Abstract

Calcarenite sand, as a key geotechnical material in the construction of South China Sea islands and reefs, is limited in its engineering applications due to its significant high compressibility characteristics. This study proposes a treatment method combining Enzyme-Induced Calcium Carbonate Precipitation (EICP) with coir fiber. Through a series of one-dimensional compression tests, the effects of different grouting times (0, 3, 6, 9), coir fiber contents (0%, 0.2%, 0.4%, 0.6%, 0.8%), and relative densities (30%, 60%, 90%) on the compressive characteristics of calcarenite sand were systematically investigated. The research findings indicate that as the number of EICP grouting cycles increases, the reduction in the void ratio of the samples gradually diminishes. Under the same conditions, the addition of coir fiber initially leads to a decrease in the reduction of the void ratio, followed by an increasing trend. The experimental data under various conditions were successfully fitted using the Harris function, elucidating the relationships between the model parameters b and c and the factors of calcium carbonate content, coir fiber content, and initial void ratio. Additionally, the Lasso regularization method was employed, and a polynomial model equation was established using Matlab software based on the method of defining training and testing datasets (with the parameter b as a 4th-order polynomial and the c as a 3rd-order polynomial). Validation demonstrated that the constructed model equations possess high predictive accuracy and generalization capability. This study not only deepens the understanding of the one-dimensional compressive deformation of calcarenite sand under the synergistic effect of coir fiber and EICP technology, but also provides a theoretical basis for the rapid assessment and optimization of the compressive characteristics of calcarenite sand foundations in the construction of South China Sea islands and reefs.

Similar content being viewed by others

Introduction

Marine calcareous sand (CS) is a kind of marine sediment rich in calcium carbonate and other carbonate insoluble substances1,2. Different from terrestrial sand, its particle shape is extremely irregular, and the strength is much lower than that of siliceous sand, which has the characteristics of high compressibility and low strength3,4,5,6. Given that calcarenite sand is a common foundation material in the construction of South China Sea islands and reefs, its compression characteristics under external load have attracted much attention. If the calcareous sand foundation is not properly treated, it may lead to uneven settlement and other problems, which seriously affects the stability of reef buildings7. Although the traditional reinforcement methods such as mechanical reinforcement and chemical treatment are effective, they are usually accompanied by high costs and potential ecological and environmental problems8,9.

In recent years, EICP mineralization (urease-induced calcium carbonate precipitation) has gradually gained attention as a novel ground improvement technique in geotechnical engineering. It catalyzes the hydrolysis of urea to produce carbonate ions by urease, and then combines with calcium ions in the soil to form calcium carbonate precipitation, so as to achieve the purpose of stabilizing the soil10,11. Compared with MICP (microbial induced calcium carbonate precipitation) mineralization technology, EICP technology eliminates the process of microbial culture and metabolic production of urease, simplifies the construction process, and avoids problems such as microbial ecological security monitoring12. Currently, the feasibility of EICP technology for the reinforcement of calcarenite sand has been preliminarily verified. Qiwu13 used different calcium sources (calcium chloride, calcium acetate, calcium lactate, calcium nitrate) to carry out EICP cementation of calcareous sand. The results showed that different types of calcium sources would affect the compressive strength, permeability and crystal type of calcium carbonate precipitation. Zhang14 proposed a parallel injection method for EICP cementation of calcareous sand, which effectively improved the compressive strength and overall water conductivity of the sample. Liu15 combined EICP technology with casein to treat calcareous sand, which solved the problem of low crystallinity and insufficient cementation strength of calcium carbonate by pure EICP technology. However, the sole application of EICP mineralization treatment tends to increase the brittleness of the material. Jiang et al.16 demonstrated that as the degree of EICP cementation increases, the strength of calcarenite sand specimens improves, but their brittleness also becomes more pronounced. Therefore, researchers have begun to explore the combination of fiber reinforcement techniques with biomineralization technologies to further enhance the mechanical properties of calcarenite sand. Early studies demonstrated that synthetic materials such as polypropylene fibers, carbon fibers, and basalt fibers, when combined with EICP or MICP technologies, could significantly improve the mechanical properties of cemented sand17,18,19,20. However, due to the issues of poor degradability and high cost associated with these materials, renewable resources such as plant and animal fibers have gradually become new research hotspots21. Yao et al.22 used wool in combination with MICP technology to treat sand, significantly improving the compressive strength and flexural performance of the samples. Zhang23 used sisal fiber as a reinforcing material in EICP-cemented calcareous sand. The results indicated that this method effectively enhanced the mechanical strength and toughness of the cemented sand. Jiang et al.24 reinforced EICP-cemented calcarenite sand specimens with coir fiber, thereby improving their brittle failure mode. This indicates that fiber reinforcement technology can effectively enhance the strength and toughness characteristics of EICP-treated calcarenite sand.

Meanwhile, significant progress has also been made in the study of the compressive characteristics of calcarenite sand. Zhang et al.25 conducted one-dimensional compression tests on calcarenite sand and found that its large internal pores and susceptibility to fragmentation make it highly compressible under external loading. Sun et al.26 used an MTS universal testing machine to subject both quartz sand and calcarenite sand to stepwise loading under confined conditions. The results indicated that calcarenite sand is more easily compressed than quartz sand. Liu et al.27 clarified the effects of calcium carbonate content and particle size on the compressive characteristics of calcarenite sand through confined compression tests in the laboratory. Yuan et al.28 found that the deformation of calcarenite sand specimens is jointly controlled by particle reorientation and particle breakage. When the vertical stress increases, particle breakage is intensified, leading to a significant increase in deformation. Therefore, calcarenite sand is highly compressible under confined conditions, a characteristic that poses a potential threat in engineering practice. To address this issue, Chen et al.29 improved calcarenite sand using an environmentally friendly polymer. Consolidation-compression tests indicated that the polymer significantly enhanced its compressive deformation characteristics. Guo et al.30 reinforced calcarenite sand specimens using the MICP mixing method and found that the compressive characteristics of the calcarenite sand were considerably improved after cementation. However, to date, studies on EICP technology, especially the reinforcement of calcarenite sand by combining fiber reinforcement with EICP to investigate its one-dimensional compressive characteristics, remain limited.

In one-dimensional compression tests, the void ratio e of calcareous sand samples exhibits a decreasing trend with increasing vertical pressure. In existing studies, many researchers believe that S-shaped curve functions, such as the Logistic function, Gompertz function, and Harris function, can effectively describe the compression deformation behavior of soils31,32,33. Zhao34 demonstrated through engineering examples that the two-stage loading consolidation test described by the Harris expression yields results equivalent to those of standard consolidation tests. They pointed out that the Harris function has a shape similar to the soil’s e-lgp curve, which can effectively calculate the soil’s pre-consolidation pressure. Wang35 analyzed various functional expressions and concluded that the S-shaped Harris function was highly accurate and suitable for describing the e-lgp curve. These studies collectively demonstrate that the S-shaped function provides a highly accurate description of the compression curve for a single soil. However, when it comes to the application of EICP technology, particularly for calcarenite sand specimens cemented by EICP with fiber incorporation to form composite materials, discussions regarding the applicability of the aforementioned S-shaped curve are still limited. Therefore, to further investigate and validate the applicability of the S-shaped curve in such composite materials, this study employs the Harris function to explore its suitability in describing the one-dimensional compressive characteristics of calcarenite sand cemented by EICP with fiber incorporation.

Coir fiber, as a green and environmentally friendly natural material, is widely distributed in the South China Sea region. It is easily accessible and cost-effective36, making it an ideal choice as a reinforcement material for the experiment. In this study, calcareous sand was treated using a combination of EICP and coir fiber reinforcement. The main variables controlled were the number of EICP grouting cycles, coir fiber content, and relative density. One-dimensional compression tests were conducted to investigate the effects of these factors on the compressive properties of the samples. Based on the test results, a Harris function model was developed to describe the conditions under different experimental setups. This study further investigates the effects of the combined action of coir fiber reinforcement and EICP cementation on the one-dimensional compressive characteristics of calcarenite sand. It is expected to provide new strategies and methods for the treatment and prediction of calcarenite sand foundations in the construction of South China Sea islands and reefs.

Materials and methods

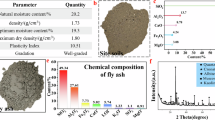

Calcareous sand and fibers

The calcarenite sand used in the experiments was collected from an island reef in the South China Sea. To remove the minor impurities present in the original sand, the collected calcarenite sand was subjected to washing and drying processes. Subsequently, indoor physical property tests were conducted on the sand. The specific physical parameters are presented in Table 1. X-ray diffraction (XRD) analysis revealed that the mineral composition of the sand is predominantly biogenic aragonite, with minor amounts of quartz and other minerals. The calcium carbonate content exceeds 85%, and the XRD test results are shown in Fig. 1.

During the preliminary analysis of the retrieved calcarenite sand, it was found that the particle sizes were predominantly less than 2 mm, with particles larger than 2 mm accounting for less than 3% of the total. Based on this observation, all particles larger than 2 mm were removed from the samples prior to testing. Subsequently, a particle size distribution test was conducted, and the resulting gradation curve is shown in Fig. 2. Combining the data from Fig. 2 and Table 1, the uniformity coefficient (Cu) and curvature coefficient (Cc) of the sand sample were determined to be 4.49 and 1.07, respectively. These values indicate that the calcarenite sand used in this study has a poorly graded particle distribution.

Coir fibers with a 10–12 mm length were selected as the reinforcing material24. The basic physical and mechanical parameters37 are shown in Table 2. According to numerous studies by scholars38,39,40, treating coir fiber with a strong alkali (NaOH) can effectively increase the thickness of the fiber cell wall and the surface cellulose content. This enhances the durability and mechanical strength of coir fiber. Additionally, the roughness of the coir fiber surface is increased after treatment, which helps to enhance the friction between the fiber and soil particles. Based on these findings, in this study, coir fibers that had been washed were soaked in a 10% NaOH solution by mass.

Preparation of urease

In current research, urease is primarily extracted from bacteria or plant cells41,42. Although bacteria are a common source for urease extraction, the extraction process typically involves ultrasonic lysis to disrupt bacterial cells, thereby facilitating the extraction of urease. However, this method requires high-precision equipment and is relatively complex to operate. Therefore, researchers tend to prefer extracting urease from plant materials. Among plant sources, legume and cucurbit seeds are considered good sources of urease. Existing studies have found that urease extracted from jack beans has high activity, but since jack beans are not widely cultivated in China and are relatively ex-pensive, finding a cheaper and more accessible alternative source is particularly important. According to the research of Gao et al.43, it has been found that soybeans not only provide urease with high activity but are also abundant in pro-duction, low in cost, and easily accessible in China. Therefore, this experiment selects soybeans as the primary source for urease extraction.

By referring to the methods of extracting urease from soybeans by Jiang16,24 and Qiwu13, the specific extraction steps are as follows: (1) Crush the soybeans using grinding equipment and pass them through a 100-mesh standard sieve to obtain soybean powder. (2) Mix a specified amount of soybean powder with water at a mass ratio of 1:10 and stir the mixture on a magnetic stirrer for 30 min. (3) After stirring, refrigerate the mixture at 4 °C for 12 h. (4) Transfer the refrigerated solution to centrifuge tubes and centrifuge at 4500 rpm for 20 min. After centrifugation and filtration, the soybean urease solution is obtained. The extraction process is shown in Fig. 3. The cementation solution used in the experiments was prepared by mixing urea at a concentration of 0.75 mol/L with an equal volume of anhydrous CaCl2 solution.

Sample preparation and test scheme

The samples were prepared using a cutting ring with an inner diameter of 61.8 mm and a height of 20 mm. The specific sample preparation process is as follows: (1) Assemble and secure the permeable stone, cutting ring and fixed ring components. According to the preset sample preparation parameters, weigh a specific amount of calcareous sand and coir fiber, then mix them evenly with an appropriate amount of water. Next, place the mixture into the cutting ring in three layers, compacting each layer to the desired height using vibration. Finally, seal the top using a cork that has a hole. (2) Use a peristaltic pump to perform cyclic grouting on the samples, maintaining a low flow rate of 5–8 mL/min for the grouting process. (3) After completing the required number of grouting cycles as per the experimental plan, stop the grouting and place the samples in a constant temperature chamber at 30 °C for 5 days. During the cyclic grouting process, first inject the urease solution, then allow the samples to sit for 6 h before injecting the cementation solution. This injection process is repeated every 6 h. (Based on preliminary experimental studies on urease activity, its activity significantly diminishes after 24 h at room temperature. Therefore, after three injections of the cementation solution, the urease solution needs to be reinjected.) The volume of each solution injected is 1.5 times the initial void volume of the sample.

The experiment uses the number of cementation solution injections, N, as one of the variables to investigate the effect of different degrees of cementation on the compressive properties of calcareous sand samples. Additionally, considering the significant impact of varying coir fiber content and the initial relative density of calcareous sand samples on their compressive properties, this study investigates these three factors. The specific experimental plan is detailed in Table 3, with three parallel samples set for each experimental condition.

The compressive characteristics of the calcareous sand samples were determined using a GDG-4S type high-pressure consolidation apparatus. According to the “Highway Geotechnical Test Procedures” (JTG3430-2020), The saturated samples were gradually loaded with pressure levels of 50, 100, 200, 400, 800, 1600, 3200, and 4000 kPa, each sustained for 24 h. The corresponding compressive deformation under each load was recorded29,30. The sample preparation and compression test procedures are illustrated in Fig. 4.

Results

Generalized initial void ratio

When exploring the synergistic effect of coir fiber and EICP technology on the compression deformation characteristics of calcareous sand samples, the compression curve should be drawn based on the accurate initial void ratio. Therefore, the generalized initial void ratio e044,45 is introduced in this paper. This index not only considers the original pores between the calcareous sand particles, but also takes the volume of CaCO3 generated into account between the sand particles and the incorporated coir fiber in the sample, so as to accurately reflect the initial state of the cemented sand. The generalized initial void ratio can be calculated by Eq. (1),

In the formula, V is the initial volume of the sample, which is 60 cm3 in this experiment; ms, mca and mF represent the quality of dry calcareous sand, generated calcium carbonate and coir fiber, respectively. \({\rho }_{w}\) is the density of water; Gs and Gca are the relative proportion of calcareous sand and calcium carbonate, respectively, of which Gca is 2.71; \({\rho }_{F}\) is the density of coir fiber, which is 1.12 g/cm3.

Considering that calcareous sand is mainly composed of calcium carbonate, the mass of CaCO3 generated after EICP cementation was determined using the mass comparison method13. Firstly, the initial mass M1 of the dry calcareous sand is measured. Then, the calcareous sand samples undergo EICP grouting treatment, and the grouting is stopped once the cemented body reaches the predetermined number of grouting cycles. To minimize the impact of non-calcium carbonate materials such as salts and organic matter within the samples on the measurement of calcium carbonate mass. In this study, after ceasing grouting, clean water was injected into the samples at intervals of 24 h to remove salts and organ ic matter during the reaction process. After the curing of each sample is completed, the mass M2 of the dried cemented body is measured. The change in mass of the EICP-cemented calcareous sand samples (with or without coir fibers) compared to their mass before cementation (M2–M1) represents the mass of calcium carbonate generated. To ensure the accuracy of the weighing data, five replicate experiments were conducted under each set of sample conditions to enhance the precision of the CaCO3 mass determination. Table 4 shows the generalized initial void ratio values for all samples.

Compression curve

Influence of relative density

In the one-dimensional compression test, the change of void ratio e44 is calculated by recording the compression amount of the calcareous sand samples in the stable state under each level of load, and the compression curve is drawn accordingly, where the horizontal scale is the logarithm of the load pressure lgp, and the vertical coordinates is the void ratio e. In order to explore the difference of compression behavior of samples under different relative density conditions, it was found that although the test conditions were different, the e-lgp curves of each sample showed similar evolution patterns. Therefore, the natural calcareous sand (CS) and the calcareous sand mixed with 0.4% coir fiber (FS (0.4%)) were selected as examples, as shown in Fig. 5. With the increase in vertical pressure, the void ratio e of both CS and FS (0.4%) samples decreases. Moreover, samples with lower relative density exhibit a faster rate of void ratio reduction under the same pressure. A detailed analysis of the data during the loading process reveals that as the vertical pressure is applied from 0 to 4000 kPa, the void ratio e of the EICP-S specimen decreases by 51.4% when the relative density Dr is 30%, while the void ratio e of the EICP-FS specimen decreases by 46%. When Dr is increased to 60%, the void ratios of the EICP-S and EICP-FS specimens decrease by 45.5% and 40.8%, respectively. Under a relative density condition of 90%, the reductions are 47.5% and 44.4% for the EICP-S and EICP-FS specimens, respectively. These results indicate that, under the same relative density conditions, incorporating coir fiber into calcarenite sand can somewhat improve the compressive performance of the material. However, this improvement is not as significant as the effect of relative density on compressibility. On one hand, as the relative density increases, the pore volume within the sample decreases, limiting the ability of coir fibers to exert their confining effect. Therefore, under higher pressures, the fibers are compressed and deformed along with the calcarenite sand particles. On the other hand, as a biological material, coir fiber has inferior mechanical properties compared to calcarenite sand particles. When subjected to significant external forces, the fibers struggle to effectively prevent the movement of particles relative to one another. Therefore, relying solely on coir fiber to restrict the compressive deformation of calcarenite sand is highly limited. Based on this, the subsequent sections of this study focus primarily on investigating the improvement of the one-dimensional compressive performance of calcarenite sand through the combined action of coir fiber and EICP technology.

The particle crushing of calcareous sand in the compression process has remarkable effect on the compression performance. In the consolidation test, Li et al.46 found that there is a pressure threshold of 400 kPa in the calcareous sand. Once the vertical compression exceeded 400 kPa, a large number of calcareous sand particles would be broken, resulting in a sudden drop in the void ratio. Tian47 and Wu et al.48 also confirmed this finding, when the pressure of calcareous sand exceeded its specific yield point, the particle crushing inside the sample intensified, resulting in a rapid decrease in the void ratio. Guo et al.30 further elaborated on this viewpoint in compression test studies, and pointed out that in the pressure range of 200 to 400 kPa, the phenomenon of particle crushing in calcareous sand was particularly prominent, leading to a significant decrease in the void ratio.

It can be observed in Fig. 5 that, for both CS and FS (0.4%) samples, under different relative density conditions. When the vertical pressure does not exceed 400 kPa, the reduction trend of the void ratio is relatively gentle. However, once the vertical pressure surpasses 400 kPa, the decrease in the void ratio becomes more pronounced. Taking the CS specimen as an example, under a relative density of 30%, as the vertical pressure increases incrementally from 50 to 400 kPa, the reductions in the void ratio e under each load level are 0.022, 0.026, and 0.036, respectively. When the vertical pressure further increases to 800 kPa, the reduction in e reaches 0.069. Similarly, at a Dr of 60%, the reductions in e are 0.023, 0.027, 0.029, and 0.05, respectively. At Dr of 90%, these values are 0.016, 0.019, 0.026, and 0.041, respectively. It can be seen that when the vertical pressure does not exceed 400 kPa, the reductions in the void ratio are similar. However, once the vertical pressure surpasses the threshold of 400 kPa, the decrease in the void ratio becomes more pronounced. This indicates that in the early stages of the compression test, the deformation of the sample is primarily due to the relative displacement and rearrangement of particles. However, when the vertical pressure reaches a certain level, it enters the yield deformation stage, and the calcareous sand particles start to break, leading to more significant compression deformation.

Influence of relative density

The EICP technology is used to treat calcareous sand. By depositing calcium carbonate between sand particles, the particles are cemented into a tightly integrated whole, which effectively improves the ability of the sample to resist deformation49. Figure 5 shows the e-lgp curves of calcareous sand (CS) and fiber-doped calcareous sand samples (FS) after normalized processing under different grouting cycles. From Fig. 6a,d, it can be seen that when the relative density is 30%, no matter whether it is CS or FS samples, with the increase of EICP grouting cycles, the decrease of the void ratio (\(e/{e}_{0}\)) of the sample shows a decreasing trend. Meanwhile, in Fig. 6b,c,e,f, for the EICP cemented sand with up to 3 times of grouting cycles, the difference between the decreased degree in \(e/{e}_{0}\) and the untreated sand is less evident, and the values of the decreased degree are close. The phenomenon can be attributed to the fact that when the number of EICP treatments is low, especially for samples with low relative density, the samples themselves are prone to compression deformation due to the presence of a large number of internal pores. At this time, the amount of calcium carbonate generated is limited and insufficient to fill the pores within the samples, meaning that the improvement in the deformation performance of the samples is not significant.

When the number of grouting cycles was increased to 9, the reduction in the ratio \(e/{e}_{0}\) showed a significant decrease. Specifically, as shown in Fig. 6c, after nine EICP grouting cycles, the reduction in the void ratio \(e/{e}_{0}\) of the calcareous sand cemented body was only 36.54%, which is lower than the 50.11% of the untreated samples. Similarly, Fig. 6f illustrates that in calcareous sand samples containing 0.4% coir fibers, the reduction in the void ratio \(e/{e}_{0}\) without EICP-cemented treatment is almost 1.5 times that after nine cycles. Taking the scanning electron microscope (SEM) images of EICP-S and EICP-FS samples at Dr = 90% as an example for in-depth analysis, as shown in Figs. 7 and 8. When the number of grouting cycles N reaches nine, as shown in Fig. 7 for the EICP-S sample, the generated calcium carbonate deposits in the voids between the calcareous sand particles and on their surfaces. The loose calcareous sand particles are cemented together by CaCO3, significantly enhancing the structural integrity of the calcareous sand matrix. This results in a more stable connection between the sand grains, thereby improving its resistance to deformation under external forces.

In the case of the EICP-FS sample shown in Fig. 8, it is observed that the coir fibers are primarily distributed in the gaps between the calcareous sand particles. As the EICP reaction progresses, calcium carbonate begins to deposit on the surfaces between the coir fibers and the calcareous sand particles, gradually filling the voids between the sand grains. This process ultimately results in the formation of an integrated structure composed of sand grains and coir fibers, cemented together by calcium carbonate, which can be referred to as a calcareous sand-calcium carbonate composite. This composite enhances the anchoring effect of the coir fibers within the EICP-FS samples to a certain extent, thereby effectively improving the structural integrity of the cemented calcareous sand body and significantly increasing the sample’s resistance to compression.

A detailed analysis of the curves in Fig. 6a–f reveals that at lower loading pressures (p \(\le\) 400 kPa), the rate of reduction in void ratio (\(e/{e}_{0}\)) shows little difference between CS and FS samples, regardless of the number of EICP grouting cycles. However, when the pressure load exceeds the threshold (p ≥ 400 kPa), the compressive property of both CS and FS samples treated with EICP cementation improves. The specific performance is that the rate of reduction in the void ratio (\(e/{e}_{0}\)) slows down, and the compression curves become more gradual. This improvement becomes more pronounced with an increasing number of grouting cycles. This phenomenon can be further explained by referring to the schematic diagram of the failure mechanism of calcarenite sand shown in Fig. 9.

As the formation of strong connections within the samples due to the calcium carbonate generated during the EICP reaction, which helps to bear some of the external forces acting on the calcareous sand, effectively delaying the compressive deformation and failure of the sand particles. However, as the external load increases to a certain level, micro-cracks or even fractures begin to appear in the calcium carbonate between the sand particles in the EICP-S or EICP-FS samples, leading to localized detachment or rupture of the CaCO3 crystals. With further increases in pressure, the protective effect provided by the calcium carbonate diminishes until it ultimately fails, a process that first leads to the wear or abrasion of the sand particle surfaces. Under the continuous increase of external pressure, these already damaged sand particles eventually undergo fragmentation50. It is noteworthy that the presence of calcium carbonate cementation effectively delays the crushing process of calcareous sand particles, thereby significantly enhancing the compressive performance and structural stability of the samples. This suggests that the EICP technology has potential application value in improving the compressive performance of calcareous sand.

Influence of coir fiber content

The incorporation of coir fiber into calcareous sand affects its compressive properties, with varying degrees of impact depending on the fiber content. Figure 10 shows the compression curves of calcareous sand with different coir fiber contents. From the curves of each group, it can be observed that as the vertical pressure increases, the void ratio (\(e/{e}_{0}\)) gradually decreases. The reduction in \(e/{e}_{0}\) initially decreases and then increases with the increase in fiber content, reaching its minimum at a fiber content of 0.6%. To be specific, under a relative density condition of 30% (Fig. 10a), the void ratio (\(e/{e}_{0}\)) decreases by only 42.01% when the content of coir fiber is 0.6%, compared to a decrease of 50.11% in the calcareous sand sample without fiber. At a relative density of 60% (Fig. 10b), the reduction in void ratio with a 0.6% fiber content is 37.49%, which is also less than the 44.8% reduction observed in the sample without fiber. At a relative density of 90% (Fig. 10c), the reduction in void ratio for the sample without fiber is 47.5%, which is greater than the 39.85% reduction observed with a 0.6% fiber content. Notably, at a relative density of 90%, when the coir fiber content is increased to 0.8%, the reduction in void ratio (\(e/{e}_{0}\)) reaches 49.06%, surpassing the 47.51% reduction observed in the sample without fiber. The above phenomenon indicates that at lower coir fiber content, the fibers are unable to form a complete interwoven network structure within the sample, thus providing limited capability to restrict the movement and deformation of the sand particles. As the fiber content increases, there exists an optimal coir fiber content (0.6%), at which the formed fiber skeleton is relatively stable and interlocks with the irregularly shaped calcareous sand. However, when the fiber content is further increased, it becomes difficult to mix the fibers uniformly with the sand, resulting in the aggregation and even overlapping of fibers within the sample. This phenomenon is particularly pronounced in cases with smaller pore volume. This uneven distribution of fibers forms an unstable network structure, resulting in a significantly greater reduction in the void ratio (\(e/{e}_{0}\)). The extent of this reduction even surpasses that observed in the calcareous sand samples without fiber.

The calcareous sand samples containing coir fiber were subjected to 9 cycles of EICP cementation treatment. It was found that the pattern of changes in their compressive characteristics was similar to that of calcareous sand containing only fiber. As the coir fiber content increased, the reduction in void ratio (\(e/{e}_{0}\)) initially decreased and then increased, as shown in Fig. 11. Despite differences in the relative density of the samples, the compressive performance reaches its optimum at a fiber content of 0.6%, with the smallest reduction in void ratio observed at this level. Comparing the curves in Figs. 10 and 11, it is observed that the reduction in \(e/{e}_{0}\) of the cemented calcareous sand varies with different coir fiber contents. Specifically, at a relative density of 30% (Fig. 11a), the reduction in \(e/{e}_{0}\) for the cemented calcareous sand with 0.2% fiber is 36.46%, which is not significantly different from the 36.54% reduction observed in the sample without fiber. At a relative density of 60% (Fig. 11b), the reduction in \(e/{e}_{0}\) for the cemented body with 0.2% fiber is 36.08%, which shows a slight increase compared to the 35.47% reduction observed in the cemented body without fiber. When the relative density increases to 90% (Fig. 11c), the reduction in void ratio is 32.54% and 33.18% for the respective samples. This further confirms that under conditions of high relative density, the effect of low fiber content on the improvement of the compressive performance of the cemented body is relatively limited. Additionally, for the cemented body with a fiber content of 0.8%, the reduction in the void ratio \(e/{e}_{0}\) is generally higher than that of the control group without fibers. Especially at a relative density of 90% (Fig. 11c), the reduction in void ratio for the cemented body with 0.8% fiber content reached 37.7%, which is approximately 4% higher than that of the pure calcareous sand cemented body (33.68%). This phenomenon indicates that when the fiber content exceeds a certain threshold, the reinforcement effect diminishes. This may be due to the aggregation of fibers, which affects the deposition and distribution of calcium carbonate, leading to an unstable structure in the fiber-calcareous sand cemented body17. Consequently, this has a negative impact on its compressive performance, as evidenced by the greater reduction in void ratio compared to the cemented body without fibers.

When analyzing the reasons for the performance improvement of EICP cemented bodies with an increase in coir fiber content to 0.4% and even 0.6%, taking the EICP-FS sample with a relative density (Dr) of 90%, a coir fiber content of 0.6%, and subjected to nine EICP grouting cycles as an example. By discussing its SEM images, as depicted in Fig. 12. From the figure, it can be observed that a network structure composed of coir fibers has formed within the sample, and the application of EICP technology has enhanced the displacement-restraining effect of this network structure. Specifically, during the curing reaction process of EICP, calcium carbonate crystals initially deposit on the surfaces of the sand particles and fibers. As the reaction continues, these crystals not only further deposit between the sand particles but also form effective connections between the sand particles and the coir fibers. This process not only increases the roughness of the fiber surface but also significantly enhances the cementation effect between sand particles and fibers. On one hand, this cementation effect improves the integrity and stability of the material. On the other hand, when subjected to external loads, the coir fibers better serve an “anchoring” role within the cemented structure, effectively preventing relative sliding and faulting deformation of the cemented body or sand particles51.

Harris function and parameters of EICP-coir fiber cemented calcareous sand

Harris function

This study employs the Harris function to investigate the one-dimensional compression deformation characteristics of calcareous sand stabilized with coir fiber and EICP.

The expression for the Harris function is given in Eq. (2).

In the equation: e represents the void ratio of the sample; p denotes the vertical pressure load; a, b, and c are curve-fitting parameters.

In the one-dimensional compression test, to ensure that the logarithmic coordinate of the vertical load p is mathematically meaningful, this study assumes that the initial void ratio e0 of each samples (the void ratio at zero stress state) is equal to the void ratio e when p is 1 kPa. Thus, when lgp = 0, the parameter a and the Harris function are calculated according to Eqs. (3) and (4).

The Harris function from Eq. (4) was used to fit the relationship between the void ratio e and the vertical pressure in all test groups. The results indicate a good fit under all test conditions, with a coefficient of determination R2 exceeding 0.98. As an example, Fig. 13 presents the experimental data and corresponding Harris function fitting curves for the void ratio e versus the logarithmic vertical pressure (lgp) for natural calcareous sand, EICP-cemented calcareous sand, and EICP-cemented calcareous sand with fibers. The Fig. 13 shows that the fitting curves align closely with the actual data, indicating that this function provides a high level of accuracy in describing the relationship between e and lgp for the samples. It is worth noting that no matter how the relative density of the sample changes, whether it is treated by EICP, contains coir fiber, or even the fiber content changes, the Harris function can effectively capture and accurately describe the changes in the void ratio e of the sample under these conditions. Therefore, the Harris function can serve as an effective tool for quantitatively analyzing and predicting the compression characteristics of calcareous sand under the combined influence of coir fiber and EICP technology.

In the Harris function shown in Eq. (4), there are two key parameters, b and c. By fitting and analyzing the compression curves of each samples, it was found that the parameters b and c in the Harris function change with variations in fiber content, the number of EICP treatments, and the relative density of the samples. Moreover, these parameters exhibit complex nonlinear characteristics rather than a simple linear relationship. Figure 14 shows the numerical distribution of the parameters b and c in the Harris function under different experimental conditions.

Taking natural calcareous sand as an example, when the relative density is 30%, the parameters b and c are 0.0013 and 5.378, respectively. As the relative density increases to 60%, b and c change to 0.0028 and 4.774. When the relative density further increases to 90%, b and c are 0.0024 and 5.1537, respectively. Meanwhile, when 0.4% fiber is added to calcareous sand with a relative density of 60%, the parameters b and c become 0.0025 and 4.747, respectively. Under the same conditions, if the sample undergoes 9 cycles of EICP cementation treatment, the parameters b and c in the Harris function change to 0.0135 and 3.6634, respectively. It is worth noting that controlling different relative densities is essentially intended to alter the initial void ratio of the samples. In summary, the variations in parameters b and c are actually determined by multiple factors, including the initial void ratio e0, calcium carbonate content ccc, and coir fiber content w. Therefore, when the experimental conditions change, the corresponding parameters b and c will also be adjusted, leading to variations in the specific form of the Harris function model. Given this, in-depth investigation and determination of the expressions for b and c are of significant importance for accurately predicting the changes in the compression curve due to variations in experimental conditions such as initial void ratio e0, calcium carbonate content ccc, and coir fiber content w.

Determination and verification of harris function parameters

To address the complex nonlinear characteristics between the parameters b and c with various factors during the fitting process using the Harris function, this study employed Matlab programming software to solve b and c. The objective was to accurately capture the potential relationships between these parameters and the initial void ratio e0, calcium carbonate content ccc, as well as coir fiber content w, and to derive specific mathematical expressions.

Polynomial regression is an effective method commonly used to capture potential nonlinear relationships in data by altering polynomial feature dimensions (powers and products) to better fit nonlinear trends. However, as the degree of the polynomial increases, the complexity of the model also rises, which can lead to overfitting. To ensure model accuracy and avoid overfitting, this study employed Lasso regularization and the division of the dataset into training and testing sets for polynomial regression analysis52,53.

Firstly, the initial void ratio e0, calcium carbonate content ccc, coir fiber content w, and the corresponding parameters b and c for all samples were input into the program. Subsequently, different polynomial degrees were tested for b and c to find the polynomial that most accurately reflects the nonlinear relationships between these parameters and the variables. Then, Lasso regression (L1 regularization) was employed for feature selection, and a systematic search for the optimal value of the regularization parameter \(\lambda\) was conducted using tenfold cross-validation. This approach ensures that the model achieves a good fit while maintaining strong generalization capability. To evaluate the predictive performance of the model, the dataset was split into training and testing sets at a ratio of 80% to 20%. The model was trained on the training set and validated on the independent testing set to ensure its reliability. Finally, the model’s expression and performance metrics were output, including but not limited to the coefficient of determination R2, root mean square error (RMSE), mean absolute percentage error (MAPE), maximum error, Akaike information criterion (AIC), Bayesian information criterion (BIC), and the Durbin-Watson statistic. The specific solution demonstration process is illustrated in Fig. 15.

For parameter b, a 4th-degree polynomial was selected. The expression is as follows:

For parameter c, a 3rd-degree polynomial was selected. The expression is as follows:

Table 5 summarizes the performance evaluation metrics of the polynomial models for parameters b and c on both the training and testing sets. The 4th-degree polynomial model for parameter b demonstrates excellent performance. On the training set, the coefficient of determination R2 reaches 0.9058, indicating that the model can effectively explain the majority of the variance in the data. More importantly, the R2 on the testing set reaches 0.9201, demonstrating good generalization capability. The root mean square error (RMSE) for the model is 0.0012 on the training set and 0.0008 on the testing set, indicating very low prediction errors during both the training and testing phases. The model’s mean absolute percentage error (MAPE) is 23.4635% on the training set and 21.6189% on the testing set. Although these values are relatively high, they are acceptable given the small range of actual values. The maximum error (Max Error) is 0.0022 for the training set and 0.0011 for the testing set, further confirming that the model’s prediction errors are at a low level. The values for the information criteria (AIC and BIC) are -582.4865 and -571.7814 on the training set, and -131.4408 and -129.6253 on the testing set. These relatively high negative values indicate that the model maintains a good fit without being overly complex. The Durbin-Watson statistics are 1.1051 and 2.8158, respectively, suggesting a slight positive autocorrelation of residuals in the training set, while the autocorrelation is minimal in the testing set. Overall, the 4th-degree polynomial model for parameter b demonstrates excellent predictive ability and generalization capability on both the training and testing sets.

Compared to parameter b, the 3rd-degree polynomial model for parameter c also performed well. The model achieved an R2 exceeding 0.9 on both the training and testing sets, indicating that it can effectively explain the variance in the training data while also exhibiting strong generalization ability. The RMSE values for the model are 0.1446 and 0.1489 for the training and testing sets, respectively, indicating that the prediction errors are within a reasonable range. The MAPE and Max Error values in Table 5 suggest that the model’s prediction errors are at a low level. The AIC and BIC values indicate that the model maintains a good fit without being overly complex. The Durbin-Watson statistics are 1.5609 and 2.6288, respectively, suggesting a slight positive autocorrelation in the residuals for the training set, while the autocorrelation is minimal in the testing set. In summary, the 3rd-degree polynomial model for parameter c performed well on both the training and testing sets, demonstrating good predictive ability and generalization capability.

The polynomial model curves for parameters b and c were compared with the actual data, as shown in Fig. 16. The results indicate that the polynomial model curves for both b and c can accurately capture the complex variations in the actual data. This strongly confirms the validity and reliability of the models. To be more specific, in Fig. 16a, the range of parameter b is relatively small, primarily concentrated within the order of 10–3. This results in slightly insufficient fitting at certain points. However, considering the quantitative evaluation metrics in Table 5, the fitting curve for b still adequately reflects the variations in the actual data. In Fig. 16b, the polynomial curve for parameter c demonstrates a good fit. Even in the presence of data fluctuations, the curve remains stable and closely follows the actual data points, showing good adaptability.

To further evaluate the accuracy of the models, a residual analysis was conducted for the polynomial equations of parameters b and c, as shown in Fig. 17. This data reveals the differences between the model predictions and the actual values. It can be observed from the figure that the residuals are mainly concentrated around zero and are roughly balanced between positive and negative values. This indicates that the model does not exhibit significant systematic bias and demonstrates high accuracy in predicting parameters b and c. However, the residual values are not completely uniform, indicating that the model’s prediction accuracy varies at certain points. For example, in Fig. 17a, the residuals at specific points are − 1.5136 × 10–3 and 3.1835 × 10–3, and in Fig. 17b, they are − 0.3151 and 0.2104. Despite the presence of these larger residuals, they all fall within a reasonable range, suggesting that the polynomial models for parameters b and c demonstrate a certain degree of robustness and can accurately capture the data’s variations to a considerable extent.

In summary, the combination of Lasso regularization and polynomial regression, along with the proper division of training and testing sets, successfully resulted in highly accurate fitting model equations. The model can predict the parameters b and c for calcareous sand samples based on different coir fiber contents, calcium carbonate content, and relative density. By substituting these predicted values into the Harris function, it is possible to further predict the void ratio of the samples under varying vertical pressures. This approach provides a theoretical basis for predicting the compressive deformation of coir fiber and EICP-cemented calcareous sand foundations under different conditions.

Discussion

Effects of EICP and coir fiber on the one-dimensional compressive performance of calcarenite sand

Our research team is currently focused on the interaction between EICP technology and the mechanical properties of calcarenite sand reinforced with coir fiber. Previous studies have investigated the effects of EICP-cemented calcarenite sand and coir fiber-reinforced calcarenite sand on strength and toughness through triaxial testing16,24. The findings revealed that EICP cementation significantly increased the peak deviatoric stress of calcarenite sand specimens, with the enhancement becoming more pronounced as the degree of cementation increased. However, this was also accompanied by more severe brittle failure. Further experiments indicated that the addition of coir fiber to EICP-cemented calcarenite sand did not dramatically increase the specimen strength but effectively enhanced its toughness and reduced the risk of brittle failure.

Nevertheless, an extensive literature review reveals that research on the effectiveness of these two methods in improving the compressive deformation of calcarenite sand, especially one-dimensional compressive deformation, remains insufficient. Therefore, this study focuses specifically on the one-dimensional compressive deformation characteristics of calcarenite sand specimens reinforced with coir fiber and cemented by EICP. The compressive characteristics of calcarenite sand were investigated through one-dimensional compression tests. The results showed that the void ratio of the specimens gradually decreased with the increase in vertical pressure. This is primarily attributed to the irreversible plastic deformation caused by particle rearrangement and particle breakage of calcarenite sand54,55,56. Both the incorporation of coir fiber alone and its combination with EICP technology enhanced the ability of the specimens to resist deformation. While the use of coir fiber alone had limited effectiveness, EICP technology significantly improved the compressive performance of the specimens, which is consistent with previous conclusions regarding the cementation of sandy soils using MICP or EICP30,45,50. Specifically, EICP can generate calcium carbonate within the specimens, effectively filling the voids and inhibiting the breakage of sand particles, thereby enhancing the compressive performance of the specimens. As shown in the compression curves presented in this study (Fig. 5), compared with untreated specimens, those treated with EICP exhibit lower compressibility. Moreover, specimens subjected to a higher number of grouting cycles are more difficult to compress than those with fewer cycles. This observation is consistent with the conclusions drawn by Yang et al.45 in a study using MICP to cement siliceous sand to improve its compressive characteristics, thereby validating the effectiveness of EICP technology in enhancing the compressive properties of calcarenite sand. Moreover, when coir fiber is combined with EICP technology, the fibrous framework becomes closely integrated with the calcium carbonate matrix, effectively restricting the movement of sand particles and further enhancing the compressive performance of the specimens. This highlights the positive role of the synergistic interaction between the two techniques in improving one-dimensional compressive deformation characteristics.

It is worth noting that calcarenite sand, due to its porosity and fragility, exhibits compressive deformation not only from the reduction of inter-particle voids but also from the breakage of the particles themselves when subjected to external forces. However, the current understanding of particle breakage in EICP-cemented calcarenite sand during compression largely remains at the qualitative analysis level. For instance, particle breakage is inferred from the abrupt drops in deformation observed on the compression curve46,47; alternatively, X-ray imaging techniques are employed to monitor particle breakage during the compression process, thereby assessing local bond failure or particle wear from a microscopic perspective. Nevertheless, these approaches can only provide qualitative assessments and lack precise quantitative analytical data. The traditional method for quantitatively assessing particle breakage, particle size distribution (PSD) analysis, faces challenges when applied to EICP-cemented calcarenite sand, especially for specimens with high degrees of cementation. This is because, after being subjected to vertical loading, specimens with high cementation remain as multiple cohesive masses rather than individual particles, making it difficult to accurately determine the particle size distribution. Moreover, attempts to remove the CaCO₃ generated during the EICP cementation process via acid washing would inevitably cause damage to the calcarenite sand itself, thereby compromising the accuracy of the experimental results. Therefore, future research will be dedicated to developing new quantitative analytical methods to more accurately assess particle breakage in EICP-cemented calcarenite sand during compression. This will contribute to a deeper understanding of the mechanisms underlying the changes in the compressive properties of the cemented body.

Applicability and parameter determination of the Harris function model under multivariable conditions

Based on the results of the one-dimensional compression tests, this study used the Harris function model to fit the e-lgp curves under various experimental conditions. It was found that the Harris function effectively captures and accurately describes the changes in void ratio under different conditions, consistent with the findings of Zhang et al.57, who primarily focused on the compressive characteristics of calcarenite sand and glass bead specimens containing rubber fibers and analyzed them using the Harris function. During the process of solving for parameters b and c, they set parameter c as a constant (5 for calcarenite sand and 3 for glass beads) and found a good linear relationship between the other parameter b and the fiber content w. Subsequently, they derived an expression for parameter b based on the relationship between fiber content, initial void ratio e0, and parameter b. The data distribution in their study is shown in Fig. 18.

The aforementioned studies provide a novel approach for determining the parameters of the Harris function. In this study, calcarenite sand was treated using two methods, reinforcement with coir fiber and EICP cementation, and various relative densities of the specimens were set to investigate the effects of these factors on the compressive characteristics of the specimens. During the research process, the methods of Zhang et al.57 were fully referenced. However, this study considered three variables, rather than just the single variable of fiber content. Moreover, no simple linear relationships were found between the parameters b or c and the variables during the research. Attempts to set one of the parameters as a constant also yielded unsatisfactory fitting results. Given these challenges, this study employed a method combining Lasso regularization with polynomial regression. By dividing the data into training and testing sets, a polynomial model with high precision and good generalization ability was preliminarily derived. This approach, which is data-driven and closely aligned with the actual data, offers a new perspective for solving similar functional models in the future.

Nevertheless, the preliminary quartic polynomial model for b and cubic polynomial model for c proposed in this study have demonstrated good applicability for laboratory-scale research. However, the complexity of these functional forms may present challenges for their direct application in engineering practice. Constrained by current limitations in time and algorithmic capabilities, future research will be dedicated to increasing the number of specimens, more finely delineating the ranges of variation for each influencing factor, and further investigating the interaction mechanisms among relative density, calcium carbonate content, and coir fiber content on the compressive performance of calcarenite sand. Additionally, further efforts will be made to explore different data analysis and statistical modeling methods, with the aim of enhancing the precision and applicability of the developed equations, and striving for simplicity in form and broad application.

In-depth investigation and future perspectives on the compressive properties of calcarenite sand improved by coir fiber and EICP

This study combined EICP technology with coir fiber reinforcement to improve calcarenite sand and investigated the compressive deformation characteristics of this composite material through one-dimensional compression tests. However, the current research is still in its preliminary stage, and many issues remain to be addressed due to limitations in time, technology, and other factors. Therefore, future research will build on the existing achievements and further explore the compressive properties of calcarenite sand reinforced with EICP and coir fiber, both in depth and in breadth. In the process of investigating the compressive properties of calcarenite sand improved by the combined action of EICP and coir fiber, a systematic analysis was conducted on the effects of different fiber contents on the compressive performance of EICP-cemented calcarenite sand specimens. The results indicated that the improvement effect did not increase linearly with the increase in fiber content; rather, it decreased when the fiber content exceeded 0.6%. This suggests that when using coir fiber to improve calcarenite sand in conjunction with EICP technology, an optimal fiber content should be identified to achieve the best enhancement in compressive performance. However, due to the small size of the test molds, it is difficult to accurately assess the influence of fiber orientation and distribution on the compressive performance of the specimens, especially the effectiveness of the interaction between fibers and calcium carbonate under different distribution patterns. Therefore, future testing plans will employ specimens with larger diameters for compression tests and adjust fiber distribution to more accurately evaluate their impact on compressive deformation. Additionally, numerical simulations will be introduced to further investigate the effects of various conditions, such as coir fiber content, distribution, length, and calcium carbonate distribution, on the compressive characteristics of calcarenite sand.

The combination of EICP technology and coir fiber not only enhances the compressive performance of calcarenite sand but also is environmentally friendly, offering new perspectives for the application of natural materials and biomimetic technologies in practical engineering. However, this technology is currently limited to laboratory research and has not yet been widely applied in actual engineering projects. Meanwhile, considering the complexity of real engineering environments, studying only short-term deformation characteristics is far from sufficient. Future research will focus on the development of long-term performance studies. Considering the unique environmental conditions of islands and reefs where calcarenite sand is typically found, which are characterized by tidal fluctuations, future research will involve a series of wetting and drying cycle experiments. For instance, the degree of cementation and coir fiber content of EICP-S and EICP-FS specimens will be svaried. After most of the moisture in the specimens is evaporated in a constant-temperature chamber at 30 °C (the average environmental temperature for calcarenite sand is between 28 and 32 °C), the specimens will be soaked in artificial seawater for 24 to 36 h. Subsequently, one-dimensional compression tests will be conducted to investigate the deformation behavior of the specimens under wetting and drying cycles.

Additionally, as an environmentally friendly natural material, the durability of coir fiber is also an important factor that needs to be considered in practical applications. Although alkaline pre-treatment has been employed to enhance the durability of coir fiber, long-term experimental data are still lacking. Therefore, future research will focus on the long-term durability of calcarenite sand cemented with coir fiber, particularly in terms of deformation monitoring. Specifically, a one-dimensional consolidation apparatus will be employed to conduct long-term compression tests on the cemented specimens, in order to investigate the changes in the compressive behavior of EICP-FS samples under long-term loading conditions. Concurrently, to preliminarily assess the long-term stability of coir fiber and its effectiveness in bonding with calcium carbonate, coir fiber will be incorporated into calcarenite sand and subjected to EICP cementation with varying numbers of grouting cycles. Subsequently, these specimens will be cured in a constant-temperature environment at 30 °C for durations of 1, 3, 6, 12, 24, 36, and 72 months, to systematically study the corrosion of coir fiber and the stability changes in its bonding with calcium carbonate. This will not only fill the knowledge gap in the existing research regarding the material’s performance under long-term constant stress but also provide reliable data support for the durability of coir fiber in practical engineering applications.

Conclusion

This study investigated the compression deformation characteristics of calcareous sand treated with EICP technology through one-dimensional compression tests. The experiments considered the effects of different grouting cycles, coir fiber content, and initial relative density on the compressive properties of the samples. The Harris function was used to fit the experimental data, and polynomial equations for the parameters b and c were developed to predict the compressive behavior of the samples. The main conclusions are as follows:

-

(1)

The compressive properties of samples improved significantly after EICP cementation. As the number of grouting cycles increased, the reduction in the void ratio e/e0 decreased.

-

(2)

Under the same cementation conditions and relative density, the reduction in the void ratio e/e0 initially decreases and then increases with the addition of coir fiber.

-

(3)

The Harris function was used to fit the e-lgp curves of all samples, accurately describing the variations in void ratio e under different conditions. The parameters b and c in the function have a complex nonlinear relationship with the calcium carbonate content ccc, coir fiber content w, and initial void ratio e0.

-

(4)

Using Matlab programming software, 4th-degree polynomial equations for parameter b and 3rd-degree polynomial equations for parameter c were successfully constructed by combining Lasso regularization with the division of training and testing sets. These equations demonstrate high predictive accuracy and good generalization capability. Therefore, by integrating the polynomial equations for b and c with the Harris function, the compressive properties of samples under various conditions can be effectively predicted. This approach provides a theoretical basis for evaluating the compressive properties of cemented calcareous sand foundations in engineering practice.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author upon reason-able request.

References

Alcerreca, J. C., Silva, R. & Mendoza, E. Simple settling velocity formula for calcareous sand. J. Hydraul. Res. 51, 215 (2013).

Jafarian, Y., Javdanian, H. & Haddad, A. Dynamic properties of calcareous and siliceous sands under isotropic and anisotropic stress conditions. Soils Found. 58, 172 (2018).

Gang, W., Jing-jing, Z. & Xing, W. Evolution of particle crushing of carbonate sands under cyclic triaxial stress path. Chin. J. Geotech. Eng. 04, 755 (2019).

Ren, W. & Wenjuan, W. Exploration and research on engineering geological properties of coral reefs—Engaged in coral reef research for 30 years. J. Eng. Geol. 27, 202 (2019).

Shi, J., Haegeman, W. & Andries, J. Investigation on the mechanical properties of a calcareous sand: the role of the initial fabric. Mar. Georesour. Geotech. 39, 859 (2021).

Yang, S. et al. Macro-micro study of compressive deformation properties of calcareous sand with different particle fraction contents. Rock Soil Mech. 40, 3733 (2019).

Wei, H., Zhao, T., Meng, Q., Wang, X. & He, J., Experimental evaluation of the shear behavior of fiber-reinforced calcareous sands. Int. J. Geomech. 18 (2018).

Xiang-wei, F., Chun-ni, S., Jian, C., Shi-fan, W. & Yi-shan, L. An experimental study of coral sand enhanced through microbially-induced precipitation of calcium carbonate. Rock Soil Mech. 10, 2773 (2015).

Xiang-wei, F., Jing-xin, L., Jie, L. & Chun-ni, S. Study of triaxial compression test and damage constitutive model of biocemented coral sand columns. Rock Soil Mech. S1, 1 (2018).

Qian, Z., Wei-min, Y., Zhang-rong, L., Qiong, W. & Yong-gui, C. Advances in soil cementation by biologically induced calcium carbonate precipitation. Rock Soil Mech. 02, 345 (2022).

Wen, K., Li, Y., Amini, F. & Li, L. Impact of bacteria and urease concentration on precipitation kinetics and crystal morphology of calcium carbonate. Acta Geotech. 15, 17 (2020).

Arab, M. G. et al. State-of-the-art review of enzyme-induced calcite precipitation (EICP) for ground improvement: applications and prospects. Geosciences 11, 492 (2021).

Qiwu, J. et al. Experimental study on the effect of calcium sources and Ca2+ concentration on EICP cured calcareous sand. J. Eng. Geol. (2023).

Zhang, Q., Ye, W., Liu, Z., Wang, Q. & Chen, Y. Influence of injection methods on calcareous sand cementation by EICP technique. Constr. Build Mater. 363, 129724 (2023).

Liu, L. et al., Experimental study on the mechanical behavior of EICP-casein-treated calcareous sand. Mar Georesour. Geotech. 1 (2024).

Jiang, X. et al., Triaxial compression behavior and damage model of EICP-cemented calcareous sand. Geotech. Geol. Eng. 43 (2025).

Junjie, Z., Yang, S., Hanjiang, L., Mingjuan, C. & Chaochuan, W. Experimental study on the shear behavior of fiber-reinforced bio-cemented sand. J. Civ. Environ. Eng. 41, 15 (2019).

Lin, S., Lei, X., Meng, Q. & Xu, J. Properties of biocemented, basalt-fibre-reinforced calcareous sand. Proc. Inst. Civ. Eng. Ground Improv. 176, 14 (2023).

Qiu, R., Tong, H., Fang, X., Liao, Y. & Li, Y. Analysis of strength characteristics of carbon fiber–reinforced microbial solidified sand. Adv. Mech. Eng. 11, 2072157530 (2019).

Yue-han, X. et al. Mechanical behavior of microbial-induced calcite precipitation (MICP)-treated soil with fiber reinforcement. Chin. J. Geotech. Eng. 41, 675 (2019).

Iamchaturapatr, J., Piriyakul, K. & Petcherdchoo, A. Characteristics of sandy soil treated using EICP-based urease enzymatic acceleration method and natural hemp fibers. Case Stud Constr. Mater. 16, e00871 (2022).

Yao, D. et al. Effect of wool fiber addition on the reinforcement of loose sands by microbially induced carbonate precipitation (MICP): mechanical property and underlying mechanism. Acta Geotech. 16, 1401 (2021).

Zhang, J., Yin, Y., Shi, L., Bian, H. & Shi, W., Experimental investigation on mechanical behavior of sands treated by enzyme-induced calcium carbonate precipitation with assistance of sisal-fiber nucleation. Front. Earth SC-Switz 10 (2022).

Jiang, X. et al. Triaxial compression characteristics and brittleness evaluation of calcareous sand cemented with EICP and coir fiber. Results Eng. 25, 104090 (2025).

Jiaming, Z., Ren, W., Xiangfeng, S., Jianguo, L. I. & Haiyang, C. Compression and crushing behavior of calcareous sand under confined compression. Chin. J. Rock Mech. Eng. 24, 3327 (2005).

Yue, S., Yang, X., Wei, Z. & Han-long, L. Particle breakage and shape evolution of calcareous and quartz sands under compression. Chin. J. Geotech. Eng. 44, 1061 (2022).

Zhixia, L., Chengchao, G., Dingfeng, C. & Rui, H. Compression characteristics of coral calcareous sand in the south China sea. Sci. Technol. Eng. 22, 2401 (2022).

Quan, Y., Xu, S., Yan, G., Yuchao, J. & Le, S., Lateral deformation and internal stress evolution of calcareous sand with different particle sizes. Acta Scientiarum Naturalium Universitatis Sunyatseni 1 (2025).

Qingsheng, C., Jinwei, Z., Wan, P., Yuxuan, L. & Xiaokang, W. Experimental study on compression deformation characteristics of polymer solidified calcareous sand. China Sci. Paper 16, 390 (2021).

Hongxian, G., Dongrun, L. I., Ruinan, M. A. & Xiaohui, C., Oedometer test of calcareous sands solidified using the MICP mixing method. J. Tsinghua Univ. (Sci. Technol.) 59, 593 (2019).

Rücknagel, J., Christen, O., Hofmann, B. & Ulrich, S. A simple model to estimate change in precompression stress as a function of water content on the basis of precompression stress at field capacity. Geoderma 177–178, 1 (2012).

Schjønning, P., Lamandé, M., Munkholm, L. J., Lyngvig, H. S. & Nielsen, J. A. Soil precompression stress, penetration resistance and crop yields in relation to differently-trafficked, temperate-region sandy loam soils. Soil Tillage Res. 163, 298 (2016).

Somavilla, A., Gubiani, P. I., Reichert, J. M., Reinert, D. J. & Zwirtes, A. L. Exploring the correspondence between precompression stress and soil load capacity in soil cores. Soil Tillage Res. 169, 146 (2017).

Mingzhi, Z., Qiang, L., Liangwei, J. & Ming, W. Two-level-loading consolidation test based on Harris function and it’s reliability criterion. J. Railway Sci. Eng. 15, 1373 (2018).

Zhiliang, W., Mingxin, Z. & Yongchi, L. Research on mathematic model method for calculating pre-consolidation pressure and its application. Rock Soil Mech. 26, 1587 (2005).

Jiang, X. et al. Study on stress-strain relationship of coir fiber-reinforced red clay based on Duncan-Chang model. Appl. Sci. 13, 556 (2023).

Yang, H., Li, P., Yang, E., Jiang, X. & Chen, J., The strength law of coir fiber-reinforced soil based on modified Duncan-Chang model. Front. Earth Sci. (Lausanne). 10 (2023).

Esmeraldo, M. A. et al., Dwarf-Green coconut fibers: a versatile natural renewable raw bioresource. Treatment, morphology, and physicochemical properties. Bioresources. 5, 2478 (2010).

Shah, I. et al. A review on chemical modification by using sodium hydroxide (NaOH) to investigate the mechanical properties of sisal, coir and hemp fiber reinforced concrete composites. J. Nat. Fibers 19, 5133 (2022).

Xinxin, L., Sana, P., Wei, Z., Zhewen, H. & Pingping, W., Coir and its intensified composite material. Shanghai Chem. J. (in Chinese) 28 (1999).

Nemati, M. Modification of porous media permeability, using calcium carbonate produced enzymatically in situ. Enzyme Microb. Tech. 33, 635 (2003).

Hoang, T., Alleman, J., Cetin, B., Ikuma, K. & Choi, S. Sand and silty-sand soil stabilization using bacterial enzyme-induced calcite precipitation (BEICP). Can. Geotech. J. 56, 808 (2019).

Gao, Y., He, J., Tang, X. & Chu, J. Calcium carbonate precipitation catalyzed by soybean urease as an improvement method for fine-grained soil. Soils Found. 59, 1631 (2019).

Jinmei, D., Pei, W., Shouxi, C. & Hua, Z. Compression deformation characteristics of polymer SH solidified lightweight soil. J. Basic Sci. Eng. 21, 267 (2013).

Xiao, Y. et al., Restraint of particle breakage by biotreatment method. J. Geotech. Geoenviron. 146 (2020).

Li, X. & Liu, J. One-dimensional compression feature and particle crushability behavior of dry calcareous sand considering fine-grained soil content and relative compaction. B. Eng. Geol. Environ. 80, 4049 (2021).

Chaoyang, T., Hengxing, L. & Xin, L. Study on compression and crushing mechanical properties of calcareous sand considering influence of morphology and grading. J. Eng. Geol. 29, 1700 (2021).

Yongjie, W. U. et al. Experimental study of acoustic emission characteristics during one-dimensional compression rebound of calcare-ous sand. J. Eng. Geol. 29, 1711 (2021).

Cui, M., Zheng, J., Chu, J., Wu, C. & Lai, H. Bio-mediated calcium carbonate precipitation and its effect on the shear behaviour of calcareous sand. Acta Geotech. 16, 1377 (2021).

Yang, X. et al. Compression behavior of MICP-treated sand with various gradations. Acta Geotech. 16, 1391 (2021).

Yuehan, X. et al. Mechanical behavior of microbial-induced calcite precipitation (MICP)-treated soil with fiber reinforcement. Chin. J. Geotech. Eng. 41, 675 (2019).

Hastie, T., Friedman, J. & Tibshirani, R. The Elements of Statistical Learning: Data Mining, Inference, and Prediction (Springer, 2009).

James, G., Witten, D., Hastie, T. & Tibshirani, R. An Introduction to Statistical Learning (Springer, 2013).

Fushun, Y., Sa, L. & Xin, L. Experimental study on single particle strength and compression properties of calcareous coarse sand. Rock Soil Mech. 44, 1120 (2023).

Ke, J. et al., Compressibility and crushing of coral sands under one-dimensional dynamic compaction. Granul. Matter. 23 (2021).

Wei, H. et al., Particle breakage and morphology changes of calcareous sands under one-dimensional compression loading. Mar. Geophys. Res. 43 (2022).

Xiaoyan, Z., Yi, Z., Jinxun, Z., Kaiyuan, W. & Ning, W. Experimental study on permeability and consolidation of calcareous sand mixed with rubber fiber. Rock Soil Mech. 43, 2115 (2022).

Acknowledgements

The authors would like to acknowledge the financial supported from the Tertiary Education Scientific research project of Guangzhou Municipal Education Bureau(Grant No.: 2024312379, 2024312426); Special Projects in Key Fields of Higher Education in Guangdong Province (Grant No.: 2023ZDZX4044, 2023ZDZX4045); Research Capacity Enhancement Project of Key Construction Discipline in Guangdong Province (Grant No.: 2022ZDJS092); project supported by National Natural Science Foundation of China (Grant No.: 31971727); The Forest Science and Technology Innovation Program of Hunan Province (Grant No.: XLK202105-3); Hunan Provincial Natural Science Foundation of China (Grant No.: 2022JJ31005).

Author information

Authors and Affiliations

Contributions

This study was designed and completed by all the authors, each of whom played an integral role in the implementation of the project. Their specific contributions are as follows: X.J. was responsible for the investigation, conception and design of the whole study, undertook the task of data processing and analysis, and participated in the writing and revision of the paper. H.W. was mainly responsible for the design and operation of the experiment, and participated in the writing and revision of the paper. H.Y. is responsible for funding applications, ethical reviews and other matters to ensure the smooth progress of the research work. J.Y. was responsible for the drawing and modification of the charts and tables in the paper, and participated in the format modification of the paper. In the process of writing and revising papers, B.S. focuses on language polishing and stylistic unification to ensure the fluency and professionalism of the articles. Du is responsible for the writing of manuscripts that polish the language of the entire thesis. All the authors have reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jiang, X., Wang, H., Yang, H. et al. One-dimensional compression behavior of calcareous sand cemented with EICP and coir fiber. Sci Rep 15, 11954 (2025). https://doi.org/10.1038/s41598-025-96321-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96321-y