Abstract

The increasing global population and urbanization have led to a rise in kitchen food waste (KW), posing significant environmental and economic challenges. Converting KW into fish feed offers a sustainable solution for managing KW. This study investigates the conversion of KW to aquatic feed via fermentation, and the innovative use of fermented kitchen waste (FKW) as an alternative protein source in aquaculture feed. Strains L58 and O57, identified as Bacillus licheniformis and Yarrowia lipolytica, were initially screened for high enzymatic activities and salt tolerance. A mixed-strain fermentation approach was employed, with process parameters optimized through central composite designs to maximize soluble protein yield. Fermentation significantly increased the contents of soluble protein, crude protein, and crude fat while reducing total carbohydrates and crude fiber. The total amino acid content increased by 45.5%, with significant gains in 19 amino acids. Feeding trials with juvenile yellow catfish demonstrated that replacing 15–30% of fish meal with FKW significantly improved growth performance, feed utilization, and enhanced the crude protein content in fish flesh. These findings indicate that co-fermenting KW with the two strains efficiently produces high-protein aquaculture feed, offering a sustainable alternative protein source that reduces reliance on fish meal and aids in waste management.

Similar content being viewed by others

Introduction

Kitchen food waste (KW) consists of residual materials from food preparation and consumption in households, restaurants, and other food service establishments. The increase in global population and urbanization has led to a significant rise in KW, making its management a critical environmental and economic issue. The United Nations Environment Programme (UNEP) reports that approximately 1.3 billion tons of food are wasted annually, causing an economic loss of about $1 trillion1. This waste contributes significantly to greenhouse gas emissions and energy wastage. Effective KW treatment and resource utilization methods are urgently needed. Transforming KW into valuable resources like animal feed, bioenergy, or organic fertilizers through biological processes can alleviate waste management burdens and generate economic benefits.

KW, rich in carbohydrates, proteins, fats, and inorganic materials, has significant nutritional value as a feed ingredient. Converting KW into fish feed addresses both waste management and feed resource challenges. This approach utilizes KW’s high nutritional content to provide a safe and sustainable feed resource for aquaculture, supporting environmental sustainability by reducing waste and promoting economic sustainability through cost-effective fish farming.

The application of KW conversion technologies in aquaculture includes both physical and biological methods. Physical methods, such as high-temperature drying, require simple equipment and offer rapid processing speeds suitable for large-scale operations. However, they are energy-intensive and can result in nutrient oxidation, vitamin destruction, and the formation of trans fatty acids, reducing the nutritional value and utilization rate of the feed2. Microbial fermentation is a highly effective biological method for converting KW into aquafeed. Compared to physical methods like sorting, solid-liquid separation, and heat treatment, microbial fermentation is safer and more environmentally friendly. It is also more cost-effective than enzyme treatment, which involves directly adding enzymes to KW. Fermentation enhances the nutritional profile of feed through probiotics that promote host health benefits, improve nutrient utilization and bioavailability, and eliminate anti-nutritional compounds, thereby enhancing fish growth performance3. In the aquaculture industry, fish meal is the primary protein source in feeds, but it is expensive and has an unstable supply. Utilizing fermented kitchen waste (FKW) as a protein source can significantly reduce feeding costs, decrease dependence on fish meal, and promote efficient resource recycling.

Currently, there is limited literature on the application of fermentation methods for converting KW into aquaculture feed, with most studies focusing on low-nutrient-demand fish species such as Nile tilapia. Tabbara, et al.4 evaluated the effects of partially replacing fish meal with yeast-fermented oil-extracted food waste on juvenile Nile tilapia. Their findings indicated that replacing up to 30% of fish meal did not significantly impact growth performance or feed utilization. Similarly, Mo, et al.5 reported that feeding jade perch and Nile tilapia with diets containing 50% FKW did not adversely affect their immunity or feed conversion ratios compared to commercial feeds. Ao, et al.6 studied the impact of fermented KW on the growth and digestive performance of juvenile allogynogenetic gibel carp, finding that inclusion rates below 12% had positive effects. Despite these promising results, existing studies have not thoroughly detailed the fermentation processes, including specific fermentation methods, microbial strain characteristics, and factors influencing the fermentation. These aspects remain underexplored, highlighting the need for further research to fully understand and optimize the use of fermented KW as feed in aquaculture.

The core of fermentation technology lies in utilizing microorganisms. Selecting appropriate strains based on the composition of KW and optimizing fermentation conditions are crucial for effective KW treatment. Due to the significant variation in KW composition from different sources7, it becomes necessary to choose microorganisms with efficient fermentation capabilities. These strains should grow using KW as a substrate with minimal additional nutrients, efficiently hydrolyze proteinaceous substrates into soluble proteins, and promote fish growth and feed utilization. Additionally, considering inhibitory substances like salt present in KW2, it becomes imperative to either desalinate the waste prior to fermentation or select microorganisms with high salt tolerance for this process. Bacillus and yeast are commonly used strains in feed fermentation. Bacillus secretes various hydrolytic enzymes, adapts to diverse nutritional conditions, enhances fish growth, nutrient digestion and absorption, boosts immune responses, and increases disease resistance8. Yeast, known for its high protein content, can be used as single-cell protein to enhance feed protein content. It also improves the growth rate and feed utilization efficiency of aquatic animals, stimulates digestive enzyme activity, and contains β-glucan, which enhances immunity and disease resistance9.

In the preliminary experiments of this study, we investigated the composition of KW obtained from local food service establishments. The results indicated that the KW was not only abundant in total carbohydrate and crude protein but also exhibited a relatively high content of crude fat (> 15.5%) and a salt concentration ranging from 3 to 5%. To utilize this nutrient-rich KW as a substrate for fermented feed production, our study aimed to screen Bacillus and yeast strains derived from food sources capable of exhibiting high activities of amylase, protease, and lipase enzymes while demonstrating a certain level of salt tolerance. Subsequently, we employed a mixed-strain fermentation approach by optimizing fermentation conditions to maximize soluble protein yield based on the fermentation characteristics of the selected strains. The resulting FKW was then evaluated as an innovative protein source to replace fish meal in juvenile yellow catfish diets. We assessed the feasibility of using this FKW as a substitute for fish meal by examining its effects on the growth performance of juvenile yellow catfish (Pelteobagrus fulvidraco). This study aims to provide innovative microbial resources and optimize fermentation conditions for the conversion of KW into valuable feed, thereby offering valuable insights for incorporating fermented kitchen waste (FKW) into the diets of high-nutrient-demand fish species.

Materials and methods

Microorganisms and cultivation

A total of 11 Bacillus strains and 9 yeast strains, isolated from fermented foods, were assessed for their capacity to produce alpha-amylase, protease, and lipase enzymes. The bacterial seed cultures were prepared by inoculating a 2% (v/v) glycerol stock into nutrient broth medium containing 5% NaCl, followed by incubation at 37 °C with agitation at 150 rpm for 24 h. For the yeast seed cultures, a 5% (v/v) glycerol stock was inoculated into YPD medium supplemented with 5% NaCl and incubated at 28 °C with agitation at 150 rpm for 48 h.

Screening of strains for production of alpha-amylase, protease, and lipase

The potential of screened strains to produce enzymes was evaluated using liquid mediums of following composition: for alpha-amylase production medium (per liter: yeast extract 2 g, tryptone 5 g, soluble starch 15 g, K2HPO4 1 g, MgSO4 0.5 g, pH7.0), for protease production medium (per liter: skimmed milk powder 5 g, casein 5 g, yeast extract 2 g, glucose 2 g, CaCl2 1 g, pH 7.0), and for lipase production medium (per liter: yeast extract 2 g, tryptone 5 g, CaCl2 1 g and olive oil 20mL (emulsified with 10 g Gum Arabic), pH 6.5)10. The seed culture with the inoculum of 5% was transferred to 50 mL production medium and cultured at 37 °C with 150 rpm shaking for 48 h. The cultures were then centrifuged at 10,000×g for 5 min at 4 °C. The cell free supernatants were collected and used as crude enzymes for enzyme activity assay.

Enzyme activity assay

Alpha-amylase activity was determined by Bernfeld method11, using 3,5-dinitrosalicylic (DNS) as reagent to measure the amount of reducing sugars released from the starch hydrolysis reaction. The reaction mixture was composed of 1 mL crude enzyme and 5 mL 1% (w/v) starch solution which was previously dissolved in 20 mM pH 6.0 sodium citrate buffer. The reaction was performed at 45 °C for 20 min. The mixture was heated in boiled water for 5 min to stop the reaction. The One unit of alpha-amylase activity was defined as the amount of the crude enzyme that produced 1 µmol of reducing sugar as a glucose standard per minute under the assay condition.

Protease activity was determined by colorimetric method of Cupp-Enyard12 using casein as a substrate. The reaction mixture consisted of 1 mL crude enzyme and 5 mL 1% (w/v) casein solution (prepared with 20 mM sodium acetate buffer, pH7.0). After enzymatic hydrolysis reaction at 37 °C for 20 min, 5mL 10% (w/v) trichloroacetic acid solution was quickly added to terminate the reaction. The mixture centrifuged at 10,000 × g for 5 min, then 0.5 mL of the supernatants was added to 5 mL 0.5 mol/L sodium carbonate solution and mixed. One mL 0.5 mol /L Folin phenolic reagent was then added. After reacting for 30 at room temperature, the absorbance measured at 750 nm. One unit of protease was defined as the amount of the crude enzyme that produced an absorbance at 750 nm equivalent to 1 µmol of tyrosine per minute under the assay conditions.

Lipolytic activity was determined by colorimetric method of described by Castro-Ochoa, et al.13 using p-nitrophenil-laurate (pNPL) as substrate. The reaction mixture included 0.1 mL of crude enzyme, 0.8 mL of 0.05 M phosphate buffer (pH 6.5), and 0.1 mL of 0.01 M pNPL dissolved in ethanol. The reaction was conducted at 45 °C for 20 min, followed by the addition of 2 mL 95% ethanol to terminate reaction. Subsequently, the mixture underwent centrifugation at 10,000 × g for 10 min, and the absorbance of supernatant at 410 nm was measured. One unit of lipase activity was defined as the amount of the crude enzyme that produced 1 µmol of p-nitrophenol under per minute the assay conditions.

Identification of selected strains

The rpoB and 26 S rRNA gene sequence analysis was used to identified bacterial strain L58 and yeast strain O57, respectively. Briefly, the rpoB gene was amplified in a 25 µL PCR reaction concoction with a pair of primers named rpoB-F and rpoB-R (Table 1). The PCR amplification was performed under the following conditions: denaturation at 95 °C for 3 min, 35 cycles of 95 °C for 30 s, 55 °C for 30 s and 72 °C for 1.5 min, with a final extension at 72 °C for 5 min14. For 26 S rRNA gene amplification, the primers NL1 and NL4 (Table 1) were used to gain the amplicon about 600 bp. The PCR reaction was also carried out in a 25 µL PCR reaction concoction followed by an amplified program: 95 °C for 5 min, 35 cycles at 95 °C for 1 min s, 52 °C for 30 s and 72 °C for 1 min, with a final extension at 72 °C for 10 min. The amplified fragments were thereafter verified by 1% agarose gel electrophoresis for their purity and fragment length. The amplified rpoB and 26 S rRNA gene fragments were sent to Sangon Biotech (Shanghai) for Sanger sequencing. The sequences were aligned with the existing data in National Center for Biotechnology Information (NCBI) database with BLSAT tool. The phylogenetic tree was constructed by the Maximum-Likelihood method with 1000 bootstrap tests using MEGA 11 software. The GenBank accession numbers for the rpoB sequence of L58 and the 26rRNA sequence of O57 are PQ043212 and PQ039848, respectively.

KW fermentation

Fermentation procedure

The KW raw material was collected from post-consumption waste generated by local food service establishments. The pre-treatment involved filtering to remove excess moisture, drying the KW at 60 °C, grinding it, and sieving through an 18-mesh sieve. The treated KW was stored at 4 °C and used as a substrate for fermentation, with its main components shown in Table 6. The fermentation process was conducted using solid-state fermentation. A total of 35 g of pre-treated KW was placed in a flask, mixed with 65 mL of distilled water, and allowed to absorb water for 1 h. The mixture was then sterilized at 121 °C for 20 min. After cooling, it was inoculated with pre-prepared seed culture at a specified ratio and mixed thoroughly. Solid-state fermentation was carried out under controlled conditions, with the solid material stirred at 8 h intervals to ensure proper aeration and uniform distribution of the substrate. After fermentation, the material was dried at 45 °C to a constant weight for subsequent analysis.

Sigle factor tests

The four parameters selected as experimental factors for their influence on the soluble protein content of KW were determined through preliminary experiments. These factors included strain ratio, inoculum amount, fermentation temperature, and fermentation time. The baseline fermentation conditions were established as a strain ratio of 1:2 (O57:L58 v/v), an inoculum amount of 10% (v/v), a fermentation temperature of 37 °C, and a fermentation time of 96 h. The experimental levels for each factor were as follows: (a) strain ratio (1:3, 1:2, 1:1, 2:1, 3:1, 4:1 O57:L58 v/v), (b) inoculum amount (4%, 6%, 8%, 10%, 12%, 14% v/v), (c) fermentation temperature (28 °C, 31 °C, 34 °C, 37 °C, 40 °C), and (d) fermentation time (48, 72, 96, 120, and 144 h).

Optimization of fermentation conditions using central composite design (CCD)

A central composite design (CCD) was employed to investigate the effects of various fermentation conditions on the production of soluble protein. The experimental design was carried out using Design Expert software (Version 8.0.5), utilizing a four-factor, five-level CCD approach. The independent variables included strain ratio (A), inoculum amount (B), temperature (C), and fermentation time (D), with the response variable being soluble protein content (Y). Each factor was tested at five levels, coded as (– 2, – 1, 0, + 1, +2). The levels of the factors are presented in Table 2.

Analytical methods

FKW samples were ground into powder and diluted with distilled water to obtain supernatant for soluble protein content determination. Soluble protein content was quantified by a colorimetric method with Folin Phenol reagent using bovine serum protein as the standard for the calibration curve15.

Proximate analysis was estimated according to the standard procedures of AOAC16 for the determination of the dry matter, crude protein, total carbohydrate, crude fat, crude fiber and total ash. The enzyme activity of FKW was determined by the methods described in 2.3. The total spores count (CFU/mL) was determined by standard agar plate technique. The diluted samples were heated in a water bath at 90 °C for 15 min, and then plated on TSB-agar plates and incubated at 35 °C for 48 h for colony count.

Amino acids composition was determined by hydrolyzed the sample with HCL and followed by the HPLC method using pre-column derivatization with phenyl isothiocyanate (PITC). The sample dilution was mixed with 12 mol/L HCl in a ratio of 1:1, and then hydrolyzed at 150 ℃ for 1 h. The product of hydrolysis was dried with nitrogen to remove concentrated hydrochloric acid. The mixture was then redissolved in 1 mL of distilled water. 200 µL of the solution was mixed with 100 µL 1mol/L acetonitrile solution of triethylamine, and then 100 µL 0.2 mol/L acetonitrile solution of PITC were added, mixed and reacted at room temperature for 1 h. Then 400 µL n-hexane was added and violently shook for 5–10 s, then stratified, 200 µL of the lower layer solution was diluted with 800 µL of distilled water. 10 µL of the dilution was injected into the RP-HPLC system (Agilent 1100 series) equipped with C18 column (250 × 4.6 mm, 5 μm, Dikma). The wavelength of detector was set at 334 nm. The elution system consisted of A:0.05 mol/L sodium acetate in water adjusted pH to 6.5 with acetic acid and B: methanol mixed with acetonitrile and water in a ratio of 20:60:20. The elution was carried out after injection at a flow rate of 1 mL/min with a linear gradient as follows: 0–39 min, 5–48% B; 40–45 min, 100% B; 45–60 min, 5% B.

Replacement of fish meal with FKW in diets of juvenile yellow catfish (Pelteobagrus fulvidraco)

Experimental diet

Four experimental diets were formulated with isonitrogenous and isolipidic compositions, utilizing fish meal and soybean meal as protein sources, wheat flour as a carbohydrate source, fish oil as a fat source, and supplemented with vitamin and mineral premixes to achieve final crude protein content of 47% and crude fat content of 9.5%. The replacement levels of fish meal by FKW in the diets varied at 0%, 10%, 30%, and 50%. Table 3 presents the composition and nutrient levels of the experimental feeds.

Feeding trail

Juvenile yellow catfish were sourced from a local hatchery in Guangdong and acclimated for two weeks before the experiment. Prior to the feeding trial, the fish were fasted for 24 h. Healthy, disease-free fish with an average body weight of (2.80 ± 0.05) g were selected and randomly distributed into 12 tanks, with 30 fish per tank. The experiment consisted of four treatment groups, each with three replicates. Feeding occurred twice daily at 8:00 AM and 4:00 PM, ensuring apparent satiation. A static water rearing system with continuous aeration was utilized to maintain the dissolved oxygen concentration above 6 mg/L. Water quality was ensured through microcirculation water exchange. During the experimental period, water temperature ranged from 28 to 32 °C, pH values were maintained between 7.5 and 8.0, and ammonia nitrogen and nitrite concentrations were kept below 0.2 mg/L and 0.1 mg/L, respectively. Daily measurements of ammonia nitrogen, nitrite, pH, and dissolved oxygen were conducted using aquaculture test kits provided by Luheng Biological Co., Ltd. (Hangzhou, China). The experiment lasted for eight weeks.

Growth performance and nutrient utilization induces

After the feeding trial, the fish were fasted for 24 h and then weighed. Subsequently, the number and total weight of yellow catfish in each tank were recorded. Three fish from each tank were randomly selected, anesthetized using eugenol (1:10000), and measured for body length and weight. Dorsal muscle samples were then collected for nutrient composition analysis. The growth performance and nutrient utilization indices were calculated using the method described by Xu, et al.17.

Ethics declarations

The experiments were approved by the Ethics Committee of the Hanshan Normal university. All methods were conducted in accordance with the relevant regulations and guidelines of the Hanshan Normal university. All the methods are reported following the recommendations in the ARRIVE guidelines.

Statistical analysis

Results are presented as mean ± standard error (mean ± SE, n = 3). Data were analyzed by one-way analysis of variance (ANOVA) using SPSS 22. The significance of differences between mean values was assessed using Duncan’s multiple comparisons to determine the statistical difference between means. Statistical significance was defined as p < 0.05.

Results

Screening of strains

To screen for strains with high amylase, protease, and lipase activities, 11 Bacillus strains and 9 yeast strains from fermented food sources were evaluated. All Bacillus strains showed significant alpha-amylase activity (159.5-228.3 U/mL), with strain L58 being the highest. Yeast strains had lower alpha-amylase activity, with only three showing minimal activity (Fig. 1a). Bacillus strains had protease activities between 76.8 and 179.8 U/mL, with strains L58, N18, and D54 showing higher activities, while yeast strains generally exhibited lower protease activities except for strain O57 (Fig. 1b). For lipase activity, Bacillus strains ranged from 0.06 to 0.29 U/mL, whereas yeast strains varied more significantly (0-0.97 U/mL), with strain O57 having the highest activity (Fig. 1c). Based on these results, Bacillus strain L58, with high alpha-amylase and protease activities, and yeast strain O57, with high lipase and protease activities, were selected for subsequent KW fermentation experiments.

Identification of selected strains

Strain L58, cultured on TSB plates at 37 °C for 24 h, formed round, opaque, white colonies with raised centers and smooth edges. Gram staining showed Gram-positive, purple rod-shaped cells in pairs or chains with visible sporulation. It tested positive for catalase, methyl red, and Voges-Proskauer tests, and could hydrolyze starch and utilize citrate. Metabolic activities included producing acid and gas during glucose and maltose fermentation and growing in 5–10% NaCl concentrations. Its rpoB gene amplification yielded a 1190 bp PCR product, showing 100% similarity to Bacillus licheniformis ATCC 14,580 (CP034569.1) in BLAST analysis. Phylogenetic analysis placed strain L58 within the same cluster as Bacillus licheniformis (Fig. 2a). Based on results above, strain L58 was conclusively identified as Bacillus licheniformis.

Strain O57, cultured on YPD plates at 28 °C for 48 h, formed round, white, opaque colonies with smooth surfaces and well-defined edges. Microscopic examination revealed oval-shaped cells. It tested positive for glucose, sucrose, maltose, and xylose fermentation, as well as the litmus milk test, but negative for gelatin liquefaction and urea hydrolysis. The 26 S rDNA amplification produced a 582 bp fragment, showing 99% homology with Yarrowia lipolytica NRRL YB-423 (NG_055393.1) in BLAST analysis. Phylogenetic analysis confirmed that strain O57 clusters closely with Yarrowia lipolytica (Fig. 2b). Based on morphological characteristics, physiological and biochemical tests, and gene sequence analysis, strain O57 was identified as Yarrowia lipolytica.

Optimization of fermentation process parameters

Effect of fermentation process parameters on soluble protein production

Figure 3a shows that when the ratio of Y. lipolytica O57 to B. licheniformis L58 ranged from 2:1 to 4:1, the soluble protein content varied between 123.7 and 143.5 mg/g, significantly higher than other ratios or individual strains (p < 0.05). This increase is due to the elevated protease activity and synergistic interaction between the strains. Figure 3b illustrates the impact of inoculum size on soluble protein content. An optimal inoculum size of 10–14% resulted in a significant increase in soluble protein content compared to other levels. Fermentation temperature also plays a crucial role in microbial growth and enzyme production. As shown in Fig. 3c, the soluble protein content increased with temperature between 28 and 34 °C, peaking at 34–40 °C with values ranging from 153.1 to 154.7 mg/g. However, temperatures above 40 °C resulted in a decrease in soluble protein content.

Figure 3d shows that soluble protein content increased with fermentation time, peaking at 96 h with a value of 151.1 mg/g. No significant difference was observed between 72 h and 120 h (p > 0.05). Initially, microorganisms rapidly proliferated and produced protease, converting insoluble proteins to soluble proteins. However, prolonged fermentation led to further metabolism of these proteins, reducing their concentration.

Optimization of fermentation conditions using response surface methodology

Based on the results of single factor trail, the fermentation process for optimizing soluble protein production from KW was conducted using Response Surface Methodology (RSM) with a central composite design (CCD). The results are shown in Table 4. A quadratic model (Eq. 1) was employed to describe the relationship between soluble protein content and various fermentation conditions with each variable representing its actual value. Y denotes the predicted value of soluble protein content.

Variance analysis of the model coefficients (Table 5) indicated that the model is highly significant (p < 0.0001), with a non-significant lack-of-fit term (p = 0.125), suggesting a good fit between the model and the experimental data. The model demonstrated a high correlation between predicted and observed values (R2 = 0.958), explaining 95.8% of the variation in the experimental results (adjusted R2 = 0.919). Additionally, the low coefficient of variation (C.V. = 2.78%) indicates high reliability of the experimental findings.

The regression coefficient significance test (Table 5) shows that the linear effects of inoculum amount (B) and fermentation time (D) on soluble protein are highly significant (p < 0.0001). The effect of fermentation temperature (C) is significant (p < 0.05), while the strain ratio (A) is not significant (p = 0.33). The quadratic terms of all four factors also have significant effects. Interactions between inoculum amount and temperature (BC, p < 0.01) and between temperature and fermentation time (CD, p < 0.05) significantly impact soluble protein content. Figure 4a shows that increasing inoculum amount and temperature to optimal values raises soluble protein content from 140 to 164.2 mg/g, but further increases reduce it. Similarly, Fig. 4b indicates that raising temperature and fermentation time to their optimal points increases soluble protein content.

To optimize soluble protein content, the model equation was solved using Design Expert software. The predicted maximum content was 171.6 mg/g with a strain ratio of 3:1, inoculum amount of 12.9%, temperature of 31 °C, and fermentation time of 116 h. Validation experiments confirmed this, with an average soluble protein content of 175.6 ± 1.79 mg/g (Fig. 5a), aligning closely with the predicted value.

Additionally, viable cell counts for both strains were measured at different fermentation times. Figure 5b shows rapid microbial growth initially, stabilization, and then decline. At 24 and 48 h, bacterial counts grew significantly. By 96 h, both bacterial and yeast counts peaked at 8.69 ± 0.10 and 8.47 ± 0.22 log CFU/g, respectively, indicating robust microbial growth. Afterward, the soluble protein content reached its peak as microorganisms had utilized most nutrients, leading to substantial soluble protein production. However, by 128 h, viable counts decreased due to metabolic by-product accumulation, degrading soluble protein content.

Nutritional analysis of FKW

Using the optimized fermentation conditions, which included a strain ratio of 3:1, an inoculum amount of 12.9% (v/v), a temperature of 31 °C, and a fermentation time of 116 h, a mixed-strain fermentation process was carried out to produce fermented kitchen waste (FKW). The composition of FKW was then analyzed and compared to that of the unfermented KW substrate, with the results presented in Table 6. The results demonstrate that the fermented group exhibited significantly higher levels of soluble protein, crude protein, and crude fat compared to the unfermented group (p < 0.05). Conversely, the total carbohydrate and crude fiber contents were significantly lower in the fermented group (p < 0.05). No significant difference was observed in the total ash content between the two groups (p > 0.05). Furthermore, the fermented feed retained high activities of amylase, protease, and lipase enzymes, and contained Bacillus licheniformis spores with a spore count of 8.10 Log CFU/g.

As presented in Table 7, the FKW exhibited a significant increase of 45.5% in total amino acid content compared to the unfermented KW. Nineteen of the measured amino acids showed significant increases (p < 0.05), except for aspartic acid and glutamic acid, with lysine demonstrating the highest increase at 103.7%. The overall content of essential and non-essential amino acids increased by 45.5% and 22.8%, respectively. Notably, lysine, valine, and threonine among the essential amino acids displayed remarkable increases at rates of 103.7%, 95.8%, and 93.4%, respectively. These findings suggest that the selected strains with high protease activity effectively hydrolyzed macromolecular proteins into individual amino acids during food waste fermentation, thereby augmenting the nutritional value of the feed.

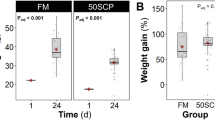

Effect of FKW on the growth performance and feed utilization in the diet of juvenile yellow catfish

Different levels of FKW were incorporated as a replacement for fish meal in the diets of juvenile yellow catfish, and subsequent evaluations of growth and feed utilization parameters were conducted. The results are presented in Table 8. No significant differences were observed in survival rates among the experimental groups (p > 0.05). Regarding growth indicators, compared to the control group (G0) without FKW supplementation, the groups with 10% and 30% replacement exhibited significant improvements in final body weight (FBW) and weight gain (WG) (p < 0.05). Conversely, the group with 50% replacement demonstrated significant reductions in FBW and WG (p < 0.05). Furthermore, the weight gain rate (WGR) and specific growth rate (SGR) were significantly higher in the group with 15% replacement compared to the control group (G0) (p < 0.05), while these rates showed a notable decrease in the group with 50% replacement. Regarding feed utilization, the feed conversion ratio (FCR) was significantly lower in the 15% and 30% replacement groups compared to the control (G0) (p < 0.05), whereas the 50% replacement group exhibited a higher FCR than the control (p < 0.05). The protein efficiency ratio (PER) was significantly higher in the 10% replacement group compared to the control (G0), similar for the 30% replacement group, and significantly lower for the 50% replacement group. No statistically significant differences were observed among groups with respect to condition factor (CF) values (p > 0.05). Considering the impact of different replacement levels on the muscle composition of yellow catfish (Table 9), no significant differences were observed in moisture, crude fat, and ash content among the groups (p > 0.05). However, in terms of crude protein content, the G10 group exhibited an increase of 8.1% compared to the control group (G0), while the G50 group showed a decrease of 7.0% relative to the control.

The findings suggest that substituting an appropriate quantity of FKW for fish meal can significantly enhance the growth performance of yellow catfish, reduce the feed conversion ratio, improve protein efficiency, and marginally increase the crude protein content in fish muscle, without impacting moisture, crude fat, and ash content. Using weight gain rate as the evaluation metric, a quadratic curve model was employed to fit the data, determining that the optimal proportion of FKW to replace fish meal in the diet of juvenile yellow catfish is 21.5% (Fig. 6).

Discussion

Fermentation strains

B. licheniformis is renowned for its enzymatic activity, making it ideal for fermenting plant protein feed. Recent research indicates that B. licheniformis increases soluble protein content, reduces antinutritional factors, and enhances protein digestibility and immune response in koi fish18. It also improves growth performance, immunity, and disease resistance in juvenile Nile tilapia, while promoting intestinal health19. Y. lipolytica is an ascomycete yeast known for its ability to biosynthesize polyunsaturated fatty acids. It is used extensively in biotechnology and is classified as a Generally Recognized as Safe (GRAS) microorganism20, suitable for food and feed. The yeast cells are rich in protein and essential amino acids, making single-cell protein (SCP) from Y. lipolytica a cost-effective protein source for animal feed. It efficiently uses lipids and hydrophobic compounds but has limited capacity to metabolize carbohydrates, alcohols, sugar alcohols, and organic acids, primarily utilizing glucose, glycerol, and acetate21. Consequently, fermenting agro-industrial by-products solely with Y. lipolytica often yields unsatisfactory results.

Co-fermentation with multiple strains can leverage synergistic interactions between strains, yielding superior fermentation results compared to single-strain fermentation. In this study, B. licheniformis and Y. lipolytica, both renowned for their elevated enzymatic activities, were selected and combined for the purpose of fermenting KW, thereby addressing the limitations associated with single-strain fermentation. B. licheniformis exhibited remarkable amylase and protease activities, while Y. lipolytica demonstrated robust lipase and protease activities. These complementary enzymatic properties facilitate the efficient utilization of crucial nutrients present in KW, such as starch, proteins, and fats. The results demonstrate that co-fermentation with these two strains enhances their synergistic effects significantly, improving protein solubility in raw materials, augmenting hydrolytic enzyme activity in products, and promoting the growth of both microorganisms more effectively than single-strain fermentation.

Influence of fermentation process parameters

To maximize the beneficial properties of the strains and enhance product yield, selecting optimal process parameters is essential. This study conducted single-factor experiments to identify the highest yield ranges for each factor, followed by CCD optimization. Under optimized conditions, the soluble protein content increased from 154.7 mg/g to 175.6 mg/g. Inoculum amount and fermentation time had the most significant effects, with temperature also influencing soluble protein yield.

Temperature significantly affects microbial metabolism, maximizing enzyme activity and metabolic rates at optimal levels, and shortening fermentation cycles. Conversely, lower temperatures slow enzymatic reactions, extending fermentation cycles. Yusuf, et al.22 identified temperature as a critical factor in protein enrichment during fermentation of mixed cottonseed and rapeseed meal feed using B. clausii and Saccharomyces cariocanus, aligning with our findings. Inoculum amount influences the adaptation period for strains to acclimate to the substrate. An appropriate inoculum size shortens the adaptation phase, allowing microorganisms to rapidly enter the logarithmic growth phase and reducing the overall fermentation cycle duration. It also prevents excessive nutrient consumption due to overly large inoculum sizes, which could negatively impact target product production. As shown in Fig. 6, viable cell counts for both strains reached approximately 6.0 log CFU/g after 24 h of fermentation, indicating vigorous growth and rapid adaptation to the KW substrate.

Nutrient composition of FKW

Although KW is rich in nutrients, however, direct use it as feed for aquatic animals may not meet the nutritional demands of specific fish species due to nutrient limitations7. This study found that fermentation significantly increased the soluble protein, crude protein, and crude fat contents of the feed compared to the unfermented group (p < 0.05). Conversely, total carbohydrate and crude fiber contents were significantly reduced (p < 0.05), with no significant difference in total ash content (p > 0.05). The high protease activity of the strains used enhanced the solubility of hydrolyzed proteins, while microbial biomass growth, particularly yeast, increased single-cell protein accumulation, thereby boosting overall crude protein content. Microbial fermentation also enzymatically degraded starch and crude fiber into smaller carbohydrate molecules, improving nutrient absorption and reducing the energy required for digestion. Similar results were reported by Sharawy, et al.23, who found that fermenting soybean meal with Saccharomyces cerevisiae increased crude protein content and reduced crude fiber content in shrimp feed. Hassaan, et al.24 reported that fermentation with S. cerevisiae increased protein content by 13.65% and decreased crude fiber by 49.2%. High dietary crude fiber levels negatively impact fish digestion, reducing digestibility and feed efficiency.

This study demonstrated that fermentation with selected strains significantly increased the crude fat content in FKW. The Y. lipolytica strain, known for its high lipid production, enhanced the crude fat content, making the fermented feed a potential alternative for fish species with high fat requirements. The impact of microbial fermentation on crude fat content varies with different strains. For instance, Zhou, et al.25 reported an increase in crude fat when fermenting soybean meal with Candida utilis, while Lim and Lee26 found no significant change with Aspergillus oryzae, and Refstie, et al.27 observed a decrease with lactic acid bacteria.

Amino acid composition is crucial for feed protein’s nutritional value, affecting protein utilization efficiency and animal health. Plant-based protein feeds like soybean meal and corn often lack essential amino acids such as lysine and methionine. This study’s analysis revealed high levels of glutamic and aspartic acids in KW, likely due to monosodium glutamate in Chinese cuisine, but lower levels of essential amino acids needed for fish growth. Fermentation promotes microbial proliferation, increasing protein content and converting native proteins into microbial proteins. The study found that mixed-strain fermentation significantly increased total amino acid content and most individual amino acids in fermented kitchen waste (FKW), including substantial increases in essential amino acids like lysine, valine, and threonine. This improvement enhances the nutritional value of the feed. Additionally, increases in reducing amino acids such as tryptophan, methionine, and cysteine enhance the antioxidant activity of the feed, potentially boosting the antioxidant capacity and immune function of aquatic animals28.

Replacement of fish meal with FKW in diets of juvenile yellow catfish

The crude protein content of kitchen waste (KW) ranges between 17% and 27%, which is insufficient for high-nutrient-demanding fish species7. However, for herbivorous and omnivorous fish with lower protein requirements, KW can replace fish meal adequately. Studies on substituting KW for fish meal have focused on low-nutrient-demanding species like grass carp29 and Nile tilapia30. Yellow catfish (Pelteobagrus fulvidraco), which requires a high dietary protein content (over 44% crude protein in diets) for optimal growth31, is a rapidly growing freshwater aquaculture species in China. This study explores the feasibility of incorporating mixed-strain fermented KW into juvenile yellow catfish diets as a substitute for fish meal.

The survival rates of juvenile yellow catfish in all groups showed no significant differences compared to the control group, indicating good adaptation to the feeding conditions. Growth indicators revealed that the final average weight, weight gain rate, and specific growth rate of the yellow catfish initially increased and then decreased as the proportion of FKW replacing fish meal increased. The best growth performance was observed with 15% and 30% replacement, while the 50% replacement group showed poorer growth and some inhibition compared to the control group.

Regarding feed utilization, the 30% replacement group significantly reduced the feed conversion ratio and achieved the highest protein efficiency ratio, indicating better feed utilization and reduced feed consumption per unit of weight gain. This improvement is attributed to microbial fermentation breaking down large protein molecules into smaller, easily digestible peptides and amino acids, enhancing the nutritional value and utilization of the feed by fish. The high enzyme activity strains used in fermentation retained activities such as amylase, protease, and lipase, along with B. licheniformis spores, which aid in feed digestion, as supported by previous studies32,33.

The inclusion of B. licheniformis spores and their metabolic products in the fermented feed can promote the secretion of digestive enzymes and enhance intestinal peristalsis, improving feed digestibility and growth performance34. However, the 50% replacement group showed adverse effects on growth performance and feed utilization, possibly due to changes in feed pH and certain fermentation metabolites affecting feed palatability and intake. Similar findings have been reported in studies using high levels of fermented soybean meal to replace fish meal in diets for black sea bream, which also resulted in negative effects on growth performance and feed utilization efficiency25.

The fat, ash, and moisture content of the yellow catfish muscle in all experimental groups exhibited minimal variation and were largely unaffected by the feed factors. However, the group with a small replacement ratio (G15) demonstrated higher crude protein content. This increase can be attributed to the presence of yeast products in the fermented feed, which have been reported by Abdel-Tawwab, et al.35 to enhance growth and protein deposition in fish. The body composition of aquatic animals directly reflects their nutritional utilization of feed and indicates the quality of aquatic products. These findings suggest that substituting fish meal with FKW does not adversely impact the nutritional quality or commercial value of yellow catfish.

Data availability

The datasets generated and analyzed during the current study are available in the Genbank repository, accession number (PQ043212 and PQ039848). The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding authors.

References

United Nations Environment, P. Food Waste Index Report 2024. Think Eat Save: Tracking Progress to Halve Global Food Waste (2024).

Georganas, A. et al. Bioactive compounds in food waste: a review on the transformation of food waste to animal feed. Foods 9, 291 (2020).

Dawood, M. A. O. & Koshio, S. Application of fermentation strategy in Aquafeed for sustainable aquaculture. Reviews Aquaculture 12, 987–1002. https://doi.org/10.1111/raq.12368 (2020).

Tabbara, M., Monzer, S., Zein Eddine, R., Abiad, M. & Saoud, I. Bioprocessing post-consumer food waste for use as a fish feed ingredient. Aquac. Res. 53, 2383–2391. https://doi.org/10.1111/are.15756 (2022).

Mo, W. Y., Man, Y. B., Zhang, F. & Wong, M. H. Fermented food waste for culturing Jade perch and nile tilapia: growth performance and health risk assessment based on Metal/loids. J. Environ. Manage. 236, 236–244. https://doi.org/10.1016/j.jenvman.2019.01.102 (2019).

Ao, H. et al. Effects of dietary fermentation products of kitchen waste on growth, apparent digestibility, digestive enzyme activities and serum biochemistry in juvenile allogynogenetic Gibel carp (Carassius auratus Gibelio) Var. CAS III. J. World Aquaculture Soc. 52, 895–912. https://doi.org/10.1111/jwas.12826 (2021).

Ho, K. S. & Chu, L. M. Characterization of food waste from different sources in Hong Kong. J. Air Waste Manag. Assoc. 69, 277–288. https://doi.org/10.1080/10962247.2018.1526138 (2019).

Kuebutornye, F. K. A., Abarike, E. D. & Lu, Y. A review on the application of Bacillus as probiotics in aquaculture. Fish Shellfish Immunol. 87, 820–828. https://doi.org/10.1016/j.fsi.2019.02.010 (2019).

Øverland, M., Karlsson, A., Mydland, L. T., Romarheim, O. H. & Skrede, A. Evaluation of Candida utilis, Kluyveromyces Marxianus and Saccharomyces cerevisiae yeasts as protein sources in diets for Atlantic salmon (Salmo salar). Aquaculture 402–403, 1–7. https://doi.org/10.1016/j.aquaculture.2013.03.016 (2013).

Saun, N. K., Mehta, P. & Gupta, R. Purification and physicochemical properties of lipase from thermophilic Bacillus aerius. J. Oleo Sci. 63, 1261–1268. https://doi.org/10.5650/jos.ess14094 (2014).

Bernfeld, P. In Methods in Enzymology 1149–1158 (Academic, 1955).

Cupp-Enyard, C. Sigma’s non-specific protease activity assay—casein as a substrate. J. Vis. Exp. 899, 36 (2008). http://europepmc.org/abstract/MED/19066538.

Castro-Ochoa, L. D., Rodríguez-Gómez, C., Valerio-Alfaro, G. & Oliart Ros, R. Screening, purification and characterization of the thermoalkalophilic lipase produced by Bacillus thermoleovorans CCR11. Enzym. Microb. Technol. 37, 648–654. https://doi.org/10.1016/j.enzmictec.2005.06.003 (2005).

Ki, J. S., Zhang, W. & Qian, P. Y. Discovery of marine Bacillus species by 16S rRNA and RpoB comparisons and their usefulness for species identification. J. Microbiol. Methods. 77, 48–57. https://doi.org/10.1016/j.mimet.2009.01.003 (2009).

Lowry, O. et al. J. Biol. Chem. 193, 265–275. https://doi.org/10.1016/S0021-9258(19)52451-6 (1951).

Latimer, G. W. Official Methods of Analysis of AOAC INTERNATIONAL (Oxford University Press, 2023).

Xu, J. et al. Effect of dietary fish meal replacement with spray dried chicken plasma on growth, feed utilization and antioxidant capacity of largemouth bass (Micropterus salmoides). Aquaculture Rep. 24, 101112. https://doi.org/10.1016/j.aqrep.2022.101112 (2022).

Zhao, M. J. et al. Co-fermentation of Bacillus subtilis and Bacillus licheniformis and its application in the feeding of Koi. Aquac. Res. 53, 6056–6068. https://doi.org/10.1111/are.16077 (2022).

Han, B. et al. Effects of dietary Bacillus licheniformis on growth performance, immunological parameters, intestinal morphology and resistance of juvenile nile tilapia (Oreochromis niloticus) to challenge infections. Fish Shellfish Immunol. 46, 225–231. https://doi.org/10.1016/j.fsi.2015.06.018 (2015).

Groenewald, M. et al. Yarrowia lipolytica: safety assessment of an oleaginous yeast with a great industrial potential. Crit. Rev. Microbiol. 40, 187–206. https://doi.org/10.3109/1040841X.2013.770386 (2014).

Fickers, P. et al. Hydrophobic substrate utilisation by the yeast Yarrowia lipolytica, and its potential applications. FEMS Yeast Res. 5, 527–543. https://doi.org/10.1016/j.femsyr.2004.09.004 (2005).

Yusuf, H. A., Piao, M., Ma, T., Huo, R. & Tu, Y. Enhancing the quality of total mixed ration containing cottonseed or rapeseed meal by optimization of fermentation conditions. Fermentation 7, 63. https://doi.org/10.3390/fermentation7040234 (2021).

Sharawy, Z., Goda, A. M. A. S. & Hassaan, M. S. Partial or total replacement of fish meal by solid state fermented soybean meal with Saccharomyces cerevisiae in diets for Indian Prawn shrimp, Fenneropenaeus indicus, postlarvae. Anim. Feed Sci. Technol. 212, 90–99. https://doi.org/10.1016/j.anifeedsci.2015.12.009 (2016).

Hassaan, M. S., Soltan, M. A. & Abdel-Moez, A. M. Nutritive value of soybean meal after solid state fermentation with Saccharomyces cerevisiae for nile tilapia, Oreochromis niloticus. Anim. Feed Sci. Technol. 201, 89–98. https://doi.org/10.1016/j.anifeedsci.2015.01.007 (2015).

Zhou, F. et al. Partial replacement of fish meal by fermented soybean meal in diets for black sea Bream, Acanthopagrus schlegelii, juveniles. J. World Aquaculture Soc. 42, 184–197. https://doi.org/10.1111/j.1749-7345.2011.00455.x (2011).

Lim, S. J. & Lee, K. J. A microbial fermentation of soybean and cottonseed meal increases antioxidant activity and gossypol detoxification in diets for nile tilapia, Oreochromis niloticus. J. World Aquaculture Soc. 42, 494–503. https://doi.org/10.1111/j.1749-7345.2011.00491.x (2011).

Refstie, S., Sahlström, S., Bråthen, E., Baeverfjord, G. & Krogedal, P. Lactic acid fermentation eliminates indigestible carbohydrates and antinutritional factors in soybean meal for Atlantic salmon (Salmo salar). Aquaculture 246, 331–345. https://doi.org/10.1016/j.aquaculture.2005.01.001 (2005).

Li, X., Zheng, S. & Wu, G. Amino Acids in Nutrition and Health: Amino Acids in the Nutrition of Companion, Zoo and Farm Animals (ed. Guoyao, W.) 133–168 (Springer International Publishing, 2021).

Mo, W. Y., Choi, W. M., Man, K. Y. & Wong, M. H. Food waste-based pellets for feeding grass carp (Ctenopharyngodon idellus): adding Baker’s yeast and enzymes to enhance growth and immunity. Sci. Total Environ. 707, 134954. https://doi.org/10.1016/j.scitotenv.2019.134954 (2020).

Tabbara, M., Monzer, S., Zein Eddine, R., Abiad, M. & Saoud, I. Bioprocessing post-consumer food waste for use as a fish feed ingredient. Aquac. Res. 53, 2383–2391. https://doi.org/10.1111/are.15756 (2022).

Chen, Z. et al. Effects of dietary protein level on the growth, reproductive performance, and larval quality of female yellow catfish (Pelteobagrus fulvidraco) broodstock. Aquaculture Rep. 24, 101102. https://doi.org/10.1016/j.aqrep.2022.101102 (2022).

Gatesoupe, F. J. Live yeasts in the Gut: natural occurrence, dietary introduction, and their effects on fish health and development. Aquaculture 267, 20–30. https://doi.org/10.1016/j.aquaculture.2007.01.005 (2007).

Zhang, M. et al. Study of fermented feed by mixed strains and their effects on the survival, growth, digestive enzyme activity and intestinal flora of Penaeus vannamei. Aquaculture 530, 735703. https://doi.org/10.1016/j.aquaculture.2020.735703 (2021).

Burr, G., Hume, M., Neill, W. H. & Gatlin, D. M. III Effects of prebiotics on nutrient digestibility of a soybean-meal-based diet by red drum Sciaenops ocellatus (Linnaeus). Aquac. Res. 39, 1680–1686. https://doi.org/10.1111/j.1365-2109.2008.02044.x (2008).

Abdel-Tawwab, M., Abdel-Rahman, A. M. & Ismael, N. E. M. Evaluation of commercial live bakers’ yeast, Saccharomyces cerevisiae as a growth and immunity promoter for fry nile tilapia, Oreochromis niloticus (L.) challenged in situ with Aeromonas hydrophila. Aquaculture 280, 185–189. https://doi.org/10.1016/j.aquaculture.2008.03.055 (2008).

Funding

This research was funded by the Science and Technology Project of Chaozhou City (202102GY19), Guangdong Provincial Key Laboratory of Functional Substances in Medicinal Ed-ible Resources and Healthcare Products (2021B1212040015).

Author information

Authors and Affiliations

Contributions

Conceptualization, Yun Li and Hui Zhu; methodology, Yun Li and Fei Zhou; validation, Yun Li and Hui Zhu; formal analysis, Yun Li; investigation, Fei Zhou, Yiyan Zhang and Yinhua Zheng; writing—original draft preparation, Yun Li; writing—review and ed-iting, Yun Li and Hui Zhu; funding acquisition, Yun Li and YuZhong Zheng. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, Y., Zhu, H., Zhou, F. et al. Enhanced bioconversion of kitchen food waste into aquaculture feed using a mixed culture of Bacillus licheniformis and Yarrowia lipolytica. Sci Rep 15, 16497 (2025). https://doi.org/10.1038/s41598-025-98265-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-98265-9