Abstract

To enhance the insulation performance, strength, and fire resistance performance of foamed concrete, this paper investigates the effects of incorporating nano-silica aerogel and expanded perlite. A comprehensive comparison and analysis were conducted on the dry density, water absorption, mechanical performance, thermal conductivity, fire-resistant insulation, and microstructure of both Nano-SiO2 Aerogel Foamed Concrete (NSAFC) and Expanded Perlite Foamed Concrete (EPFC). The findings indicate that as the Nano-SiO2 Aerogel (NSA) content increases, the water absorption of the foamed concrete gradually rises. Conversely, the water absorption of the foamed concrete test blocks first increases and then decreases with an increase in Expanded Perlite (EP) content. It is noteworthy that, incorporating 10% NSA and EP reduces the dry density of foamed concrete by 12.7% and 7.8%, respectively. When EP content reaches 6%, the 28-d flexural and compressive strengths of the foamed concrete test blocks increase by 73.5% and 54.2%, respectively. Similarly, at NSA content of 6%, the 28-d flexural and compressive strengths increase by 70.5% and 39.6%, respectively. The fire-resistant insulation tests demonstrate that NSAFC exhibits superior thermal insulation and fire resistance performance compared to EPFC. Furthermore, SEM images demonstrate that the pore structure of NSAFC is more uniform.

Similar content being viewed by others

Introduction

The building sector consumes approximately 40% of total energy consumption1,2, with a building’s energy efficiency closely tied to its thermal insulation performance. The incorporation of thermal insulating materials can significantly decrease a building’s energy consumption3,4. In recent years, foamed concrete, an emerging thermal insulation material, has gained widespread adoption in the building energy-saving industry due to its advantages over ordinary concrete, including low density, superior thermal insulation, excellent fire resistance performance, and ease of construction5,6. Numerous studies have focused on developing high-performance foamed concrete by reducing its thermal conductivity and density while enhancing its mechanical strength. Zhou et al.7 investigated the impact of various admixture ratios on the attributes of lightweight, high-strength foamed concrete. This was achieved through the application of chemical foaming and the strategic incorporation of three materials—silica fume, slag, and fly ash—in optimized proportions within a cement-fine sand matrix. Li et al.8 examined the influence of foaming gas and cement type on the thermal conductivity of foamed concrete. Their results indicated that the thermal conductivity of foamed concrete is directly proportional to the thermal conductivity of the foaming gas. To enhance the structural integrity of foamed concrete, some researchers incorporated basalt fibers with silica fume. They prepared 18 mixtures with varying contents of foaming agents, basalt fibers, and silica fume, and systematically evaluated the physicomechanical performance, durability, and thermal insulation properties of the resultant foamed concrete. Based on these findings, a highly durable foamed concrete was developed9. Falliano et al.10 discovered that polymer fibers significantly increased the flexural strength of foamed concrete, with minimal impact on its compressive strength. Zhang et al.11 added fly ash to foamed concrete and observed that as the fly ash dosage increased, the dry bulk weight and thermal conductivity of the foamed concrete first decreased and then increased, while the compressive strength gradually declined. At a fly ash dosage of 40%, the dry bulk weight and thermal conductivity of the foamed concrete reached their minimum values of 336 kg/m³ and 0.0824 W/(m·K), respectively, with a compressive strength of 0.63 MPa.

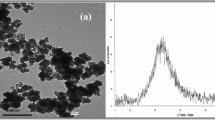

Nano-SiO2 Aerogel (NSA) have superior properties such as highly nanoporous, thermal conductivity as low as 0.013 W/(m·K) at room temperature, excellent insulating properties, and good fire safety12,13,14. Expanded Perlite (EP)is a lightweight porous material obtained by the high-temperature expansion treatment of perlite ore15,16, which is well accepted by the market and exerts its effect with its good heat preservation efficacy and superb stability, as well as a wide range of applications with universal utility, especially in the fire-resistant heat preservation and energy saving to play an excellent performance17,18,19.

In this study, the composite foamed concrete with good thermal insulation, mechanical properties and light weight was prepared by using ordinary Portland cement as matrix, using 2%, 4%, 6%, 8%, 10% mass of NSA and EP, respectively. In this paper, the changes in the dry density, water absorption, mechanical performance, thermal conductivity, fire-resistant insulation of NSAFC and EPFC materials were investigated. Then, the samples’ pore structure, chemical composition, and micromorphology were analyzed. The results of the study can provide a reference for the development of cement-based multifunctional materials. The results of this experiment have important guiding significance for industrial application, which can help optimize the formula of foamed concrete, improve its performance, expand its application range, and have a positive impact on construction, transportation, environmental protection and other fields.

Materials and methods

Materials

Ordinary silicate cement (P·O42.5) of grade 42.5 MPa provided by Zhucheng City Jiuqi Building Materials Co. in Shandong Province was utilized. The water-reducing agent is FDN-C (Na2SO4 content of 18%) naphthalene water-reducing agent, brown powder, water reduction rate of up to 20% or more. Foaming agent for animal protein blowing agent, supplied by Jiangsu Tingan Fire Protection Materials Co. Foam stabilizer is produced by Dongguan Shanyi Plasticizing Co., Ltd, the main ingredient is calcium stearate, analytical purity. The NSA was produced by Zhongning Technology Co., Ltd (Shenzhen, China). EP is manufactured by Henan Yixiang New Material Co. Ltd, the particle size is 0.4–0.6 mm, a packing density of 0.35 g/cm³, a cylinder compressive strength of 51KPa.

Mixture design and sample preparation

The control sample (K0) of the blends used in the experiment was determined based on the results of previous experiments conducted by the group. Ten groups of mixes were selected for this experiment, the first five groups were NSAFC groups the last five groups were EPFC groups, and the number of samples was in the form of NSFC/EPFC-a/b, where a is the percentage of cement replaced by an equal mass of NSA, and similarly, b is the percentage of cement replaced by an equal mass of EP (Among them, a and b are the optimal test proportions summarized according to the reading of a large number of literature and relevant standards). Specific mix ratio are shown in Table 1. In this study, the dry density, water absorption, mechanical performance, thermal conductivity, and fire-resisitant insulation of NSAFC and EPFC were tested respectively. In addition, the chemical composition and microstructure of the test block were studied to reveal its mechanism.

The production process of the specimen is shown in Fig. 1. Firstly, we weighed each component material according to the proportion, and poured the weighed cement, water-reducing agent, foam stabilizer, and NSA/EP into the NJ-160 cement mortar mixer slowly, and mixed them for 2 min, then added 2/3 of the weighed water according to the water-cement ratio (0.45), and stirred it for 2 min to get the mixed cement mortar with NSA/EP. Then added the remaining 1/3 of water, and stirred for 3 min, while the foaming agent was diluted with water by 1:40, and high-speed mixer mixing to produce foam, the foam should be added to the mixing slurry within 1 min, and stirred for 2 min, static stop 15s, clean up the foam inside the wall of the mixer, and then stirred for another 1 min, to complete the mixing. The mixture was then poured into the corresponding molds and cover with plastic wrap. After 48 h of curing at room temperature, the specimens were taken out of the molds and put into the cement constant temperature and humidity standard curing box for 28d for testing, of which the mechanical performance were measured once in 7d.

Test Mthods

Dry density

By JG/T 266–201120 to test the dry density of foamed concrete, the specimen was placed in the drying oven at a temperature of (60 ± 5)℃ dry to the front and back of the two times separated by 4 h the difference in mass is not greater than 1 g, remove the specimen and wait for the specimen to be cooled to room temperature, weigh the sample drying mass, accurate to 1 g, the formula (1) calculated dry density.

Eq: \(\:\rho\:\)0 ----dry density in kg/m³, accurate to 0.1; \(\:{m}_{0}\)----dry mass of the specimen in g; V----volume of the specimen, in mm3.

Water absorption

According to the standard JG/T 266–201120, after testing the dry density, the specimen is put into the electrothermal thermostatic water bath box with a water temperature of (20 ± 5) ℃, and then the water is added to 1/3 of the height of the specimen, and kept for 24 h, and then added to 2/3 of the height of the specimen, and then, after 24 h, the water is added to be higher than the specimen by more than 30 mm, and kept for 24 h. The specimen is finally removed from the water, and the surface water is wiped off with a wet cloth, and the mass of each specimen should be weighed immediately, accurate to 1 g, and the water absorption rate is calculated by:

Eq: WR ----water absorption, %, accurate to 0.1; \(\:{m}_{g}\)----mass of specimen after water absorption, in g; \(\:{m}_{0}\)----mass of specimen after drying, in g.

Flexural and compressive strengths

The flexural and compressive strengths test was by JG/T 266–201120. Three samples were taken from each mixture. The flexural strength of the specimens was determined at 7 and 28 days of curing, respectively, with a sample size of 40 mm × 40 mm × 160 mm, and the flexural strength of the mixtures was obtained by averaging the three samples. After completion of the flexural test, the fracture specimens were subjected to a compressive strength test, the compressive test was conducted on a bearing surface size of 40 mm × 40 mm, and the compressive strength of the mixture was obtained by averaging six samples.

Thermal conductivity

The thermal conductivity of each mixture was tested on three samples respectively, by the requirements of JG/T 266–201120. The thermal conductivity of the mixtures was measured at the end of the 28-day curing cycle, with a sample size of 300 mm × 300 mm × 30 mm. Before the test, the surface of the specimen was polished and smoothed, and then the sample was placed in the electric blast thermostatic drying oven, and the temperature was set to 60 °C. The mass was weighed every 4 h until the difference of the mass was no more than 1 g. Then the sample was regarded as having been dry. The test was carried out using a JTRG-III thermal conductivity tester, with the temperature of the hot plate set at a target temperature of 40 °C during the measurement period and the target temperature of the cold plate set at 5 °C, and readings were taken after the heat flow had stabilized. The thermal conductivity of the mixture was obtained by averaging the three samples. This instrument uses a symmetrical arrangement of a single specimen with two heat flow meters, and the test specimen is placed in a flat plate that is parallel to each other and has a constant temperature, in the steady state, the heat flow meter and the center measurement portion of the specimen, have a one-dimensional constant heat flow, and at this time, the output of the hot, cold plate heat flow meter is measured and the surface temperature value and the value of thermal conductivity can be calculated for that averaged temperature.

Fire resistance and heat insulation

The fire resistance performance and thermal insulation of the specimen are assessed by recording the IR pyrometer test temperature when the specimen is subjected to the flame of the ethane torch at its center point21. The infrared pyrometer measures the surface temperature of an object. A butane torch produces a flame of approximately 600 °C, simulating a fire with an unrestricted oxygen supply. Three specimens, blank group K0, NSAFC-10%, and EPFC-10%, were tested separately, and the temperatures at five-minute intervals were recorded at the center of the spray surface of the specimen subjected to the gun and at the center of the opposing surface.

X-ray diffraction

After the flexural strength test, a sufficient number of small pieces were selected from the middle of the broken specimens, which were ground and passed through a 200-mesh sieve for the phase analysis test. The chemical composition of the samples was quantitatively analyzed by an X-ray diffractometer (model: Rigaku SmartLab SE, Japan). The instrument used a Cu target with a maximum tube flow rate of 60 mA, a maximum tube pressure of 60 kV, a diffraction angle scanning range of 10°−80°, a step size of 0.02° used for the test, and a scanning speed of 5°/min. XRD patterns were analyzed using the Jade 9.0 software.

Scanning electron microscope

At the end of the flexural test, the SEM specimen was taken from the middle height of the crack cross-section side in the bending test samples since the mixture on both sides of the tensile crack was not damaged, thus reflecting the true structure of the mixture as much as possible. The samples were pumped and sprayed with gold for micro-morphological characterization. A scanning electron microscope (model: TESCAN MIRA LMS ) was used to observe the micromorphology of the samples, and an energy spectrum scanner (model Oxford Xplore 30) was used for elemental scanning and analysis at the end of the observation.

Results and discussions

Water absorption

Figure 2(a) shows the change in water absorption of NSAFC or EPFC. The NSA has a very high specific surface area22, which can increase the effective surface area of the foamed concrete specimen when added, thus increasing the water absorption rate. The addition of NSA will also affect the crystal morphology and arrangement of the hydration reaction of the cement23, which will increase the microscopic defects and porousness in the structure of the test block, and thus increase the water absorption rate.

The water absorption of foamed concrete increases first and then decreases with the increase of EP content. The reason is that EP has a good affinity to the cement matrix, which is conducive to compatibility with the cement cementing system and promotes the hydration reaction of cement, which helps to form more capillary structures, thus increasing the water absorption performance of the test block24. However, too high content (> 4%) may cause the instability of the pore structure, and eventually lead to the closure or blockage of the pore, thus reducing the water absorption of the test block25.

In general, both NSA and EP affect the water absorption rate of foamed concrete test blocks, and after comparative analysis, NSA has a greater impact on the water absorption rate of foamed concrete test blocks. The incorporation of more EP can reduce the water absorption rate of the foamed concrete test block, in addition, the lower water absorption rate of foamed concrete can improve its impermeability, which is conducive to the application of foamed concrete in the retaining wall and embankment, waterproofing of building facades and underground structures.

Thermal conductivity and dry density

Fig. 2(b) represents the change of thermal conductivity of NSAFC and EPFC materials. It can be seen that the thermal conductivity of both NSAFC and EPFC specimens decreases gradually with the increase in the content of NSA and EP. When the content of NSA was 10%, the thermal conductivity of the test block was 0.186 W/(m·K), which was 30.9% lower than that of the K0 group. This is because NSA has nanoscale characteristics, and the distance between its tiny particles is shorter, which is conducive to hindering heat conduction26,27, in addition, NSA has a porous structure, and these microscopic pores can reduce the conduction of gases and heat. Therefore, the incorporation of NSA can effectively reduce the rate of heat conduction inside the foamed concrete test block and lower the thermal conductivity.

When the content of EP was 10%, the thermal conductivity of the test block was 0.201 W/(m·K), which was 25.3% lower than that of the K0 group. This is because EP has a microscopic pore structure, and these pores can reduce the conduction of thermions and thermal radiation, and play the role of heat insulation, in addition, EP, as a kind of lightweight aggregate, has a lower density and heat capacity28,29, after the addition of EP, the average heat capacity of the whole of the EPFC may increase, which slows down the rate of storing and releasing heat when the temperature changes.

Figure 2(c) represents the change in dry density of NSAFC and EPFC. When the content of NSA was 10%, the dry density of the test block was 772 kg/m3, which was 12.7% lower than that of the K0 group. The incorporation of NSA helps to improve the foaming effect of the blowing agent, which makes the bubbles more uniform, fine, and stable, these fine bubbles can reduce the bulk density of the cement specimen, which further reduces the dry density of the cement specimen. In addition, the NSA has good volcanic ash activity, and can react with calcium hydroxide in the hydration products of cement to generate more C-S-H gels30, these gels fill in the pores of the cement matrix, making the structure of the test block more dense, thus reducing its dry density.

When the content of EP was 10%, the dry density of the test block was 815 kg/m3, which was 7.8% lower than that of the K0 group. This is because when EP is mixed into the foamed concrete, due to its lightweight properties, it will reduce the weight of the overall material, thus decreasing the dry density of the test block, secondly, the porous structure of EP can form more voids in the foamed concrete, and these voids further reduce the mass of the test block and increase its volume, which leads to the decrease of the dry density.

Mechanical performance

From Fig. 3, it can be seen that the flexural and compressive strengths of foamed concrete specimens first increased and then decreased with the increase of NSA content and EP content. From Fig. 3, When the NSA content is 6%, the 28-d flexural strength and 28-d compressive strength of the NSAFC specimens reach a maximum of 5.8 MPa and 6.7 MPa, respectively. The reason for this is analyzed: the moderate addition of NSA could fill the microscopic pores and cracks in the cement matrix, which helped to increase the densification and the structural stability of specimens, thus improving the mechanical properties; however, too high a dosage (> 6%) may lead to aggregation or agglomeration between particles, which affects the bonding with the cement matrix and makes the internal structure of the specimen loose, thus affecting the mechanical properties of the foamed specimen.

From Fig. 3, When the EP content is 6%, the 28-d flexural strength and 28-d compressive strength of the NSAFC specimens reach a maximum of 5.9 MPa and 7.4 MPa, respectively. The reason for this is analyzed: with the increase of EP content, the interaction between the particles increases, and the overall stability and mechanical properties of the test blocks are improved; however, too much doping (> 6%) will increase the porosity of the test block, making more voids and bubbles in the test block, and this increase in porosity may lead to a decrease in the overall densification of the test block. In addition, too much EP will disturb the crystal structure of the cement matrix, which will affect the mechanical properties of the test block.

In short, the EP admixture has a better effect on the improvement of the mechanical performance of the foamed concrete, when the amount of EP admixture of 6%, the 28d flexural strength and compressive strength of the foamed concrete specimen are increased by 73.5% and 54.2%, respectively. While when the amount of NSA is 6%, the 28d flexural strength and compressive strength of the foamed concrete specimen are increased by 70.5% and 39.6%, respectively.

Fire resistance and heat insulation

Fig. 4(a) indicates the temperature changes of the center of the heated surface and the opposite of the heating surface by infrared thermometer when different specimens were subjected to the flame of the butane gun at the center point of the specimen. The analysis of Fig. 4(a) shows that: three kinds of foam concrete materials with different ratios have excellent thermal insulation properties, and the temperature at the center of the heated surface reaches approximately 614 ℃ at 30 min, and the opposite sides of NSAFC, EPFC and FC material heating surface are 72.5℃, 81.4℃ and 115.6℃ respectively. The adiabatic rates were 88.17%, 86.72%, and 81.14%, respectively.

From Fig. 4(b), it can be seen that none of the heated specimen surfaces were damaged, therefore, in terms of thermal insulation performance, the NSAFC material had the best thermal insulation performance, the EPFC material was the second best, and the FC material had the worse thermal insulation performance. Fire resistance performance of insulation materials is important for buildings, especially high-rise buildings, to allow sufficient time for evacuation before the structural integrity of the building is compromised.

Composition and surface chemistry

The XRD spectra of NSAFC and EPFC materials are illustrated in Fig. 5. As can be seen from Fig. 5, the XRD spectra of NSAFC and EPFC show similar features in terms of diffraction peaks, except that the individual diffraction peaks have slightly different intensities. XRD analysis shows that NSAs and EP affect the formation and decomposition of calcium compounds in foamed concrete-based materials, respectively, increasing in Ca(OH)2 content and a decrease in calcium carbonate content. NSA exhibits high pozzolanic activity, enabling it to react with the cement hydration product Ca(OH)₂ through a pozzolanic reaction, thereby generating more C-S-H gel. In contrast, EP has lower pozzolanic activity, resulting in a slower or less complete reaction with Ca(OH)₂. As a consequence, less Ca(OH)₂ is consumed in EPFC, leading to a higher intensity of the Ca(OH)₂ diffraction peak. On the one hand, the increased content of Ca(OH)2 can have an impact on the crystal structure and microscopic properties in the cement, helping to form a tighter structure and a more uniform finished product, while also helping to improve the mechanical performance and durability of foamed concrete-based materials, making them more resistant to chemical erosion, moisture penetration, and other environmental effects31. On the other hand, the reduction of CaCO3 content can improve the resistance of cement-based materials to sulfate attack, and the reduction of CaCO3 may also affect the compressive strength and other physical properties of concrete32.

The comparison in Fig. 5 shows that the Ca(OH)2 diffraction peak intensity in EPFC is higher than that in NSAFC, which also verifies that the mechanical performance of EPFC are superior to those of NSAFC.

Microstructure

Figure 6 shows the microscopic morphology of NSAFC and EPFC materials at 200 μm scale for 28-d. From Fig. 6, it can be seen that the structure of the foamed concrete specimens without the addition of NSA and EP is not dense. With the increase in the dosage of NSA and EP, the microstructure of the specimen at this scale was gradually densified. As shown in Fig. 6, at the scale of 200 μm, compared with the specimen with EP, the pore size and distribution of the specimen with NSA are more uniform. This is because the particle size of NSA is extremely small, enabling it to effectively fill the micro-pores and transition zones in the cement matrix, resulting in a denser and more uniform pore structure. This filling effect reduces the formation of larger pores, thereby improving the uniformity of pore distribution. The uniform pores can enhance the thermal insulation performance of the specimen.

Conclusion

NSAFC and EPFC materials were prepared by substituting ordinary silicate cement (P·O42.5) with NSA and EP, in some of the foamed concrete materials by incorporating different dosing amounts. A comprehensive investigation was conducted into the dry density, water absorption, mechanical performance, thermal conductivity, fire-resistant insulation, and microstructure of these materials. Based on the findings, the following conclusions can be drawn:

-

1.

(1) The water absorption rate of the foamed concrete materials exhibits an upward trend as the incorporation of NSA increases. Conversely, the water absorption rate of the foamed cementitious materials initially rises and then declines with an increase in EP incorporation. These differing changes in water absorption rate are primarily attributed to the distinct effects that NSA and EP have on the pore structure of the foamed concrete materials.

-

2.

(2) In terms of enhancing mechanical performance, the incorporation of EP yields superior results compared to NSA for foamed concrete materials. Specifically, when 6% of EP was incorporated, the 28-d compressive strength of the foamed concrete specimens improved by approximately 54.2%. In contrast, when 6% of NSA was incorporated, the 28-d compressive strength of the specimens increased by about 39.6%.

-

3.

(3) With the increase of the dosage of NSA, the thermal conductivity of the foamed concrete-based material decreased by 30.9%, and the dry density decreased by 12.7%, while the dosage of EP decreased the thermal conductivity of the foamed concrete-based material by 25.3%, and the dry density decreased by 7.8%. In practical engineering applications, foamed concrete materials as thermal insulation materials, lightweight and low thermal conductivity is very important.

-

4.

(4) In many countries and regions there are strict regulations on the fire performance of building materials, fire resistance performance for engineering materials is a key indicator that must be considered, at temperatures up to 614 ℃, NSAFC and EPFC materials are not damaged on the surface, and compared with EPFC materials NSAFC materials have better thermal insulation.

-

5.

(5) NSAFC and EPFC exhibit significant advantages in terms of environmental friendliness, fire resistance, durability, and structural performance, making them high-performance building insulation materials. Although polystyrene foam (EPS) and rock wool boards perform well in certain aspects, such as thermal insulation, their poor fire resistance, environmental impact, and durability limit their widespread application in modern construction. Therefore, NSAFC and EPFC hold great potential for application in green building and sustainable development fields.

-

6.

(6) The exceptional fire resistance of NSAFC and EPFC, holds significant implications for high-rise building applications. In high-rise structures, where fire safety is a critical concern due to the potential for rapid vertical fire spread and challenges in evacuation, the use of non-combustible materials like NSAFC and EPFC can substantially enhance building safety.

As expected, the NSA has a more significant effect on the reduction of thermal conductivity of the foamed cementitious materials, while the EP has a better effect on the improvement of the mechanical performance of the foamed cementitious materials. However, in this study, only the effects of incorporating NSA and EP on the foamed cementitious materials were discussed separately, and a comparative analysis was made. The effect of compound incorporation of both of them still needs to be further investigated.

Environmental impact assessment and economic feasibility

Recyclability and reuse potential

The NSA has a high degree of chemical stability and durability and is not prone to degradation or chemical reactions, which allows it to remain intact after the building is demolished. NSA usually comes in powder or block form and is easy to separate and recycle from building materials. The recovered NSA can be reused to produce new insulation materials, such as composite insulation panels or insulation mortar. NSA can be used in industrial insulation, pipeline insulation and other fields to reduce the need for new materials. In addition, recycled NSA can be used to make lightweight composites, adsorbents (such as oil treatment), or acoustic materials.

EP is an inorganic material that is not easily degraded or aged and has good durability. EP usually exists in granular form and is easy to separate and recycle from building materials. Recycled EP can be used to produce lightweight concrete, reducing the self-weight of building structures. EP can also be used for soil improvement or as a horticultural substrate to improve soil permeability and water retention. In addition, EP’s porous structure makes it suitable for use as a water treatment or industrial filtration material.

Trade-offs and net environmental benefits

(1) Environmental impact during the production phase.

NSA: The production process of NSA, such as sol-gel methods and supercritical drying, is energy-intensive, resulting in a significant carbon footprint. Additionally, the extraction and processing of silicon sources (e.g., sodium silicate or tetraethyl orthosilicate) required for NSA production also have environmental impacts.

EP: The production of EP involves heating perlite to temperatures between 800 °C and 1200 °C, which consumes substantial energy and generates carbon emissions.

(2) Environmental benefitsduring the use phase.

NSA: The extremely low thermal conductivity of NSA significantly reduces the energy consumption of buildings, thereby decreasing carbon emissions during the use phase. The long lifespan of NSA also reduces the frequency of material replacement, minimizing long-term environmental impacts.

EP: The lightweight nature of EP reduces the amount of material required for building structures, lowering resource consumption. Additionally, the fire-resistant properties of EP enhance building safety, reducing the risk of fire and its associated environmental impacts.

(3) Environmental impact during the disposal phase.

Recyclability: The chemical stability of NSA makes it easy to recycle and reuse, reducing the environmental pressure from waste. Similarly, the inorganic nature of EP allows it to be easily recycled and reused, minimizing waste generation.

Low Pollution: Neither NSA nor EP degrades or releases harmful substances after disposal, resulting in minimal environmental impact.

(4) Comprehensive environmental impact.

NSA: Although the production of NSA is energy-intensive, its high thermal insulation performance and long lifespan significantly reduce the energy consumption and carbon emissions of buildings during the use phase, resulting in a high overall environmental benefit.

EP: While the production of EP is also energy-intensive, its lightweight, fire-resistant, and recyclable properties give it a high environmental benefit in construction applications, particularly in lightweight concrete and horticulture.

Economic feasibility

Table 2. shows the comparison of NSAFC and EPFC with traditional building insulation materials. Although the initial costs of NSAFC and EPFC may be slightly higher than those of traditional materials such as EPS and rock wool boards, their excellent thermal insulation performance, fire resistance, durability, and long-term economic benefits make them highly economically viable in practical applications. Particularly in high-rise buildings, green buildings, and projects with high fire safety requirements, the comprehensive cost-performance advantages of NSAFC and EPFC are more pronounced. In the future, with advancements in production technology and large-scale application, their costs are expected to further decrease, enhancing their economic feasibility even more.

Data availability

Data will be made available by the corresponding author upon request.

References

Adhikary, S. K. & Ashish, D. K. Turning waste expanded polystyrene into lightweight aggregate: towards sustainable construction industry. Sci. Total Environ. 837, 155852. https://doi.org/10.1016/j.scitotenv.2022.155852 (2022).

Berardi, U. A cross-country comparison of the Building energy consumptions and their trends. Resour. Conserv. Recycl. 123, 230–241. https://doi.org/10.1016/j.resconrec.2016.03.014 (2017).

Song, Y. et al. Foamed geopolymer insulation materials: research progress on insulation performance and durability. J. Clean. Prod. 444, 140991. https://doi.org/10.1016/j.jclepro.2024.140991 (2024).

Peng, Z. et al. Direct conversion of blast furnace ferronickel slag to thermal insulation materials. Constr. Build. Mater. 412, 134499. https://doi.org/10.1016/j.conbuildmat.2023.134499 (2024).

Gencel, O. et al. Lightweight foam concrete containing expanded perlite and glass sand: Physico-mechanical, durability, and insulation properties. Constr. Build. Mater. 320, 126187. https://doi.org/10.1016/j.conbuildmat.2021.126187 (2022).

Shi, J. et al. Physico-mechanical, thermal properties and durability of foamed geopolymer concrete containing cenospheres. Constr. Build. Mater. 325, 126841. https://doi.org/10.1016/j.conbuildmat.2022.126841 (2022).

Zhou, B., Zhao, Y. & Li, Z. New type of lightweight high-strength foamed concrete blocks, IOP Conference Series: Earth and Environmental Science 570(5) 052015. (2020). https://doi.org/10.1088/1755-1315/570/5/052015

Li, T., Huang, F., Zhu, J., Tang, J. & Liu, J. Effect of foaming gas and cement type on the thermal conductivity of foamed concrete. Constr. Build. Mater. 231, 117197. https://doi.org/10.1016/j.conbuildmat.2019.117197 (2020).

Gencel, O. et al. Basalt fiber-reinforced foam concrete containing silica fume: an experimental study. Constr. Build. Mater. 326, 126861. https://doi.org/10.1016/j.conbuildmat.2022.126861 (2022).

Falliano, D., De Domenico, D., Ricciardi, G. & Gugliandolo, E. Compressive and flexural strength of fiber-reinforced foamed concrete: effect of fiber content, curing conditions and dry density. Constr. Build. Mater. 198, 479–493. https://doi.org/10.1016/j.conbuildmat.2018.11.197 (2019).

Zhang, D., Ding, S., Ma, Y. & Yang, Q. Preparation and properties of foam concrete incorporating fly Ash. Materials 15 (18), 6287. https://doi.org/10.3390/ma15186287 (2022).

Shah, S. N., Mo, K. H., Yap, S. P. & Radwan, M. K. H. Towards an energy efficient cement composite incorporating silica aerogel: A state of the Art review. J. Building Eng. 44, 103227. https://doi.org/10.1016/j.jobe.2021.103227 (2021).

Liu, Z. et al. Atmospheric drying Preparation and microstructure characterization of fly Ash aerogel thermal insulation material with superhydrophobic. Constr. Build. Mater. 303, 124425. https://doi.org/10.1016/j.conbuildmat.2021.124425 (2021).

Zhang, H. et al. Dynamic thermal performance of ultra-light and thermal-insulative aerogel foamed concrete for Building energy efficiency. Sol. Energy. 204, 569–576. https://doi.org/10.1016/j.solener.2020.04.092 (2020).

Jia, G. H., Guo, J. M. & Li, Z. Controllable Preparation of aerogel/expanded perlite composite and its application in thermal insulation mortar. Constr. Build. Mater. 394 https://doi.org/10.1016/j.conbuildmat.2023.132257 (2023).

Alexa-Stratulat, S. M. et al. Effect of expanded perlite aggregates and temperature on the strength and dynamic elastic properties of cement mortar. Constr. Build. Mater. 438 https://doi.org/10.1016/j.conbuildmat.2024.137229 (2024).

Yan, Y. et al. Application of expanded perlite immobilized microorganisms in cementitious materials. J. Building Eng. 76, 106834. https://doi.org/10.1016/j.jobe.2023.106834 (2023).

Yan, Y. et al. Mechanical properties and Frost resistance of self-healing concrete based on expanded perlite with different particle sizes as microbial carrier. Constr. Build. Mater. 422, 135450. https://doi.org/10.1016/j.conbuildmat.2024.135450 (2024).

Jalali, M. R., Kaushik, D., Verma, S. & Singh, H. A coupled model of finite element method and Mie theory for heat transfer inside expanded perlite vacuum insulation panels (VIPs) at high temperatures. Int. J. Heat Mass Transf. 219, 124885. https://doi.org/10.1016/j.ijheatmasstransfer.2023.124885 (2024).

JG/T266-. Foam concrete, Ministry of Housing and Urban-Rural Development of the People’s Republic of China, 2011. (2011).

Yu, Z. L. et al. Fire-Retardant and thermally insulating Phenolic-Silica aerogels. Angewandte Chemie-International Ed. 57 (17), 4538–4542. https://doi.org/10.1002/anie.201711717 (2018).

Zhang, X. et al. Tough, ultralight, and Water-Adhesive graphene/natural rubber latex hybrid aerogel with sandwichlike cell wall and biomimetic Rose-Petal-Like surface. ACS Appl. Mater. Interfaces. 12 (1), 1378–1386. https://doi.org/10.1021/acsami.9b18948 (2020).

Goyal, R., Verma, V. K. & Singh, N. B. Hydration of Portland slag cement in the presence of nano silica. Constr. Build. Mater. 394, 132173. https://doi.org/10.1016/j.conbuildmat.2023.132173 (2023).

Kapeluszna, E., Kotwica, L. & Nocun-Wczelik, W. Comparison of the effect of ground waste expanded perlite and silica fume on the hydration of cements with various tricalcium aluminate content - Comprehensive analysis. Constr. Build. Mater. 303, 124434. https://doi.org/10.1016/j.conbuildmat.2021.124434 (2021).

Jia, G., Li, Z., Liu, P. & Jing, Q. Preparation and characterization of aerogel/expanded perlite composite as Building thermal insulation material. J. Non-cryst. Solids. 482, 192–202. https://doi.org/10.1016/j.jnoncrysol.2017.12.047 (2018).

Meng, F., Elsahati, M., Liu, J. & Richards, R. F. Thermal resistance between amorphous silica nanoparticles. J. Appl. Phys. 121 (19). https://doi.org/10.1063/1.4983753 (2017).

Liu, M., Qiu, L., Zheng, X. H., Zhu, J. & Tang, D. W. Study on the thermal resistance in secondary particles chain of silica aerogel by molecular dynamics simulation. J. Appl. Phys. 116 (9). https://doi.org/10.1063/1.4894511 (2014).

Rashad, A. M. A synopsis about perlite as Building material - A best practice guide for civil engineer. Constr. Build. Mater. 121, 338–353. https://doi.org/10.1016/j.conbuildmat.2016.06.001 (2016).

Raji, M. et al. Kacem Qaiss, utilization of volcanic amorphous aluminosilicate rocks (perlite) as alternative materials in lightweight composites. Compos. Part. B-Engineering. 165, 47–54. https://doi.org/10.1016/j.compositesb.2018.11.098 (2019).

Wan, Y., Wang, J. & Li, Z. Effect of modified SiO2 aerogel on the properties of inorganic cementing materials. Mater. Lett. 341, 134217. https://doi.org/10.1016/j.matlet.2023.134217 (2023).

Barbhuiya, S. A., Gbagbo, J. K., Russell, M. I. & Basheer, P. A. M. Properties of fly Ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 23 (10), 3233–3239. https://doi.org/10.1016/j.conbuildmat.2009.06.001 (2009).

Heidari, A. & Shourabi, F. N. Mechanical properties of ultra-high performance concrete based on reactive powder concrete: effect of sand-to-cement ratio, adding glass fiber and calcium carbonate. Constr. Build. Mater. 368, 130108. https://doi.org/10.1016/j.conbuildmat.2022.130108 (2023).

Acknowledgements

Data will be made available by the corresponding author upon request.

Author information

Authors and Affiliations

Contributions

Wanying Qu: Methodology, Conceptualization, Data curation, Formal analysis, Writing – original draft. Kailu Liu: Methodology, Conceptualization, Funding acquisition, Supervision, Writing – review & editing. Haoyang Zeng: Writing – review & editing, Software. Qiuyan Hu: Formal analysis.Li Wang: Data curation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Qu, W., Liu, K., Zeng, H. et al. Effect of SiO2 aerogel and perlite on properties of foamed concrete. Sci Rep 15, 10945 (2025). https://doi.org/10.1038/s41598-025-96026-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-96026-2