Abstract

Basement-addition for existing building plays a crucial role in alleviating urban land shortage. However, the disturbance induced by basement-addition construction to the stability of the building foundation and superstructure has not been well understood. The objective of this paper is to investigate the performance of typical structural components involved in a basement-addition project. They include the columns in the superstructure, the strip foundation beneath the columns, and the piles used for reinforcing the strip foundation during excavation. A three-dimensional finite element model is established, using a basement-addition project of an existing building as a case example. The calculated results by the finite element model align well with the measured data, confirming the model’s validity. Based on this, the stress and deformation characteristics associated with the selected structural components during basement-addition construction are investigated. The findings indicate that the stress and deformation characteristics of the structural components are highly sensitive to the depth of the foundation pit excavation, with these characteristics intensifying as excavation depth increases. The excavation of the initial soil layer has the most significant impact. Upon completion of the excavation, the maximum settlement values for the strip foundation (SF), column foot, and pile are -18.6 mm, −13.79 mm, and −16.1 mm, respectively. The underground diaphragm wall (UDW) exhibits maximum vertical and horizontal displacements of 7.6 mm and 18.1 mm, respectively. The pile primarily experiences compressive internal forces, with its axial force showing little sensitivity to excavation depth. The pile’s maximum bending moment, shear force, and axial force are 21.2 kN·m, 34 kN, and −2,481 kN, respectively. The internal forces and deformations of structural components demonstrate distinct spatial distribution patterns, with values increasing closer to the foundation pit’s center. Therefore, it is crucial to enhance monitoring of the displacement and internal forces of the central components of the foundation pit to prevent engineering accidents. These research findings will contribute positively to the design optimization and construction guidance of similar engineering structures.

Similar content being viewed by others

Introduction

With the rapid development of our economy, more and more people flock to cities1,2,3,4,5. As a result, many cities have problems such as land shortage, traffic congestion, and parking difficulties6,7,8,9,10. In the early stage of urban construction, it was restricted by various conditions11,12. Many buildings in the city center do not have underground parking13,14,15,16. In recent years, the number of cars has increased rapidly17,18. However, the number of parking Spaces in China is seriously insufficient19,20. The problem of difficult parking has become one of the main factors restricting the further development of the city21,22,23,24,25.

If the underground space of the existing building is strengthened and reformed, this may become one of the effective ways to solve the problem of parking difficulty and land shortage26,27,28. There are many advantages to retrofit existing buildings with additional underground floors. For example: make full use of existing urban facilities, save demolition costs, and enhance the seismic performance of the structure, and so on.

The implementation of underground layer improvement project for existing buildings belongs to the development and utilization of underground space29,30. Some scholars have carried out research on the development and utilization of underground space31,32,33,34. Ren et al.35 studied the deformation of foundation pit and the internal forces of structural members by using the method of field monitoring. Ge et al.36 used PLAXIS software to study the impact of deep foundation pit excavation on the surrounding environment. Meanwhile, Shi et al.37 invented a combined support system and construction method for foundation pit. Mu et al.38 studied the influence of foundation pit excavation on shield tunnel structure by using numerical simulation method. In addition, Cui et al.39 proposed an enclosure system suitable for multiple excavation requirements. The internal force and deformation of the supporting structure are studied by the method of field monitoring and numerical simulation. Tong et al.40 studied the rule of influence of foundation pit excavation on horizontal deformation of pile groups by using numerical simulation method. In addition, Huang et al.41 studied the variation characteristics of pressure arch during excavation through theoretical and numerical simulation methods. Zhou et al.42 analyzed the mechanical response of different types of rock mass during tunnel construction by using the similarity model test method. Moreover, Miao et al.43 used FLAC 3D software to study the impact of tunnel excavation on adjacent bridge piles. Zhang et al.44 studied the mechanical characteristics of subway stations by combining theoretical analysis with indoor model tests. Furthermore, Wang et al.45 analyzed the influence of river excavation on the underside subway tunnel by using numerical simulation method and on-site monitoring method.

To sum up, the development and utilization of underground space related issues are increasingly concerned by scholars. And has already obtained relatively rich results. On the one hand, previous research methods mainly include numerical simulation36,38,39,40, similar model test42, field monitoring35,37,39, and theoretical analysis41,44. On the other hand, the research objects mainly include: deep foundation pit excavation engineering35,36,37, subway station engineering44, and tunnel excavation engineering41,42,43. In addition, the main contents of the research are: the deformation law of the foundation pit itself39,40,41, the internal force and displacement of the supporting system35,36,44, and the influence of the foundation pit and tunnel excavation on the surrounding environment36,39,44. However, in the previous major studies, few scholars carried out in-depth research on the implementation of the existing buildings with additional floors.

It should be noted that compared with new buildings, the reconstruction of underground additional layers of existing buildings is restricted by many conditions26. For example, the surrounding environment is complex, the construction space is small, and the construction technology is high and so on. Therefore, the process of transformation is relatively difficult. In addition, all aspects of relevant standards and technologies need to be further improved. Underground layer addition technology is still in the preliminary exploration stage, and there are few examples for reference26. It is worth noting that in the process of underground layer construction of existing buildings. Foundation pit excavation will cause the foundation of the building to separate from the soil. This may cause uneven settling of the column foot. This results in the redistribution of internal forces in the superstructure. If the uneven settlement is too large, it is very likely to cause cracking, tilting and even collapse of the superstructure. This may affect the structural safety and normal use of existing buildings. Therefore, it is significant to study the construction mechanics behavior of the underground layer of existing buildings.

In view of this, on the basis of the above research results. This paper carries out related research on the background of an existing building basement-addition project. The research content mainly includes four parts: Firstly, design reinforcement scheme and excavation scheme. Secondly, a 3D finite element model is established by MIDAS GTS NX software based on the modified Mohr-Coulomb constitutive model. And the numerical calculation is carried out. Thirdly, the reliability of the model is verified by comparing the numerical results with the measured results. Finally, the performance of typical structural components in existing building basement-addition is studied. The conclusion can be used for reference in the design and construction of similar projects.

Project overview

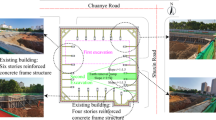

The research object of this paper is the basement-addition project of an existing building. This existing building is located in a typical stratum in a certain area of Zhengzhou City. The complex surrounding environment and construction technology bring severe challenges to construction technology and environmental safety. The existing building is a frame structure, and the foundation is a strip foundation. The above-ground part has four floors, each of which is 4 m high. The building has no basement. According to the requirements of the proprietor, a basement with a depth of 5 m will be excavated under the building. This is a typical underground layer addition project for existing buildings.

The main construction process of the project is as follows: The first step: the existing building is reinforced with anchor static pile (referred to as “pile”) and underground diaphragm wall. The second step: excavate the foundation pit within the scope of the existing building reinforcement area. The foundation pit is constructed by open excavation method. The length is 19.5 m, the width is 18 m, and the excavation depth is 5 m. In addition, the retaining structure of the foundation pit is mainly composed of the underground diaphragm wall. The width and height are 0.6 m and 7 m, respectively. And the embedment depth is 2 m. According to the geotechnical engineering investigation report, simplified the soil for 3 layers. From top to bottom are: mixed fill, silty clay, and silty sand. This study does not consider the influence of groundwater on the excavation of foundation pit. Figure 1 is the section diagram of the existing building for the reconstruction of additional floors. Table 1 summarizes the soil layer mechanical parameters.

Design of technology

Reinforcement measures

In this renovation project, piles are used as replacement piles for strip foundation. There are two piles under each column. Figure 2 is the schematic diagram of the design scheme of pile replacement. The concrete construction method mainly includes three parts: firstly, pile holes are constructed on both sides of the intersection of strip foundation and column. Secondly, the piles are pressed into the foundation soil by hydraulic jacks. Thirdly, the connection between pile and strip foundation is treated to ensure reliable connection. It should be noted that the diameter of the pile is 0.3 m. The distance between the center of the pile and the edge of the column is 0.2 m.

In addition, the main reinforcement measures of this renovation project are underground diaphragm wall. The underground diaphragm wall has four surfaces. Among them, two surfaces are overlapped with the strip foundation. The lap length is 0.3 m. Figure 3 is a schematic diagram of the location of the underground diaphragm wall and the foundation. It should be noted that the building in this study has a total of 16 columns. To facilitate the study, it is necessary to number the columns as shown in Fig. 3. Table 2 summarizes the parameters of the various support structures involved in the investigated existing building basement-addition project.

Design of foundation pit excavation scheme

The principle of foundation pit excavation is “longitudinal segmentation, vertical stratification, timely support after excavation”. Each layer and section of the foundation pit are excavated separately. The foundation pit was excavated 8 times in total. The soil within the excavation range is divided into four layers for excavation. The thickness of the first layer is 2 m, and the other three layers are 1 m. Each layer is divided into two parts: the side area and the middle area. The two parts were excavated separately. The specific process is as follows. Excavation stage 1: excavate the soil on both sides of the first layer. Excavation stage 2: excavate the soil in the middle of the first layer. Excavation stage 3: excavate the soil on both sides of the second layer. Excavation stage 4: excavate the middle soil of the second layer. Excavation stage 5: excavate the soil on both sides of the third layer. Excavation stage 6: excavate the middle soil of the third layer. Excavation stage 7: excavate the soil on both sides of the fourth layer. Excavation stage 8: excavate the middle soil of the fourth layer. Figure 4 shows the excavation process of foundation pit. To be clear, each excavation is carried out after the water has fallen 3 m below the excavation face. Therefore, the influence of groundwater on excavation is not considered in this study.

Model building and numerical calculation

Basic assumptions

The construction process and site conditions are complicated. In order to facilitate the study, the numerical model needs to be simplified to some extent: Firstly, the process of drilling the strip foundation is not considered. Pile and strip foundation are fixed connection. Secondly, the pile is a continuous whole without considering the lap relationship between piles. Besides, other basic assumptions are consistent with reference46.

Modeling approach

In this study, MIDAS GTS NX (version 2022) software was used to build a 3D finite element model. In this paper, the construction mechanics behavior of existing buildings in the reconstruction of underground layer is studied. In fact, the determination of model size is a intricate process, and many factors require to be considered19,36,37. Such as: balance accuracy and computational time37, the influence of boundary effects and surrounding buildings19,36. As a result, on the basis of referring to the above reference, and several modeling calculations were carried out. Finally, the length (X), height (Y) and height (Z) of the model are 56 m, 56 m and 25 m, respectively. The calculation model is shown in Fig. 5. The number of units and nodes in the model are 15,978 and 13,498, respectively. The model coordinate system is shown in Fig. 5. The X-axis points to the deep excavation width. The Y-axis points to the length of the deep excavation. In addition, the positive direction of the Z-axis points straight up. The top surface of the model was left free, the lateral sides of the model were fixed in the horizontal direction while vertical movement was allowed, and the bottom boundary was fixed in the vertical and horizontal directions. The modified molar Coulomb constitutive relation is used in the numerical model.

Material properties

In addition, elastic constitutive relation is adopted for all structural members. In the model, both the soil mass and the strip foundation are 3D solid units. Both the underground diaphragm wall and the floor are 2D surface units. 1D beam elements are used for beams, columns, and piles.

Simulated construction

The construction content of this study mainly includes three parts. They are underground diaphragm wall construction, pile construction, and soil layered excavation. The concrete process of simulated construction consists of 14 parts. The details are shown in Table 3. It should be noted that the completion of foundation pit excavation in this study refers to “excavation stage 8”.

Comparative of simulation and field measurements

In this study, strip foundations 1 and 2 were selected as monitoring locations (see Fig. 6 for specific locations). The displacement calculation results of the monitoring position were extracted.The results were compared with the corresponding actual monitoring values, and the contrast chart was drawn. Figure 6 presents the comparison of vertical displacement of the strip foundation when the excavation is completed.

Obviously, the results of both methods show a change law of “small at both ends, large in the middle”. When the excavation is completed, the maximum vertical displacement of strip foundation 1 is about 13.3 mm. The simulated result is 11.47 mm. In addition, the monitored maximum vertical displacement of strip foundation 2 is about 20.1 mm. The simulation result is 18.48 mm. They are all in the middle of the strip foundation. And the maximum displacement is always going to be straight down. In addition, the minimum vertical displacement monitored by strip foundation 1 is about 7.2 mm. The result of simulation is 5.95 mm. The minimum vertical displacement monitored by strip foundation 2 is about 7.1 mm. The result of simulation is 5.63 mm. The positions that appear are at both ends of the strip foundation. Minimum displacement is straight up. It can be seen that the difference between the monitored value and the simulated value is small. The trend of change is relatively close. This shows that the numerical simulation results are in good agreement with the actual monitoring results. The feasibility of the numerical model established in this paper is verified. In addition, the maximum displacement value is less than the value specified in the specification. The foundation pit is in a safe state. This also reflects that the selection of the retaining structure of the excavation of the foundation pit is reliable. At the same time, it also shows that the construction process of the foundation pit excavation is reasonable. In addition, it also reflects the rationality and reliability of the parameters related to the model in this numerical calculation.

In addition, it can be found that the middle displacement of the strip foundation is vertical downward. And the end is moving straight up. This is mainly because the middle part of the strip foundation is unconstrained and belongs to the free plane. Therefore, when the excavation is completed, the vertical displacement in the middle of the strip foundation is downward. The two ends of the strip foundation are bonded to the underground diaphragm wall. The vertical displacement of the end is constrained and cannot move downward. In order to maintain balance and deformation coordination, a vertical upward displacement is therefore present.

At the same time, it can also be found that the field monitoring results are different from the numerical simulation results. The results of field monitoring are a little bigger. But the differences between them are small. The reasons for the difference may be: the numerical simulation can not fully consider the complexity of the actual construction conditions, resulting in a certain difference between the simulation results and the actual deformation. For instance: other loads that may appear inside the building (such as: furniture, appliances, stairs, and so on). There may also be a period of rain. However, these factors are not all accurately considered in the numerical simulation. The occurrence of these situations may lead to large on-site monitoring data. In summary, the numerical simulation results are close to the field monitoring results, and the difference is not significant. And the rule of change is similar. This shows that the design of the foundation pit excavation model has a certain rationality and reliability. On the basis of this model, we can carry out the relevant research on the construction mechanics behavior of the underground layer addition project of the existing building.

Numerical result

The excavation of foundation pit will have a certain influence on the building and supporting structure. The study of the influence of foundation pit excavation is helpful to clarify the concrete situation of construction mechanics behavior in the process of underground layer reconstruction of existing buildings. Through the analysis, it is helpful to scientifically guide the design and construction of the existing building underground layer reconstruction project. The main objects of this study are: strip foundation, underground diaphragm wall, column foot, and pile. The main contents of the research include the following parts: vertical displacement of strip foundation and column foot; displacement of underground diaphragm wall; displacement and internal force of pile. Apparently, the number of pile, strip foundation and underground diaphragm wall involved in this study is quite large. In order to facilitate research, it is necessary to carry out their numbers. The specific content of the number is shown in Fig. 7.

Z-direction displacement of strip foundation

The displacement in the Z direction can reflect the deformation of the strip foundation in the vertical direction. If the displacement of the strip foundation is too large in the Z direction, the displacement of the superstructure will also increase. This may have a certain adverse impact on the safety of the building. Therefore, the Z-direction deformation analysis of strip foundation has important reference value for evaluating the stability and safety of existing buildings during excavation. Figure 8 presents the Z-direction displacement cloud map of the strip foundation. Obviously, excavation will have a certain influence on the displacement of strip foundation. With different excavation depth, the displacement of strip foundation is constantly changing. This also shows that excavation will indeed have a certain impact on the existing buildings. Specifically, as the depth of excavation continues to increase, the displacement of strip foundation in Z direction shows a trend of increasing in general. In excavation stage 1, the maximum displacement is -12.6 mm. The location appears in the middle of strip foundations 1 and 4. In excavation stage 2, the maximum displacement is −16.5 mm. The location appears in the middle of strip foundations 2 and 3. When the excavation is completed, the maximum displacement is −18.6 mm. The location of the appearance is also in the middle of strip foundations 2 and 3. In addition, the maximum displacement is negative. It indicates that the center of the strip foundation has settled. It is worth noting that, it can be found from the calculation of the resulting cloud map that the distribution of these maximum displacements is not uniform, but local. It can be seen that in the process of foundation excavation, the middle of the foundation is the main area of settlement.

In order to display the maximum value change of Z-direction displacement of strip foundation more intuitively. The numerical results were extracted and the strip chart was drawn. Figure 9 is the comparison diagram of Z-direction displacement of strip foundation. Figure 9a shows that from excavation stages 1 to 8, the maximum displacement on the whole shows a trend of “rapid increase at first, and then slow increase”. The displacement increment is larger during excavation stages 1 and 2. They are 12.6 mm and 3.9 mm respectively. Obviously, the displacement increment of excavation stage 1 is the largest. Figure 9b presents that from excavation stages 1 to 8, the minimum displacement shows a trend of “slow increase”. Excavation stage 1 produced the largest displacement increment of 2.88 mm. It can be seen that excavation stages 1 and 2 have the greatest influence on vertical displacement of strip foundation. The influence of other excavation stages is relatively small.

In other words, the excavation of the first layer of soil has the greatest influence on the vertical deformation of the strip foundation. This is because with the excavation of the first layer of soil, this part of the ground soil no longer bears the load transmitted by the superstructure (see Fig. 4 for details). The pile will bear the load transmitted by the superstructure, which causes the settlement to occur. When other soil is excavated, the foundation soil no longer transfers the upper load, and the excavation of soil only reduces the side friction resistance of the pile. Therefore, when excavating other soils, the change of vertical displacement is relatively small. It is important to note that the amount of displacement increase can be positive or negative. This may be due to uplift deformation at the bottom of the pit when the foundation pit is excavated, which hinders the settlement of the pile. Pile and strip foundation bear the upper load together, which affects the deformation of strip foundation. In addition, at construction stage 9, the maximum displacement increases, while the minimum displacement decreases. This is mainly due to the effect of the roof and floor set in the construction stage 9. Therefore, in the design and construction of similar projects, we should not only pay attention to the reinforcement design of existing buildings, but also optimize the earthwork excavation scheme. At the same time, in the construction process, it is necessary to do relevant monitoring work in the middle of the foundation.

Displacement of column foot in Z direction

The displacement in the Z direction can reflect the deformation of the column foot of the building in the vertical direction. If the displacement in the Z direction is too large, it indicates that the displacement of the superstructure is also larger. This can cause the building to lean. The result of column foot displacement in Z direction is extracted and the curve is drawn. Figure 10 illustrates the comparison diagram of column foot displacement in the Z direction. Obviously, the excavation has a certain influence on the displacement of the column foot. With different excavation depth, the displacement of column foot is constantly changing. This also shows that excavation will indeed have a certain impact on the existing buildings.

Figure 10a illustrates the vertical displacement curves of column feet of Z1, Z2, Z3 and Z4 in different construction stages. In general, the change pattern of Z1 and Z4 is similar. Moreover, the displacement change rules of Z2 and Z3 are also similar. The vertical displacement of Z2 and Z3 is greater than that of Z1 and Z4. The vertical displacement values of Z2 and Z3 are negative. This indicates that settlement has occurred. On the contrary, the vertical displacement values of Z1 and Z4 are mainly positive, which indicates that mainly vertical upward displacement has occurred. Z1 and Z2 are taken as examples to illustrate in details.

The vertical displacement of Z1 and Z2 showed different changing rules. This shows that the excavation of foundation pit has a spatial effect on the vertical displacement of column foot. For Z1, from excavation stage 1 to 8, the vertical displacement showed a trend of “increasing”. In excavation stage 1, the displacement is -0.15 mm. In excavation stage 2, the displacement is 0.39 mm and the increase is 0.54 mm. In excavation stage 8, the displacement is 3.4 mm and the increase is 3.55 mm. Also, for Z2. From excavation stages 1 to 8. Although the vertical displacement fluctuates, it shows a “decreasing” trend. In excavation stage 1, the displacement is −9.6 mm. In excavation stage 2, the displacement is −8.8 mm and the reduction is 0.8 mm. In excavation stage 8, the displacement is −8.17 mm and the reduction is 0.63 mm. This is the result of the joint action of excavation unloading and uplift of pit bottom. On the one hand, excavation unloading will cause the strip foundation to sink (see Fig. 8 for details). The column is attached to the strip foundation, so the column will also sink. On the other hand, in the process of foundation pit excavation, the soil at the bottom of the pit will produce rebound effect. Relevant research results show that the rebound capacity of the central pit bottom is much greater than that of the pit corner position36,37,40. Since the pile is connected to the soil at the bottom of the pit, the rebound of the soil will cause the pile to have upward force. The force is greater in the middle and smaller at the edges. As a result, the vertical displacement of Z2 decreases. And the vertical displacement of Z1 increases. It should be noted that at construction stage 9, the Z1 displacement decreases and the Z2 displacement increases. This is because the construction stage 9 is the roof and floor construction stage. The top and bottom panels also have a gravitational effect, which has a greater effect on the central column48,49.

Figure 10b presents the vertical displacement curves of column feet of Z5, Z6, Z7 and Z8 in different construction stages. In general, the change law of Z5 and Z8 is similar, and the displacement change law of Z6 and Z7 is similar. The vertical displacement of Z6 and Z7 is greater than that of Z5 and Z8. The vertical displacement values of Z6 and Z7 are mainly negative. That means there’s been a settlement. On the contrary, the vertical displacement values of Z5 and Z8 are mainly positive. This suggests that a major vertical upward shift has occurred. Take Z5 and Z6 as examples to illustrate. For Z5. From excavation stages 1 to 8, the vertical displacement showed a trend of “decreasing first, then increasing”. In excavation stage 1, the displacement is 1.64 mm. In excavation stage 2, the displacement is -0.33 mm. The reduction is 1.97 mm. In excavation stage 8, the displacement is 2.28 mm and the increase is 0.64 mm. Also, for Z6. From excavation stages 1 to 8, although the vertical displacement fluctuates. It generally shows a trend of “first rapid increase, then slow increase”. The displacement of excavation 1 is 0.48 mm. The displacement of excavation 2 is −12.57 mm and the increase is 13.05 mm. The displacement of excavation 8 is −13.79 mm and the increment is 1.22 mm.

This is also the result of the joint action of excavation unloading and uplift of pit bottom. Excavation and unloading of the foundation pit will lead to the subsiding of the noodle foundation (see Fig. 8 for details). The columns are connected to the strip foundation, so the columns will also have subsidence. In excavation stage 2, the soil beneath Z5 and Z6 is excavated. As a result, both Z5 and Z6 experienced a large settlement. In the subsequent excavation stages, the uplift of the bottom of the pit gradually increased. Therefore, the settlement of Z5 is inhibited. Thus settlement is reduced. And then it shows a vertical upward trend. In addition, Z6 is located in the middle of the foundation pit. On the one hand, it is greatly affected by the load. On the other hand, it is also affected by the rebound of the bottom of the foundation pit. Therefore, it shows a trend of increasing settlement.

In addition, the changes in Fig. 10d and a are similar. Meanwhile, Fig. 10c and b also show a similar rule. This is mainly because the frame structure is relatively symmetrical, and the foundation pit is also symmetrical excavation.

In order to show the settlement deformation law of column foot in the process of foundation pit excavation more intuitively. Extract column foot displacement in Z direction. And draw a 3D mapping surface diagram of column foot displacement in the Z direction (see Fig. 11 for details). Obviously, excavation stage 1 takes on a different shape from the other excavation stages. In excavation stage 1, the column foot presents a “saddle shape” settlement law. In other excavation stages, the column foot presents “concave” settlement law. This is mainly because the excavation stage 1 is the excavation of both sides of the first layer of soil. The strip foundation on both sides is empty. So there is a large settlement deformation in the middle of the strip foundations. At this time, the middle part of the soil is still retained. And play the role of supporting the foundation, so the deformation is small. Then the settlement law of “saddle shape” is presented. In addition, in the other construction stages, the middle of the four strip foundations is empty. So the settlement displacement is large. The two ends of the strip foundation are overlapped with the underground diaphragm wall, so the deformation is small. Then it shows a “concave” settlement law.

Displacement of underground diaphragm wall in Z direction

The vertical deformation of underground diaphragm wall has important reference value for the safety and stability of superstructure. Figure 12 presents the Z direction displacement cloud map of underground diaphragm wall. Obviously, in different construction stages, the displacement is different. In excavation stage 1, the maximum displacement is 2.9 mm. The minimum displacement is 1.8 mm. In excavation stage 8, the maximum displacement is 7.6 mm. The minimum displacement is 5.6 mm. The vertical displacement of the underground diaphragm wall meets the minimum value required by the current relevant specifications36,37. The minimum values appear in the underground diaphragm walls 3 and 4. The maximum value occurs in the middle of the underground diaphragm walls 1 and 2. This is because in the process of foundation pit excavation, the soil is gradually excavated, and the strip foundation gradually becomes a free surface. The upper load is mainly borne by pile and underground diaphragm wall. Therefore, the vertical displacement of the underground diaphragm walls 1 and 2 on the lap side is constrained by the strip foundation, and the displacement is smaller. However, the vertical of the underground diaphragm walls 3 and 4 is not constrained by the strip foundation, and the displacement is larger. This also shows that the underground diaphragm wall plays a strengthening role in the process of foundation pit excavation. It is worth noting that, it can be found from the calculation of the resulting cloud map that the distribution of these maximum displacements is not uniform, but local.

In order to display the maximum value change of Z direction displacement of the underground diaphragm wall more intuitively. The results of numerical calculation are extracted and histogram is drawn. Figure 13 illustrates the comparison of Z direction displacement of the underground diaphragm wall. It can be seen from Fig. 13a that the maximum displacement presents a trend of “first increasing and then decreasing”. The stages with relatively large displacement increment are: excavation stages 1, 3, 5, and 7. The displacement increments are 2.9 mm, 1 mm, 1.1 mm, and 1 mm, respectively. Obviously, the displacement increment of excavation stage 1 is the largest.

It can be seen from Fig. 13b that the minimum displacement also shows a trend of “first increasing and then decreasing”. The displacement increment of excavation stages 1, 3, 5, and 7 is relatively large. The displacement increments are 1.8 mm, 0.8 mm, 0.8 mm, and 0.8 mm, respectively. Obviously, the displacement increment of excavation stage 1 is the largest. As can be seen from Fig. 4, in excavation stages 1, 3, 5 and 7, the excavated soil is the two sides of each layer. And the amount of excavation is larger than other excavation stages. This may be the cause of displacement increases. Therefore, in the design and construction process of similar projects. It is necessary to consider the influence of excavation mode. In addition, when the construction stage is 9, the maximum and minimum displacement values show a downward trend. This is mainly because the roof and floor are set at this stage. The vertical displacement of the underground diaphragm wall is constrained by the gravity action of the roof and floor.

Displacement of underground diaphragm wall in XY direction

The horizontal displacement of the underground diaphragm wall will affect the superstructure and adjacent soil. Figure 14 illustrates the XY displacement cloud map of the underground diaphragm wall. Obviously, in different construction stages, the displacement is different. In excavation stage 1, the maximum displacement is 8.1 mm. When the excavation is completed, the maximum displacement is 18.1 mm. The minimum displacement at all excavation stages is close to 0. The minimum values appear in underground diaphragm walls 3 and 4. This is because the strip foundations prevents the deformation of the underground diaphragm wall. On the contrary, the maximum value occurs in the middle and upper parts of underground diaphragm walls 1 and 2. This is because soil is gradually removed during excavation. The middle and upper parts of the underground diaphragm walls 1 and 2 are free surfaces. So the horizontal displacement is bigger than the other side. On the contrary, the displacement of the part embedded with the soil is hindered by the soil. Therefore, the displacement is relatively small. This also shows that the underground diaphragm wall plays a strengthening role in the process of foundation pit excavation. Therefore, it is necessary to strengthen the design and monitoring of the underground diaphragm wall. It is worth noting that, it can be found from the calculation of the resulting cloud map that the distribution of these maximum displacements is not uniform, but local.

In order to display the change of the maximum displacement value more intuitively. The results of numerical calculation are extracted and histogram is drawn. Figure 15 shows the displacement comparison diagram of the underground diaphragm wall in the XY direction. As can be seen from Fig. 15a, the maximum displacement generally presents a trend of “increasing”. In addition, the displacement increment generated during excavation stages 1, 3, 5, and 7 are relatively large. The displacement increments are 8.1 mm, 4.8 mm, 3 mm, and 2.1 mm, respectively. Obviously, the displacement increment of excavation 1 is the largest. It can be seen from Fig. 4 that the excavated soil in the excavation stages 1, 3, 5, and 7 are the two sides of each layer. And the excavation volume is larger than other excavation stages. This can cause displacement to increase by a larger amount. Therefore, in the design and construction process of similar projects. It is necessary to strengthen the design of excavation methods. In addition, the displacement remains almost the same at construction stage 9. This is mainly because although construction stage 9 set the roof and floor. And the setting of structural members can restrain the deformation of underground diaphragm wall. However, when the roof and floor are set, the horizontal displacement of the ground connecting wall has been generated. Thus the displacement in the horizontal direction remains essentially the same.

It can be seen from Fig. 15b that excavation stage 1 has the largest increase in displacement. Although the displacement of excavation stages 3, 5, and 7 also increased. But the increase is diminishing. This shows that excavation stage 1 has the greatest influence on the horizontal deformation. Therefore, it is necessary to set reasonable excavation conditions. The construction content of excavation stage 1 is one of the key points of design. In addition, it can also be seen that the displacement change of excavation stages 2, 4, 6, and 8 are close to 0. This shows that the displacement of these stages is basically unchanged from the previous stage. This is mainly because during excavation stages 1, 3, 5, and 7. The excavated soil is the two sides of each layer. The soil on both sides is in direct contact with the underground diaphragm wall. This will produce a force of interaction effect. When the soil on both sides is excavated, the underground diaphragm wall is separated from the soil. It forms an empty plane. As a result, the horizontal displacement increases a lot. In other excavation stages, the soil is not in contact with the underground diaphragm wall. Therefore, excavation has little effect on displacement. Then, the displacement remains unchanged. This also verified the reliability of the model established in this study.

Displacement of pile in Z direction

Pile is one of the main components of reinforcement measures in this study. The vertical deformation of pile has an important influence on the safety and stability of superstructure. Figure 16 illustrates the pile displacement cloud map in the Z direction. Obviously, in different construction stages, the displacement is different. In excavation stage 1, the maximum value is -10.5 mm, which appears at pile 1–4. The minimum value is 1.8 mm and appears at pile 2–2. In excavation stage 2, the maximum value is −13.7 mm, which appears at pile 2–4. The minimum value is 2.2 mm and appears in pile 3 − 1. In excavation stage 3, the maximum value is −13.3 mm, which appears at pile 2–4. The minimum value is 3 mm and appears at pile 3 − 1. In excavation stage 4, the maximum value is −14 mm, which appears at pile 2–4. The minimum value is 3.5 mm and appears at pile 3–7. In excavation stage 6, the maximum value is −16.1 mm, which appears at pile 2–4. The minimum value is 5.1 mm and appears at pile 3–7. During the construction stage of roof and floor, the maximum value is −16.1 mm, which appears at pile 2–4. The minimum value is 5.6 mm and appears at pile 2–2. Although the maximum and minimum values appear at different places. However, it can be found that only in excavation stage 1, the maximum displacement occurs in pile 1–4. The other stages all appear at pile 2–4. Both piles are located in the middle of the foundation pit. The minimum displacement occurs mainly at pile 2–2, pile 3 − 1, and pile 3–7. These piles are mainly distributed around the foundation pit.

This is because when in excavation stage 1, the strip foundation on both sides becomes a free surface. The upper load force is mainly borne by the pile and the underground diaphragm wall. Therefore, the vertical displacement of pile 1–4 is the largest. The piles and the underground diaphragm wall all around bear the load together. Thus the displacement is minimal. In addition, in other construction stages. The middle soil is excavated, and the lower part of the middle strip foundation becomes the free surface. The upper load force is mainly borne by pile and underground diaphragm wall. And the intermediate load is relatively larger. Therefore, the displacement of the middle pile (pile 2–4) is the largest. This also shows that the pile plays a strengthening role in the process of foundation pit excavation. In addition, the maximum vertical displacement mainly occurs at the top of pile in the middle of foundation pit. This shows that the central position of the pile is the weak point of this renovation project. It is necessary to strengthen the design, construction and monitoring of piles in the central position. It is worth noting that, it can be found from the calculation of the resulting cloud map that the distribution of these maximum displacements is not uniform, but local.

In order to more intuitively show the maximum change of pile displacement in the Z direction. The numerical results were extracted and the strip charts were plotted. Figure 17 is a comparison diagram of pile displacement in the Z direction. As can be seen from Fig. 17a, the maximum displacement generally presents a trend of “increasing”. The displacement increments of excavation stages 1 and 2 are large, which are 10.5 mm and 3.2 mm, respectively. Obviously, the displacement increment of excavation stage 1 is the largest. This is because the two stages of excavation stages 1 and 2 will cause the strip foundation to separate from the lower soil mass and form a free surface. The upper load is mainly borne by pile and underground diaphragm wall. Therefore, a relatively larger change in displacement is generated. It can be seen that the excavation method of foundation pit will have a great influence on the displacement of piles. So, choose the reasonable way of foundation pit excavation is important.

It can be seen from Fig. 17b that the minimum displacement value presents a trend of “first increasing, and then decreasing”. The displacement increment of excavation stages 1, 3, 5, and 7 are relatively large. They are 1.8 mm, 0.8 mm, 1 mm and 0.9 mm, respectively. Obviously, the displacement increment of excavation 1 is the largest. It can be seen from Fig. 4 that the excavated soil in the excavation stages 1, 3, 5, and 7 is the two sides of each layer. And the excavation volume is larger than other excavation stages. This may affect the displacement change of the pile. Therefore, in the similar engineering design and construction process, it is important to consider the effect of excavation method.

The bending moment of the piles

The change of pile bending moment has an important influence on the safety and stability of the superstructure. Figure 18 illustrates the cloud map of pile bending moment. Obviously, in different construction stages, the bending moment is different. The maximum and minimum values also occur in different places. When in excavation stage 1, the maximum value is 38 kN·m, which appears at pile 2–4. The minimum value is -43 kN·m, which occurs in pile 3–3. In excavation stage 2, the maximum value is 27 kN·m, which appears at pile 2–6. The minimum value is −28 kN·m, which occurs in pile 4–4. In excavation stage 3, the maximum value is 52 kN·m, which appears at pile 3–3. The minimum value is −43 kN·m and occurs in pile 2–5. In excavation stage 4, the maximum value is 22 kN·m, which appears at pile 3–3. The minimum value is −22 kN·m, which occurs at pile 3–3. In excavation stage 6, the maximum value is 19 kN·m, which appears at pile 4–5. The minimum value is −20 kN·m, which occurs in pile 3–3. When the roof and floor are constructed, the maximum value is 21.2 kN·m, which occurs in pile 4–5. The minimum value is −21 kN·m and occurs in pile 1–5. By comparison, the maximum and minimum bending moments of pile body mainly appear at the top of pile in the middle of foundation pit. This also reflects that the joint between pile and strip foundation is a weak point prone to bending failure. Design, construction and monitoring need to be strengthened to ensure reliable connections between piles and strip foundations. It is worth noting that, it can be found from the calculation of the resulting cloud map that the distribution of these maximum bending moment is not uniform, but local.

In order to more intuitively show the change of the maximum bending moment value. The results of numerical calculation are extracted and histogram is drawn. Figure 19 is the comparison diagram of pile bending moment. As can be seen from Fig. 19a, the maximum value generally presents a trend of “up and down fluctuation”. The increment of bending moment produced by excavation stage 1, 3, 5, and 7 are relatively large. They are 38 kN·m, 25 kN·m, 29 kN·m, and 19 kN·m, respectively. Obviously, the largest increment was obtained at excavation stage 1. It can be seen that the soil on both sides of excavation will cause the increase of the maximum bending moment. In addition, the bending moments generated by excavation stage 2, 4, 6, and 8 are all reduced. The reductions were 11 kN·m, 30 kN·m, 32 kN·m, and 17 kN·m, respectively. It can be seen that the excavation of the middle soil will cause the reduction of the maximum bending moment.

As can be seen from Fig. 19b, the minimum value also presents a trend of “up and down fluctuation” in general. The increment of bending moment produced by excavation stage 1, 3, 5, and 7 is relatively large. They are 43 kN·m, 15 kN·m, 24 kN·m, and 24 kN·m, respectively. Obviously, the increment is the largest in excavation stage 1. It can be seen that the soil on both sides of excavation will cause the increase of the minimum bending moment. In addition, the bending moment value of excavation stages 2, 4, 6, and 8 all decrease. The reductions were 15 kN·m, 21 kN·m, 26 kN·m, and 23 kN·m, respectively. It can be seen that the excavation of intermediate soil will cause the reduction of the minimum bending moment.

It is worth noting that significant fluctuation of pile bending moment can be observed. This can reflect the complexity of the influence of excavation process on pile bending moment. This phenomenon may be due to the combined effect of excavation sequence and soil heterogeneity37,52.

In summary, excavation stage 1 has the greatest influence on the maximum and minimum bending moments of piles. It can be seen that it is very important to choose a reasonable excavation method. Therefore, in the design and construction, the excavation method needs to be optimized. In particular, we should pay attention to the reasonable design of the position and scope of the first excavation.

The shear force of the piles

The change of pile shear force has important reference value for the safety of superstructure. Figure 20 presents the shear cloud diagram of pile. Obviously, at different stages of construction, the shear force is different. In excavation stage 1, the maximum value is 46 kN, which appears at pile 2–4. The minimum value is -50 kN and appears at pile 3–3. In excavation stage 2, the maximum value is 30 kN, which appears at pile 3–3. The minimum value is −32 kN and appears at pile 4–6. In excavation stage 3, the maximum value is 80 kN, which appears at pile 3–3. The minimum value is −65 kN and occurs in pile 2–5. In excavation stage 4, the maximum value is 22 kN, which appears at pile 3–3. The minimum value is −29 kN and occurs in pile 1–5. In excavation stage 6, the maximum value is 27 kN, which appears at pile 4–5. The minimum value is −33 kN and occurs in pile 1–5. When the roof and floor are constructed, the maximum value is 34 kN, which occurs in pile 4–5. The minimum value is −34 kN and occurs in pile 1–5. It can be seen that the maximum and minimum values mainly appear in the middle of the foundation pit. This also reflects that the pile in the middle of the foundation pit is vulnerable to shear failure. It is necessary to strengthen the design, construction and monitoring to ensure that the piles in the middle of the foundation pit meet the design and construction requirements. It is worth noting that, it can be found from the calculation of the resulting cloud map that the distribution of these maximum shear force is not uniform, but local.

In order to display the change of the maximum value of shear force more intuitively. The results of numerical calculation are extracted and histogram is drawn. Figure 21 is a comparison diagram of shear forces of piles. As can be seen from Fig. 21a, the maximum value generally presents a trend of “up and down fluctuation”. The increment of shear force produced during excavation stages 1, 3, 5 and 7 is larger, which are 46 kN, 50 kN, 27 kN and 7 kN, respectively. It can be seen that the soil on both sides of excavation causes the increase of the maximum shear force. The largest increment was observed at excavation stages 1 and 2, which were both close to 50 kN. In addition, the shear forces produced during excavation stages 2, 4 and 6 are all reduced. The reductions were 16 kN, 58 kN, and 22 kN, respectively. It can be seen that the excavation of intermediate soil will cause the maximum shear force to decrease.

As can be seen from Fig. 21b, the minimum value also presents a trend of “up and down fluctuation” in general. The increment of shear force is larger during excavation stages 1, 3, 5, and 7. They are 50 kN, 33 kN, 8 kN, and 15 kN, respectively. Obviously, the increment is the largest in excavation stage 1. It can be seen that the soil on both sides of excavation will cause the increase of the minimum shear value. In addition, the shear forces produced during excavation stages 2, 4, 6 and 8 are all reduced. The reductions were 18 kN, 36 kN, 4 kN, and 13 kN, respectively. It can be seen that the excavation of intermediate soil will cause the minimum shear value to decrease.

It is worth noting that significant fluctuations in pile shear force can also be observed. This can reflect the complexity of the influence of foundation pit excavation process on pile shear force. This phenomenon may be due to the combination of excavation sequence and soil heterogeneity47,52.

To sum up, the increment of pile shear force is the largest during excavation stages 1 and 2. It can be seen that the excavation method of foundation pit will have a great influence on the shear value of pile. Therefore, it is very important to choose a reasonable excavation method of the foundation pit.

The axial force of the piles

The axial force variation of piles is an important reference for the safety of superstructure. Figure 22 presents the pile axial force cloud diagram. Obviously, in different construction stages, the axial force is different. In excavation stage 1, the maximum value is -2,003 kN, which appears at pile 3–5. The minimum value is 37 kN and appears at pile 3 − 1. In excavation stage 2, the maximum value is −2,559 kN, which appears at pile 3–3. The minimum value is 1.6 kN and appears at pile 3 − 1. In excavation stage 3, the maximum value is −2,532 kN, which appears at pile 3–3. The minimum value is 12 kN and appears at pile 3 − 1. In excavation stage 4, the maximum value is −2,528 kN, which appears at pile 2–4. The minimum value is 7.4 kN and appears at pile 4–7. In excavation stage 6, the maximum value is -2,499 kN, which appears at pile 2–4. The minimum value is 14.4 kN and appears at pile 4–7. When the roof and floor are constructed, the maximum value is −2,481 kN, which appears at pile 2–4. The minimum value is 10.9 kN and appears at pile 4–7. It should be noted that the maximum axial force value is negative. This shows that the main axial force of pile is pressure. By comparison, the maximum axial force of pile body mainly appears at the top of pile in the middle of foundation pit. This also reflects that the top of the pile in the middle of the foundation pit is a weak point prone to compression failure. It is necessary to strengthen the design, construction and monitoring to ensure that the piles in the middle of the foundation pit meet the design and construction requirements. It is worth noting that, it can be found from the calculation of the resulting cloud map that the distribution of these maximum axial force is not uniform, but local.

In order to more intuitively show the change of the maximum value of axial force. The results of numerical calculation are extracted and histogram is drawn. Figure 23 presents the comparison diagram of pile axial force. As can be seen from Fig. 23a, the maximum axial force generally presents a trend of “first increasing and then decreasing”. The axial force produced during excavation stage 1 and 2 is increased, and the increments were 2,003 kN and 556 kN, respectively. Obviously, the increment of axial force in excavation stage 1 is the largest. It can be seen that the soil on both sides of excavation will cause the change of the maximum axial force. In other stages, although the axial force is decreasing, the change is not large. The axial force values are all close to -2,500 kN. It should be noted that the maximum axial force is lower than the designed bearing capacity of the pile (−2,915.6 kN).

As can be seen from Fig. 23b, the minimum value generally presents a trend of “up and down fluctuation”. In excavation stages 1, 3, 5, and 7, the axial force are increased. The increments were 37 kN, 10.4 kN, 8 kN, and 5.5 kN, respectively. It can be seen that the maximum axial force increases when the soil is excavated on both sides. The axial force increment is the largest when the excavation 1 is carried out. In addition, the axial forces generated during excavation stages 2, 4, 6, and 8 are all reduced. The reductions were 35.4 kN, 4.6 kN, 1 kN, and 7.5 kN, respectively. It can be seen that the excavation of intermediate soil will cause the reduction of the minimum axial force.

In summary, the axial force increment is the largest when the excavation stage 1 is carried out. The axial force is most sensitive to excavation stage 1, but not to other excavation stages. Therefore, attention should be paid to the design and construction of excavation stage 1.

Discussion

In this paper, the construction mechanics behavior of existing building underground layer reconstruction project is studied. The results show that the excavation of foundation pit will have a certain influence on the stress and deformation characteristics of structural members. The stress and deformation characteristics of structural members are sensitive to the depth of foundation pit excavation. It increases with the increase of excavation depth. Obviously, the soil disturbance caused by the underground layer of the existing building will have an adverse effect on the foundation of the building. It threatens the stability of superstructure and engineering safety. The research results have a positive effect on the design optimization and construction guidance of similar engineering structures. However, the results also show that the excavation of the first layer of soil has the greatest influence on the stress and deformation characteristics of the structural members. Therefore, it is necessary to discuss the relevant contents of excavation stages 1 and 2 involved in the excavation of the first soil layer.

This discussion chooses the strip foundation as the research object. The total displacement of strip foundation during excavation stages 1 and 2 are discussed. Figure 24 presents the total displacement deformation cloud map. Obviously, the total displacement of strip foundation will change with different excavation depth. As can be seen from Fig. 24a, in excavation stage 1, the maximum total displacement is 12.6 mm, which occurs in the middle of strip foundations 1 and 4. The displacement vector is going straight down. That means there’s been a settlement. The maximum displacement occurred in a large range, accounting for about 8.1% of the total. As can be seen from Fig. 24b, in excavation stage 2, the maximum total displacement is 16.5 mm. The location of the maximum value has changed, and it appears in the middle of strip foundations 2 and 3. The direction of the displacement vector is straight down, indicating that settlement has also occurred. The maximum displacement occurred in a large range, accounting for about 8.1% of the total. It can be seen that the maximum vertical deformation will occur in the middle of the strip foundation during the excavation of the foundation pit. Therefore, the middle part is the weak part. It is necessary to focus on the reinforcement design and construction monitoring of the middle part of the strip foundation to ensure safety.

The main shortcomings of this study are as follows: Firstly, it does not take into account the influence of possible surrounding buildings, pipelines, roads, and site loads. Secondly, the impact of possible rainfall is not considered. Thirdly, the mechanical properties and deformation of the building superstructure have not been analyzed and studied. In addition, there are no comparative analysis of the influence of changes in pile diameter, underground diaphragm wall thickness, floor height and other factors53,54.

Future research directions are as follows: Firstly, further enrich the influencing factors. Consider the environment around the foundation pit more comprehensively. The influence factors such as pipeline, soil structure, rain weather, buildings, roads and site load around the deep excavation are included in the future study. Secondly, on the basis of this study, the mechanical properties and deformation of the building superstructure will be further studied. Thirdly, compare and analyze the influence of changes in pile diameter, length, underground diaphragm wall thickness, floor height and other factors. In addition, carry out research on the underground addition of other types of existing buildings. And finally, the effects of dynamic loads (e.g. traffic, wind), the bearing capacity, buckling, and settlement risk related issues of piles are also an important direction for future research.

It is worth noting that groundwater seepage may have a certain impact on soil deformation and pile settlement49,50. Meanwhile, the overlapping effect of piles may also have a certain impact on soil deformation and pile settlement51,52. However, these effects are complex49,50,51,52. It is necessary to analyze and study according to the actual situation of different projects. Therefore, in the future, we will carry out relevant research on the overlap effect of groundwater seepage and piles.

Conclusions

In this paper, a 3D finite element model is established by taking an existing building basement-addition project as an example. The mechanical behavior of typical structural components induced by basement-addition construction is studied. The main conclusions are as follows:

-

(1)

In this study, MIDAS GTS NX is used to numerically simulate the construction process of underground additional layers of existing buildings. The simulation results are in good agreement with the measured data. During the construction process, the settlement of strip foundation, underground diaphragm wall, column foot and pile is small, and the frame structure tends to be safe. It is feasible to adopt the reinforcement measures of “pile + underground diaphragm wall” to transform the underground space with additional layers.

-

(2)

Excavation stages 1 and 2 have the greatest influence on the construction mechanical behavior of the existing building underground layer addition reconstruction project. Therefore, the excavation of the first layer of soil is the key construction stage of foundation pit excavation. The deformation and internal force distribution of strip foundation, column foot and pile have obvious spatial characteristics. The closer to the center of the foundation pit, the greater the value. Attention should be focused and necessary measures should be taken.

-

(3)

The vertical displacement of strip foundation is mainly settlement. With the increase of excavation depth, the settlement becomes larger. When the excavation is completed, the maximum displacement is -18.6 mm. The location appears in the middle of strip foundations 2 and 3. The vertical displacement of column foot is also mainly settlement. The vertical displacement at excavation 1 was “saddle shaped”. The other stages were “concave shaped”. The vertical displacement is also increasing. The maximum displacement is −13.79 mm. It appears in Z6, 7, 10, and 11.

-

(4)

The displacement of underground diaphragm wall increases with the increase of excavation depth. When the excavation is completed, the maximum vertical displacement is 7.6 mm, which appears in the middle of the underground diaphragm walls 1 and 2. The minimum vertical displacement is 5.6 mm, which appears in the middle of underground diaphragm walls 3 and 4. The maximum horizontal displacement is 18.1 mm and occurs in the middle of underground diaphragm walls 1 and 2.

-

(5)

The vertical displacement of pile is mainly settlement. As the depth of excavation continues to increase, it becomes larger. When the excavation is completed, the maximum displacement is -16.1 mm, which appears at pile 2–4. The main internal force of pile is pressure. The axial force is not sensitive to the depth of excavation. When the construction is completed, the maximum bending moment, shear force, and axial force of the pile are 21.2 kN·m, 34 kN, and −2,481 kN, respectively. The maximum values occur in pile 4–5, 4–5, and 2–4, respectively.

Data availability

Data available on request from the corresponding author.

References

Guo, P. et al. Minimum cover depth Estimation for underwater shield tunnels. Tunn. Undergr. Space Technol. 115 (5), 104027. https://doi.org/10.1016/j.tust.2021.104027 (2021).

Guo, P. et al. Analysis of observed performance of a deep excavation straddled by shallowly buried pressurized pipelines and underneath traversed by planned tunnels.Tunnelling and underground space technology. https://doi.org/10.1016/j.tust.2022.104946 (2023).

Zhang, R. et al. Analysis of ground surface settlement in anisotropic clays using extreme gradient boosting and random forest regression models. J. Rock Mech. Geotech. Eng. 13, 1478–1484. https://doi.org/10.1016/j.jrmge.2021.08.001 (2021b).

Guo, P., Gong, X. & Wang, Y. Displacement and force analyses of braced structure of deep excavation considering unsymmetrical surcharge effect. Comput. Geotech. 113 (SEP.), 103102. https://doi.org/10.1016/j.compgeo.2019.103102 (2019).

Guo, P. et al. Predicting response of constructed tunnel to adjacent excavation with Dewatering.Geofluids, 2021(3):1–17. https://doi.org/10.1155/2021/5548817 (2021).

Wang, X. et al. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 123, 104416. https://doi.org/10.1016/j.tust.2022.104416 (2022).

Luo, N. et al. Research on damage failure mechanism and dynamic mechanical behavior of layered shale with different angles under confining pressure. Deep Undergr. Sci. Eng. 2 (4), 337–345. https://doi.org/10.1002/dug2.12063 (2023).

Li, J. C. et al. A time-domain recursive method to analyse transient wave propagation across rock joints. Geophys. J. Int. 188 (2), 631–644. https://doi.org/10.1111/j.1365-246X.2011.05286.x (2012).

Shikary, C. & Rudra, S. Assessment of urban-to-urban interaction and its impact on urban development: a study on a backward district of Eastern India. Environ. Dev. Sustain. 26, 16863–16886. https://doi.org/10.1007/s10668-023-03314-w (2024).

Guo, P. et al. Soil creep effect on Time-Dependent deformation of deep braced Excavation. Adv. Mater. Sci. Eng. https://doi.org/10.1155/2022/5655592 (2022).

Xu, C. et al. Sustainable development pathways for energies in Yangtze river delta urban agglomeration. Sci. Rep. 13, 18135. https://doi.org/10.1038/s41598-023-44727-x (2023).

Li, J. C., Li, H. B. & Zhao, J. An improved equivalent viscoelastic medium method for wave propagation across layered rock masses. Int. J. Rock. Mech. Min. Sci. 73, 62–69. https://doi.org/10.1016/j.ijrmms.2014.10.008 (2015).

Rahajeng, A. et al. Assessment of regional development pattern towards sustainability urban areas: empirical evidence from Yogyakarta urban areas. Environ. Dev. Sustain. 26, 25827–25848. https://doi.org/10.1007/s10668-023-03709-9 (2024).

Zhao, L. & Ding, L. Wireless sensor network based on IoT automation technology application in green supply chain management of automobile manufacturing industry. Int. J. Adv. Manuf. Technol. https://doi.org/10.1007/s00170-024-14804-0 (2024).

Lin, W., Mathewson, F. & Xiao, J. Screening through investment: evidence from the Chinese automobile industry. Rev. Ind. Organ. 64, 471–513. https://doi.org/10.1007/s11151-024-09949-x (2024).

Li, J. C. Wave propagation across non-linear rock joints based on time-domain recursive method. Geophys. J. Int. https://doi.org/10.1093/gji/ggt020 (2013).

Kumar, D. & Bassill, N. P. Analysing trends of computational urban science and data science approaches for sustainable development. Comput. Urban Sci. 4, 33. https://doi.org/10.1007/s43762-024-00142-0 (2024).

Wang, Y. et al. Simplified analytical solutions for tunnel settlement induced by axially loading single pile and pile Group. J. Eng. Mech. https://doi.org/10.1061/(asce)em.1943-7889.0002035 (2021).

Wang, Y. et al. Performance of deep braced excavation under embankment surcharge load. Geotech. Geol. Eng. 41, 3575–3586. https://doi.org/10.1007/s10706-023-02474-w (2023).

Lin, B. The Spatial–Temporal evolution of China’s automobile manufacturing cluster network and its influencing factors. J. Knowl. Econ. https://doi.org/10.1007/s13132-024-01735-0 (2024).

Zhang, X. & Han, H. Characteristics and factors influencing the expansion of urban construction land in China. Sci. Rep. 14, 16040. https://doi.org/10.1038/s41598-024-67015-8 (2024).

Zhang, Y. et al. Smart City construction and urban green development: empirical evidence from China. Sci. Rep. 13, 17366. https://doi.org/10.1038/s41598-023-44061-2 (2023).

Shi, Y. et al. Spatiotemporal evolution and influencing factors of Urban-rural construction land in rural industrialized areas in China: case studies in Changyuan City and Xinxiang County of Henan Province. Chin. Geogr. Sci. 33, 850–864. https://doi.org/10.1007/s11769-023-1383-8 (2023).

Song, X. et al. Development vs. conservation in limited urban sprawl: an integrated framework for resolving the urban boundary dilemma in China. J. Geogr. Sci. 34, 1371–1393. https://doi.org/10.1007/s11442-024-2252-9 (2024).

Zheng, Y. et al. The relationship between basin urbanization and ecosystem services in China: a case study of central China (CC) urban agglomeration. Urban Ecosyst. 27, 993–1010. https://doi.org/10.1007/s11252-023-01496-9 (2024).

Chi, Z. & Deng, M. Progressive failure mechanism of existing-supplementary double-layer piles retaining excavation beneath existing underground space. Sci. Rep. 14, 24357. https://doi.org/10.1038/s41598-024-75987-w (2024).

Simpson, B. & Vardanega, P. J. Results of monitoring at the British library excavation. Geotech. Eng. 167 (GE2), 99–116. https://doi.org/10.1680/geng.13.00037 (2014).

Yin, H. et al. Sheltering effect induced by established station to the new station excavation in Zhengzhou. Archiv Civ. Mech. Eng. 23, 175. https://doi.org/10.1007/s43452-023-00716-5 (2023).

Foraboschi Paolo.Specific structural mechanics that underpinned the construction of Venice and dictated Venetian architecture.Engineering Failure Analysis, 78:169–195. https://doi.org/10.1016/j.engfailanal.2017.03.004 (2017).

Wang, S. et al. Comparative investigation on deformation monitoring and numerical simulation of the deepest excavation in Beijing. Bull. Eng. Geol. Environ. 80, 1233–1247. https://doi.org/10.1007/s10064-020-02019-y31 (2021).

Zhang, R., Chang, H. & Goh, A. T. C. Review of recent developments in AI-based data processing and prediction for braced excavation design. Intell. Transp. Infrastructure. 3, liae014. https://doi.org/10.1093/iti/liae014 (2024).

Ma, S. et al. Research on the protection effect and parameter optimization design of isolation pile-diaphragm wall combination support structure. Sādhanā 49, 82. https://doi.org/10.1007/s12046-024-02432-z (2024).

Li, J. C. et al. Assessment of underground tunnel stability to adjacent tunnel explosion.Tunnelling and Underground Space Technology incorporating Trenchless Technology Research, 35(APR.):227–234. https://doi.org/10.1016/j.tust.2012.07.005 (2013).

Hu, W. et al. Experimental study on deformation and passive Earth pressure behind cantilever pile retaining walls in narrow excavations. Geotech. Geol. Eng. 42, 7041–7061. https://doi.org/10.1007/s10706-024-02912-3 (2024).

Ren, D. et al. Deformation behavior of a Large-Scale excavation and the effect of an adjacent foundation pit on the excavation. Int. J. Civ. Eng. 22, 1493–1505. https://doi.org/10.1007/s40999-024-00960-7 (2024).

Ge, C. et al. Influence of deep foundation pit excavation on surrounding environment: a case study in Nanjing, China. Acta Geophys. https://doi.org/10.1007/s11600-024-01425-0 (2024).

Shi, X. et al. Stability analysis of deep foundation pit with a double-row cast-in-place piles and diagonal steel lattice braces under sloped excavation conditions. Sci. Rep. 14, 22761. https://doi.org/10.1038/s41598-024-73528-z (2024).

Mu, Z. et al. Analysis of shield tunnel response to bilateral pit excavation with a focus on perimeter pressure and deformation mechanisms. Sci. Rep. 14, 23167. https://doi.org/10.1038/s41598-024-72731-2 (2024).

Cui, X. et al. Observed characterization of multilevel retaining structure for deep excavation of subway station. Urban Rail Transit. 10, 89–106. https://doi.org/10.1007/s40864-023-00208-y (2024).

Tong, L. et al. Lateral bearing performance and mechanism of piles in the transition zone due to pit-in-pit excavation. Acta Geotech. 17, 1935–1948. https://doi.org/10.1007/s11440-021-01341-3 (2022).

Huang, X. et al. Evolution of 3D stress arch in surrounding rock during segmented excavation of a circular tunnel. Geotech. Geol. Eng. 43, 1. https://doi.org/10.1007/s10706-024-02994-z (2025).

Zhou, R. et al. Excavation-induced deformation and stress responses of a highway tunnel in fault fracture rock zone with high geo-stress: a case study of Xiangjunshan tunnel. Environ. Earth Sci. 83, 145. https://doi.org/10.1007/s12665-024-11447-y (2024).

Miao, Y. et al. Study on influence of shallow buried tunnel excavation on adjacent Bridge piles. Geotech. Geol. Eng. 41, 3321–3333. https://doi.org/10.1007/s10706-023-02457-x (2023).

Zhang, Q. et al. Study on the mechanical behavior of a foundation pit retaining structure adjacent to the pile foundation of a subway station. Environ. Earth Sci. 80, 704. https://doi.org/10.1007/s12665-021-09996-7 (2021).

Wang, H. et al. Numerical analysis of the effect of river channel excavation on existing subway tunnels. Geotech. Geol. Eng. 42, 4225–4244. https://doi.org/10.1007/s10706-024-02759-8 (2024).

Zhao, P., Sun, Y., Wang, Z. & Guo, P. Mechanical characteristics of deep excavation support structure with asymmetric load on ground surface. Symmetry 16, 1309. https://doi.org/10.3390/sym16101309 (2024).

Boulkhiout, R. & Messast, S. Contribution to the numerical simulation of the seismic response of RC frame taking into consideration soil–structure interaction. Arab. J. Geosci. 16, 251. https://doi.org/10.1007/s12517-023-11343-y (2023).

Xu, D. et al. Study on secondary collapse of the bottom frame masonry structure in semi-ruined state based on FEM–FDEM. Sci. Rep. 14, 29405. https://doi.org/10.1038/s41598-024-80612-x (2024).

Zeng, C. et al. Characteristics of ground deformation induced by pre-excavation dewatering considering blocking effect of adjacent structure. J. Zhejiang Univ. (Engineering Science). 02, 55. https://doi.org/10.3785/j.issn.1008-973X.2021.02.014 (2021).

He, S. et al. Influence of groundwater seepage on deformation of foundation pits with suspended impervious curtains. J. Zhejiang Univ. (Engineering Science). 04, 53. https://doi.org/10.3785/j.issn.1008-973X.2019.04.012 (2019).

Zeng, C. et al. Barrier effects of surrounding group piles on deformation of foundation pits induced by dewatering. Chin. J. Geotech. Eng. 11, 45. https://doi.org/10.11779/CJGE20220255 (2021).

Zhao, P. et al. Mechanical response of elevated Bridge piles to adjacent deep excavation. Sci. Rep. 15, 1766. https://doi.org/10.1038/s41598-025-85853-y (2025).

Yu, F. et al. Performance of double-row piles retaining excavation beneath existing underground space. Int. J. Phys. Mod. Geotech. 19, 167–180 (2019).

Shan, H. et al. Influence of Soil Excavation on Bearing Behavior of Pile Group Foundation Composed of Underpinning Piles and Existing Piles. J. Testing Eval. 52, 1021–1034 (2024).

Acknowledgements

This research was funded by the Opening Project of State Key Laboratory of Explosion Science and Technology (Beijing Institute of Technology), grant number KFJJ23-05 M; the Fundamental Research Funds for the Central Universities, grant numbers JZ2023HGQA0094 and JZ2023HGTA0193, the Tongling Huabao Project Management Co., LTD Sponsored Research Project, grant numbers 2024tlxyxdz214 and 2025tlxyxdz067.

Author information

Authors and Affiliations

Contributions

Conceptualization, P.Z. and P.G.; methodology, P.G.; software, P.Z.; validation, Z.W. and P.Z.; formal analysis, P.Z. and Z.W.; investigation, P.Z. and Y.Q.; resources, P.G. and Z.W.; data curation, P.Z.; writing—original draft preparation, P.Z. and Y.Q.; writing—review and editing, P.G. and Z.W.; visualization, Y.Q.; supervision, P.G.; project administration, Z.W. and P.Z.; funding acquisition, P.G. and Z.W. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, P., Qiu, Y., Wang, Z. et al. Performance of typical structural components in basement-addition for existing building. Sci Rep 15, 12779 (2025). https://doi.org/10.1038/s41598-025-97939-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-97939-8