Abstract

In this theoretical study, potential K2TiI6 perovskite material has been used as the absorber layer of the investigated perovskite solar cells (PSCs). The SCAPS-1D program was used to conduct the numerical analysis where 10 different hole transport layers (HTLs) and 4 electron transport layers (ETLs) were used to find the best optimum device structure. While various HTLs were studied, D-PBTTT-14 showed the best-optimized performance and therefore it was chosen as the final HTL material for further studies in combination with 4 ETL materials. Different device parameters such as the thickness of the absorber, HTL, and ETL layers; doping concentrations, and defect densities are varied in this work to optimize the investigated device structures. Moreover, the effect of temperature, series and shunt resistance, J-V curve, Q-E curve, recombination and generation rates were explored in this study. After optimizing various device parameters, the device with CdZnS ETL demonstrated superior performance compared to other ETL devices. It achieved a power conversion efficiency (PCE) of 26.21%, fill factor (FF) of 88.06%, short-circuit current density (Jsc) of 20.951 mA/cm², and an open-circuit voltage (VOC) of 1.4205 V. Under fully optimized conditions, LBSO, Nb2O5, and PC60BM ETL devices showed PCE of 22.06%, 23.24%, and 23.12%, respectively. Based on the findings of this study, it can be stated that this work could be valuable for the practical implementation of K2TiI6 absorber-based PSCs.

Similar content being viewed by others

Introduction

Our modern civilization in the 21st century is strongly dependent on energy with the electricity demand increasing every year. Conventionally, we are heavily dependent on the use of natural resources which is decreasing at a fast rate. Therefore, the necessity for research and applications of renewable energy sources is increasing1,2,3. Wide applications of solar cells could be one of the best ways to meet the ever-increasing demand for energy along with replacing reliance on natural resources. Solar cells are environmentally friendly and need low maintenance costs and there is a great potential to improve their performance as well4,5,6. Based on the materials, solar cells can be classified into different types such as first-generation, second-generation, and third-generation solar cells7,8. The first-generation solar cells include silicon-based mono-crystalline and poly-crystalline solar cells. This technology is less efficient compared to the other technologies. Currently, second and third-generation thin film solar cells are gaining popularity due to their prospective as cost-effective energy sources with sustainability9. Thin film solar cells are showing a rising efficiency that makes them suitable for industrial-scale productions. Among the existing thin film technologies, perovskite thin film solar cells demonstrate a high potential for their outstanding performance due to the suitable optoelectronic properties of perovskite materials that show great appeal for photovoltaic application10,11,12.

Different types of absorber materials are used in PSCs which are classified into organic and inorganic materials. Among the organic absorber materials, Methylammonium Lead Iodide (MAPbI3)13, Methylammonium Tin Iodide (MASnI3)14, Formamidinium Lead Iodide (FAPbI3)15 etc. have demonstrated outstanding performance where the PCE exceeded 20%. Cesium Lead Iodide (CsPbI3)16, Cesium Lead Bromide (CsPbBr3)17, and Cesium Tin Iodide (CsSnI3)18 are some of the popular inorganic absorber materials. Over the last decade, they have shown great growth in improving performances. However, the presence of Pb in solar cells is detrimental to the environment. Different studies have shown its toxicity has a detrimental impact on the environment and animal life19. Some recent studies have found K2TiX6 (X = I, Cl, Br)20 as a good candidate for use in optoelectronic devices as it is non-toxic and has good optical properties. In a recent study, K2TiI6 as an absorber layer showed a PCE of 4.382%21 studied using a SCAPS-1D simulator. While this absorber shows great potential for further exploration, there have been no significant studies conducted yet utilizing a large number of device structures with this promising absorber material.

In PSCs, the ETL layer takes electrons from the perovskite layers to reduce the electron-hole recombination. However, its high resistance often blocks the transportation of electrons22. There are two types of ETL materials: organic and inorganic materials. According to previous studies, ETL materials such as PCBM23, ZnO24, C6025, SnO222, TiO226, WOx27, etc. have been used for solar cell applications in recent years. Organic ETL can improve the performance of solar cells by enhancing charge extraction, and transportation. It provides stability28 to the structure without electrode interlayers. However, as ETL layers are mostly thin, their deposition can harm photoactive layers, and increase the complexity of fabrication and costs29. In the case of inorganic ETL materials, it can improve the performances of solar cells by facilitating the carrier extraction and suppression of charge recombination at the interface between the perovskite and contributes to achieving a higher PCE. However, ETL can be deposited using a low-temperature process, rendering it suitable for industrial-scale production30. In recent research, CdZnS31, LBSO32, Nb2O533, and PC60BM23 have demonstrated excellent performances utilizing these ETLs in PSCs. CdZnS has a high absorption coefficient that makes it suitable for solar energy harvesting34. Nb2O5, LBSO, and PC60BM also have excellent carrier mobility and optical properties to be used as ETLs. Using LBSO ETL in a structure of CsSnBr6 based PVSc showed 29.13% of PCE35. CdZnS ETL in a CH3NH3SnI3 based PVSc structure demonstrated a PCE of 29.24%31,34. In two other recent studies, PC60BM and Nb2O5 ETL reported higher PCE of 22.61%36 and 16.85%37 respectively.

The HTL in PSCs can improve the hole transportation and recombination which can lead to enhanced performance38. It also helps to stabilize the perovskite layer and decreases nonradiative recombination. Organic types of HTL materials such as PEDOT: PSS, Spiro-OMeTAD, and PTAA are good at passivating defects in the PSCs which leads to enhanced long-term stability and performance39. Some materials are printable which makes them suitable for commercial and large-scale productions. It can also improve the absorption rate of light leading to higher efficiency38,40. Inorganic HTLs have high hole mobility and good chemical stability, significantly enhancing both the stability and performance of solar cell devices41. Organic-inorganic materials such as C6PcH242, C6TBTAPH243, CuAlO244, D-PBTTT-1445, MoO346, MWCNTs47, NiCo2O448, MEH-PPV49, PTAA50, Tin doped Nitrogen oxide51 have been used as HTL material in many recent studies. However, these HTL materials are also investigated in this work.

In this study, the SCAPS-1D simulator was used to determine the performance of different device structures by studying 10 HTLs and 4 ETLs having K2TiI6 as the absorber layer. In total, 96 different combinations of PSC structures were extensively studied. To conduct so many combinations of PSC experimentally is very expensive and time-consuming. Therefore, this numerical approach was executed by studying the PSCs’ performances using the SCAPS-1D program. At first, performances for all the 96 combinations were studied and after that, the best four combinations of PSCs were chosen for further simulations. However, this work gives notable outlines of the optimization of K2TiI6 absorber-based PSCs.

Methodology

SCAPS-1D numerical solution

Solar Cell Capacitance Simulator (SCAPS-1D)52 was developed at Gent University located in Belgium. This program is designed to do simulation and analysis of solar cells. This program is used to study different characteristics of solar cells such as J-V curve, C-V, and C-f ac characteristics. It also examines the effect of semiconductor properties such as energy band, doping concentration, defect density, etc53. The SCAPS-1D program uses two fundamental equations of semiconductors called Poisson equation Eq. (1) and continuity equation Eqs. (2) and (3) to study these effects54,55. The Poisson’s equation used for the device is as follows:

Here, ψ denotes the potential of the electric field, ε0 is the permittivity in free space whereas εr represents permittivity in a relative medium. q is the amount of charge, ρn and ρp represent the distributions of electrons and holes. In Poisson’s equation, NA and ND symbolize the densities of acceptors and donors.

The continuity equation used for electrons and holes:

Here, Jn denotes the current density for holes and Jp shows the current densities of holes. Gn and Gp indicate the rate of electrons and hole generation recombination respectively.

Equations (4) and (5) represent the relation of charge carrier drift diffusions to calculate the current densities of the electrons and holes of solar cells. Here q represents the total number of charges, µn and µp are the mobility of electron and hole carriers respectively.

The performance of a photovoltaic cell is measured by the quality fill factor (FF). FF depends on the product value of the maximum voltage and maximum current representing the maximum power to the calculated theoretical power (Pt), considering the open circuit voltage (Voc) and short circuit current (Jsc) shown in Eq. (6). The power conversion efficiency (PCE) is shown in the Eq. (7) shows the ratio of output energy that can be found from the photovoltaic solar cells to the given input energy. Its performance relies on the product of Voc, Jsc, and FF to the given input power as shown in the equation.

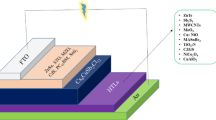

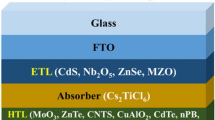

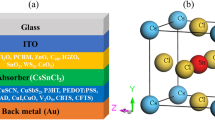

K2TiI6 absorber-based PSC structure

Figure 1 shows the investigated PSC structure (FTO/ETL/K2TiI6/HTL/Au). In this structure, FTO is a window layer above which there is a glass layer. Four different ETL layers; PC60BM, CdZnS, LBSO, and Nb2O5 were studied for different configurations. Below the ETL layer, K2TiI6 was selected as the absorber layer of the device. The effect of MoO3, PTAA, MWCNTS, C6PcH2, NiCo2O4, D-PBTTT-14, TiO2:N, CuAlO2, nPB, and C6TBTAPH2 as the HTL layers were investigated in this study. In the back contact layer, gold (Au) was the proposed back contact metal. Studies were conducted on key elements of the device to determine characteristics of the solar cell such as photoelectric and electrical characteristics. The entire study followed a numerical simulation approach using the SCAPS-1D program using data from Tables 1, 2 and 3. All of the simulations were carried out under the 1.5 AM solar radiation condition having a power density of 100mW/cm2.

Results and discussion

Device optimization

HTL optimization

To select the ideal HTL for the studied PSC structure, the performances of different HTL materials were examined (Fig. 2) at the beginning of this study. Among the studied materials five demonstrated PCE over 5%: C6TBTAPH2 (5.13%), C6PcH2 (5.37%), nPB (5.38%), MoO3 (5.57%), and DPB-TTT-14 (5.59%). Voc of the C6TBTAPH2, C6PcH2, nPB, MoO3, and DPB-TTT-14 HTLs were 1.1854, 1.2261, 1.2742, 1.299 and 1.3035 (mA/cm2) respectively. Almost identical performances were seen for Jsc and FF for the HTL materials. However, Considering the performance evaluation in terms of PV parameters, DPB-TTT-14 was deemed as the most suitable HTL layer.

Energy band alignment

When excitons are produced in the absorber layer of the solar cell structure, they tend to move from the absorber to the ETL and HTL. Proper band alignment is essential in this charge extraction process. The band offset, including the conduction band offset (CBO) and valence band offset (VBO), plays a vital role in charge extraction57. The band offset can be positive or negative, depending on the different barrier heights of the materials’ conduction and valence bands. For smoother carrier extraction, the HTL and ETL with the absorber material should have minimum valence band offset and conduction band offset, respectively. When the conduction band of the perovskite is positioned below the ETL, a spike-like band alignment occurs, whereas if the conduction band of the absorber is positioned above the ETL, a cliff-like band alignment occurs58,59. Spike-like band offsets between the absorber and ETL facilitate the electron extraction process. Moreover, this type of spike-like CBO can reduce charge trapping-induced non-radiative recombination60. Conversely, a cliff-like VBO boosts the extraction of holes towards the back metal contact61. Figure 3 depicts the energy band diagram of the device structure with DPB-TTT-14 as the HTL and LBSO, Nb2O5, CdZnS, PC60BM as ETL. Within four device structures, a cliff-like CBO has been observed for CdZnS/PC60BM/ Nb2O5 ETL and perovskite layer. In contrast, the CBO for LBSO ETL and perovskite layer shows a somewhat cliff-like band alignment. The cliff-like CBO in the LBSO ETL device leads to recombination, adversely affecting the overall device performance, as evident from further studies. However, the CdZnS ETL exhibits the most promising band alignment with the perovskite layer, showing a minimal spike. This is advantageous for smooth electron transportation and reduced recombination.

Optimization of absorber, ETL and HTL thickness

Figure 4 represents the impact of PCE, FF, Jsc, and Voc on the thickness variation of the absorber, ETL, and HTL layers. At first, the effect of K2TiI6 absorber layer thickness considering all four different configurations using LBSO, Nb2O5, PC60BM, and CdZnS ETL were studied. The absorber thickness was varied from 0.2 μm to 1 μm to observe the performance of PV parameters. With the increase in thickness of the absorber layer, a greater number of photons can be captured which results in the enhanced generation of electron-hole pairs in the absorber leading to an increase in PV performance62. However, a higher thickness can lead to the degradation of PCE after reaching an optimum point. From Fig. 4a, it is evident that absorber K2TiI6 showed the optimum PCE of 22.82% at a thickness of 0.4 μm for the CdZnS ETL combination. The optimum thickness of 0.2 μm was kept for the absorber layer when LBSO, Nb2O5, and PC60BM ETL-based devices were considered. Similar to the change of PCE, increasing absorber thickness can grow the number of photon absorption which may lead to enhanced short-circuit current Jsc. CdZnS showed the highest Jsc at 0.4 μm whereas all other ETL layers showed maximum Jsc at 0.2 μm. Open-circuit voltage showed a reverse trend in performance in comparison to Jsc. LBSO and PC60BM had comparable performance which were mostly stable. CdZnS and Nb2O5 had a drop in Jsc value when the thickness was increased. The absorber had a sharp increase in FF when thickness was increased from 0 μm to 0.2 μm. From 0.2 μm to 1 μm, a constant growth in FF was observed.

A suitable ETL can lower the recombination rate and increase the transmittance in the PSCs63. In Fig. 4b, the ETL thickness was varied from 0.02 μm to 0.5 μm. LBSO, Nb2O5, and CdZnS showed a constant PCE performance when the thickness of ETLs was varied. However, PCE deteriorated from 15.94 to 2.98% in the PC60BM ETL structure. Similarly, for Jsc and Voc in the CdZnS, LBSO, and Nb2O5 ETL structures, all had a stable constant performance. However, the PC60BM ETL PSC structure showed degradation in Jsc from 13.418 to 2.615 (mA/cm2) as the thickness got thicker from 0.02 μm to 0.5 μm. For all of the ETL layers, FF was steady with respect to the thickness of the ETL layers. From the observations, the ETL layers got insignificantly impacted when LBSO, Nb2O5, and CdZnS were chosen as the ETL layer whereas PC60BM as an ETL layer was mostly affected negatively by the thickness variation. Therefore, keeping the ETL thickness minimum was the ideal choice, and therefore it was selected as 0.02 μm.

A thicker HTL, compared to the electron transport layer (ETL), is essential for reducing recombination by ensuring a swift and balanced movement of charge carriers toward the terminal64. As a result, this study maintained a higher thickness of the HTL than the ETL. Besides, the increased thickness of HTL offers an extra benefit of enhancing the light absorption capabilities65. From Fig. 4c, it can be witnessed that a minor impact on the performances of PV parameters is observed for the HTL thickness variation. Unlike the previous result, PC60BM along with the other three ETL layers showed a stable performance when HTL thickness was altered. CdZnS showed the highest efficiency of 22.87% among all the ETL devices while varying HTL thickness. The LBSO ETL PSC combination maintained no change having PCE around 10.6%. Similarly, Nb2O5 and LBSO showed a closely similar performance. Like PCE performances, stable performance of FF, Jsc, and Voc was observed when the HTL layers’ thickness was varied. No major changes in results were found, so keeping thickness at the minimum to lower the fabrication cost by 0.4 μm was chosen for the HTL layers for further investigations.

Optimization of acceptor density, donor density, and defect density of absorber

To investigate the impact of the acceptor density of the absorber layer, NA is varied from 1014 cm− 3 to 1019 cm− 3 (Fig. 5(a)). The device with CdZnS ETL showed constant performance when the acceptor density varied from 1014 cm− 3 to 1018 cm− 3 then it slightly dropped from 22.91 to 22.69%. Moreover, PC60BM and LBSO ETL-based PSCs also showed stable PCE when NA was varied from 1014 to 1018; then both of the structures showed improvement as NA was increased from 1018 cm− 3 to 1019 cm− 3. In all of the configurations, FF and Voc were constant with respect to altering NA from 1014 cm− 3 to 1018 cm− 3, and then performance increased a little. Voc has a reverse relationship compared to JSC performances which can be seen in the graph. The VOC of PC60BM and Nb2O5 improved when NA was increased from 1018 cm− 3 to 1019 cm− 3. K2TiI6 absorber in the CdZnS and LBSO ETL PSCs did not affect the performances as the acceptor density variation. Overall, the impact of increasing acceptor density seemed to be having a low impact. So, 1014 as NA was kept as it can curb the cost of manufacturing without showing any negative effect on our PSC performance.

This study also explored the effect of donor density (Fig. 5(b)), by changing the ND value from 1013 cm− 3 to 1019 cm− 3. Increasing donor density from 1014 cm− 3 to 1018 cm− 3 in the absorber showed no effect on PCE in the PC60BM and LBSO ETL-based devices. However, PCE, FF, and Voc dropped sharply when ND was further enhanced. CdZnS had volatile PCE and FF performance, showing a declining performance from 1015 cm− 3 to 1016 cm− 3, and then PCE, FF, and Voc improved linearly, and sharply as the donor density increased in absorber. Absorber donor density varied from 1017 cm− 3 to 1019 cm− 3 for Nb2O5 ETL-based devices where PCE and Jsc showed a declining trend. FF and Voc were improved when the donor density of the absorber layer was increased. PC60BM and LBSO when used as the ETL layers, as we varied ND from 1013 cm− 3 to 1018 cm− 3, a stable Jsc was found. In the CdZnS ETL configuration structure, an opposite trend of performance to Voc was found as Jsc started to decrease after ND reaching 1016 cm− 3.

To study the defect density of the absorber, simulations were carried out varying the absorber defect density, Nt from 1011 cm− 3 to 1016 cm− 3 (Fig. 5(c)). Higher defect densities have a detrimental effect on PSCs66. Increasing defect densities in the absorber increases the recombination rate67. As the recombination rate increases the formation electron-hole barrier slows down the process of getting electrons in the contact layers68. Therefore, when Nt is increased above a tolerable range, the performance of PSCs drops. In all of the ETL configurations, Nt had a tolerable effect on PCE and Jsc as the Nt of the absorber was increased from 1011 cm− 3 to 1014 cm− 3, but PCE dropped swiftly as Nt was further enhanced. An increasing Nt showed declining FF only when Nb2O5 was considered as the ETL layer. PC60BM and LBSO ETL devices showed consistent behaviour as the Nt changed whereas Nb2O5 and CdZnS showed declining Voc when the Nt was further increased from 1013 cm− 3.

Optimization of donor density of ETL, acceptor, and defect density of HTL

Figure 6a demonstrates the change of PV parameters when simulations were carried out with varying donor density (ND) of the ETL layers. The PSC performance using CdZnS as an ETL remained unchanged against the variation of ND. A higher doping density enhanced the performance of LBSO and Nb2O5 ETL devices where PCE increased from 16.37 to 20%, and 20.7–22.36% respectively. PC60BM ETL device showed a stable PCE and CdZnS and PC60BM ETL devices showed no change in FF against a varying ND. FF enhanced continuously at higher values of ND in the LBSO and Nb2O5 ETL devices. A small margin of change was witnessed in Jsc and Voc performances for ND variation in all ETL devices.

The doping concentration in the HTL significantly controls the electric field intensity at the HTL/absorber interface, making the role of acceptor density in the HTL crucial for solar cell performance. A stronger electric field leads to more efficient electron-hole pair separation, thereby improving the overall efficiency of the device69. The effect of the absorber acceptor density NA of the HTL layers in PSCs is seen in Fig. 6b. PCE and FF show rapid improvement, suggesting that the electron hole seperation is smoother due to increased electric filed intensity in the HTL/ absorber interface. When NA was enhanced where the PCE of LBSO, Nb2O5, PC60BM, and CdZnS ETL devices jumped from 18.70 to 21.98%, 19.21–23.15%, 19.75–23.04%, 22.8–26.10% respectively. Therefore, it can be stated that the acceptor density of the HTL layer played a vital role in the improved performance of the investigated devices.

The total defect density in the active layer is a critical factor that can significantly influence the performance of solar cells. The efficiency of these devices is closely tied to the characteristics of the interfaces and the presence of various defects, including point defects, stacking faults, and grain boundaries. A higher defect density in the hole transport layer (HTL), caused by factors such as dislocations, native defects, or the incorporation of unwanted foreign atoms, can lead to the formation of shallow or deep traps. The defect density of the HTL layer varied from 1015 cm− 3 to 1020 cm− 3 as shown in Fig. 6c. All of the investigated devices remained unaffected by the varying defect density which means the structures have consistent behavior in PV performance having higher defect density. This, in turn, can be associated with the high carrier mobility of DPB-TTT-14 HTL or the substantial absorption coefficient of K2TiI6. Similar trends have been reported in previous studies70,71.

Effect on various parameters on device performance

Effect of series resistance, shunt resistance, and temperature

Series resistance (Rs) refers to the accumulation of different resistances at the semiconductor and metal layers72,73. A higher series resistance can decrease FF and PCE. Sometimes it can also degrade the performance of Voc. In this work, the Rs of the PSCs were varied from 0 Ω-cm2 to 6 Ω-cm2 (Fig. 7(a)). Jsc and Voc showed no change in performance when Rs were studied. PCE and FF in all of the configurations declined linearly and showed degradation in performance at a higher Rs. This study also explored the shunt resistance (Rsh) by varying it from 10 Ω-cm27 to 10 Ω-cm2 for the investigated devices (Fig. 7(b)). Increasing shunt resistance helps to overcome the resistance at the p-n junction interface74,75. Hence, more current can flow, improving the overall performance of the PSCs. When Rsh was increased from 10 Ω-cm2 to 100 Ω-cm2, a sharp increase in all PV parameters was observed. After that, it became constant when subjected to more Rsh in these devices.

Temperature has a profound impact on the overall performance and stability of PSCs. With an increasing temperature, electron holes start to collide more, and increasing defects deteriorate FF and PCE. This study varied temperature from 300 K to 450 K in the simulation of the devices (Fig. 7(c)). PC60BM and Nb2O5 ETL-based devices were more affected by PCE than CdZnS and LBSO. A similar effect was observed in the performance of FF. With the change in temperature, the PC60BM ETL device was highly affected whereas in the other configurations, Voc decreased steadily. However, there was no major change in Jsc with the variation of temperature.

Current density and quantum efficiency

The probable maximum power that can be generated in a PSC depends on the open-circuit voltage and current density. Figure 8(a) and (b) show the J-V curve before and after the optimization of the PSC structures. The maximum current density was significantly improved after optimization whereas the maximum open circuit voltage decreased slightly in the devices leading to an overall improvement in power efficiency.

Figure 8(c) and (d) show the initial and final optimized conditions of the quantum efficiency-wavelength graph. Quantum efficiency refers to how well a PSC can use captured photons to generate electricity at a specific wavelength76. Before optimizing, the quantum efficiency of the structures was not decent, the LBSO, and PC60BM structures showed less than 20% quantum efficiency in most of the parts between a condition of 300 nm to 800 nm light spectrum; the CdZnS and Nb2O5 ETL PSC configurations had considerably better quantum efficiency response. Optimizing the configurations, the quantum efficiency response against wavelength significantly improved in all of the devices. The CdZnS ETL device showed the best response and the other configurations had a similar performance response. The improved quantum efficiency response over a light spectrum denotes the enhanced efficiency of converting the captured photons to produce electricity at a much higher rate.

Effect of generation and recombination

The generation of carriers in the PSCs demonstrates the creation of both the electrons and holes in the PSC. At the time electrons jump from the valence band to the conduction band, holes are created in the valence band simultaneously. The carrier generation (Fig. 9(a)) is the highest in the ETL regions as the maximum electrons are generated caused by a higher rate of absorption of photons. The optimized conditions (Fig. 9(b)) show a much better carrier generation between the positions of 0.2 μm to reach the ETL regions where the maximum carrier generation rate is found.

Figures 9(c) and (d) are the initial and final Recombination rate-position graphs. Recombination occurs when electrons and holes combine and neutralize each other. Defect states in layers and the lifetime of charge carriers cause recombination. To get a better performance of PSC a lower recombination rate is expected. Over the whole PSC position, a lower recombination rate can be observed in Fig. 9(d) compared to Fig. 9(c).

Effect of thickness of absorber with thickness of ETL

Figure 10 represents the PCE of the CdZnS, PC60BM, Nb2O5, and LBSO ETL devices when the thickness of ETL varied against the absorber layer. It is apparent that when the thickness of the absorber is between 550 nm and 700 nm and ETL the thickness is less than 100 nm maximum PCE was achieved. When PC60BM was the ETL layer, the optimum condition for PCE was found as the thickness of PC60BM between 20 nm and 50 nm and the absorber thickness was at a condition of greater than 600 nm. The best PCE for this condition was found as 27.92%. The optimum PCE condition for Nb2O5 as the ETL layer was seen when the thickness of the absorber layer exceeded 600 nm and the ETL layer was kept at more than 30 nm. A similar trend was observed for the LBSO layer which showed the maximum PCE of 26.84%.

Effect of absorber thickness with defect density

Nt of absorber between 1011 cm− 3 to 1014 cm− 3 and a thickness of absorber between 500 nm and 700 nm showed the maximum PCE performance using CdZnS as the ETL layer (Fig. 11). When PC60BM was used as ETL, the device achieved the highest efficiency of 27.95% after optimization. The best condition was gained when Nt was 1014 cm− 3 and the absorber thickness was between 600 nm and 700 nm. 550 nm to 700 nm of absorber thickness and Nt of 1011 cm− 3 to 1013 cm− 3 demonstrated the maximum PCE for the Nb2O5 and LBSO ETL devices.

Comparison of SCAPS-1D results with previous work

The results of this investigation are compared with those of a prior study in Table 4. Too little research has been done on using K2TiI6 perovskite as an absorber layer. Nonetheless, a recent theoretical investigation found a maximum PCE of 4.3593% using this absorber which is quite low. Therefore, this numerical analysis has been conducted using several combinations of HTL materials with different ETLs. The device structures obtained exceptional PCE after adjusting various device parameters, which is noticeably superior to that stated in earlier research.

Conclusions

Using the SCAPS-1D simulation tool, a comprehensive investigation was conducted on the lead-free perovskite material K2TiI6. Four device structures incorporating CdZnS, PC60BM, LBSO, and Nb2O5 ETL were analyzed in this study. Performance improvements were achieved by simultaneously optimizing the K2TiI6 absorber layer, CdZnS, PC60BM, LBSO, Nb2O5 ETLs, and DPB-TTT-14 HTL. The key findings are summarized below:

-

1.

Initially, HTL optimization was conducted where 10 device structures were analyzed with CdZnS ETL and 10 different HTLs. Based on the PV parameters of these device structures, the numerical study aimed to choose an HTL material that offers the best performance. HTL material DPB-TTT-14 demonstrated superior performance based on the PV parameters, which is why this HTL material was used in further simulations and device optimization.

-

2.

Variations in the thickness of the absorber, ETL, and HTL layers can enhance device performance. Optimizing the absorber layer thickness resulted in an increased PCE of 22.82% for the device with a CdZnS ETL. However, a minor influence on PV parameters was observed after optimizing the ETL and HTL layer thicknesses.

-

3.

After optimizing the defect density of the absorber layer, as well as the donor and acceptor densities, significant improvements were observed in LBSO, PC60BM, and Nb2O5 ETL devices. It is evident that the PCE of these devices notably increased (> 20%) compared to prior optimizations.

-

4.

Varying the acceptor density leads to a significant improvement in device parameters, with the PCE of devices using LBSO, Nb2O5, PC60BM, and CdZnS ETL increasing from 18.70 to 21.98%, 19.21–23.15%, 19.75–23.04%, and 22.8–26.10%, respectively.

The outstanding results of this study will pave the way for the fabrication of lead-free, environmentally friendly, and sustainable K2TiI6 based perovskite solar cells. This extensive work with multiple device structures will be helpful for researchers in further analyzing K2TiI6 based devices. Additional engineering can be done for stability and performance enhancement which may lead to more insight for device fabrication.

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study and are available from the corresponding author on reasonable request.

References

Kirsch, S. Running out? Rethinking resource depletion. Extr. Ind. Soc. 7, 838–840 (2020).

Holechek, J. L., Geli, H. M. E., Sawalhah, M. N. & Valdez, R. A. Global assessment: can renewable energy replace fossil fuels by 2050? Sustain 14, (2022).

Deshmukh, M. K. G., Sameeroddin, M., Abdul, D. & Sattar, M. A. Renewable energy in the 21st century: A review. Mater. Today Proc. 80, 1756–1759 (2023).

Bati, A. S. R. et al. Next-generation applications for integrated perovskite solar cells. Commun. Mater. 4, 2 (2023).

Ehrler, B. et al. Photovoltaics reaching for the Shockley–Queisser limit. ACS Energy Lett. 5, 3029–3033 (2020).

Correa-Baena, J. P. et al. Promises and challenges of perovskite solar cells. Science. 358, 739–744 (2017).

Dambhare, M. V., Butey, B. & Moharil, S. V. Solar photovoltaic technology: A review of different types of solar cells and its future trends. J. Phys. Conf. Ser. 1913, 012053 (2021).

Zhang, H. et al. Review on efficiency improvement effort of perovskite solar cell. Sol Energy. 233, 421–434 (2022).

Basumatary, P. & Agarwal, P. A short review on progress in perovskite solar cells. Mater. Res. Bull. 149, 111700 (2022).

Khan, M. I. et al. Structural, electrical and optical properties of hetrostructured MoS2/ZnO thin films for potential perovskite solar cells application. J. Mater. Res. Technol. 20, 1616–1623 (2022).

Song, T. B. et al. Perovskite solar cells: film formation and properties. J. Mater. Chem. A. 3, 9032–9050 (2015).

Datta, S., Baul, A., Sarker, G. C., Sadhu, P. K. & Hodges, D. R. A comprehensive review of the application of machine learning in fabrication and implementation of photovoltaic systems. IEEE Access. (2023).

Kim, D. W. et al. Efficient MAPbI3-based perovskite solar cells exceeding 21% efficiency via aging treatment. Chem. Eng. J. 475, 146451 (2023).

Panda, P. et al. Design of MASnI3 perovskite solar cell with chalcogenide ETLs to achieve high photo conversion efficiency[1], Design of MASnI3 perovskite solar cell with chalcogenide ETLs to achieve high photo conversion efficiency of 3. Optik (Stuttg). 296, 171550 (2024).

Huang, Z. et al. Anion–π interactions suppress phase impurities in FAPbI3 solar cells. Nature 623, 531–537 (2023).

Zhang, J. et al. Polar species for effective dielectric regulation to achieve high-performance CsPbI3 solar cells. Adv. Mater. 34, 2202735 (2022).

Zhang, Z. et al. Accelerated sequential deposition reaction via crystal orientation engineering for low-temperature, high‐efficiency carbon‐electrode CsPbBr3 solar cells. Energy Environ. Mater. 7, e12524 (2024).

Wang, G. et al. Inorganic CsSnI3 perovskite solar cells: the progress and future prospects. Sol RRL. 6, 2100841 (2022).

Sani, F., Shafie, S., Lim, H. N. & Musa, A. O. Advancement on lead-free organic-inorganic halide perovskite solar cells: a review. Mater. (Basel). 11, 1008 (2018).

Ju, M. G. et al. Earth-abundant nontoxic titanium(IV)-based vacancy-ordered double perovskite halides with tunable 1.0 to 1.8 ev bandgaps for photovoltaic applications. ACS Energy Lett. 3, 297–304 (2018).

Simulation, S. C. Lead-free and stable potassium titanium halide perovskites: synthesis, characterization and solar cell simulation. (2022).

Zeng, W. et al. Multi-functional strategy: ammonium citrate-modified SnO2 ETL for efficient and stable perovskite solar cells. ACS Appl. Mater. Interfaces. 14, 43975–43986 (2022).

Raza, E. et al. Numerical simulation analysis towards the effect of charge transport layers electrical properties on cesium based ternary cation perovskite solar cells performance. Sol Energy. 225, 842–850 (2021).

Derbali, L., Bouhjar, F., Derbali, A. & Soucase, B. M. Enhanced ZnO-based ETL and nanostructured interface modification for improved perovskite solar cells efficiency. Opt. Mater. (Amst). 145, 114440 (2023).

Lee, H. J. & Na, S. I. Investigation of PCBM/ZnO and C60/BCP-based electron transport layer for high-performance pin perovskite solar cells. J. Alloys Compd. 921, 166007 (2022).

Raj, A. et al. Effect of doping engineering in TiO2 electron transport layer on photovoltaic performance of perovskite solar cells. Mater. Lett. 313, 131692 (2022).

Yu, X. et al. Fullerene modification of WO3 electron transport layer toward high-efficiency MA‐free perovskite solar cells with eliminated light‐soaking effect. Interdiscip Mater. (2023).

Bin, H., Wang, J., Li, J., Wienk, M. M. & Janssen, R. A. J. Efficient electron transport layer free small-molecule organic solar cells with superior device stability. Adv. Mater. 33, 2008429 (2021).

Liu, Z. et al. Anion-doped thickness‐insensitive electron transport layer for efficient organic solar cells. Macromol. Rapid Commun. 43, 2200190 (2022).

Ye, S. et al. A strategy to simplify the preparation process of perovskite solar cells by co-deposition of a hole-conductor and a perovskite layer. Adv. Mater. 28, 9648–9654 (2016).

Khan, Z., Noman, M., Tariq Jan, S. & Daud Khan, A. Systematic investigation of the impact of kesterite and zinc based charge transport layers on the device performance and optoelectronic properties of ecofriendly Tin (Sn) based perovskite solar cells. Sol Energy. 257, 58–87 (2023).

Shivesh, K., Alam, I., Kushwaha, A. K., Kumar, M. & Singh, S. V. Investigating the theoretical performance of Cs2TiBr6-based perovskite solar cell with La-doped BaSnO3 and CuSbS2 as the charge transport layers. Int. J. Energy Res. 46, 6045–6064 (2022).

Shamna, M. S. & Sudheer, K. S. Numerical simulation analysis towards the effect of charge transport layers electrical properties on cesium based ternary cation perovskite solar cells performance. J. Photonics Energy. 12, 32211 (2022).

Patidar, D., Saxena, N. S. & Sharma, T. P. Structural, optical and electrical properties of CdZnS thin films. J. Mod. Opt. 55, 79–88 (2008).

Bouazizi, S., Tlili, W., Bouich, A., Soucase, B. M. & Omri, A. Design and efficiency enhancement of FTO/PC60BM/CsSn0.5Ge0.5I3/Spiro-OMeTAD/Au perovskite solar cell utilizing SCAPS-1D simulator. Mater. Res. Express. 9, 0–12 (2022).

Ghosh, R., Singh, A. & Agarwal, P. Study on effect of different HTL and ETL materials on the perovskite solar cell performance with TCAD simulator. Mater. Today Proc. https://doi.org/10.1016/J.MATPR.2023.06.161 (2023).

Hosen, A., Mian, M. S., Ahmed, S. R. & Al Improving the performance of lead-free FASnI3‐based perovskite solar cell with Nb2O5 as an electron transport layer. Adv. Theory Simulations. 6, 2200652 (2023).

Bai, X., Tang, H., Yang, Q., Wang, Y. & Shokri, A. M. Achieving high-efficiency perovskite-based solar cells through engineering hole-transport layer. Mater. Chem. Phys. 304, 127829 (2023).

Chen, K. et al. Simultaneously modifying hole transport material and perovskite via a crown ether-based semiconductor toward efficient and stable perovskite solar cells. Sol RRL. 7, 2200987 (2023).

Xu, H. et al. Printable hole transport layer for 1.0 cm2 organic solar cells. ACS Appl. Mater. Interfaces. 12, 52028–52037 (2020).

Parida, B. et al. Effect of compact TiO2 layer on structural, optical, and performance characteristics of mesoporous perovskite solar cells. Mater. Today Commun. 18, 176–183 (2019).

Dao, Q. D. et al. Fabrication, characterization and simulation analysis of perovskite solar cells with dopant-free solution-processible C6PcH2 hole transporting material. Opt. Quantum Electron. 54, 278 (2022).

Dao, Q. D., Tran, N. A. & Doan, T. H. Liquid crystal semiconductor C6TBTAPH2 for hole transport materials in pervoskite solar cells: fabrication, characterization, and simulation. Opt. Mater. (Amst). 132, 112820 (2022).

Singh, N., Agarwal, A. & Agarwal, M. Performance evaluation of lead–free double-perovskite solar cell. Opt. Mater. (Amst). 114, 110964 (2021).

Alipour, H. & Ghadimi, A. Optimization of lead-free perovskite solar cells in normal-structure with WO3 and water-free PEDOT: PSS composite for hole transport layer by SCAPS-1D simulation. Opt. Mater. (Amst). 120, 111432 (2021).

Shamna, M. S. & Sudheer, K. S. Device modeling of Cs2PtI6-based perovskite solar cell with diverse transport materials and contact metal electrodes: a comprehensive simulation study using solar cell capacitance simulator. J. Photonics Energy. 12, 1–17 (2022).

Mohammed, K. A. M. et al. Improving the performance of perovskite solar cells with carbon nanotubes as a hole transport layer. Opt. Mater. (Amst) 138, (2023).

Mottakin, M. et al. Photoelectric performance of environmentally benign Cs2TiBr6-based perovskite solar cell using spinel NiCo2O4 as HTL. Optik (Stuttg). 272, 170232 (2023).

Jarwal, D. K., Dubey, C., Baral, K., Bera, A. & Rawat, G. Comparative analysis and performance optimization of low-cost solution-processed hybrid perovskite-based solar cells with different organic HTLs. IEEE Trans. Electron. Devices. 69, 5012–5020 (2022).

Karthick, S., Bouclé, J. & Velumani, S. Effect of bismuth iodide (BiI3) interfacial layer with different HTL’s in FAPI based perovskite solar cell – SCAPS – 1D study. Sol Energy. 218, 157–168 (2021).

Pochont, N. R. & Sekhar, Y. R. Numerical simulation of nitrogen-doped titanium dioxide as an inorganic hole transport layer in mixed halide perovskite structures using SCAPS 1-D. Inorganics 11, 1–17 (2023).

Burgelman, M., Nollet, P. & Degrave, S. Modelling polycrystalline semiconductor solar cells. Thin Solid Films. 361–362, 527–532 (2000).

Burgelman, M., Decock, K., Khelifi, S. & Abass, A. Advanced electrical simulation of thin film solar cells. Thin Solid Films. 535, 296–301 (2013).

Hossain, M. K. et al. An extensive study on multiple ETL and HTL layers to design and simulation of high-performance lead-free CsSnCl3-based perovskite solar cells. Sci. Rep. 13, 2521 (2023).

Mouhib, H. et al. Numerical investigation of eco-friendly MASnI3 perovskite-based solar cell: effect of defect density and hole transport layer. Model. Simul. Mater. Sci. Eng. 30, 035011 (2022).

Kumar, S. & Murugesan, M. Lead-free and stable potassium titanium halide perovskites: synthesis, characterization and solar cell simulation. Energies 15, (2022).

Cheng, N. et al. A simulation study of valence band offset engineering at the perovskite/Cu2ZnSn(Se1-xSx)4 interface for enhanced performance. Mater. Sci. Semicond. Process. 90, 59–64 (2019).

Bala, N. & Kumar Mallik, S. Investigation of impact of kesterites as hole transport layer on (FA)2BiCuI6 based ecofriendly double perovskite solar cell to obtain optimized PCE above 25%. Results Opt. 16, 100731 (2024).

Jan, S. T. & Noman, M. Comprehensive analysis of heterojunction compatibility of various perovskite solar cells with promising charge transport materials. Sci. Rep. 13, 19015 (2023).

Nisika et al. Energy level alignment and nanoscale investigation of a-TiO2/Cu-Zn-Sn-S interface for alternative electron transport layer in Earth abundant Cu-Zn-Sn-S solar cells. J. Appl. Phys. 126, 193104 (2019).

Arockiya Dass, K. T., Hossain, M. K. & Marasamy, L. Highly efficient emerging Ag2BaTiSe4 solar cells using a new class of alkaline earth metal-based chalcogenide buffers alternative to cds. Sci. Rep. 14, 1473 (2024).

Hosen, R. et al. Effect of various layers on improving the photovoltaic efficiency of Al/ZnO/CdS/CdTe/Cu2O/Ni solar cells. J. Alloy Metall. Syst. 4, 100041 (2023).

Yu, M. et al. The influence of the electron transport layer on charge dynamics and trap-state properties in planar perovskite solar cells. RSC Adv. 10, 12347–12353 (2020).

Tress, W. et al. The role of the hole-transport layer in perovskite solar cells - reducing recombination and increasing absorption. https://doi.org/10.1109/PVSC.2014.6925216 (2014).

Liu, Y. et al. Influence of hole transport layers on internal absorption, charge recombination and collection in HC(NH2)2PbI3 perovskite solar cells. J. Mater. Chem. A. 6, 7922–7932 (2018).

Taheri, S., Ahmadkhan kordbacheh, A., Minbashi, M. & Hajjiah, A. Effect of defects on high efficient perovskite solar cells. Opt. Mater. (Amst). 111, 110601 (2021).

Astakhov, O. et al. Relationship between absorber layer defect density and performance of a-Si:H and µc‐Si:H solar cells studied over a wide range of defect densities generated by 2 mev electron bombardment. Sol Energy Mater. Sol Cells. 129, 17–31 (2014).

Kavanagh, S. R., Scanlon, D. O., Walsh, A. & Freysoldt, C. Impact of metastable defect structures on carrier recombination in solar cells. Faraday Discuss. 239, 339–356 (2022).

Ranjan, R. et al. SCAPS study on the effect of various hole transport layer on highly efficient 31.86% eco-friendly CZTS based solar cell. 13.

Wahid, M. F. et al. Performance enhancement of lead-free CsSnI3 perovskite solar cell: design and simulation with different electron transport layers. IEEE Access. 12, 8296–8312 (2024).

Hossain, M. K. et al. Numerical simulation and optimization of a CsPbI3-based perovskite solar cell to enhance the power conversion efficiency. New. J. Chem. 47, 4801–4817 (2023).

Heredia-Rios, M. J., Hernandez-Martinez, L., Linares-Aranda, M., Moreno-Moreno, M. & Méndez, J. F. Analysis of losses associated with series resistance (Rs) in simple-structured c-Si solar cells. Energies 17 https://doi.org/10.3390/en17071520 (2024).

Sarker, K., Sumon, M. S., Orthe, M. F., Biswas, S. K. & Ahmed, M. M. Numerical simulation of high efficiency environment friendly CuBi2O4-Based Thin-Film solar cell using SCAPS-1D. Int. J. Photoenergy. 2023, 2–12 (2023).

Valeti, N. J., Prakash, K. & Singha, M. K. Numerical simulation and optimization of lead free CH3NH3SnI3 perovskite solar cell with CuSbS2 as HTL using SCAPS 1D. Results Opt. 12, 100440 (2023).

Dhass, A. D., Natarajan, E. & Ponnusamy, L. Influence of shunt resistance on the performance of solar photovoltaic cell. In Proc. - ICETEEEM 2012, Int. Conf. Emerg. Trends Electr. Eng. Energy Manag. 382–386 https://doi.org/10.1109/ICETEEEM.2012.6494522 (2012).

Huang, X., Han, S., Huang, W. & Liu, X. Enhancing solar cell efficiency: the search for luminescent materials as spectral converters. Chem. Soc. Rev. 42, 173–201 (2013).

Chen, M. et al. Cesium titanium(IV) bromide thin films based stable lead-free perovskite solar cells. Joule 2, 558–570 (2018).

Samanta, M., Ahmed, S. I., Chattopadhyay, K. K. & Bose, C. Role of various transport layer and electrode materials in enhancing performance of stable environment-friendly Cs2TiBr6 solar cell. Optik (Stuttg). 217, 164805 (2020).

Chakraborty, K., Choudhury, M. G. & Paul, S. Study of physical, optical, and electrical properties of cesium titanium (IV)-based single halide perovskite solar cell. IEEE J. Photovoltaics. 11, 386–390 (2021).

Moiz, S. A., Alahmadi, A. N. M. & Aljohani, A. J. Design of a novel lead-free perovskite solar cell for 17.83% efficiency. IEEE Access. 9, 54254–54263 (2021).

Mamta, Maurya, K. K. & Singh, V. N. Sb2Se3 as an HTL for Mo/Sb2Se3/Cs2TiF6/TiO2 solar structure: performance evaluation with SCAPS-1D. Heliyon 8, e10925 (2022).

Acknowledgements

The SCAPS-1D program was kindly provided by Dr. M. Burgelman of the University of Gent in Belgium. This work was funded by the Researchers Supporting Project Number (RSPD2025R763) King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

M. K. Hossain: Conceptualization, Methodology, Software, Validation, Formal analysis, Investigation, Data curation, Writing – original draft, Writing – review & editing, Supervision, Project administration; K.M. Sadat, M.S. Uddin, and A.K. Datta: Software, Validation, Formal analysis, Investigation, Data curation, Writing – original draft; P. Kanjariya, M.S. Reddy, R. Kalia, B. Selvaraj, A.A.A. Bahajjaj, R. Balachandran, A. Hajjiah, and R. Haldhar: Validation, Formal analysis, Writing – review & editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hossain, M., Sadat, K., Uddin, M. et al. An investigation of hole transport layers and electron transport layers to produce highly efficient K2TiI6-based perovskite solar cells. Sci Rep 15, 19014 (2025). https://doi.org/10.1038/s41598-025-98351-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-98351-y