Abstract

A qualified circuit breaker possesses an inherent electrical life upon leaving the factory. During its operational lifespan, this electrical life gradually diminishes due to various factors, including electrical and mechanical wear. The electrical life of a circuit breaker is designed based on service conditions, with resource reserves optimized at the end-of-life stage to achieve efficient and environmentally friendly design principles. The mechanism of arc erosion on contacts has been analyzed, and the wear loss caused by arc erosion has been calculated. A portion of the heat generated during arc combustion contributes to contact wear, leading to the establishment of an electrical life prediction model for circuit breakers based on heat utilization efficiency. This model is tested and validated using the Monte Carlo method, confirming its accuracy. Based on this prediction model, a green design framework for optimizing electrical life distribution has been proposed. This approach minimizes unnecessary resource reserves while enhancing resource utilization efficiency.

Similar content being viewed by others

Introduction

In power systems, the circuit breaker is a critical electrical component utilized in switching equipment. Research on performance design, fault diagnosis, and other aspects can enhance its performance, prevent failures, and assess its reliability. The U.S. Army Corps of Engineers collected and analyzed a database of circuit breakers over several decades. Thompson and Barriga researched the details of that database to provide new insight to failure trends, and revealed limitations of previous circuit breaker statistics1. Žarković and Stojković proposed AI method, including fuzzy expert systems, unsupervised machine learning and artificial neural network, to improve health assessment of high-voltage SF6 circuit breaker and it is applied to predict end-life and accelerated aging2. Combined fractal technology and probabilistic neural network, Yao and Wang proposed a fault diagnosis model to classify and identify faults for small circuit breaker3. In order to improve fault diagnosis of circuit breaker, Sun et al. proposed a 2-D convolution neural network method of fault diagnosis for conventional circuit breaker contact system4. High Voltage Direct Current (HVDC) systems are now well-integrated into AC systems, especially in renewable energy sources. HVDC circuit breaker is applied to meet requirements of DC grids and connected AC grids. For HVDC circuit breaker, its technologies and development were comprehensive reviewed5. He et al. proposed a kind of high-performance and economical multi-port hybrid DC circuit breaker, which can break full fault current with lower costs, and its performances were verified by four-terminal HVDC system in PSCAD/EMTDC6. There is no current zero-crossing in DC circuits, Sen and Mehraeen proposed oscillatory circuit that can improve the fault current extinction and significantly reduce voltage slew rate, so it is able to interrupt high DC current with low arc7. Zhao et al. used Markov model on reliability model of hybrid DC circuit breaker to analyses the influence of different redundancy components and modes for weak components, which can provide reliability prediction and design of hybrid DC circuit breaker8. For fast interrupting fault in DC systems, Ray et al. proposed a coupled inductor-based hybrid DC circuit breaker topology with zero current, and it is verified by simulation9. For mechanical DC circuit breaker, the fault current can be broken quickly and reliably depends on dynamic characteristics of LC resonant commutation branch. That was researched by Qu et al. and they proposed feasibility basis for parameter design10. The conventional electromechanical circuit breakers, as effective and reliable devices, had been proven for circuit protection. With the new technologies of power distribution development, solid-state circuit breakers have been increasing in research and development. The technologies of solid-state circuit breakers were comprehensively reviewed and provided suggestions for future development11. Xu et al. proposed a novel solid-state circuit breaker based on mixture device for DC distribution systems, which can actively interrupt faults and is not affected by parameters of outer circuit12. Based on Reverse Blocking IGCT semiconductor technology, Qi et al. designed a kind of solid-state circuit breaker and DC fault protection was tested for shipboard power systems, which can greatly reduce fault energy13. During the operation of a circuit breaker, the metal material between movable and static contacts gradually diminishes due to electrical wear. Arc erosion is associated with energy losses such as electrical and mechanical wear, and results in electrical life termination of the circuit breaker when contact wear accumulates to a failure threshold. Based on the concept of green design, this paper optimizes the calculation of contact wear, carries out the green design of circuit breaker’s electrical life, and makes the circuit breaker upgrade from a simple industrial product to an environment-friendly product.

The service life of electrical equipment is specified in the relevant standards, laws and regulations of electrical equipment. When the electrical equipment reaches the specified service life, it shall be withdrawn in time. Accurately predicting the remaining useful life (RUL) of electrical equipment, which can reduce unplanned maintenance, is essential for accident prevention. The electrical life is a critical performance metric for circuit breakers, contactors, and similar devices, which are influenced by various factors, with arc erosion caused by arc current being the most significant. Based on arcing phase angle, Zheng et al. proposed erosion model of AC contactor to simulate electrical life distribution characteristics under random operations, and they find that the electrical life distribution is closely related to manufacturing dispersion14. Based on contact erosion loss, Li et al. proposed an online reliability evaluation method that can predict electrical life of AC contactor, and simulate the electrical life test with Monte Carlo15. The lifetime consumption and degradation of components, such as insulation systems of electrical machines, is generally evaluated by statistical method. That is a very time-consuming and expensive process, but Gale et al. proposed a method of reliability-oriented design16. The electrical connector is essential for motor vehicle, Liskiewicz et al. proposed a surface design that controls metal interface and ensures low contact resistance to extend service life of electrical contacts17. The overviews of super capacitors mainly focus on materials, electrical and thermal modeling, etc., Liu et al. reviews the failure mechanisms, lifetime modeling, and reliability-oriented design in energy storage applications18. Based on improved convolution neural network and long short-term memory, Ren et al. proposed a prediction method to solve that problem19. The health state and remaining life estimation are important parameters for battery replacement, Zhang et al. proposed a novel on-line synthesis method to estimate that parameters based on the fusion of partial incremental capacity and artificial neural network20. Siu et al. proposed an effective and reliability solution for the design of hybrid circuit breaker, which can provide high-reliability protection feature for DC micro grid with low conduction loss, bidirectional current flow, and galvanic isolation function21. Although the electrical life of electrical equipment is specified in the relevant IEEE standards, only the time of electrical life is specified, and how to carry out the prediction of electrical life and how to design the electrical life reasonably are not considered. Therefore, this paper carries out the research on the electrical life prediction of circuit breakers, drives the electrical industry to carry out electrical life prediction, design and other research, finally forms the industry standard of electrical life.

The rapid growth of electrical and electronic equipment brings new challenges. In order to deal with these challenges, this paper takes the electrical life of circuit breaker as an example to carry out the green design research of electrical life and develop “green” electrical equipment with low energy consumption and low cost. Li et al. reviewed recent advances in biodegradable materials and processing strategies for electronics22. If the concept of green design can be applied to design and manufacture products, it will greatly reduce environment impact. Based on the extension theory and concept of Green DNAs, Ko proposed green design method that includes green technology, green material, and green manufacturing23. Logesh and Balaji researched continuous involvement of lean manufacturing to identify and eliminate waste in all stages, which can reduce effects on green environment24. Previous studies established green model of technological change in production, but the green economy also requires changing products. Therefore, the incentive of green product innovation was researched in industrial networks25. Zhang et al. proposed a method of design schemes to evaluate environmental impact and life cycle cost, and to achieve optimal integration of environmental impact and cost26. Based on analytical hierarchy process and technique for order of preference by similarity to ideal solution, Singh et al. researched eight aspects to examine priority and assure successful green manufacturing execution in various enterprises27. For circuit breakers, conducting green design of electrical life presents a new technical challenge. In order to solve this problem, this paper proposes a method to distribute the electrical life reasonably in the production process, which can reduce the input of raw materials in the design and production links, and reduce the management of waste when the electrical life is over, thus improving the utilization of resources. In the whole life cycle of the circuit breaker, the impact on the environment is reduced, and the circuit breaker becomes an environment-friendly green product and makes a beneficial contribution to environmental protection.

The remainder of this study is organized as follows. In “Calculated wear amount of arc erosion contact”, the wear amount of arc erosion contact was calculated. In “Established prediction model of electrical life”, the prediction model of electrical life was established. In “Monte Carlo simulation and analysis”, the test of electrical life was simulated and analyzed by Monte Carlo method. In “Established green design model of electrical life”, the green design model of electrical life was established. Conclusions were presented in “Conclusions”.

Calculated wear amount of arc erosion contact

The electrical life of circuit breakers is defined by the number of “make-break” times it can complete. This functionality relies on the coordinated operation of multiple components, including the operating mechanism, arc extinguishing chamber, movable contact, static contact, and others. Consequently, the internal structure of a circuit breaker is complex and electromechanical in nature. The miniature circuit breaker (MCB), despite its simpler design, still incorporates these essential components. Its internal structure is illustrated in Fig. 1.

The contact system of a circuit breaker comprises components such as contacts, the operating mechanism, and the arc extinguishing chamber. This system is crucial for achieving the electrical life of the circuit breaker. The contacts consist of movable and static contacts. Key design parameters for the contacts include breaking distance, contact pressure, and over travel. The action process of the movable and static contacts is illustrated in Fig. 2.

In Fig. 2a, the breaking distance (lb) is the shortest distance between movable and static contacts when the contact is in breaking state. In Fig. 2b, the contact pressure (F) is the pressure generated between movable and static contacts under the action of connecting rod structure. In Fig. 2c, when the movable and static contacts are kept in closed position, then the static contact is moved away, the distance between movable and static contacts is extra trip (le) that the movable contact can move. After the connecting rod of static contact is moved away, the movable angle of connecting rod of movable contact is θ.

Due to the influence of various factors such as material properties and arcing time, it is challenging to establish an accurate arc mathematical model during the electrical life testing process. Consequently, accurately calculating the electrical life of a circuit breaker is difficult, and it can only be roughly estimated based on relevant parameters. The electrical life of a circuit breaker typically ranges from hundreds to thousands of times, reflecting its multi-cycle operational characteristics. Therefore, the accumulation of contact wear is the key factor affecting the electrical life.

In Fig. 2, the movable contact is taken as an example, it is assumed that the contacting surface area is S between movable and static contacts, and the movable contact thickness is h. The volume V of movable contact is calculated in Eq. (1).

The electrical wear of contacts is a process involving heat transfer, and the arc’s lifecycle from generation to extinction is accompanied by changes in energy and temperature. Initially, the high-temperature arc melts the metallic material of the contacts. Subsequently, during arc combustion and extinction, the arc causes evaporation and spatter erosion of both liquid and gaseous metallic materials. The heat involved in this process is quantified by Eq. (2).

where, c is the specific heat capacity of metal material for movable contact, mj is the mass loss of movable contact during the jth operation, Tr is the boiling point of metal material for movable contact, T0 is the initial temperature of metal material for movable contact, pj is the required heat for electrical wear during the jth operation for movable contact.

The electrical wear of the movable contact is closely related to the metal material, arc current, and duration. Therefore, the electrical wear rate is expressed by Eq. (3).

where, \(\frac{{{\text{d}}w}}{{{\text{d}}t}}\) is the electrical wear rate, w is the amount of contact wear, t is time, K is a constant related to the contact material, I is the effective value of arc current.

The arc current is a transient current containing direct current component and alternating current component, that is a variable related to time t, and is represented by function i(t). Its effective value can be expressed by Eq. (4).

where, t1 is the start point of arc current, t2 is the end point of arc current.

From Eqs. (3) and (4), it can be observed that arc wear exhibits an exponential characteristic, and electrical wear is exacerbated as the arc current increases.

In the electrical life test, the arc current exhibits randomness, leading to stochastic contact wear. The electrical life of circuit breakers typically ranges from hundreds to thousands of times. When the number of tests is sufficiently large, assumptions regarding electrical wear can be made based on the law of large numbers.

-

(1)

The electrical wear is equivalent to the Joule integral of arc current, but the efficiency of heat released by the arc to be absorbed by the electrical wear should be considered.

-

(2)

Electrical wear primarily occurs on the movable contact; therefore, the calculation focuses on the electrical wear of the movable contact, while the electrical wear of the static contact is neglected.

-

(3)

In each “closing and opening” operation, the relationship between the wear amount w of movable contact and the abrupt current i(t) can be calculated by the Eqs. (3) and (4). As shown in Eq. (5).

-

(4)

The wear amount of movable contact is linearly superimposed, and the total wear amount W is calculated, as shown in Eq. (6).

where, wj is the wear amount of movable contact during the jth operation and n is the times of electrical life.

-

(5)

The electrical wear of the movable contact can be equivalently expressed by the mass loss of the movable contact during operation.

-

(6)

For the amount of wear, the effects of other factors are neglected.

Established prediction model of electrical life

In the course of conducting an electrical life test, a data acquisition system is employed to gather current data. Firstly, the sampling rate f of data acquisition system is set. Then the current data is collected, and the collected data iω is a discrete value, and fitting the discrete value to obtain an arc current curve. Finally, the numerical calculation is performed on the collected current data to obtain the Joule integral of arc current, as shown in Eq. (7).

where, I is the effective value of arc current, tr is the arcing time, f is the sampling rate, iω is the ωth discrete value of arc current, M is the number of discrete points for arc current.

In the process of arc combustion, the heat generated is categorized into three distinct components: the first component accounts for electrical wear on the contacts; the second component involves heat radiation into the surrounding air; and the third component facilitates heat conduction, thereby elevating the overall temperature of the circuit breaker. For the electrical wear of contacts, it is assumed that the average efficiency of heat dissipation is denoted by η. This relationship is articulated in Eq. (8), which is derived from assumption (1) and Eq. (5) to (7).

According to Eqs. (6) and (8), it can be calculated by Eq. (9).

According to law of energy conservation, the loss mass of contact is calculated by Eq. (10).

where, r is arc resistance.

According to Eq. (10), the mass lost mj is calculated during the jth operation of movable contact, as shown in Eq. (11).

where, the arc resistance r varies randomly, and its statistical average value can be obtained through a large number of tests.

In engineering design, mj is regarded as the characteristic parameter of contact performance degradation. It is widely accepted that a circuit breaker is not suitable for operation when the volume of the movable contact decreases to less than 1/3 of its original volume. That is the extra trip design in Fig. 2c. Therefore, the 2/3 of volume reduction of movable contact is equivalent to that caused by electrical wear.

According to Eqs. (1) and (11), the allowed number N of electrical life can be calculated for movable contact, that is, the inherent electrical life N of movable contact can be predicted, as shown in Eqs. (12) and (13).

where, ρ is material density of movable contact.

If it is known that the wear number of movable contact is nx, the remaining electrical life of movable contact can be predicted Nx, as shown in Eq. (14).

From Eq. (14), it can be seen that theoretically, Nx decreases linearly with the increase of nx, which is consistent with assumption (4). In the process of electrical life test, with the deterioration of contact metal material performance and the aggravation of arc erosion, Nx decreases with the increase of nx at an accelerated rate, which is not a linear relationship. Between theoretical and actual values of Nx and nx, the above relationship can be described as a nonlinear relationship, as shown in Fig. 3.

In Fig. 3, the relationship between theoretical and actual values is influenced by the contact material, arc current, arc time, and so on. The electrical life of movable contact directly affects the electrical life of circuit breaker. Therefore, the inherent electrical life N and the residual electrical life Nx of movable contact are theoretically analyzed and calculated, that can be equivalent to a prediction model of electrical life for circuit breaker. The model can be used to predict the intrinsic electrical life and residual electrical life of circuit breaker.

Monte Carlo simulation and analysis

In the design stage, it is essential to verify the performance of a product through rigorous testing. The accuracy of failure data in reflecting the electrical life performance of a product increases with the number of samples used in electrical life tests. However, this testing method requires significant investment in terms of test samples, manpower, time, and other associated costs. In laboratory settings, the Joule integral serves as a measurable value that can be successively recorded and cumulatively calculated during electrical life tests for circuit breakers. Accurately measuring contact wear and heat released by arcs poses considerable challenges. The application of the Monte Carlo method to validate theoretical models for predicting electrical life not only reduces economic and temporal expenditures but also facilitates timely identification and correction of model discrepancies. Consequently, we employ the Monte Carlo method to simulate the theoretical prediction model for electrical life established herein. The specific methodology is outlined as follows.

Based on electrical life prediction model, the electrical life of contact is equivalent to the number X of test times, when the electrical wear of contact is accumulated to reach total wear amount W, as shown in Eq. (15).

In Eq. (15), the arc current i(t) varies randomly due to factors such as the arcing time tr, so that pj also varies randomly.

The certain type of MCB is taken as an example in electrical life test. When the opening angle φ is about 60°, three representative arc currents were collected as shown in Fig. 4.

In Fig. 4, the expected current i(φ) and arc current are converted to per-unit values for electrical life test. The horizontal axis represents current angle. The vertical axis represents current amplitude. The expected current is a standard sinusoidal current that disappears when the arc current is present during electrical life test.

In Fig. 4, the certain type of MCB is taken as an example in electrical life test. Observed its arcing time tr, it is found that tr changes 3–6 ms.

It is taken as an example in Fig. 4. The Monte Carlo method is applied to simulate electrical life test, and the specific steps are as follows.

Step 1: The arc current is simplified as a random variable related to arc time: i(t) = Imsin(ωtr + ψ), which is equivalent to f = 50 Hz current, ω = 2πf, and ψ represents initial phase of current.

Step 2: The arc time tr is randomly distributed in from 3ms to 6ms, so uniformly distributed random numbers are generated in interval [3ms, 6ms], and its value is represented as tr.

Step 3: The varying arc current randomly generated based on expected current, and the initial phase of the expected current ψ = 0. The arc current is calculated based on per-unit conversion as shown in Eq. (16).

Step 4: The Fig. 3 was taken as an example, when that opening angle of MCB is 60° and the arcing time tr was in random distribution of 3–6 ms. The arc extinction angle was between 114° and 168°. The total Joule integral Qλ of 4000 times of electrical life was calculated, as shown in Eq. (17).

where, Ij is the effective value of the jth arc current, and trj is the jth arc time.

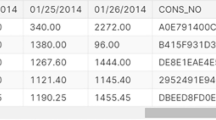

Step 5. In Fig. 4, the electrical life test of 10 MCBs was simulated by Monte Carlo with Matlab programming. The electrical life of each MCB is 4000 times, and its total Joule integral Qλ was calculated and shown in Table 1.

In Table 1, the total Joule integral Qλ is from 28.86 A2·s to 28.97 A2·s for 10 Monte Carlo simulation results. If the number of Monte Carlo simulation is increased, the value of Qλ may change. As can be seen from Table 1, the range of Qλ does not large with the increase of simulation times. Therefore, 10 simulations can represent the experimental results.

The average value of Qλ was calculated according to Table 1, as follows.

\(\overline {{{Q_\lambda }}} =\,{\text{28}}.{\text{912}}\)

Based on the assumption (1) of Sect. 1, it is further assumed that Qλ is known and equal to average value. The Eq. (18) is obtained from Eq. (9).

When tr randomly varies between 3ms and 6ms, the electrical life test is simulated by Monte Carlo according to Eqs. (6), (8), (16) and (18). W can be obtained at 4000 times of electrical life, and then η is calculated. 10 MCBs were selected for the Monte Carlo simulation test of electrical life, and the efficiency η was obtained, as shown in Table 2.

In Table 2, the efficiency η is from 55.70 to 56.79% for 10 Monte Carlo simulation results. If the number of Monte Carlo simulation is increased, the value of η may change. As can be seen from Table 2, the range of η does not large with the increase of simulation times. Therefore, 10 simulations can represent the experimental results.

The average value of η was calculated according to Table 2, as follows.

\(\overline {\eta } =\,{\text{56}}.{\text{29}}\%\)

Through the above calculation, it can be found that the arc burns and releases heat, when less than 56.29% of the heat is absorbed, then the electrical life of MCB is more than 4000 times; when 56.29% of the heat is absorbed, the electrical life of MCB is equal to 4000 times; when more than 56.29% of the heat is absorbed, the electrical life of MCB is less than 4000 times.

In Table 1, the electrical life of the fourth MCB is taken as an example. The statistical relationship is shown in Fig. 5, between electrical life and efficiency η.

In Fig. 5, the efficiency η fluctuates between 55.78% and 56.56% as times increases for electrical life of MCB. If η is regarded as a constant, there is a linear relationship between wear of movable contact and times of electrical life.

Established green design model of electrical life

The theory of assured reliability uses performance margin model to describe the reliability of product. It is emphasized that the performance margin of an object determines its reliability, and the corresponding performance margin model is presented in Eq. (19).

where, m is performance margin of product, p is performance parameter of product, and pth is failure performance parameter of product.

m is used to represent the working state of product, the following three situations may exist.

-

(1)

When m > 0, the product works normally;

-

(2)

When m < 0, the product fails;

-

(3)

When m = 0, the product is in an unstable critical state.

Where, m is an uncertain random variable and the normal working of product is that m is greater than 0.

Considering the uncertainty of performance parameter p and failure criterion parameter pth, the following three cases are possible.

-

(1)

Both p and pth are uncertain variables;

-

(2)

p is a random variable and pth is an uncertain variable;

-

(3)

pth is a random variable and p is an uncertain variable.

If the above performance margin model is used to represent electrical life of contact, Eqs. (14) and (19) are expressed correspondingly, that is, m represents Nx, pth represents N, p represents nxmj. Based on performance margin model and electrical life prediction model, the performance degradation process of electrical life is comprehensively considered. From the point of view of energy conservation, the electrical life can be equivalent to energy conversion between contact wear and Joule integral. It is assumed that the movable contact of qualified circuit breaker is specified in design, the failure energy threshold Eλ, and the energy E0 has been stored when leaving factory. In the process of use, the energy loss ΔE occurs with electrical wear of contact and other reasons, and the residual energy of contact is Ex. The relationship between the above parameters is shown in Eq. (20).

where, ΔE and Ex are random variables.

As m = Ex - Eλ, p = ΔE, pth= E0, then the performance margin model of electrical life is as shown in Eq. (21).

As the test times of electrical life increase, ΔE increases gradually. When the residual energy Ex is less than failure energy threshold Eλ specified in the design, m is changed from m > 0 to m < 0, it is determined that electrical life fails. In conjunction with Fig. 3, the above process is described as an “energy-electrical life relationship”, as shown in Fig. 6.

The electrical life is represented by times of test τ, and the relationship between energy and electrical life is represented by E(τ). In the ideal case, when the wear of movable contact is reduced to 1/3 of initial state, the electrical life is considered to be invalid, which is shown as the “Idea curve” in Fig. 6. The traditional design concept considers the margin of electrical life and safety factor k (k > 1). The relationship between the energy and electrical life is represented as kE(τ), which is represented as the “Classic curve” in Fig. 6. Electrical life failure is a complex performance and degradation process, which is affected by random load, random strength and other factors. If the passive elimination of circuit breaker is fully considered, the electrical life is designed according to the concept of green design. The relationship between energy and electrical life is shown as the “Green curve” in Fig. 6. Base on the ideal curve and Eu=Eλ, it can be seen that the difference between traditional design and green design concepts on resource utilization for electrical life of circuit breaker.

It is assumed that the designed electrical life of circuit breaker is τu. The electrical life of circuit breaker is τv, which is passively eliminated due to technological progress and other reasons. Their resource utilization rates of traditional design are ηuc and ηvc respectively. Their resource utilization rates of green design are ηug and ηvg respectively. The relationship between the above parameters is shown in Eqs. (22)–(25).

In Fig. 6, the residual energy of movable contact is expressed as Ev, Evg, Evc in the Idea curve, Green curve and Classic curve respectively at time τv. Their relationship is compared, as shown in Eq. (26).

At time τu, the residual energy of movable contact is expressed as Eu, Eug and Euc respectively, and their relationship is compared, as shown in Eq. (27).

At time τu and τv, the resource utilization rates ηuc, ηug, ηvc, ηvg are compared respectively, as shown in Eqs. (28) and (29).

It can be observed from Eqs. (26) to (29) that circuit breakers designed in accordance with green design principles not only reduce resource reserves but also minimize resource waste during passive elimination. Furthermore, the rate of resource utilization is enhanced. Consequently, a well-considered design of electrical lifespan will have a direct impact on both the performance of circuit breakers and overall resource utilization.

Conclusions

The electrical wear of the movable contact is a key factor affecting the electrical life of circuit breakers. Therefore, this study investigates the wear mechanism of the movable contact and its impact on the electrical life of the circuit breaker. The specific research process and results are as follows.

-

(1)

The mechanism of arc erosion on movable contacts is analyzed, and the electrical wear of the movable contact is equated to the Joule integral of the arc current. It is assumed that the electrical wear can be equivalently expressed in terms of the mass lost by the movable contact during operation. The equations for calculating contact wear due to arc erosion are derived.

-

(2)

A portion of the heat released by arc combustion is utilized for the electrical wear of the movable contact. An electrical life prediction model of the circuit breaker is established based on heat utilization efficiency, enabling the prediction of both the inherent and remaining electrical life of circuit breakers.

-

(3)

The Monte Carlo method is employed to simulate the established electrical life prediction model. It is found that the heat absorption efficiency of 56.29% during arc combustion is negatively correlated with an electrical life of 4000 times. Statistical analysis of the test results verifies the accuracy of the model.

The concept of green design for electrical life is introduced for the first time in the electrical field, and the circuit breaker is selected as a case study for research. This research has practical application value for the green design of electrical products, which is not limited to the green design of electrical life. For manufacturers, the specific research values and recommendations are as follows.

-

(1)

A green design model for electrical life is established, which reduces resource consumption in the design of circuit breakers. By comparing resource utilization between traditional design and green design approaches for electrical life, it is evident that the green design model significantly improves resource efficiency.

-

(2)

Currently, the green design of circuit breakers has certain limitations, and further research is needed on their electrical life prediction models. The concept of green design for electrical life requires additional investigation and refinement to enable broader application across various electrical fields.

-

(3)

The manufacturers can refer to Fig. 6 when carrying out the electrical life design of circuit breakers. First, the circuit breakers that have been produced are selected for electrical life test and the “Idea curve” curve is drawn. Then, the failure data of circuit breakers’ electrical life are counted and the “Classic curve” is drawn. Finally, the green design is carried out based on the relationship between the above two curves and the “Green curve” is obtained.

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Thompson, C. C. & Barriga, C. I. Relationship between historical trends, equipment age, maintenance, and circuit breaker failure rates. IEEE Trans. Ind. Appl. 55 (6), 5699–5707 (2019).

Zarkovic, M. & Stojkovic, Z. Artificial intelligence SF6 circuit breaker health assessment. Electr. Power Syst. Res. 175, 105912 (2019).

Yao, Y. & Wang, N. Fault diagnosis model of adaptive miniature circuit breaker based on fractal theory and probabilistic neural network. Mech. Syst. Signal Process. 142, 106772 (2020).

Sun, S. et al. Fault diagnosis of conventional circuit breaker contact system based on time–frequency analysis and improved Alexnet. IEEE Trans. Instrum. Meas. 70, 3508512 (2020).

Mohammadi, F. et al. HVDC circuit breakers: a comprehensive review. IEEE Trans. Power Electron. 36 (12), 13726–13739 (2021).

He, J. et al. A high-performance and economical multi-port hybrid DC circuit breaker. IEEE Trans. Ind. Electron. 67 (10), 8921–8930 (2020).

Sen, S. & Mehraeen, S. Improving low-voltage DC circuit breaker performance through an alternate commutating circuit. IEEE Trans. Ind. Appl. 55 (6), 6127–6136 (2019).

Zhao, S., Yan, X., Wang, B., Wang, E. & Ma, L. Research on reliability evaluation method of DC circuit breaker based on Markov model. Electr. Power Syst. Res. 173, 1–5 (2019).

Ray, A., Rajashekara, K., Banavath, S. N. & Pramanick, S. K. Coupled inductor-based zero current switching hybrid DC circuit breaker topologies. IEEE Trans. Ind. Appl. 55 (5), 5360–5370 (2019).

Qu, L., Yu, Z., Huang, Y. & Zeng, R. Research on effect of circuit parameters on breaking characteristics of mechanical DC circuit breaker. Electr. Power Syst. Res. 179, 106075 (2020).

Rodrigues, R., Du, Y., Antoniazzi, A. & Pietro, C. A review of solid-state circuit breakers. IEEE Trans. Power Electron. 36 (1), 364–377 (2021).

Xu, X. et al. An efficient and reliable solid-state circuit breaker based on mixture device. IEEE Trans. Power Electron. 36 (9), 9767–9771 (2021).

Qi, L. et al. Solid-state circuit breaker protection for DC shipboard power systems: breaker design, protection scheme, validation testing. IEEE Trans. Ind. Appl. 56 (2), 952–960 (2020).

Zheng, S. et al. Analysis of electrical life distribution characteristics of AC contactor based on performance degradation. IEEE Trans. Compon. Packag. Manuf. Technol. 8 (9), 1604–1613 (2018).

Li, K. et al. Electrical performance degradation model and residual electrical life prediction for AC contactor. IEEE Trans. Compon. Packag. Manuf. Technol. 10 (3), 400–417 (2020).

Gale, M., Giangrande, P., Madonna, V. & Buticchi, G. Reliability-oriented design of electrical machines: the design process for machines’ insulation systems MUST evolve. IEEE Ind. Electron. Mag. 14 (1), 20–28 (2020).

Liskiewicz, T. W., Kubiak, K. J., Mann, D. L. & Mathia, T. G. Analysis of surface roughness morphology with TRIZ methodology in automotive electrical contacts: design against third body fretting-corrosion. Tribol. Int. 143, 106019 (2020).

Liu, S., Wei, L. & Wang, H. Review on reliability of supercapacitors in energy storage applications. Appl. Energy. 278, 115436 (2020).

Ren, L. et al. A data-driven Auto-CNN-LSTM prediction model for lithium-ion battery remaining useful life. IEEE Trans. Ind. Inf. 17 (5), 3478–3487 (2021).

Zhang, S. et al. Synchronous Estimation of state of health and remaining useful lifetime for lithium-ion battery using the incremental capacity and artificial neural networks. J. Energy Storage. 26, 100951 (2019).

Siu, K. K. M., Ho, C. N. M. & Li, D. Design and analysis of a bidirectional hybrid DC circuit breaker using AC relays with long life time. IEEE Trans. Power Electron. 36 (3), 2889–2900 (2021).

Li, W. et al. Biodegradable materials and green processing for green electronics. Adv. Mater. 32 (33), 2001591 (2020).

Ko, Y. T. Modeling an innovative green design method for sustainable products. Sustainability 12 (8), 3351 (2020).

Logesh, B. & Balaji, M. Experimental investigations to deploy green manufacturing through reduction of waste using lean tools in electrical components manufacturing company. Int. J. Precis. Eng. Manuf.-Green Technol. 8, 365–374 (2021).

Dugoua, E. & Dumas, M. Green product innovation in industrial networks: a theoretical model. J. Environ. Econ. Manag. 107, 102420 (2021).

Zhang, L., Dong, W., Jin, Z., Li, X. & Ren, Y. An integrated environmental and cost assessment method based on LCA and LCC for automobile interior and exterior trim design scheme optimization. Int. J. Life Cycle Assess. 25, 633–645 (2020).

Singh, M., Singh, K. & Sethi, A. S. Analytical hierarchy process and TOPSIS for selecting best parameters of green manufacturing. Meas. Bus. Excellence. 24 (3), 345–365 (2020).

Acknowledgements

Science and Technology Plan Project of State Administration of Market Supervision (2023MK076).

Author information

Authors and Affiliations

Contributions

All authors wrote and reviewed the main manuscript text.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhou, J., Shang, Z. Green design of circuit breaker electrical life to improve resource utilization. Sci Rep 15, 13542 (2025). https://doi.org/10.1038/s41598-025-97665-1

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-97665-1