Abstract

With the increasing strength and depth of coal mining, the proportion of mining under complex conditions is becoming more and more significant. The energy accumulation model and mechanical model of suspended roof are established by analyzing of the stress distribution law of suspended roof, which is based on complicated geological conditions of hard roof, hard coal and soft floor. The study of energy evolution processes of the soft floor and suspended roof suggest that the energy releasing caused by soft floor failure is the fundamental reason for rock burst, and the suspended roof also has an influence on the floor damage. Prevention technology of side-bottom pressure relief and roof cutting by large diameter drilling hole on coal and surrounding factors are proposed by this study. After applying the above method to the 1306 working face, the coal dusts in the three boreholes of the coal wall are reduced from 2.9 kg/m, 3.1 kg/m, 3.0 kg/m to 2.5 kg/m, 2.6 kg/m, 2.7 kg/m respectively, and the average amount of coal dusts is reduced from 3.0 to 2.6 kg/m, which is far less than the critical value. Therefore, this study has achieved effective prevention and control of rockburst in roadway under the complex conditions of hard suspended roof, impact coal mass, and soft floor, ensuring safe mining of the working face and providing methodological reference for similar mining conditions.

Similar content being viewed by others

Introduction

With the large-scale mining of coal resources in China, the number of deep mine is gradually increasing. Rockburst, one of the main dynamic disasters in the deep complex mining, seriously affects the safe and efficient production in mine1,2,3,4,5. As a special form of rock burst, floor impact failure often occurs in mining environments where the floor is relatively weak. When the energy of the coal rock system exceeds the bearing limit of the surrounding rock, it will be released in the lower strength floor, causing tunnel floor heave and coal rebound, and then results in equipment damage and casualties. As a result, it has an huge influence on safe mining6,7,8,9.

At present, many scholars have studied the mechanism and mechanical reasons of rock burst under the condition of hard roof and soft floor of roadway. Lyu et al.10 studied the occurrence regularity of rockburst under the influence of factors such as hard roof, faults, and mining, and believed that the main reason was the difference in energy between the superposition energy of the rockburst source area and the energy consumed by coal rock instability under the sudden increase of rockburst. Zhou et al.11 analyzed the failure form of the roadway floor near the hard roof goaf in Ordos area, and believed that the roadway floor bears the load transferred from the hard roof to the floor through “roof → rib → floor” path, and the load reached the critical condition of impact failure, leading to the impact failure of the roadway floor. Wang et al.12 compared the evolution mechanism of static stress and dynamic stress of two different types of rock burst, and the measures of caving mining, deep-hole blasting and large-diameter hole are put forward. Zhang et al.13 established mechanical model of the instability of composite coal in hard roof in different mining stages, and believed that the rockburst is mainly caused by the dynamic load formed by the fracture of the long cantilever structure and the static load formed by the failure and instability of the coal body. Wang et al.14 analyzed the transformation process of impact energy in burst-resistance zone (BRZ), burst-inoculation zone and stable zone, and proposed theoretical equations for calculating strain energy, dissipation energy and impact vibration kinetic energy. Song et al.15 developed a possible full-waveform optimization inversion method to analyze the focal mechanism of a thick-hard roof zone, and studied the main controlling factors of induced rockburst through stress field inversion. The above studies are all aimed at hard roof, weak floor or composite roof, and few literatures are aimed at the mechanism of rockburst under the conditions of hard roof, coal burst and weak floor.

With the gradual development of mining technology, there have been a large number of applications of rock burst prevention methods under the conditions of hard roof and soft floor. Deep hole blasting technology and blasting pressure relief technology are widely used in hard roof16,17,18. The large diameter drilling method has also achieved good effect on the pressure relief of the hard roof19,20. Hydraulic fracturing technology and water jet technology are used to prevent and control high energy rock burst area21,22. In addition to the above rockburst prevention technologies, Tai et al.23 proposed a technology for mine ground fracturing to control rock bursts, including fracturing devices, fracturing processes, crack monitoring techniques and control programs, etc. Malan et al.24 investigates the unique problems associated with the design of rockburst support for shallow-dipping tabular excavations, and a system of timber packs and elongates is proposed for the protection of rockburst roadways. Huang et al.25 designed the support structure for the rockburst roadway by determining the strain sensitive threshold of coal, and verified through engineering experiments that the support structure provides sufficient confining pressure to the disturbance sensitive area.

Taking the 1301 working face of Guotun Coal Mine as the research background, this paper analyzes the mechanism of rock burst and studies the prevention and control measures based on the complex conditions of hard suspended roof, impact coal mass, and soft floor. By analyzing the energy accumulation and release law of the weak floor under the action of hard suspended roof, this paper puts forward measures such as pressure relief of the side floor, treatment of the suspended roof structure and strengthening the support strength, which reduces the risk of rock burst and ensures the safe mining of the working face.

Engineering background

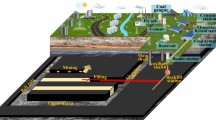

General situation of coal seam

The buried depth of No.3 coal seam in Guotun coal mine in Shandong province, China, is about 800 m. The thickness of coal seam ranges from 0.73 to 5.31 m (3.47 m on average). It belongs to relatively stable coal seam, and its firmness coefficient is 2 –3. The No.3 coal seam has strong impact tendency. The direct roof of coal seam is siltstone (2.1 m), the basic roof is medium sandstone (10.6 m), the direct floor is composed of sandy mudstone (1.2 m), and the basic floor is sandstone(16.0 m), as shown in Fig. 1.

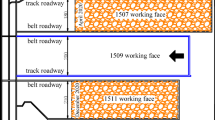

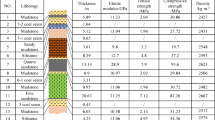

The mining method of 1306 working face is small coal pillar mining along the goaf (Fig. 2). The coal pillar width is 5 m. According to the rock properties of coal seam (Table 1), top and bottom plate, the No.3 coal seam has the characteristics of hard roof, hard coal seam and soft floor, respectively. It has the occurrence conditions of floor rock burst, so the probability of rock burst is relatively higher.

Stress distribution of the hard roof 1306 working face

As the immediate roof of the 1306 working face has high strength, it is easy to form a suspended roof structure. The suspended roof structure supports the concentrated stress of overlying strata, which can cause the phenomena of stress concentration and energy accumulation. When the concentrated stress transferred to the roadway, the coal is subjected to the self-weight of the overlying strata and the additional stress of the suspended roof structure, and a large amount of elastic energy are accumulated in coal pillar.

Figure 3 shows the stress distribution of 1306 working face with soft floor. I, II and III is the abutment pressure distribution curve of normal working face, soft floor coal seam and suspended roof structure in soft floor coal seam, respectively. The direct floor consists of mudstone, where the stress and energy produced by coal body and overlying strata are absorbed by soft floor. Compared with the stress of normal working face (I), the value of stress of II is decreased correspondingly, and the influence range of supporting stress is increased from A to B. As can be seen from curve III, when the soft floor has a suspended roof, the energy generated by the suspended roof can be transferred to the coal body, which leads to the sharp increase of the stress at the coal wall, and makes the stress of the coal body increase rapidly. And the peak stress of suspended roof is greater than that of the normal working face, and the abutment pressure range increases to B. Therefore, the suspended roof can increase the abutment pressure, shorten the distance between the peak and the roadway, and expand the influence range of the abutment pressure.

Stress distribution of working face with soft floor. I (black): abutment pressure distribution curve of normal working face; II (blue): abutment pressure curve of soft floor coal seam; III (red): abutment pressure distribution curve of suspended roof structure in soft floor coal seam. (A) stress influence range of normal working face; (B) stress influence range of soft floor.

Under the circumstance of the joint load of overlying strata and suspended roof, the energy of coal body can be transferred to the lower strength immediate floor. The immediate floor is “clamped” by the coal and the basic floor, and the energy is released from the immediate floor to the roadway, and finally the floor impact failure is formed.

Mechanism of impact energy

Energy accumulation model

Because of the affection by the stress of overlying strata and suspended roof, the coal with high impact tendency can accumulate a large amount of elastic energy, resulting in the energy release of the failure of soft floor, which is the main reason of floor rock burst.

The strong impact coal mass, soft immediate floor and hard basic floor constitute an energy accumulation area. According to the differential rheological model, this area can be simplified as an energy accumulation model formed by two Hookes (coal body and main floor) and a Kelvin (immediate floor), as shown in Fig. 4. In this model, Hm is a strong impact coal body (represented by spring), Hd is soft immediate floor (represented by glue cylinder), Ht is hard basic floor (represented by spring).

Due to the high compressive strength and strong impact tendency of coal body, large elastic energy can be accumulated through the overlying hard rock stratum and suspended roof. When the deformation limit of coal body is reached, the energy will transfer to the soft immediate floor. Hd is a weak rock stratum, which has the common characteristics of elastic body and viscous body. According to the definition of generalized Kelvin, its stress can be expressed as:

where, \(\:{\sigma\:}_{H}\) is total stress, \(\:{\sigma\:}_{e}\) is the spring stress, \(\:{\sigma\:}_{v}\) is the cylinder sticking stress, \(\:{\epsilon\:}_{e}\) is the spring strain, \(\:{\epsilon\:}_{v}\) is the cylinder sticking strain, \(\:{K}_{d}\) is elastic coefficient of soft immediate floor, η is viscosity coefficient.

The hard basic floor cannot be destroy by he accumulated energy, when the stress of coal seam and immediate floor is transferred to the basic floor. The energy will be released from the soft floor of roadway to form floor rock burst. According to the energy accumulation model and energy transfer process, the impact load on the immediate floor should be weakened by reducing the coal strength.

Stress analysis of suspended roof

The immediate roof lithology has hard characteristic, and it is easy to form a suspended roof on the side of the goaf. The additional stress generated by suspended roof can increase the stress of coal body and aggravate the damage degree of floor. In order to analyze the influence of the rectangular cantilever structure on the roadway and coal body, the mechanical model of the cantilever part is simplified as illustrated in Fig. 5. In this paper, the stress analysis of the suspended roof shows that the suspended roof can be regarded as a rectangular cantilever beam with a linearly distributed force acting above the cantilever.

-

(1)

Roadway pillars are in elastic state.

The length of the cantilever structure of the roof is l, the weight of the cantilever is G1, the point A between the coal pillar and the immediate roof is a clamped support structure, and the cantilever structure performs work around point A.

According to the bending moment calculation of bending beam, the bending moment of point A is:

where M1 is the bending moment of overlying strata to point A; M2 is the bending moment of direct roof to point A; q is the uniform load of overlying strata; ηi is the stress transfer coefficient of each rock stratum; φ is the inclined subsidence angle of overlying strata; γ is the bulk density of immediate roof; h is the thickness of immediate roof.

According to the relationship between force and energy, the deformation energy of the cantilever structure is equal to the work done by the external force, and the external force all acts on point A, so the additional energy of the coal pillar by the cantilever beam is:

where θ is the corner angle of the cantilever beam; EI is the bending rigidity of the cantilever beam.

In this case, the energy produced by the cantilever beam is only related to the cantilever length l. Since the coal pillar is in an elastic state, it is not enough to reach the load limit of the coal pillar, so as the coal pillar bears all the energy of the cantilever beam.

-

(2)

Roadway pillars are in plastic state.

The stress around the roadway is affected by mining, and the upper part of the coal pillar gradually enters into plastic failure, which cannot fully support the immediate roof. At this time, the cantilever length of the immediate roof is increased from l to l + b + c, the weight of cantilever increases from G1 to G2, and the clamped support point of the cantilever beam is also transferred from point A to point B. The energy on the cantilever structure will be transferred to the coal body.

Similarly, the bending moment of the cantilever structure at point B is:

where M3 is the bending moment of roadway supporting force at point B; M4 is the bending moment of coal pillar supporting force at point B; b is the width of roadway; c is the width of coal pillar; fz is the supporting force of roadway support; fh is coal pillar support force; K is the coal pillar support coefficient.

According to the above analysises (ignoring the energy loss), the amount of work done by the immediate roof at point B is equal to the deformation energy transferred from the immediate roof to the coal wall, which is:

It can be seen from Eq. (10) that b and c are constants, and the energy accumulated at the coal body is directly proportional to the cantilever length l, and inversely proportional to the fz and fh, respectively.

Based on the above results, in order to reduce the energy accumulated at the coal wall, one can not only reduce the strength of the coal wall, release the accumulated elastic energy and reduce the energy transferred into the immediate floor, but also change the external influencing factors, such as shortening the cantilever length, increasing the support force of roadway and coal pillar.

Failure mechanism of roadway

According to the characteristics of energy accumulation and energy transfer of suspended roof in roadway, the soft floor rock burst model with suspended roof is obtained.

Shown in Fig. 6 is the floor rock burst occurrence process can be divided into energy accumulation area, coal release area and stress affected area. As an additional energy source of floor rock burst, the suspended roof is the main structure that aggravates the occurrence of rock burst, and provides most of the stress and energy.

With the slow sinking of suspended roof, the additional stress exceeds the ultimate bearing value of the coal pillar, and the coal pillar will not play the main supporting role after plastic failure. The whole length of the suspended roof will extend to the coal wall of the roadway, the weight of the suspended roof will increase from G1 to G2, and the length of the suspended roof will increase from l to l + b + c (l + b + c ≫ l). It can be seen from Eq. (10) that the energy generated by the suspended roof will be greatly increased and transferred to the coal wall of the roadway. The coal body will be affected by the combined action of the self-weight of the overlying strata and the additional stress of the suspended roof, a large amount of elastic energy will be accumulated at the coal body and forming an energy accumulation area.

From the previous section, it can be seen that the overlying strata and the suspended roof transfer energy to the soft immediate floor through the coal body. Due to the low strength of the immediate floor and the pressing force from the coal body and the basic floor, the energy can easily reach the bearing limit of the weak floor. The roadway serves as the energy release space, under the combination of hard suspended roof structures, impact coal mass, and soft floor, the floor of the roadway can bulge or deform, resulting in floor impact failure.

Impact energy control technology

Control methods

The analysis of the mechanism of rockburst in soft bottom working faces under suspended roof conditions suggested that the main factors affecting rockburst in roadway include the strength of the roof, floor, as well as the suspended roof structure. Therefore, the control methods for rockburst are determined based on the above factors.

-

(1)

Relief of pressure on the roadway side.

Loosening treatment should be carried out on both sides of the roadway, such as blasting pressure relief, that reduce the vertical stress on both sides of the roadway, transfer the stress of the coal body edge of the roadway to the depth of the coal body, and reduce the stress and energy at the coal wall.

-

(2)

Destruction of suspended roof.

As an additional energy source for strong impact, the suspended roof structure not only increases the stress on the coal pillars in the roadway, but also increases the force of the roof on the coal wall, which is an important factor to aggravate the occurrence of strong rock burst. Drilling and cutting the roof to release pressure, transforming it into an ideal structure non-suspended roof, eliminating the stress generated by the suspended roof reduce the energy accumulated at the coal wall.

-

(3)

Relief of pressure on the roadway floor.

Due to the accumulation of elastic energy in the suspended roof structure transmitted to the weak direct bottom through the coal body and protruding from the roadway floor, the floor pressure relief method can be used to weaken this phenomenon. In general, the pressure relief groove is excavated on the bottom plate to cut off high-level stress transmission and transfered to the deeper hard bottom plate. This method can slowly release the energy of the floor, which is conducive to releasing the accumulated elastic energy in the floor and slowing down the occurrence of rockburst.

Engineering application

According to the above theoretical analysis, preventive measures are utilized for the floor rock burst of return airway in 1306 working face.

-

(1)

Pressure relief at side and floor plate.

Borehole blasting is carried out on the roadway side. The hole depth is 8.0–0.0 m, the hole diameter is 42 mm, the drill hole is inclined upward 3–5°, the drilling distance from floor is 1.2 m, the spacing between the two holes is 5 m, the explosive amount is 1/2 –1/3 of the hole depth.

In the middle of the roadway floor, pressure relief groove is excavated along the roadway, the groove width is 0.4–0.5 m, the groove depth is 1.4 m, and the distance between the two grooves is 5.0 m, and cover the relief groove to ensure the integrity of the roadway, as shown in Fig. 7.

-

(2)

Large diameter hole cutting top.

Large diameter boreholes are arranged in the suspended roof area of the roadway to cut off the roof, shorten the length of the suspended roof, and reduce the transmission of additional energy of the suspended roof. The drilling depth is 15–18 m, the hole diameter is 110 mm, and the distance between the two holes is 1.0–2.0 m, the borehole is perpendicular to the roof (Fig. 8).

Engineering verification

The pressure relief effect of floor rock burst in return laneway of 1306 working face was tested by drilling cuttings method. Boreholes are drilled in the return laneway. The diameter of the borehole is 42.0 mm, the depth is 7.0 m, the spacing is 8.0 m, the drilling distance from bottom is 1.2 m, and the drilling direction is vertical to the roadway, distance between borehole 1 and the mining face is 35 m, as shown in Fig. 9.

As shown in Tables 2 and 3; Fig. 10, before pressure relief, the average coal dusts is 3.0 kg/m and the maximum is 3.1 kg/m, which has reached the critical value of rock burst (the critical coal dusts is 3.1 kg/m). After the pressure relief, the average amount of coal powder is reduced to 2.6 kg/m, which is far less than the critical coal quantity. The measured data show that the danger of rock burst in the roadway is eliminated and can be safely exploited.

Conclusions

-

(1)

By analysis of the complex conditions of hard suspended roof, impact coal mass, and soft floor, it is concluded that the energy release caused by soft floor failure is the basic cause of rock burst, and the suspended roof is an important factor to aggravate the damage of the floor. The stress distribution law of soft floor under the condition of suspended roof is obtained by theoretical analysis. Compared with normal coal seam, the suspended roof structure of soft floor can increase the abutment pressure at coal wall, shorten the distance between peak value and roadway, and increase the influence range of abutment pressure.

-

(2)

The energy accumulation model of roadway floor is constructed, and the energy accumulation and release process are explained by elastic mechanics. Through the mechanical model of suspended roof, the energy generated by rectangular cantilever structure is directly proportional to the cantilever length, and inversely proportional to the supporting force of roadway and coal pillar. The mechanism of rock burst in soft floor coal seam under the suspended roof structure is also analyzed.

-

(3)

According to the mechanism of rock burst in soft floor coal seam, the prevention measures of rock burst are adopted for the return airway of working face, including side-bottom pressure relief and roof cutting by large diameter drilling hole, which is verified by drilling cuttings method. The coal dusts in the three boreholes of the coal wall are reduced from 2.9 kg/m, 3.1 kg/m, 3.0 kg/m to 2.5 kg/m, 2.6 kg/m, 2.7 kg/m respectively, and the average amount of coal dusts is reduced from 3.0 to 2.6 kg/m, which is far less than the critical value. Through the application of combined prevention measures, the rockburst of the roadway coal body has been eliminated, the working face has achieved safe mining, and the economic benefits of the coal mine have been improved.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Zhou, J., Zhang, Y. L., Li, C. Q., He, H. N. & Li, X. B. Rockburst prediction and prevention in underground space excavation. Undergr. Space. 14 (02), 70–98 (2024).

Gale, W. J. A review of energy associated with coal bursts. Int. J. Min. Sci. Technol. 28 (05), 755–761 (2018).

Kan, J. L., Dou, L. M., Li, X. W., Li, J. Z. & Chai, Y. J. Investigating the destressing mechanism of roof deep-hole blasting for mitigating rock bursts in underground coal mines. Geomat. Nat. Hazards Risk. 13 (01), 2508–2534 (2022).

Simser, B. P. Rockburst management in Canadian hard rock mines. J. Rock Mech. Geotech. Eng. 11 (05), 1036–1043 (2019).

Pan, Y. S. & Wang, A. W. Disturbance response instability theory of rock bursts in coal mines and its application. Geohazard Mech. 1 (01), 1–17 (2022).

Yang, H. R., Lian, Q. W., Shang, J. & Chen, X. L. Numerical simulation study of the effect of fine view pore structure on rock burst. Minerals 13 (02), 146 (2023).

Yang, C., Zhu, S. Y., Wang, Z. G. & Li, F. L. Deformation and failure of floor in mine with soft coal, soft floor, hard roof and varying thicknesses of coal seam. Eng. Fail. Anal. 115, 104653 (2020).

Charlie, C., Li; Zhao, T. B., Zhang, Y. B. & Wan, W. K. A study on the energy sources and the role of the surrounding rock mass in strain burst. Int. J. Rock. Mech. Min. Sci. 154, 105–114 (2022).

Xu, P. B., Shao, J. J., Fan, D., Chang, J. H. & Zhang, N. Analysis of pressure relief effect of borehole in rock burst mine. Energy Rep. 8 (S2), 156–161 (2022).

Lyu, P. F. & Geng, Y. J. Unified mechanism of rock burst induced by coal mine earthquake and its activity and response characteristics. Shock Vib. 1–14 (2023).

Zhou, J. L. et al. Mechanism and prevention of coal bursts in gob-side roadway floor under thick and hard roof in the deep mining area of Ordos. Int. J. Coal Sci. Technol. 11 (01), 80–101 (2024).

Wang, G. F. et al. Rockburst mechanism and control in coal seam with both syncline and hard strata. Saf. Sci. 115, 320–328 (2019).

Zhang, J. W., Dong, X. K., Bai, J. J. & Jia, L. L. The mechanism and prevention of rockburst induced by the instability of the composite hard-roof coal structure and roof fractures. Eng. Fract. Mech. 310 (11), 110512 (2024).

Wang, J., Ning, J. G., Jiang, J. Q., Bu, T. T. & Shi, X. S. Research on the energy criterion for rockbursts induced by broken hard and Thick rock strata and its application. Geotech. Geol. Eng. 35 (02), 731–746 (2017).

Song, C. H. et al. Moment tensor and stress field inversions of mining-induced seismicity in a thick-hard roof zone. Rock Mech. Rock Eng. 57 (03), 2267–2287 (2024).

Zou, J. P. et al. Effective evaluation of deep-hole blasting for controlling strong tremors induced by deep coal mining-A case study. Int. J. Rock Mech. Min. Sci. 159 (SC), 1–12 (2022).

Liu, W. J., Yang, K., He, X., Zhang, Z. N. & Xu, R. J. Mechanism and control technology of rockburst induced by thick hard roof and residual coal pillar: A case study. Geofluids 2023(1), 1–16 (2023).

Zhang, D. et al. Energy evolution law during failure process of coal–rock combination and roadway surrounding rock. Minerals 12 (12), 1535–1552 (2022).

Zhang, W. L. et al. Fracture analysis of multi-hard roofs based on microseismic monitoring and control techniques for induced rock burst: A case study. Arab. J. Geosci. 12 (24), 847–854 (2019).

Hu, X. C. et al. Experiment on rockburst process of borehole and its acoustic emission characteristics. Rock. Mech. Rock. Eng. 52 (03), 783–802 (2019).

Wu, W. D. et al. Investigation into pressure appearances and hydraulic fracturing roof-cutting technology in mining working face under residual pillars: A case study. Energies 16 (09), 3914 (2023).

Sun, Y. X., Fu, Y. K. & Wang, T. Field application of directional hydraulic fracturing technology for controlling thick hard roof: A case study. Arab. J. Geosci. 14 (06), 1–15 (2021).

Tai, Y., Yu, B. & Kuang, T. J. An innovative technology of fracturing hard strata from the ground for precontrol of rock burst in a coal mine. Energy Sci. Eng. 11 (02), 565–584 (2023).

Fuławka, K., Pytel, W. & Mertuszka, P. The effect of selected rockburst prevention measures on seismic activity-case study from the Rudna copper mine. J. Sustain. Min. 17 (01), 1–10 (2018).

Huang, W. P. et al. Research on the prevention and manage of rockburst in deep-seam mining roadways. Energy Sci. Eng. 12 (10), 4260–4277 (2024).

Acknowledgements

H.W. was supported by the Fundamental Research Program of Shanxi Province(20210302124487) and Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi(2021L587).

Author information

Authors and Affiliations

Contributions

Conceptualization, H.W. and K.W.; methodology, H.W.; data curation, D.S. and D.Q.; writing—original draft preparation, H.W.; writing—review and editing, H.W. and D.S.; visualization, H.W.; project administration, H.W., K.W. and X.L. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wei, H., Li, X., Shi, D. et al. Appearance mechanism and prevention technology of impact energy of roadway floor on additional load. Sci Rep 15, 12882 (2025). https://doi.org/10.1038/s41598-025-96798-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-96798-7