Abstract

Collapsible loess in Northwestern China challenges infrastructure backfilling. This study creates a new loess - based cement composite slurry (LCCS) with 8% cement and additives. LCCS has a high 180 - mm slump, a low permeability of 2.1 × 10⁻⁶ cm/s at 8% cement, and its collapsibility coefficient is less than 0.009. Durability tests show it has 27% better frost resistance than plain cement slurry, though with more sulfate - induced mass loss. LCCS uses 30% less cement than conventional CLSM, cutting costs and carbon emissions. Thus, it’s a promising green alternative for backfilling in such areas.

Similar content being viewed by others

Introduction

In recent years, with the in - depth implementation of China’s “One Belt, One Road” initiative, numerous infrastructure projects have sprung up in the northwestern collapsible loess region. However, some backfill work in these projects is faced with challenges such as narrow workspaces, small backfill volumes, large backfill depths, and restricted heterogeneous spaces. These factors prevent dense backfilling. Moreover, the porous, weakly - cemented, collapsible nature of loess, along with its vertically - developed joints, causes many problems in actual engineering applications, leading to uneven settlement of filling projects.

The American Concrete Institute (ACI)1 defines Controlled Low - strength Materials (CLSM), a high - flowability backfill material. Generally, the 28 - day strength of CLSM is less than 8.3 MPa2. This new green engineering material boasts advantages like high flowability, water stability, and low economic cost. Its engineering characteristics vary according to application purposes3. CLSM was first applied using construction - site soil in 19644. In 2017, the concept of “fluidized solidified soil” emerged in China during the backfilling of the base trench for the comprehensive pipeline corridor in the Beijing Urban Subcenter, and since then, it has been popularized on different scales across China5.

Loess consolidation research has attracted increasing attention, with new findings constantly emerging. Hu Zaiqiang et al.6 used a prediction model to study the permeability coefficient of lime - amended loess and established the mathematical relationships among volumetric water content, permeability coefficient, and matrix suction. Baldovino J A7tested the compressive and split - tensile strengths of lime - treated fine - grained soils at different times and found that lime treatment could significantly improve their physical properties. Zhang Y8 used fly ash and cement to improve loess and conducted freeze - thaw durability, freeze - swell, and thaw - weakening tests. The results showed that fly ash slightly enhanced the freeze - thaw durability and frost resistance of loess, while cement effectively cut off the water infiltration path in soil samples. Cheng Z9 carried out percussion and direct shear tests and used FLAC3D software for numerical simulation to explore the effects of desulfurization ash and fly ash on loess strength, concluding that desulfurization ash had a better modification effect. Abdullah’s10 study on fly - ash - based polymer - cured clay indicated that the geopolymer could improve the clay’s durability against dry - wet cycles, but these cycles also caused decomposition damage to geopolymer products, reducing the cured soil’s integrity and durability. Chen Rui11 used geopolymer to cure loess and studied the shear - strength deterioration law under dry - wet cycles through triaxial tests, proposing an empirical formula for strength deterioration. In general, different curing agents have varying advantages and disadvantages in terms of improvement effect, environmental protection, and durability. Cement, being reliable in quality and inexpensive, is an ideal admixture for improving loess.

However, cement - cured soil has drawbacks such as low early strength, susceptibility to dry shrinkage and cracking, and poor mechanical properties when the organic matter content is high. To enhance the properties of cemented soil and expand its application range, many researchers12,13,14 at home and abroad have conducted relevant studies. One common improvement method is adding appropriate additives to hydraulic soil. For example, Wang Shubo15 explored the effect of concrete additives on the mechanical properties of cemented soil through indoor tests and found that they could effectively increase the unconfined compressive strength. Hu Jianlin et al.16 investigated the impact of iron tailing sand on cemented - soil mechanical properties and found that the unconfined compressive strength first increased and then decreased with the increase in iron tailing sand content. Hou Shupeng et al.17 studied the effect of polyacrylamide on the anti - cracking properties of cemented soil and found that it had a positive effect with an optimal dosage. These additives can significantly improve the performance of cemented soil, such as increasing its compressive strength and cracking resistance.

Based on previous research, this paper aims to develop a self - compacting, high - flowability loess - based fluid backfill material with suitable strength. Using Lanzhou - area loess as the test material, cement as the curing agent, and naphthalene sulfonic acid formaldehyde condensate, sodium sulfate, sodium thiosulfate, and ethylene glycol as additives, this study analyzes the variation rules of the permeability coefficient and collapsibility coefficient with cement dosage and curing age by testing the engineering hydrophysical properties of loess - based cement slurries. In Northwest China, the annual alternation of winter and summer, freeze - thaw cycles, and wet - dry cycles affect the material’s durability, and the resulting quality loss and strength damage cannot be ignored. Therefore, durability tests are conducted on loess - based cement composite additive slurries. By comparing with loess - based cement slurries without additives, this study explores the influence rules and roles of concrete additives on loess - based cement composite additive slurries during freeze - thaw and sulfate - dry - wet cycles, providing a reference for future engineering practices.

Compared with existing loess - improvement studies, this research innovatively combines cement with a composite additive system (naphthalene sulfonic acid formaldehyde condensate, sodium sulfate, sodium thiosulfate, and ethylene glycol) to develop a CLSM - type backfill material. This material overcomes the limitations of traditional cement - stabilized loess, such as low early strength and poor frost resistance, and achieves a balance among high flowability, environmental sustainability, and cost - effectiveness. The proposed composite additive system offers a novel solution for treating collapsible loess in cold and sulfate - rich regions.

Previous studies mainly focused on single - additive systems like lime or fly ash, which have difficulties in balancing early strength, durability, and environmental impact. For example, lime - treated loess has poor freeze - thaw resistance, and fly - ash - based materials require high curing temperatures. This study fills this gap by proposing a multi - additive system to address these issues.

Materials and methods

Test material

Test loess

The soil for this test was taken from a construction site in Pengjiaping area of Lanzhou City, and the basic physical properties are shown in Table 1.

Cement

The cement utilized in this experimental investigation is Qilianshan brand ordinary Portland cement, marked P.O 42.5. It is gray and powdery, with its compositional details provided in Table 2.

Test water

The water utilized in this experimental investigation was tap water sourced from Lanzhou city, except for the osmosis test, which employed distilled water.

Test additives

(1) Naphthalenesulfonic acid formaldehyde condensate.

Naphthalene sulfonic acid formaldehyde condensate is a kind of high efficient water reducing agent for concrete, which is yellowish brown and powdery.

(2) Sodium sulfate.

Sodium sulfate is a concrete early-strengthening agent that comes in a white, powdery form.

(3) Sodium thiosulfate.

Sodium thiosulfate is a concrete early strength agent, colorless, transparent monoclinic crystals.

(4) Ethylene glycol C2H4(OH)2 (antifreeze).

Glycol is a concrete antifreeze that is colorless and in liquid form.

Specimen preparation and maintenance

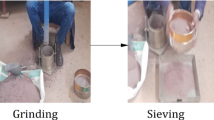

This study investigated loess-based cement slurry with cement dosages set at 4%, 6%, 8%, 10%, and 12% of the loess mass. The water content corresponding to a slump of 180 mm was selected as the benchmark for testing. Specimens were cured for 7, 14, 28, and 60 days for permeability and collapsibility evaluations, while sulfate dry-wet cycles and freeze-thaw cycles were conducted after 28 days of standard curing. Collapsibility tests employed Φ61.8 mm × 20 mm ring-knife specimens, and permeability tests used Φ61.8 mm × 40 mm specimens. The slurry was prepared by mixing air-dried loess (sieved through 2 mm), cement, and additives in a rotary mixer for 10 min at a fixed water-to-solid ratio of 0.45. Demolded specimens were labeled and cured in a controlled chamber (20 ± 2 °C, RH ≥ 95%) until reaching target ages. Key experimental procedures are illustrated in Fig. 1.

Engineering hydrophysical properties test design

The permeability of soil is a fundamental property, and the collapsibility of loess is one of its most unfavorable engineering geological characteristics. In this study, samples were prepared with cement dosages of 4%, 6%, 8%, 10%, and 12%. Permeability tests and collapsibility coefficient tests were conducted on the loess-based cement slurry specimens after curing periods of 7, 14, 28, and 60 days. This allowed for the analysis of the permeability resistance and collapsibility performance of the loess-based cement slurry material.

Durability test design

In this paper, we selected the loess-based cement composite additive slurry specimens with 8% cement, 8% naphthalene sulfonic acid formaldehyde condensate doping, 3% sodium sulfate doping, 0.5% sodium thiosulfate doping, 0.08% ethylene glycol doping to carry out the experimental study, and conducted the freezing and thawing cyclic test and the sulfate-drying and wetting cyclic test on them, respectively.The percentage of the concrete additive relative to the cement mass.

Freeze-thaw cycle test design

The freeze-thaw cycle test apparatus utilized in this study is a DTR-11 type concrete rapid freeze-thaw chamber, with each freeze-thaw cycle lasting 24 h. Specifically, the low-temperature phase of -20 °C lasts for 12 h, followed by a normal temperature phase of 20 °C for another 12 h. The freeze-thaw cycle test employed loess-based cement composite additive slurry specimens measuring 70.7 mm × 70.7 mm × 70.7 mm. Each group included three parallel specimens, and an equal number of loess-based cement slurry specimens were prepared as a control group. After production, all specimens were placed in a standard curing box for 28 days.

For the freeze-thaw cycle test, six groups of specimens were prepared: one group before the freeze-thaw cycle and five groups subjected to 1, 5, 10, 15, and 25 freeze-thaw cycles, respectively. Prior to initiating the freeze-thaw cycle test, all specimens were numbered and weighed. Specimens that had completed the curing period were then placed into the rapid freeze-thaw chamber, and the test parameters were adjusted according to the chamber’s control panel.

At the conclusion of the freeze-thaw cycle test, each group of specimens was visually inspected and described, and their weights were recorded. Unconfined compressive strength tests were conducted on specimens that exhibited a mass change of 5% or less before and after the freeze-thaw cycles. See Fig. 2 (A) for an illustration of the freeze-thaw cycle specimens.

Sulphate-dry-wet cycle test design

The sulfate-wet/dry cycle test apparatus used in this study is a concrete sulfate wet/dry cycle chamber. A 6% Na2SO4 solution was selected, with each cycle lasting 24 h. Specifically, the first phase involves immersion in the Na2SO4 solution for 16 h, followed by high-temperature drying for 8 h. The sulfate-wet/dry cycle test employed specimens measuring 70.7 mm × 70.7 mm × 70.7 mm. Specimens were divided into five groups: one group of loess-based cement composite additive slurry specimens before the sulfate-wet/dry cycle, and four groups subjected to 1, 5, 15, and 25 cycles, respectively. Each group included three parallel specimens, while an equal number of loess-based cement slurry specimens served as a control group. After production, all specimens were placed in a standard curing box for 28 days.

Prior to initiating the sulfate-wet/dry cycle test, all specimens were numbered and weighed. Specimens that had completed the curing period were then placed into the concrete sulfate wet/dry test chamber, and the test parameters were adjusted according to the chamber’s control panel. At the conclusion of the sulfate-wet/dry cycle test, each group of specimens was visually inspected and described, and their weights were recorded. Unconfined compressive strength tests were conducted on each group of specimens. See Fig. 2 (B) for an illustration of the sulfate-wet/dry cycle specimens.

Results and discussion

Permeability

Relationship between cement dosage and permeability coefficient

The permeability coefficient reduction rate (Δk) was calculated as follows:

Where: kiand ki+1 represent the permeability coefficients at adjacent cement dosages.

Figure 3 (A) depicts the relationship between cement dosage and the permeability coefficient of loess - based cement slurry material. As the cement dosage increases, the permeability coefficient generally exhibits a decreasing trend. Notably, when the cement dosage ranges from 4 to 8%, the reduction rate of the permeability coefficient is relatively rapid. This is because the internal pores of the original loess are large and the compactness is poor. With the increase in cement dosage, the hydration products generated by the cement hydration reaction increase continuously. These products quickly fill the soil pore space, reducing the internal pore space between particles. Consequently, the resistance to water passing through the loess - based cement slurry increases, enhancing its impermeability performance. In contrast, when the cement dosage is between 8% and 12%, the permeability coefficient of the loess - based cement slurry decreases slowly. This is because the internal pores of the slurry have been mostly filled at this stage, and any further increase in cement dosage only marginally improves the impermeability resistance, leading to a slow decline in the permeability coefficient. For instance, when the cement dosage increased from 4 to 8%, the average change in the permeability coefficient (Δk) was 18.3% per 2% increment in cement dosage, while from 8 to 12%, Δk decreased to 6.5% per 2% increment. This clearly indicates that at lower cement dosages, the pore - filling effect of hydration products plays a dominant role, but once the cement dosage exceeds 8%, the pore - filling reaches a saturation state.

Relationship between curing age and permeability coefficient

Figure 3 (B) illustrates the relationship between curing age and permeability coefficient. As shown in the figure, the permeability coefficient of loess-based cement slurry decreases by approximately 11.77–35.05% as the curing age increases from 7 days to 60 days. With the growth of curing age, the cement within the loess-based cement slurry continues to undergo hydration reactions, leading to an increase in cementitious compounds that fill the internal pores. This process enhances the resistance to water passage through the material, thereby improving its impermeability performance.

As the curing age increases, the continuous hydration of cement generates more gel-like compounds, which further fill the internal pores of the loess-based cement slurry. This results in increased resistance to water penetration, thus enhancing the impermeability of the material. These findings indicate that extending the curing age positively affects the reduction of the permeability coefficient of loess-based cement slurry.

In engineering applications, proper curing of loess-based cement slurry materials after construction can effectively improve their impermeability, highlighting the importance of adequate curing time for optimal performance.

Collapsibility

Relationship between cement dosage and coefficient of collapsibility

As shown in Fig. 4 (A), the collapsibility coefficient of loess-based cement slurry material significantly decreases with increasing cement dosage. Specifically, when the cement dosage increases from 4 to 12%, the collapsibility coefficient is reduced by approximately 68–74%. Under all levels of pressure, the collapsibility coefficient does not exceed 0.009, which is well below the 0.015 threshold for defining collapsible loess. This indicates that adding cement can effectively eliminate the collapsibility of loess.

This phenomenon can be attributed to the chemical reactions induced by the addition of cement, which generate cementitious compounds that encapsulate soil particles and enhance the water stability of the soil. As the cement dosage increases, these cementitious compounds form a denser mesh structure, ultimately preventing the wetting-induced collapsibility of the soil samples.

Relationship between curing age and coefficient of collapsibility

As shown in Fig. 4 (B), the coefficient of collapsibility of loess-based cement slurry material decreases with increasing curing age. Specifically, when the curing age increases from 7 days to 60 days, the collapsibility coefficient is reduced by approximately 6–25%. For cement dosages greater than 8%, the reduction in the collapsibility coefficient becomes more pronounced as the curing age increases. This phenomenon can be attributed to the fact that, at lower cement dosages, the reaction time required for full hydration is relatively short, leading to a less effective cementing effect. As the cement dosage increases, the time required for complete hydration extends, and the amount of hydration products also increases. Consequently, the hydration products bond more tightly with the loess particles, significantly enhancing the material’s resistance to collapsibility.

Durability test analysis

Freeze-thaw cycle test

Freeze-thaw cycle test specimen appearance analysis

As depicted in Fig. 5, the freeze - thaw cycle test results for loess - based cement slurry and loess - based cement composite additive slurry specimens exhibit distinct characteristics.

For the loess - based cement slurry specimens, after 1 freeze - thaw cycle, the surface shows minimal change. However, as the number of cycles increases, the damage becomes more severe. After 5 cycles, partial surface detachment and edge erosion occur. By 10 cycles, surface detachment worsens, accompanied by the appearance of small cracks. At 15 cycles, the surface is completely peeled off, with increased edge erosion and longer but shallow cracks. After 25 cycles, the specimen is severely damaged, with complete detachment around it, large deformation, and significantly larg.

In contrast, the loess - based cement composite additive slurry specimens demonstrate better freeze - thaw resistance. After 1 cycle, there is little change. After 5 cycles, although partial surface detachment occurs, the erosion degree is less than that of the loess - based cement slurry specimens. At 10 cycles, only a small number of cracks appear on the upper surface, which are smaller compared to those on the loess - based cement slurry specimens at the same cycle number. After 15 cycles, the cracks extend and expand, and after 25 cycles, while the specimen shows increased angular erosion and more cracks, its damage degree is still less than that of the loess - based cement slurry specimens at 25 cycles, with better integrity.

These results indicate that the loess - based cement composite additive slurry specimens can effectively delay the destructive impact of the freeze - thaw cycle. The damage is relatively minor after 1 and 5 cycles, and becomes significantly more severe after 25 cycles compared to previous cycles. The enhanced frost resistance of the composite additive slurry can be attributed to two mechanisms. Firstly, the naphthalene sulfonic acid formaldehyde condensate improves particle dispersion, reducing internal pore connectivity and thus minimizing water migration during freeze - thaw cycles. Secondly, ethylene glycol functions as an antifreeze, lowering the freezing point of pore water and alleviating ice - induced expansion stress.The composite additives promote ettringite and C-S-H gel formation, filling pores and creating a dense matrix (supported by reduced permeability in Sect. “Permeability”). This microstructure explains the enhanced mechanical and durability properties.

Analysis of changes in specimen quality for freeze-thaw cycle tests

Prior to the freeze-thaw cycle test, the mass of the loess-based cement composite additive slurry specimen and the loess-based cement slurry specimen were first weighed, and the mass of the specimen after the freeze-thaw cycle was weighed. The change in mass of the specimens after the freeze-thaw cycle is expressed as the rate of mass loss.The rate of loss of specimen mass is calculated as shown in the following equation:

Where: m0i is the mass (g) of the ith specimen before the freeze-thaw cycle test, mni is the mass (g) of the ith specimen after the freeze-thaw cycle test, ∆mi is the mass loss rate (%) of the ith specimen after N freeze-thaw cycles, ∆mn is the average mass loss (%) of a set of specimens after N freeze-thaw cycles.

As shown in Fig. 6, the mass changes of loess-based cement composite additive slurry specimens and loess-based cement slurry specimens under freeze-thaw cycle conditions follow a similar trend. In the early stages (1 and 3 freeze-thaw cycles), the mass increase of loess-based cement slurry specimens is greater than that of loess-based cement composite additive slurry specimens. This is because the internal pores of the loess-based cement slurry specimens expand more significantly due to the initial freezing and thawing cycles, leading to greater damage compared to the loess-based cement composite additive slurry specimens, which have smaller pore volumes and fewer pores. Consequently, the inflow of moisture into the larger pores causes a greater mass increase in the loess-based cement specimens.

After 10, 15, and 25 freeze-thaw cycles, the mass loss rate of loess-based cement composite additive slurry specimens is lower than that of loess-based cement slurry specimens. This can be attributed to the addition of additives, which enhances the tensile strength of the loess-based cement composite additive slurry specimens. The improved tensile strength allows these specimens to better resist the expansion stress caused by freeze-thaw cycles, thereby delaying their destruction and resulting in a smaller mass loss rate compared to the loess-based cement slurry specimens.

The test results indicate that, under the same freeze-thaw cycle conditions, the average mass loss rate of loess-based cement slurry specimens was higher compared to loess-based cement composite additive slurry specimens. Furthermore, the mass changes in loess-based cement slurry specimens were more significant both before and after the freeze-thaw cycles compared to those of loess-based cement composite additive slurry specimens.

Freeze-thaw cycle test specimen strength and result analysis

After subjecting the specimens to varying numbers of freeze - thaw cycles, unconfined compressive strength tests were conducted.

As shown in Fig. 7, which depicts the relationship between the freeze - thaw cycle and unconfined compressive strength, it is evident that incorporating concrete additives significantly enhances the unconfined compressive strength of the loess - based cement composite additive slurry specimens. Under identical freeze - thaw cycle conditions, the unconfined compressive strength of these specimens is consistently higher than that of the loess - based cement slurry specimens. Specifically, after 1, 5, 10, 15, and 25 freeze - thaw cycles, the unconfined compressive strengths of the loess - based cement slurry specimens are 0.96 MPa, 0.91 MPa, 0.81 MPa, 0.74 MPa, and 0.61 MPa respectively, while those of the loess - based cement composite additive slurry specimens are 1.13 MPa, 1.08 MPa, 0.99 MPa, 0.93 MPa, and 0.83 MPa. These results clearly demonstrate that the addition of concrete additives can effectively boost the unconfined compressive strength of the specimens.

Figure 8 further illustrates the changes in unconfined compressive strength (UCS) during the freeze-thaw process. After the first freeze-thaw cycle, the UCS of the loess-based cement composite additive slurry specimens and the loess-based cement slurry specimens decreased by 0.88% and 2.04%, respectively, indicating a relatively small reduction in strength at this stage. As the number of freeze-thaw cycles increased, the UCS of both types of specimens continued to decline. However, the rate of strength loss for the loess-based cement slurry specimens was consistently higher than that for the loess-based cement composite additive slurry specimens. After 25 freeze-thaw cycles, the UCS of the loess-based cement composite additive slurry specimens and the loess-based cement slurry specimens decreased by 27.19% and 37.76%, respectively, reaching their maximum strength reduction values.

In summary, under the same freeze-thaw cycle conditions, loess-based cement composite additive slurry specimens exhibit higher unconfined compressive strength (UCS) and experience smaller strength reductions after 1, 5, 10, 15, and 25 freeze-thaw cycles compared to loess-based cement slurry specimens.

The enhanced UCS of the composite additive slurry can be attributed to the synergistic effects of sodium sulfate and sodium thiosulfate. Sodium sulfate accelerates the early hydration process of cement, promoting the rapid formation of a more stable microstructure. Sodium thiosulfate enhances the sulfate resistance of the material, contributing to a denser microstructure. Together, these additives lead to improved structural integrity and reduced permeability, as discussed in Sect. "Relationship between cement dosage and permeability coefficient". The denser microstructure effectively increases the load-bearing capacity of the composite additive slurry, resulting in higher UCS.

Sulphate-dry-wet cycle test

Appearance analysis of sulfate-dry and wet cycle test specimens

As shown in Fig. 9(A), for the loess-based cement slurry specimens, after one sulfate-dry-wet cycle, the appearance changes are consistent with those of the loess-based cement composite additive slurry specimens, showing no significant alteration. This is because, after one sulfate-dry-wet cycle, although sulfate ions enter the specimen, the reaction between the cement and sulfate has not fully completed, and the expansion stress generated during the reaction has not reached a level sufficient to cause structural damage. After five sulfate-dry-wet cycles, slight dislodgement occurs on the upper surface and sides of the specimen. After 15 cycles, further exfoliation and some cracking appear on the surface. After 25 sulfate-dry-wet cycles, the corners of the specimens are eroded, and peeling occurs on all surfaces.

As shown in Fig. 9(B), for the loess-based cement composite additive slurry specimens, after one sulfate-dry-wet cycle, there is no significant change in appearance compared to before the test. After five sulfate-dry-wet cycles, the surface of the specimens shows slight detachment, but the overall appearance remains largely unchanged except for the upper surface. After 15 cycles, surface peeling increases, and the corners of the specimens exhibit slight peeling. After 25 cycles, the corners of the specimens are severely damaged, and the bottom soil of the loess-based cement composite additive slurry specimens also dislodges. All surfaces of the specimen experience dislodgement, leading to severe damage. Compared to the loess-based cement slurry specimens, the degree of surface damage is greater for the loess-based cement composite additive slurry specimens.

The test results show that under sulfate-dry-wet cycle conditions, both loess-based cement composite additive slurry specimens and loess-based cement slurry specimens experienced erosion to varying degrees. However, the loess-based cement slurry specimens exhibited greater resistance to erosion compared to the loess-based cement composite additive slurry specimens.

Analysis of changes in the quality of specimens in the sulfate-dry and wet cycle test

Before conducting the sulfate-dry-wet cycle test, the initial mass of both the loess-based cement composite additive slurry specimens and the loess-based cement slurry specimens was measured. The mass of the specimens was also measured after each sulfate-dry-wet cycle. The rate of mass loss was calculated using the same formula as for the freeze-thaw cycle test.

As shown in Fig. 10, the mass change trends of loess-based cement composite additive slurry specimens and loess-based cement slurry specimens under sulfate-dry-wet cycling conditions are similar. The mass loss rates of both types of specimens increased progressively with 1, 5, 15, and 25 sulfate-dry-wet cycles. Specifically, after 1, 5, 15, and 25 sulfate-dry-wet cycles, the mass loss rates for the loess-based cement composite additive slurry specimens were 0.95%, 2.71%, 4.94%, and 7.1%, respectively, while those for the loess-based cement slurry specimens were 0.75%, 2.08%, 3.64%, and 5.48%, respectively.

Based on these results, it is evident that the mass loss rate of loess-based cement composite additive slurry specimens was significantly higher than that of loess-based cement slurry specimens. In the early stages (1 and 5 cycles), the mass loss rate was relatively small, primarily due to the decomposition of hydration products caused by the reaction between sulfate ions and the hydrated cement. As the number of sulfate-dry-wet cycles increased to 15 and 25, the mass loss rate increased significantly. This is attributed to the tensile capacity of the specimens reaching its limit, leading to specimen expansion and surface peeling, which resulted in greater mass loss. The addition of sodium sulfate to the loess-based cement composite additive slurry specimens made them more susceptible to erosion during the sulfate-dry-wet cycles, thereby increasing their mass loss rate.

The test results indicate that the mass loss rates of both types of specimens increased with the number of sulfate-dry-wet cycles. Notably, the average mass loss rate of loess-based cement composite additive slurry specimens was consistently higher than that of loess-based cement slurry specimens under sulfate-dry-wet cycling conditions.

Analysis of changes in the quality of specimens in the sulfate-dry and wet cycle test

After subjecting the specimens to varying numbers of sulfate-dry-wet cycles, they were removed and tested for unconfined compressive strength (UCS). As shown in Fig. 11, which illustrates the relationship between sulfate-dry-wet cycling and UCS, it is evident that under the condition of dry-wet cycling with a 6% Na2SO4 solution, the UCS of both loess-based cement composite additive slurry specimens and loess-based cement slurry specimens exhibited a decreasing trend. Based on these test results, it can be concluded that the addition of concrete additives enhances the initial unconfined compressive strength of the specimens but does not prevent the overall decrease in strength due to prolonged exposure to sulfate-dry-wet cycles.

As shown in Fig. 12, the strength loss rates of loess-based cement composite additive slurry specimens and loess-based cement slurry specimens after 1, 5, 15, and 25 sulfate-dry-wet cycles were 1.17%, 5.85%, 14.62%, and 26.02%, and 0.68%, 4.08%, 12.93%, and 22.45%, respectively. Based on these test results, it is evident that the strength loss rate of loess-based cement composite additive slurry specimens was significantly higher than that of loess-based cement slurry specimens.

During the sulfate-dry-wet cycling process, the strength loss rate of loess-based cement composite additive slurry specimens was consistently greater than that of loess-based cement slurry specimens. This can be attributed to the presence of sodium sulfate in the composite additive slurry specimens prior to the sulfate-dry-wet cycling. The pre-existing sodium sulfate leads to stronger erosion in the sulfate solution and increased crystal formation during the drying phase, resulting in a more significant loss of strength.

The test results indicate that the strength loss of loess-based cement composite additive slurry specimens is lower than that of loess-based cement slurry specimens. This can be attributed to sodium sulfate acting as an early-strength agent, which accelerates the hardening and strength development of the specimens. However, during sulfate-dry-wet cycles, the accelerated infiltration and corrosion due to sodium sulfate have a negative impact on the durability of the specimens. Therefore, when using sodium sulfate, it is crucial to control its incorporation amount to prevent overuse from adversely affecting the performance of the specimens.

While strength indices were not the primary focus, unconfined compressive strength tests (Figs. 7 and 8) confirm the material meets CLSM standards (28d strength ~ 1.13 MPa), validating its suitability for roadbed applications.

Conclusions

(1) Cement dosage (4–12%) significantly reduces permeability and collapsibility of loess-based slurry, with optimal effects at 8% dosage.

(2) Composite additives enhance frost resistance (25% lower strength loss vs. plain cement slurry) but slightly reduce sulfate durability due to sodium sulfate sensitivity.

(3) The proposed material meets CLSM standards (flowability > 180 mm, 28d strength ~ 1.13 MPa), offering a viable solution for loess backfilling in cold regions.

(4) This study has certain limitations. Firstly, the long - term performance of the materials beyond 60 days was not evaluated. Secondly, the economic and environmental impacts of using the additives need further in - depth life - cycle assessment.

Data availability

The data supporting this study’s findings are available from the corresponding author upon reasonable request.

References

Janardhanam, R., Burns, F. & Peindl, R. D. Mix design for flowable fly-ash backfill material. J. Mater. Civil Eng. 4 (3), 252–263 (2000). doi: 10.1061/(ASCE)0899–1561(1992)4:3(252).

Zhang, J. et al. Preparation of CaO-containing carbon pellet from recycling of carbide slag: effects of temperature and H3PO4. Waste Manage. 84, 64–73. https://doi.org/10.1016/j.wasman.2018.11.033 (2019).

Wu, H., Huang, B., Shu, X. & Yin, J. Utilization of solid wastes/byproducts from paper mills in controlled low strength material (CLSM). Constr. Build. Mater. 118, 155–163. https://doi.org/10.1016/j.conbuildmat.2016.05.005 (2016).

Adaska, W. S. Controlled low St rength materials. Concr. Int. 19 (4), 41–43 (1997).

Zhang, X. G. Study on long spiral drilled premixed fluid solidified soil composite foundation in subcenter of Beijing. Building Technol. Dev. 45 (2), 59–62 (2018). (in Chinese).

Hu, Z. Q., Liang, Z. C., Guo, J., Feng, Z., Wang, K., & She, H. C. Prediction of water permeability coefficient of unsaturated lime-improved loess [J]. Chin. J. Geotech. Eng, 42 (s2), 26–31. https://doi.org/10.11779/CJGE2020S2005(2020). (in Chinese)

Zhang, Y., Johnson, A. E. & White, J. D. Freeze-thaw performance of cement and fly Ash stabilized loess. Transp. Geotechnics. 21, 100279–100279. https://doi.org/10.1016/j.wasman.2018.11.033 (2019).

Cheng, Z. et al. Strength tests and numerical simulations of loess modified by desulfurization Ash and fly Ash. Materials 15 (2), 512. https://doi.org/10.3390/ma15020512 (2022).

Shahin, W. Systematic approach to assessing the applicability of fly-ash-based geopolymer for clay stabilization. Can. Geotech. J. 57 (9), 1356–1368. https://doi.org/10.1139/cgj-2019-0215 (2020).

Chen, R., Zhang, X., Hao, R. Y. & Bao, W. X. Shear strength deterioration of geopolymer stabilized loess under wet-dry cycles: mechanisms and prediction model. Rock. Soil. Mech. 43 (5), 1164–1174. https://doi.org/10.16285/j.rsm.2021.1355 (2022). (in Chinese).

Yilmaz, Y. & Ozaydin, V. Compaction and shear strength characteristics of colemanite ore waste modified active Belite cement stabilized high plasticity soils. Eng. Geol. 155, 45–53. https://doi.org/10.1016/j.enggeo.2013.01.003 (2013).

Anagnostopoulos, C. A. Strength properties of an epoxy resin and cement-stabilized silty clay soil. Appl. Clay Sci. 114, 517–529. https://doi.org/10.1016/j.clay.2015.07.007 (2015).

Laguros, J. G. Discussion of use of class C fly ashes for the stabilization of an expansive soil by Erdal Oka. J. Geotech. GeoEnviron. Eng. 128 (11), 965–966. 10.1061/ (2002). (ASCE)1090-0241(2002)128:11(965).

Kaya, Z. Effect of slag on stabilization of sewage sludge and organic soil. Geomech. Eng. 10 (5), 689–707. https://doi.org/10.12989/gae.2016.10.5.689 (2002).

Wang, S. B. Experimental Reserch on the Additive of Cement-Stabilized Soil in Laboratory. [dissertation/master’s thesis]. Tianjin: Tianjin University. (2007). (2007).

Hu, J. L., Gao, P. F., Cui, H. G., Zhang, Y. L. & Zheng, R. H. Study on strength characteristics and micropores of cement soil from iron ore tailing. Build. Sci. 39 (3), 74–80. https://doi.org/10.13614/j.cnki.11-1962/tu.2023.03.011 (2023). (in Chinese).

Hou, S. P., Zhu, J. Y., Chen, L. L., Wang, S. & Song, J. Q. Experimental study on the influence of PAM on cemented soil Anti-crack performance. Bull. Chin. Ceramic Soc. 35 (10), 3314–3318. https://doi.org/10.16552/j.cnki.issn1001-1625.2016.10.039 (2016). (in Chinese).

Funding

The author declares that the conduct, writing, and publication of this study were supported by funding. This study was supported by the Gansu Provincial Science and Technology Department (project number: 23YFGA0083) and the Lanzhou Science and Technology Plan Project (2024-4-5).

Author information

Authors and Affiliations

Contributions

Wuquan Zhu: Conceptualization, Data curation, Funding acquisition, Investigation, Methodology, Validation, Writing–original draft, Writing–review and editing. Zhao Long: Formal Analysis, Investigation, Methodology, Resources, Writing–original draft. Laping He: Formal Analysis, Investigation, Writing–original draft. Shuaihua Ye: Formal Analysis, Investigation, Software, Validation, Writing–original draft. Yiqiao Mao: Formal Analysis, Investigation, Methodology, Writing–original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhu, W., Long, Z., He, L. et al. Hydro-physical properties and durability study of cement slurry material based on loess. Sci Rep 15, 13198 (2025). https://doi.org/10.1038/s41598-025-97713-w

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-97713-w