, h.

Comprehensive coal consumption

The comprehensive coal consumption is defined as the ratio of the total amount of coal to the total power generation during the heat storage-release process.

\(\:{\text{G}}_{\text{cm}}\),\(\:{\text{G}}_{\text{sm}}\) are the coal consumption during heat storage and heat release, t/h. \(\:{\text{P}}_{\text{c}}\),\(\:{\text{P}}_{\text{s\:}}\) are the power generation of the unit during heat storage and heat release, MW. \(\:{\text{t}}_{\text{c}}\), \(\:{\text{t}}_{\text{s}}\) are the time during the process of storage and heat release.

Result analysis

Performance analysis of heat storage process

Heat storage performance analysis of single steam source and multi-steam source heating

The 50% THA condition is established as the reference for heat storage. Live steam and reheat steam are extracted to transfer heat to molten salt, facilitating heat storage under this reference condition. It is essential to ensure that the diversion flow of live steam and reheat steam does not exceed specified limits; excessive live steam diversion flow can lead to overheating of the reheater, while excessive reheat steam diversion flow may disrupt the balance of the unit’s axial thrust. Consequently, the diversion flow ratio of live steam must not exceed 20%, and the diversion flow ratio for reheat steam must not exceed 30%. The heat storage duration is set at 6 h, with a heat release duration of 4 h. The efficiencies of the pipeline and the molten salt heat exchanger are 0.99 and 0.98, respectively. The comparison of peak shaving performance under heat storage mode is illustrated in Fig. 4.

In the single steam source heating storage mode, a portion of the live steam is directly discharged into the condenser after heat exchange, bypassing the cylinder for work doings. As a result, only a limited flow of steam is available to achieve the intended depth of peak shaving. Conversely, in the multi-steam source heating mode, the steam continues into the cylinder to perform work post-heat exchange. The maximum heat storage capacity of the single steam source heating mode is 41 MW, whereas the maximum depth of peak shaving achieved is 13.79%. In the multi-steam source heating storage mode, the maximum heat storage capacity is elevated to 50 MW, with a peak shaving depth of 13.2%. Notably, the maximum depth of peak shaving under both heating modes is comparable; however, the heat storage capacity is greater in the multi-steam source heating configuration.

Under the heat storage phase, the thermal efficiency of heat storage decreases as the quantity of heat storage increases. When the heat storage amount is constant, the thermal efficiency of the multi-steam source heating storage mode outperforms that of the single steam source heating storage mode. In the single steam source heating storage approach, the sensible heat of high-temperature steam is utilized, while low-temperature steam is discharged into the condenser without further use after heat exchange, leading to increased cold-source losses and a decrease in thermal efficiency. Conversely, in the multi-steam source heating storage strategy, the steam is reused in the cylinder for work after heat exchange, which reduces cold-end losses and results in higher thermal efficiency. A comparison of thermal efficiency under the heat storage mode is illustrated in Fig. 5.

Impact of steam split ratio on peak shaving performance and economy

The diversion flow of live steam and reheat steam significantly influences the enhancement of peak shaving capacity and thermal efficiency. The steam split ratio is defined as the ratio of the diversion flow of reheat steam to the flow of live steam. A steam split ratio greater than 1 indicates that the flow of reheat steam is greater than that of live steam. When the steam split ratio equals 1, it signifies that the diversion flow of reheat steam matches that of live steam.

To ensure the safe operation of the unit, the diversion flow of reheat steam and live steam must not exceed 200 t/h and 150 t/h, respectively. Table 3 below presents the distribution of peak shaving shares under varying steam split ratios.

For a constant amount of heat storage, a larger steam split ratio corresponds to a greater proportion of the reheat steam split flow, resulting in an increased peak shaving increment. The increment of peak shaving, when combined with the unit mass of reheat steam, exceeds that of live steam due to the higher enthalpy of reheat steam and the greater efficiency of the mid-pressure cylinder. Maintaining a constant heat storage level while increasing the steam split ratio enhances the depth of peak shaving. The variations in thermal efficiency at different steam split ratios under heat storage mode are illustrated in Fig. 6, while the variations in peak shaving increment at different steam split ratios under the same mode are depicted in Fig. 7.

Performance analysis of heat release process

Using the 75% THA condition as the reference point for energy release, the heat release process involves heating feedwater with molten salt in a hot salt tank to achieve the appropriate steam grade before it enters the cylinder to perform work. The steam generated during this process is aligned with the parameters of live steam, reheat steam, and cold reheat steam, respectively. The peak promotion capacity is outlined in Table 4.

When the heat release capacity is held constant, and the feed water is heated to match the steam grade, it is observed that the greater the enthalpy difference between the feed water and steam, the smaller the steam increment added to the system. Consequently, the increment associated with cold reheat steam is the highest, while the increment for reheat steam is the lowest. Due to variations in steam grade, the work output potential also differs. As indicated in Table 4, the peak shaving capacity is maximized when the steam parameters after heat exchange align with those of cold reheat steam.

Equivalent round-trip efficiency reflects the energy utilization and losses that occur during the energy storage-release process. In the steam heating storage-release strategy, the equivalent round-trip efficiency ranges from 40 to 51%. As shown in Fig. 8, this efficiency gradually decreases with increasing released heat, which is influenced by the grade of the steam. The trend remains consistent: when the heat-released steam is reheat steam, the equivalent round-trip efficiency varies between 40.04% and 41.12%. In contrast, when using live steam, the efficiency ranges from 47.79 to 49.07%. Additionally, when the released steam is cold reheat steam, the efficiency varies from 49.49 to 50.81%, demonstrating the highest equivalent round-trip efficiency in this scenario. For constant heat storage-release durations, a larger peak increment results in enhanced energy conversion and utilization, leading to an increase in equivalent round-trip efficiency. The equivalent round-trip efficiency curve across different heat release conditions is depicted in Fig. 8.

During the storage-release process, comprehensive coal consumption rises as heat release capacity increases. In the heat storage phase, high-grade steam is utilized to heat molten salt, leading to decreased thermal efficiency. Specifically, as heat storage capacity increases by 1 MW, coal consumption escalates by 1.33 g/kWh. In the heat release phase, the steam produced post-heat release possesses varying grades, resulting in different coal consumption rates. If the heat release capacity increases by 1 MW, coal consumption will rise by 0.5 g/kWh, 0.52 g/kWh, and 0.61 g/kWh when matched with reheat steam, live steam, and cold reheat steam, respectively. The lowest comprehensive coal consumption, indicating the best economic efficiency, occurs when the steam is matched with the grade of reheat steam in the storage-release process. The comprehensive coal consumption curve under varying heat release conditions is illustrated in Fig. 9.

The peak shaving and peak promotion characteristics of storage-release process

The molten salt storage-release mode represents an effective heat transfer mechanism. Through the integration of the coupled system, both the heating capacity and heating area are enhanced, which improves the peak shaving and peak promotion capabilities of the unit.

Figure 10 illustrates the thermoelectric characteristic curve of the storage-release process. When the unit is not coupled to the molten salt energy storage system and the live steam flow reaches its rated value, the maximum thermal load is 267.78 MW, corresponding to a generation load of 291.42 MW. Under conditions of minimum steam admission, the maximum thermal load reduces to 102.92 MW, with the corresponding generation load at 153.53 MW. In the multi-steam source heating strategy, the live steam split flow bypasses the high-pressure cylinder and the reheat steam split flow does not pass through the medium-pressure cylinder, resulting in a decrease in power generation load and a downward shift of the thermoelectric characteristic curve. The greater the heat storage capacity, the more significant the translation amount. During the heat release phase, both the live steam flow and the heating load increase. With heat storage capacities of 30 MW and 50 MW, the maximum heating loads are 293.98 MW and 311.46 MW, respectively. As heat release capacity increases, the peak capacity for promoting load also rises, expanding the control range of power generation load, and gradually shifting the thermoelectric characteristic curve upward. Furthermore, under the multi-steam source energy storage mode, the peak shaving and peak promotion capabilities are significantly enhanced.

Conclusion

Molten salt serves as an excellent material with favorable thermodynamic properties for energy storage. To mitigate the reliance on fossil fuels and the adverse effects of carbon dioxide on the atmosphere, clean energy has been integrated into the power grid on a large scale. The use of molten salt energy storage in conjunction with a cogeneration unit for peak shaving can effectively reduce the incidence of wind and solar energy curtailment. The multi-steam source energy storage mode is proposed based on the heat transfer characteristics of molten salt. Compared to the single steam source storage mode, the multi-steam source configuration demonstrates higher heat storage and thermal efficiency while maintaining the same peak shaving capacity during the storage phase. The steam diversion ratio also impacts both peak shaving capacity and thermal efficiency; increasing steam diversion enhances peak shaving effectiveness. During the steam release phase, various strategies can be employed to match the grade of superheated steam or hot water. Aligning with the grade of superheated steam is a viable option when it is necessary to increase grid load to alleviate pressure on electricity consumption. Simulation calculations indicate that peak capacity and round-trip efficiency are maximized when superheated steam is matched with the grade of cold reheat steam. Additionally, from a comprehensive coal consumption perspective, optimal economy is achieved when superheated steam aligns with the grade of reheat steam.

Various steam resources can be integrated under the multi-steam source energy storage model to achieve diversified energy utilization. Different grades of steam and hot water can be obtained for application in various scenarios. This multi-steam source energy storage mode enhances the flexibility and adaptability of the energy system, presenting significant prospects for application in industrial, agricultural, and other fields.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Thomas, B. et al. Molten Salt Storage for Power Generation. Chemie Ingenieur Technik 93(4):534–546. (2021).

Nicole, P. et al. Thermal energy storage – overview and specific insight into nitrate salts for sensible and latent heat storage. J. Nanatechnol. 2015, 6:1487–1497 (2015).

Adrián, C. et al. Molten Salts for Sensible Thermal Energy Storage: A Review and an Energy Performance Analysis. Energies 1197(14). (2021).

Fernández, A. G. et al. Thermal characterization of an innovative quaternary molten nitrate mixture for energy storage in CSP plants. Solar Energy Mater. Solar Cells 132, 172–177 (2015).

Bernagozzi, M., Panesar, A. S. & Morgan, R. Molten salt selection methodology for medium temperature liquid air energy storage application. Appl. Energy 2019 (248), 500–511 (2019).

Raud, R., Stuart, B., Teng-Cheong, O., Geoffrey, W. & Steinberg Theodore A Optimized salt selection for solar thermal latent heat energy storage. Advanced sustainable systems. 2018, 11. Enrique Julia, J. (2018).

Navarrete, N., Mondragon, R., Wen, D., Elena Navarro, M. & Ding, Y. Thermal energy storage of molten salt -based nanofluid containing nano-encapsulated metal alloy phase change materials. Energy 167:912–920. (2019).

Kondaiah, P. & Pitchumani, R. Influence of corrosion-resistant coatings on the post-corrosion thermal stability and fouling of molten salts for high temperature thermal energy storage. J. Energy Stor. 2024, 92 (2024).

Gonzalez, M. et al. Graphitization as efficient inhibitor of the carbon steel corrosion by molten binary nitrate salt for thermal energy storage at concentrated solar power. Solar energy materials and solar cells. 203 (2019).

Bonk, A., Hanke, A., Braun, M., Ding, W. & Bauer, T. Synthetic biofuels by molten-Salt catalytic conversion: corrosion of structural materials in ternary molten chlorides. Advanced engineering materials 24(7) (2022).

Sarvghad, M., Steinberg, T. A. & Will, G. Corrosion of steel alloys in eutectic NaCl + Na2CO3 at 700℃and Li2CO3 + K2CO3 + Na2CO3 at 450 ℃ for thermal energy storage.solar energy materials and solar cells. 170, 48-59. (2017).

Sarvghad, M. et al. Investigation of the corrosion of electro-less nickel-plated alloys in molten salt and its effect on phase change properties for energy storage applications. Solar energy 236, 512–521 (2022).

Nualsing, D., Pannucharoenwong, N., Echaroj, S. & Rattanadecho, P. Investigation of molten salts incorporated with anodic aluminum oxide as thermal energy storage fluid on heat transfer efficiency. Case Stud. Therm. Eng. 2023, 49. (2023).

Hossain, M. Z., Kassaee, M. H., Jeter, S. & Teja, A. S. A new model for the thermal conductivity of molten salts. Int. J. Thermophys. 35 (2), 246–255 (2014).

Zhang, Y., Song, X., Yang, R. & Li, X. Performance of molten salt thermal energy storage system based on reheat steam extraction from coal-fired power plants. J. Chin. Soc. Power Eng. 44 (3), 448–453 (2024).

Prieto, C. et al. Use of molten salts tanks for seasonal thermal energy storage for high penetration of renewable energies in the grid. J. Energy Stor. 86 (2024).

Mahya Shahabi, N. et al. Design of a Molten Salt Metal-Air Battery with High-Energy Density. REWAS 2022: Energy Technologies and CO2 Management (Volume II). 2022, 47–57 (2022).

Zhang, S. et al. Quasi-solid-state electrolyte for rechargeable high-temperature molten salt iron-air battery. Energy Storage Mater. 35, 142–147 (2021).

Prieto, M. J. et al. On the Convenience of Using Simulation Models to Optimize the Control Strategy of Molten-Salt Heat Storage Systems in Solar Thermal Power Plants. Energie 990(10), (2017).

Wei, H. et al. Research on large-scale renewable energy power consumption by peak shaving system of coal-fired power unit integrated with thermal energy storage. Therm. Power Gener. 52 (2), 79–89 (2023).

Li, M., Sun, C. & Han, X. Research on peak regulation performance of coupled molten salt heat storage system for thermal power units. Turbine Technol. 66 (3), 198–202 (2019).

Miao, L., Liu, M., Zhang, K., Zhao, Y. & Yan, J. Thermodynamic analysis on the Coal-Fired power plant integrated with power-to-Heat molten salt thermal energy storage system. J. Eng. Thermophys. 44 (11), 3000–3006 (2023).

Peng, J. et al. Feasibility analysis of peak shaving for coal-fired units based on molten salt heat storage. Therm. Power Generation. 53 (1), 99–106 (2024).

Ren, J. et al. Analysis of flexibility and energy consumption characteristics of coal-fired power system integrated with molten salt thermal storage. J. Eng. Therm. Energy Power. 39 (2), 145–153 (2024).

Zuo, F., Han, W. & Yao, M. Application status and development trend of molten salt energy storage in novel power systems. Therm. Power Generation. 52 (2), 1–9 (2023).

Acknowledgements

This research was funded by Science and Technology project of State Grid Gansu Electric Power Company “Molten salt Heat storage thermal power cogeneration Unit of its peak operation and peak regulation capacity technology Research”, grant number LNKJ-QT-20230822-YF08.

Author information

Authors and Affiliations

Contributions

Lin-kui FENG conceived the theory, Yao-fei FENG and Ke LU collate and calculate the data, Ping WANG, Kai ZHAO and Zhi-de GU analyzed the results. Yan-nan REN and Sheng-lu XIE write the manuscript. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Feng, Lk., Feng, Yf., Lu, K. et al. The analysis of molten salt energy storage mode with multi-steam sources heating in thermal power unit peak shaving operation. Sci Rep 15, 11305 (2025). https://doi.org/10.1038/s41598-025-95901-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-95901-2