Abstract

Solid propellant slurry is a high solid content suspension, and its rheological properties are very complex. In order to solve the problem that it is hard to estimate the process propertie of 3,3-bis(azidomethyl) oxetane-tetrahydrofuran copolyether (PBT) solid propellant slurry, the concept of liquid film thickness in propellant was proposed by analyzing the mesoscopic structure of PBT solid propellant slurry, and the calculation method of liquid film thickness under different propellant packing grade ratios is given. Four kinds of filler particle size are used as examples, the theory of tight packing of tertiary particles was extended to multi-gradation. Furthermore, based on the theory of packing, the relationship between the liquid film thickness of the propellant and the particle size of the filler is obtained, that is, the liquid film thickness becomes thinner with the decrease of the particle radius and changes proportionally with the particle radius. In this work, the analysis method provides theoretical guidance for propellant formulation design, thereby reducing the number of experiments, shortening the propellant formulation development cycle, and reducing labor and material costs.

Similar content being viewed by others

Introduction

3,3-bis(azidomethyl) oxetane-tetrahydrofuran copolyether (PBT) solid propellant has been widely used in various solid rocket motors due to its high energy, insensitive and low characteristic signals1,2,3,4. In the preparation process of PBT, good process propertie is a necessary condition to ensure its casting molding5,6,7,8. The process performance of propellant slurry is too poor, and the gas in the slurry will not be discharged, forming pores and cracks, increasing the combustion surface, which will lead to an increase in the pressure of the engine combustion chamber9,10,11. In severe cases, the engine will disintegrate. Therefore, in rencent years, researchers have carried out a lot of research work on the process propertie of propellant slurry12,13,14,15,16, including the effects of composition, interface and manufacturing process on the rheological properties of propellant slurry. However, the research methods used are mainly experimental verification, resulting in a relatively long experimental period and relatively large consumption of manpower and material resources.

In order to reduce the number of experiments, the prediction model of PBT propellant slurry process parameters was established17,18,19,20. PBT propellant consists of two phases, one is a continuous phase composed of binder matrix, and the other is a dispersed phase composed of solid particles such as oxidant and metal fuel (accounting for 70% ~ 90% of the total mass fraction of the propellant)21,22,23,24. Therefore, the process propertie of PBT propellant is determined by the properties of solid particles, matrix and solid particle / matrix interface25,26,27,28. Due to the large amount of solid particles filled in the propellant slurry, it is difficult to characterize the mesoscopic structure, and the stress distribution during the flow process is unknown. It has been a great challenge to study the rheological behavior of PBT and predict the process propertie of PBT in theory. In recent years, there have been many reports on the prediction of the process propertie of composite solid propellants by theoretical methods29,30,31,32,33,34,35,36. Furnas calculated the particle size distribution of maximum packing density by mathematical model, and proposed the grading method of optimizing particle size distribution to achieve minimum viscosity29,30. According to the theory of dense packing of solid fillers, Yang estimated the maximum solid filling volume fraction, designed the particle size ratio of the filler system, and established the empirical expression of the viscosity of the slurry31,32. Xiao proposed the rolling gradation of propellant, which can reflect the flow characteristics of propellant slurry33. Richard established a new method to predict the maximum packing fraction and the viscosity of solutions with a size distribution of suspended particles34,35. At present, there are many estimates of macroscopic process parameters for the rheological properties of propellant slurry at home and abroad, but there are few estimates of mesoscopic process parameters. There are many studies on the dispersed phase and the interface phase. However, there is a lack of research on the characteristics of the liquid film coated on the surface of the matrix phase, especially on the surface of the propellant filler particles, and there is no prediction scheme for the response.

Herein, from the mesoscopic structure of the PBT propellant slurry point of view, we proposed the concept of liquid film thickness related to the gradation of packing particles (Fig. 1). The thickness of the liquid film is composed of a cross-linked network polymer matrix, which reflects the evolution of the structural characteristics of the matrix with particle size during the mixing of propellant slurry. In addition, we explored the relationship between the close packing density of liquid-attached particles and the thickness of liquid film and the particle size of filler particles. It provides theoretical guidance for propellant formulation design, reduces the number of experiments, shortens the development cycle of propellant formulation, and reduces the cost of manpower and material resources.

Experiment

Materials

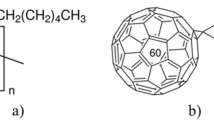

3,3-bis(azidomethyl) oxetane-tetrahydrofuran copolyether (PBT) were provided by Liming Research Institute of Chemical Industry, its chain ratio of the two is 5:5, and the average molecular weight is about 5000. Bis (2,2-dinitropropyl) acetal and Bis (2,2-dinitropropyl) formal equal mass ratio mixture (A3) were provided by Shanghai Space Propulsion Technology Research Institute. Ammonium perchlorate (AP) particle size 380 μm, 150 μm were provided by Dalian Gaojia Chemical Co., Ltd. Ultrafine ammonium perchlorate (AP) of particle size 10 μm was provided by Shanghai Space Propulsion Technology Research Institute. Aluminum powder (Al) of particle size 29 μm was obtained by Ansteel Group Aluminum Power Co., Ltd. Boron trifluoride Triethanolamine Complex (T313). Toluene diisocyanate (TDI) was offered by Gansu Yingguang Juyin Chemical Industry Co., Ltd.

Preparation of propellant formulation and sample

The formulation and component content of the propellant is shown in Table 1. The synthesis steps of propellant slurry are as follows. Firstly, the components such as binder, plasticizer and bonding agent are weighed in proportion. Secondly, aluminum powder is added to premix evenly to make slurry. Finally, the weighed oxidant is added to the slurry and mixed in VKM-5 vertical kneading machine for 160 min ~ 180 min.

Experimental facilities and methods

Rheological properties test

Rheological testing of the propellant slurry was conducted. Both the shear stress and viscosity of propellant slurry were measured by using a Viscotester iQ rheometer (Thermo Scientific HAAKE, Germany), where viscosity of the shear rate is 0.05 s− 1, 40 ℃ and shear stress test conditions: shear rate from 0.05 s− 1 uniformly increased to 2 s− 1, 60 °C.

Results and discussion

Liquid film thickness

Definition of liquid film thickness

In the composite solid propellant slurry, the solid filler particles are used as the dispersed phase, and the crosslinked network polymer matrix is used as the continuous phase. There is an interaction between the two. This effect includes: (1) The continuous phase matrix has a wetting effect on the dispersed phase particles. Due to the wetting effect of the continuous phase matrix, the surface of the particles is covered with a layer of liquid and has a certain thickness. (2) Dispersed phase particles have adsorption effect on continuous phase matrix.

According to the above two interactions between the continuous phase matrix and the dispersed phase particles, the solid filler particles in the propellant slurry are not closely contacted and stacked, but are coated by a continuous phase matrix with a certain thickness. Therefore, the thickness of the matrix coated on the surface of the solid filler particles is called the liquid film thickness of the propellant. In the propellant slurry, the dispersed phase particles are uniformly wrapped by the continuous phase matrix, and there is no specific adsorption layer, so the liquid film thickness is an imaginary physical quantity. However, this physical quantity can provide guidance for the design of propellant process propertie and mechanical properties.

Solution of liquid film thickness

The mesoscopic structure of the composite solid propellant slurry is assumed as follows: (1) It is assumed that the ammonium perchlorate (AP) particles and aluminum (Al) particles in the composite solid propellant are standard spherical particles, and each particle is uniformly dispersed in the continuous phase matrix. (2) It is assumed that the continuous phase matrix first fills the voids between the solid particles, and then the excess matrix is coated on the surface of each solid particle to form a liquid film. As shown in Table 2, the continuous phase matrix can be divided into two parts: liquid film and interstitial liquid. The calculation formula of the Spherical volume is as follow;

where \(\:{N}_{i}\) is the number of filler particles i, \(\:{R}_{i}\) is the radius of filler particle i, \(\:{\delta}_{i}\) is the liquid film thickness on particle surface, \(\:{V}_{matrix}\) is the total volume of the continuous phase matrix, it can be determined by the difference between the total volume of the propellant V and the total volume of the filler particles. \(\:{V}_{void}\) is the volume of the matrix filled in the voids generated by the accumulation of spherical particles.

liquid film thickness\(\:\:{\delta}_{i}\) is attached to the particles surrounded by it. The particles are tightly packed called liquid-attached particles, and its radius is \(\:{R}_{i}+{\delta}_{i}\). Volume of liquid film is the difference between \(\:{\delta}_{i}\) and the solid content of all particles tightly packed.

where \(\:{V}_{film}\) is the volume of liquid film.

For the formulated composite solid propellant, the total volume V, the total volume of packing particles \(\:{V}_{solid}\), and the size of packing particles \(\:{R}_{i}\) can be calculated, but the volume of the matrix filled in the void \(\:{V}_{void}\) cannot be solved, \(\:{V}_{void}\) is related to the bulk density of liquid-attached particles. Therefore, based on the above analysis, the liquid film thickness of the propellant is required to be solved, it is necessary to further obtain the relationship between the close packing density of liquid-attached particles and the thickness of liquid film and the particle size of filler particles, this is \(\:{\delta}_{i}\left({R}_{i}\right)\).

The solution of packing density

The packing density of the particles is related to the gradation of the filler particles and the different packing modes. For example, when single-sized particles are stacked, they are stacked in the most compact and orderly manner, and their packing density can reach 0.76; when the particles are randomly tightly packed, the packing density is about 0.64, while when the particles are randomly loosely packed, the packing density is only about 0.60. In composite solid propellants, the filler particles are usually multi-graded. When the particles of multiple sizes are stacked, some smaller particles can just fill the voids generated by the accumulation of large particles, so the overall packing density will increase. The packing density tends to be much larger than the packing density generated by the accumulation of single-sized particles.

The modified three-parameter model for four gartion particle system

As shown in Table 2, the particle size gradation of propellant filler is selected. Taking a composite solid propellant system as an example, the propellant filler contains three particle sizes of oxidant (AP) and one particle size of aluminum powder ( Al).

There are multi-graded particles in the propellant system, and the interaction between particles of different sizes must be considered in the process of packing. Wong37 studied the problem of the accumulation of tertiary spherical particles, and proposed a three-parameter model to predict the bulk density of tertiary spherical particles. Based on the three-parameter model, the interaction between particles of different sizes during the accumulation process produces three different effects, which will change the packing density. The three effects are loosening effects, wall effects, and wedging effects. These effects still exist in the stacking process of quaternary particles. Kwan38 obtained the relationship formula of these three effects with the change of particle size ratio through experimental research as follow.

where \(\:{a}_{ij}\) is the loosening effects, \(\:{b}_{ij}\) is the wall effects, \(\:{c}_{ij}\) is the wedging effects, \(\:{s}_{ij}\) is the particle size ratio of particle i to particle j.

For the four gradation particles system in Table 2, the three-parameter model needs to be modified to predict the packing density of the four-level spherical particles. It is assumed that there is always one dominant size class and there exist only interactions between the dominant size class and each non-dominant size class. In the following formulation, the diameters of size class 1, size class 2, size class 3 and size class 4 are denoted by d1, d2, d3 and d4, respectively (note that d1< d4< d2< d3). According to the dominant particle size, the expression formula of packing density is explored respectively.

When size class 1 is dominant

If the particle 1 dominates after stacking, the larger particles 2, 3 and 4 will produce the wall attachment effect and the wedge effect with the particle 1, respectively. The packing density of the ternary mix when particle 1 is dominant (denoted by ϕ1*) may be obtained from the following equation:

Where \(\:{\varnothing}_{i}\) is the packing density of single-size particle i. \(\:{a}_{ij}\) is the loosening effects between particle i and particle j, \(\:{b}_{ij}\) is the wall effects between particle i and particle j, \(\:{c}_{ij}\) is the wedging effects between particle i and particle j, \(\:{f}_{i}\) is the Solid volume fraction of particle i.

When size class 2 is dominant

If particle 2 dominates after accumulation, there are only loosening effect and wall effect between smaller particles 1 and particle 4 and particle 2, respectively, and only wall effect and wedging effect between larger particle 3 and particle 2. The packing density of the ternary mix when particle 1 is dominant (denoted by ϕ2*) may be obtained from the following equation:

When size class 3 is dominant

After accumulation, if particle 3 is dominant, there are only loosening effect and wall effect between the smaller particles 1, 4 and 2 and particle 3, respectively. The packing density of the ternary mix when particle 1 is dominant (denoted by ϕ3*) may be obtained from the following equation:

When size class 4 is dominant

After accumulation, if particle 4 is dominant, there is a loosening effect and a wall effect between the smaller particles 1 and 4, and a wall effect and a wedging effect between the larger particles 2 and 3 and the particles 4, respectively. The packing density of the ternary mix when particle 1 is dominant (denoted by ϕ4*) may be obtained from the following equation:

In general, it is impossible to determine which particle category is dominant and which equation should be used to calculate the bulk density. Therefore, the final packing density formula of the four-level coordination system is as follows

Where \(\:{\varnothing}\) represents the final packing density of the four-grade particle system.

As shown in Fig. 2, using MATLAB software to solve the packing density formula, the packing density of the four-stage filler particles of the composite solid propellant under different proportions is obtained. In Fig. 2, the three coordinates are the proportions of AP particles with sizes of 10, 150 and 380, respectively. The color line is the isoline of packing density, and the direction of arrow pointing is the direction of increasing packing density, it shows that the packing density of the filler varies greatly under different AP particle gradations. The red dot is the particle grading packing density of the four-graded filler of the composite solid propellant shown in Table 2, and the value is 0.785.

The relationship between the thickness of the liquid film and the radius of the particles

The relationship between liquid film thickness and particle radius \(\:{R}_{i}\)(\(\:{R}_{i}={d}_{i}/2\)) is relatively complex39,40,41,42,43,44. According to research on different systems, the relationship could be linear or nonlinear. Based on these two possibilities, this paper adopts two simplified assumptions. A1 Assume that all particles have the same liquid film thickness, the liquid film thickness is independent of the particle radius, and the liquid film thickness at this time is recorded as δ; A2 Assume that the liquid film thickness is proportional to the radius of the particles, the liquid film thickness decreases with the decrease of the radius, and the liquid film thickness of each size particle is expressed as follow.

Where \(\:{R}_{i}\) is the particle radius, \(\:{d}_{i}\) is the particle diameter, \(\:{\delta\:}_{i}\) is the liquid film thickness, \(\:k\) is the ratio factor of liquid film thickness to particle radius.

Of course, the actual situation is more complex than these two assumptions. Therefore, the conclusions derived from these assumptions may not provide precise guidance for propellant formulation design. However, to some extent, they can still offer directional suggestions for the design of propellant formulations.

Assumption 1

(A1) yields a packing density of ϕ = 0.748 and a liquid film thickness of δ = 1.42 μm. Assumption 2 (A2) yields a packing density of ϕ = 0.786, with the liquid film thicknesses for particles 1 through 4 determined as δ1 = 0.38 μm, δ2 = 5.71 μm, δ3 = 14.46 μm, and δ4 = 1.10 μm, respectively. Additionally, the particle numbers determined by the propellant gradation in Table 2, combined with the volume formula for spheres, can be used to calculate the volume fractions of the liquid-coated particles, vi’. This allows for the derivation of the packing density of the liquid-coated particles, denoted as ϕ’.

Where \(\:{v}_{i}^{{\prime\:}}\) is the volume fraction of each liquid-attached particle, \(\:V\) is the total volume of propellant, \(\:{\varnothing\:}^{{\prime\:}}\) is the packing density of the liquid-attached particles.

In Table 3, it can be concluded that the difference between the values of \(\:{\varnothing\:}^{{\prime\:}}\) and the values of \(\:\varnothing\:\) is smaller in A2, so A2 is more reasonable than A1 because the liquid film thickness of the propellant is proportional to the radius of the filler particles. This conclusion is consistent with the three-phase model proposed by Hashin and Christensen45,46. According to the calculation of three-phase model, the ratio of liquid film thickness to the radius of filler particles is a fixed value.

In order to further verify the above conclusion, under the premise that the volume fraction of the solid filler is 0.63 and the mass fraction is 0.75, five different particle gradations are selected according to the direction of the increase of the particle packing density in Fig. 2.

Table 4 shows that the close packing density of particles under each gradation is given. From gradation 1 to gradation 5, the close packing density of filler particles is increasing, and gradation 5 is the optimal gradation.

Figure 3 shows the liquid film thickness of particles with different sizes under different gradations. From gradation 1 to gradation 5, the liquid film thickness of particles of each size increases continuously. This shows that under the better filler particle gradation, the thicker the continuous phase matrix that the particles can adsorb, the larger the packing density and the less the gap when they are tightly packed. When the continuous phase matrix is added, there will be more matrix coated on the surface of the filler particles. The rheological properties of propellant slurry were tested by rheometer. From Fig. 4 (a), it can be seen that the viscosity of propellant slurry decreases gradually from Gradation 1 to Gradation 5. From Fig. 4 (b), it can be seen that the shear stress of propellant slurry decreases gradually from Gradation 1 to Gradation 5. Both tests show that the thickness of liquid film increases gradually, which verifies that the thickness of liquid film of propellant is related to the particle size of filler particles.

Conclusion

In this paper, based on the mesoscopic structure of PBT propellant slurry, the concepts of liquid film thickness and liquid-attached particles are proposed by analyzing the characteristics of dispersed phase and continuous phase in composite solid propellant slurry. By calculating the close packing density of liquid-attached particles, the thickness of liquid film is solved.

Firstly, according to the previous particle packing theory, a packing theory for propellant filler particles was developed, which can be used to deal with the system containing four particle gradations (or more particle gradations). Then, by calculating the Loosening effects, Wall effects and Wedging effects between the four particles respectively, and using MATLAB software to solve the packing density formula, the packing density of the four-level filler particles under different proportions can be obtained. Furthermore, the liquid film thickness solution formula is used to solve its specific value.

Results of this study suggest that the liquid film thickness of the propellant becomes thinner with the decrease of the particle radius and changes proportionally with the radius of the particles. Moreover, based on the five propellant formulations, theoretical and experimental verifications were carried out, which can illustrate the correctness of the above conclusions.

More importantly, the mesoscopic structure of propellant slurry with different composition and gradient can be analyzed by proposing and solving the liquid film thickness of liquid attached particles, rather than just using the ' average ' concept of volume fraction, and the calculation method of liquid film thickness under different propellant filler gradations is given. The analysis method provides theoretical guidance for propellant formulation design, thus reducing the number of experiments, shortening the development cycle of propellant formulation, and reducing the cost of manpower and material resources.

Data availability

The datasets generated and/or analyzed in this study are not publicly available, but can be obtained from the corresponding authors upon reasonable request.

References

Yu, H. et al. Combustion of ammonium dinitramide based solid propellant with PBT as energetic binders. Propellants Explos. Pyrotech. 49(4), e202300231 (2024).

Li Miaomiao, Z. & Zhipeng, C. Research on performance of PBT/Bu-NENA low-vulnerability propellant. FirePhysChem 2 (4), 367–373 (2022).

Ye, G., Zhou, W. & Zhibin, S. Investigation into mechanical properties of PBT propellant under accelerated aging at alternating temperature and constant strain. J. Phys. Conf. Ser. 2285(1), 012037 (2022).

Weijing, W. et al. Comparative research on tension-compression mechanical properties of the azide propellant. J.Phys. Conf. Ser. 2285(1), 012024 (2022).

Ehtasimul Hoque, S. et al. Rheo-kinetic study of 4‐(Dimethylsilyl) Butyl ferrocene‐grafted HTPB‐based composite propellant and evaluation of casting rate. Asia-Pacific J. Chem. Eng. 18(5), e2960 (2023).

Zhang Jing, W. et al. Influence of solid filler on the rheological properties of propellants based on energetic thermoplastic elastomer. Materials 16 (2), 808–808 (2023).

Wang Yi, W. et al. Rheological impact of particle size gradation on GAP propellant slurries. ACS Omega. 7 (43), 38536–38542 (2022).

Jain Mukesh, Balasubramanian, K. et al. Rheological, viscoelastic and slip flow behaviour of composite propellant Slurry—A review. Reviews Adv. Sci. Eng. 4 (4), 291–300 (2015).

Siva, V., Sivakumar, R. & Prasaad, L. D. Combustion instabilities and its control techniques for liquid propellant rocket engine. Int. J. Veh. Struct. Syst. 15 (1), 122–126 (2023).

Myong Won Yoon; Kyung-Moo Kim. Case study of combustion instability in solid propellant rocket motors. J. Korean Soc. Aeronaut. Space Sci. 31 (1), 133–140 (2003).

Rastogi, R. P., Rao, A. P. & Syal, V. Intrinsic instability during combustion of composite solid propellants. J. Non-Equilib. Thermodyn. 10 (3), 163–170 (2009).

Santhosh, G., Reshmi, S., Reghunadhan, C. P. & Nair Rheokinetic characterization of polyurethane formation in a highly filled composite solid propellant. J. Therm. Anal. Calorim. 140 (1), 213–223 (2020).

Guo, L., Dong, C. & Ke, L. Influence of hole-pressure error on pasty propellant rreological test results. IOP Conf. Ser. Mater. Sci. Eng. 677(3), 032071 (2019).

Lade, W. Effect of aluminum nanoparticles on rheological behavior of HTPB-based composite rocket propellant. J. Energ. Mater. 37 (2), 125–140 (2019).

Shen, W. W. et al. Effects of formulation and temperature on the rheological behavior of Nitroguanidine-Based propellants. Mater. Sci. Forum. 4564 (1), 262–268 (2018).

Martinez-Pastor, J., Franco, P. & Franco-Menchon, J. A. Optimization of extrusion process of double-base propellants from their rheological properties. Int.J. Mater. Form. 12 (2), 307–320 (2019).

Lade Rohit, W. et al. Effect of aluminium nanoparticles on rheology of AP based composite propellant: experimental study and mathematical modelling. Mol. Simul. 47 (6), 526–535 (2021).

Yue, W. Z. et al. Experimental study of rheological properties of solid propellant slurry at low-shear rate and numerical simulation. J. Appl. Polym. Sci. 137 (42), 49287 (2020).

Rohit Lade, K., Wasewar, R. & Sangtyani Influence of the addition of aluminium nanoparticles on thermo-rheological properties of hydroxyl-terminated polybutadiene-based composite propellant and empirical modelling. J. Therm. Anal. Calorim. 138 (1), 211–223 (2019).

Jain Mukesh, S. et al. Studies on rheological behavior of composite propellant slurry on sequential incorporation of ingredients to predict qualitative mixing pattern. Adv. Sci. Eng. Med. 7 (10), 849–854 (2015).

Zhao, J. Effect of particle/matrix interface parameters on mechanical properties of high-energy propellant based on three-dimensional RVE model. J. Phys. Conf. Ser. 2783 (1), 012067 (2024).

Huang, W. et al. Molecular dynamics simulation of bonding role of Cyclic Borate ester in improving mechanical properties of the HTPB propellant. Mater. Today Commun. 39 (1), 108692 (2024).

Zhang, L. et al. Mesoscale mechanics investigation of multi-component solid propellant systems. e-Polymers 24 (1), 20240006 (2024).

Zhang, J. et al. Unraveling and in-situ observation on the interfacial mechanical behavior of the NEPE propellant reinforced by NPBA via molecular dynamics simulation. Chem. Eng. Sci. 299, 120463–120463 (2024).

He Liming, H. & Wei, M. Zhongliang. Effect of components on the curing of glycidyl Azide polymer spherical propellant through rheological method. Royal Soc. Open. Sci. 5 (10), 181282 (2018).

Alessandra Zumbo, L. et al. Rheological and mechanical characterization of 3D-Printable solid propellant slurry. Polymers 16 (5), 576 (2024).

Dombe Ganesh, J. et al. Studies on effect of solid loading on slip flow behaviour of HTPB based propellant slurry by rotational rheometry. Adv. Sci. Eng. Med. 9 (2), 85–90 (2017).

Aranguren, M. I. Effect of reinforcing fillers on the rheology of polymer melts. J. Rheol. 36 (6), 1165–1182 (1992).

Furnas, C. C. Grading aggregates I – Mathematical relations for beds of broken solids of maximum density. Ind. Eng. Chem. 23 (9), 1052–1058 (1931).

Farris, R. J. Prediction of the viscosity of the multimodal suspensions from unimodal viscosity data. Trans. Soc. Rheology. 12 (2), 281 (2000).

Yang Kexi. Calculation of maximum solid filling amount for solid propellants. J. Propuls. Technol. 6 (5), 55–62 (1985).

Yang Kexi, T. & Zeming, W. G. Estimation of viscosity for composite solid propellant slurry. J. Propuls. Technol. 6 (4), 19–23 (1985).

Xiao Yanghua. Optimization study on grading composition-method of grading composition with rolling particles. J. Propuls. Technol. 14 (4), 60–67 (1993).

Richard, D. S. A generalized model to predict the viscosity of solutions with suspended particles. I. J. Appl. Polym. Sci. 48, 25–36 (1993).

Richard, D. S. A new method to predict the maximum packing fraction and the viscosity of solutions with a size distribution of suspended particles. II J. Appl. Polym. Sci. 48, 37–55 (1993).

Sadler, L. Y. & Sim, K. G. Minimize solid-liquid mixture viscosity by optimizing particle size distribution. Chem. Eng. Prog. 87 (3), 68–71 (1991).

Wong, V. & Kwan A K H. A 3-parameter model for packing density prediction of ternary mixes of spherical particles. Powder Technol. 268 (1), 357–367 (2014).

Kwan, A. K. H., Chan, K. W. & Wong, V. A 3-parameter particle packing model incorporating the wedging effect. Powder Technol. 237 (3), 172–179 (2013).

Tao, J. et al. Characteristics of particle-wet wall impact damage: Effects of liquid film parameters. Wear 562–563, 205627 (2025).

Gareth Morris, K., Hadler, J. & Cilliers Particles in thin liquid films and at interfaces. Curr. Opin. Colloid Interface Sci. 20 (2), 98–104 (2015).

Coertjens, S., Moldenaers, P., Vermant, J. & Isa, L. Contact angles of microellipsoids at fluid interfaces. Langmuir 30, 4289–4300 (2014).

Morris, G., Neethling, S. J. & Cilliers, J. J. Predicting the failure of a thin liquid film loaded with spherical particles. Langmuir 30, 995–1003 (2014).

Hanyang Mo, G. et al. A numerical study of the mechanism of liquid film spread and distribution on spherical particles including wall effects. Powder Technol. 375 (20), 182–198 (2020).

Milacic, E., Baltussen, M. W. & Kuipers, J. A. M. Direct numerical simulation study of droplet spreading on spherical particles. Powder Technol. 354, 11–18 (2019).

Hashin, Z. The elastic moduli of heterogeneous materials. J. Appl. Mech. 29 (1), 2938–2945 (1962).

Christensen, R. M. & Lo, K. H. Solutions for effective shear properties in three phase sphere and cylinder models. J. Mech. Phys. Solids. 27 (4), 315–330 (1979).

Acknowledgements

This work was greatly supported by the Natural Science Foundation of China (12272184 and 12402436) and National Key Laboratory of Energetic Materials, China (2023-XXXX-LB-036-09).

Author information

Authors and Affiliations

Contributions

Ye-wei Shen: Investigation, Writing, Formal analysis; Mao-fa Yang: Conceptualization, Validation; Hong-Guang Zhang: Data Curation, Writing; Li-ping Huang: Methodology; Shu-min Xing: Investigation; Xian-ren Zhang: Methodology, Investigation; Yi-min Luo: Investigation; Sen Xu: Supervision, Project administration, Funding acquisition.Xingliang Wu: Project administration, Funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Shen, Yw., Yang, Mf., Zhang, HG. et al. Theoretical characterization of mesoscopic structure of PBT propellant based on liquid film thickness. Sci Rep 15, 12968 (2025). https://doi.org/10.1038/s41598-025-97596-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-97596-x