Abstract

Rocking foundations offer potential benefits, such as energy dissipation and reduced superstructure ductility demand during severe earthquake loadings. However, it can result in residual deformations at the soil-foundation interface, and uncertainties regarding its performance still remain, particularly for pile-supported structures. For the foundation of structures like tall bridges supported by pile groups, the system’s behavior during rocking motions can be influenced by various factors, such as static vertical safety factor, pile-to-cap connection, and pile length. The present study explores influences of pile-to-cap connections on the rocking behavior of the system for different pile group lengths and static safety factors. A physical single-degree-of-freedom (SDOF) structural model with a novel semi-fixed pile-to-cap connection was developed for this study. Results indicate that unrestricted rocking on unattached connections lead to significantly lower residual settlements than those for fixed connections. Also, semi-fixed connections reduce settlements for long pile groups, with a slight decrease in resistance moment capacity. Moreover, unattached connections demonstrate a superior energy dissipation ratio of the system compared to that for fixed ones, in long pile groups with low bearing safety factors. The current study would expand our insight into the performance of different pile-to-cap connections under various conditions during rocking motions.

Similar content being viewed by others

Introduction

Over the past few decades, it has become evident that conventional foundation design codes, such as EC81, which avoid mobilizing the full capacity of the soil bed, do not necessarily lead to a safe structure under extremely large and unforeseen earthquakes. Therefore, designing a structure to behave elastically and experience no residual drift under unpredictable large earthquakes presents a significant challenge. In such cases, designing very large and strong foundations becomes not only uneconomical but potentially insufficient for achieving a safe design.

Thankfully, recent studies demonstrate that rocking foundations can be a valuable strategy for improving overall seismic performance2. When the structure’s foundation is allowed to some limited uplift and rotation about its longitudinal axis, rocking foundation occurs, and the structure’s performance during this motion is noted as the rocking behavior. Numerous investigations using small-scale3,4,5,6 and large-scale physical models7,8 under gravity (1 g) conditions, models subjected to higher acceleration with centrifuges9,10,11,12,13,14,15, and various numerical modeling techniques16,17,18,19, have investigated foundation uplift and rocking behavior. These studies consistently demonstrate that rocking foundations can lead to several benefits namely: reduced ductility demand in the superstructures, minimized residual and plastic drift within the structure, and decreased base shear forces applied to the structure due to energy dissipation at the soil-foundation interface2,10,15,17. Figure 1 compares the performance of a bridge with a conventional foundation to that of a bridge with a rocking foundation.

Despite the growing interest in rocking behavior and its benefits, some concerns regarding possible structure overturning following uplift still remain. Additionally, uncertainties associated with the rocking performance require further investigations. Consequently, many foundation design codes, with the exception of the New Zealand Structural Design Code20, still do not explicitly consider the nonlinear behavior of foundations. This code acknowledges the potential benefits of rocking as an energy dissipation mechanism but emphasizes the need for detailed modeling and study in such cases. Furthermore, foundation rocking can lead to residual deformations in the bed soil, such as settlement and rotation, which can impair the serviceability of the structure. Fortunately, various soil rehabilitation techniques can be employed to mitigate these residual deformations. These techniques include soil layer compaction3,4, geogrid and geocell reinforcement5, concrete pads13, and unattached piles8,21. As the understanding of the rocking behavior grows and its drawbacks diminish, this phenomenon can be utilized to enhance the stability of critical structures, such as bridges.

Bridges, as crucial components of urban and intercity infrastructure, play a pivotal role in transportation networks. Damage or collapse of these structures not only incurs substantial repair costs but also disrupts traffic flow for extended periods. Extensive research has demonstrated the potential of employing rocking behavior in bridge foundations as an effective seismic mitigation strategy. Anastasopoulos et al.22 using numerical modeling provided evidence that rocking bridge foundations can maintain stability under severe earthquakes, albeit with some foundation settlement and rotation, while bridges with conventional foundations experienced failure.

Moreover, bridges are subjected to substantial loads from various sources, including structural weight, traffic, wind, and seismic events. These forces exert significant stresses on the bridge foundation system. When the foundation site lacks adequate load-bearing capacity, deep foundations or pile groups become necessary to control settlement and enhance bearing capacity. Consequently, the rocking behavior of piled-raft foundations, where the bridge’s cap or raft sits on a pile group, requires careful consideration.

Numerous studies have explored the rocking behavior of piled foundations. Allmond & Kutter23 investigated the rocking behavior of piled foundations in liquefiable soils, highlighting the critical role of the pile-to-cap connection during rocking motions. Their research demonstrated that unattached connections with shear keys effectively prevented sliding while allowing cap separation. Additionally, Antonellis & Panagiotou24 and Rele et al.25 using numerical modeling explored the rocking behavior of bridge piled foundations. Numerical modeling case study by Sakellariadis et al.26 show the benefits of rocking behavior in existing piled foundations of the bridges with retrofitted and widened decks. Guan et al.8 employed large-scale physical model tests (scale factor of 1/5) to compare the behavior of fixed and unattached (free) pile-to-raft connections. To prevent damage to the connection during uplift and downward movements of the raft, rubber sheets were placed between the raft and pile heads. Their study revealed that the free pile-to-raft connection model experienced significantly less residual drift, cracking, and overall damage compared to the fixed connection model. Ko et al.27 utilized centrifuge modeling to investigate the behavior of the fixed and free connections for the model with short piles (length less than two-thirds of the raft width) under a high static vertical safety factor (≈ 10). The latter study indicated that the foundation settlement was considerably greater in the fixed connection model compared to that in the free connection. Additionally, the damping ratio was also observed to be higher in the fixed connection.

However, it’s important to note that these valuable studies examined the behavior of fixed and free connections within a limited scope, focusing on a single pile model configuration. Also, Moosavian et al.28 conducted a study using a small-scale physical model to examine the impact of the pile length on rocking behavior, but exclusively for free connection models. More recently, Siber & Anastasopoulos29 used numerical modeling to explore the seismic behavior of bridges with piled foundations, comparing configurations with different pile counts. Their study only demonstrated that models with fewer piles facilitated full mobilization of soil-foundation bearing capacity, reducing the bridge’s flexural demand without pile damage. Consequently, a comprehensive study of pile-to-cap connections and their key role in the rocking behavior of piled foundations remains lacking.

On the other hand, several studies on shallow foundations indicated the crucial role of the foundation’s static vertical safety factor (FSV) on rocking behavior. Studies3,4,6 have shown that foundations with high FSV tend to uplift rather than sinking during rocking motions. Besides, pile group length can significantly impact the foundation’s rocking stiffness, energy dissipation capacity, and residual settlements following an earthquake event. Unfortunately, a critical knowledge gap exists regarding the combined effects of pile group length, FSV, and pile head connection type on the rocking behavior of piled-raft foundations. Therefore, this study intends to expand the investigation for considering a wider range of safety factors and pile group lengths. This broader investigation allows for a more comprehensive understanding of the seismic performance of pile-to-raft connections under different circumstances.

Furthermore, according to the importance of a bridge serviceability, the concept of controlled rocking for bridges’ piled-foundation has gained traction in recent study30. This research also explores a novel semi-fixed pile-to-raft connection developed to achieve some limited rocking behavior. This innovative system prevents complete separation of the raft from the pile group while allowing for a controlled vertical degree of cap uplift unlike a fully fixed connection. In other words, the connection utilizes not only the superstructure’s weight for recentering but also incorporates restraining mechanisms to manage bridge deck displacement.

In summary, present study aims to investigate the performance of three pile-to-raft connection types (fixed, semi-fixed, and free) under eight different combinations of static vertical safety factors and pile group lengths. The investigation employs a small-scale physical model of an SDOF structure subjected to slow cyclic loads. The model was developed in the Soil Dynamics Laboratory of Amirkabir University of Technology. To assess the performance of three connection types, this study evaluates key parameters such as normalized moment, rocking stiffness, energy damping ratio, and residual settlement.

Methods and materials

Physical model (structure & piled-raft) description

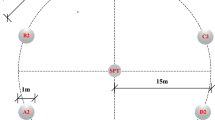

The present study employs a single-degree-of-freedom (SDOF) model representing a simplified cross-section of a bridge structure. A concentrated mass, representing the bridge deck, is achieved by placing weight plates on two platforms integrated into the model. This concentrated mass is connected to the 15 cm × 15 cm steel rigid square footing (pile cap) with 2 cm thickness, through a single pier. The center of mass is located at 45 cm above the foundation base. The ratio of the mass center height to base width (h/B) exceeding 2.5 ensures that rocking behavior dominates over sliding in the foundation, justifying the exclusion of sliding in this study. To limit deformations to the soil-foundation interface, the structure and its component connections (deck-to-pier and pier-to-pile cap) are modeled as rigid. Also, an abrasive sheet is attached to the foundation bottom to simulate the friction between the footing base and soil.

Four piles are placed at the corners of the footing as shown in Fig. 2. The diameter of the piles is 2 cm, and the distance between center to center of piles is 12 cm. The pile-to-cap connections are implemented in three forms: fully fixed, free (unattached), and semi-fixed, as described below:

The Fixed Connection This connection restrains rotation, horizontal, and vertical displacements at the pile head relative to the pile cap. A nut tightens the threaded section of the pile head after placement in the cap hole to achieve this fixed connection. This kind of pile-to-cap connection is depicted in Fig. 2-b and 3.

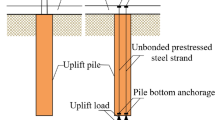

The Free (unattached) Connection This configuration, shown in Figs. 2-a and 3, allows vertical displacement and rotation at the pile head-to-cap interface. However, a shear key prevents horizontal displacement and sliding, similar to the approach used by Allmond & Kutter23.

The Semi-Fixed Connection This kind of connection, as illustrated in Fig. 3, is similar to the fixed connection; however, unlike the fixed connection, the semi-fixed connection allows for a limited amount of initial vertical displacement at the pile head (Fig. 4). After exceeding a predetermined displacement value (4 mm), the vertical displacement becomes restrained. Figures 3b and 4 demonstrate that a pin embedded in the pile’s hollow stem controls cap displacement by interacting with the slotted hole walls. This slotted hole is covered with rubber to prevent sand intrusion, as trapped sand particles would restrict the cap’s intended vertical freedom.

To comprehensively investigate the behavior of pile-to-raft connections under various conditions, three pile group lengths are considered: short (10 cm by L/B = 2/3), medium (30 cm by L/B = 2), and long (50 cm by L/B = 3.3), where B is the foundation width (15 cm). For each pile group length, multiple static safety factors are evaluated. This involves changing the superstructure surcharge or weight for a given pile group length with a specific bearing capacity, resulting in variations in the foundation’s vertical static safety factor. Consequently, the performance of the three pile-to-raft connection types is examined under different combinations of pile group lengths and static safety factors.

To ensure accurate representation of prototype behavior, all dimensions and specifications of the physical model were scaled by a consistent factor of 1/20, as indicated by N = 20 in Table 1. This table details the relationships between model and prototype quantities, including the scaling factor for each parameter. These scaling factors are derived from the well-established principles of the dimensional analysis applied to small-scale physical model under 1 g conditions31. Recognizing that the soil’s elastic modulus is influenced by confining stress, Table 1 incorporates an alpha exponent into its scaling factor. This exponent assumes a value of 0.5 for sand and 1 for clay. The scaling law of the model dimensions can be referenced to the past relevant studies (like Asli et al.5).

The schematic view of the physical model with the testing apparatus is depicted in Fig. 5. The pile group is considered floating since the tip of the longest pile is sufficiently far from the tank floor. Considering the container depth and the soil height of 70 cm, the distance between the tip of the longest pile (50 cm) and the container base exceeds 10 times the pile diameter and is greater than the pile cap width (15 cm), minimizing the container’s base effects.

The testing system

The testing setup consists of two independent loading systems, clearly illustrated in the overall view of the model and apparatus (Fig. 6). One system applies vertical loading to evaluate the foundation’s vertical bearing capacity, while the other applies horizontal cyclic loading to perform rocking tests.

The vertical loading system

In the vertical loading system, a pneumatic pressure cylinder applies a vertical load to a rigid plate with dimensions identical to the pile cap. A load cell and a vertical LVDT connected to a data logger measure the applied vertical load and resulting displacement of the foundation accurately.

The horizontal loading system

As shown in Figs. 5 and 6, the horizontal loading system, used for rocking tests, induces horizontal cyclic displacement at the center of masses of the model superstructure through a servomotor. This system allows for rotation, settlement, and sliding of the structure foundation due to the model’s central hinged joint and a sliding joint at the connection of the superstructure to the lateral displacement arm. The system utilizes various instruments connected to a data logger. A rotary encoder attached to the center and back of the superstructure measures the structure’s rotation. An LVDT positioned on the foundation measures the foundation’s settlement. A load cell connected to the lateral displacement lever measures the force applied to displace the model. All these measurements are collected through a data logger to analyze the model’s rocking responses.

Soil properties and bed preparation procedures

In this study, standard uniform dry silica Firouzkouh sand, known as D1, was employed as the bed soil. The soil’s main properties are summarized in Table 2.

The soil’s behavior under loading is influenced by its initial state relative to the critical state line, which is dependent upon both the void ratio and the confining stress. In geotechnical tests, the vertical distance (void ratio difference) of both the model and prototype soils from the critical state line must be equalized to replicate prototype soil behavior. To achieve this, when the stress on the model soil is reduced, its void ratio is increased, loosening the model soil, thus equalizing the vertical distance from the critical state line. Given the typical sand’s critical state line slope of 0.03 (Wood31), and the soil’s maximum and minimum void ratios (Table 2), the relative density of both the model soil and the prototype soil sample is determined using Eq. 1. In Eq. 1, \({e}_{P}\), \({e}_{M}\), \(\lambda\), and N are respectively, the prototype soil’s void ratio, the model soil’s void ratio, critical state line slope, and the scale factor of the physical model (N = 20). For the purposes of this study, the model soil is prepared in a looser state, with a relative density of 50% (eM = 0.71), to simulate the behavior of soil with a relative density of 85% (eP = 0.62) under field conditions.

Soil container (testing tank)

A rigid-walled soil container of 128 cm in length, 84 cm in width, and 76 cm in height is employed. Plexiglas sheets were installed along two longitudinal sides of the container to visualize soil deformations and particle’s movements.

The bed soil preparation method

A raining system is utilized to uniformly fill the container as displayed in Fig. 7. This method allows for controlling the relative density of the bed soil by adjusting the height of the hopper and the rate of the sand discharge. The hopper’s dimensions (122 cm length, 78 cm width, and 35 cm height) were chosen to cover the container’s surface entirely. To get the appropriate height of pouring for required density, the raining system was calibrated using different raining heights. The calibration data is given in Table 3, from which the height of 20–25 cm would meet the relative density of 50% for the bed soils in experiments.

The careful preparation of the tests and the gentle placement of the structure on the pile group, minimized soil disturbance, leading to highly repeatable results, as evidenced by Figs. 19 and 20.

Determination of the vertical safety factor

Vertical loading tests were conducted to obtain a reliable assessment of the vertical safety factor of the piled rafts. Figure 8 presents a compilation of the vertical bearing capacity curves for the model with varying pile lengths. The bearing capacity was determined using the intersection point of two tangent lines drawn to the respective curve, as shown in the Fig. 8.

Simulation of rocking and uplift

Seismic loads, transmitted through bedrock and soil layers to the structure, induce lateral displacements. Structures with concentrated mass, such as tall bridges, can be modeled as SDOF systems to analyze earthquake-induced displacements. Alternatively, applying earthquake-induced displacements directly to the structure’s mass center can simulate seismic excitation. Studies7,9 have shown comparable ultimate responses under both direct bedrock excitation and mass center horizontal displacement loading. Consequently, the current study employs slow cyclic displacement to simulate foundation rocking. A slow loading rate of 1 mm/s was selected to minimize inertial effects5. This cyclic displacement consisted of three phases, with the number of cycle repetitions and the amplitude of each loading phase specified in Fig. 9. The parameter d/dCr represents a drift ratio, normalized by the critical drift (dCr). Critical drift refers to the displacement required to overturn an SDOF structure placed on the rigid base, equaling half of the foundation’s width.

The testing program

To cover all parameters under investigations, twenty-four tests were performed within eight series. Table 4 presents the pile length, vertical static safety factor (FSV), and bearing capacity for each test series.

Each test code given in next sections, uniquely identifies model characteristics such as pile group length, vertical static safety factor, and pile-to-cap connection type. For example, the code: '50 FREE L’ signifies a 50cm length pile group with a free connection to the cap under light loading or high safety factor (FSV = 10). To summarize, test codes combine the terms ‘FREE’, ‘SEM’, and ‘FIX’ (representing free, semi-fixed, and fixed connections, respectively) with the series ID from Table 4.

Testing results

This section initially examines moment-rotation & settlement-rotation curves for fixed and free pile-to-cap connections under some different pile group lengths and safety factors. Subsequently, the impact of semi-fixed connections on these curves is discussed. The study then explores the effects of pile-to-cap connection type on rocking stiffness, residual settlement, and energy damping ratio under all considered conditions.

Fixed versus free connections

Figure 10 presents moment-rotation and settlement-rotation curves for the fixed and free pile-to-cap connections under different safety factors and pile group lengths. The rocking moment is normalized using the overturning moment of an SDOF structure with mass M and foundation width B on a rigid base, which equals to MgB/2. The model rotation is normalized by the overturning angle (arctan(0.5H/B)), and also the foundation settlement or displacement is normalized by the footing width (B).

As evident in Figs. 10a and d, with an increase in loading amplitude during phase three, the foundation on free piles reaches its threshold uplift whereas, in the fixed connection due to existing resistance, the uplift is much smaller. Figure 10d clearly highlights the difference between settlements and uplifts of footings rested on fixed and free long (50cm) piles under medium safety factor (FSV = 7).

Figure 10a, reveals that in the fixed connection model, the moment increases significantly with growing load amplitude until the load direction reverses and unloading begins. In contrast, the resistance moment in the free connection model remains constant following foundation uplift.

The moment-rotation trend in Fig. 10b is similar to that in Fig. 10a. Additionally, Fig. 10e demonstrates that for a heavier load (i.e.: lower static vertical safety factor, FSV = 4), no uplift occurs during rocking motions, even in the free connection model. However, foundation settlement is still less in the free connection model compared to that in the fixed connection model.

Figure 10c shows that short pile groups with fixed connections mobilize less resistance than longer piles. Consequently, the difference in rocking moment between free and fixed connections decreases, making the two curves more similar.

Figure 10-f indicates that for short piles under a low safety factor, the footing does not uplift even in the free connection model. However, foundation settlement remains smaller in the free connection compared to that in the fixed connection model. In all cases depicted in Fig. 10, the footing rotation is greater in the free connection model relative to the fixed connection model.

Semi-fixed connections

Figure 11 presents the moment-rotation and settlement-rotation curves for a 50 cm pile group model under high static safety factor (FSV = 10) with three distinct pile-to-cap connection types. Figure 11 sections a & d, b & e, c & f respectively show the moment-rotation and settlement-rotation curves for fixed, semi-fixed, and free connections.

In the semi-fixed connection, due to the limited vertical degree of freedom, the footing initially uplifts. Then, as the foundation reaches the maximum allowable vertical freedom, the restraint connection becomes activated, mitigating further uplift. Beyond a normalized angle of 0.1, foundation uplift is effectively constrained, and the connection behaves similarly to a fully fixed connection. At maximum rotations, the resistance moment increases exponentially. In this condition, the semi-fixed connection’s performance is similar to that of the fixed connection with a slightly greater foundation rotation and a marginally lower resistance moment.

The settlement-rotation curves in Figs. 11 and 12 demonstrate that the foundation displacement mechanism in the semi-fixed connection model lies between the free and fixed ones.

As shown in Fig. 12, The free connection model exhibits a footing uplift of approximately 2% of the footing width (B) per loading cycle. In contrast, the semi-fixed connection experiences a significantly smaller uplift of about 0.5% per cycle. The fixed connection, however, undergoes a settlement of approximately 0.5% of the footing width during unloading.

It is important to note that during rocking motions, the bed soils become more compacted in the direction of initial loading, mobilizing the resistance around the piles under compression. Consequently, foundation settlement during unloading is slightly more pronounced compared to that of the loading phase. This observation holds true for all three connection types.

Figure 13 depicts the soil disturbance resulting from rocking test for the model with 30 cm piles and a medium safety factor (FSV = 7). Figure 13a, b, and c correspond to the free, fixed, and semi-fixed connections, respectively. In Fig. 13b, both soil settlement and heaving respectively beneath and beyond the footing are clearly visible. Based on Fig. 13, Soil disturbance intensity and settlement around the foundation in the fixed connection model is greater than those in the free connection model. Figure 13c shows that the extent of soil disturbance is intermediate between that of the fixed and free connections.

Prior to discussing the rocking stiffness and damping energy ratio of the system, these parameters have to be defined. Also, the normalized rotation amplitude (NRA) and normalized moment amplitude (NMA) parameters would be introduced. NMA and NRA define the variation range of normalized moment and rotation per cycle, respectively. Based on Fig. 14, NMA is determined by summing the maximum and minimum normalized moment within a single cycle; similarly, NRA is calculated by summing the maximum and minimum normalized rotation within a cycle.

As illustrated in Fig. 14, rocking stiffness is defined as the ratio of the sum of moments corresponding to maximum and minimum rotation to the sum of maximum and minimum rotations.

The energy dissipation ratio is determined by the ratio of the area enclosed by a hysteresis loop to the maximum input energy in a cycle.

Equations 2 and 3 present the equations for determining stiffness and energy dissipation ratio. It is noteworthy that the rocking stiffness is dimensionless since it is calculated from the normalized moment.

The rocking stiffness

To investigate the influence of pile-to-cap connection type on the rocking stiffness, the variation of rocking stiffness with respect to normalized rotation amplitude (NRA) for a representative model is initially presented in Fig. 15. Subsequently, the maximum rocking stiffness for all models under varying pile group lengths and safety factors is given in Table 5.

Figure 15 presents data for a model with a 50 cm pile group and medium safety factor, where each point represents a test cycle. The figure shows that the free connection model experiences the greatest footing rotation, while the fixed connection model exhibits the least. Additionally, Fig. 15 also indicates that the rocking stiffness decreases with increasing footing rotation.

Based on Fig. 15 and Table 5, the fixed connection model has the highest rocking stiffness, followed by the semi-fixed model, while the free connection model having the lowest.

Due to the initial resistance against uplift in the fixed connection, the stiffness obtained in each cycle within the fixed connection model surpass those observed in other models. In the semi-fixed connection model, with a limited vertical degree of freedom, the foundation’s resistance against uplift is initially reduced, so the stiffness in the semi-fixed connection model is lower than that in the fixed connection model. However, after reaching the defined uplift level, the semi-fixed connection also reaches full fixity, and its resistance against uplift increases, so the stiffness in the semi-fixed connection will be greater than that in the free connection model.

Additionally, Table 5 shows that variations in pile group length and safety factor have no significant impacts on the differences in rocking stiffness between the various connection types. This is evidenced by the consistent stiffness ratios between the fixed and free connections (column 4 of Table 5) and between the semi-fixed and fixed connections (column 6 of Table 4) across different conditions.

It should be noted that in this analysis, the rocking stiffness calculated from the results for each loading cycle, as depicted in Fig. 14 and Eq. 2, differs from that of the residual rocking stiffness remaining after loading.

Residual settlements

To examine the impact of connection type on the residual settlement, Fig. 16 presents the residual settlement at the end of each loading phase after five cycles, plotted against the NRA for a representative model. Also, Table 6 provides a summary of the last residual settlements for all connection types across various conditions. Figure 16 clearly demonstrates that the residual foundation settlement increases with increasing the NRA.

Figure 16 and Table 6 show that, regardless of pile length and safety factor, foundations with free connections settle the least, while those with fixed connections settle the most. Semi-fixed connections fall between these two extremes. The increased settlement of fixed connections can be attributed to cyclic two-way (compression-tension) loading on the piles during rocking. This causes more severe soil degradation around the piles compared to that for free connections (as shown in Fig. 13), where the piles are subjected to one-way compressive loading, resulting in greater settlement.

Figure 16 clearly shows that as the safety factor increases, the difference in settlement between different connection types becomes more pronounced. Additionally, Table 6 confirms that this difference in settlement is also more significant for longer pile group. For instance, a 50 cm pile group under light loads or high safety factors experiences a 226% greater settlement in the fixed model compared to that in the free model. However, under heavy loads, this difference reduces to about 8% for the same pile length. For short 10 cm pile groups under heavy loads, the settlement difference is only 4%. These results indicate that the settlement difference between connection types is most pronounced for long pile groups under high safety factors, where the uplift potential is greatest.

Figure 16 and Table 6 demonstrate that by only limited vertical degree of freedom in the semi-fixed connection, the residual foundation settlement is reduced compared to that in the fixed connection. Specifically, for long pile group lengths under high safety factors, the residual settlement in the semi-fixed connection model is reduced by 20% to 30% relative to that in the fixed connection model.

The damping ratio

It is essential to note that, according to Eq. 3, the energy dissipation ratio of the system is proportional to hysteretic damping. Hysteretic damping encompasses total energy dissipation, which includes not only material viscous damping but also damping due to soil yielding, foundation impacts, and soil disturbance around piles in piled foundations. As a result, the piled foundation characteristics influence the damping ratio and maximum energy absorbed by the system.

To streamline the analysis, Fig. 17 initially compares the energy dissipation ratio per cycle for fixed and free connections under different pile group lengths (50 cm and 10 cm) and safety factors (FSV = 10 and FSV = 4). Subsequently, Fig. 18 illustrates the energy dissipation ratio with respect to NRA for a single model with all three connections. For a comprehensive overview, Table 7 summarizes the average damping ratio for each model under all studied conditions.

Figure 17a and Table 7 reveal that for medium (30 cm) and long (50 cm) pile lengths (i.e.: L > 2B), the fixed connection exhibits a higher energy dissipation ratio than that for the free connection under a high safety factor (FSV = 10). Conversely, under low (FSV = 4) and medium (FSV = 7) safety factors, the free connection exhibits a higher ratio.

This seemingly paradoxical behavior can be attributed to the interplay between soil disturbance around the piles and the influence of the foundation’s safety factor. In long (L > 2B) pile groups, under high safety factor or light loading conditions, the fixed connection leads to greater soil disturbance around the piles compared to that of the free connection (Fig. 13). This increased soil disturbance contributes to higher energy dissipation in the fixed connection, resulting in a higher damping ratio. In contrast, as loading increases and safety factor decreases, the energy dissipation due to soil yielding beneath the foundation becomes more pronounced, while the energy dissipation due to soil disturbance around the piles diminishes because of reduction in foundation uplift potential.

Additionally, under low safety factor conditions, as shown in the moment-rotation curves of Fig. 10, when the footing rotation increases, the resistance moment for the fixed connection increases exponentially, leading to a higher maximum energy absorbed by the system. However, for the free connection, the resistance moment remains relatively constant with increasing rotation amplitude, resulting in lower energy absorption compared to that for the fixed connection. Consequently, under low safety factor, the denominator of the damping ratio, which is the maximum energy absorbed by the system, increases in the fixed connection, leading to a decrease in the damping ratio compared to that in the free connection.

Figure 17b and Table 7 demonstrate that for short pile groups (10 cm, L < B), shorter than the foundation width, under both moderate and heavy loadings, fixed connections exhibit higher damping ratios than free connections. Due to limited soil mobilization around short piles, the maximum moment resistance is similar for both fixed and free connections (Fig. 10). Therefore, the maximum energy absorbed by the system is nearly equal for both connection types. As a result, the fixed connection model exhibits a higher energy dissipation ratio because of greater residual settlement.

Expanding upon Ko et al.27, who observed consistently higher energy damping ratio in fixed connections for short pile groups (L < B) under high safety factors (FSV > 10), the present study reveals a more nuanced relationship between connection type, energy damping, and other influencing parameters. Under different safety factors and pile group lengths, the free connection can even exhibit higher energy damping ratio than that of the fixed connection.

Figure 18 shows no clear correlation between energy dissipation ratio and NRA. However, due to the soil’s initial loose relative density, subsequent soil densification under repeated loading caused a gradual decrease in energy dissipation ratio as footing rotation increased.

Figures 18 and Table 7 show that the dissipation ratio for the semi-fixed connection generally follows the same pattern as the fixed connection. Because the semi-fixed connection results in less foundation settlement, its energy dissipation ratio is typically lower than that of fixed connection models. However, there is one exception in Table 7 where the semi-fixed connection has a higher ratio. The relationship between the fixed and free connections is mirrored by the semi-fixed and free connections. For instance, for short pile groups under all conditions and long pile groups under high safety factors, the semi-fixed connection has a higher damping ratio than that for the free connection.

Tests repeatability

To examine the reliability of experiments, four out of the 24 tests were repeated. These tests were randomly selected to encompass a diverse range of parameters, including pile group length, pile-to-cap connection types, and foundation safety factors.

A selection of the repeatability test results is presented in Figs. 19 and 20. These figures, respectively, illustrate the normalized moment amplitude (NMA) and residual settlement of each cycle for both 50 FIX H and 10 FREE H models. The consistent trends observed in the repeated tests for both NMA and residual settlement demonstrate the reliability of the experimental results.

Summary and conclusions

The present study investigates the performance of three types of pile-to-cap connections—free, semi-fixed, and fixed—under eight different conditions. These conditions vary in pile group length (2B/3, 2B, and 3.3B, B is the foundation’s width) and foundation static safety factor (FSV = 4, 7, and 10). The investigations were conducted using a small-scale physical model of a bridge developed in the soil dynamics laboratory of Amirkabir University of Technology. The square model foundation (B = 15 cm) rests on four rigid piles embedded in Firouzkouh D1 sand with a relative density of 50%. A novel semi-fixed connection, allowing limited vertical displacement, was introduced to explore the potential benefits of combining the characteristics of both free and fixed connections. Important outcomes regarding the rocking responses of piled foundations are as follows:

-

The primary factor influencing the performance of various pile-to-cap connections is foundation uplift. Conditions that amplify uplift, such as long pile groups and high safety factors, make the differences between connection types more noticeable.

-

Fixed connection models consistently exhibited higher resistance moments compared to those of semi-fixed and free models across all safety factor and pile group length conditions. Footing rotation was greatest in free models, followed by semi-fixed and then fixed models. Rocking stiffness, calculated based on cyclic load values, followed the same trend, with fixed models displaying the highest stiffness and free models the lowest. Pile shaft degradation were more pronounced in fixed connections due to two-way cyclic loading, resulted in greater residual settlement compared to those of semi-fixed and free connections. Conversely, free connections experienced the least residual settlement.

-

Semi-fixed connections, with the limited vertical degree of freedom, experience less soil disturbance and, consequently, less degradation. This fact results in lower residual settlements compared to those of fixed connections. For long pile groups under high safety factors, semi-fixed connections offer a substantial reduction in residual settlement (up to 30%) with only a 10% decrease in the resistance moment capacity. However, for shorter pile groups, semi-fixed connections would not perform optimally as the piles can move with the footing, reducing the effective constraint force. Also, the semi-fixed connections, in long piles, can enhance overturning prevention and control residual rotation.

-

The difference of energy damping ratio between fixed and free connection models depends on pile group length and safety factor. For short pile groups (shorter than the foundation width), under all safety factors (light and heavy loads), the damping ratio in fixed and semi-fixed connections is greater than that of the free connection model. In models with long pile groups (more than the twice of the foundation width), under high safety factors (FSV = 10, light loads), the damping ratio in fixed and semi-fixed connections is greater than that of free connections. However, under moderate (FSV = 7) or low safety factors (FSV = 4, heavy loads), the dissipation ratio in the free connection model is higher than that in fixed and semi-fixed connection models. The damping ratio for semi-fixed connections follows a similar trend to fixed connections but is generally lower.

As previous studies8,23,24,25,27,28,29 have not conducted such comprehensive investigations involving different types of pile-to-cap connections under different pile group lengths and safety factors, the findings of the present study would be a novel contribution to the area of rocking behavior of single degree of freedom structures rested on piled foundations.

Data availability

The datasets and findings generated and/or analyzed during this study are available from the corresponding author upon reasonable request.

Abbreviations

- FREE:

-

Free (Unattached) pile-to-cap connection

- FIX:

-

Fixed pile-to-cap connection

- SEM:

-

Semi-fixed pile-to-cap connection

- FSV, FS:

-

Vertical Static Safety Factor

- A/AC :

-

Critical contact area ratio

- d:

-

Applied displacement or deck’s drift

- dCr :

-

Critical deck’s drift

- MR :

-

Overturning moment

- m:

-

Structural mass

- B:

-

Footing or cap width

- D:

-

Pile’s diameter

- L:

-

Pile’s length

- \({\theta }_{R}\) :

-

Overturning rotation

- H:

-

Applied load center height

- \(\theta\) :

-

Foundation rotation

- NMA:

-

Normalized Moment Amplitude

- NRA:

-

Normalized Rotation Amplitude

- NM:

-

Normalized moment

- Kr:

-

Rocking stiffness

- \(\Delta {E}_{cycle}\) :

-

Dissipated energy

- \(\Delta {E}_{el}\) :

-

Maximum energy input to the system

- W:

-

Residual settlement

References

Eurocode 8 - Design of Structures for Earthquake Resistance -Part 2: Bridges. (1998).

Gazetas, G. 4th. Ishihara lecture: Soil–foundation–structure systems beyond conventional seismic failure thresholds. Soil Dyn. Earthq. Eng. 68, 23–39 (2015).

Anastasopoulos, I., Kourkoulis, R., Gelagoti, F. & Papadopoulos, E. Rocking response of SDOF systems on shallow improved sand: An experimental study. Soil Dyn. Earthq. Eng. 40, 15–33 (2012).

Drosos, V. et al. Soil-foundation-structure interaction with mobilization of bearing capacity: Experimental study on sand. J. Geotech. Geoenviron. Eng. 138, 1369–1386 (2012).

Asli, S. M., Hosseini, S. M. M. M. & Jahanirad, A. Effect of soil reinforcement on rocking isolation potential of high-rise bridge foundations. Soil Dyn. Earthq. Eng. 115, 142–155 (2018).

Moradi, M., Hosseini, S. M. M. M. & Khezri, A. Investigation of rocking mechanism of shallow foundations on sand via PIV technique. Earthq. Eng. Struct. Dyn. 52, 1762–1784 (2023).

Shirato, M. et al. Large-scale experiments on nonlinear behavior of shallow foundations subjected to strong earthquakes. Soils Found. 48, 673–692 (2008).

Guan, Z., Chen, X. & Li, J. Experimental investigation of the seismic performance of bridge models with conventional and rocking pile group foundations. Eng. Struct. 168, 889–902 (2018).

Gajan, S. & Kutter, B. L. Capacity, settlement, and energy dissipation of shallow footings subjected to rocking. J. Geotech. Geoenviron. Eng. 134, 1129–1141 (2008).

Gajan, S., Thomas, J. M., & Kutter, B. L. Soil-foundation-structure interaction: Shallow foundations. Centrifuge Data Report for test series SSG04. UCD/CGMDR Preprint at (2006).

Gajan, S., Kutter, B. L., Phalen, J. D., Hutchinson, T. C. & Martin, G. R. Centrifuge modeling of load-deformation behavior of rocking shallow foundations. Soil Dyn. Earthq. Eng. 25, 773–783 (2005).

Hakhamaneshi, M. & Kutter, B. L. Effect of footing shape and embedment on the settlement, recentering, and energy dissipation of shallow footings subjected to rocking. J. Geotech. Geoenviron. Eng. 142, 4016070 (2016).

Deng, L. & Kutter, B. L. Characterization of rocking shallow foundations using centrifuge model tests. Earthq. Eng. Struct. Dyn. 41, 1043–1060 (2012).

Deng, L., Kutter, B. L. & Kunnath, S. K. Centrifuge modeling of bridge systems designed for rocking foundations. J. Geotech. Geoenviron. Eng. 138, 335–344 (2012).

Kokkali, P., Abdoun, T. & Anastasopoulos, I. Centrifuge Modeling of Rocking Foundations on Improved Soil. J. Geotech. Geoenviron. Eng. 141, 4015041 (2015).

Gajan, S. & Kutter, B. L. Contact Interface model for shallow foundations subjected to combined cyclic loading. J. Geotech. Geoenviron. Eng. 135, 407–419 (2009).

Anastasopoulos, I. & Kontoroupi, Th. Simplified approximate method for analysis of rocking systems accounting for soil inelasticity and foundation uplifting. Soil Dyn. Earthq. Eng. 56, 28–43 (2014).

Sakellariadis, L., Anastasopoulos, I. & Gazetas, G. Fukae bridge collapse (Kobe 1995) revisited: New insights. Soils Found. 60, 1450–1467 (2020).

Khamesi, S. O. & Hosseini, S. M. MM A numerical study of influential parameters on rocking response of shallow foundations of single degree of freedom (SDOF) structures. J. Eng. Res. 11, 100055 (2023).

NZS-1170.5, Structural Design Actions, Earthquake Actions- New Zealand. (2004).

Ko, K.-W., Ha, J.-G., Park, H.-J. & Kim, D.-S. Soil-rounding effect on embedded rocking foundation via horizontal slow cyclic tests. J. Geotechn. Geoenviron. Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0001848 (2018).

Anastasopoulos, I., Gazetas, G., Loli, M., Apostolou, M. & Gerolymos, N. Soil failure can be used for seismic protection of structures. Bull. Earthq. Eng. 8, 309–326 (2010).

Allmond, J. D. & Kutter, B. L. Design considerations for rocking foundations on unattached piles. J. Geotech. Geoenviron. Eng. 140, 4014058 (2014).

Antonellis, G. & Panagiotou, M. Seismic response of bridges with rocking foundations compared to fixed-base bridges at a near-fault site. Bridg. Eng. 19, 1–14 (2014).

Rele, R. R., Dammala, P. K., Bhattacharya, S., Balmukund, R. & Mitoulis, S. Seismic behaviour of rocking bridge pier supported by elastomeric pads on pile foundation. Soil Dyn. Earthq. Eng. 124, 98–120 (2019).

Sakellariadis, L., Marin, A. & Anastasopoulos, I. Widening of existing motorway bridges: Pile group retrofit versus nonlinear pile-soil response. J. Geotech. Geoenviron. Eng. 145, 4019107 (2019).

Ko, K.-W., Ha, J.-G., Park, H.-J. & Kim, D.-S. Centrifuge modeling of improved design for rocking foundation using short piles. J. Geotech. Geoenviron. Eng. https://doi.org/10.1061/(ASCE)GT.1943-5606.0002064 (2019).

Moosavian, S. M. H., Ghalandarzadeh, A. & Hoseini, A. A rehabilitation approach for rocking foundations: Vertical-monotonic and horizontal-cyclic loading. Eng. Struct 245, 112814 (2021).

Sieber, M. & Anastasopoulos, I. Seismic performance of a rocking pile group supporting a bridge pier. J. Geotech. Geoenviron. Eng. 151, 4024145 (2025).

El-Hawat, O., Fatahi, B. & Taciroglu, E. Novel post-tensioned rocking piles for enhancing the seismic resilience of bridges. Earthq. Eng. Struct. Dyn. 51, 393–417 (2022).

Wood, D. M. Geotechnical Modelling. (CRC Press, 2004).

Author information

Authors and Affiliations

Contributions

All authors participated to the conception and design of the research. Material preparation, data collection and analysis were performed by Amin Amiri, Seyed Majdeddin Mir Mohammad Hosseini and Abbas Soroush. The first draft of the manuscript was written by Amin Amiri and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Amiri, A., Mir Mohammad Hosseini, S.M. & Soroush, A. Experimental study of influencing pile to cap connections on the rocking behaviors of piled foundations. Sci Rep 15, 14937 (2025). https://doi.org/10.1038/s41598-025-98940-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-98940-x