Abstract

In this paper, Cement Asphalt (CA) mortar specimens mixed with polyurethane polycarboxylate and ordinary commercial polycarboxylate water-reducing agents have been prepared. The pore structure has been determined by scanning electron microscopy (SEM) and nuclear magneti2c resonance (NMR) characterization. In accordance with the concept of fractal dimension, the fractal model has been engaged to quantify the pore volume of Cement Asphalt (CA) mortar, Through the application of the Pearson correlation coefficient coupled with regression analysis, the relationship between fractal dimension and compressive and flexural performance has been analyzed. The results have shown that when the content of polyurethane polycarboxylate is 0.8%, compared to ordinary polycarboxylate, its 28-day compressive and flexural strength is increased by 35.29% and 39.13%, respectively, and the total porosity is reduced by 31.19%, and the proportion of harmful macropores is reduced by 76.02%. The influence of polyurethane polycarboxylates on the pore structure and uniformity of Cement Asphalt (CA) mortar is due to the longer molecular chains of cellulose ether and associated polyurethane. These chains possess the capability to elongate, intertwine, and fuse with a myriad of Cement Asphalt (CA) mortar particles, thereby constructing an intricate three-dimensional network. According to the analysis of fractal dimension and nuclear magnetic resonance test data, the Cement Asphalt (CA) mortar ‘s pore volume fractal dimension is greater than 3, indicating that the pore structure has fractal characteristics. In addition, as the fractal dimension increases, the correlation coefficients are 0.9113 and 0.9074, respectively, proving that the fractal dimension of pore structure is significantly positively correlated with flexural and compressive strength, This suggests that the fractal dimension of the pore volume acts as a pivotal link, correlating the mechanical properties with the microscale characteristics of Cement Asphalt (CA) mortar .

Similar content being viewed by others

Introduction

Cement emulsified asphalt mortar is classified as a cement-based porous material, where its microstructure plays a crucial role in defining its macroscopic characteristics. The pore structure, a key element of its microstructure, significantly influences several material properties including impermeability, frost resistance, strength, thermal conductivity, and water absorption1. As mortar structures become more complex as emulsified asphalt is added, testing and analyzing its microstructure becomes more difficult. The presence of higher asphalt levels obstructs the hydration process in cement, the average and total porosity of Cement Asphalt (CA) mortar increases over time, while polycarboxylate water-reducing agents can greatly optimize cement hydration. Zhang Y et al.2 it has been found through experiments that emulsified asphalt can lengthen the induction period of cement hydration, and asphalt particles on the cement surface impede water contact, delaying the hydration process. Li W and the team3 explored the impact of emulsified asphalt on the Cement Asphalt (CA) mortar’s microstructure, employing Mercury Intrusion Porosimetry (MIP) for analysis. They discovered that the incorporation of emulsified asphalt impedes cement hydration, leading to a progressive weakening of the mortar’s mechanical properties. Liu4 examined the evolution of Cement Asphalt (CA) mortar’s microporous structure using asphalt extraction and filtration, investigating how the degree of cement hydration influences its long-term mechanical properties using MIP and NMR techniques. As cement continuously hydrates, the pore structure of Cement Asphalt (CA) mortar continues to refine and its mechanical properties become more effective. Amino ester polycarboxylates have a smaller molecular structure than ordinary polycarboxylates, which can accelerate the early cement hydration and fill the pores of their fresh mortar5. The microstructure of cement-based materials can be measured using different methods, including constant temperature and humidity drying (CTHD), mercury intrusion porosimetry (MIP), and SEM, although all of these methods are capable of detecting the interconnected pore structure of Cement Asphalt(CA) mortar, all have certain limitations. The classic Kozeny-Carman model is based on the assumption that parallel capillary bundles can accurately predict water permeability by utilizing the discrete pore size distribution when saturated; The impact of the water cement ratio on the pore structure and water permeability of saturated mortar is basically consistent. The pore size distribution obtained from mercury intrusion testing has significant variability and is difficult to reflect the effects of water cement ratio. The pore structure characteristics obtained from dry state testing and the pore size classification method established based on this have obvious limitations. Due to the comprehensive influence of pore structure on the physical and mechanical properties of hardened cement-based materials, and the fact that low field magnetic resonance technology can avoid significant effects of drying pretreatment, the use of this technology to achieve testing and analysis of saturated pore structure is of great value for scientific research on cement-based materials.

In recent years, NMR, as an emerging microstructural testing method with fast, continuous, and non-invasive properties, has been progressively incorporated into pore structure analysis of Cement Asphalt (CA) mortar. Deng6 evaluated the effectiveness of MIP, CTHD, and NMR in testing the pore structure of Cement Asphalt (CA) mortar. Nuclear magnetic resonance (NMR) offers a more precise assessment of pore size distribution and interconnected porosity in Cement Asphalt (CA) mortar than alternative methods, according to their findings. Low-field nuclear magnetic resonance has gradually become a common method in the research of cement-based materials due to its advantages in fast, non-destructive, and in-situ technology. Low-field nuclear magnetic resonance can provide various information such as pore size, pore distribution, specific surface area, and quantification of hydration products, which can adapt to various research needs such as analysis of hydration process in cement-based materials, evolution of pore structure during service, principle of admixture action, and the influence of temperature or pressure on hydration and pore structure. At the same time, existing research mainly focuses on the water-cement ratio of Cement Asphalt (CA) mortar and emulsified asphalt to explore their impact on work and mechanical properties. As an indispensable additive, polycarboxylate superplasticizer has a flexible and diverse molecular structure and a variety of small molecular functional groups, which can reduce the demand for water and reduce the liquid-solid ratio, which greatly affects the internal structure and overall mechanical properties of the slurry. Therefore, the study measured and analyzed the microstructure of Cement Asphalt (CA) mortar using SEM and NMR methods. We established a fractal model of pore volume and calculated the changing dimensionality of the pore structure in Cement Asphalt (CA) mortar. It uncovered the evolutionary patterns in the microporosity characteristics of Cement Asphalt (CA) mortar and established a linkage between flexural and compressive strength and the fractal size of the pore volume. These findings offer both experimental evidence and a theoretical framework to explore the interplay between microstructure and macroscopic performance in Cement Asphalt (CA) mortar.

Material

Cement

In this experiment, we utilized P·O 42.5, a grade of standard Portland cement, for our cementitious needs. The relevant chemical and mineralogical compositions are detailed in Table 1, and the material’s physical characteristics are shown in Table 2.

Fine aggregates

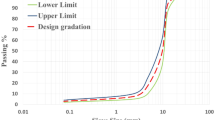

Quartz sand is used as fine aggregate. Table 3 details the particle size distribution of the sand used.

Emulsified asphalt

The emulsified asphalt used is anionic emulsified asphalt (using anionic emulsified asphalt agent), Table 4 displays its performance indicators.

Aluminum powder

All indicators of aluminum powder used meet the requirements of the standard (GBT2085.1-2007), and the main components are shown in Table 5.

Expansion agent

UEA expansion agent is employed as an expansion agent, and its main components are calcium aluminate cement clinker, alunite, and gypsum. Table 6 presents the physical and chemical traits of the U-shaped expansion agent.

Admixtures

Polycarboxylate7

The employed water-reducing agent is a common polycarboxylate variety, its molecular formula is shown in Fig. 1, with its solid content specified at 20.5%.

The laboratory has self-made polyurethane polycarboxylate, its molecular formula is shown in Fig. 2 and its performance indicators are as follows: Table 7.

Thickener

Using commercially available cellulose ether thickeners.

Defoamers

Using commercially available organosilicon-based acid and alkali-resistant, high-temperature resistant defoamers.

Thixotropic agents

Using polyurethane-based strong pseudo plastic thixotropic agents for sale.

Water

Domestic water supply.

Mix proportions

The mixing ratio is designed according to the “Temporary Technical Conditions for Cement Emulsified Asphalt Mortar for Ballastless Track of CRTSII Slabs for Passenger Dedicated Railways” standard, three CA mortars with different air-conditioning ratios (0.4, 0.5 and 0.6) were designed, as shown in Table 8.

It is required that CA mortar specifications dictate an air content exceeding 0.35 and a water-to-cement ratio capped at 0.58 to obtain appropriate processing performance and strength. In all experiments, the ratio of water to cement was set at 0.48, incorporating two varieties of water-reducing agents, polyurethane polycarboxylate and commercially available polycarboxylate, were added in the laboratory, with a dosage of 0.8%.

Preparation methods

Measure the raw materials based on the specified blending proportions. Additives, water, and emulsified asphalt are placed in a mixing pot, and CA mortar is prepared using the “wet first, then dry stirring” mixing process. The mixture is stirred at a speed of 50r/min for 30 s, followed by the addition of ordinary commercially available polycarboxylate superplasticizers and laboratory-prepared polyurethane polycarboxylates of the same dosage. After stirring at a medium speed (90r/min), pre-mixed dry materials are added, and a uniform fresh CA mortar is made. After passing the inspection according to the specifications, the formed specimen is wrapped in a wet towel and placed in a completely sealed plastic box. The plastic box is then placed in an environment at (25 ± 2) ℃ and a relative humidity of (65 ± 5)% for 28 days of curing.

Test methods

Analysis of pore structure

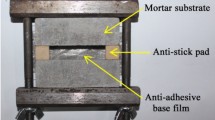

The MesoMR23-060 H low-field nuclear magnetic resonance imaging analyzer is adopted, the resonance frequency is set at 23.403 MHz, employing a permanent magnet, the temperature of the magnet is maintained at (32.00 ± 0.02)°C, and the probe coil diameter does not exceed 60 mm. The test sample (40 mm x 40 mm x 80 mm) was cut off from the designated sample 40 mm x 40 mm x 160 mm.

SEM

The TESCAN field emission scanning electron microscope facilitated the detection of the internal microstructure of the CA mortar in this experiment. The instrument model is MIRA3 LMH eds: One Max 20. The scanning electron microscope (SEM) has a resolution of 1.0 nm (15 kV) and an acceleration voltage of 0.5-30 kV. It can clearly observe the sample morphology and analyze the microstructure components. After the standard curing of the test sample reaches its age, take a thin sheet from the middle part, soak it in anhydrous ethanol for 24 h to terminate cement hydration, dry it in an oven for more than 12 h, and observe the sample after being sprayed with gold.

Determination of compressive and flexural strengths

CA mortar’s compressive and flexural strength is ascertained following the standard cement testing protocol for strength assessment (GB/T17671-2021). During the experiment, the bending strength was first tested using a TYE-300D cement mortar bending and compression testing machine at a rate of 50 N/S10N/S until the prism broke. Then, the remaining two half specimens from the bending strength test were used to test the CA mortar’s compressive strength at a loading rate of 2400 N/s.

Performance test

The flowability of CA mortar is defined by the J-shaped funnel flow test time requirement. The opening of the funnel-shaped container is first sealed, and then the freshly mixed CA mortar is poured into the upper funnel-shaped vessel. Then open the funnel’s opening to allow the mortar to flow, and start timing and recording at the same time. The time when the CA mortar flows completely downwards in the funnel is used as an indicator of the fluidity of the CA mortar.

Fractal model

The fractal properties of the pore structure in cement-based materials have been demonstrated by many studies. The use of appropriate fractal models can effectively assess the intricacy of the pore structure, and fractal models are used as representative parameters of pore structure characteristics. The box dimension is a commonly used dimension, defined mathematically as follows: Assume F to be a non-empty subset bounded within the realm of real numbers, and N is the size that covers the F set δ the minimum number of boxes. Then the box size can be calculated using a formula.

Employ low-field NMR technology to assess the pore radius at a designated relaxation rate. Assuming that the pores in CA mortar are regular spherical pores, we proceed with the measurement process. Together with the definition of box size, a selection of n spherical boxes, varying in size, has been chosen. Each box has a corresponding aperture size ri ( i = 1,2…n ), designed to cover all pores that are equal to or larger than ri in size. Using the principle of equal volume, convert pores with a size exceeding ri into pores that are ri in radius, determine the quantity of pores that are ri in size (Nci), and obtain a set of data [r1, Nc1], [r2, Nc2], [rn, Ncn]. Linear regression is applied to the reciprocal of pore size and the logarithm of the count of transformed pores, and the corresponding box dimension is derived from the angle of inclination of the regression line. The model described above is Considering the volume of pores as the basis, and the computed value of the box dimension reflects the distribution characteristics of pore volume. Therefore, the model is designated as the ‘fractal dimensional model of pore volume,’ with the derived fractal dimension being referred to as the ‘fractal dimension of pore volume’. Convert the above model into specific expressions:

In the formula, the variable r denotes the pore size, while N represents the count of pores with a size not less than r, and D is the fractal dimension of pore volume8.

Processing method of NMR data

In light of the relaxation mechanism’s dictates of nuclear magnetic resonance (NMR), in situations where the external magnetic influence is weak or the echo spacing is sufficiently short, the time of transverse relaxation (T2) of CA mortar samples lacking large pores is predominantly influenced by the relaxation of surface fluids9,10. T2 can be ascertained based on the specific surface area of the channel, thus it can be expressed in the following manner:

In the formula, VP: Total volume of pores; S: Total surface area of pores; ρ:Relaxation rate. The correlation of the surface-to-volume ratio (S/V) to the pore radius (r) is presented by the following expression:

As shown in the equation, FS is used as the geometric shape factor, and the columnar pores of CA mortar are usually taken as FS=2. Therefore, The interplay of pore radius and relaxation time is captured in this equation:

The spectral area under the T2 relaxation time energy spectrum curve is directly proportional to the fluid content of CA mortar post-water retention. This implies a correlation between the spectral area and the mortar’s porosity. By obtaining the T2 energy spectrum curves from CA mortar samples prior to and following numerous drying cycles, one can establish a relationship between the signal strength of the energy spectrum and the porosity. This relationship is derived from the differences in mass and spectral area between the dried and undried samples. Therefore, this study established the correlation between the intensity of the energy spectrum signal and the degree of porosity through experiments, as illustrated in the subsequent equation.

In the formula, SA: spectral signal strength; PO: porosity;

Hence, by linking the pore radius to relaxation time and the energy spectrum signal to porosity, the T2 energy spectrum curve measured by nuclear magnetic resonance can be easily converted into a pore size distribution map.

Conclusions and commentary

SEM analysis of CA mortar

The microstructure of the polished CA mortar was visualized using SEM scanning, as depicted in Figs. 3, 4, 5, 6 and 7. From Figs. 3 and 4, it is evident from the observation that in CA mortar, standard sand, cement hydration products, pores, and asphalt are uniformly distributed. The mortar, where cement hydration products form the continuous phase and asphalt serves as the dispersed phase, displays a loose porous structure. Complex interfacial structures among unhydrated cement particles, standard sand, cement hydration products, pores, and asphalt were not observed. In the mortar, one can observe flocculent or granular hydrated calcium silicate (C-S-H gel), rolled leaf calcium hydroxide (C-H), and clustered hydrated products (AFt). The pore structure appears nearly circular, with block, sheet, and needle-shaped hydrated products observable within some of the pores. Figures 4 and 5 distinctly shows a clear interface between the asphalt film and the other hydration products, delineated by the blue line. The dispersed asphalt is distributed discontinuously in the form of a membrane in space, and is enveloped on the surface of sand, pores, andhydration products.

In the early stage of maintenance, CA mortar, after being mixed with different types of polycarboxylate water-reducing agents, contains certain C-S-H and C-H, as well as pores with varying porosity ratios. As the curing age increases, cement hydration forms more C-S-H, C-H, and AFt, which continuously increases and fills in the pore structure. Resulting in gradual shrinkage and reduction of pores, gradual emulsification of asphalt and chelation with hydration products, smoother pore walls, denser overall mortar, and optimized pore structure. From the above figure, it is evident that under the same curing age, the overall pore density of the mortar in the blank group, ordinary commercial polycarboxylate group, and polyurethane polycarboxylate group gradually increases, the quantity of macroscopic pores increases, the pore structure becomes looser, and the filling of the spatial structure by hydration products decreases.

Comparing Figs. 3, 4 and 5, it is found that under the same curing age and A/C ratio, the microstructure of CA mortar mixed with polyurethane polycarboxylate prepared in the laboratory is similar to that of CA mortar mixed with ordinary commercial water-reducing agent, with a large number of interconnected pores. However, compared with CA mortar mixed with polyurethane polycarboxylate prepared in the laboratory, more cracks are present in the CA mortar mixed with ordinary commercial water-reducing agent. At the same time, it can be seen that the number of pores in CA mortar mixed with polyurethane polycarboxylate is significantly reduced, and the pore size and degree of penetration are both significantly reduced. The results showed that the hydration of the silicate phase and the formation of calcium hydroxide and C-S-H gel were more effectively promoted by polyurethane polycarboxylate. Consequently, the hydration of the slurry is accelerated, the total porosity of the mortar is reduced, and the early strength in compression of the mortar, especially within the 24-hour age, is improved5,11.

CA mortar microstructure: evolutionary principles

The micropore structure of CA mortar was qualitatively assessed via SEM, then precisely quantified through NMR analysis, leading to an in-depth, quantitative study of its porous architecture. Figures 8 and 9 provide a visualization of the pore size distribution within CA mortar. The results have shown that the curves depicting pore size distribution in CA mortar exhibit a bimodal shape, with peaks at 10–30 nm and 1000–4000 nm, respectively.

The bimodal distribution of mortar pore size remained unaffected by the curing age and the type of polycarboxylate water reducer, however, the location and dimensions of the peaks changed to some extent with increasing curing age and the type of polycarboxylate water reducer used. As the curing time increases, the first peak decreases while the second peak increases (the first and second peaks move from left to right), and the most widely distributed pore size gradually shifts from the first peak to the second peak. It was found that the type of water reducer has a much greater effect on the CA mortar’s pore configuration than the change in curing age. Therefore, the following quantitative analysis mainly starts with the type of water reducer.

The pore structure classification principle proposed by Chen L J12 is adopted: macropore (d > 1000 nm), capillary pore (d = 100–1000 nm), transition pore (d = 10–100 nm), and gel pore (d < 10 nm). The experimental results are presented in Table 9. The maximum and minimum possible pore diameters of CA mortar are 3823.29 nm and 17 nm, correspondingly, which are scattered within the range of transition pore and macropore. At the same time, as the curing age and A/C ratio increase, the average pore size progressively decreases.

The evolution of CA mortar at each stage of curing age shows an increase in total porosity. Additionally, the ratio of transition pores and gel pores in pore volume progressively decreases, while the ratio of gross pores and macro pores gradually increases. The results demonstrate that the incorporation of polyurethane polycarboxylates densifies the pore structure and augments the quantity of small pores, corroborating the qualitative findings from SEM analysis13. Consequently, the combination of the two testing methods can more comprehensively, qualitatively, and quantitatively characterize the pore structure of CA mortar. Based on the comprehensive analysis of SEM and NMR structures, it can be concluded that the main reason for such changes in pore structure is that after polyurethane modification of polycarboxylate, it will reduce the ion density in the polycarboxylate molecules and the adsorption capacity of the polycarboxylate14. The surface of cement particles will experience a reduced concentration of adsorbed polycarboxylate, and the the pore solution will see an increase in residual polycarboxylate concentration, this causes a significant drop in surface tension along the gas-liquid interface, the outcome is an increased air content in the newly prepared cement mortar15. Improved air entrainment ability led to a reduction in large bubbles to small ones. However, ordinary polycarboxylates with sulfonic acid groups incorporated into their structure did not enhance the pore structure. As a result, numerous large pores were still retained within the solidified slurry16.

The mechanical strength of the hardened cement mortar decreases as its porosity increases17, but due to differences in pore size distribution and average pore size, this correlation is discrete and indirect. Differences in aeration capacity and bubble stability can alter the mechanical properties of hardened cement mortar due to different pore structures. Usually, distributed between 10 and 200 µ The small pores within the range of m significantly improve the mechanical properties of cement mortar, while those distributed between 500 and 1600 µ The large pores within the range of m hinder the mechanical properties of hardened cement mortar. As shown in Figs. 10 and 11, the specimens mixed with ordinary polycarboxylate decreased the compressive and flexural strength of hardened cement mortar due to their high porosity and larger pore size, while the polyurethane polycarboxylate test group increased the compressive and flexural strength due to the decrease in porosity and finer pore size18.

As the age increases, the total porosity shows a decreasing trend, and the pore volume ratio of macroscopic pores gradually decreases. The changes in pore volume ratios of other pore types are different. The results obtained from the SEM images depicted in Figs. 3, 4 and 5 reveal that as the curing process progresses, the hydration products of cement gradually increase, the pore structure continuously fills and refines, and the macroscopic pores gradually evolve into smaller-sized pores. Therefore, the pore volume ratio of the macroscopic pores gradually decreases. The hydration effect of cement in the early stage of maintenance also promotes the continuous demulsification of emulsified asphalt, resulting in different changes in pore volume ratios of other pore types19.

The dispersed asphalt particles continue to aggregate, filling some of the pore structures, preventing water from entering, and nuclear magnetic resonance cannot identify the closed pores in this part. As the curing age progresses, additional hydration products from ongoing hydration penetrate the initially closed pores, causing them to reopen and become detectable via NMR. Simultaneously, further demulsification processes may lead to the migration and reshaping of the asphalt pore structure. Therefore, within certain pore size ranges, the pore volume ratio fluctuates, and the distribution of pore sizes irregularly varies with the curing age. It is evident that the addition of polycarboxylate superplasticizer has been proven to be an important factor affecting the evolution of pore structure in CA mortar. The nuclear magnetic resonance and analysis results more quantitatively reflect the changes in the pore structure of CA mortar20.

The fractal properties of CA mortar

Fractal models were used to process nuclear magnetic resonance data based on pore size distribution. Plot a logarithmic graph with the number of boxes on one axis and the reciprocal of the CA mortar radius on the other. The formula lnN = Dln(1/r) + C is used for fitting. As shown in Figs. 12, 13 and 14, the high goodness of fit (> 0.99) after fitting indicates that the pore structure of CA mortar exhibits pronounced fractal characteristics, aligning well with the pore volume fractal model of the box fractal mode.

Table 10 presents the volume fractal dimension and the goodness of fit for CA mortar. Analysis reveals that the fractal dimension of the pore volume in CA mortar exceeds 3, aligning with the fundamental principle that volume fractal dimensions are typically greater than 3. During the identical curing period, the integrated fractal dimension of the pore changes with the type of polycarboxylate, indicating a decrease in the complexity of the pore structure.

A correlation analysis linking the fractal dimension of pore volume to interlayer porosity is detailed in Table 11. The fractal dimension is found to increase with the presence of gel pores and decrease with the increase in capillary and macro pores. This indicates that a higher proportion of smaller pores results in a larger fractal dimension, reflecting a more complex pore structure. This pattern is consistent with the changes noted on the curve depicting pore size distribution, validating that the fractal dimension of the pore volume acts as a numerical indicator of the distribution of pore sizes within the CA mortar’s structure.

Correlation analysis of strength versus pore morphology in CA mortar

Figures 15 and 16 display the flexural strength and compressive test outcomes of CA mortar blended with various polycarboxylates at different stages of curing. Based on the above microanalysis, due to the fact that the strength of CA mortar mainly comes from cement hydration products, which fill the spatial structure less and fail to form an effective continuous phase, the hydration of cement in other experimental groups is hindered compared to the addition of polyurethane polycarboxylates, and the degree of cement hydration is reduced. Therefore, the decrease in both the quantity and rate of cement hydration leads to a reduction in the strength of CA mortar.

As the curing age progresses, both the compressive and flexural strengths of CA mortar progressively enhance. The cause lies in the fact that as the curing age increases, the hydration of cement continues, and the hydration products of cement gradually increase and fill the pores21.

Emulsified asphalt gradually demulsifies and the hydration products fill the spatial structure, becoming denser over time, and as a result, the strength steadily increases. Studying the microporous structure aims to delineate the link between the microporous architecture and the macroscopic properties, thereby revealing the microscopic mechanism of macroscopic performance and proposing methods for regulating macroscopic performance from a microscopic perspective. Therefore, regression analysis was conducted on fractal dimension, compressive strength, and flexural strength (Figs. 17 and 18). Meanwhile, correlation analysis was conducted between compressive strength and flexural strength with fractal dimension and interlayer porosity (Tables 12 and 13). The flexural strengths and compressive of CA mortar exhibit a positive correlation with the fractal dimension, increasing as the fractal dimension rises. The correlation coefficients are 0.91127 and 0.90737, respectively. According to the definition of fractal dimension, an increase in this value indicates a higher level of complexity in the structure of the object being described, and facilitates a more rational distribution of pore structure. Thus, a heightened fractal dimension signifies a more intricate pore architecture, inherently linked to an enhancement in the material’s strength. Therefore, the strength of the CA mortar increases with the augmentation of the fractal dimension. Compressive strength and flexural strength are related to gel pores, capillary pores, and macro pores to a certain extent. As the proportion of gel pores increases, both compressive strength and flexural strength exhibit an upward trend, whereas they tend to decrease as the proportion of capillary and macro pores expands. Clearly, the fractal dimension stands out as a comprehensive and insightful parameter for characterizing the intricate pore size distribution within materials, effectively substituting for multiple interval pore volume parameters. Its adoption enables the formulation of a predictive model correlating strength with pore structure, which in turn lays the groundwork for optimizing the macroscopic performance of CA mortar through a microscopic approach.

A model for the stability effect of amino ester polycarboxylate acid on CA mortar

The above results are based on the original stability model of freshly mixed CA mortar mixed with polyurethane polycarboxylic acid, as shown in Fig. 19. This model illustrates the influence of polyurethane polycarboxylates on the uniformity of CA mortar, but further analysis techniques such as XRD are needed to understand the effects of polyurethane polycarboxylates on the hydration of CA mortar and cement.

Original model of stabilization effect of CA mortar mixed with polyurethane polycarboxylate. After adding polyurethane polycarboxylates, the distribution of various particles and bubbles in N1 is more uniform than that in C0.  sand;

sand;  cement particle;

cement particle;  bubble;

bubble;  asphalt particle;

asphalt particle;  aminoester polycarboxylate molecular chain;

aminoester polycarboxylate molecular chain;  liquid phase;

liquid phase;  settle down;

settle down;  loat up.

loat up.

A high workability multi-component suspension is considered as freshly mixed CA mortar. Various components with different densities in the liquid phase can cause gravity settling and buoyancy floating of suspended particles such as bubbles, asphalt particles, sand, and cement particles. Cement particles and sand will precipitate and deposit, while asphalt particles and bubbles will float and accumulate (Fig. 20, mixed with commercially available polycarboxylate), After adding polyurethane polycarboxylates, the polyurethane molecular chains can elongate and form a three-dimensional network by entanglement or combination with different particles of freshly mixed CA mortar. Generate a wide range of bridging effects in the liquid phase (Fig. 21, polyurethane-based polycarboxylates)22. Therefore, polyurethane polycarboxylates can effectively suppress the upward and downward trend of different particles or bubbles owing to gravity settlement, thereby improving the stability and uniformity of the bubble structure of mortar, and also improving the hardened pore structure.

The asphalt within hardened CA mortar is categorized into two forms: free asphalt and structural asphalt. Structural asphalt refers to asphalt that is tightly bound to the inorganic phase (C-S-H) through physical or chemical interactions (Fig. 21), free asphalt refers to the remaining asphalt (Fig. 20)23. Compared to free asphalt, structural asphalt constitutes a structural mechanical membrane that possesses significantly greater mechanical strength24. The typical interface morphology in Figure C0 exhibits two main characteristics. Firstly, the free asphalt film is almost ubiquitous throughout the microscopic image, with only a small amount of cement hydration products penetrating the asphalt film. Secondly, many circular parts representing pores are irregularly distributed in the asphalt film. The typical interface surface morphology of N1 also exhibits two main characteristics. The hydration products of cement and structural asphalt are the main framework of the entire micrograph, and secondly, the large pores in the matrix are significantly reduced25. These morphologies once again indicate that compared to C0, the number of bubbles and asphalt particles floating to the surface of N1 is reduced due to the improvement effect of polyurethane polycarboxylates26.

Conclusion

The morphological characteristics of the pore structure as well as the distribution of pore sizes in CA mortar were investigated. The variations in the microstructure and the distribution of pore sizes within CA mortar, influenced by the A/C ratio and curing age, were examined through SEM and NMR techniques. The key findings are summarized as follows:

-

(1)

The SEM results indicate that the microstructure of CA mortar mainly exhibits a loose and porous spatial structure, with cement hydration products as a continuous phase, asphalt as a dispersed phase, and CA mortar as a typical porous material. Compared to polyurethane polycarboxylates, the average pore size volume of CA mortars of ordinary polycarboxylate increased by 3% and the total porosity increased by 8%. This is due to the reduction of hydration products generated by cement hydration, which hinders the hydration process of cement.

-

(2)

Due to the longer molecular chains of cellulose ether and associated polyurethane, the influence of aminoester polycarboxylates on the pore structure and uniformity of CA mortar is affected. These chains can stretch, entangle, and combine with different particles of CA mortar to form a three-dimensional network, which can increase the consistency of CA mortar and generate a wide range of bridging effects. The upward and settlement trends of different bubbles or particles in CA mortar are reduced. In addition, the triterpenoid saponins in polyurethane polycarboxylates act as inhalation surfactants, 3% reduction in air bubbles in CA mortar.

-

(3)

Utilizing the concept of box dimension and combined with nuclear magnetic resonance test data, a fractal model for the pore volume of CA mortar has been proposed, which has been proven to have obvious fractal characteristics in the pore structure of CA mortar. Correlation analysis has shown that the fractal dimension of pore volume in CA mortar is positively correlated with compressive and flexural strength, indicating that the fractal dimension of pore volume can serve as a bridge connecting the macroscopic properties and microstructure of CA mortar.

Data availability

If you need raw data, please contact the first author of the article: Shuncheng Xiang, 410571462@qq.com.

References

Fu, Q., Zheng, K. R., Xie, Y. J., Zhou, X. L. & Cai, F. L. Fractal characteristics of pore volume of cement emulsified asphalt mortar. J. Silic. 41, 1551–1557 (2013).

Zhang, Y. et al. Study on the rheological properties of fresh cement asphalt paste. Constr. Build. Mater. 534–544 (2012).

Li, W. et al. Influence of cationic asphalt emulsion on the water transportation behavior and durability of cement mortar. Case Stud. Constr. Mater. 17, e01548 (2022).

刘赞群 田青, 等. CRTS II 型水泥乳化沥青砂浆静态力学性能发展的微观分析. 中国科学: 技术科学, 44: 681–686. (2014).

Shuncheng, X. et al. Influence of a polyurethane-modified polycarboxylate on properties of cement mortar. J. Appl. Polym. Sci. 139(11) (2021).

Deng, D. H., Ye, T., Yuan, Q. & Wang, Y. Comparison of pore structure and testing methods of cement emulsified asphalt mortar. J. Build. Mater. 19, 933–938 (2016).

Shuncheng Xiang, T. et al. Investigation of the effects of polyurethane-modified polycarboxylate at ambient temperature on the characteristics of cement with supplementary cementitious materials. Polymers 15, 3602 (2023).

Jiang, N. The his torical evolution of the concept of box dimension. J. Dialectics Nat. Res. 4, 84–90 (2020).

Wyrzykowski, M., McDonald, P. J., Scrivener, K. L. & Lura, P. Water redistribution within the microstructure of cementitiousmaterials due to temperature changes studied with 1H NMR. J. Phys. Chem. C. 121, 27950–27962 (2017).

McDonald, P. J., Gajewicz, A. M. & Morrell, R. 1H NMR characterisation of pore water in cement materials. In Proceedings of the36th Cement and Concrete Science Conference 5–6 (2016).

Zheng, H. et al. Mechanical properties and microstructure of waterborne polyurethane-modified cement composites as concrete repair mortar. J. Building Eng. 84, 108394 (2024).

陈立军,窦立岩 张春玉,等. 混凝土孔结构的分类命名与高性能混凝土的孔结构种类. 混凝土 (07), 28–30 (2012).

Koohestani, B. Effect of saline admixtures on mechanical and microstructural properties of cementitious matrices containing tailings. Constr. Build. Mater. 156, 1019–1027 (2017).

He, Y. et al. Effects of polycarboxylate superplasticisers with various functional groups on the pore structure of cement mortar. Adv. Cem. Res. 32 (11), 510–518 (2020).

Khanjani, Z. & Jamshidzadeh, Z. Impacts of air-entrained agents and curing time on mechanical and durability characteristics of structural lightweight concrete. Innov. Infrastruct. Sol. 7(2) (2022).

Tambara Júnior, L. U. D. et al. Influence of polycarboxylate superplasticizer and calcium sulfoaluminate cement on the rheology, hydration kinetics, and porosity of Portland cement pastes. J. Build. Eng. 106120 (2023).

Lootens, D. & Bentz, D. P. On the relation of setting and early-age strength development to porosity and hydration in cement-based materials. Cem. Concr. Compos. 68, 9–14 (2016).

Jin, S. et al. Multiscale model for the scale effect of tensile strength of hardened cement paste based on pore size distribution. Constr. Build. Mater. 325, 126775 (2022).

Chen, X. & Wu, S. Influence of water-to-cement ratio and curing period on pore structure of cement mortar. Constr. Build. Mater. 38, 804–812 (2013).

Ji, Y. et al. Fractal characterization on pore structure and analysis of fluidity and bleeding of fresh cement paste based on 1H low-field NMR. Constr. Build. Mater. 445–453 (2017).

Qiang, W. et al. Compressive strength development and microstructure of Cement-asphalt mortar. J. Wuhan Univ. Technology-Mater Sci. Ed. 26 (2011).

Xiang, S., Tan, Y. Gao, Y. & Li, L. Synthesis of comb-polyurethane-modified polycarboxylate at room temperature and its interaction on behavior of cement mortar. J. Appl. Polym. Sci. 139(11), e51793 (2022).

单炜. 沥青混合料强度构成机理的探讨. 2005全国高速公路沥青路面早期破损病因与防治技术研讨会论文集 105–110 (2005).

Huadong, S., Ding, Y., Jiang, P., Wang, B. & Zhang, A. Deming Wang,Study on the interaction mechanism in the hardening process of cement-asphalt mortar. Constr. Building Mater. 227, 116663 (2019).

Dzhamev, B. K. Increasing the monolithic nature of masonry made of cellular concrete blocks by using polyurethane foam glue as a masonry mortar. Stroitel’nye Materialy. 786(11), 4–9 (2020).

Jiang, S., Li, J., Zhang, Z., Wu, H. &, Liu, G. Factors influencing the performance of cement emulsified asphalt mortar: A review. Constr. Build. Mater. 279, 122479 (2021).

Acknowledgements

The authors gratefully acknowledge the financial support from the National Natural Science Foundation of China (General Program: 52209154, 52278239, and 52308234) Chunhui Project Foundation of the Education Department of China (HZKY20220358), Hunan Provincial Youth Science and Technology Talent Support Plan (2022RC1175), Natural Science Foundation of Hunan Province (2025JJ50245), Hunan Provincial Department of Education Project(24A0242, 24B0284 and 23C0127), Hunan Provincial Innovation Foundation for Postgraduate (CX20220869). The authors thank Lulu Li from the Ex-port-Import Bank of China Hunan Branch for providing the literature translation assistance.

Author information

Authors and Affiliations

Contributions

Shuncheng Xiang:ValidatiWriting -review & editing, Project administrationon, Ming Yuan:Writing -original draft, Conceptualization, Xin Yang:Funding acquisition, Supervision, Lulu Li:Validation, Supervision, Yingli Gao:Methodology, Resources, Haotian Yu:Investigation, Methodology, Huan Zhou:Methodology, Software, Tingxiang Zheng:Data curation, Supervision, Jin Zhang:Software, Methodology, Zhen Jiang:Funding acquisition, Data curation,

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xiang, S., Yuan, M., Yang, X. et al. Evolution law of microporous structure in cement asphalt (CA) mortar under the action of polyurethane polycarboxylates. Sci Rep 15, 21457 (2025). https://doi.org/10.1038/s41598-025-96359-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-96359-y