Abstract

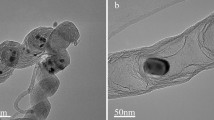

This study utilized solid waste-copper slag to substitute 30% cement to produce composite cementitious materials. To achieve the desired performance standards, single-doped PPF or CF, and single-doped or double-doped multi-wall carbon nanotubes (MWCNTs)/graphene oxide (GO) have been used as reinforcing materials to prepare environmentally friendly copper slag-based cement (CSC) composites. SEM analysis was conducted to investigate and assess the ordered structure of MWCNTs and GO. Subsequently, a solution of MWCNT/GO nanoparticles was generated by dispersing MWCNT/GO with a gum Arabic (AG) surfactant. Following ultrasonic treatment, the clear liquid was collected and combined with 30% solid waste copper slag and 70% cement to form a composite cementitious matrix. The inclusion of carbon nanomaterials enhanced the sample’s compressive strength by over 41.6% compared to the control samples. It was equivalent to 97.1% of blank group C0, and the bending strength was about 93.8% of C0 group of the same age. In addition, the hydration products, gelation and crystallization, pore structure and microstructure of CSC materials were analyzed by quantitative X-ray diffraction (QXRD), scanning electron microscopy (SEM), fourier transform infrared (FTIR) spectroscopy, and nitrogen adsorption specific surface area and porosity measurement (BET). The CSC sample, with double-doped optimized MWCNT/GO exhibited the most favorable microstructure and strongest nucleation effect. As a result, the hydration degree of the CSC cementitious material was improved, which contributed to the formation of a greater amount of amorphous calcium-silicate-hydrate (C–S–H) phase, a finer C–A–S–H phase. The samples doping a combination of MWCNTs and GO exhibited synergistic enhancement. This novel nanocomposite cementitious material incorporated carbon nanoparticles into the mixture with solid waste, resulting in a solid composite cementitious material. The production of reinforced concrete is based on solid waste and demonstrates significant environmental advantages.

Similar content being viewed by others

Introduction

The generation of copper slag, a byproduct of mining and metallurgical industries, is steadily increasing, and its disposal as waste poses significant environmental challenges1,2,3. With abundant copper resources and the largest copper mine, Jiangxi serves as a major province of mining and metallurgy in China. Copper mine reserves have reached 9 million tons, accounting for 22% of total reserves. Copper slag consists of waste residue produced during the copper smelting process, with estimates showing that for every ton of refined copper generated, 2.2 tons of copper slag will be discharged. The annual discharge of copper slag reached 2857.8 tons in 2023 alone. Similar to other types of waste4,5,6, copper slag can also be employed as an aggregate or admixture to prepare copper slag-based cement composites (CSC) in the construction industry7,8. Numerous nations have accumulated a significant quantity of copper slag (CS) due to its low utilization efficiency, with this slag predominantly stored in uncovered heaps. This waste occupies significant amounts of valuable land, resulting in environmental pollution, with the primary chemical constituents of cement composites based on copper slag. Copper slag powder composite cement conforms to the standard of Portland cement, with better performance than ordinary Portland cement9,10,11.

The CS powder exhibits low pozzolanic activity, resulting in a small cohesive force between the particles and the hydration products, and the adsorption of water molecules is affected, which exhibits a slight effect on reducing water condensation12. With 30% CS instead of the same proportion of cement, the cement clinker is diluted, the induction period is prolonged, and the initial setting and final setting time of CSC composite cement are prolonged. As a construction engineering material, CSC will inevitably produce micro-cracks during the service life of the project, similar to all cement-based materials. The expansion of micro-cracks and even fracture development will destroy the integrity of the concrete structure and reduce durability13,14. Specifically, the cracking process in cement initiates with isolated nano-cracks, with these cracks combining to form micro-cracks, which in turn form macro-cracks. Traditional fibers, such as chopped carbon fiber (CF) or acrylic fiber (PPF), exhibit good crack resistance and inhibit crack propagation on a macroscale, however, they remain ineffective in delaying the initiation of microcracks. To address this limitation, a growing trend in numerous applications involves the utilization of finer, randomly dispersed carbon nanomaterials15,16,17,18.

Progress in nanotechnology has produced nano-reinforced materials, such as carbon nanotubes (CNTs) and graphene oxide (GO), which transfer the enhancing behavior from the macro level to the nanoscale. Compared to traditional fibers19, MWCNTs exhibit excellent mechanical properties and high aspect ratios as one-dimensional toughening materials19,20,21,22. The unique mechanical properties of these materials make them suitable as reinforcing materials to develop high-quality cement-based composites. Zhang et al. employed two distinct classes of carbon nanotubes—hydroxylated carbon nanotubes (CNTCOOH) and conventional multi-walled carbon nanotubes (CNTPL)—to investigate the influence of carbon nanotubes on the mechanical integrity of cement-based tailings backfill (CTB). The leading inferences revealed that: the bridging effect of CNTs inhibited significantly the expansion of the cracks occurred within CTB specimens, representing good integrity after failure23. Qin, R.‘s research shows that when the micro-cracks of CNT composite cementitious materials are generated, CNT changes the fracture process of cement-based materials, significantly increases the fracture energy, thereby improving the overall mechanical properties, and finds a nanoscale interface transition zone24. Compared with ordinary mortar and composite samples prepared with ordinary surfactants, the flexural and compressive strength of functionalized SWCNT samples at 56 days increased by 17% and 23%, respectively, and the stiffness, fracture energy and ductility of all CNT reinforced samples were significantly higher25. The geopolymer slurry with 0.1 wt% functionalized MWCNTs and 30% fly ash replaced by GBFS has higher compressive and flexural strength and lower water absorption capacity26.

Researchers have assessed the dispersion of CNTs and other nanomaterials in cement-based materials to develop crack-free and durable building materials, with the theoretical strength and elastic strain capacity of CNTs exhibiting values 100 and 60 times that of steel23,24,25,26, respectively. These attributes position CNTs as an optimal nano-reinforcement material for the fabrication of high-strength, high-performance composite materials. Incorporating high concentrations of CNTs into cement composites may cause the CNTs to cluster together, leading to agglomeration in the microstructure, resulting in pores forming within the hydration matrix. Due to powerful van der Waals interactions between their particles, CNTs tend to form entangled clusters, causing them to agglomerate and bond together. Therefore, the uniform dispersion of CNTs in cement materials may serve as the most critical issue for the successful production of CNT/cement composites27.

Similar to CNTs, GO possesses a two-dimensional structure with a unique atomic thickness and excellent mechanical properties28, with an estimated intrinsic strength and Young’s modulus of 100 GPa and 1 TPa, respectively. MWCNTs and GO can be physically dispersed into aqueous solution through the hydrophilic and hydrophobic groups of AG, and the unique structure and high specific surface area of GO may be beneficial to improving adhesion between graphene sheets and cement products. Mohsen et al. demonstrated that the compressive strength and flexural strength increased by 20.2% and 57.33%, respectively, when 0.04 wt% GO was added to cement slurry29.

This effect is attributed to the presence of oxygen-containing functional groups, which offer adsorption sites for hydration product, thereby facilitating the formation of the crystal nuclei of cement hydrates. Kaur et al. found that superplasticizer-stabilized GO and functionalized CNTs as three-dimensional hybrid reinforcements had a positive synergistic effect on the mechanical properties and pore structure refinement of cement nanocomposites. The results showed that the compressive strength and splitting tensile strength of the nanomaterial-optimized samples increased by 43.08 and 52.20%, respectively30. In addition, the chemical reaction and covalent bonds between the cement matrix and GO functional groups led to accelerated hydration development, a refined pore structure, and enhanced bonding between the cement and fiber, thus, improving the load transfer of the cement composites. Bhojaraju, C. et al. ' s study determined the effect of graphene (G) and graphene oxide (GO) on the corrosion resistance of cement composites31. Zhang, S., & Zhang, Z. By adding 0.025% EGO AACM grouting material compared with cement water glass grouting material, obtained 7-d age compressive strength and flexural strength, respectively, increased by 161.2% and 2.9%32. The GO / C obtained by Qiao, W.et al.by electrophoretic deposition (EPD) method has a significant enhancement effect. The single fiber pull-out test results show that GO/CF15/60 (15 V for 60 min) has the best bonding performance with the cement matrix, and the bonding strength of the matrix is increased by 262%33 compared with the untreated CF sample.

In recent years, research on the reinforcing effect of MWCNT/GO on cementitious materials has attracted increasing attention. Lu et al. demonstrated that the incorporation of an equal amount of GO and CNTs (hybrid by mass ratio) contributed to the dispersion of CNTs in aqueous solution, resulting in a synergistic enhancement in the mechanical properties and microstructure of cement pastes, which was significantly better than an equal amount of CNTs or GO alone34. CF and PPF continue to be used in engineering technology as mainstream reinforcing and toughening materials, receiving extensive attention from various researchers. In terms of improving the comprehensive performance of copper slag composite cementitious materials, which serve as the most effective selected reinforcing material, no systematic comparative study has determined the mass ratio of reinforcing materials doped with CF/PPF fibers, single and mixed MWCNT/GO, and the resulting performance improvement and correlation between dispersibility and mechanical properties. Although carbon nanomaterials have significantly contributed to improving the mechanical properties of cementitious materials, the mechanical behavior, hydration morphology, and pore characteristics of solid waste copper slag composite cementitious materials have not been studied.

The present investigation evaluated CSC composites fabricated with the substitution of 30% cement by copper slag. According to the optimized ratio we investigated single-doped PPF (0.1 wt%) and single-doped CF (0.1 wt%)/ordinary reinforcing materials, single-doped MWCNTs (0.08 wt%) and single-doped GO (0.04 wt%), and double-doped carbon nanomaterials (0.08 wt% MWCNTs: 0.04 wt% GO), which served as the working performance of the composite slurry matrix. We also examined the optimization of mechanical properties, microstructure, and porosity.

Experiment

Raw materials

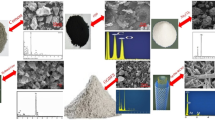

Copper slag was derived from Jiangxi Copper Co., Ltd. It was a high-temperature water-quenched waste residue with small particle size and black, dense, hard, and wear-resistant glass phase35. P٠O42.5 ordinary Portland cement was produced by Jiangxi Conch Cement Co., Ltd. By testing the chemical composition of copper slag and cement36, the chemical composition (mass fraction) of copper slag powder and the chemical composition (mass fraction) of cement are shown in (Table 1), referring to the ‘Cement Chemical Analysis Method (GB/T176-2008)’, the chemical composition of cement is mainly CaO and SiO237, and the chemical composition of copper slag is mainly Fe2O3 and SiO2, while the content of CaO is less.

Figure 1 shows the microscopic morphology of the raw material. It can be seen that the copper slag (Fig. 1a) is similar to the cement particle size (Fig. 1b), and the particles are irregular and randomly distributed. MWCNTs are cluster-like filaments (Fig. 1c) and GO is like a folded smoke-like cloud (Fig. 1d). The physical properties of MWCNTs and GO are shown in (Tables 2 and 3), respectively. AG (C12H7ClN2O3, AR, molecular weight 2.5 × 105~1 × 106) was purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). The composition of AG is as follows: d-galactose 44.0%, l-arabinose 24.0%, d-glucuronic acid 14.5%, l-rhamnose 13.0%, 4-O-methyl-d-glucuronic acid 1.5%, protein 2%, impurity 1.0%. The dispersion medium was distilled water.

PPF and CF were purchased from Shenzhen Jia Sheng New Material Co., Ltd. PPF is a synthetic fiber like white wool. It exhibits good strength, thermal properties, chemical properties and other related ductility properties, and it is utilized in the construction industry to enhance the durability of building materials and prevent the formation of cracks. The CF is a high-strength and high-modulus fiber with a carbon content of 97%, and it possesses the characteristics of high temperature resistance, friction resistance, thermal conductivity and corrosion resistance38. Both PPF and CF have good acid and alkali resistance in terms of chemical properties. The morphology is shown in (Fig. 2), and the specific parameters are shown in (Tables 4 and 5).

The samples were tested by SEM (German ZEISS Sigma 300), and the specific surface area and porosity (BET, Micromeritics ASAP 2460), to understand microstructural characteristics and surface morphology of the cement paste39.

Seven groups of cementitious material samples with different ratios (including a group of blank samples C0) were prepared, and the material ratio was shown in (Table 6). Nanomaterial dispersions mixed with cementitious materials need to be prepared in advance. Toughening materials need to use the same proportion of AG-assisted dispersion in the slurry, and the amount and proportion of nano-materials were MWCNTs (0.08 wt%)/GO (0.04 wt%). Initially, AG was completely dissolved using a magnetic stirrer. Subsequently, the nanomaterials were disseminated in the AG solution and thoroughly stirred. Ultimately, the ultrasonic time with a power of 900 W lasted for a minimum of 25 min. The preparation process of the MWCNTs&GO dispersion is shown in (Fig. 3).

The interlocking structure of MWCNT/GO might physically hinder agglomeration39, indicating that GO helped MWCNTs to disperse into AG surfactant dispersion. It was worth noting that the MWCNT/GO hybrid exhibits optimal for dispersion stability. The prepared nanofluid sample is shown in (Fig. 4).

According to the standard GB/T 8074 − 2008 ‘cement specific surface area determination method’, the specific surface area of copper slag-based cement composites was tested by Brinell method. According to the standard GB/T 208–2014 ‘cement density determination method’, the density of copper slag-based cement composites was tested. According to the standard GB/T 17671 − 2021 ‘Cement mortar strength test method (ISO method)’, the flexural strength and compressive strength of cement mortar were tested40. According to the standard GB/T1346-2011 ‘Cement standard consistency water consumption, setting time, stability test method’, the standard consistency water consumption, stability and setting time of copper slag cement composite materials were tested.

Specimens Preparation

The procedure for preparing specimens is illustrated in (Fig. 5). To create a suspension, MWCNTs and GO of the appropriate mass were also added to the AG solution and magnetically agitated for five minutes. A 30-minute ultrasonic treatment with a power of 900 W was employed to enhance the suspension of MWCNTs and GO, which had a volume of 480 ml. MWCNTs and GO were included into the cement slurry at a concentration of 0.08wt. % and 0.04wt. % of the cement mass, respectively. In addition to MWCNTs and GO doped individually, a mixing ratio of 2:1 was determined for GO and MWCNTs.

Dry mixed copper slag cement powder was added for stirring after the MWCNTs & GO suspension was poured all at once to the stirring pot with a water-to-cement ratio (w/c) of 0.4. 120 s of slow stirring, followed by 60 s of fast stirring for casting. Cement mixtures including PPF and CF as single nanomaterials were mixed and poured similarly. At 20 °C and 95% humidity, all samples underwent curing. After demolding (24 h later), the samples were stored in a special curing box for curing to the corresponding age.

Experiments and measurement

Flowability

The fluidity of the composite cementitious material, which is crucial to its pore structure and preparation process, will be impacted by the addition of various reinforcing components. The slump test was performed in accordance with China standard(GB/T 2419 − 2005)to evaluate its fluidity. The ideal cone should be placed in the center of a wet, level glass plate. Slowly poured the fresh mixture into the cone until the top edge was flat. Following a 30-second vibration period, the cone was leveled vertically, and the two diameters of the newly mixed pastes were measured vertically. The fluidity could be inferred from the average value.

Compressive and mechanical property

According to the China standard (GB/T 17671 − 2021), the mechanical property was tested by YAW-300 cement pressure27 testing machine to test the compressive strength of the samples cured for 3-d, 7-d and 28-d. The compressive strength test of 40 × 40 × 40 mm3 cube test block was carried out at a loading rate of 1 kN / s, and the average value was taken41. The 40 × 40 × 160 mm3 specimen was tested to evaluate the mechanical property on a three-point bending test system with a span of 100 mm and a stroke control of 0.2 kN / s.

X-ray diffraction (XRD)

The sample fragments after the test in Sect. 2.3.2 were ground into powder. X-ray diffractometer (Cu-Kα, 40 kV, 40 mA, Japan Rigaku Smart Lab SE) was used to analyze the mineral phase of the hydration products of the sample. The angle range, scanning speed and increment were set to 5 °− 90 ° (2θ), 1 °/min, 0.02 °, respectively. The quantitative phase composition of the samples was determined through Quantitative X-ray diffraction (QXRD) Rietveld refinement analysis data, maintaining consistent instrumental parameters throughout the measurements. Data processing and refinement were conducted utilizing both Jade 6.0 and TOPAS 6 software packages, with phase identification achieved by matching experimental diffraction patterns against reference standards from the PDF-4 + database (ICDD).

Scanning electron microscope (SEM)

The microstructure of different samples was detected and observed by electron microscope (Zeiss Gemini 300), and the composition of the micro-area was analyzed. Before testing the sample, the sample was dried and cut into tiny flakes.

Specific surface and porosity

The cement slurry samples were subjected to N2 adsorption isotherm experiments. After drying and degassing at 105 ℃, the experiment was carried out. The N2 adsorption isotherms strongly depend on the sample preparation method. The N2 adsorption and desorption isotherms were plotted using the experimental data. The CSC specimens were measured according to the China standard (GB/ T19587-2017). Based on Langmuir and BET theory, two types of specific surface areas were calculated. The distribution of mesoporous size was calculated according to BJH theory, and the PSD of micropores was calculated by HK theory. When the relative pressure of the test was close to 1 but not completely 1, the specific surface, porosity and other indicators were tested according to the N2 adsorption rate42.

Fourier transform infrared spectroscopy

To examine and confirm the hydration products, the samples were subjected to testing and analysis using FTIR with the Ameriaca Thermo Fisher Scientific Nicolet iS20 instrument. The absorption test was carried out in the wavenumber range of 400 ~ 4000 cm− 1 by potassium bromide tableting method. The transmittance data were converted by OMNIC program and then analyzed in depth.

Results and discussion

Fluidity of the CSC pastes

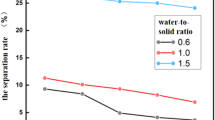

The influence of cement paste and copper slag composite cement paste with different reinforcing materials on the fluidity is shown in (Fig. 6). It could be found that the fluidity decreased with the addition of ordinary reinforcing materials and increased with the addition of nanomaterials. The C0 paste shows the maximum fluidity of 226 mm, while that of CSC1 without any reinforcing material was 209 mm, and the fluidity was slightly reduced by 7.5%. For CSC2 samples with PPF fibers and CSC6 samples with CF fibers, the fluidity data were 175 mm and 187 mm, respectively, which decreased by 22.6 and 17.3% compared with C0. The fluidity of the CSC paste is decreased by the doped nanomaterials.

When MWCNTs were introduced alone, the CSC3 sample’s fluidity decreased by 15.5% to 191 mm, which was considered low. The CSC5 samples doped with GO and the CSC4 samples doped with MWCNT/GO had fluidity data of 192 mm and 197 mm, respectively. These values were 15.0 and 12.8% less than the C0 samples, while the fluidity was marginally less than the CSC1 samples.

As per the China standard (GB/T 2419 − 2005), if the water-binder ratio is 0.5, the flowability of cement mortar shall be at least 180 mm. The fluidity of the cement mortar in the other samples exceeded 180 mm, which was in accordance with the specifications, in addition to the CSC2 sample. The addition of copper slag to the composite cement slurry, as well as the incorporation of single and double nano-reinforced materials, resulted in a similar fluidity of the slurry compared to pure cement36. These additions also helped regulate the fluidity of the cement slurry. The composite solid waste admixture of doubly doped nanoparticles could be used to generate a slurry that met the flow performance requirements.

PPF fibers exhibit hydrophobic characteristics and possess inadequate adhesion with cement paste. Furthermore, these fibers have a low surface free energy and a highly smooth surface structure, which can lead to easy slippage or debonding from the paste. Upon mixing with cement paste, PPF fibers tend to agglomerate, causing a minor impediment to the movement of paste, thereby reducing fluidity. Both PPF and CF fibers exert a hindrance on slurry flow, with PPF demonstrating a slightly greater inhibitory effect. Although the incorporation of nano-reinforced materials introduces a minimal resistance to slurry particles, the introduction of uniformly dispersed AG nanomaterials enhances paste viscosity, thereby negatively affecting the fluidity of the fresh paste.

XRD result

Quantitative X-ray diffraction (QXRD) Rietveld refinement technique with internal standard method43 was used to analyze the hydration products of blank samples C0 and CSC samples at 28-d ages of seven samples, as shown in (Fig. 7a). According to the Debye-Scherrer formula44, the crystal phase and component content of hydrates were quantitatively analyzed. On this basis, the approximate proportion of amorphous substances was further analyzed and calculated. Most of these amorphous substances are C-(A)-S-H gels30.

XRD was used to qualitatively and quantitatively evaluate the content of some characteristic mineral crystal phases, and the formation of amorphous hydration products such as C-S-H gel and C-A-S-H in the slurry was tested and evaluated45. The hydration degree of silicates (i.e., C3S and C2S) in the sample can be evaluated by evaluating the peak intensity of the strong Portlandite peak at 2θ = 18.02 °. However, the amount of formed C-S-H and C-A-S-H can be predicted by testing the reduction of peak strength of C3S components at 2θ = 32.12 °45,46,47,48,49.

CSC4 exhibits the most complicated crystal phase of any of the seven samples, as seen in (Fig. 7b). There are approximately a dozen main crystal phases, including, Calcium Silicate (Ca3SiO5), Calcium Silicate (Ca2SiO4), Calcium Aluminum Oxide (Ca3Al2O6), Brownmillerite (Ca2(Al, Fe+ 3)2O5), Calcite (CaCO3), Dolomite (CaMg(CO3)2), Quartz(SiO2), Portlandite (Ca(OH)2), Ettringite(Ca6Al2(SO4)3-(OH)12·26H2O), Fayalite(Fe2SiO4), Magnetite(Fe3O4). Furthermore, the CSC4 sample included 50.4% amorphous phase (more than the C0 sample).

The number of crystal phase types in CSC4 samples is not significantly different from those of CSC2, CSC3, CSC5, and CSC6. It is suspected that active dispersant (AG) is also added to the five CSC2, CSC3, CSC4, CSC5, and CSC6 samples. The CSC1 sample contains a minimal number of crystal phases and a low concentration of amorphous phases. It is thought to be caused by the lack of nano-dispersed active agents and the inclusion of just 30% copper slag replacements with poor activity.

QXRD analysis reveals five peaks with higher intensity in CSC4 sample’s main crystal phase components: 18.02 ° (2θ), 31.02 ° (2θ), 26.62 ° (2θ), and 19.40 ° (2θ), representing Portlandite, Dolomite, Quartz, and Calcite, respectively. This is slightly different from the XRD image analysis data for the other CSC2, CSC3, CSC5, and CSC6 samples. The Portlandite content in the CSC4 sample remains lower than that in the C0 sample. If the hydration activity of the sample is determined by the concentration of Portlandite, the CSC4 sample is still inferior to C0.

The CSC4 sample’s major crystal phase composition comprises four peak angles: 32.12 ° (2θ), 32.74 ° (2θ), 32.92 ° (2θ), and 33.94 ° (2θ), representing the five mineral phases of Ca3SiO5(C3S), Ca2SiO4(C2S), Ca3Al2O6(C3A), and Brownmillerite (C4AF). These are the primary components of cement found in all samples. In comparison to other samples, the CSC4 sample has the minimum C3S content, indicating that the hydration degree is the best.

The peak angle positions for the typical crystal phases that may still be detected with low intensity are 35.94 ° (2θ) and 35.60 ° (2θ), representing Fayalite (Fe2SiO4) and Magnetite (Fe3O4). These are the primary components of copper slag, as evaluated in five samples of CSC1, CSC2, CSC3, CSC4, CSC5, and CSC6. These two mineral phases were not found in the pure cement C0 sample. Compared to the other four samples, the CSC4 sample has 0.6 wt% of Fe2SiO4 and Fe3O4, which is much lower than the CSC1 sample. It is possible that the Fayalite (Fe2SiO4) mineral phase participates in the hydration reaction to generate the amorphous phase. In addition to the normal amorphous phase of C-A-S-H and C-S-H gel, the sample’s hydration products contain C-F-S-H50. It may be the following reactive process:

The CSC4 sample was optimized by adjusting the MWCNT and GO mixing ratio. CSC4 outperforms all other samples at forming the amorphous phase. The CSC4 sample had the highest amorphous phase content (50.4 wt%), surpassing the 47.4 wt% of the C0 sample, 43.9 wt% of the CSC3 sample containing single MWCNTs, and 46.6 wt% of the CSC5 sample containing single GO, as shown in (Fig. 7c).

The test findings demonstrate that the optimal amount of nanomaterials can improve the content of amorphous C–S–H and C–A–S–H in the composite cement matrix, as well as promote hydration of the slurry51. It is worth noting that the CSC4 sample with the best MWCNT to GO ratio facilitates the hydration process of the composite cementitious material. CSC2 and CSC5 samples doped with PPF and CF have lower amorphous phase content than nano-modified samples. The CSC1 sample without reinforcing material and active agent had the lowest activity and amorphous phase content. Furthermore, the crystal phase type and amorphous phase content of the sample are related to the strength of the sample slurry. This is supported by the mechanical strength results from samples C0 and CSC4. The rationale could be that AG-actively distributed MWCNT and GO serve as nanocomposite fillers, nucleation sites, and bridging media.

They also provide an ideal reaction field for the development of hydration products. Hydration products adhere to the surfaces of carbon nanomaterials, which is consistent with earlier research findings51. MWCNTs not only start nucleation but also spread across GO sheets, in line with earlier findings52. The hydrophilic group of the active dispersant AG and the cement matrix’s C-(A / F)-S-H gel chain form a three-dimensional network that promotes the creation of a solid cementitious matrix53.

Mechanical properties of the CSC

Seven sets of experiments were conducted to verify the favorable impact of the ideal hybrid ratio of MWCNT/GO on the mechanical qualities of solid waste copper slag cement paste. AG was introduced to enhance the dispersion of MWCNTs, followed by the addition and dispersion of GO to create a mixed dispersion of MWCNTs and GO. Seven samples were subjected to compressive strength testing. The mechanical strength of the CSC composite pastes in the blank group C0 and six other groups is depicted in (Fig. 8). The addition of 30% copper slag resulted in a decline in the mechanical characteristics of CSC1, as compared to sample C0. The compressive strength of the material at 3-d, 7-d, and 28-d reduced by 19.2, 49.3, and 40.8% respectively. Similarly, the flexural strength declined by 38.1, 36.7, and 36.1% respectively.

The addition of toughening PPF, CF materials, and MWCNT/GO nanoparticles caused a considerable improvement in the mechanical characteristics of the samples, as compared to CSC1. In comparison to the C0 sample, the 3-d compressive strength of the CSC2 sample only exhibited a 5.5% rise, while the other ages showed a considerable loss compared to the blank sample. Specifically, the 28-d compressive strength declined by 24.6%. The 3-dimensional flexural strength experienced a reduction of 27.1%, while the 28-day flexural strength saw a fall of 28.5%. The compressive strength of the CSC6 sample declined by 4.9% at 3-d and by 23.3% at 28-d. Similarly, the flexural strength decreased by 33.9% at 3-d and by 18.7% at 28-d. The compressive strength and flexural strength of CSC1 samples exhibited the most noticeable improvement compared to CSC6 samples. The early compressive strength of CSC3, CSC4, and CSC5 samples with nano-materials, whether it was single-doped GO, MWCNTs, or mixed GO/MWCNTs hybrid mixture, exhibited an increase in comparison to CSC1. Specifically, the compressive strength of the CSC4 sample containing a combination of MWCNTs and GO (with a weight% of 0.08 wt% MWCNTs and 0.04 wt% GO) was more than 41.6% higher than the CSC1 group at the same age. Additionally, the compressive strength of CSC4 sample at 7-d and 28-d also reached 96.2% and 97.1% of the C0 group, respectively. Additionally, there was an increase in the flexural strength21. The 3-dimensional cement paste exhibited superior flexural strength compared to the C0 blank group at the same age, surpassing it by a margin of 15.3%. Furthermore, the flexural strength at 28-d exceeded that of the blank group by 2.08%.

The compressive strength of the sample CSC3,3-d doped solely with CNTS surpassed 35.2% of the blank group C0 at the same age. Additionally, the compressive strength at 7-d and 28-d also achieved 80.8% and 86.8% of the blank group C0, respectively. When compared to the C0 blank group of the same age, the 3-d flexural strength showed a rise of more than 2.5%, while the flexural strength had a small improvement. The 28-d flexural strength was merely 79.2% of the strength exhibited by the C0 group.

The 3-d compressive strength of the CSC5 sample reinforced by GO single-doped exceeded 6.4% of the blank group C0 at the same age. Additionally, the compressive strength at 7-d and 28-d reached 85.1% and 83.6% of the blank group C0, respectively. The 3-d flexural strength of this group exhibited a 0.85% increase compared to the blank group, with a small overall improvement in flexural strength. Despite being smaller than the experimental test results of the blank, the 28-d flexural strength of CSC4 was around 93.8% of the C0 group. When comparing these three nano-toughened samples, as well as CSC2 and CSC6 samples, it was found that the sample CSC4, which included a hybrid mixture of MWCNTs and GO, exhibited superior mechanical capabilities.

The micro-morphology of composite cementitious pastes

Figure 9 displays the SEM pictures of the unaltered sample and the composite material following 28-d of hydration. The C0 microstructure of CF, PPF and double-doped GO/CNT reinforced copper slag composite cement paste and blank sample was analyzed using these microstructures. Figure 9a–h show the presence of CH, C–S–H gel, pores, fractures, MWCNTs, GO, PPF fibers, carbon fiber CF, flake AFm, and needle-like ettringite. The fracture surface of the sample exhibited visible PPF fibers and appeared as white filaments. Figure 9a, b display the standard SEM structures of the C0 sample and CSC1 sample after 28-d, respectively. The unfilled cement sample, devoid of nano-materials or fiber materials, contained a high concentration of hydrated substances and had a rather compact matrix. However, there were several microcracks present in the cross section of the cementitious material. The addition of copper slag resulted in a greater variety of hydration products in the CSC1 slurry, as depicted in (Fig. 9b). This included the formation of aluminum-containing gel and flake AFm. The mild activity and filling action of copper slag contribute to hydration and increase the density of the matrix.

Conversely, in the case of the PPF fiber sample group, it was evident that the PPF was distinctly detached from the composite cementitious matrix. There was a noticeable space between the fiber and the hydration matrix, as depicted in (Fig. 9c, d). The absence of hydrating substances on the surface of PPF fibers indicated that PPF did not contribute to the hydration process of composite cement. In the above image, the PPF’s radial direction was significantly distorted, making it prone to being pulled out from the cementitious matrix. This results in the formation of holes, which suggested that the hardness and strength of PF were inferior to those of cement hydration substances. The PPF might be extracted from the copper slag cementitious matrix. The PPF had poor strength, and both radial and circumferential deformations were noticeable. There was a gap between the PPF and the cementitious matrix, and the matrix section was clearly apparent. The presence of a cavity indicated that the bonding strength between PPF and the cementitious material was minimal or non-existent. Therefore, PPF could only serve as a general anti-cracking substance for cement plastering.

Figure 9e, f represent samples of CSC4 mixed with MWCNT/GO ratios that have been tuned. Observation of nano-scale morphology was attainable. The combination of C–A–S–H gel, needle-shaped Aft, silk-like MWCNTs, flower-shaped GO, and flake Ca (OH)2 created a compact structure. The tight binding between exposed MWCNTs and GO with hydration products was evident. GO sheets adhered to calcium hydroxide crystals through adsorption, while MWCNTs gather in proximity. The hydration gel zone did not contain any re-agglomerated MWCNTs. The optimization of the double doping ratio significantly impacted the dispersion effect.

Due to the inappropriate ratio, the excessive content of MWCNT/GO might sharply deteriorate the material properties, no matter whether it was single-doped or double-doped28. After the two-dimensional flaky GO was cemented with the hydration product, it was embedded in the cement composition in a three-dimensional petal shape. Hydration products seemed to enclose nanoparticles filled with micropores and introduced unfilled pores. GO nanosheets had good embedment in cement hydration products, and provide compatibility and large surface. Thin and ductile geometry mad it easier to cement more hydrated substances.

The schematics of Fig. 9e, f clearly demonstrate the uniform and dense embedding of MWCNTs within the C–S–H or C–A–S–H gel on the CSC microstructure matrix. The gel particles were intricately linked by needle-shaped Aft and wire-shaped MWCNTs, like a combination of matrix entities and woven textiles. The needle-like structure surrounding C-A-S-H was created by MWCNTs participating in the hydration reaction. These MWCNTs could act as bridges, hence increasing the strength properties of CSC4. There was a direct relationship between the amount of hydration products in the CSC sample and the strength result.

The samples containing carbon nanocomposites consisted of either MWCNTs or GO, either separately or in combination. These reinforced CSC materials had the ability to fill gaps and connected fissures at the nanoscale. The SEM images revealed a compact microstructure without any clusters of MWCNTs and GO aggregates. This observation suggested that the dispersion of MWCNTs was improved when mixed with GO, resulting in a more pronounced enhancement effect.

Furthermore, it was noteworthy that GO and MWCNTs tended to intersect and create a unique three-dimensional configuration that was integrated inside the cement matrix. The interlocking phenomenon was likely to significantly enhance the microstructure of CSC4 cement paste samples and enhance the mechanical properties of cement paste. The hydration products in cement, such as C-S-H and CH, were interconnected by GO and MWCNTs, resulting in the formation of a hydration matrix. The outermost layer of MWCNTs and the flat two-dimensional surface of GO established a robust interfacial connection with C-S-H and CH through covalent bonding28.

There were well-dispersed MWCNTs and GO in the hardened cement slurry. The high aspect ratio of MWCNTs could effectively prevent micro-crack propagation and acted as a bridge to anchor the matrix on both sides of the crack with the two-dimensional GO, thereby inhibiting crack surface separation.

This was also consistent with the excellent mechanical properties of the sample. The CF embedded in the hydration products can be seen in (Fig. 9g, h), corresponding to the CSC6 sample doped with CF, next to ettringite and C-S-H gel. And there were some traces around the crack, where CF or ettringite was lifted. In the copper slag cementitious slurry, CF could be used as a micro-aggregate, and CF could also work closely with the CSC matrix to provide good and effective crack resistance. There were many block and angular crystal structures in the cementitious matrix, which could be judged as granular SiO2 crystals and Ca (OH)2, and C-A–S–H cluster gel particles were observed.

The micro-cracks of the cementitious material were reduced, the voids in the matrix were reduced, and the matrix became dense. This indicated that the addition of 0.1 wt% CF could effectively anchor the hydration products. In Fig. 9b, CF was embedded in the cementitious material and closely combined with the composite cementitious material. The strength gain could be attributed to the partial surface of CF participating in hydration.

To enhance the discernment of hydration products within the SEM imagery, energy dispersive spectroscopy (EDS) was employed as a supplementary means. In alignment with descriptions found in the literature, a comprehensive investigation into the correlation between the composition and microstructure of MWCNT/GO nanocomposite cement and CF/PPF composite cement was conducted. For this purpose, EDS analysis was performed on both the 3-day and 28-day samples. The analysis figures are depicted in (Figs. 10 and 11), and the elemental distribution maps are illustrated within the figures. The C-S-H gel is mainly composed of Ca, Si and O, and contains a small amount of Al, S and Fe. The oriented rod-like or needle-like is AFt, the irregular hexagonal flake is Ca (OH)2, and the C-S-H gel is an amorphous hydration product. In the slurry, MWCNT & GO nanomaterials have been cemented with hydration products. Through the EDS surface scan data of the sample, 7.64 wt % of C element was measured in the cementitious matrix, which can be judged that the nanomaterials have been interlaced with ettringite and C-S-H gel.

In the early age 3-d samples, petal-like and worm-like hydration products can be observed in the SEM images, as shown in (Fig. 10). Through EDS test, 12.90 wt % of element C was tested in the cementitious matrix containing GO nanomaterials, and 20.42 wt % of element C was tested in the cementitious matrix containing MWCNT nanomaterials. MWCNT & GO nanomaterials can speculate petal-like and worm-like hydration products, which are petal-like hydration products with GO and MWCNT as the crystal nucleus, respectively. The test of the characteristic area of the early age sample shows that worms and petal-like hydration products are common. EDX test data showed the presence of carbon elements, but the content was different, as shown in (Figs. 12 and 13).

It can be speculated that it may be due to MWCNT & GO absorbing a large number of water molecules and ions, becoming the nucleation site of hydration products, and adjusting and refining the complex morphology of gel mixed crystals. MWCNT & GO is directly involved in hydration and is closely combined with hardened hydration products to form a stable multiphase network matrix, which improves the structure of cement mortar and enhances the mechanical properties of cement-based composites, which is consistent with the increase of the strength of the samples mixed with nanomaterials.

The conventional toughening material, CF / PPF, is incorporated into the cement paste; however, its effectiveness is limited due to its non-nanoscale dimensions. Through SEM and EDS tests, as shown in (Fig. 14), although there is C element, it is found that there is almost no inlaid hydration product on the surface of CF / PPF. It is inferred that CF / PPF may not affect the morphology and distribution of cement hydration products.

This may be due to the large specific surface area of MWCNT & GO promotes the hydration of cement and the nucleation of hydration products, provides more favorable gelling sites for the growth of hydration products, and optimizes its crystal morphology and distribution. At the same time, MWCNT & GO as a nanomaterial can fill the pores and cracks in the cement mortar, make the hardened mortar more uniform and denser, inhibit the development of microcracks in the cement mortar, and ultimately improve the microstructure of the hardened cement mortar. Improve the mechanical properties of CSC cement based composite material.

The pore structure of composite cementitious pastes

The BET specific surface area and porosity of the samples were tested at 28-d of age. The mean pore diameters of the 28-day samples of CSC2, CSC3, CSC4, CSC5, and CSC6 were 19.18, 8.41, 6.99, 18.53, and 13.50 nm, respectively. Both materials have a mesoporous distribution, and the capillary within the pore experiences condensation, which may be studied using the BJH (Barret-Joyner-Halenda) method. BJH was derived from the Kelvin equation. The Fig. 15 displays the curve that represents the relationship between the pore size distribution (Fig. 15a), porosity, and specific surface (Fig. 15b). This curve helps to explain the variation in the compactness of different hydration matrices of CSC when comparing carbon nanomaterials to traditional reinforcing materials. The porosity values for CSC2, CSC3, CSC4, CSC5, and CSC6 were 6.49, 11.68, 12.49, 8.25, and 6.79%, respectively. Porosity was the measure of the overall volume of small pores per unit mass of porous substances. The addition of 30% copper slag composite cementitious material culminated in a notable enhancement in the compactness of the composite material following filling and hydration with either trace single-doped MWCNTs or co-doped MWCNTs and GO. Figure 15b strongly demonstrates that CSC2 and CSC6 display an unacceptable pore structure, characterized by the lowest specific surface area and the smallest porosity. Conversely, the pore structure of CSC3 and CSC4 samples was deemed outstanding. Based on the favorable mechanical qualities seen in CSC4, it could be inferred that increased mechanical strength was typically associated with improved pore structure, optimized porosity, and smaller pore size. By optimizing the ratio of MWCNT to GO, the inclusion of hybrid nanofiller composites could greatly enhance the aforementioned pore properties. The porosity of CSC5, CSC2, and CSC6 samples dropped by 34.0, 48.1, and 45.7%, respectively. This suggests that the use of GO alone, as well as other common materials such as PPF or CF, did not have a substantial filling effect on the CSC composites.

The CSC2, CSC3, CSC4, CSC5, and CSC6 samples had Languir surface areas of 152.5, 291.7, 339.9, 141.6, and 127.7 m2/g respectively. The Languir surface areas of the CSC4 sample was the only one that met the specified standard value for the specific surface area of cement paste.

Figure 16 shows that the adsorption-desorption curves of the CSC samples are comparable, and that mesopores are the samples’ primary pores. The CSC4 sample showed the largest data of the Languir specific surface area, whereas the CSC2 and CSC6 samples exhibit a declining trend in Languir specific surface area as regular reinforcing elements were substituted for carbon nanoparticles. The porosity of the sample doped with the ideal ratio of MWCNT/GO was greatly reduced, and the sample doped with MWCNTs performed better than the combined sample doped with GO. The one-dimensional filling of MWCNTs and the two-dimensional filling of GO were identified as the causes of this phenomena. Densifying the pore structure was achieved through a more effective filling effect created by the combination of distinct nano-dimensions. The isothermal adsorption and desorption curves of these five samples indicated that the CSC5, CSC2, and CSC6 samples’ isothermal adsorption and desorption ‘hysteresis loop’ was of the H3 type, in accordance with the 2015 International Union of Pure and Applied Chemistry (IUPAC) reclassification criteria for ‘hysteresis loop’. The accumulation of a layered structure, known as the H3 type, results in materials with slit mesoporous or macroporous structures.

The H3 type ‘hysteresis loop’ has two different characteristics: i) the adsorption branch is similar to the type II isothermal adsorption line. (ii) The lower limit of the detachment branch is usually located at the P/P0 pressure point caused by cavitation. This type of ‘hysteresis loop’ is a typical feature of non-rigid aggregates of flake particles.

Furthermore, the fact that these pore networks consist of macropores suggested that pore aggregates did not fill them entirely. The CSC3 and CSC4 samples’ isothermal adsorption and desorption “hysteresis loop” was H4. The ‘hysteresis loop’ of the H4 type was comparable to that of the H3 type. However, the adsorption branch consisted of type I and type II isotherms, and a conspicuous adsorption quantity was present at the lower end of P/P0, which was associated with micropore filling.

The H4-type ‘hysteresis loop’ was usually found in the aggregate of zeolite molecular sieves, some mesoporous zeolite molecular sieves and micro-mesoporous carbon materials. It was a typical curve of activated carbon-type solids with narrow fracture pores, which indicated that the incorporation of nanomaterials could achieve the effect of nano-filling. Especially with the optimal ratio of MWCNT/GO, the nano-filling effect was further significant.

Figure 17 shows the Most probable apertures of CSC2, CSC3, CSC4, CSC5 and CSC6 samples, which are 3.616, 3.054, 2.830, 3.280 and 3.105 nm, respectively. Figure 18 shows the threshold apertures of CSC2, CSC3, CSC4, CSC5 and CSC6 samples, which are 53.5, 80.0, 90.0, 130.0 and 95.0 nm, respectively. According to the data of the Most probable apertures, the pore size of all samples belongs to the range of mesopores, and the threshold apertures belongs to the size of macropores. The data of Figs. 15, 16, 17 and 18 demonstrated that the copper slag composite cementitious materials were not significantly affected by the scale and content of the reinforcing materials, and that the slightly bigger pore size was associated with non-nano filling. Regarding the space between PPF fibers and hydrates that did not participate in hydration, as well as the increased pore size brought on by the size impact of CF, an increase in PPF and CF in regular toughening materials might, in this instance, gradually increase the porosity of the material.

The initial gel structure of the CSC4 sample exhibited a high level of density and uniformity. Based on several BET nitrogen adsorption test indicators, it could be reliably inferred that the optimal ratio of MWCNTs and GO co-doped copper slag cementitious material results in reduced porosity and improved mechanical qualities. While the porosity percentage remained consistent, the bridging effect was anticipated to be readily apparent as the pore size varies. This evidence corroborated the hypothesis that carbon nanofillers enhanced the density of cement pastes by refining the pore structure, which aligned with the significant rise in compressive strength43.

TG and DTG results

Figure 19 displays the thermogravimetric (TG) and differential thermogravimetric (DTG) curves of the C0 and CSC composite pastes54. According to Fig. 19a, CSC4 sample showed the highest weight loss rate of 24.76% (residual mass of 75.24%), while sample CSC2 had the lowest weight loss rate of 20.22% (residual mass of 79.78%). The blank sample C0 showed the highest weight loss rate of 24.28% (residual mass 75.88%), and the other four samples were sorted according to the weight loss rate: CSC3 (weight loss rate 24.64, residual mass 75.36%), CSC5 (weight loss rate 21.74, residual mass 78.26%), CSC6 weight loss rate 21.66 (residual mass 78.34%), CSC1 weight loss rate 22.09 (residual mass 77.91%). Moreover, the final weight loss rate of CSC3 sample was very close to that of CSC4 sample. The DTG curve (Fig. 19b) clearly showed that the first endothermic peak, resulting from the dehydration and rupture of C–(A)–S–H gel and ettringite45, occurred at around 100 °C. The lowest endothermic peak was observed in the CSC2 sample, at 90.1 °C, while the highest endothermic peak was observed in the CSC3 sample, at 103.0 °C. The DTG curves that include MWCNTs and GO exhibit elevated peaks for the degradation of C–S–H gel and ettringite.

Observably, the CSC4 of composite cementitious samples, when mixed with MWCNT/GO, yielded a greater quantity of hydration products. The temperature range of 394 °C to 483 °C had a prominent peak, which could be attributed to the process of Portlandite (Ca (OH)2) decomposition55. CSC4 had the most pronounced rise in portlandite degradation. The decomposition of dolomite (CaMg(CO3)2) and calcite (CaCO3) took place within the temperature range of 730 to 760 °C and 760 to 859 °C.

The amount of non-evaporable water was calculated using the mass loss of the sample from room temperature to the completion point of silicate decomposition (500 °C)56. Compared with Ca (OH)2, C–S(A)–H gel is an amorphous material, and a large amount of bound water exists in C–S(A)–H gel and AFt by different forms57.

The presence of Ca (OH)2 in the paste can be divided into two parts: uncarbonated Ca (OH)2 in cement hydration products and carbonized CaCO3 formed during carbonization58. The XRD of this sample shows that it contains CaMg (CO3)2, which decomposes with CaCO3 in the range of about 730 ~ 860 °C, and there will be CO2 precipitation, the quality of the sample will decrease, and the carbonization reaction degree of the sample at 28 days is very small, and the carbonized Ca (OH)2 can be ignored. The content of Ca (OH)2 was calculated according to the simplified formula (1).

where \(\:{W}_{\text{C}\text{H}}\) = CH content (%); \(\:{W}_{{\text{H}}_{2}\text{O}}\) = mass loss from thermal decomposition of CH (%); \(\:{M}_{\text{C}\text{H}}\) = molar mass of CH, 74 g/mol; \(\:{M}_{{\text{H}}_{2}\text{O}}\) = molar mass of H2O, 18 g/mol.

The decomposition of C-S-H gel and AFt will occur in a wide temperature range, and the decomposition temperatures of C-S-H gel and AFt overlap each other59,60.

It can be seen from Table 7 that the Ca (OH)2 content of the C0 group and the CSC1 group at 28-d of hydration was 11.82 and 11.10%, respectively, while the Ca (OH)2 content of CSC3 and CSC4 was 11.30 and 11.48%, respectively, which was very close to the Ca (OH)2 content of the blank group C0. Therefore, the content of Ca (OH)2 produced by hydration can be used as an indicator to infer the degree of hydration of CSC slurry promoted by carbon nanomaterials.

By analyzing the data in Fig. 19a, the portlandite and non-evaporable water content of each sample can be calculated, as shown in (Fig. 20). The portlandite of CSC4 shows the highest content.

The calculation results of non-evaporable water content also showed that CSC4 had the highest non-evaporable water content and CSC3 had the lowest non-evaporable water content53, which were 12.53 and 10.36%, respectively. The portlandite and non-evaporable water contents61 of other CSC samples were showed in (Table 7).

The findings indicated that the inclusion of GO alone in the composite slurry of solid waste led to a decrease in the amount of hydration products. Conversely, the inclusion of MWCNT/GO composite slurry with the optimal ratio resulted in an increase in the content of hydration products. Both the CSC3 and CSC4 samples exhibited a larger amount of hydration product, which aligned with the results obtained for compressive strength. Hence, the combination of double-doped MWCNT/GO paste exhibited a synergistic activation and nucleation impact during the hydration process, resulting in an increased production of hydration products.

FTIR spectral results

Figure 21 depicts the fourier transform infrared (FTIR) spectra of the solidified paste after 28-d. The 3644 cm− 1 peak was attributed to the bending vibration of the OH group in hydrotalcite62. The presence of the faint peaks at 1650 cm− 1 and 876 cm− 1 could be attributed to the bending vibration of calcium silicate. The spectral peak of calcium silicate in the CSC1 sample was the most prominent, whereas C0, CSC2, CSC6, CSC5, CSC3, and CSC4 followed in declining order of strength. It was confirmed that the samples of double-doped or single-doped MWCNT or GO, or doped with additional toughening fibers PPF and CF, exhibited an increasing trend in the calcium silicate spectral peaks. The sample with the most pronounced spectral peak augmentation was the CSC4 sample. The spectral peaks at 3644 cm− 1 were seen in CSC4 and CSC3 suggesting that calcium silicate was consumed by the CSC pozzolanic process comprising MWCNT and GO.

The absorption peak at around 978 cm− 1 was associated with the asymmetrical stretching vibration of the Si-O-Si bond, which was connected to the C–S–H or C–A–S–H gel62. The absorption peaks of the CSC6, CSC5, and CSC3 samples were near them other, with the absorption peak at 978 cm− 1 of the CSC6 sample being comparatively faint. Undoubtedly, the CSC2 sample was a type of organic toughening compound, and the absorption peak observed in this case was the least intense.

The CSC4 sample represented the maximum peak value of the composite system63. The results aligned with the other test indicators. This suggested that the combination of MWCNT/GO could stimulate the initiation of CSC and enhance its volcanic activity when used in the right proportion. The absorption peak at around 1650 cm− 1 was ascribed to the bending vibration of the H-O-H group. The frequency of 3438 cm− 1 corresponded to the stretching vibration of the O-H group in water molecules. The H-O-H absorption peak at 1650 cm− 1 of the CSC4 sample was more pronounced compared to the CSC5 and CSC3 samples. This suggested that the CSC4 sample exhibited a stronger pozzolanic reaction, which was in line with the compressive strength findings. Peaks at 876 cm− 1 were observed in all samples, indicating the bending vibration of the C-O bond in CO2- 345.

The weak bands at 479 and 1424 cm− 1 of all samples were related to the asymmetric stretching of the C-O bond in the CO2- 3 group in calcite27, which might be formed during carbonization. It could be analyzed that all samples have a certain degree of carbonization, and the degree of hydration of carbonization increased with the increase of volcanic ash activity. The peak intensity of CSC6 and CSC5 at 457 cm− 1 was not much different, CSC6 sample was slightly stronger, followed by five samples in addition to the strength of the more obvious, according to the strength of the order of CSC4, CSC3, C0, CSC1, CSC2. At 457 cm− 1, the peak was caused by the bending vibration of Si–O–Al. The CSC samples all showed C–A–S–H gel formed by pozzolanic reaction54. It was inferred that C–A–S–H was formed by polymerizing Al3+ released from CSC into C–S–H gel structure64. The CSC2 samples toughened by organic materials did not have this advantage, so the peak strength at 457 cm− 1 was the weakest45.

Conclusions

This study investigated the disparities in the enhancement65,66 and fortification of nanomaterials (MWCNT/GO) and conventional fiber materials (PPF/CF) when used as additions in the CSC matrix39,67, the enhancement mechanism diagram is shown in (Fig. 22). The performance test conducted on the slurry indicated that the addition of conventional fiber or nanomaterial dispersion led to a decrease in the fluidity of the sample. Compliance with the China standard and careful consideration of water-cement ratio adjustment were necessary. The mechanical index test confirmed that the nanomaterial reinforced sample outperforms the standard fiber sample. The advancement of techniques and procedures in the preparation of novel nanocomposite cementitious materials had expanded the opportunities for reinforcing concrete with solid waste and had provided a cost-effective approach for recovering copper slag. The addition of PPF/CF single-doped conventional reinforcing material had no influence on strength or compactness, but it did enhance its macro-scale toughness.

The mechanical characteristics of CSC reinforced with MWCNT&GO were greatly enhanced. Specifically, the hybrid MWCNT/GO (0.08 wt% MWCNTs and 0.04 wt% GO) samples had nearly attained the same levels of compressive and flexural strength as the blank group. The results of the SEM, EDS and QXRD tests further demonstrated that MWCNTs provided a significant interfacial adhesion between the C-S-H gel of the cement matrix and the GO sheet, and the morphology of hydration products has changed, in addition to the nucleation effect. Peng, H., et al. also showed that the morphology and distribution of cement hydration products changed beneficially after adding GO, and the porosity of hardened cement slurry decreased15. Lv, S.et al. believed that GO nanosheets have a template effect that can regulate the formation of flower-like crystals16. These studies all believe that nano-scale filling effect can improve the strength of cement paste, which is consistent with the conclusion of this work.

Mohsen, M. O. et al. found that the bending strength of cement paste with CNTs content of 0.12 wt% could be increased by 44.38%29, which was basically consistent with the compressive strength of CSC4 sample in this work was 41.6% higher than that of CSC1 at the same age. Pan, Z. et al. also pointed out that two-dimensional GO sheets themselves have crack dedirection, which may form an effective barrier to nanoscale crack propagation in cement slurry matrix17. The CSC4 sample group with the optimal ratio of MWCNT/GO has a narrower fracture pore at the nanoscale, indicating that the incorporation of nanomaterials can achieve the effect of nano-fillers, which has not been reported in other literatures. The working performance of CSC samples doped with nanomaterials is similar to the reported results on the machinability of CNT cement slurry18.

The findings of the porosity and specific surface area tests indicated that adding common toughening compounds like CF and PPF might cause the material’s porosity to gradually rise. The cement slurry was more compact and had less porosity in the optimal ratio of MWCNTs and GO co-doped CSC. The composite slurry including nanomaterials had a high content of portlandite, the highest level of non-volatile water, and an increase in hydration products, according to the results of the TG and DTG analysis. The FTIR spectrum analysis revealed that the calcium silicate’s spectral peaks of the samples doped with MWCNTs or GO were more significantly enhanced than those samples doped with PPF and CF. FTIR spectrum analysis showed that the spectral peaks of calcium silicate. To improve the copper slag-based cement composites cement material more effectively at the nanoscale, it is finally suggested to optimize the ratio of MWCNT to GO. The composite material can not only consume a significant amount of solid waste but also prepare building materials, converting waste into treasure, low carbon, and environmental protection.

Data availability

The data used to support the findings of this study are available from the corresponding author upon request.

Abbreviations

- MWCNTs:

-

Multi-walled carbon nanotubes

- CNTs:

-

Carbon nanotubes

- GO:

-

Graphene oxide

- CS:

-

Copper slag

- CSC:

-

Copper slag-based cement composites

- AG:

-

Arabic gum

- CF:

-

Chopped carbon fiber

- PPF:

-

Acrylic fiber

- SEM:

-

Scanning electron microscope

- XRD:

-

X-ray diffraction

- FTIR:

-

Fourier transform infrared spectroscopy

References

Phiri, T. C., Singh, P. & Nikoloski, A. N. The potential for copper slag waste as a resource for a circular economy: A review—Part I. Miner. Eng. 180, 107474 (2022).

Wang, D., Wang, Q. & Huang, Z. Reuse of copper slag as a supplementary cementitious material: Reactivity and safety Resour. Conserv. Recycl. 162105037 (2020).

Guo, H., Wang, Z., An, D. & Huo, J. Collaborative design of cement-based composites incorporated with Cooper slag in considerations of engineering properties and microwave-absorbing characters. J. Clean. Prod. 283, 124614 (2021).

Ma, H. et al. Research on the effect of 60℃ thermal cycling on the properties of alkali-activated fly ash-slag materials: A new perspective. Constr. Build. Mater. 416, 135192 (2024).

Ma, H. & Wu, C. Mechanical and microstructural properties of alkali-activated fly ash-slag material under sustained moderate temperature effect. Cem. Concr. Compos. 134, 104744 (2022).

Liu, S., Ouyang, J. & Ren, J. Mechanism of calcination modification of phosphogypsum and its effect on the hydration properties of phosphogypsum-based supersulfated cement. Constr. Build. Mater. 243, 118226 (2020).

He, R. et al. Copper slag: the leaching behavior of heavy metals and its applicability as a supplementary cementitious material. J. Environ. Chem. Eng. 9 (2), 105132 (2021).

Singh, J. & Singh, S. P. Development of alkali-activated cementitious material using copper slag. Constr. Build. Mater. 211, 73–79 (2019).

Panda, S., Sarkar, P. & Davis, R. Abrasion resistance and slake durability of copper slag aggregate concrete. J. Build. Eng. 35, 101987 (2021).

Mirnezami, S., Hassani, A. & Bayat, A. Evaluation of the effect of metallurgical aggregates (steel and copper slag) on the thermal conductivity and mechanical properties of concrete in jointed plain concrete pavements (JPCP). Constr. Build. Mater. 367, 129532 (2023).

Panda, S., Alnounou, M. A., Jawhara, B. & Sarkar, P. Bond strength and corrosion behavior of rebar embedded in copper slag concrete composites. Constr. Build. Mater. 416, 135134 (2024).

Edwin, R. S., Gruyaert, E. & De Belie, N. Valorization of secondary copper slag as aggregate and cement replacement in ultra-high-performance concrete. J. Build. Eng. 54, 104567 (2022).

Dawood, E. T. & Ramli, M. High strength characteristics of cement mortar reinforced with hybrid fibres. Constr. Build. Mater. 25 (5), 2240–2247 (2011).

Chung, D. D. L. Comparison of submicron-diameter carbon filaments and conventional carbon fibers as fillers in composite materials. Carbon 39 (8), 1119–1125 (2001).

Peng, H., Ge, Y., Cai, C. S., Zhang, Y. & Liu, Z. Mechanical properties and microstructure of graphene oxide cement-based composites. Constr. Build. Mater. 194, 102–109 (2019).

Lv, S. et al. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 49, 121–127 (2013).

Pan, Z. et al. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 58, 140–147 (2015).

Collins, F., Lambert, J. & Duan, W. H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotube–OPC paste mixtures. Cem. Concr. Compos. 34 (2), 201–207 (2012).

Pereira-de-Oliveira, L. A., Castro-Gomes, J. P. & Nepomuceno, M. C. Effect of acrylic fibres geometry on physical, mechanical and durability properties of cement mortars. Constr. Build. Mater. 27 (1), 189–196 (2012).

Chen, T., Zheng, X., Zhao, X. & Liu, J. Study on the effect of polyacrylonitrile fiber on the properties of steel slag-cement cementitious materials. Innovat. Infrastruct. Solut. 8 (8), 206 (2023).

Lopes, J. P., Ferrari, V. J., Camões, A., Souza, A. & Fangueiro, R. Effects of nanoparticles on the mechanical behaviour of fibre-reinforced concrete. Proceedings of the Institution of Civil Engineers-Construction Materials, 176 (4), 161–170. (2020).

Brown, L. & Sanchez, F. Influence of carbon nanofiber clustering on the chemo-mechanical behavior of cement pastes. Cem. Concr. Compos. 65, 101–109 (2016).

Zhang, H., Cao, S. & Yilmaz, E. Carbon nanotube reinforced cementitious tailings composites: links to mechanical and microstructural characteristics. Constr. Build. Mater. 365, 130123 (2023).

Qin, R., Zhou, A., Yu, Z., Wang, Q. & Lau, D. Role of carbon nanotube in reinforcing cementitious materials: an experimental and coarse-grained molecular dynamics study. Cem. Concr. Res. 147, 106517 (2021).

Parveen, S., Rana, S., Fangueiro, R. & Paiva, M. C. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem. Concr. Res. 73, 215–227 (2015).

Li, F., Liu, L., Yang, Z. & Li, S. Physical and mechanical properties and micro characteristics of fly ash-based geopolymer paste incorporated with waste granulated blast furnace slag (GBFS) and functionalized multi-walled carbon nanotubes (MWCNTs). J. Hazard. Mater. 401, 123339 (2021).

Gu, X. et al. Study on the synergistic effect of calcium carbide residue-fly Ash enhanced desulphurisation gypsum under high temperature maintenance condition. Constr. Build. Mater. 412, 134706 (2024).

Zhou, C. et al. Enhanced mechanical properties of cement paste by hybrid graphene oxide/carbon nanotubes. Constr. Build. Mater. 134, 336–345 (2017).

Mohsen, M. O. et al. Hybrid effect of GNPs, GOs, and CNTs on the flexural and compressive strengths of cement paste. J. Build. Eng. 73, 106679 (2023).

Kaur, R. & Kothiyal, N. C. Positive synergistic effect of superplasticizer stabilized graphene oxide and functionalized carbon nanotubes as a 3-D hybrid reinforcing phase on the mechanical properties and pore structure refinement of cement nanocomposites. Constr. Build. Mater. 222, 358–370 (2019).

Bhojaraju, C., Mousavi, S. S. & Ouellet-Plamondon, C. M. Influence of GGBFS on corrosion resistance of cementitious composites containing graphene and graphene oxide. Cem. Concr. Compos. 135, 104836 (2023).

Zhang, S. & Zhang, Z. Optimal development and performance evaluation of electrolytic graphene oxide synergistic all-solid waste cementitious grouting material. Constr. Build. Mater. 449, 138407 (2024).

Qiao, W. et al. Using graphene oxide to enhance the bonding properties between carbon fibers and cement matrix to improve the mechanical properties of cement-based composites. Constr. Build. Mater. 453, 138992 (2024).

Lu, D., Shi, X. & Zhong, J. Understanding the role of unzipped carbon nanotubes in cement pastes. Cem. Concr. Compos. 126, 104366 (2022).

Feng, Y. et al. Modification of glass structure via CaO addition in granulated copper slag to enhance its pozzolanic activity. Constr. Build. Mater. 240, 117970 (2020).

Phiri, T. C., Singh, P. & Nikoloski, A. N. The potential for copper slag waste as a resource for a circular economy: A review–Part II. Miner. Eng. 172, 107150 (2021).

Xiao, Q. H., Cao, Z. Y., Guan, X., Li, Q. & Liu, X. L. Damage to recycled concrete with different aggregate substitution rates from the coupled action of freeze-thaw cycles and sulfate attack. Constr. Build. Mater. 221, 74–83 (2019).

Zheng, H. et al. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part. B: Eng. 233, 109639 (2022).

Du, Y. et al. Hybrid graphene oxide/carbon nanotubes reinforced cement paste: an investigation on hybrid ratio. Constr. Build. Mater. 261, 119815 (2020).

López-Buendía, A. M., Romero-Sánchez, M. D., Climent, V. & Guillem, C. Surface treated polypropylene (PP) fibres for reinforced concrete. Cem. Concr. Res. 54, 29–35 (2013).

Zhang, L. et al. Study on the reinforcing mechanisms of nano silica to cement-based materials with theoretical calculation and experimental evidence. J. Compos. Mater. 50 (29), 4135–4146 (2016).

He, H. et al. Pore structure representations based on nitrogen adsorption experiments and an FHH fractal model: case study of the block Z shales in the Ordos basin, China. J. Petrol. Sci. Eng. 203, 108661 (2021).

Wang, J. et al. Quantitative determination of quaternary solid waste-based binders and its hydrates by XRD. Constr. Build. Mater. 425, 135888 (2024).

Debye, P. & Scherrer, P. Interferenzen an Regellos orientierten teilchen Im Röntgenlicht. I. Nachr. Von Der Gesellschaft Der Wissenschaften zu Göttingen Mathematisch-Physikalische Klasse. 1916, 1–15 (1916).

Wang, H. et al. Enhancement mechanism of micro-iron ore tailings on mechanical properties and hydration characteristics of cement-steel slag system. J. Build. Eng. 79, 107882 (2023).

Zhao, L. et al. Synergistic effects of silica nanoparticles/polycarboxylate superplasticizer modified graphene oxide on mechanical behavior and hydration process of cement composites. RSC Adv. 7, 16688–16702 (2017).

Singh, L. P., Bhattacharyya, S. K., Shah, S. P., Mishra, G. & Sharma, U. Studies on early stage hydration of tricalcium silicate incorporating silica nanoparticles: part II, Constr. Build. Mater. 102, 943–949 (2016).

Kanchanason, V. & Plank, J. Effectiveness of a calcium silicate hydrate—Polycarboxylate ether (C–S–H–PCE) nanocomposite on early strength development of fly ash cement. Constr. Build. Mater. 169, 20–27 (2018).

Sun, J. et al. Effects of synthetic C-S-H/PCE nanocomposites on early cement hydration. Constr. Build. Mater. 140, 282–292 (2017).

Noguchi, N. et al. Hydration of ferrite-rich Portland cement: evaluation of Fe-hydrates and Fe uptake in calcium-silicate-hydrates. Constr. Build. Mater. 288, 123142 (2021).

Guo, L., Zhou, M., Wang, X., Li, C. & Jia, H. Preparation of coal gangue-slag-fly Ash geopolymer grouting materials. Constr. Build. Mater. 328, 126997 (2022).

Ma, C., Chen, G., Cao, L., Zhou, H. & Ren, W. Effects and mechanisms of waste gypsum influencing the mechanical properties and durability of magnesium oxychloride cement. J. Clean. Prod. 339, 130679 (2022).

Zhang, Q. et al. Preparation and hydration process of copper slag-granulated blast furnace slag-cement composites. Constr. Build. Mater. 421, 135717 (2024).

Qu, F. Performance of sustainable and low-carbon cementitious composites under aggressive environmental conditions. (Doctoral dissertation, University of Technology Sydney, 2022).

Nsiah-Baafi, E. Investigation of strategies for risk minimisation of adverse Alkali-silica reaction in concrete. (Doctoral dissertation, University of Technology Sydney, 2021).

Cao, Y. & Detwiler, R. J. Backscattered electron imaging of cement pastes cured at elevated temperatures. Cem. Concr. Res. 25 (3), 627–638 (1995).

Sun, R. et al. Effect of white mud on properties of alkali activated slag. Constr. Build. Mater. 392, 131944 (2023).

Ge, W. et al. Hydration characteristics, hydration products and microstructure of reactive powder concrete. J. Building Eng. 69, 106306 (2023).

Li, W. et al. Study on the early cement hydration process in the presence of cationic asphalt emulsion. Constr. Build. Mater. 261, 120025 (2020).

Li, W. et al. Influence of Metakaolin on the hydration and microstructure evolution of cement paste during the early stage. Appl. Clay Sci. 229, 106674 (2022).

Zhou, Y., Sun, J. & Zhang, Z. Effects of high-volume ground slag powder on the properties of high-strength concrete under different curing conditions. Crystals 11 (4), 348 (2021).

Shao, J., Gao, J., Zhao, Y. & Chen, X. Study on the pozzolanic reaction of clay brick powder in blended cement pastes. Constr. Build. Mater. 213, 209–215 (2019).

Sun, W., Zhou, F., Liu, J. & Shao, J. Experimental study on Portland cement/calcium sulfoaluminate binder of paste filling. Eur. J. Environ. Civil Eng. 26 (5), 1706–1721 (2022).

Zhang, Y. et al. Preparation and characterization of cement treated road base material utilizing electrolytic manganese residue. J. Clean. Prod. 232, 980–992 (2019).

Zalnezhad, A., Hosseini, S. A., Shirinabadi, R. & Korandeh, M. E. Feasibility of using copper slag as natural aggregate replacement in microsurfacing for quality enhancement: microscopic and mechanical analysis. Constr. Build. Mater. 354, 129175 (2022).

Zhang, Z., Wang, Q. & Huang, Z. Value-added utilization of copper slag to enhance the performance of magnesium potassium phosphate cement. Resour. Conserv. Recycl. 180, 106212 (2022).

Dehghan, M., Al-Mahaidi, R. & Sbarski, I. Investigation of CNT modification of epoxy resin in CFRP strengthening systems. Polym. Compos. 37 (4), 1021–1033 (2016).

Acknowledgements

The authors would like to thank the National Natural Science Foundation of China (51668021), Natural Project of Jiangxi University of Technology (23ZRZD02).

Author information

Authors and Affiliations

Contributions

Bingzhi Xiang: Writing—review & editing, Resources, Project administration, Methodology, Funding acquisition, Conceptualization. Guoxiang Yang: Writing—original draft, Visualization, Investigation, Formal analysis, Data curation. Ruifeng Cheng: Visualization, Investigation, Data curation, Formal analysis. Zhongjian Zhang: Validation, Investigation, Data curation. Jielu Zhu: Validation, Investigation, Data curation. Yong Zhou: Validation, Investigation, Data curation. Fanghua Liu: Validation, Investigation, Data curation. Junwei Song: Validation, Investigation, Data curation.All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Xiang, B., Yang, G., Cheng, R. et al. Synergistic effect of MWCNTs and GO as a reinforcing phase on copper slag-based cement composites. Sci Rep 15, 13283 (2025). https://doi.org/10.1038/s41598-025-97227-5

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-97227-5