Abstract

A high-performance Ce3+-doped (Gd, Tb)3(Ga, Al)5O12 (GTAGG: Ce) single crystal was engineered and characterized, demonstrating a high application potential for advanced X-ray imaging. A transparent 1-inch diameter single crystal was grown using the Czochralski method, demonstrating a significant advancement in large-scale scintillator production. Comprehensive characterization using X-ray diffraction and electron probe micro-analysis confirmed the crystal’s structural integrity. Photoluminescence and radioluminescence spectroscopy demonstrated efficient bidirectional energy transfer between Ce3+ and Tb3+ ions, a critical mechanism enhancing the performance of the scintillator. X-ray imaging tests were performed using crystals with a thickness of 100 μm at the Aichi Synchrotron Radiation Center. Comparison with the industry-standard LuAG: Ce scintillator showed that the GTAGG: Ce crystal produced 2.4 times higher light output and achieved a high spatial resolution of 0.85 μm. The results indicated that GTAGG: Ce is suitable for the next generation of high-performance X-ray imaging detectors in scientific and medical imaging applications.

Similar content being viewed by others

Introduction

X-ray imaging is widely applied for medical diagnostics, airport security controls and non-destructive testing1,2. Recent advancements in X-ray imaging methods combined with monochromatic X-rays have enabled successful sub-micron and micron-scale imaging, sparking significant interest in high-resolution synchrotron radiation X-ray imaging research3,4,5,6. In particular, Kameshima et al. (2019) demonstrated X-ray transmission imaging of 200 nm line-and-space patterns, further highlighting the growing potential and relevance of this technique in various fields7. The main components of an X-ray imaging system are the scintillator layer and an optical imaging sensor. For projecting the object onto the image sensor, X-rays must be converted into UV or visible light within the scintillator layer. Thus, the characteristics of the scintillator play a crucial role in defining the quality of the X-ray imaging results.

Sensitivity is one of the most critical factors for scintillators in achieving high-resolution X-ray imaging. The overall X-ray detection efficiency of the scintillator material can be expressed as the product of two key parameters: the scintillator’s light yield per unit of absorbed X-ray energy (measured in photons per mega electron-volt) and the probability of interaction between the scintillator and the incident X-rays at the specific energy of the X-ray source. Approximately, this relationship can be represented as:

where LY and Edep are the light yield of scintillators and the deposited energy by the scintillators. The deposited energy in scintillator materials is influenced by both their density and effective atomic number. Therefore, optimizing these properties, alongside maximizing light yield, is essential for attaining high sensitivity in detection applications. This multifaceted approach enhances the scintillator’s performance, allowing for improved interaction with incoming radiation and ultimately leading to more accurate and efficient detection capabilities.

Oxide single-crystal scintillators constitute a significant class of functional materials characterized by their high density, elevated effective atomic number, and demanded physical and chemical stability, making them particularly advantageous for X-ray imaging applications. Among these materials, Ce3+-doped Gd3(Ga, Al)5O12 (GAGG: Ce) has emerged as a promising candidate, distinguished by its prompt decay kinetics and high light yield8,9. Despite the significant progress achieved with the development of GAGG: Ce scintillators, the luminescence properties of oxide-based scintillator materials have largely stagnated in recent years. This lack of substantive advancements has subsequently constrained further improvements in the sensitivity of X-ray imaging systems employing these scintillator detectors. To overcome this limitation, we have focused on co-doping with Ce3+ and Tb3+ ions in garnet crystal structure. Recent studies on Ce3+ and Tb3+ co-doped scintillators have shown that efficient energy transfer between Ce3+ and Tb3+ can enhance luminescence and scintillation properties10,11,12,13,14. In our previous research on Ce3+ and Tb3+ co-doped (Gd, Y)3(Ga, Al)5O12 (GYAGG: Ce,Tb) crystals scintillators grown by micro-pulling-down (µ-PD) method, the integrated intensity, calculated from the area of the radioluminescence spectra, increased with higher Tb3+ concentrations15. The GYAGG: Ce0.5%,Tb15%, in particular, exhibited almost 1.7 times higher intensity compared to GAGG: Ce15. However, the GYAGG crystal structure exhibits a higher melting point than the GAGG structure, resulting in substantial compositional shifts associated with the evaporation of gallium oxides during the scaling-up process for practical X-ray imaging applications. Consequently, GAGG was selected as the preferred host material and applied Ce3+ and Tb3+ co-doping for this study.

This study presents the first successful growth of a large-scale (1-inch diameter) Ce3+ and Tb3+ co-doped GAGG single crystal using the Czochralski (Cz) method, demonstrating a significant development of high-performance scintillators for advanced X-ray imaging applications. A systematic investigation of the crystal’s performance was conducted through the construction and characterization of an X-ray imaging detector, focusing on the key parameters including detection sensitivity and spatial resolution. Comparative analysis against a commercial Ce3+-doped Lu3Al5O12 (LuAG: Ce) scintillator was performed to quantitatively assess the enhanced performance achieved through the synergic Ce3+ and Tb3+ co-doping strategy, providing comprehensive insights into the material’s potential for advanced imaging applications.

Materials and methods

A mixture of 4 N Gd2O3, Tb4O7, CeO2, Ga2O3 and Al2O3 powders was used as the starting materials. The 1-inch diameter (Gd0.835Tb0.15Ce0.015)3Ga3.09Al2O12 (GTAGG: Ce) single crystal was grown by Cz method. At this stage, Ga2O3 was introduced 3% excess of the stoichiometric composition to offset any loss due to evaporation. The crystal was grown utilizing an iridium crucible in an atmosphere composed of N2 + 2%O2 with a < 100 > GAGG: Ce single crystal employed as the seed. The seed pulling rate and rotation rate were 0.7 mm/hour and 10.0 rot/min, respectively.

The quantitative chemical analysis of the crystals for the Gd, Tb, Ce, Ga, and Al contents along the growth direction was performed by the electron probe micro-analysis (EPMA, JXA-8530 F, JEOL) equipped with wavelength dispersive spectrometers (WDS). In addition, the remaining pieces of the grown crystals were crushed and employed for the powder X-ray diffraction (XRD) analysis (SmartLab, Rigaku) to verify the crystal phase in the 2θ range of 10o-70o with 0.02o step using a D8 DISCOVER (Bruker) diffractometer. The Cu Kα X-ray source was used, and the accelerating voltage and current were 40 kV and 40 mA, respectively.

A piece of sample with the dimensions of 5 mm× 5 mm× 0.8 mm were cut from the initial part of the grown crystal, and mirror polished for the luminescence measurements. The photoluminescence (PL) emission and excitation (PLE) spectra were acquired at room temperature with a spectrometer (FLS1000, Edinburgh Instructions) equipped with Xe lamp as the excitation source. The radioluminescence (RL) spectra excited by X-ray (operated at 40 kV, 30 mA) were measured by SR-163 spectrometer (ANDOR TECHNOLOGY) equipped with the charge-coupled device (CCD) detector DU-420OE (ANDOR TECHNOLOGY).

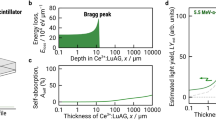

The X-ray imaging detector was constructed using a GTAGG: Ce scintillator plate that was developed in this study. The imaging performance was compared with that of a commercially available LuAG: Ce scintillator (Hamamatsu Photonics K.K.). The GTAGG: Ce scintillator was polished to a thickness of 100 μm, consistent with the specifications of the LuAG: Ce scintillator. The detector configuration followed the same design as previously described3. A CS-71 M CMOS sensor (BITRAN CORPORATION) was used as the optical sensor, with a cooling temperature range between − 5 and 0 ℃ via air cooling.

X-ray imaging tests were conducted using beamline BL8S2 at the Aichi Synchrotron Radiation Center (AichiSR16). Continuous X-rays with photon energies ranging from 7 keV to 24 keV were utilized, with a maximum beam size of 40 mm× 8 mm, which was reduced to 5–6 mm using a slit. The photon flux density was 6.2 × 108 photons·s-1·mm-2 at 9.8 keV. A micro resolution test chart (RC-04, JIMA), with a minimum spatial frequency of 5,000 lp/mm, was placed in front of the scintillator. The transmitted images of the test chart were captured, and both the light output and spatial resolution were evaluated. The detailed evaluation method is described in Ref. 3.

Results and discussions

The as-grown crystal with a length of 90 mm is shown in Fig. 1(a). The crystal surface exhibits a slight cloudiness attributable to surface roughness. This surface morphology is likely induced by selective evaporation of gallium-oxide components and thermal etching processes occurring during the crystal growth process17. After cutting the crystals into a 5 mm thick plate along the growth direction and performing mirror polishing, the interior regions of the crystals exhibit a high degree of transparency (Fig. 1(b)). The absence of cracks and the high transparency indicate a successful crystallization process. The terminal regions of the crystal exhibited inclusions, which are likely a consequence of segregation, as corroborated by the results from EPMA presented in the subsequent section. To identify the crystal phases, an X-ray diffraction analysis was performed. As shown in Fig. 1(c), the XRD patterns reveal a single cubic phase (Ia-3d) with high crystallinity and phase purity.

The compositional homogeneity within the central regions of the grown crystals was systematically analyzed using EPMA. Fig. 2 presents the detailed compositional profiles obtained along the primary growth axis of the GTAGG: Ce crystal, where Cs and Co represent the actual and nominal compositions, respectively. The average solidification fraction (g) was approximately 0.64, with g defined by the following equation:

The effective segregation coefficients (keff) for the Gd, Tb, Ce, Ga, and Al elements were quantified using the following equation:

The determined keff values were 0.97 for Gd, 1.18 for Tb, 0.21 for Ce, 0.87 for Ga, and 1.12 for Al. These experimentally derived segregation coefficients are consistent with findings from previous research on related material systems18,19. The observed partitioning behavior provides important insights into the thermodynamics and kinetics governing the incorporation of dopants and host lattice components during the crystal growth process. The segregation coefficient values indicate the relative propensity of each element to partition into the solid crystal phase versus the remaining liquid melt. Elements with keff > 1, such as Tb and Al, preferentially incorporate into the growing crystal, while those with keff < 1, like Ce, tend to partition more strongly into the residual liquid.

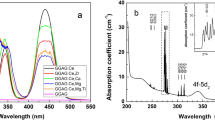

The PL and PLE spectra of GTAGG: Ce single crystal are presented in Fig. 3. Fig. 3(a) shows the excitation spectrum monitoring the Tb3+ 5D4→7F5 emission at 543 nm, as well as the emission spectrum obtained under excitation of the Tb3+ 4f→5d1 transition at 278 nm. The excitation spectrum for Tb3+ emission at 543 nm exhibits broad and intense bands at 330 nm and 280 nm, corresponding to the 4f→5d1 high-spin (HS) and low-spin (LS) transitions of Tb3+ ions, respectively. Additionally, a weaker and narrower set of bands at 373 nm are attributed to the 7F6 →5G6 transition. The presence of broad excitation bands associated with Ce3+ ions, specifically at 430 nm (4f → 5d1) and 340 nm (4f → 5d2), confirms energy transfer from Ce3+ to Tb3+ ions. Furthermore, the low-energy region of the band associated with the 4f→5d1 high-spin transition of Tb3+ reveals narrow lines corresponding to the 8S7/2 →6PJ transitions within Gd3+ ions. The presence of these characteristic Gd3+ excitation lines provides evidence of energy transfer from the Gd3+ sublattice to Tb3+ ions20. Fig. 3(b) further confirms the synergistic energy transfer mechanisms among Ce3+, Gd3+, and Tb3+ ions. Specifically, the excitation spectrum for Ce3+ emission at 520 nm, besides Ce3+ excitations bands at 330 nm and 430 nm, comprises the 4f → 5d1 high-spin (at 330 nm) and low-spin (280 nm) transitions of Tb3+ ions, along with the 8S7/2 →6PJ transitions within Gd3+ ions. The excitation spectra presented in Fig. 3 highlight the strong interactions between Ce3+ ↔ Gd3+ ↔ Tb3+ ions within the garnet lattice, ultimately leading to efficient radiative transitions within Tb3+ and Ce3+ ions. The emission spectra excited at 278 nm, corresponding to the Tb3+ 4f→5d1 LS transition (Fig. 3(a)), and at 430 nm, corresponding to the Ce3+ 4f→5d1 transition (Fig. 3(b)), exhibit consistent spectral features. These spectra include characteristic Tb3+ emission lines associated with the 5D4→7F6 (~ 480 nm), 5D4→7F5 (~ 550 nm), 5D4→7F4 (~ 590 nm), 5D4→7F3 (~ 625 nm) and 5D4→7F2 (~ 680 nm) transitions. Additionally, a broad emission band spanning 470 nm to 780 nm is observed, originating from the 5d1→4f transition within Ce3+ ions. However, the relative emission intensity ratios between Tb3+ and Ce3+ differ under the two excitation wavelengths. This observation provides a crucial conclusion regarding the efficiency of the energy transfer process among Gd3+, Tb3+, and Ce3+ ions, highlighting that it is significantly influenced by the concentrations of Gd3+ and Tb3+ ions. Specifically, the energy transfer efficiency from Gd3+ ions to both Ce3+ and Tb3+ ions is significantly higher than the energy transfer from Tb3+ ions to Ce3+ ions. This discrepancy is attributed to the difference in the concentration of Gd3+ ions, which are present in full occupancy. As a result, the excitation energy can migrate efficiently among Gd3+ ions due to their proximity, facilitating effective energy transfer to Ce3+ and Tb3+ ions. In contrast, in the bidirectional energy transfer process between Tb3+ and Ce3+ ions, the low concentration of Tb3+ ions prevents efficient energy migration among them. Consequently, energy transfer is limited to Tb3+ and Ce3+ ions that are in close spatial proximity. This restriction results in the excitation energy being localized to both Tb3+ and Ce3+ ions rather than undergoing extensive migration as in the case of Gd3+ ions21,22,23,24. The coexistence of both the broad Ce3+ emission and the narrow Tb3+ emission lines under direct Ce3+ excitation suggests the presence of an efficient bidirectional energy transfer mechanism that occurs via non-radiative processes, where the Ce3+ ions act as sensitizers, absorbing the excitation energy and then transferring it to populate the emitting 5D4 energy state of the Tb3+ ions25. A key factor governing the energy transfer dynamics between the Tb3+ and Ce3+ ions is the energy level alignment between their respective electronic configurations. If there had been a large energy mismatch between the Ce3+ 5d1 and Tb3+ 5D4 excited states, the energy transfer from Tb3+ to Ce3+ would have been less efficient, resulting in the dominance of Tb3+ emission features in the spectrum10,25. However, the GAGG host lattice chosen in this study plays a crucial role in optimizing the energy level alignment. Specifically, the Gd atoms within the GAGG lattice lower position of the Ce3+ 5d1 excited state10,25. This brings the Ce3+ and Tb3+ energy levels into closer resonance, thereby enhancing the efficiency of the energy transfer process from the Tb3+ sensitizer to the Ce3+ activator ions. By carefully tailoring the host lattice composition to achieve optimal energy level alignment, it is possible to maximize the energy transfer efficiency and thereby enhance the scintillation and luminescence performance of GTAGG: Ce crystal.

Fig. 4 presents the results of radioluminescence measurement for the GTAGG: Ce crystal at room temperature. The RL spectrum for the GAGG: Ce crystal grown by the µ-PD method is used as a reference. The GAGG: Ce crystal exhibits Ce3+ 5d1→4f emission, which is observed in the wavelength range of 450–700 nm. In contrast, GTAGG: Ce crystal shows both Ce3+ 5d1→4f and Tb3+ 4f→4f emissions, which is consistent with the PL emission spectra shown in Fig. 3. The presence of an intense emission lines from the Tb3+ ions, coupled with the absence of detectable emission from the Gd3+ ions, further confirms that the efficiency of the energy transfer process is governed by the concentrations of both Gd3+ and Tb3+ ions. Specifically, the low concentration of Tb3+ ions limits the efficiency of energy transfer from Tb3+ to Ce3+ ions, resulting in an incomplete transfer of excitation energy. Consequently, strong luminescence from the Tb3+ ions is observed, as the excitation energy remains localized within the Tb3+ and Ce3+ ions.

Fig. 5 illustrates the X-ray transmission images of the test chart captured using a 4x objective lens with a 10 ms exposure time. Fig. 5(a) presents the image captured using the GTAGG: Ce scintillator developed in this study, while Fig. 5(b) presents the image captured using a commercially available LuAG: Ce scintillator. To ensure consistency, the system configuration, positioning, and displayed values such as contrast and brightness were adjusted to be the same. Both images depict the shape of the chart, however, there is a notable difference in brightness. This difference in brightness is thought to be attributable to the differences in the light output of the scintillators. Fig. 6(a) shows the relationship between the exposure time and the average pixel values in the blank region of the X-ray transmission images. GTAGG: Ce demonstrates a greater average pixel value than LuAG: Ce when subjected to the same exposure time. The scintillation light output in X-ray imaging detectors is quantified by the slope of the relationship between average pixel value and X-ray exposure time. Fig. 6(b) compares the scintillation light output values of LuAG: Ce and GTAGG: Ce, indicating that the scintillation light output of GTAGG: Ce is approximately 2.4 times higher than that of LuAG: Ce.

Fig. 7(a) displays the contrast transfer function (CTF) for LuAG: Ce and GTAGG: Ce scintillators, derived from the X-ray transmission images of the test chart. A CTF value of 10% is represented by the horizontal black dotted line in Fig. 7(a). At this 10% CTF, LuAG: Ce showed a spatial frequency of 420 lp/mm, corresponding to a line width of 1.2 μm, whereas GTAGG: Ce demonstrated a spatial frequency of 590 lp/mm, corresponding to a line width of 0.85 μm. The spatial resolution of the imaging system is conventionally defined at the 10%-level of the CTF. Therefore, GTAGG: Ce exhibits significantly better spatial resolution, approaching the effective pixel size (0.69 μm) of an X-ray imaging detector with a 4x objective lens. This excellent spatial resolution of GTAGG: Ce is illustrated in Figs. 7(b) and (c), which show the X-ray transmission images of the test chart corresponding to a line width of 0.9 μm. Comparative analysis of the acquired images demonstrates substantial differences in spatial resolution characteristics between the two scintillator materials. The LuAG: Ce scintillator produces images with notable spatial degradation and compromised edge definition, resulting in significant image blur. In contrast, the GTAGG: Ce scintillator exhibits improved spatial resolution, enabling precise discrimination of linear features within the test pattern. This enhancement in image quality is conclusively attributed to the higher light output of GTAGG: Ce, which directly contributes to an improved signal-to-noise ratio (SNR). The SNR was evaluated using the equation below, where the SNR was calculated at a specific region in the X-ray transmission image.

This measurement was repeated in five different locations within the image to determine the average and the standard deviation of the SNR values. The SNR of GTAGG: Ce was 73 ± 5, compared to 58 ± 2 for LuAG: Ce. This higher SNR facilitates the detection of line boundaries that were previously indiscernible in the images obtained using LuAG: Ce. The increased light output effectively amplifies the signal received by the detector, reducing the influence of background noise and thereby allowing finer structural details to be resolved.

Fig. 8 presents X-ray transmission images of the µ-SD card captured with a 4x objective lens and a 10 ms exposure time. Notably, the imaging revealed internal fine structures, successfully depicting features smaller than 5 μm (Fig. 8(b)). These results indicate that the GTAGG: Ce scintillator we developed demonstrates significant potential for practical applications in high-performance X-ray imaging detectors.

Conclusions

A bulk single crystal of GTAGG: Ce with a 1-inch dimension was successfully grown for the first time using the Czochralski method. The grown crystal demonstrated excellent optical quality with high transparency and absence of cracks, indicating a well-executed crystallization process. Powder X-ray diffraction analysis confirmed the presence of a single garnet phase without any secondary phases. The composition distributions along with the growth direction of the crystal were characterized by the EPMA. The effective segregation coefficient of Gd, Tb, Ce, Ga and Al ions were 0.97, 1.18, 0.21, 0.87 and 1.12, respectively, which is consistent with previously reported garnet crystals. Spectroscopic investigations revealed simultaneous emission bands from Ce3+ and Tb3+ ions in both photoluminescence and radioluminescence measurements. This observation provided evidence for efficient bidirectional energy transfer mechanisms between Ce3+ and Tb3+ ions, attributed to optimal energy level alignment between the Ce3+ 5d1 and Tb3+ 5D4 energy states. Performance evaluation through X-ray transmission imaging, conducted at the Aichi Synchrotron Radiation Center beamline, enabled quantitative assessment of scintillation light output and spatial resolution characteristics in comparison with commercial LuAG: Ce scintillators. The GTAGG: Ce scintillator demonstrated approximately 2.4 times greater light output than LuAG: Ce, along with an improved spatial resolution of 0.85 μm. These findings indicate that GTAGG: Ce can be a promising candidate as a scintillator for high-performance X-ray imaging detectors, highlighting its potential in advancing imaging technologies in scientific and medical applications.

Data availability

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Martin, T. & Koch, A. Recent developments in X-ray imaging with micrometer Spatial resolution. J. Synchrotron Rad. 13, 180–194 (2006).

Nikl, M. & Yoshikawa, A. Recent R&D trends in inorganic Single-Crystal scintillator materials for radiation detection. Adv. Opt. Mater. 3, 463–481 (2015).

Yoshino, M. et al. Development and performance evaluation of a thin GAGG:Ce scintillator plate for high resolution synchrotron radiation X-ray imaging. J. Inst. 19, P10030 (2024).

Mashita, R. et al. Insights into the cavitation morphology of rubber reinforced with a nano-filler. Sci. Rep. 13, 5805 (2023).

Yashiro, W., Voegeli, W. & Kudo, H. Exploring frontiers of 4D X-ray tomography. Appl. Sci. 11, 8868 (2021).

Kameshima, T. & Hatsui, T. Development of 150 Mpixel lens-coupled X-ray imaging detectors equipped with diffusion-free transparent scintillators based on an analytical optimization approach. J. Phys. : Conf. Ser. 2380, 012094 (2022).

Kameshima, T. et al. Development of an X-ray imaging detector to resolve 200 Nm line-and-space patterns by using transparent ceramics layers bonded by solid-state diffusion. Opt. Lett. OL. 44, 1403–1406 (2019).

Kamada, K. et al. Composition engineering in Cerium-Doped (Lu,Gd)3(Ga,Al)5O12 Single-Crystal scintillators. Cryst. Growth. Des. 11, 4484–4490 (2011).

Kamada, K. et al. Cz grown 2-in. Size Ce:Gd3(Al,Ga)5O12 single crystal; relationship between al, Ga site occupancy and scintillation properties. Opt. Mater. 36, 1942–1945 (2014).

Omuro, K. et al. Tailoring scintillation and luminescence through Co-doping engineering: A comparative study of Ce,Tb Co-doped YAGG and GAGG Garnet crystals. J. Alloys Compd. 1008, 176550 (2024).

Wu, T. et al. Wide concentration range of Tb3+ doping influence on scintillation properties of (Ce, Tb, Gd)3Ga2Al3O12 crystals grown by the optical floating zone method. Materials 15, 2044 (2022).

Gorbenko, V. et al. LPE growth of single crystalline film scintillators based on Ce3+ doped Tb3 – xGdxAl5–yGayO12 mixed garnets. Crystals 7, 262 (2017).

Zorenko, Y. et al. Scintillating screens based on the LPE grown Tb3Al5O12:Ce single crystalline films. Opt. Mater. 65, 73–81 (2017).

Korzhik, M. et al. Cross-sensitization of Ce3+ and Tb3+ luminescence in (Gd, Y)3Al2Ga3O12 scintillation ceramics. J. Lumin. 265, 120226 (2024).

Omuro, K. et al. Insights into luminescence and energy transfer processes in Ce3+- and Tb3+ co-doped (Gd, Y)3Al2Ga3O12 Garnet single crystals. J. Lumin. 273, 120663 (2024).

Aichi synchrotron radiation center. https://www.aichisr.jp/en/index.html.

Ueno, M. et al. Bulk single crystal growth of W Co-Doped Ce:Gd₃Ga₃Al₂O₁₂ by Czochralski method. IEEE Trans. Nucl. Sci. 67, 1045–1048 (2020).

Kamada, K. et al. Crystal growth and scintillation properties of Ce doped Gd3(Ga, Al)5O12 single crystals. IEEE Trans. Nucl. Sci. 59, 2112–2115 (2012).

Kamada, K. et al. Growth and scintillation properties of 3 in. Diameter Ce doped Gd3Ga3Al2O12 scintillation single crystal. J. Cryst. Growth. 452, 81–84 (2016).

Bartosiewicz, K. et al. The temperature dependence studies of rare-earth (Dy3+, Sm3+, Eu3+ and Tb3+) activated Gd3Ga3Al2O12 Garnet single crystals. J. Lumin. 189, 126–139 (2017).

Markovskyi, A. et al. Composition engineering of Tb3-xGdxAl5-yGayO12:Ce single crystals and their luminescent, scintillation and photoconversion properties. J. Alloys Compd. 849, 155808 (2020).

Khanin, V. et al. Exciton interaction with Ce3+ and Ce4+ ions in (LuGd)3(Ga,Al)5O12 ceramics. J. Lumin. 237, 118150 (2021).

Bartosiewicz, K. Elemental fluctuation in Gd3Al2Ga3O12:Ce crystals imposed by Li+ and Mg2+ Co-Doping: the impact on defects, luminescence, and scintillation properties. Metals 13, 422 (2023).

Bartosiewicz, K., Babin, V., Kamada, K., Yoshikawa, A. & Nikl, M. Energy migration processes in undoped and Ce-doped multicomponent Garnet single crystal scintillators. J. Lumin. 166, 117–122 (2015).

Bartosiewicz, K. et al. Micro-Inclusion engineering via Sc incompatibility for luminescence and photoconversion control in Ce3+-Doped Tb3Al5 – xScxO12 Garnet. Materials 17, 2762 (2024).

Acknowledgements

We would like to thank the following individuals for their support: Mr. Yoshihiro Nakamura of Institute of Multidisciplinary Research for Advanced Materials (IMRAM), Tohoku University and Mr. Issei Narita of Institute for Materials Research (IMR), Tohoku University.

Author information

Authors and Affiliations

Contributions

K.O. conducted all aspects of this study, including conceptualization, methodology, resources, investigation, formal analysis, data curation, and visualization, and drafted the original manuscript. M.Y., S.Y., and K.N. contributed to funding acquisition and investigation, with a primary focus on X-ray imaging experiments. L.G. and K.J.K. contributed to crystal growth and the provision of materials. K.K. provided methodology and resources. K.B. contributed to funding acquisition and the interpretation of optical measurement data. T.H. contributed to the investigation and collection of luminescence data. J.K. provided methodology. A.Y. supervised the project. All authors reviewed and edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Omuro, K., Yoshino, M., Gushchina, L. et al. Crystal growth and characterization of 1-inch GTAGG: Ce single crystal for sub-micron resolution synchrotron radiation X-ray imaging. Sci Rep 15, 12993 (2025). https://doi.org/10.1038/s41598-025-96031-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-96031-5