Abstract

This is the first report for C–Se bond formation involving the reaction of aryl halides with arylboronic acid and selenium powder to synthesis of unsymmetrical diaryl selenides in the presence of CuI as a homogeneous catalyst. A wide range of aryl halides react with various substituted groups under optimal conditions to provide the desired unsymmetrical diaryl selenides with good to high yields. Also, the same reactions were investigated in the presence of M-MCF@Gua-Cu as a reusable magnetic nanocatalyst under optimal conditions. The M-MCF@Gua-Cu catalyst allows for simpler (easy work-up) and greener methodology. In addition, the advantages of the presented method include the use of arylboronic acid/Se as a safe and cost-effective arylselenating system, the simplicity of operation, and green and cheap solvent.

Similar content being viewed by others

Introduction

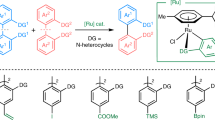

Selenium-containing compounds have received much attention due to their dual function in organic synthesis as catalysts and reaction mediators1,2. This interest extends beyond organic chemistry as these compounds show a diverse array of promising biological activities including cardiovascular disease prevention, anti-tumor and anti-viral properties, anti-oxidant effects, and anti-cancer potential3,4,5,6. Consequently, the development of efficient synthetic methods for organoselenium compounds is of great importance (Fig. 1)7,8.

Conventional synthetic methods for C–Se bond formation suffer from significant drawbacks, including harsh reaction conditions (such as high temperature and the use of toxic and polar solvents), and the need for expensive and toxic reagents9,10. Therefore, various methods have been proposed for the production of diarylselenides11,12. Transition-metal-catalyzed carbon-heteroatom bond formation is the most efficient method for the carbon-selenium bonds formation in diaryl selenides13. A number of transition-metal salts and catalysts, such as Ni14,15, Pd16,17, Fe18,19, and Cu20,21, have been reported for the carbon-selenium bond formation. Also, to avoid handling unstable and foul-smelling reagents such as selenol22,23,24,25, other types of selenium compounds are used (diaryl diselenide26,27, aryl selenoate28 and aryl selenocyanate29,30). In 2003, the cross-coupling reaction between aryl iodides and phenylselenol in the presence of CuI as a catalyst, toluene as a solvent, and K2CO3 as a base was carried out for the synthesis of diaryl selenides (Scheme 1a)22. In addition, a study reported the synthesis of unsymmetrical diaryl selenides via the CuO nanocrystal-catalyzed cross-coupling reaction of aryl halides with diaryl diselenides. This method used recyclable CuO nanocrystals as catalyst in DMSO as solvent with KOH as base (Scheme 1b)9. In recent years, aryl boronic acids and their derivatives have emerged as attractive building blocks for C–C and C–heteroatom bond formation due to their accessibility and stability12,31,32,33. A method for the synthesis of unsymmetrical diaryl selenides via cross-coupling reactions, involving the use of arylboronic acids and diaryl diselenides with indium or iron catalysts in DMSO solvent, has been reported by Wang et al. (Scheme 1b)34,35. Although these reagents have improved reaction conditions, they are usually prepared through laborious processes that are difficult to work with and are not suitable for sensitive functional groups36,37. This weakness limits the use of these methods for the synthesis of diaryl selenides. Another method used for the arylation of selenium in these reactions is the three-component reaction between two equivalents of an aryl halide and a selenium source. In this system, arylselenating nucleophiles are prepared from the reaction of the Se-source with an aryl halide, and following the subsequent reaction with the second aryl halide molecule, symmetrical diaryl selenides are produced38. Therefore, among selenium reagents, elemental selenium (or selenium powder) shows specific promise for Se-arylation due to its atom economy, low cost and stability39,40. Taniguchi described a copper-catalyzed route to symmetrical diaryl selenides using aluminum as a reductant. The reaction proceeds through the key intermediate PhSeCu, formed from the copper-catalyzed reaction of aryl iodides with selenium. Next, this intermediate proceeded via a homo-coupling reaction with aryl iodides to synthesize symmetrical diaryl selenides. (Scheme 1c)41.

Therefore, creating effective and simple techniques for producing unsymmetrical diaryl selenides has been considered42. To our understanding, the synthesis of unsymmetrical diarylselenides using aryl halides, arylboronic acid for aryl group transfer, and selenium powder as selenium donor has not been previously reported. In continuation of our studies on the synthesis of unsymmetrical diaryl selenides, herein, we report the three-component coupling of aryl halides, arylboronic acid derivatives, selenium powder and CuI as a homogeneous catalyst (Scheme 1d).

On the other hand, heterogeneous catalysts have attracted much attention due to their superior efficiency in chemical and pharmaceutical industries, important organic transformations, high yield due to phase separation and catalyst reusability43,44,45,46.

In recent years, the use of mesoporous silica has become one of the most attractive catalytic supports for the heterogenization of homogeneous catalysts. Significant progress in the fabrication and analysis of these materials has led to a better understanding of their performance47,48. In comparison to other types of nanoparticles, silica mesoporous exhibit unique properties such as varying structures and relatively large pore sizes, which often give rise to improved activity and selectivity49,50. Mesocellular silica foam, also called MCF, is classified as a mesoporous material characterized by the presence of windows and cells. The spherical cells are connected by windows, resulting in a coherent and continuous three-dimensional (3D) pore system51,52,53. MCF has a network of pores with diameters of 20–40 nm, which are connected by windows with diameters of 10–20 nm. In addition, the specific surface area of MCF can be up to 1000 m2/g54,55. Also, magnetic mesocellular foam (M-MCF) can be synthesized by embedding magnetic nanoparticles (MNPs) within the porous structure of siliceous mesocellular foam, which can be easily separated and recovered in chemical reactions using an external magnetic field56,57. Also, in the continuation of this project, the synthesis of unsymmetrical diaryl selenides was investigated using boronic acid derivatives, selenium powder and aryl halides in the presence of copper-complex functionalized magnetic mesocellular foams (M-MCF@Gua-Cu) as a reusable magnetic nanocatalyst (Scheme 1d).

Result and discussion

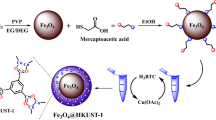

The preparation of M-MCF@Gua-Cu magnetic nanocatalyst was presented in Scheme 2. After the synthesis of MCF mesoporous using the reported methods, magnetic nanoparticles were placed inside the pores of MCF silica foam. Then M-MCF nanoparticles were modified using (3-chloropropyl)trimethoxysilane and M-MCF@n-Pr-Cl nanoparticles was obtained. In the next step, M-MCF@Gua nanoparticles were obtained by immobilizing guanine as a ligand on the surface of M-MCF@n-Pr-Cl. Finally, the synthesis of M-MCF@Gua-Cu nanocatalyst was carried out by loading copper particles on the surface of M-MCF@n-Pr-Cl. The nanocatalyst was identified using scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), high-resolution transmission electron microscopy (HR-TEM), fourier transform infrared spectroscopy (FT-IR), Brunauer–Emmett–Teller (BET), vibrating sample magnetometer (VSM), atomic absorption spectroscopy (AAS), X-ray diffraction (XRD) and thermogravimetric analysis (TGA) techniques and its catalytic activity in the synthesis of unsymmetrical diaryl selenides was investigated.

Characterization of M-MCF@Gua-Cu

Figure 2 shows the FT-IR spectra of the materials obtained during each step of the synthesis process for the M-MCF@Gua-Cu nanocatalyst. Absorption bonds at around 589 and 632 cm−1 in every spectrum are attributed to the Fe–O bond, while absorption bands at approximately 455, 802, and 1083 cm−1 are associated with Si–O–Si stretching vibrations58. Furthermore, the detected absorbance at 3442 cm−1 is a result of the surface O–H groups stretching vibrations59. In Fig. 2b presented, the bonds observed at 2854 and 2923 cm−1 represent the aliphatic C-H stretching vibrations60. Furthermore, the presence of two bonds at 1467 cm−1 and 1685 cm−1 in the spectrum of M-MCF@Gua (Fig. 2c) is indicative of C=C and carbonyl amide stretching vibrations, respectively. The bending vibrations related to C–N and N–H bonds appeared at 1371 cm−1 and 1588 cm−1. Also, the absorption of 3321 cm−1 is due to the surface stretching vibrations of N–H groups. The analysis of the M-MCF@Gua spectrum indicated that guanine was effectively fixed on the surface of M-MCF magnetic nanoparticles. To confirm the formation of a guanine-copper complex on M-MCF@Gua magnetic nanoparticles, spectral shifts in N–H bending and stretching vibrations were observed in M-MCF@Gua-Cu spectrum (Fig. 2d). In addition, the decrease in the intensity of the band at 1685 cm−1 indicates a decrease in the amide vibration effect, which is probably due to the interaction between the nitrogen and copper atoms.

As shown in Fig. 2e, the FT-IR spectrum of the recovered M-MCF@Gua-Cu nanocatalyst shows significant similarity with the FT-IR spectrum of the fresh catalyst. These findings provide evidence that the chemical structure of the nanocatalyst remains stable during the reaction.

The SEM images of the synthesized M-MCF@Gua-Cu catalyst at different scales, along with the corresponding EDX analysis, are shown in Figs. 3 and 4. The morphology of M-MCF@Gua-Cu was observed with similar irregular spherical shapes with an average size of 15–20 nm. The presence of nitrogen, carbon, iron, silica, oxygen, and copper elements in the catalyst structure is validated by the EDX analysis, and the X-ray mapping analysis in Fig. 5 demonstrates the uniform distribution of all elements. In addition, the amount of copper loaded on the nanocatalyst surface was measured as 1.18 mmol g−1 using atomic absorption spectroscopy.

Figure 6 shows the HR-TEM images of the M-MCF before loading the copper complex. These images confirm that the MCF structure consists of spherical voids connected by “windows”. Also, HR-TEM images clearly show γ-Fe2O3 spherical nanoparticles as dark spots inside MCF silica pores61.

Figure 7 shows the wide-angle XRD patterns of the synthesized M-MCF, M-MCF@Gua-Cu and recovered M-MCF@Gua-Cu. In the case of M-MCF, various diffraction peaks were observed over 2-theta at 30.4°, 35.8°, 43.5°, 54.0°, 57.5°, and 63.1°, indicating the characteristic crystalline phase of γ-Fe2O3 nanoparticles (Fig. 7a)62. The XRD pattern of the synthesized catalyst in Fig. 7b shows almost the same peaks, which indicates the preservation of the structural integrity of the M-MCF upon the incorporation of the copper complex into the support. In addition, the structure of the recycled nanocatalyst was investigated using XRD analysis to compare with the fresh catalyst (Fig. 7c). It was observed that the XRD spectra of recycled and fresh nanocatalyst are almost similar and show the same peaks. The results confirmed that the nanocatalyst retained its chemical structure throughout the recycling process.

Figure 8 shows the nitrogen adsorption-sorption isotherms of M-MCF and M-MCF@Gua-Cu. The isotherms are of type IV, which showed the characteristics of mesoporous materials63. Table 1 documents the pore volume and the BET surface area for the M-MCF nanoparticles shown in Fig. 8a. After loading the copper complex, most of the mesoporous pores were filled with the complex. However, the adsorption isotherm of the nanocatalyst still shows the characteristic type IV isotherm (Fig. 8b). It is important to mention that the surface area of the nanocatalyst is often lower than the MCF surface area due to the presence of the copper complex inside the mesoporous pores.

The magnetic hysteresis curves of M-MCF, M-MCF@Gua-Cu and recovered M-MCF@Gua-Cu are shown in Fig. 9. The samples exhibit typical superparamagnetic behavior. Figure 9a,b show that the saturation magnetic values of pure M-MCF and M-MCF@Gua-Cu are 23.24 emu g−1 and 20.10 emu g−1, respectively. These values are sufficiently high for magnetic separation with magnets. From these observations, it can be concluded that the decrease in the saturation magnetization of M-MCF@Gua-Cu is the result of the attached non-magnetic organic group, namely guanine. Then, the magnetic curve of the recovered catalyst was measured to study its structural stability under the applied conditions. As shown in Fig. 9c, the magnetization curve of the recovered catalyst (14.94 emu g−1) is almost the same as that of the fresh catalyst.

The thermal properties of M-MCF nanoparticles and M-MCF@Gua-Cu nanocatalyst were investigated by thermal analysis (TGA) in order to confirm the presence of different functional groups on the surface of nanoparticles (Fig. 10). As can be read from Fig. 10a, the decrease in weight of around 1% before 190 °C is due to the evaporation of moisture that is physically adsorbed. Additionally, the weight loss of approximately 3.4% between 220 and 550 °C is attributed to the decomposition of Si–OH surface groups. The TGA curve of the nanocatalyst shows two weight loss stages, which are attributed to the loss of water and organic solvent molecules during heating up to 200 °C and the decomposition of the organic groups immobilized on the M-MCF surface above 280 °C (Fig. 10b).

Catalytic studies

Optimization of the reaction conditions for the synthesis of diaryl selenides in the presence of a homogeneous catalyst (CuI)

We started our studies to optimize the C–Se cross-coupling reaction under homogeneous conditions, and iodobenzene and phenylboronic acid were selected as model coupling partners. At first, the reaction was carried out with CuI as a homogeneous catalyst, K2CO3 as a base, and selenium powder as the selenium source in DMSO solvent at 100 °C (Table 2, entry 1). Under these conditions, the reaction failed to completely produce the desired unsymmetrical diaryl selenide. Only 65% yield was observed with Na2CO3 as base in this reaction (Table 2, entry 2). Changing the base to Cs2CO3 was not effective for the reaction (Table 2, entry 3). No products were obtained using Et3N as the organic base (Table 2, entry 4). KOH provided the diphenyl selenide product in good to excellent yield (Table 2, entry 5). Also, we investigated how the amount of KOH affects this reaction (Table 2, entry 6). The results showed that 3 mmol KOH was suitable for the desired conversion. Then we investigated the effect of different solvents, such as H2O, dimethylformamide (DMF), dimethyl sulfoxide (DMSO) and polyethylene glycol (PEG-200) (Table 2, entries 7–9). Among all the tested solvents, DMSO as solvent gave a satisfying yield (Table 2, entry 5). We then turned our attention to finding the optimal reaction temperature by adjusting it from 80 to 120 °C (Table 2, entries 10–11). Lowering the reaction temperature to 80 °C resulted in a decrease of the product yield to 65% (Table 2, entry 10), whereas a yield of 95% was achieved at 100 °C (Table 2, entry 5). It is important to mention that without a catalyst, the reaction did not take place (Table 2, entry 12). The reaction was investigated in the presence of CuI as a homogeneous catalyst under optimal conditions (Table 2, entry 5). In addition, the effect of other copper salts was also tested. When Cu(OAc)2 and CuCl2 salts were used as catalysts, 55% and 75% yields were obtained, respectively (Table 2, entries 13–14). The amount of the catalyst was also optimized and 50 mg (25 mol%) was obtained as the appropriate amount for the reaction (Table 2, entries 15–17).

Having the optimal reaction conditions (Scheme 3), we explored the variety of aryl halides in this Cu-catalyzed cross-coupling reaction (Table 3). Aryl halides containing electron-donating and electron-withdrawing groups were combined with phenylboronic acid or 4-methylphenylboronic acid to produce unsymmetrical diaryl selenides with good to high yields. As expected, higher yields were obtained under optimal conditions (Table 2, entry 5) for electron-withdrawing aryliodides than electron-donating groups. Also, the results showed that 4-methylphenylboronic acid is more reactive than phenylboronic acid. It is also observed that aryl iodides are more reactive than aryl bromides and chlorides under similar reaction conditions. The selectivity of the synthesis of unsymmetrical diaryl selenides was investigated by testing the reaction of 4-Chlorobromobenzene as a dihalogenated aryl halide. The results showed that the bromide functional group has higher reactivity (Table 3, entry 11).

Based on the results obtained (Table 2, entries 5 and 12) and the previously reported mechanisms38,64,65,66,67,68, two plausible reaction mechanism for the synthesis of unsymmetrical diaryl selenides are described in Scheme 4a,b. In the first possible mechanism, we hypothesize that initially the reaction between Se and KOH occurs and leads to the formation of potassium diselenide69. Then, potassium diselenide reacts with CuI to form stable copper diselenide. In the next step, the oxidative-addition reaction of copper diselenide with arylboronic acid creates intermediate A41, which is then converted to intermediate B. Then, the key intermediate C is provided by the reaction of intermediate B with aryl halides through cleavage of the C-X bond. Finally, the desired product is obtained through reductive elimination of the C intermediate, restarting the cycle (Scheme 4a). Another explanation for this process is that diaryl diselenides are likely formed from the reaction of aryl halides with selenium in the presence copper and KOH in cycle A,67 which then couple with arylboronic acids in cycle B68 (Scheme 4b).

Optimization of the reaction conditions for the synthesis of diaryl selenides in the presence of a heterogeneous catalyst (M-MCF@Gua-Cu)

In continuation of our research on forming C-Se bonds, we investigated synthesis of unsymmetrical diaryl selenides by reacting aryl halides with phenylboronic acid or 4-methylphenylboronic acid, Se powder, and the recoverable magnetic nanocatalyst M-MCF@Gua-Cu. Our research started by using iodobenzene and phenylboronic acid as reactants to improve the reaction parameters (Table 4). To determine the amount of nanocatalyst, it was natural to try smaller amounts of catalyst. When the amount of M-MCF@Gua-Cu was decreased from 50 to 10 mg, a decrease in product yield was observed (Table 4, entries 1–4). As a result, the amount of 30 mg (3.54 mol%) was chosen as the optimal amount, and more amounts of catalyst did not significantly impact the reaction yield. Next, we examined how the solvent impacts the reaction by testing different solvents like DMF, H2O, DMSO, Dioxane, and PEG-200 (Table 4, entries 5–8). When DMSO was used as the solvent, 80% product yield was observed. When the reaction was performed in PEG-200 (Table 4, entry 3) using the same reaction conditions, the product yield increased to 94%. A significant amount of the diaryl selenide product was obtained when K2CO3 was employed as the base (Table 4, entry 10). Additionally, the product yield increased to 94% by using KOH in the reaction, while keeping other reaction conditions constant (Table 4, entry 3). We then turned our attention to finding the optimal reaction temperature by adjusting it from 90 to 130 °C (Table 4, entries 13–14). The yield of the product decreased with decreasing reaction temperature, while a yield of 94% was obtained when the reaction was carried out at 120 °C (Table 4, entry 3).

Under optimal conditions (Scheme 5), we studied the coupling reaction of different aryl halides and phenylboronic acid or 4-methylphenylboronic acid using the M-MCF@Gua-Cu magnetic nanocatalyst (Table 5). The corresponding diaryl selenides were synthesized with good to high yields, ranging from 70 to 94%, as shown in Table 5. Among the different types of aryl halides, it is worth noting that aryl iodides show the highest levels of reactivity, as shown in Table 5. It is interesting to observe that even aryl bromides and chlorides, which are considered to be less reactive substrates, can still be converted to the corresponding unsymmetrical diaryl selenides with good to high yields under similar reaction conditions. It was observed that aryl halides containing electron-donating groups underwent a slow conversion. Aryl halides containing electron-withdrawing groups showed good reactivity. In addition, to investigate the selectivity of this system, the reaction of dihalogenated 4-Chlorobromobenzene was studied in heterogeneous conditions. The test results showed that the bromide functional group exhibited a higher level of reactivity (Table 5, entry 11). It should be mentioned, the products listed in entries 1 and 2 in Table 3 and entries 3, 4, and 5 in Table 5 are symmetrical. However, they come from different starting materials.

Reusability of the catalyst

In addition to showing high catalytic performance, the cyclability of heterogeneous catalysts represents a great advantage. To achieve this, the catalytic recycling experiment was conducted using the reaction of iodobenzene and phenylboronic acid as model reactions. After each run, the nanocatalyst was recovered with a magnetic instrument, washed with ethanol, dried before use, and its efficiency was evaluated in the next step. The above procedure was repeated, finding that the nanocatalyst could be reused more than five times without significant decrease in its performance (Fig. 11). Furthermore, after five times of catalyst reuse, the copper content on the recycled nanocatalyst surface was re-evaluated using atomic absorption spectroscopy, which resulted in a measurement of 1.143 mmol/g.

The advantages and disadvantages of heterogeneous (M-MCF@Gua-Cu) catalysts in compare with homogeneous (CuI) are as follows: (a) the synthesis of M-MCF@Gua-Cu involves several steps that make it complicated and expensive. (b) the required reaction temperature is higher when using M-MCF@Gua-Cu is used. (c) the solvent used with the heterogeneous catalyst is a green solvent (PEG). (d) M-MCF@Gua-Cu is magnetically recyclable, allowing it to be easily separated from the reaction mixture using a simple magnet and reused several times (five runs).

Conclusion

In summary, a new and concise route for the synthesis of unsymmetrical diarylselenides has been developed for the first time using a copper-catalyzed three-component coupling reaction of aryl halides, phenylboronic acid, and selenium powder. One of the advantages of this method is the in site production of highly reactive aryl selenolates using arylboronic acid with selenium powder to prevent the use of selenols and diphenyl diselenides. Using CuI as a homogeneous catalyst in DMSO at 100 °C, various unsymmetrical diaryl selenides were synthesized from the reaction of arylboronic acid and aryl halides containing electron-withdrawing and electron-donating groups in good to high yields. Also, we used M-MCF@Gua-Cu as a new and magnetically reusable heterogeneous nanocatalyst for the synthesis of the desired unsymmetrical diaryl selenides using this system, and all the products were obtained with good yield in a suitable reaction time.

Experimental

Preparation of M-MCF

For the synthesis of M-MCF, in the first step, mesocellular silica foams (MCF) were synthesized using the method previously reported in the literature70,71. First, a solution of Pluronic P123 (0.4 mmol) and hydrochloric acid (75 mL, 1.6 M) was prepared at room temperature. After that, ammonium fluoride (NH4F) (0.6 mmol) and 1,3,5-trimethylbenzene (TMB) (17 mmol) were added and stirred for 45 min at 40 °C. Then tetraethyl orthosilicate (TEOS) (21 mmol) was added to the mixture and stirred for 20 h. The resulting mixture was transferred to an autoclave and kept at 110 °C for 24 h. Finally, the solid product (MCF) was calcined in air at 550 °C for 5 h. Then, to prepare magnetic mesocellular silica foam, magnetic nanoparticles were incorporated into the pores of MCF in the following method. Fe(NO3)3·9H2O was added to methanol solution containing 1 g of foam and subsequently subjected to drying process at 80 °C. To synthesize the iron propionate complex, a mixture of propionic acid (4.6 ml) and foam impregnated with Fe(NO3)3·9H2O was stirred at 80 °C for 4 h. Subsequently, the resulting composite was subjected to heat treatment at 300 °C for 30 min, resulting in the production of a solid product identified as M-MCF63,72.

Preparation of M-MCF@Gua-Cu

Synthesis of the M-MCF@Gua-Cu nanocatalyst involved combining 1 g of M-MCF magnetic nanoparticles with 3 mL (3-chloropropyl)trimethoxysilane (CPTMS) in 30 mL of toluene under reflux conditions for 24 h. The resulting M-MCF@n-Pr-Cl was then separated using a magnetic field and dried at 50 °C for 5 h. Next, M-MCF@n-Pr-Cl (1 g) and guanine (2.5 mmol) were mixed in ethanol (30 mL). This mixture was stirred at 80 °C for 24 h. A magnetic field was used to separate M-MCF@Gua, after which it was washed with ethanol and dried at 60 °C. Finally, the preparation of M-MCF@Gua-Cu nanocatalyst consisted of dispersing 1 g of modified M-MCF@Gua in ethanol with a volume of 30 ml. After that, the reaction mixture was stirred for 24 h following the addition of 2.5 mmol of Cu(NO3)2·3H2O. Upon the end of the reaction, the final product was gathered with a magnet, rinsed with ethanol, and subjected to a drying process at 50 °C.

Preparation of diaryl selenides in the presence of a homogeneous catalyst (CuI)

In the synthesis process, a 5 mL round-bottom flask was employed, which contained 2 mL of DMSO as the solvent. Then, CuI (50 mg, 25 mol%), phenylboronic acid or 4-methylphenylboronic acid (1.0 mmol), selenium powder (1.5 mmol), aryl halide (1.0 mmol), and KOH (3.0 mmol) were added. The mixture was stirred at 100 °C and the progress of the reaction was continuously monitored by thin layer chromatography (TLC). After the reaction was finished, the catalyst underwent filtration and the mixture was subjected to extraction with ethyl acetate and water. The resulting organic layer was dried using anhydrous sodium sulfate and concentrated by evaporation of the solvent. The obtained crude material was purified via silica gel column chromatography (n-hexane:ethyl acetate, 9:1). Finally, the desired products were obtained with a yield of 70–95%.

Preparation of diaryl selenides in the presence of a heterogeneous catalyst (M-MCF@Gua-Cu)

A mixture of phenylboronic acid or 4-methylphenylboronic acid (1.0 mmol), Se (1.5 mmol), aryl halides (1.0 mmol), KOH (4.0 mmol) and M-MCF@Gua-Cu (30 mg, 3.5 mol%) in 2 mL of PEG was stirred at 120 °C. The reaction progress was monitored using TLC and the M-MCF@Gua-Cu nanocatalyst was magnetically removed once the reaction was complete. Next, the organic layer was separated using ethyl acetate and dehydrated with Na2SO4, followed by concentrating the solvent under reduced pressure. Finally, silica gel column chromatography using n-hexane:ethyl acetate (9:1) was used to purify the products further, and pure products were obtained with a yield of 70–94%.

Selected spectral data

Diphenyl selenide.73 Oil, 1H NMR (300 MHz, CDCl3): δ = 7.64–7.62 (m, 4 H), 7.29–7.22 (m, 6 H) ppm; 13C NMR (75 MHz, CDCl3): δ = 131.1, 130.5, 128.7, 127.2 ppm.

Phenyl(p-methoxyphenyl) selenide.74 Oil, 1H NMR (300 MHz, CDCl3): δ = 7.60–7.53 (m, 4H), 7.47–7.42 (m, 2H), 7.36–7.33 (m, 1H), 7.04–6.98 (m, 2H), 3.88 (s, 3H) ppm.

Phenyl(p-tolyl) selenide.73 Yellow oil, 1H NMR (300 MHz, CDCl3): δ = 7.46–7.42 (m, 4H), 7.29–7.25(m, 3H), 7.14 (d, J = 8.0 Hz, 2H), 2.36 (s, 3H) ppm.

Phenyl(o-tolyl) selenide.75 Yellow oil, 1H NMR (300 MHz, CDCl3): δ = 7.31–7.07 (m, 9H), 2.48 (s, 3H) ppm; 13C NMR (75 MHz, CDCl3): δ = 139.4, 138.5, 132.8, 132.4, 130.9, 129.5, 127.6, 127.1, 126.4, 126.3, 21.7 ppm.

Phenyl(4-nitrophenyl) selenide.76 m.p. 54–56 °C, 1H NMR (300 MHz, CDCl3): δ = 8.08–7.99 (m, 2H), 7.69–7.59 (m, 2H), 7.45–7.43 (m, 3H), 7.36–7.34 (m, 2H) ppm; 13C NMR (75 MHz, CDCl3): δ = 145.8, 143.3, 135.3, 129.5, 129.3, 128.8, 126.8, 123.4 ppm.

Phenyl(2-naphyl) selenide.73 m.p. 50–52 °C, 1H NMR (500 MHz, CDCl3): δ = 7.91 (d, J = 1.8 Hz, 1H), 7.73–7.70 (m, 1H), 7.68–7.64 (m, 2H), 7.47–7.42 (m, 3H), 7.41–7.37 (m, 2H), 7.23–7.18 (m, 3H) ppm; 13C NMR (125 MHz, CDCl3): δ = 133.9, 132.8, 132.3, 131.9, 131.0, 130.3, 129.3, 128.7, 128.4, 127.9, 127.7, 127.3, 126.4, 126.2 ppm.

Phenyl(4-chlorophenyl) selenide.74 Yellow oil, 1H NMR (500 MHz, CDCl3): δ = 7.49–47 (m, 2H), 7.40–7.36 (m, 2H), 7.30–7.28 (m, 3H), 7.26–7.21 (m, 2H) ppm; 13C NMR (125 MHz, CDCl3): δ = 134.1, 133.5, 133.1, 130.6, 129.5, 129.4, 127.6 ppm.

Di(p-tolyl) selenide.76 Yellow oil, 1H NMR (300 MHz, CDCl3): δ = 7.29 (d, J = 8.1 Hz, 4H), 7.15 (d, J = 7.8 Hz, 4H), 2.37 (s, 6H) ppm (Fig. S13).

O-tolyl(p-tolyl) selenide. Yellow oil, 1H NMR (500 MHz, CDCl3): δ = 7.28–19 (m, 5H), 7.13–7.06 (m, 3H), 2.46 (s, 3H), 2.43 (s, 3H) ppm; 13C NMR (125 MHz, CDCl3): δ = 139.8, 138.9, 133.2, 132.8, 131.3, 130.9, 130.2, 129.9, 127.5, 126.8, 22.6, 22.2 ppm.

(4-nitrophenyl)(p-tolyl) selenide.77 m.p. 82–84 °C, 1H NMR (500 MHz, CDCl3): δ = 8.01 (d, J = 8.8 Hz, 2H), 7.53 (d, J = 8.3 Hz, 2H), 7.33 (d, J = 8.1 Hz, 2H), 7.24 (d, J = 7.7 Hz, 2H), 2.42 (s, 3H) ppm; 13C NMR (125 MHz, CDCl3): δ = 146.0, 144.6, 139.7, 136.1, 130.9, 129.3, 125.8, 123.8, 21.2 ppm.

(4-chlorophenyl)(p-tolyl) selenide.76 m.p. 70–72 °C, 1H NMR (500 MHz, CDCl3): δ = 7.51 (d, J = 8.0 Hz, 2H), 7.37 (d, J = 8.7 Hz, 2H), 7.11–7.08 (m, 4H), 2.35 (s, 3H) ppm; 13C NMR (125 MHz, CDCl3): δ = 137.9, 137.1, 133.3, 132.9, 132.3, 130.0, 129.9, 127.6, 21.0 ppm.

Data availability

The 1H NMR and 13C NMR spectra of the selected products are available in the supporting information of this article.

References

Reich, H. J. & Hondal, R. J. Why nature chose selenium. ACS Chem. Biol. 11, 821–841 (2016).

Kumar, S. et al. Facile synthesis, structural evaluation, antimicrobial activity and synergistic effects of novel imidazo [1, 2-a] pyridine based organoselenium compounds. Eur. J. Med. Chem. 123, 916–924 (2016).

Casaril, A. M. et al. Antidepressant-like effect of a new selenium-containing compound is accompanied by a reduction of neuroinflammation and oxidative stress in lipopolysaccharide-challenged mice. J. Psychopharmacol. 31, 1263–1273 (2017).

Han, X., Song, X., Yu, F. & Chen, L. A ratiometric near-infrared fluorescent probe for quantification and evaluation of selenocysteine-protective effects in acute inflammation. Adv. Funct. Mater. 27, 1700769 (2017).

Engman, L. et al. Synthesis, antioxidant properties, biological activity and molecular modelling of a series of chalcogen analogues of the 5-lipoxygenase inhibitor DuP 654. Bioorg. Med. Chem. 3, 1255–1262 (1995).

dos Santos, E. d. A., Hamel, E., Bai, R., Burnett, J. C., Tozatti, C. S. S., Bogo, D., Perdomo, R. T., Antunes, A. M., Marques, M. M. & de FC Matos, M. Synthesis and evaluation of diaryl sulfides and diaryl selenide compounds for antitubulin and cytotoxic activity. Bioorg. Med. Chem. Lett. 23, 4669–4673 (2013).

Manjare, S. T., Kim, Y. & Churchill, D. G. Selenium-and tellurium-containing fluorescent molecular probes for the detection of biologically important analytes. Acc. Chem. Res. 47, 2985–2998 (2014).

Rodrigues, J., Saba, S., Joussef, A. C., Rafique, J. & Braga, A. L. KIO3-Catalyzed C(sp2)-H bond selenylation/sulfenylation of (Hetero) arenes: synthesis of chalcogenated (Hetero) arenes and their evaluation for anti-alzheimer activity. Asian J. Org. Chem. 7, 1819–1824 (2018).

Reddy, V. P., Kumar, A. V., Swapna, K. & Rao, K. R. Copper oxide nanoparticle-catalyzed coupling of diaryl diselenide with aryl halides under ligand-free conditions. Org. Lett. 11, 951–953 (2009).

Kundu, D., Ahammed, S. & Ranu, B. C. Visible light photocatalyzed direct conversion of aryl-/heteroarylamines to selenides at room temperature. Org. Lett. 16, 1814–1817 (2014).

Fernandes, R. A., Bhowmik, A. & Yadav, S. S. Advances in Cu and Ni-catalyzed Chan–Lam-type coupling: synthesis of diarylchalcogenides, Ar2–X (X= S, Se, Te). Org. Biomol. Chem. 18, 9583–9600 (2020).

Barcellos, A. M. et al. Organoboron compounds as versatile reagents in the transition metal-catalyzed C-S, C–Se and C–Te bond formation. Coord. Chem. Rev. 442, 214012 (2021).

Beletskaya, I. P. & Ananikov, V. P. Transition-metal-catalyzed C-S, C–Se, and C–Te bond formations via cross-coupling and atom-economic addition reactions. Achievements and challenges. Chem. Rev. 122, 16110–16293 (2022).

Fang, Y., Rogge, T., Ackermann, L., Wang, S.-Y. & Ji, S.-J. Nickel-catalyzed reductive thiolation and selenylation of unactivated alkyl bromides. Nat. Commun. 9, 2240 (2018).

Liu, Y. et al. Construction of diverse C-S/C–Se bonds via nickel catalyzed reductive coupling employing thiosulfonates and a selenosulfonate under mild conditions. Org. Chem. Front. 9, 1375–1382 (2022).

Iwasaki, M., Kaneshika, W., Tsuchiya, Y., Nakajima, K. & Nishihara, Y. Palladium-catalyzed peri-selective chalcogenation of naphthylamines with diaryl disulfides and diselenides via C-H bond cleavage. J. Org. Chem. 79, 11330–11338 (2014).

Qiao, H. et al. Palladium-catalyzed direct ortho-C–H selenylation of benzaldehydes using benzidine as a transient directing group. Org. Lett. 21, 6914–6918 (2019).

Xu, M., Zhang, X. H. & Zhong, P. Iron-Catalyzed Direct Sulfenylation and Selenylations of Phenylpyrazoles: Synthesis of Fipronil Derivatives with Disulfides Promoted by a Catalytic Amount of Iodine. Synth. Commun. 42, 3472–3481 (2012).

Sun, Q.-X. et al. Iron-catalyzed thiolation and selenylation of cycloalkyl hydroperoxides via C-C bond cleavage. J. Org. Chem. 86, 11987–11997 (2021).

Mukherjee, N., Kundu, D. & Ranu, B. C. Copper-Silver Dual Catalyzed Decyanative C-Se Cross-Coupling. Adv. Synth. Catal. 359, 329–338 (2017).

Mandal, A., Sahoo, H. & Baidya, M. Copper-catalyzed 8-aminoquinoline-directed selenylation of arene and heteroarene C-H bonds. Org. Lett. 18, 3202–3205 (2016).

Gujadhur, R. K. & Venkataraman, D. A general method for the formation of diaryl selenides using copper (I) catalysts. Tetrahedron Lett. 44, 81–84 (2003).

Capperucci, A., Petrucci, A., Faggi, C. & Tanini, D. Click Reaction of Selenols with Isocyanates: Rapid Access to Selenocarbamates as Peroxide-Switchable Reservoir of Thiol-Peroxidase-Like Catalysts. Adv. Synth. Catal. 363, 4256–4263 (2021).

KumaráBhunia, S., Dasa, P. & Jana, R. Atom-economical selenation of electron-rich arenes and phosphonates with molecular oxygen at room temperature. Org. Biomol. Chem. 16, 9243–9250 (2018).

Mukherjee, N., Chatterjee, T. & Ranu, B. C. Transition metal-and solvent-free synthesis of unsymmetrical diaryl sulfides and selenides under ball-milling. ARKIVOC 2016, 53–61 (2015).

Movassagh, B. & Hosseinzadeh, Z. A highly efficient copper-catalyzed synthesis of unsymmetrical diaryl-and aryl alkyl chalcogenides from aryl iodides and diorganyl disulfides and diselenides. Synlett 27, 777–781 (2016).

Ivanova, A. & Arsenyan, P. Rise of diselenides: Recent advances in the synthesis of heteroarylselenides. Coord. Chem. Rev. 370, 55–68 (2018).

Senol, E., Scattolin, T. & Schoenebeck, F. Selenolation of Aryl Iodides and Bromides Enabled by a Bench-Stable PdI Dimer. Chem. Eur. J. 25, 9419–9422 (2019).

Guan, Y. & Townsend, S. D. Metal-Free Synthesis of Unsymmetrical Organoselenides and Selenoglycosides. Org. Lett. 19, 5252–5255 (2017).

Thanna, S. et al. Thermal and Photoinduced Copper-Promoted C-Se Bond Formation: Synthesis of 2-Alkyl-1, 2-benzisoselenazol-3 (2 H)-ones and Evaluation against Mycobacterium tuberculosis. J. Org. Chem. 82, 3844–3854 (2017).

Scalambra, F., Lorenzo-Luis, P., de los Rios, I. & Romerosa, A. New achievements on C–C bond formation in water catalyzed by metal complexes. Coord. Chem. Rev. 443, 213997 (2021).

Estopiñá-Durán, S. et al. Aryl boronic acid catalysed dehydrative substitution of benzylic alcohols for C-O bond formation. Chem. Eur. J. 25, 3950–3956 (2019).

Kolekar, Y. A. & Bhanage, B. M. Pd-Catalyzed Oxidative Aminocarbonylation of Arylboronic Acids with Unreactive Tertiary Amines via C-N Bond Activation. J. Org. Chem. 86, 14028–14035 (2021).

Wang, M., Ren, K. & Wang, L. Iron-catalyzed ligand-free carbon-selenium (or tellurium) coupling of arylboronic acids with diselenides and ditellurides. Adv. Synth. Catal. 351, 1586–1594 (2009).

Ren, K., Wang, M. & Wang, L. Lewis acid InBr3-catalyzed arylation of diorgano diselenides and ditellurides with arylboronic acids. Org. Biomol. Chem. 7, 4858–4861 (2009).

Rampon, D. S. et al. Transition metal catalysed direct selanylation of arenes and heteroarenes. Dalton Trans. 48, 9851–9905 (2019).

Ma, W. et al. Chelation-assisted transition metal-catalysed C-H chalcogenylations. Org. Chem. Front. 7, 1022–1060 (2020).

Shirvandi, Z., Atashkar, B., Zolfigol, M. A. & Rostami, A. Transition-metal-catalyzed one-pot selenylation of electrophilic arylating agents using triphenyltin chloride/Se as a phenylselenating agent. Org. Biomol. Chem. 20, 4625–4634 (2022).

Matsumura, M., Kumagai, H., Murata, Y., Kakusawa, N. & Yasuike, S. Simple and efficient copper-catalyzed synthesis of symmetrical diaryl selenides from triarylbismuthanes and selenium under aerobic conditions. J. Organomet. Chem. 807, 11–16 (2016).

Zhang, S., Karra, K., Heintz, C., Kleckler, E. & Jin, J. Microwave-assisted Cu2O-catalyzed one-pot synthesis of symmetrical diaryl selenides from elemental selenium. Tetrahedron Lett. 54, 4753–4755 (2013).

Taniguchi, N. Mono-or dichalcogenation of aryl iodide with sulfur or selenium by copper catalyst and aluminum. Synlett 2005, 1687–1690 (2005).

Ma, Y. T., Liu, M. C., Zhou, Y. B. & Wu, H. Y. Synthesis of organoselenium compounds with elemental selenium. Adv. Synth. Catal. 363, 5386–5406 (2021).

Haye, E., Busby, Y., da Silva Pires, M., Bocchese, F., Job, N., Houssiau, L. & Pireaux, J.-J. Low-pressure plasma synthesis of Ni/C nanocatalysts from solid precursors: Influence of the plasma chemistry on the morphology and chemical state. ACS Appl. Nano Mater. 1, 265–273 (2017).

Zhang, Q., Yang, X. & Guan, J. Applications of magnetic nanomaterials in heterogeneous catalysis. ACS Appl. Nano Mater. 2, 4681–4697 (2019).

Cui, X., Li, W., Ryabchuk, P., Junge, K. & Beller, M. Bridging homogeneous and heterogeneous catalysis by heterogeneous single-metal-site catalysts. Nat. Catal. 1, 385–397 (2018).

Vásquez-Céspedes, S., Betori, R. C., Cismesia, M. A., Kirsch, J. K. & Yang, Q. Heterogeneous catalysis for cross-coupling reactions: an underutilized powerful and sustainable tool in the fine chemical industry?. Org. Process Res. Dev. 25, 740–753 (2021).

Wei, H., Lv, Y., Han, L., Tu, B. & Zhao, D. Facile synthesis of transparent mesostructured composites and corresponding crack-free mesoporous carbon/silica monoliths. Chem. Mater. 23, 2353–2360 (2011).

Li, R. et al. Formation of nitrogen-doped mesoporous graphitic carbon with the help of melamine. ACS Appl. Mater. Interfaces 6, 20574–20578 (2014).

Violi, I. L., Zelcer, A. s., Bruno, M. M., Luca, V. & Soler-Illia, G. J. Gold Nanoparticles supported in zirconia–ceria mesoporous thin films: a highly active reusable heterogeneous nanocatalyst. ACS Appl. Mater. Interfaces 7, 1114–1121 (2015).

Manzano, M. & Vallet-Regí, M. Mesoporous silica nanoparticles for drug delivery. Adv. Funct. Mater. 30, 1902634 (2020).

an excellent catalyst for racemization of amines. Shakeri, M., Tai, C. w., Göthelid, E., Oscarsson, S. & Bäckvall, J. E. Small Pd nanoparticles supported in large pores of mesocellular foam. Chem. Eur. J. 17, 13269–13273 (2011).

Feng, X. et al. Tetraethylenepentamine-modified siliceous mesocellular foam (MCF) for CO2 capture. Ind. Eng. Chem. Res. 52, 4221–4228 (2013).

Chen, L. et al. Mesoporous zeolitic imidazolate framework-67 nanocrystals on siliceous mesocellular foams for capturing radioactive iodine. ACS Appl. Nano Mater. 3, 5390–5398 (2020).

Pompe, C. et al. Stability of mesocellular foam supported copper catalysts for methanol synthesis. Catal. Today 334, 79–89 (2019).

Lende, A. B., Bhattacharjee, S., Lu, W.-Y. & Tan, C.-S. Hydrogenation of dioctyl phthalate over a Rh-supported Al modified mesocellular foam catalyst. New J. Chem. 43, 5623–5631 (2019).

Jermy, B. R. et al. Magnetic mesocellular foam functionalized by curcumin for potential multifunctional therapeutics. J. Supercond. Novel Magn. 32, 2077–2090 (2019).

Barrera, G. et al. Magnetic properties of nanocomposites. Appl. Sci. 9, 212 (2019).

Haydari, Z., Elhamifar, D., Shaker, M. & Norouzi, M. Magnetic nanoporous MCM-41 supported melamine: a powerful nanocatalyst for synthesis of biologically active 2-amino-3-cyanopyridines. Appl. Surf. Sci. Adv. 5, 100096 (2021).

Shirvandi, Z., Rostami, A. & Ghorbani-Choghamarani, A. Magnetic mesocellular foams with nickel complexes: as efficient and reusable nanocatalysts for the synthesis of symmetrical and asymmetrical diaryl chalcogenides. Nanoscale Adv. 4, 2208–2223 (2022).

Ghorbani-Choghamarani, A., Tahmasbi, B., Hudson, R. H. & Heidari, A. Supported organometallic palladium catalyst into mesoporous channels of magnetic MCM-41 nanoparticles for phosphine-free C-C coupling reactions. Microporous Mesoporous Mater. 284, 366–377 (2019).

Xie, W. & Zang, X. Immobilized lipase on core–shell structured Fe3O4–MCM-41 nanocomposites as a magnetically recyclable biocatalyst for interesterification of soybean oil and lard. Food Chem. 194, 1283–1292 (2016).

Shirvandi, Z., Ghorbani-Choghamarani, A. & Rostami, A. A palladium (0)–threonine complex immobilized on the surface of magnetic mesocellular foam: an efficient, stable, and magnetically separable nanocatalyst for Suzuki, Stille, and Heck cross-coupling reactions. RSC Adv. 13, 17449–17464 (2023).

Lee, D. et al. Filtration-free recyclable catalytic asymmetric dihydroxylation using a ligand immobilized on magnetic mesocellular mesoporous silica. Adv. Synth. Catal. 348, 41–46 (2006).

Rostami, A., Rostami, A. & Ghaderi, A. Copper-catalyzed thioetherification reactions of alkyl halides, triphenyltin chloride, and arylboronic acids with nitroarenes in the presence of sulfur sources. J. Org. Chem. 80, 8694–8704 (2015).

Rostami, A., Rostami, A., Ghaderi, A., Gholinejad, M. & Gheisarzadeh, S. Copper-catalyzed C-S bond formation via the cleavage of C–O bonds in the presence of S8 as the sulfur source. Synthesis 49, 5025–5038 (2017).

Kundu, D., Roy, A. & Panja, S. Transition metal catalyst, solvent, base free synthesis of diaryl diselenides under mechanical ball milling. Curr. Org. Synth. 19, 477–483 (2022).

Singh, D. et al. An efficient one-pot synthesis of symmetrical diselenides or ditellurides from halides with CuO nanopowder/Se0 or Te0/base. Org. Lett. 12, 3288–3291 (2010).

Taniguchi, N. Aryl-or alkylation of diaryl disulfides using organoboronic acids and a copper catalyst. Synlett 2006, 1351–1354 (2006).

Yadav, D., Dixit, A., Raghothama, S. & Awasthi, S. K. Ni nanoparticle-confined covalent organic polymer directed diaryl-selenides synthesis. Dalton Trans. 49, 12266–12272 (2020).

Han, Y., Lee, S. S. & Ying, J. Y. Pressure-driven enzyme entrapment in siliceous mesocellular foam. Chem. Mater. 18, 643–649 (2006).

Chrzanowska, A., Derylo-Marczewska, A. & Wasilewska, M. Mesocellular silica foams (MCFs) with tunable pore size as a support for lysozyme immobilization: Adsorption equilibrium and kinetics, biocomposite properties. Int. J. Mol. Sci. 21, 5479 (2020).

Shokri, Z., Azimi, N., Moradi, S. & Rostami, A. A novel magnetically separable laccase-mediator catalyst system for the aerobic oxidation of alcohols and 2-substituted-2, 3-dihydroquinazolin-4 (1H)-ones under mild conditions. Appl. Organomet. Chem. 34, e5899 (2020).

Zhang, S. et al. Potassium tert-Butoxide-Promoted Aerobic Dehydrazination of Arylhydrazines: From Arylhydrazines to Substituent Aromatics. Eur. J. Org. Chem. 27, e202400270 (2024).

Jang, J., Kim, R. & Kim, D. Y. Photocatalyst-free photoredox synthesis of diaryl selenides by reaction of diselenides with aryldiazo sulfones. Synth. Commun. 51, 720–726 (2021).

Perin, G., Duarte, L. F. B., Neto, J. S., Silva, M. S. & Alves, D. Alternative Metal-Free Synthesis of Diorganoyl Selenides and Tellurides Mediated by Oxone. Synlett 29, 1479–1484 (2018).

Sun, N. et al. Trichloroisocyanuric Acid-Promoted Synthesis of Arylselenides and Aryltellurides from Diorganyl Dichalcogenides and Arylboronic Acids at Ambient Temperature. Adv. Synth. Catal. 363, 3577–3584 (2021).

Wu, S., Shi, J. & Zhang, C.-P. Cu-Mediated arylselenylation of aryl halides with trifluoromethyl aryl selenonium ylides. Org. Biomol. Chem. 17, 7468–7473 (2019).

Acknowledgements

We gratefully acknowledge the financial support of this research by the University of Kurdistan.

Author information

Authors and Affiliations

Contributions

Zeinab Shirvandi did experimental works and manuscript draft. Nadya Ghorashi did the experimental works. Amin Rostami supervised the research project and is the corresponding author of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shirvandi, Z., Ghorashi, N. & Rostami, A. Copper catalyzed carbon-selenium bond formation via the coupling reaction of aryl halides, phenylboronic acid and Se. Sci Rep 15, 13114 (2025). https://doi.org/10.1038/s41598-025-96747-4

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96747-4