Abstract

Water scarcity in arid regions is a significant factor constraining industrial development globally. Xinjiang, which has a huge potential for economic development, is constrained for its local industry development owing to the scarcity of water resources. Enhancing the efficiency of industrial water consumption is thus crucial to alleviate the conflict between water resource constrain and economic development. This study investigated the industrial water consumption efficiency in the economic zone of the northern slope of the Tianshan Mountains (EZNSTM) of Xinjiang from 2001 to 2020. The super-efficient SBM and Tobit model were used to identify the key drivers of regional industrial water consumption efficiency. Factors including economic development, government influence, industrial structure, and urbanization levels were found to affect the overall industrial water consumption efficiency. On the contrary, being open to the outside world and natural resource endowment did not significantly impact the water consumption efficiency. This paper identified the disparities in industrial water use and consumption efficiency across different regions of the EZNSTM and elucidated the primary factors influencing industrial water consumption efficiency in the area, which provided a critical foundation for coordinating future economic development and water resource utilization.

Similar content being viewed by others

Introduction

Water resources are the cornerstone of human survival and socio-economic development1. However, many countries and regions around the world are facing serious water scarcity2. Specifically, approximately 55% of the worldwide nations experience water shortages, among which 80 countries and regions, representing 40% of the global population, are in the state of severe water scarcity3. Industrialization, as a key pillar of economic growth and societal development, depends on water resources4. Besides consuming large quantities of water, industrial activities, such as cooling, cleaning, production, processing, etc., result in severe contamination of both surface and groundwater, posing multiple adverse effects on the environment and human health5. In China, rapid economic development has placed immense pressure on the sustainability of water resources, leading to severe negative environmental and human health impacts. Subsequently, improving industrial water consumption efficiency is crucial to alleviating water shortages and reducing ecological and environmental pressures, which are the keys to sustainable industrial development and steady economic growth6. The river basins in the northwestern region of China, such as the Heihe basin7, Shiyang River basin8, Tarim River basin9, and Ertix River basin10, all face severe pressure on their water resources11,12. Northwestern China is one of national most economically promising regions, but water shortages limit its economic development. The deterioration of local water quality and unsustainable water use have drawn significant attention11,13,14,15. Over-extraction of groundwater and growing agricultural irrigation demand are key contributors to the increasing pressure on water resources16. Additionally, increased rare earth element mining alters surface and groundwater chemical properties17. Although some studies focus on agriculture and ecology in the northwest, few research has focused on the spatial distribution and driving factors of industrial water use efficiency and its driving factors18. Therefore, improving industrial water efficiency and optimizing water resource management are essential for promoting sustainable economic growth and ensuring water security in this region19,20.

Research on industrial water consumption is complex, involving comprehensive consideration of various economic activities and environmental factors21,22,23. Using the EIO-LCA model and Structural Decomposition Analysis (SDA), researchers found that changes in production structures and shifts in consumption patterns improved industrial water consumption efficiency in the US from 2005 to 201024. In China, industrial water plays an active role in promoting economic growth25,26,27. However, its overuse leads to resource wastage and adverse impacts on the environment and economy25. The industrial water consumption changes alongside the development of industrial economy with decrease in consumption at the source and increase in consumption of recycled industrial water26. The main drivers of industrial water consumption are changes in water resource prices, economic GDP, environmental pollution, and the volume of industrial water consumption27.

Process-based mathematical models have been extensively used in the research of industrial water consumption efficiency. However, limitations exist for these models. For instance, EIO-LCA28 and Leontief IO29 cannot dynamically display certain trends. SDA model30, GM model31, and Cobb–Douglas model32,33 require high accuracy of data34, are complex in computation35, and consider external environmental factors36, leading to unstable prediction results. The super-efficiency SBM model, an advanced DEA method, excels in evaluating DMU efficiency, particularly in handling asymmetric efficiency losses by accurately capturing deviations in resource utilization37,38. By optimizing the input–output ratio, it mitigates the impact of extreme data, making it ideal for resource-limited environments with diverse objectives39. Its wide use in energy efficiency, environmental management, agriculture, and industry highlights its versatility40,41. The Tobit model complements the SMB functions by addressing the shortcomings of traditional regression methods, especially for truncated or constrained dependent variables. It overcomes biases caused by data truncation, providing more accurate estimates and revealing deeper drivers in areas like income, consumption, and emissions42,43,44. Together, the super-efficiency SBM and Tobit models solve efficiency and data truncation issues, offering a robust framework for decision-makers. This framework identifies factors influencing industrial water use efficiency, supporting optimal resource allocation and sustainable development. It also helps policymakers understand dynamic changes in water use efficiency and formulate effective resource management strategies45,46.

Bordering Central Asia and Russia, Xinjiang is the largest province of China, and serves as a vital node of the “Silk Road Economic Belt”47,48,49. Since the implementation of the “Tenth Five-Year Plan” in 2001, Xinjiang’s industry has expanded rapidly with value-added sectors increased more than sevenfold, from $6 billion to $50 billion. 83% of the regional heavy industry and 62% of its light industry are concentrated in the economic zone on the northern slopes of the Tianshan Mountains (EZNSTM), accounting for over 40% of the regional GDP. Meanwhile, the rapid industrial development has led to significant water resource consumption, creating a sharp contradiction of water resource shortage and industrial economic development in this region50. Improving overall industrial water consumption efficiency is crucial not only to reduce water and related energy costs but also to increase industrial output values with higher competitivity51. The overall industrial water consumption efficiency is also essential for ensuring the sustainable development of the regional economy, which has been demonstrated in the acyl chloride industry in Jiangsu Province21. Significant improvement in industrial water consumption efficiency has been made during industrialization in developing countries52 as evidenced by changes in industrial water consumption in Tianjin from 2001 to 2015 by improved production output, technological level, and industrial structure53. However, due to differences in geography, economic development, policy inclination, and spatial and temporal distribution of industrial water consumption efficiency and its driving factors in the unique area of EZNSTM remain unclear, which would hinder the development of the local industrial economy and optimization of water resource allocation. Correspondingly, the objectives of this study were to (1) characterize the spatial and temporal distribution of overall industrial water consumption efficiency, industrial technical efficiency, and industrial scale efficiency in the northern slope economic belt of the Tianshan Mountains and (2) identify the key factors affecting industrial water consumption efficiency using the Super SBM Tobit model.

Materials and methods

Overview of the research area

The northern slope of the Tianshan Mountains in Xinjiang is located in the Xinjiang Uyghur Autonomous Region of western China, occupying merely 5.7% of the total land area of Xinjiang. Despite its relatively small geographical footprint, this area encompasses over half of the region’s heavy industry. Key cities within this economic corridor include Karamay, Urumqi, Changji, Shihezi, Tacheng, and Bortala Mongolian Autonomous Prefecture. According to the "Xinjiang Statistical Yearbook" and the "Announcement of the Seventh National Population Census of the Xinjiang Uyghur Autonomous Region," these six areas—Urumqi, Karamay, Changji Hui Autonomous Prefecture, Bortala Mongolian Autonomous Prefecture, Tacheng, and Shihezi—account for 57% of the population and 78% of the industrial output within the Tianshan Northern Slope Economic Belt.

Data on industrial water resources

Industrial production typically requires large amounts of water for cooling, cleaning, processing, etc.5. As a result, industrial water consumption accounts for a significant portion and impacts water resource allocation dramatically21,54,55,56. The data on industrial water consumption in the economic zone of the north slope of Tianshan Mountain were obtained from Xinjiang Water Resources Bulletin, Xinjiang Statistical Yearbook, and Xinjiang Body Ecological and Environmental Protection Department’s Annual Statistical Report. The data on industrial wastewater discharge, industrial energy consumption, industrial population, scientific research expenditure, pollutant discharge, investment in pollution control, and environmental protection personnel in the sub-region were obtained from the Xinjiang Statistical Yearbook and the Annual Statistical Report of the Xinjiang Department of Ecological and Environmental Protection. The Location and elevation map of the study area is shown in Fig. 1a.

Variable selection and data sources

Sources of indicators for the super-efficiency SBM indices

To accurately assess the relationship between water consumption efficiency and industrial production in measuring industrial water consumption efficiency, the input and output variables were carefully selected and obtained from the Xinjiang Statistical Yearbook, Xinjiang Water Resources Bulletin, and the Xinjiang Department of Environment and Ecological Protection’s Annual Statistical Report21,54,56. Specifically, the Super SBM model used industrial water consumption, industrial employment, and construction investment as input variables, and industrial output value and wastewater discharge as output variables. Industrial water consumption was the primary input data, which directly impacted industrial production; industrial employment reflected the contribution of human resources to the production efficiency; and construction investment represented the level of enterprise investment in industrial facilities, machinery, and equipment. Industrial output value was a key economic indicator, which measured the output of industrial activities, while wastewater discharge assessed the environmental impact of industrial activities, especially on the quality and management of water resources.

Description of Tobit regression variables

To ensure Tobit regression analysis can comprehensively cover the various factors affecting industrial water demand, variables were also carefully selected considering factors affecting the efficiency of industrial water use with data obtained from the Xinjiang Statistical Yearbook51. For Tobit regression analysis, the following factors were taken into consideration: (1) The level of economic development is typically positively correlated with industrial water demand, with economic growth often driving increased water demand; (2) Changes in industrial structure directly reflect the impact of industrial growth on water demand; (3) Regions with a higher degree of openness typically attract more foreign investment and establish export-oriented industries, which lead to significant differences in water demand and efficiency standards; (4) Governmental influence directly impacts the management and efficiency of industrial wastewater treatment and water resource utilization; and (5) Increase in urbanization accompanies industrialization and modernization, potentially further increasing the demand for industrial water.

Introduction to the model

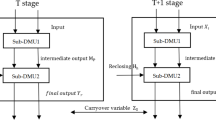

Super SBM efficiency measurement model

DEA is a commonly used method for efficiency measurement. However, traditional DEA models cannot calculate the efficiency scores for effective DMUs as these models are based on radial approaches that do not take into account the slackness in inputs and outputs57. The super-efficiency SBM model effectively addresses these issues58,59. In this study, an input–output indicator system was developed, which included undesirable outputs and used the super-efficiency SBM model to assess the industrial water consumption efficiency in selected cities of Xinjiang. The super-efficiency scores were then used to evaluate the relative industrial water efficiency across different provinces. Details are available in prior studies60,61,62. The efficiency score of industrial water consumption is described by:

where \(\rho\) represents the efficiency score of industrial water consumption. An efficiency score of 1 indicates optimal performance at the frontier level. The greater the value of ρ is, the higher the efficiency is. The variable n denotes the total number of decision-making units (DMUs). The parameters m, q1, and q2 represent the number of inputs, desirable outputs, and undesirable outputs within each DMU, respectively. The terms xik, ygrk, and ybrk correspond to the input vector, desirable output vector, and undesirable output vector of each DMU. X, Yg, and Yb are the matrices representing inputs, desirable outputs, and undesirable outputs, respectively. The variable λ is a column vector. The slack variable s-, sg, and sb measure the slack in inputs, desirable outputs, and undesirable outputs, respectively.

Tobit model

To further investigate the factors influencing industrial water consumption efficiency in the Northern Tianshan Economic Belt of Xinjiang, this study employed the Tobit regression model based on maximum likelihood estimation51. The model analyzed the determinants of efficiency in the following way63:

where YTE represents the comprehensive efficiency of industrial water consumption, which is a dependent variable. Xj,it denotes the j-th influencing factor, serving as the independent variable, where i and t represent different prefecture-level cities and years, respectively. β0 and βj are the parameters to be estimated for the corresponding variables, and εit is the random error term.

Data management

The object of this study was the industrial water consumption in six typical regions of the economic zone on the north slope of Tianshan Mountain from 2001 to 2020. Since the Xinjiang Statistical Yearbook and the Xinjiang Ecological and Environmental Protection Department’s Annual Statistical Report only included wastewater discharge statistics from 2003 to 2015, linear interpolation was used to estimate the missing data to provide a more extended data series64,65. Industrial energy consumption, industrial employment population, scientific research funding, pollutant emissions, pollution control investment, and environmental protection personnel data were extracted from the Xinjiang Statistical Yearbook to create an Excel table for the north slope of the Tianshan Mountains economic zone and the six typical areas, which were visualized through the software ArcGIS and Origin.

Spatial distribution of industrial water consumption indicators on the northern slopes of the Tianshan mountains

Distribution of industrial water consumption and output value

As shown in Fig. 1b, there were significant regional differences in the scale of industrial activities and dependence on water resources. Urumqi, Shihezi, and Changji exhibited high water consumption, whereas Bortala had relatively low water consumption. The proportion of industrial water consumption to total water consumption also showed large fluctuations across the regions (Fig. 1c).For instance, Urumqi and Karamay had industrial water consumption proportions of 3% and 54%, respectively, while Tacheng and Bortala had proportions as low as 0.9%. As shown in Fig. 2a, from 2001 to 2020, Urumqi had the highest average annual GDP, followed by Changji, and Bozhou had the lowest.

(a) Spatial distribution of industrial output value; (b) Proportion of energy consumption by region; (c) Distribution map of wastewater discharge in different regions. Notes: In the diagram, high-pollution, medium-pollution, and low-pollution energy sources respectively refer to energy production processes characterized by water demand while generating significant, moderate, and minimal pollutant emissions. This classification derives from the categorization of pollutant emission characteristics during energy utilization, primarily based on national/regional environmental protection regulations, industry standards, and relevant environmental impact assessment studies. The study area is a typical area selected in the northern slope of Tianshan Mountain.

Influence the spatial distribution of industrial water consumption index

As shown in Fig. 2b, Urumqi has the highest proportion of low pollution energy (60%). The proportion of high and moderate pollution energy is relatively high, about 21% and 33% respectively. Changji has the highest proportion of high pollution energy (30%), while moderate and low pollution energy only account for 8% and 3% respectively. In Karamay, energy consumption is mainly concentrated in moderate pollution (55%) and low pollution (30%). The proportion of high pollution energy in Shihezi is significant (18%), while the proportion of moderate and low pollution energy is extremely low (0.4% and 1.3%, respectively). Bozhou has the lowest energy consumption ratio.

As shown in Fig. 2c, Urumqi had the highest industrial wastewater discharge, comparable to that of Shihezi. In contrast, Bortala had the lowest industrial wastewater discharge. The industrial wastewater emissions of Changji and Kelamayi were similar, each around 4000 tons.

As illustrated in Fig. 3a, b, the employment population, R&D funding (Research and development expenditure), investments in industrial pollution control, and the number of environmental protection agency personnel showed an upward trend from 2001 to 2010, while the volume of transactions in the technology market showed a downward trend. From 2011 to 2020, R&D funding and technology market transactions exhibited an upward trend, while the other indicators showed a negative growth trend. Among these, the employment population, investments in industrial pollution control, and environmental protection agency personnel were positively correlated with industrial technological efficiency. R&D funding and technology market transactions were positively correlated with scale efficiency.

(a) Change chart of various indicators; (b) Correlation chart of indicators (*p ≤ 0.05). Notes: The indicators in the Figure are the actual indicators that affect the industrial technical efficiency and industrial scale efficiency in the northern slope of Tianshan Mountain,* means p ≤ 0.05., Red represents a positive correlation, and blue generally indicates a negative correlation. The study area is a typical area selected in the northern slope of Tianshan Mountain.

Spatial and temporal distribution of industrial Water consumption efficiency index

The overall industrial water consumption efficiency in Bortala was the highest at 1.08, while the lowest efficiency was found in the Tacheng region at 1.02 (Fig. 4). Shihezi also exhibited a high industrial water consumption efficiency of 1.07, the highest among the six studied regions. Conversely, Urumqi had the lowest water consumption efficiency at 1.00. Notably, Shihezi’s industrial water consumption technology was the most advanced among the regions, with an efficiency of 1.07, while Tacheng had the lowest technological efficiency.

During the study period, the average value of overall industrial water consumption efficiency exhibited a fluctuating trend, consistently remaining above 1. This period was divided into four phases: 2001–2005, 2006–2010, 2011–2015, and 2016–2020, as shown in Fig. 5.

From the first stage (2001–2005) to the second stage (2006–2010), the increase in overall industrial water consumption efficiency was driven by improvements in industrial technical efficiency and scale efficiency. In the transition from the second phase to the third phase (2011–2015), although technical efficiency improved, the efficiency of technology declined, leading to a decrease in the overall industrial water consumption efficiency. The decline of the overall industrial water consumption efficiency from the third stage (2011–2015) to the fourth stage (2016–2020) was attributed to the decrease in industrial technical efficiency, despite advancements in industrial technology during this period.

Results of factors affecting industrial water efficiency

As shown in Table 1, the regression coefficient of the economic development level was positive with a P-value of 0.006, indicating that economic development had a significantly positive impact on industrial water consumption efficiency. The regression coefficient for government influence was negative with a P-value of 0, suggesting a significantly negative impact of government influence on industrial water consumption efficiency. The regression coefficients of industrial structure and urbanization level were positive, with P-values greater than 0.05 but less than 0.1, indicating that both industrial structure and urbanization level had a significantly positive impact on industrial water consumption efficiency at the 10% significance level. The P-values for natural endowment and openness to the outside world were greater than 0.1, indicating that their impacts on industrial water consumption efficiency were not significant.

Discussion

Industrial water usage and its proportional

This study found that the industrial water consumption and its proportion in the total water consumption of the Tianshan North Slope Economic Belt did not completely increase with the increase of industrial energy consumption and total output (Fig. 2b). For example, Urumqi’s energy consumption far exceeds other regions (Fig. 2b), but industrial water consumption and its proportion in total water consumption are not the highest. Bozhou has the lowest average annual industrial production value (Fig. 2a), but its industrial water consumption is not the lowest (Fig. 1b). As shown in Fig. 2a, Urumqi had the highest average annual GDP, followed by Changji, and Bozhou had the lowest from 2001 to 2020. This contrasts with Tianjin and Beijing, where industrial water use rises with industrial growth66,67. The difference may be due to Tianjin and Beijing’s advanced infrastructure, which links industrial water use to industrial output. However, in the Tianshan Mountains’ north slope, geographic constraints and limited resources restrict the ability to increase water use alongside industrial growth. Additionally, the region’s industrial structure, with fewer resource-intensive industries, results in stable water demand despite the increase of industrial output.

Thus, we recommend differentiated water management policies. Cities like Urumqi, with diverse industries, should implement flexible strategies to improve water use efficiency. In contrast, areas like Shihezi, with a less diversified industrial structure, should focus on optimizing industries and promoting low-energy, high-efficiency sectors to reduce water dependence. Moreover, regional coordination of water resources and technical support should be enhanced to improve efficiency and promote sustainable economic and environmental development.

Industrial water consumption efficiency

Generally, economically developed regions had high industrial water usage, and the overall efficiency of industrial water consumption tended to be maintained at a high level55. However, others argued that the overall efficiency of industrial water consumption was not solely dependent on the level of economic development but was more closely related to local industrial structure, types of energy consumed, and their quantities68,69,70. A similar pattern was observed in the study of industrial water consumption efficiency in the EZNSTM. For example, Urumqi, as the provincial capital, did not exhibit the highest overall industrial water efficiency, industrial technological efficiency, or technological advancement. Conversely, these metrics were all higher in Bozhou than in Urumqi. This phenomenon was attributed to the higher total and variety of industrial energy consumption in Urumqi and its diversified industrial structure71. As shown in Fig. 2b, Urumqi’s consumption of the three types of industrial energy all exceeded 20%. In contrast, Bozhou displayed the opposite trend, where high-pollution, high-consumption energy consumption accounted for 1% and low-pollution, low-consumption energy consumption accounted for 0.2% (Fig. 2b). Additionally, industrial wastewater discharge in Bozhou was lower, indicating that compared to Urumqi, Bozhou had a smaller industrial scale and a more homogeneous industrial structure. Therefore, the industrial water consumption efficiency in Bozhou was higher than in Urumqi72. Previous studies have indicated that the complexity of industrial structures and the diversity of energy consumption patterns have a certain impact on the efficiency of industrial water resource consumption73. Different industrial types and energy consumption models may exert distinct effects on water use efficiency74,75. In our comparative analysis, although Bozhou’s industrial scale is relatively small and its industrial structure is less diversified, the region’s energy consumption predominantly consists of low-pollution and low-energy-intensity sources (Fig. 2b), contributing to its higher industrial water resource utilization efficiency (Fig. 4). In contrast, Urumqi has a larger industrial scale and a more diversified energy consumption structure, with a significant proportion of high-pollution and high-energy-intensity energy types (Fig. 2b), which partially hinders its water resource utilization efficiency (Fig. 4). However, industrial diversification alone does not fully account for reduced water use efficiency. Instead, the disparities in efficiency are more significantly influenced by the combined effects of energy consumption structures and pollution emission levels. Therefore, differences in water resource utilization efficiency are closely linked to industry types, energy consumption patterns, and pollution control capabilities, with the interplay of these factors ultimately determining overall efficiency76,77.

The continuous development of water-saving technologies, water-saving facilities, and water conservation concepts, along with the ongoing improvement of water-saving policies for enterprises, effectively promoted the overall industrial Water consumption efficiency78. From 2001 to 2010, the growth rate of overall industrial water consumption efficiency exhibited an upward trend. However, from 2010 to 2020, the growth rate of overall industrial water consumption efficiency declined, which was attributed to a slowdown in the growth rates of employment in the industry, investment in industrial pollution control, staffing in environmental agencies, and research and development funding, leading to a decrease in the rate of industrial technological efficiency growth21,70. Consequently, the overall industrial water consumption efficiency growth rate fell in the latter decade. Despite a reduction in the total investment in industrial pollution control by the post-2010, research and development funding and technological market transaction volumes continued to rise, suggesting that the efforts in the initial phase had matured water-saving technologies and facilities, and enhanced corporate water conservation awareness. As a result, the overall industrial water consumption efficiency gradually tended toward high efficiency and stability23, reducing the scope for further improvements in water conservation and leading to a slowdown in the growth rate of overall industrial water consumption efficiency.

Factors affecting industrial water consumption efficiency

This study identified the level of economic development and government influence as the main factors affecting the overall industrial water efficiency in the Northern Tianshan Economic Belt. Generally speaking, in more economically developed areas, there is a favorable environment for the development of local production facilities, water-saving technologies, and water conservancy policies, which helps enhance the overall industrial water efficiency55,70. In the study area, the level of economic development had a positive significant effect on the overall industrial water efficiency, similar to findings by Yang79, indicating that the impact of economic development levels on the overall industrial water consumption efficiency in the Northern Tianshan Economic Belt cannot be overlooked. Prior research also showed that the government influence had a significant negative effect on the overall industrial water efficiency70. A similar pattern was observed in this study area, possibly due to the low investment in industrial wastewater treatment funds for source control measures such as industrial water-saving devices and technologies80. This study found that industrial wastewater pollution prevention and control expenditures in the Northern Tianshan Economic Belt were mainly used for post-contamination remediation, with funds invested in preemptive wastewater management accounting for only 7%-14% of the total investments (https://www.zgtjnj.org/index.aspx), leading to a scenario where pollution management costs were high but relatively less effective80.

Overall, higher levels of industrial development correlated with higher overall industrial water efficiency68,70, while urbanization facilitated the modernization of industrial technologies and water resource management81, which helped improve water consumption efficiency and reduce water wastage82,83. In the Northern Tianshan Economic Belt, water supply was primarily allocated to agriculture (https://www.zgtjnj.org/index.aspx), with a smaller proportion dedicated to industry, thus limiting industrial development and resulting in a minimal impact of secondary sector output growth on the overall industrial water consumption efficiency84,85. Additionally, owing to the vast territory and sparse population of the Northern Tianshan Economic Belt in Xinjiang, the level of urbanization contributed less significantly to the industry86.

Due to the limited water resources in the western region, even a small increase in water supply can significantly impact the overall industrial water consumption efficiency87. Previous research suggests that when water is abundant, conservation efforts diminish88. However, in this study, we found that natural resource endowment had little effect on industrial water consumption efficiency, aligning with prior findings82,86. Over the past two decades, exports have dominated trade in the region, with imports accounting for only 10%-35% (https://www.zgtjnj.org/index.aspx), so foreign trade openness has little influence on industrial water efficiency. This may be due to this model’s drawback for accounting for other economic and socio-environmental factors that could affect this relationship.

Additionally, the model has several limitations. First, it assumes a linear relationship between economic structure and water use, whereas this relationship may be non-linear, especially across different industries and regions89. Second, although external factors have been considered, some endogenous issues, like technological innovation rates and regional policies, were not adequately included in this model, potentially affecting water efficiency estimates90. Our results reveal the driving factors that affect industrial water use efficiency in different regions. However, further research is still needed in optimizing the model structure and input parameters in the future to more accurately evaluate and clarify the impact mechanism of industrial water use efficiency.

Conclusion

Bozhou, Changji, Shihezi, and Karamay exhibited higher industrial water consumption efficiency, whereas Urumqi and Tacheng had lower efficiency. Bozhou and Karamay also showed higher industrial technical efficiency, while the others had lower technical efficiency. Shihezi demonstrated significant industrial scale efficiency compared to the others. From 2001 to 2010, increased employment, R&D funding, pollution control investment, and environmental staff improved industrial technology, boosting overall water consumption efficiency. However, from 2011 to 2020, a decline in these factors led to lower technical efficiency and slower improvement in water efficiency. Economic development, government influence, industrial structure, and urbanization had a substantial impact on water efficiency, while foreign trade and natural resources had a minimal effect. To enhance efficiency, ongoing efforts in economic and technological innovation, industrial optimization, and policy support are essential for more efficient industrial water use.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Dos Santos, S. et al. Urban growth and water access in sub-Saharan Africa: Progress, challenges, and emerging research directions. Sci. Total Environ. 607, 497–508. https://doi.org/10.1016/j.scitotenv.2017.06.157 (2017).

Matos, C., Nogueira, P., Magalhaes, P., Santos, C. & Bentes, I. Water consumption assessment and classification in industrial buildings: The case study of continental advanced antenna, Vila Real, Portugal. Sci. Total Environ. https://doi.org/10.1016/j.scitotenv.2023.166445 (2023).

Wada, Y. et al. Global monthly water stress: 2. Water demand and severity of water stress. Water Resour. Res. https://doi.org/10.1029/2010wr009792 (2011).

Weerasooriya, R. et al. Industrial water conservation by water footprint and sustainable development goals: A review. Environ. Dev. Sustain. 23, 12661–12709. https://doi.org/10.1007/s10668-020-01184-0 (2021).

Wakeel, M., Chen, B., Hayat, T., Alsaedi, A. & Ahmad, B. Energy consumption for water use cycles in different countries: A review. Appl. Energy 178, 868–885. https://doi.org/10.1016/j.apenergy.2016.06.114 (2016).

Xiao, H., Zhang, L. & Chai, Z. in 3rd International Symposium on Earth Observation for Arid and Semi-Arid Environments (ISEO). (2017).

Deng, X., Zhao, C. Identification of water scarcity and providing solutions for adapting to climate changes in the Heihe River Basin of China. Adv. Meteorol. (2015).

Hu, W., Resources, M. O. W., Chinansfc, N. N. S. F. O. & Union, E. in International symposium on sustainable water resources management and Oasis-hydrosphere-desert Interaction in Arid Regions.

Huang, Q., Zhao, G., Guo, Z. & Zhou, H. Study on optimization of water resources allocation in the Tarim River. J. Hydroelectr. Eng. 34, 38–46 (2015).

Fan, J. et al. Dynamic assessment and sustainability strategies of ecological security in the Irtysh River basin of Xinjiang, China. Chin. Geograph. Sci. 33, 393–409 (2023).

Wang, Z., Li, Z., Zhan, H. & Yang, S. Effect of long-term saline mulched drip irrigation on soil-groundwater environment in arid Northwest China. Sci. Total Environ. 820, 153222 (2022).

He, G., Liu, H., Wang, J., Zhao, Y. & He, F. Energy-water security challenge: Impact of energy production on water sustainable developments in Northwest China in 2017 and 2030. Sci. Total Environ. 766, 144606 (2021).

Yang, P. et al. Risk assessment of water resource shortages in the Aksu River basin of northwest China under climate change. J. Environ. Manag. 305, 114394 (2022).

Huang et al. Land use change impacts on the amount and quality of recharge water in the loess tablelands of China. Sci. Total Environ. (2018).

Anzhou, Z. et al. Impact of human activities and climate variability on green and blue water resources in the Weihe River basin of Northwest China. Sci. Geographica Sin. 36, 571–579 (2016).

Kumar, R., Srivastava, S. K. & Singh, R. P. Extent of groundwater extraction and irrigation efficiency on farms under different water-market regimes in Central Uttar Pradesh. Agric. Econ. Res. Rev. 22 (2009).

Hong-De, L. I., Wei-Yi, M., Shun-Zhi, W., Yan-Mei, T. & Shu-Feng, W. Analysis on surface water quality in the upper reaches of the Ogan River Basin. Arid Zone Res. 23, 393–398 (2006).

Ma, J. Z., Wang, X. S. & Edmunds, W. M. The characteristics of ground-water resources and their changes under the impacts of human activity in the arid Northwest China: A case study of the Shiyang River Basin. J. Arid Environ. 61, 277–295 (2005).

Yue, Z., Alun, G. & Bolin, P. Relationship between industrial water consumption and economic growth in china based on environmental Kuznets Curve. Energy Procedia 105, 3557–3564 (2017).

Rott, U. Multiple use of water in industry: The textile industry case. Environ. Lett. 38, 1629–1639 (2003).

Wang, B., Wang, X. & Zhang, X. An empirical research on influence factors of industrial water use. Water https://doi.org/10.3390/w11112267 (2019).

Qin, J. & Wang, M. Assessing the performance of industrial water resource systems in China with total constraints on water consumption and pollution emissions. Environ. Sci. Pollut. Res. 30, 110251–110279. https://doi.org/10.1007/s11356-023-29900-z (2023).

Jin, W., Zhang, H.-Q., Liu, S.-S. & Zhang, H.-B. Technological innovation, environmental regulation, and green total factor efficiency of industrial water resources. J. Clean. Prod. 211, 61–69. https://doi.org/10.1016/j.jclepro.2018.11.172 (2019).

Wang, B. H., Small, M. J. & Dzombak, D. A. Improved efficiency reduces US industrial water withdrawals, 2005–2010. Environ. Sci. Technol. Lett. 2, 79–83. https://doi.org/10.1021/acs.estlett.5b00023 (2015).

Sun, D., Shi, M., Wei, J. & Chen, Z. Economic contribution and rebound effect of industrial water: The case of the Yangtze River Delta. Water Resour. Econ. https://doi.org/10.1016/j.wre.2023.100222 (2023).

Lei, S., Deng, L. & Ieee. in 6th International Symposium on Computational Intelligence and Design (ISCID). 69–71 (2013).

Zhang, X., Zhao, D., Wang, T. & Wu, X. Industrial water consumption forecasting based on combined CEEMD-ARIMA model for Henan province, central chain: A case study. Environ. Monitor. Assess. https://doi.org/10.1007/s10661-022-10149-x (2022).

Egilmez, G. & Park, Y. S. Transportation related carbon, energy and water footprint analysis of US manufacturing: An eco-efficiency assessment. Transport. Res. Part D-Transport Environ. 32, 143–159. https://doi.org/10.1016/j.trd.2014.07.001 (2014).

Gim, H. U. The economic effects affected on the daegu-gyeongbuk region for the lack of water—based on the analysis of induced effects through “the output-output model. J. Korea Region. Econ. 7, 187–214 (2009).

Samsudin, M. S., Azid, A., Khalit, S. I., Sani, M. S. A. & Lananan, F. Comparison of prediction model using spatial discriminant analysis for marine water quality index in mangrove estuarine zones. Mar. Pollut. Bull. 141, 472–481. https://doi.org/10.1016/j.marpolbul.2019.02.045 (2019).

Li, Y., Huang, S. & Qu, X. Water pollution prediction in the three gorges reservoir area and countermeasures for sustainable development of the water environment. Int. J. Environ. Res. Public Health https://doi.org/10.3390/ijerph14111307 (2017).

Sun, Y., Ma, M. & Miao, X. in Annual Conference Proceedings of China Agriculture System Engineering Society. 189–193 (2010).

Mahaboob, B., Ajmath, K. A., Venkateswarlu, B., Narayana, C. & Praveen, J. P. in International Conference on Applications of Fluid Dynamics (ICAFD). (2019).

Yang, Z., Liu, H., Yang, T. & Xu, X. A path-based structural decomposition analysis of Beijing’s water footprint evolution. Environ. Earth Sci. 74, 2729–2742. https://doi.org/10.1007/s12665-015-4484-6 (2015).

Cheng, M. L. & Han, Y. A modified Cobb–Douglas production function model and its application. IMA J. Manag. Math. 25, 353–365. https://doi.org/10.1093/imaman/dpt012 (2014).

Tang, X. et al. in 8th International Conference on Information and Management Sciences. 589–590 (2009).

Han, Z., Li, X., Yan, Z. & Zhong, K. Interaction and spatial effects of green technology innovation and financial agglomeration: empirical evidence from China under the goal of “double carbon”. Front. Environ. Sci. 10, 984815 (2022).

Ma, X., Zhao, X., Zhang, L., Zhou, Y. & Chen, H. Spatial-temporal characteristics and influencing factors of atmospheric environmental efficiency in China. Environ. Sci. Pollut. Res. 28, 12428–12440 (2021).

Zheng, Z., Ma, Z., Li, M. & Xia, J. Regional water budgets and hydroclimatic trend variations in Xinjiang from 1951 to 2000. Clim. Change 144, 447–460 (2017).

Bi, G. B., Song, W. & Wu, J. A clustering method for evaluating the environmental performance based on slacks-based measure. Comput. Ind. Eng. 72, 169–177 (2014).

Zhang, H., Su, X. & Ge, S. A slacks-based measure of efficiency of electric arc furnace activity with undesirable outputs. J. Serv. Sci. Manag. 04 (2011).

Liu, W. B., Wongchai, A. & Peng, K. C. Adopting super-efficiency and tobit model on analyzing the efficiency of teacher’s colleges in Thailand. Int. J. New Trends Educ. Implication (2012).

Austin, P. C., Escobar, M. & Kopec, J. A. The use of the Tobit model for analyzing measures of health status. Qual. Life Res. 9, 901–910 (2000).

Debnath, A. K., Blackman, R. & Haworth, N. A Tobit model for analyzing speed limit compliance in work zones. Saf. Sci. 70, 367–377 (2014).

Li, J., Huang, Z., Zhou, L., Dai, Y. & Yang, Y. A Comparative study of the driving factors of water resources use efficiency in China’s agricultural and industrial sectors. Water 16, 387 (2024).

Zhao, J., Wang, Y., Zhang, X. & Liu, Q. Industrial and agricultural water use efficiency and influencing factors in the process of urbanization in the middle and lower reaches of the Yellow River Basin, China. Land 11, 1248 (2022).

Zhou, X., Xue, Z. & Seydehmet, J. An empirical study on industrial eco-efficiency in arid resource exploitation region of northwest China. Environ. Sci. Pollut. Res. 28, 53394–53411 (2021).

Zheng, Z., Ma, Z., Li, M. & Xia, J. Regional water budgets and hydroclimatic trend variations in Xinjiang from 1951 to 2000. Clim. Change 144, 447–460. https://doi.org/10.1007/s10584-016-1842-7 (2017).

Li, A., Liu, Y., Chen, G. & Hu, M. Scenario analysis of low-carbon development of energy industry with restriction of water resource in Xinjiang. J. Water Clim. Change 10, 263–275. https://doi.org/10.2166/wcc.2018.178 (2019).

Sun, Y. et al. Analysis of spatiotemporal evolution patterns and driving forces of reservoirs on the northern slope of the Tianshan Mountains in Xinjiang. Sustainability https://doi.org/10.3390/su15118824 (2023).

Ding, X., Fu, Z. & Jia, H. Study on urbanization level, urban primacy and industrial water utilization efficiency in the Yangtze River economic belt. Sustainability https://doi.org/10.3390/su11236571 (2019).

Shang, Y. et al. Decomposition methods for analyzing changes of industrial water use. J. Hydrol. 543, 808–817. https://doi.org/10.1016/j.jhydrol.2016.10.053 (2016).

Shang, Y. et al. Decomposition of industrial water use from 2003 to 2012 in Tianjin, China. Technol. Forecast. Soc. Change 116, 53–61. https://doi.org/10.1016/j.techfore.2016.11.010 (2017).

Liu, X. Y. & Peng, D. Y. Green efficiency of industrial water resource in China and its influencing factors: Empirical evidence from China’s 30 provinces. Appl. Ecol. Environ. Res. 18, 3057–3072. https://doi.org/10.15666/aeer/1802_30573072 (2020).

Wang, M., Huang, Y. & Li, D. Assessing the performance of industrial water resource utilization systems in China based on a two-stage DEA approach with game cross efficiency. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2021.127722 (2021).

Liu, K.-D., Yang, G.-L. & Yang, D.-G. Investigating industrial water-use efficiency in mainland China: An improved SBM-DEA model. J. Environ. Manag. https://doi.org/10.1016/j.jenvman.2020.110859 (2020).

Chen, Y., Zhu, B., Sun, X. & Xu, G. Industrial environmental efficiency and its influencing factors in China: Analysis based on the Super-SBM model and spatial panel data. Environ. Sci. Pollut. Res. 27, 44267–44278. https://doi.org/10.1007/s11356-020-10235-y (2020).

Xu, S., Wu, T. & Zhang, Y. The spatial-temporal variation and convergence of green innovation efficiency in the Yangtze River Economic Belt in China. Environ. Sci. Pollut. Res. 27, 26868–26881. https://doi.org/10.1007/s11356-020-08865-3 (2020).

Wu, W.-P. et al. Green efficiency of water resources in Northwest China: Spatial-temporal heterogeneity and convergence trends. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2021.128651 (2021).

Li, D., Li, Y., Tian, G. & Mendako, R. K. The impact of environmental regulation on the green overall factor productivity of forestry in the Yangtze River economic belt. Forests https://doi.org/10.3390/f14102004 (2023).

Hong, M., Tian, M. & Wang, J. The impact of digital economy on green development of agriculture and its spatial spillover effect. China Agric Econ Rev 15, 708–726. https://doi.org/10.1108/caer-01-2023-0004 (2023).

Sun, F., Guo, J., Huang, X., Shang, Z. & Jin, B. Spatio-temporal characteristics and coupling coordination relationship between industrial green water efficiency and science and technology innovation: A case study in China. Ecol. Indic. https://doi.org/10.1016/j.ecolind.2024.111651 (2024).

Guo, Y., Sayed, T. & Essa, M. Real-time conflict-based Bayesian Tobit models for safety evaluation of signalized intersections. Acc. Anal. Prev. https://doi.org/10.1016/j.aap.2020.105660 (2020).

Noor, N. M., Al Bakri Abdullah, M. M., Yahaya, A. S. & Ramli, N. A. in Materials Science Forum. 278–281 (Trans Tech Publ).

Kahya, E. A new unidimensional search method for optimization: Linear interpolation method. Appl. Math. Comput. 171, 912–926. https://doi.org/10.1016/j.amc.2005.01.098 (2005).

Bao, C. & He, D. Scenario modeling of urbanization development and water scarcity based on system dynamics: A case study of beijing–Tianjin–Hebei urban agglomeration, China. Int. J. Environ. Res. Public Health 16, 3834 (2019).

Shang YiZi, S. Y. et al. Drivers of industrial water use during 2003–2012 in Tianjin, China: A structural decomposition analysis (2016).

Bao, C. & Fang, C.-L. Water resources flows related to urbanization in China: Challenges and perspectives for water management and urban development. Water Resour. Manage 26, 531–552. https://doi.org/10.1007/s11269-011-9930-y (2012).

Zhou, Z., Wu, H. & Song, P. Measuring the resource and environmental efficiency of industrial water consumption in China: A non-radial directional distance function. J. Clean. Prod. https://doi.org/10.1016/j.jclepro.2019.118169 (2019).

Zou, D. & Cong, H. Evaluation and influencing factors of China’s industrial water resource utilization efficiency from the perspective of spatial effect. Alex. Eng. J. 60, 173–182. https://doi.org/10.1016/j.aej.2020.06.053 (2021).

Shi, Q., Chen, S., Shi, C., Wang, Z. & Deng, X. The impact of industrial transformation on water use efficiency in Northwest Region of China. Sustainability 7, 56–74. https://doi.org/10.3390/su7010056 (2015).

Hasanbeigi, A. & Price, L. A technical review of emerging technologies for energy and water efficiency and pollution reduction in the textile industry. J. Clean. Prod. 95, 30–44. https://doi.org/10.1016/j.jclepro.2015.02.079 (2015).

Li, H. & Shi, J.-F. Energy efficiency analysis on Chinese industrial sectors: An improved Super-SBM model with undesirable outputs. J. Clean. Prod. 65, 97–107 (2014).

Byers, W., Lindgren, G., Noling, C. & Peters, D. Water Use in Industries of the Future. (Industrial Water Management: A Systems Approach, Second Edition, 2010).

Bauer, D. et al. Water-energy nexus: Challenges and opportunities. (2014).

Yasmeen, R., Hao, G., Ye, Y., Shah, W. U. H. & Tang, C. The synergy of water resource agglomeration and innovative conservation technologies on provincial and regional water usage efficiency in China: A super SBM-DEA approach. Water 15, 3524 (2023).

Sun, D. et al. Integrated analysis of the water–energy–environmental pollutant nexus in the petrochemical industry. Environ. Sci. Technol. 54, 14830–14842 (2020).

Shang, Y., Lu, S., Li, X., Sun, G., Shang, L., Shi, H., Lei, X., Ye, Y., Sang, X. and Wang, H. Drivers of industrial water use during 2003–2012 in Tianjin, China: A structural decomposition analysis. J. Clean. Prod. 140, 1136–1147, https://doi.org/10.1016/j.jclepro.2016.10.051 (2017).

Yang, Y. Evaluation of China’s water-resource utilization efficiency based on a DEA-Tobit two-stage model. Water Supply 21, 1764–1777. https://doi.org/10.2166/ws.2020.349 (2021).

Ding, N., Liu, J., Yang, J. & Lu, B. Water footprints of energy sources in China: Exploring options to improve water efficiency. J. Clean. Prod. 174, 1021–1031. https://doi.org/10.1016/j.jclepro.2017.10.273 (2018).

Hubacek, K., Guan, D., Barrett, J. & Wiedmann, T. Environmental implications of urbanization and lifestyle change in China: Ecological and Water Footprints. J. Clean. Prod. 17, 1241–1248. https://doi.org/10.1016/j.jclepro.2009.03.011 (2009).

Bai, M., Zhou, S., Zhao, M. & Yu, J. Water use efficiency improvement against a backdrop of expanding city agglomeration in developing countries A case study on industrial and agricultural water use in the Bohai Bay Region of China. Water 9, https://doi.org/10.3390/w9020089 (2017).

Liu, Y., Lu, F., Xian, C. & Ouyang, Z. Urban development and resource endowments shape natural resource utilization efficiency in Chinese cities. J. Environ. Sci. 126, 806–816. https://doi.org/10.1016/j.jes.2022.03.025 (2023).

Wu, F., Zhan, J., Zhang, Q., Sun, Z. & Wang, Z. Evaluating impacts of industrial transformation on water consumption in the Heihe River basin of northwest China. Sustainability 6, 8283–8296 (2014).

Shang, Y. et al. Drivers of industrial water use during 2003–2012 in Tianjin, China: A structural decomposition analysis. J. Clean. Prod. 140, 1136–1147. https://doi.org/10.1016/j.jclepro.2016.10.051 (2017).

Liu, B., Li, Y., Hou, R. & Wang, H. Does urbanization improve industrial water consumption efficiency?. Sustainability https://doi.org/10.3390/su11061787 (2019).

Hong, M., Tian, M. & Wang, J. (CAER-01-2023-0004, 2023).

Guo, Y., Hu, Y., Shi, K. & Bilan, Y. Valuation of water resource green efficiency based on SBM–TOBIT panel model: Case study from Henan province, China. Sustainability 12, 6944 (2020).

Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 130, 498–509 (2001).

Tran, K. C. & Tsionas, E. G. Endogeneity in stochastic frontier models: Copula approach without external instruments. Econ. Lett. 133, 85–88 (2015).

Acknowledgements

Not applicable.

Funding

This work was supported by the Third Xinjiang Scientific Expedition Program [grant number 2021xjkk0804); XPCC Finance Science and Technology Project [grant number S2023BC4834]; and the Corps Science and Technology Bureau (E4M40990A).

Author information

Authors and Affiliations

Contributions

Haixia Duo: Conceptualization; Data curation; Formal analysis; Methodology; Roles/Writing—original draft; Writing—review & editing Ning Wang: Conceptualization; Data curation; Formal analysis; Methodology; Roles/Writing—original draft; Writing—review & editing Yunfeng Qiao: Conceptualization; Data curation; Writing—review & editing Zhao Li: Formal analysis; Methodology; Writing—review & editing Guang Yang: Conceptualization; Data curation; Methodology; Writing—review & editing Hongguang Liu: Formal analysis; Methodology; Writing—review & editing Gang Chen: Conceptualization; Data curation; Methodology; Writing—review & editing Fadong Li: Conceptualization; Data curation; Writing—review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Duo, H., Wang, N., Qiao, Y. et al. Industrial water consumption efficiency and driving factors based on the super-efficient SBM and Tobit approach. Sci Rep 15, 12461 (2025). https://doi.org/10.1038/s41598-025-96650-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-96650-y