Abstract

Fault-tolerant control (FTC) is crucial for enhancing the safety, reliability, and tracking performance of steer-by-wire (SBW) systems. This paper focuses on actuator effectiveness reduction faults and establishes an analytical model of the SBW system that incorporates motor disturbances, steering feedback, and self-aligning torque characteristics. To solve the inadequate tracking accuracy resulting from actuator fault and system disturbances, an adaptive sliding mode fault-tolerant control strategy based on a variable-speed reaching law (VSRL-ASMFTC) is proposed. By integrating an adjustment function into the constant-velocity reaching polynomial and designing an adaptive law, dynamic updating of the control law is achieved. Furthermore, the closed-loop stability of the system is proven based on Lyapunov’s stability criterion. The example information demonstrates that the proposed method reduces the root mean square (RMS) of tracking error by nearly 40% in three typical conditions compared to adaptive fault-tolerant control methods (ASMFTC), and the disturbances of the controller are relatively slighter. This indicates that the VSRL-ASMFTC mitigates system chattering, optimizes the system’s anti-disturbance capability and robust stability, and improves fault tolerance efficiency in the presence of actuator failures. It maintains good tracking performance of the system, which provides a basis for the design of high-performance fault-tolerant control strategies.

Similar content being viewed by others

Introduction

In recent years, with the rapid development of electronic technology, the application potential of the SBW system in the fields of new energy vehicles and intelligent driving significantly increasing, thanks to its advantages such as high flexibility, low energy consumption, and ease of integration. The SBW system eliminates traditional mechanical connections and controls the steering actuator through electronic signals, achieving decoupling between driver input and front-wheel steering motion1. This design not only improves the response speed of the steering system but also facilitates the implementation of higher-level intelligent driving functions. However, as the SBW system relies on electronic signals and electronic control units (ECU), it raises stringent requirements for functional safety and reliability2. In practical applications, due to the large number of electronic components in the SBW system, it may encounter various faults, such as sensor faults, actuator faults, and ECU faults. These faults may not only lead to steering system failure but also pose severe threats to driving safety, resulting in significant economic losses and casualties. Therefore, considering redundancy design based on the original steering hardware architecture and incorporating fault-tolerant strategies beyond the steering function algorithms are crucial for enhancing the functional safety and reliability of the steering system.

Fault-tolerant technology mostly adopts redundancy in the form of hardware redundancy and software redundancy. Hardware redundancy involves doubling or even tripling some key electronic components, such as sensors and actuators, based on the basic structure of the SBW system. For example, the Infiniti Q50 employs a steering shaft backup equipped with a clutch mechanism, Xu, Paredes et al. adopts a dual-motor redundancy structure3,4,5, enabling steering functionality in the event of a failure in the SBW system. The disadvantage of achieving fault tolerance solely through hardware redundancy is its complex structure and high cost. Therefore, it is necessary to reduce the total number of redundant components without sacrificing fault-tolerant performance.

Software redundancy primarily enhances redundancy by designing controller software, thereby improving the fault-tolerant performance of the system. There are extensive research has been conducted to explore this critical issue6,7,8,9,10. Zhou studies finite-time adaptive fuzzy FTC for SBW systems with intermittent actuator faults, ensuring closed-loop signal boundedness and tracking error convergence within prescribed performance bounds11. Chen presents a novel complete model-free integral reinforcement learning fault tolerant control scheme to solve the tracking problem of SBW system12. Zhao proposes a high-precision rack force estimation algorithm to enhance the robustness of the SBW system in the event of sensor failures13. Liu maintains tracking performance in the SBW system under actuator faults by adopting Performance-Preserving Robust Control and Adaptive Fault-Tolerant Control14. Mortazavizadeh introduces a novel Fault Detection, Isolation, and Reconfiguration control technique to improve the fault-tolerant characteristics of the SBW system in the presence of sensor failures15. Wu presents a tube-based model predictive control (MPC) framework to guarantee vehicle stability in steering processes and maintain the tracking performance16. Huang achieves better steering performance in the event of actuator faults by utilizing two-stage Kalman filtering and MPC17. Although the above researches have yielded promising results, the high complexity and unpredictability of automotive driving conditions, as well as noise interference and uncertainties in the external environment, inevitably limit the precision of fault-tolerant mechanisms. Therefore, it is particularly crucial to enhance the robustness and anti-interference capabilities of fault-tolerant control strategies.

Among various nonlinear robust control methods, Sliding Mode Control (SMC) has demonstrated outstanding performance advantages in solving complex fault-tolerant issues in systems due to its exceptional disturbance rejection capabilities18,19. He reconstructs faults and disturbances through a sliding mode observer and utilizes the observed and reconstructed values to adjust the SMC law online, thereby enhancing the ability to resist disturbances and improving the accuracy of fault-tolerant control20. Zhang employs cooperative game theory, terminal SMC, and feedback linearization method to achieve system stability under actuator fault disturbances21. Jung adopts a passive decomposition and SMC approach to realize steering angle tracking control in the presence of motor torque faults22. Huang utilizes a sliding mode predictive fault-tolerant strategy and a chaotic particle swarm optimization algorithm to improve the disturbance rejection capabilities and robustness in the case of actuator faults23. PAN introduces a nonsingular SMC scheme with fixed-time stability characteristics to address issues such as slow steering angle tracking response, insufficient fault-tolerant performance, and system parameter perturbations in SBW systems24.

Although SMC can significantly reduce the sensitivity of the system to external disturbances and parameter variations, resulting in good transient dynamics, due to the switching characteristics of SMC, the state trajectory cannot move strictly along the sliding surface towards the equilibrium point. Therefore, chattering phenomena often occur in practical applications of SMC. The selection of the Sliding Mode Reaching Law (SMRL) can alter the dynamic characteristics of SMC, mitigate the chattering problem caused by its switching characteristics, and enhance the control accuracy and stability of the system. Therefore, considerable research efforts have been devoted to the design of SMRL by relevant researchers. SUN designs a combined SMRL based on terminal reaching exponent and proportional reaching, which effectively suppresses chattering and shortens the reaching time25. Tian employs fuzzy control to adjust the parameters of SMRL in real-time, resulting in effective attenuation of system chattering and improved tracking performance26. Deng uses a neural network to adjust the SMRL based on the real-time state of the vehicle, thereby reducing system chattering27. HUANG applies a novel SMRL to improve the performance of discrete SBW systems with disturbances28. Zhang adopts an adaptive variable exponent reaching law to mitigate system chattering and improve robustness29. Although the above studies have achieved significant results in suppressing system chattering, the theoretical derivation and practical application are not carried out in the SBW system with fault. Whether these methods can improve tracking performance in the presence of disturbances and actuator failures remains an area of ongoing research.

The key contributions of this work are outlined as follows:

-

a)

Establishes a model of the SBW system that incorporates actuator partial failure, motor torque disturbances, steering feedback, and self-aligning torque characteristics.

-

b)

Propose a novel VSRL-ASMFTC strategy. Based on the analysis of the design principles of sliding mode control laws, the traditional constant-speed reaching term is improved by incorporating an adjustment function. By controlling the approaching speed based on the distance to the sliding surface, a variable-speed approaching is achieved, which reduces system chattering without sacrificing accuracy. By designing adaptive laws, adaptive adjustment of control parameters is achieved, ensuring that the SBW steering system maintains high tracking performance and robustness when actuators fail.

-

c)

Illustrate examples under three typical steering conditions (step steering, sinusoidal steering, and double lane-change steering) demonstrate that the control strategy can provide technical support for enhancing the handling stability, driving safety, and path tracking accuracy of SBW vehicles, and holds significant importance for promoting the development of new energy vehicles and intelligent driving technologies.

The rest of this paper is organized as follows. Section 2 covers the dynamic modeling of SBW systems, Sect. 3 focuses on the design of fault-tolerant controllers, Sect. 4 presents example illustration, and Sect. 5 concludes the discussion.

Problem formulation

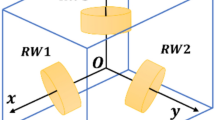

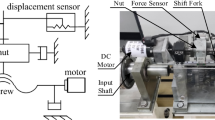

The SBW system consists of two parts as shown in Fig. 1: (1) The road feel feedback assembly mainly includes the hand wheel, the hand where sensor and the hand wheel motor. Its function is to drive the hand wheel motor to achieve the feedback torque instructions given by the controller, thereby providing the driver with an appropriate steering feel. (2) The steering actuation assembly mainly compose of the steering motor, the pinion angle sensor, the steering wheels and the steering shaft. Its function is to drive the steering motor to quickly and accurately execute the instructions given by the controller, thereby realizing the driver’s steering intention. The SBW system eliminates the traditional mechanical connection, achieving decoupling between the driver’s operation and the steering movement of the front wheels.

The steering actuation motor is a three-phase surface-mounted permanent magnet synchronous motor. The equation of steering motor model is as follows:

where Jm is the moment of inertia of the steering motor, θm is the steering motor angle, Bm is the viscous friction of the steering motor, \({\tau _{mf}}\) is the torque exerted on the motor shaft by the two steered wheels through the rack and pinion gearbox, \({\tau _{md}}\) is the motor torque pulsation disturbances, \(\tau _{m}^{ * }\) is the torque control input for the steering motor. The equation of the front wheel is as follow:

where δf is the steering angle of the front wheel center, \({J_{f}}\) is the moment of inertia of the front wheel, \({B_{f}}\) is the viscous friction of the front wheel, \({\tau _{fs}}\)is the resistance moment of the front wheel rotation, \(sign({\dot {\delta }_f})\) is the sign function, \({\tau _e}\)is the self-aligning torque, \({\tau _{fm}}\)is the torque applied on the steering arm by the steering motor through the rack and pinion gearbox.

Assuming that the transmission ratio between the steering front wheel and the steering motor is 1/r, the following relationship can be obtained:

Differentiating (3) twice, we obtain the following relationships:

Based on Eqs. (1)-(4), the equivalent model of the steering actuation assembly for the SBW system is obtained as:

where \({J_{eq}}\) is the equivalent moment of inertia, \({B_{eq}}\) is the equivalent viscous friction, \({\tau _{eq}}\) is the equivalent drive torque.

Furthermore, the formula for the self-aligning torque30 is:

where l is the tire trail, \({F_y}\)is the lateral force. When the front wheel side slip angle is less than 4°, there is a linear relationship between the side slip angle and the lateral force:

where \({k_1}\) is the front wheel cornering stiffness, the front wheel side slip angle can be expressed as:

where \(\beta\)is the sideslip angle, \({\omega _r}\) is the yaw rate, a is the distance from the center of the front wheel to the center of the vehicle gravity, \({V_{CG}}\) is the longitudinal velocity of the vehicle. According to the yaw motion of the vehicle, \({\omega _r}\) and \(\beta\) can be described by the following equation:

where b is the distance from the center of the rear wheel to the center of the vehicle gravity, is the rear wheel cornering stiffness, m is the mass of the vehicle, \({I_z}\) is the moment of inertia of the vehicle. Then use(10)-(11) in (9), there is:

The equation of the road feel feedback assembly for the SBW system is as follows:

where \({J_h}\) is the moment of inertia of the hand wheel, \({\theta _h}\) is the hand wheel angle, \({B_h}\) is the viscous friction of hand wheel, \({C_h}\) is the stiffness of the hand wheel, \({\tau _h}\) is the torque input by the driver, \({\tau _r}\) is the feedback torque of the hand wheel motor. Assuming the transmission ratio between the hand wheel angle and the front wheel angle is N, the reference angle of the front wheel is as follows:

The equations for a three-phase surface-mounted permanent magnet synchronous motor in the synchronous rotating d-q axis31 are as follows:

where \({u_d}\)、\({u_q}\) are the d − q-axis stator voltages, respectively, \({i_d}\)、\({i_q}\)are the d − q-axis stator currents, respectively, \({R_s}\) is the stator resistance, \({\omega _e}\) is the rotor electrical speed, \({L_d}\)、\({L_q}\) are the d − q-axis stator synchronous inductances, respectively, for a three-phase surface-mounted permanent magnet synchronous motor \({L_d}={L_q}\), \({\psi _f}\) is the flux linkage due to the permanent magnet. The corresponding electromagnetic torque equation is as follows:

where \({p_n}\) is the number of poles.

Considering the 6th and 12th harmonic term, the flux linkage can be described as follows:

where \({\psi _{f0}}\)is the known constant average direct current (DC) amplitude, \({\psi _{f6}}, {\psi _{f12}}\) are the 6th and 12th harmonic amplitudes of the flux linkage, respectively, \({\theta _e}\) is the electrical angle of the rotor.

Due to the analog-to-digital converter offset of the motion controller and the current offset error of the current tracking amplifier, a DC current offset always exists at the motor terminals. This can lead to disturbances in the output torque of the motor, which will affect the accuracy and tracking performance of the system. The actual current can be expressed as follows:

where \({i_{dis}}\) is the current disturbance32 and can be expressed as follows:

where \({{\varvec{\Delta}}}{i_a}, {{\varvec{\Delta}}}{i_b}\) is the DC current offsets of phases a and b, use(20)-(21) in (19), there is:

Therefore, the motor disturbance can be expressed as:

The main parameters of the SBW system model are shown in Table 1.

According to the self-aligning, the steering feedback and the motor disturbance described in Eqs. (12)-(14)、(15)、(22)-(24), respectively, the SBW system in formulas (5)-(8) can be fully expressed.

Fault tolerant controller design

In practical systems, due to the complex and demanding operations of actuators, their components are highly susceptible to failures, leading to the loss of steering and tracking performance. A fault in the torque section of a steering motor is a common type of actuator failure, the main manifestation is that the motor still retains partial working capability, but its output torque cannot reach the expected level. This fault is primarily caused by changes in the internal parameters of the motor. Adaptive compensation control for actuator faults involves designing an adaptive compensation control law that adjusts and reconfigures itself in response to system faults. This allows for the reallocation of actuator resources to achieve the control objective of tracking a reference model. The SMC exhibits strong robustness, and by selecting an appropriate reaching law, the dynamic characteristics of SMC can be altered to achieve dynamic adjustment of the reaching speed.

Based on the above SBW system, an adaptive sliding mode fault-tolerant control strategy with a variable speed reaching law (VSRL-ASMFTC) is designed for the fault of partial torque failure in the steering motor. The fault model is described as follows:

where u is the actual input torque, \({u_c}\)is the ideal input torque, \(\sigma\) is the failure degree of motor torque, since there is only one steering motor, so \(0<\sigma <1\)。

According to Eq. (5)-(8), there is:

The sliding mode function is:

Where c is the sliding mode surface parameter and is greater than zero, e is the error between the reference angle and the front wheel angle. It is obtained by combining formula (26):

A common exponential reaching law includes both an exponential reaching term and a constant-speed reaching term:

where \(\eta , k\) are adjustment parameters, the larger the value of \(\eta\), the more chattering there will be. SMRL can alter the dynamic characteristics of SMC and reduce system chattering by incorporating an adjustment function within the constant-speed reaching term:

From the above equation, it can be seen that when the system state is far from the sliding surface, i.e., when s > 1, y(s) = 1. And when the system state is close to the sliding surface, i.e., s < 1, y(s) < 1. Furthermore, as s approaches 0, y(s) gradually decreases thereby reducing the high-frequency oscillations of the system state near the sliding surface and effectively suppressing chattering. The resulting variable speed reaching law is as follows:

where \(sat(s)\) is saturation function. From the above equation, it can be deduced that when s > 1, the reaching switching speed remains constant. When s < 1, the reaching switching speed decreases, and resulting in less chattering.

Taking:

Design a Lyapunov function as:

where \(\tilde {p}=\hat {p} - p,\gamma\) is the control parameter, thus there is:

Taking:

So:

Design the control law and adaptive law as follows:

where \(signb=signQ\), thus there is:

According to the Lyapunov stability criterion, the system is stable.

Based on the error between the reference angle and the front wheel angle, PD control is adopted to regulate the torque of the hand wheel motor, providing the driver with road feel. The control parameters are kp and kd. The main parameters of the control strategy used in this paper are shown in Table 2.

Illustration examples

To validate the performance of the control strategy proposed in this paper, a simulation is carried out in Simulink. Assuming the failure degree of the steering motor torque is \(\sigma =0.2(t\geq7s)\), and the torque input by the driver is a step steering, i.e., \(\tau_h = 1.6N \cdot m(t\geq0.1s)\). The steering performance of VSRL-ASMFTC is shown in Fig. 2.

As illustrated in Fig. 2, the front wheel steering angle can accurately track the reference steering angle. When a fault occurs in the motor, effective compensation for torque failure can be achieved within a relatively short period of time, with insignificant chattering and good stability. To demonstrate the superiority of the proposed control strategy, a comparison is made with sliding mode fault-tolerant control (SMFTC), adaptive sliding mode fault-tolerant control (ASMFTC), and PD fault-tolerant control (PDFTC).

The control law for the SMFTC is designed based on the sliding mode function in Eq. (28) and the reaching law in Eq. (29) as follows:

The control law for the ASMFTC is designed based on the sliding mode function in Eq. (28)) as follows:

The control law for the PDFTC is designed as follows:

The main parameters of the control strategies are listed in Table 2. With the same fault and driver input torque conditions as mentioned earlier, the performance of each control strategy is illustrated in Fig. 3. As can be seen from Fig. 3, when the steering motor is operating normally, both the SMFTC and the PD FTC strategy can achieve good steering performance. However, when the motor experiences partial failure, a significant steady-state error persists in the front wheel steering angle. The above two strategies are unable to effectively compensate for the fault, and the SMFTC strategy exhibits relatively large chattering. The ASMFTC strategy can effectively compensate for faults within a relatively short period of time. However, as shown in Fig. 3(a), during the occurrence of a fault, the tracking error of the ASMFTC is significantly larger than that of the VSRL-ASMFTC. Furthermore, Fig. 3(b) clearly demonstrates that the VSRL-ASMFTC can more rapidly compensate for faults, significantly reducing the recovery time of the system in response to faults and accelerating convergence to a stable state. Additionally, VSRL-ASMFTC exhibits weaker chattering phenomena during the control process compared to the ASMFTC, enhancing the overall stability of the control.

To further visually compare the performance of various control strategies, the root mean square (RMS) values of the tracking error and the first derivative of the control torque are calculated as performance evaluation indicators. The first-order derivative of the control torque represents the rate of change of the torque over time and provides a quantitative measure of chattering. The results are presented in Table 3.

It can be seen form Table 3 that the VSRL-ASMFTC demonstrates the smallest RMS values for both tracking error and first derivative of the control torque, highlighting its superior tracking accuracy and stability. To further show the superiority of the control strategy proposed in this paper, examples are provided based on sinusoidal steering and double lane-change steering conditions. Due to the significant errors of SMFT and PDFTC that fail to meet tracking requirements, along with the excessive chattering of SMFTC, the following analysis focuses solely on comparing the performance of ASRL-ASMFTC and ASMFTC. The results for the sinusoidal steering condition and double lane-change steering condition are illustrated in Figs. 4 and 5, respectively. The calculated results of the performance evaluation indexes are presented in Table 4.

Based on the results presented in Figs. 4–5; Table 4, it is evident that, in comparison to ASMFTC, the VSRL-ASMFTC strategy exhibits significantly reduced tracking errors, shorter fault tolerance response times, faster recovery to stability after system faults, and effective mitigation of chattering phenomena during the control process. In conclusion, the VSRL-ASMFTC demonstrates marked improvements in tracking accuracy, fault tolerance speed, and the ability to maintain system stability.

Conclusion and future work

This paper focuses on the impact of actuator partial failures and disturbances in SBW systems on steering angle tracking performance, and proposes the VSRL-ASMFTC strategy. To characterize the uncertainties and partial functional failures in the actuator, an analytical model of the SBW system is established, incorporating motor disturbances, steering feedback, and self-aligning torque characteristics. By incorporating an adjustment function, dynamic regulation of the approaching and switching speeds is achieved. Furthermore, adaptive tuning of control parameters is realized through the design of adaptive laws, which not only mitigates system chattering but also enhances tracking accuracy. Illustration examples based on step steering, sinusoidal steering, and double lane-change steering conditions demonstrate that the control strategy proposed in this paper exhibits good robustness and accuracy. However, this paper idealizes motor partial failure as a constant proportional failure, which deviates from actual failure modes. In the future, we will further refine the motor failure model and adopt a more realistic approach to simulate motor failures, thereby enhancing the precision and adaptability of fault-tolerant control.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Change history

27 May 2025

The original online version of this Article was revised: In the original version of this Article, the Funding section was incomplete. The correct Funding section now reads: “This study was funded by Less Developed Regions of the National Natural Science Foundation of China [grant number 52067006 and 52462053], Young Scientists Fund of the National Natural Science Foundation of China [grant number 52302470], Ganpo Talent Support Program-Leading Academic and Technical Personnel in Major Disciplines of Jiangxi Province [grant number 20232BCJ23091], Natural Science Foundation of Jiangxi Province [grant number 20232BAB214092 and 20224BAB214045], Jiangxi Province Government Special Fund for Graduate Innovation [grant number YC2023-B207].”

References

Yin, H. et al. Steer-by-wire control algorithm using a dual-layer closed-loop model. Sci. Rep. 14, 28536 (2024).

Chao Huang, L. & Li Architectural Design and Analysis of a steer-by-wire System in View of Functional Safety concept[J]198106822 (Reliability Engineering & System Safety, 2020).

Xu, K. et al. Event-triggered adaptive fuzzy switching fault-tolerant control of dual-motor steer-by-wire system considering load fluctuation and limited communication bandwidth[J]. IEEE Trans. Fuzzy Syst. 32 (7), 4086–4098 (2024).

Paredes, J., Ademi, S. & McMahon, R. Performance of a dual Three-Phase permanent magnet machine for a Steer-By-Wire system under healthy and faulty Conditions[J]. IEEE Trans. Energy Convers. 39 (3), 1459–1467 (2024).

Shi, G., Qiao, P., Sang, D., Wang, S. & Song, M. Synchronous and fault-tolerance control for dual-motor steer-by-wire system of commercial vehicle[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering. ;238(7):1964–1980. (2024).

Sentouh, C. et al. Adaptive Observer-Based Output Feedback FTC for Nonlinear Interconnected Vehicle Dynamics with Unknown Actuator Faults[J] (IEEE Transactions on Intelligent Vehicles, 2024).

Zou, S. et al. Fault diagnosis and fault-tolerant compensation strategy for wheel angle sensor of steer-by-wire vehicle via extended Kalman filter[J]. IEEE Sens. J. 22 (2), 1756–1766 (2021).

Lan, D. et al. Fault diagnosis and prognosis of steer-by-wire system based on finite state machine and extreme learning machine[J]. Neural Comput. Appl. 34 (7), 5081–5095 (2022).

Zhang, B. et al. Neural Network Nash Game-Based Driver Assistance Fault-Tolerant Control for Steer-by-Wire Systems[J] (IEEE Transactions on Transportation Electrification, 2024).

Mahanathra, S. Prediction of Failures to Enhance Fail-Safe in Steer-by-Wire System[C]//2024 3rd Odisha International Conference on Electrical Power Engineering, Communication and Computing Technology (ODICON). IEEE, : 1–6. (2024).

Zhou, S., Li, Y. & Tong, S. Prescribed performance adaptive fuzzy output feedback control for steer-by-wire vehicle system with intermittent actuator faults[J]. Neural Comput. Appl. 36, 16057–16070 (2024).

Chen, H. et al. Fault-tolerant tracking control based on reinforcement learning with application to a steer-by-wire system[J]. J. Franklin Inst. 359 (3), 1152–1171 (2022).

Zhao, L., Zhao, X. & Li, H. Rack force fault tolerance Estimation of steer-by-wire system under different resolver faults based on sensor flows[J]. Control Eng. Pract. 147, 105941 (2024).

Liu, W. & Jiang, Z. Adaptive fault-tolerant control based on linear matrix inequalities for actuator failures in steer-by-wire system[J]. Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, : 09544070231200675. (2023).

Mortazavizadeh, S. A. et al. Fault-tolerant control of steer-by-wire systems under voltage and current sensors faults[J]. Electr. Eng. 103, 407–415 (2021).

Wu, X. et al. Fault-tolerant control for path-following of independently actuated autonomous vehicles using tube-based model predictive control[J]. IEEE Trans. Intell. Transp. Syst. 23 (11), 20282–20297 (2022).

Huang, C. et al. Actuator fault tolerant control for steer-by-wire systems[J]. Int. J. Control. 94 (11), 3123–3134 (2021).

Dao, P. N. & Duc, H. A. N. Nonlinear RISE based integral reinforcement learning algorithms for perturbed bilateral teleoperators with variable time delay[J]. Neurocomputing 605, 128355 (2024).

Shao, K. et al. Barrier function based adaptive sliding mode control for uncertain systems with input saturation[J]. IEEE/ASME Trans. Mechatron. 27 (6), 4258–4268 (2022).

He, J. et al. Fault-tolerant control of a nonlinear system actuator fault based on sliding mode control[J]. J. Control Sci. Eng. 2017 (1), 8595960 (2017).

Zhang, B. et al. Robust fault-tolerant control for four-wheel individually actuated electric vehicle considering driver steering characteristics[J]. J. Franklin Inst. 358 (11), 5883–5908 (2021).

Jung, D. Y. & Kim, S. Hardware-In-the-Loop simulation of synchronous motion control for Dual-Motor driving Steer-By-Wire system integrated with optimal finite preview Path-Tracking control[J]. IEEE Trans. Veh. Technol. 73 (3), 3311–3328 (2023).

Huang, C., Naghdy, F. & Du, H. Fault tolerant sliding mode predictive control for uncertain steer-by-wire system[J]. IEEE Trans. Cybernetics. 49 (1), 261–272 (2017).

Gongyu, P. A. N. & Siqing, L. I. U. Fixed-time sliding mode control of the steer-by-wire system with fault tolerance [J]. J. Chongqing Univ. Technology(Natural Science). 37 (6), 48–57 (2023).

LEI, S. U. N. X. C. A. O. J. A composite sliding mode control for Spmsm drives based on a new hybrid reaching law with disturbance compensation[J]. IEEE Trans. Transp. Electrification. 7 (3), 1427–1436 (2021).

Tian Tian. Research on AFSM Control Strategy of Active Front Steeringof Electric Vehicle Based on Variable Steering Ratio [D] (Jiangsu University, 2021).

Deng Longze. Research on multi-objective Sliding Mode Control Forvehicle lane-changing Trajectory Tracking [D] (Hefei University of Technology, 2021).

Hua, H. U. A. N. G. et al. Sliding Mode Control with New Reaching Law for Vehicle Steer-by-Wire System [J]43773–782 (Transactions of Beijing Institute of Technology, 2023). 8.

Zhang, D. et al. Adaptive sliding mode fault-tolerant coordination control for four-wheel independently driven electric vehicles[J]. IEEE Trans. Industr. Electron. 65 (11), 9090–9100 (2018).

Yu Zhisheng, Xia Qunsheng, Zhao Liuqi, et al. Automobile theory[M]. China machine, (2023).

Lei, Y. et al. Control Principles of Modern Permanent Magnet Synchronous Motors and MATLAB Simulation [M] (Beijing university, 2016).

Wang, H. et al. Sliding mode control for steer-by-wire systems with AC motors in road vehicles[J]. IEEE Trans. Industr. Electron. 61 (3), 1596–1611 (2013).

Funding

This study was funded by Less Developed Regions of the National Natural Science Foundation of China [grant number 52067006 and 52462053], Young Scientists Fund of the National Natural Science Foundation of China [grant number 52302470], Ganpo Talent Support Program-Leading Academic and Technical Personnel in Major Disciplines of Jiangxi Province [grant number 20232BCJ23091], Natural Science Foundation of Jiangxi Province [grant number 20232BAB214092 and 20224BAB214045], Jiangxi Province Government Special Fund for Graduate Innovation [grant number YC2023-B207].

Author information

Authors and Affiliations

Contributions

Jinwen Yang wrote the main manuscript text, Yinquan Yu proposed original research idea and provide research funding, Dequan Zeng contributed to the conception and design of the work, Yiming Hu and Xiaofeng Zhu provided guidance on the simulation section, Junhui Liu provided guidance on the theoretical section, Kai Liu reviewed and revised the article, Giuseppe Carbone and Shaohua Luo reviewed paper and gave the comments. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Open access

This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons lcence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

The Author(s) 2024.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yang, J., Yu, Y., Zeng, D. et al. An adaptive sliding mode fault-tolerant control of variable speed reaching law for steer-by-wire systems. Sci Rep 15, 12846 (2025). https://doi.org/10.1038/s41598-025-96663-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-96663-7