Abstract

The utilization of nanoparticles in concrete has been propelled by their advantageous attributes, such as their fine particle size and remarkable reactivity. To enhance these properties, various nanoparticles can be integrated into the lightweight concrete matrix. We introduce a novel technique to produce TiO2 structures resembling dandelions, featuring interfaces between anatase and TiO2 phases as well as a distinct outer layer. This approach utilizes a deep eutectic solvent-tuning method that is both user- and environmentally friendly. The formation of this remarkable external covering is attributed to the hierarchical arrangement of two-dimensional ultrathin nanosheets with mesopores in a three-dimensional configuration. The primary focus of this study is the utilization of DFNT, a nanoparticle possessing a three-dimensional structure, within the matrix of lightweight concrete. To conduct this study, concrete cases with congestion of 1000 kg/m3 were fabricated and subjected to testing. We sought to evaluate the effect of different weight ratio proportions of DFNT on the enduring characteristics of lightweight concrete, such as the contraction caused by drying, the degree of openness, the capacity to absorb water, and the speed at which ultrasonic waves travel. The inclusion of DFNT induces a transformation in the microstructural composition of lightweight concrete, shifting it from a loose needle-like structure to a more compact and cohesive microstructure characteristic of cementitious composites. Furthermore, DFNT enhances the lightweight concrete matrix by occupying the empty spaces, tiny fractures, and gaps present within it.

Similar content being viewed by others

Introduction

Lightweight concrete has gained recognition as an essential material within the realm of the building sector1. The utilization of lightweight concrete, as well as its range of applications, has significantly increased over time. In numerous scenarios, lightweight concrete provides better efficiency and lower prices compared to other conventional construction substances2. In general, lightweight concrete can be described as a lightweight and easily flowable material, making it suitable for different utilizations3,4.

However, in spite of its increasing recognition, lightweight concrete does have certain disadvantages. These include a reduced ability to absorb high amounts of water, a higher tendency to shrink when drying, a lower performance in terms of durability, and an excessive risk of cracking. These shortcomings are directly associated with its porous microstructure, specifically the presence of interconnected pores, which restricts its application in the field of construction5,6,7. Mohd Zamzani et al. further demonstrated that a decrease in the density of lightweight concrete resulted in a significant increase in the quantity of voids with larger diameters7. Additionally, the ultrasonic pulse velocity of lightweight concrete is reduced and it becomes highly susceptible to cracking when subjected to low densities8. Concrete materials are regarded as early examples where nanotechnology could significantly impact future advancements9,10,11. Hence, nanoscale particles like silica, starch, and alumina have been utilized to reinforce preformed foams12,13,14,15. The integration of suitable nanoparticles can simultaneously improve the stability and properties of the cement-based structure in lightweight concrete16.

By employing the pattern of arborescent filamentous nanomaterials, it becomes feasible to generate nanostructured particles possessing an extensive exterior zone. The substantial exterior zone of arborescent filamentous nanomaterials is attributable to the existence of fibres in lieu of pores. In this context, it is postulated that the unobstructed and filamentous configuration of DFNT can facilitate the incorporation of a substantial volume of DFNT with negligible diminution of the peripheral zone. Thus, the enhancement of the availability of DFNT locations can augment the capacity to establish communication with the surface17,18,19,20. The rationale behind this phenomenon lies in the augmented dispersal stemming from the existence of filamentous core architecture within the catalyst. The intimate coexistence of quasi-particles and molecular entities adsorbed atop the DFNT on the fibres of the nanocatalyst engenders a productive interplay between the induced charges and the reactants21.

DFNT is a substance that manifests substantial potential for deployment in lightweight concrete, although there are few commercially available products. Until now, no study has investigated the addition of DFNT to concrete and its effects on the properties of lightweight concrete. Therefore, this study aims to systematically investigate the issue. The objective is to evaluate the impact of varying mass percentages of DFNT incorporation in lightweight concrete on diverse qualities of durability.

Experimental

Substances and methods

In this research, we utilized ordinary Portland cement PO 52.5 produced by Fars Cement Company, Iran. The main ingredients used in creating the FC mixtures included standard fine sand, Portland cement (PC), distilled water, FFO-NP, and a frothing agent. The PC used conformed to the BS12 standard. It had a distinct gravity of 3.24 and a surface expanse of 3306 cm2/g. The composition and properties of the PC are detailed in Table 1, while Table 2 outlines its characteristics. Fine sand with granule dimensions ranging from 0.21 to 2.28 mm and a distinct specific weight of 2.46 g/cm3 was employed in this study, following the BS12620 criteria. The attributes of the protein-based frothing agent are listed in Table 3. Additionally, distilled water was used in formulating all FC mixtures. The protein-based frothing agent, with a mass of 1.07 kg/l as specified by the supplier, was chosen for its capacity to produce diminutive, isolated, spherical air pockets. The magnetite nanoclusters used in the investigation possessed a particle size between 55 and 75 nm and a purity level above 98.5%. Seven different FC mixtures were prepared for this research. The intended mass for the FC was determined at 1000 kg per stere. Additionally, seven different weight fractions of DFNT were incorporated, which encompassed values of 0.0%, 0.10%, 0.20%, 0.25%, 0.30%, 0.35%, and 0.40%. The ratios of sand to water and cement to cement in the experiment were 1:1.4 and 0.40, respectively, as outlined in Table 4.

Formation of DFNT

1.6 millilitres of tetrabutyltitanate were introduced into 27 millilitres of cyclohexane and 7 millilitres of 1-pentanol. Subsequently, a mixture composed of 3.4 g of cetylpyridinium bromide (CPB) and 0.9 g of urea dissolved in 40 millilitres of water was incorporated and agitated for 45 min. Following this, the resulting mixture was transferred into a reactor and subjected to heating at 75 degrees Celsius for a period of 2.6 h. The resulting material, DFNT, was then subjected to calcination in the presence of air at a temperature of 670 degrees Celsius for a duration of 3.5 h.22

Ultrasonic pulse velocity (UPV) test

Figure 4 illustrates the configuration of the converter employed in the Ultrasonic Pulse Velocity (UPV) test. The receiving (R) and transferring (T) converters were positioned at opposing extremities of each Fiber Cement (FC) case. To carry out this examination, prism cases measuring 100 × 100 × 500 mm were employed in accordance with the specifications outlined in BS12504-4 (EN, 12504-4). The transducer effectively depicted the elapsed time and velocity of the transmitted signals. The duration of pulse transmission was recorded using a digital display. The evaluation of UPV was conducted on days 10, 20, and 30. The mean UPV associated with these three FC cases was regarded as the ultimate outcome. The subsequent equation was employed to compute the velocity of ultrasonic wave dissemination:

T = transfer time (s), L = space between the convertors (mm).

Congestion test

The vacuum immersion technique was employed to determine the sponginess of the FC material. For the assessment, three cylindrical cases with dimensions of 35 mm in diameter and 40 mm in height were chosen from every individual batch of the FC mix. These cases were subjected to a 96-h drying process in an oven to eliminate any moisture content. Initially, the external zones of the FC cases were meticulously smoothed by deploying sandpaper. Upon evaluating the weight of cases dried in the oven at 110 degrees Celsius, the FC cases underwent evacuation in the presence of a vacuum ranging from 80 to 100 kPa for a duration of 3 days. Following this, the FC cases were subjected to immersion in boiling water until complete submersion was achieved. Subsequently, the scheme of immersion was upheld within an environment of negative pressure for an approximate duration of 30 h. It was comprehended that all air bubbles were eradicated from the FC specimens and heated water. Subsequent to the process of vacuum saturation, the FC specimens were extracted from the aquatic reservoir and assessed in terms of weight. The overall porosity was calculated utilizing the following equation:

v = Mass of the polished FC case, ρ = density of water.

Hydration uptake test

The water absorption experiment was successfully executed in accordance with the standards outlined in BS 1881–122. The FC specimens underwent a process of wiping and weighing in order to achieve the weight at which the exterior zone is saturated yet dry. The FC cases were subsequently subjected to oven-drying for a duration of 32 h, following which the weight of the samples was determined. The following formula was utilized to define the moisture uptake of the FC:

Wdry = Oven-dried weight (kg), Wsat = Saturated exterior zone dry weight (kg).

Drying shrinkage test

The shrinkage test was conducted according to the guidelines provided by ASTM C157. Spherical gauge lids were attached to both ends of the FC cases in order to facilitate the measurement of length differences. The FC prismatic cases were dried from the axial and radial directions. The initial length quantification (l1) was conducted directly following the demoulding process. The dampness present on the gauge lids was assiduously addressed To preempt the occurrence of inaccurate readings. The length measurements were conducted using a length comparison device that had a minim resolution of 0.003 mm over a span of 60 days. The readings were obtained at the following time points: 5–60 days. Three FC cases were subjected to testing, and the average value was provided.

Results and discussion

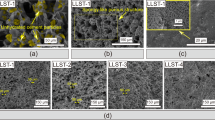

Figure 1 illustrates DFNT NPs obtained through FESEM and TEM techniques. The DFNT case exhibited tilts resembling septa, characterized by stable masses and dendrimer cords. These strings had thicknesses varying between 35 and 45 nm and were diffused in a three-dimensional manner, forming the septum structure. The presence of these threads facilitated the entry to the external surface. The diffractograms of DFNT NPs can be seen in Fig. 2. DFNT NPs demonstrated multiple distinct peaks in their crystalline structure. The X-ray diffraction (XRD) spectrum displayed diffraction patterns at angles of 2θ = 25.3°, 37.6°, 47.8°, 54,2°, and 62.4° that could be ascribed to the distinctive peaks of titanium dioxide (TiO2) in the anatase crystalline phase (JCPDS file 73-1764). FTIR serves as a highly effective method for the analysis of compound or product composition. Figure 3 depicts the FTIR spectrum of DFNT nanoparticles. Analysing the FTIR spectrum of DFNT nanoparticles revealed the presence of the Ti–O bending mode at 487 cm–1 and the deformative vibration of the Ti–OH stretching mode at 1598 cm–1. Moreover, the FTIR spectrum revealed the existence of asymmetrical and symmetrical expansion oscillations of the hydroxyl group at 3389 cm–1.

The examination of Nitrogen physisorption showcased that the BET-specific exterior zone of DFNT was 642 m2/g. The nitrogen adsorption–desorption isotherms of DFNT-supported catalysts are illustrated in Fig. 4. The DFNT exhibited a type IV isotherm, accompanied by an H1-type hysteresis loop, which signified the existence of mesopores (Table 5). The BJH approach employed the desorption branch of the nitrogen isotherm to predict the relevant range of pore sizes, which demonstrated a focused dispersion of limited pore sizes with a maximum value of 11 nm. The roughness of the outer layer of the nanoparticles was determined through analysis using atomic force microscopy (AFM). Figure 5 depicts the topographic scheme. The elevated region, depicted in a bright yellowish-white hue, was enlarged by reducing the ratio of the thickness of the outer layer to the width of the catalyst. This indicated an increase in the unevenness of the outer layer.

Table 6 illustrates the volumetric composition of DFNT in various FC mixtures, thereby indicating the bulk dry density. The intended value for the bulk dry density was set at 1000 kg/m3. It was crucial to maintain a density discrepancy of approximately 120 to 150 kg/m3 between the plastic and dry densities. The acceptable deviation between the permissible variation in dry density between the intended value and the final value varied from ± 50 kg/m3 for lower fibre-cement densities (ranging from 300 to 1300 kg/m3) to as high as ± 60 kg/m3 for higher fibre-cement densities (ranging from 1300 to 2000 kg/m3).

Dry compactions were conducted on days 10, 30, and 60. In the case of the whole FC blends, the desired mass desiccated congestions and ultimate mass desiccated congestions fell inside the satisfying allowance range of ± 50 kg per cubic meter. As an example, the disparities between the ultimate mass desiccated compactions and the desired mass desiccated congestion were ± 15 kg per cubic meter, ± 17 kg per cubic meter, ± 19 kg per cubic meter, ± 21 kg per cubic meter, ± 23 kg per cubic meter, ± 25 kg per cubic meter, and ± 27 kg per cubic meter for samples 1, 2, 3, 4, 5, 6, and 7, respectively. It is worth noting that the ultimate mass desiccated density held significant influence over the characteristics of FC. Therefore, it represented a crucial factor in determining the ultimate durability and mechanical efficacy of FC.

In this particular study, the feasibility of the FC mixtures was determined through the implementation of the flow table spread test. The main objective of this test was to ascertain the uniformity and fluidity of the fresh FC. By effectively dispersing DFNT, it was possible to augment the viscosity of the liquid phase and delay the dispersion of the FC cement particles and fillers, thereby heightening the opposition to isolation. The outcomes from the flow table dispersion assessment conducted across all the mixtures examined within this investigation are visually represented in Fig. 6. As depicted in Fig. 6, the control sample (Sample 1) exhibited the smallest slump diameter, measuring 255 mm. The inclusion of DFNT in the FC resulted in an enhancement of the manoeuvrability of the FC, as evidenced by the rise in the weight proportions of DFNT. This improvement in manoeuvrability was observed in samples 2 and 7, with slump diameters of 261 mm and 287 mm, correspondingly. The augmentation of the operability of FC with the incorporation of DFNT can be attributed to the boosting of the persistence between the structures of the blend and the amplification of the amount of unbound water, as DFNT is known as water repellent. This elucidates the corresponding augmentation in slump diameter with the attendance of DFNT, as the exterior zone of DFNT exhibited minimal porosity. This minimal porosity negatively affected the bond to the matrix. In addition, the observed trend could potentially be attributed to the influence of DFNT, which led to the generation of consistent air bubbles. These air bubbles served to enhance the stiffness of the fresh FC mixtures. DFNT could be considered a passive component that lacks any chemical interactions alongside the protein emulsifier and liquid within the froth anatomy. Furthermore, the compact and limited exterior zone of DFNT resulted in the dissipation of the cementitious matrix surrounding it. As a result, the viscosity of FC was reduced, leading to an increase in the slump diameter. Consequently, there was a subsequent improvement in the flow ability of FC due to the unhindered movement of the dispersed stage beyond the capacity of the uncured dispersion arrangement. This allowed for the incorporation of air bubbles within the cement matrix23.

The UPV testing procedure was utilized in order to specify the quality and dependability of FC through the reduction in intensity and rapidity of an ultrasonic wave as it traversed the substance. A greater UPV indicated a higher level of quality and increased solidity of the FC anatomy, whereas a lower UPV suggested that the FC cases may potentially consist of fractures and empty spaces. The outcomes of the acoustic wave speed of FC with various weight proportions of DFNT are depicted in Fig. 7. The UPV values observed in various cases were generally in close proximity, indicating marginal confinement of sizable voids during the preparation of the FC case.24 Case 5 exhibited a UPV measurement of 2208 m/s, whereas case 1 gained a UPV measurement of 1784 m/s, suggesting that the introduction of minute nanoparticles effectively filled the voids and air pockets, thereby impeding the further propagation of microcracks.25 Moreover, this served as an indication of a reduction in the number of gaps within the FC composite as a result of the presence of DFNT, particularly during the initial stages.26 This happened due to the enhancement of the acceleration of the hydration procedure. Additionally, it was observed that the UPV value significantly decreased beyond the ideal degree of DFNT inclusion (sample 5) due to the accumulation and uneven distribution of DFNT within the FC binder framework, resulting in a decrease in the acoustic wave speed (Case 6). The substantial proportion of DFNT in the FC mixture hindered the hydration procedure and consequently resulted in a diminished UPV measurement.3 Nevertheless, the UPV value measured for sample 7 still exceeded the UPV value of sample 1.

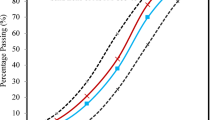

The influence of different mass ratios of DFNT on the porosity of FC is illustrated in Fig. 8. Sample 5 exhibited the lowest porosity metric, showing a reduction of about 26% compared to Sample 1 (reference). This decrease is due to the improved hydration induced by DFNT, which enhanced the filling capacity. Specifically, Sample 5 displayed a porosity of 36%, while Sample 1 attained a porosity measurement of 52% on day 30. However, when the mass ratios of DFNT exceeded 0.30%, the porosity increased. This can be attributed to the aggregation of DFNT, which reduces their ability to occupy the voids in the FC cementitious amalgam. Tiny cracks appear within the FC matrix at the boundary region due to the presence of DFNT, thereby improving the flow of liquid through them. Additionally, as the capillary action progressed to the dynamic phase, the movement of water particles across the DFNT-FC boundary led to increased diffusiveness. The variation in the transmission rate for the same DFNT mass ratio in FC was due to the scattering of inherent elements. The reference FC scenario showed significant void dimensions and interconnected cavities. The presence of DFNT improved the FC microstructure by reducing the size and number of voids, enhancing the bond between the filler (sand) and the cementitious matrix, and increasing the strength of the FC. Furthermore, the inclusion of DFNT in FC initiated the formation of obstructed pores, reducing the size of apertures and lowering the absorption coefficient of the FC composite.27

The moisture uptake potential of the FC specimens was assessed sporadically of 10, 30, and 60 epochs amid the maturation procedure, and the result is depicted in Fig. 9. Specimen 1 (reference specimen) displayed the highest level of moisture uptake percentages of 26%, 24%, and 22% at the individual maturation periods of 10, 30, and 60 days. The addition of DFNT engendered a significant improvement in the moisture uptake potential of FC. The preliminary moisture uptake potential was primarily influenced by large pores, whereas the subsequent moisture uptake potential was influenced by smaller pores. Sample 5 demonstrated a more effective reduction in initial water absorption by effectively filling macropores. From the results presented in Fig. 9, it is evident that the water absorption capacity reached its optimal level when 0.30% DFNT was included in the mixture (Sample 5). This resulted in a significant reduction of 19%, 21%, and 22% in water absorption at curing ages of 10, 30, and 60 days, respectively, as opposed to the benchmark specimen (Sample 5). The noted reduction in moisture uptake ability can be linked to the existence of DFNT, which functions as an adhesive, efficiently consolidating the FC cementitious framework and minimizing the cavities within the FC material.28,29

Figure 10a illustrates the Scanning Electron Microscopy (SEM) image of the control FC case. It is evident from Fig. 10a that the pores exhibited a substantial size and were interconnected. The incorporation of DFNT in FC resulted in an enhancement of the uniformity of the mortar slurry, ultimately leading to an increased density of the FC sample. Figure 10b reveals the presence of larger quantities of DFNT agglomerates within the FC matrix, thereby contributing to the development of a more compact and more homogeneous microstructure in contrast to the standard case. Consequently, this resulted in a reduction in the water absorption capacity. Furthermore, the incorporation of the Discrete Fiber Numerical Tool (DFNT) in Fiber Cement (FC) amplified the capacity to fill gaps and enhanced the formation of enhanced the formation of hydration products due to the heightened hydration procedure commenced by DFNT. As the weight fraction of DFNT exceeded 0.30%, the penetration ability of FC escalated. This phenomenon, potentially attributed to the accumulation of DFNT, diminished its ability to occupy empty spaces.

Concrete desiccation contraction refers to the diminution in concrete volume, chiefly due to a decrease in overall size caused by insufficient ambient humidity levels. This occurrence is a common origin of concrete cracking. The compound made from FC binder is considered a rheological material, meaning this volume change entails both elastic and viscous processes. The results of the desiccation contraction assessment for FC with varying mass ratios of DFNT are shown in Fig. 11. It is clear from Fig. 11 that desiccation contraction augmented over time for all blends. Generally, case 1 (the reference scenario) shows the most significant diminution in moisture content. Adding DFNT to FC significantly diminished the desiccation contraction.30 The existence of 0.30% DFNT in the FC mix (Sample 5) provided the best result. The DFNT had the ability to assimilate tensile energy as the FC contracts. This assimilation transpired at the point where the DFNT and FC matrix interlaced. As a result, the assimilated energy was distributed to the surrounding framework, reducing intense tensile stress within the FC framework. This diminution ultimately improved resistance to crack genesis. However, in the event that the proportion of DFNT within the FC cementitious framework surpasses 0.30% in terms of weight, an inadequate distribution of DFNT within the FC framework results in a balling effect of the nanoparticles. This balling effect hinders the dispersion of tensile stress from the FC region to other areas through the DFNT surface, thereby diminishing its effectiveness. This elucidation provides justification for the absence of notable enhancement in relation to the resistance to desiccation contraction fissuring beyond the mass proportion of 0.30%. When the optimal amount of DFNT is uniformly distributed across the FC binder matrix, the cement’s hydrated materials assemble surrounding the DFNT owing to its exceptional surface enthalpy acting as nucleation sites. The splitting tensile strength test was performed at intervals of 10, 30, and 60 days, with three specimens tested for each mix design. The average values for each formulation are presented in Fig. 12. The results indicate that the inclusion of DFNT in the concrete notably improved splitting tensile strength at all ages compared to the control specimens. Among the samples, Sample 5 demonstrated the highest splitting tensile strength.

Illustrated in Fig. 13 is the intricate relationship between the ability of water to be absorbed and the porosity of FC. It can be observed from Fig. 13 that there exists a linear relationship between its ability to absorb water and the congestion of FC. The visually captivating diagram depicted in Fig. 13 simply demonstrates that as the moisture uptake ability of FC increases, its congestion also increases. The R-squared value of 0.908 indicated a strong linear correlation among the permeability of FC and the moisture uptake. The incorporation of DFNT in the pore architecture configuration of the FC cementitious matrix brought about modifications to both the porousness and the ability of FC to absorb water. The emergence of free water distribution occurred on the exterior and flowed within the deepest section of the FC framework. Furthermore, the capacity for internal moisture uptake might have a minor influence on the permeability of FC. Moreover, the incorporation of DFNT into FC mixtures amplified the steadfastness of the cement paste, leading to a denser FC sample adorned with pores that are firmly sealed and a reduced number of unexposed ones. This consequently reduced the ability of FC to absorb water as the congestion decreased. The occurrence of DFNT in FC heightened the packing capability within the cementitious anatomy and augmented the hydration products as a result of the escalated hydration activity ignited by DFNT.

Figure 14 depicts the link between the velocity of ultrasonic wave propagation in FC and its porosity, in the presence of DFNT. It is evident that there exists a linear correlation between the velocity of ultrasonic wave propagation and the porosity of FC. The graphical representation clearly demonstrates that as the porosity decreased, the value of ultrasonic pulse velocity improved. The coefficient of determination, or R-squared value, of 0.9741 portrayed a strong correlation between the velocity of the ultrasonic pulse and the permeability of FC. The velocity of ultrasonic wave propagation in FC started to decrease once the consistency of FC transitioned from plasticity to fluidity. Furthermore, these velocities increase with the incorporation of higher-weight fractions of DFNT in FC mixtures. It is noteworthy to mention that FC exhibits an exceptional air content and consistently upholds supplementary air apertures due to the proximity within the air cavities. This resulted in a higher occurrence of void fusion that gave rise to the formation of larger intermittent pockets of air in the cementitious matrix of FC. By incorporating DFNT into FC, there was a reduction in enclosed aerated voids, incorporated aerated voids, and the capillary cavities, that enhanced the acoustic wave travel speed of FC. The speed of wave conveyance was dependent on the pliable attribute of FC.

Conclusions

This study aimed to synthesize new dendritic fibrous nano-titanium (DFNT) and investigate the impact of incorporating DFNT on the long-lastingness and mechanical characteristics of FC. Several physical and chemical analyses were performed to assess the mesoporosity, as well as morphological and textural properties of DFNT. The optimized nanostructures were employed in the fabrication of lightweight concrete. The FC cases were strengthened with DFNT at various weight proportions including 0.10%, 0.20%, 0.25%, 0.30%, 0.35%, and 0.40%. An FC congestion of 1000 kg/m3 was produced and subjected to experimentation. The endurance attributes were evaluated. Based on the conducted analysis, the following deductions were made.

-

A.

In relation to the maneuverability of FC, the control mic (without the inclusion of DFNT) exhibited the tiniest diameter of a slump, measuring 255 mm. By incorporating DFNT into FC, the maneuverability of FC was improved as the proportions of mass for DFNT increased. The enhancement in the workability of FC, caused by the presence of DFNT, may potentially be attributed to the boost of durability amidst the interplay of the components within the amalgamation and the development of the unobstructed aqueous composition, as DFNT has a tendency to disperse water.

-

B.

The UPV values observed in the varying FC cases exhibited proximity to one another, thereby suggesting a lack of significant entrapment of large voids. Notably, Sample 5 exerted a discernible effect on the UPV of FC, as it achieved a marked improvement of 21% within a span of 30% days compared to that of the control specimen. This improvement was indicative of the efficacy of DFNT in further filling up the voids and air pores, thereby effectively preventing the occurrence of microcracks.

-

C.

Sample 5 demonstrated the most favorable outcomes in terms of porosity and water absorption capacity. Porosity exhibited a decrease of 26% on day 30 when compared to the control sample, likely attributable to the elevated capacity of DFNT to fill voids. Water absorption experienced a reduction of 21% on day 30 in comparison to the control case.

-

D.

The drying shrinkage of FC, when DFNT was included, increased as the age of the mixes progressed. The drying shrinkage of the control case was observed to be the most pronounced. The inclusion of DFNT significantly reduced the drying shrinkage. The most favorable outcome was achieved with case 5. As the FC underwent shrinkage, the DFNT absorbed tensile energy and released this energy into the surrounding cementitious matrix, resulting in a decrease in the tensile stress within the FC. This decrease in tensile stress enhanced the resistance to cracking.

Data availability

All data generated or analysed during this study are included in this published article.

Abbreviations

- DFNT:

-

Dendritic fibrous nano-titanium

- PC:

-

Portland cement

- FC:

-

Fine concrete

- CPB:

-

Cetylpyridinium bromide

- TEM:

-

Transmission electron microscopy

- SEM:

-

Scanning electron microscope

- AFM:

-

Atomic force microscopy

- BET:

-

Brunauer-Emmett-Teller

- XRD :

-

X-ray diffraction

- FTIR:

-

Fourier transform infrared spectroscopy

References

Serri, E., Mydin, M. A. & Suleiman, M. Z. Thermal properties of Oil Palm Shell lightweight concrete with different mix designs. J. Teknol. https://doi.org/10.11113/jt.v70.2507 (2014).

Huang, Z., Zhang, T. & Wen, Z. Proportioning and characterization of Portland cement-based ultra-lightweight foam concretes. Construct. Build. Mater. 79, 390–396 (2015).

Mydin, M. A. The effect of raw mesocarp fibre inclusion on the durability properties of lightweight foamed concrete. J. Sci. Technol. Dev. 38, 59–66 (2021).

Raj, A., Sathyan, D. & Mini, K. M. Physical and functional characteristics of foam concrete: A review. Construct. Build. Mater. 221, 787–799 (2019).

Mydin, M. A. O., Ganesan, S., Yunos, M. Y. M., Utaberta, N. & Ismail, N. A. Structural behaviour of coir fibre-reinforced foamed concrete wall panel system. J. Teknol. 78, 169–177 (2016).

Mohd Zamzani, N., Mydin, O. M. A. & Ghani, A. Mathematical regression models for prediction of durability properties of foamed concrete with the inclusion of coir fibre. Int. J. Eng. Adv. 8, 3353–3358 (2019).

Jones, M. R., Ozlutas, K. & Zheng, L. Stability and instability of foamed concrete. Mag. Concr. Res. 68, 542–549 (2016).

Nensok, M. H., Mydin, M. A. & Awang, H. Investigation of thermal, mechanical and transport properties of ultra-lightweight foamed concrete (ULFC) strengthened with alkali treated banana fibre. J. Adv. Res. Fluid Mech. Therm. Sci. 86, 123–139 (2021).

Mounanga, P., Gbongbon, W., Poullain, P. & Turcry, P. Proportioning and characterization of lightweight concrete mixtures made with rigid polyurethane foam wastes. Cement Concr. Compos. 30, 806–814 (2008).

Wee, T. H., Daneti, S. B. & Tamilselvan, T. Effect of w/c ratio on air-void system of foamed concrete and their influence on mechanical properties. Mag. Concr. Res. 63, 583–595 (2011).

Kudyakov, A. I. & Steshenko, A. B. Cement foam concrete with low shrinkage. Trans Tech Publications 1085, 245–249 (2015).

Bokhari, A., Yusup, S., Faridi, J. A. & Kamil, R. N. M. Blending study of palm oil methyl esters with rubber seed oil methyl esters to improve biodiesel properties. Chem. Eng. Trans. 37, 571–576 (2014).

Arshad, S. et al. Assessing the potential of green CdO2 nano-catalyst for the synthesis of biodiesel using non-edible seed oil of Malabar Ebony. Fuel 333, 126492 (2023).

Zhang, Y. et al. Co-pyrolysis of lychee and plastic waste as a source of bioenergy through kinetic study and thermodynamic analysis. Energy 256, 124678 (2022).

G¨okçe, H. S., Hatungimana, D. & Ramyar, K. Effect of fly ash and silica fume on hardened properties of foam concrete. Build. Mater. 194, 1–1 (2019).

Zahmatkesh, S., Ni, B.-J., Klemeˇs, J. J., Bokhari, A. & Hajiaghaei-Keshteli, M. Carbon quantum dots-Ag nanoparticle membrane for preventing emerging contaminants in oil produced water. J. Water Proc. Eng. 50, 103309 (2022).

Yan, X. et al. Effect of anatase TiO2 on electrochemical properties of elongated bending TiO2-bronze nanowires for lithium ion batteries. Electrochim. Acta 191, 661 (2016).

Opra, D. P. et al. Vanadium-doped TiO2-B/anatase mesoporous nanotubes with improved rate and cycle performance for rechargeable lithium and sodium batteries. J. Mater. Sci. Technol. 54, 181 (2020).

Ye, X. Z., Hu, H. R., Xiong, H., Wang, Y. & Ye, J. F. Rational synthesis and lithium storage properties of hierarchical nanoporous TiO2 (B) assemblies with tailored crystallites and architectures. J. Colloid Interface Sci. 600, 530 (2021).

Li, Y. et al. Preparation of Ag3PO4/TiO2(B) heterojunction nanobelt with extended light response and enhanced photocatalytic performance. Molecules 26, 6987 (2021).

Luo, L. et al. Cation-deficient TiO2 (B) nanowires with protons charge compensation for regulating reversible magnesium storage. Nano Energy 72, 104716 (2020).

Chen, Y. & Sadeghzadeh, S. M. Dendritic fibrous nano-titanium (DFNT) with highly dispersed poly (ionic liquids) as a nanocatalyst for synthesis of dimethyl carbonate from methanol and carbon dioxide. J. Mol. Liq. 384, 122201 (2023).

Kawashima, S., Hou, P., Corr, D. J. & Shah, S. P. Modification of cement-based materials with nanoparticles. Cement Concr. Compos. 36, 8–15 (2013).

Nensok, M. H., Mydin, M. A. & Awang, H. Fresh state and mechanical properties of ultra-lightweight foamed concrete incorporating alkali treated banana fibre. J. Teknol. 84, 117–128 (2022).

Zamzani, N. M., Mydin, M. A. & Ghani, A. N. Effectiveness of ‘cocos nucifera linn’fibre reinforcement on the drying shrinkage of lightweight foamed concrete. J. Eng. Appl. Sci. 14, 3932–3937 (2019).

Suhaili, S. S., Mydin, M. A. & Awang, H. Influence of mesocarp fibre inclusion on thermal properties of foamed concrete. J. Adv. Res. Fluid Mech. Therm. Sci. 87(1), 101 (2021).

Dhasindrakrishna, K., Pasupathy, K., Ramakrishnan, S. & Sanjayan, J. Effect of yield stress development on the foam-stability of aerated geopolymer concrete. Cement Concr. Res. 138, 106233 (2020).

Chuah, S., Pan, Z., Sanjayan, J. G., Wang, C. M. & Duan, W. H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Build. Mater. 73, 113–124 (2014).

Hanus, M. J. & Harris, A. T. Nanotechnology innovations for the construction industry. Prog. Mater. Sci. 58, 1056–1102 (2013).

Xu, J., Shen, W., Corr, D. J. & Shah, S. P. Effects of nanosilica on cement grain/C–S–H gel interfacial properties quantified by modulus mapping and nanoscratch. Mater. Res Express 6, 045061 (2019).

Acknowledgements

Not Applicable.

Author information

Authors and Affiliations

Contributions

Hossein Javan: Conceptualization, Methodology; Amin Honarbakhsh: Project administration, Investigation, Formal analysis; Seyed Mojtaba Movahedifar: Investigation, Resources, Data Curation; Mehdi Nobahari: Methodology; Rahele Zhiani: Writing—Original Draft;

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Javan, H., Honarbakhsh, A., Movahedifar, S.M. et al. The use of dendritic fibrous nano-titanium to enhance the initial characteristics and durability of lightweight concrete. Sci Rep 15, 11811 (2025). https://doi.org/10.1038/s41598-025-96034-2

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96034-2