Abstract

The mechanical behavior of polycrystalline materials is significantly influenced by their evolving microstructural features. While numerous experimental techniques have sought to optimize material performance, understanding the role of microstructural morphology in dictating mechanical responses has remained challenging. Here, we demonstrate that mimicking microstructural features found in metamorphic rocks, specifically the sigmoid foliation patterns characteristic of syntectonic porphyroblasts, enables control over the mechanical response of polycrystalline aggregates under deformation. This is achieved via controlled abnormal grain growth (AGG), which induces localized stress relaxation within abnormal grains while enhancing strain-hardening in the surrounding matrix. Driven by grain boundary diffusion and locally accelerated by grain curvature in the initial stages of secondary recrystallization, this AGG process forms shape-mediated iso-stress microstructures that mitigate stress concentrations and homogenize the stress field. Our theoretically informed Monte Carlo simulations, based on an oligocrystalline elastic modified Potts model, elucidate the intricate relationship between grain size distribution, grain shape, and crystallographic orientation in shaping mechanical response. Our model provides a foundational understanding of material design principles that support key experimental observations, revealing how AGG can be strategically harnessed to engineer high-performance metallic alloys. By replicating nature’s approach to microstructural optimization, this work presents a transformative pathway for developing advanced materials with tailored mechanical properties, enhancing performance and durability.

Similar content being viewed by others

Introduction

Microstructural features are ubiquitous in designing next-generation materials since they foster thermo-mechanical properties, as seen in metal alloys used in high-temperature applications1,2,3,4,5,6, shape memory alloys with outstanding recoverable properties7, and thin films with improved magnetic properties for the semiconductor industry8. However, designing materials with a functionalized microstructure using conventional methods remains an unsettled challenge, with experimental and cost limitations9,10,11,12. Recent metallurgical advancements have emphasized enhancing microstructural functional stability via matrix hardening, lattice parameter modification, and favoring textural patterns. Nevertheless, the anisotropy of the deformations leads to microstructural incompatibilities and the emergence of stress concentrators around the largest grains, producing multimodal morphologies that deny a suitable thermo-mechanical performance13,14. Consequently, the development of functionalized microstructures becomes an alternative to improve the mechanical response of polycrystalline aggregates by locally minimizing the area of grain boundaries (GB) via abnormal growth, avoiding the difficulties caused by the emergence of stress hotspots15,16,17. Mimicry of the microstructural behavior exhibited by syntectonic porphyroblasts in metamorphic rocks presents a promising avenue for advanced material design. The foliation patterns characteristic of these structures delineate shear directions within amphibolite facies, effectively dictating structural stability and deformation parameters. This approach facilitates the engineered synthesis of hierarchically structured materials with enhanced properties18,19,20.

Microstructural functionalization of metallic alloys can be achieved through controlled abnormal grain growth (AGG) in polycrystalline aggregates, as previously proved by the outstanding behavior of alloys for high-temperature conditions21,22,23,24. These works introduced experimental methodologies to develop AGG through cyclic thermal treatments in Cu-Al-Mn alloys25,26. The experimental conditions induced the alignment of abnormal grains with the principal axis of deformation, forming non-coherent textures. This localized textural heterogeneity conferred an enhanced mechanical response to the alloy.27,28,29. Also, the evidence suggests that small grains are easily assimilated by bigger grains that grow abnormally due to the activation of massive local diffusion driven by mean curvature, generating a local softening in concomitance with a global hardening of the matrix30,31. These findings have significant practical implications for the design and performance of metallic alloys in high-temperature applications. Under this perspective, AGG becomes a feasible alternative for mechanically optimized microstructures through solid-state transformation and coherent grain texturization. However, despite the potential benefits that AGG can bring to the mechanical response of polycrystalline structures, the physical mechanisms that promote AGG (stress-free grain nucleation and evolution, second-phase particles32, preferential textures33, size advantages34, and surface phenomena35) and their initiation and predominance are poorly understood36,37.

Understanding the mechanisms that lead to AGG is essential for designing alloys with mechanical properties that enable their performance under different service conditions. For example, maintaining a stable microstructure in shape memory alloys is crucial to achieving the desired mechanical performance38,39. However, during AGG, stress-assisted localized diffusion causes an increase in the average grain size, which reduces the overall strength of the material, as described by the Hall-Petch relationship40,41,42,43. This behavior implies that when grains grow abnormally, the material weakens, becoming more susceptible to plastic deformation44,45,46. AGG can be enhanced in polycrystalline aggregates with a fine grain distribution when sufficient second-phase particles inhibit normal grain growth47,48. This behavior can cause instability at elevated temperatures, reducing the material’s toughness in high-temperature applications49. Notably, in materials with larger grains, dislocation sliding overrides sliding via grain boundaries, a mechanism more frequent in fine-grained materials, which affects the ductility and toughness of the alloy50,51.

The lack of understanding of the underlying mechanisms that modulate AGG hinders the design of effective heat treatments to manufacture oligocrystalline structures. In this regard, we present an In-silico, non-biased simulation that mimics the primary mechanisms that modulate abnormal grain growth in polycrystalline microstructures for the first time. The analysis strategy was based on a theoretically informed free energy minimization formalism through Monte Carlo sampling (TIMC)52. This formalism allows us to gain control over the emergence of abnormal grains. It elucidates how local curvature shape-based diffusion acts as the primary mechanism that promotes AGG, which helps to modulate the mechanical response of the aggregate. Our findings provide a deeper understanding of the behavior of polycrystalline structures during deformation and offer practical insights for designing heat treatments. These insights can control the emergence of shape-mediated iso-stress microstructures, enabling the fabrication of structured materials with a tailored performance.

Results

In silico engineered polydispersity

Microstructural evolution with controlled abnormal growth. Synthetic microstructures generated through the OEMP model exhibit varying degrees of abnormal grain growth and polydispersity. The model successfully reproduces microstructural features observed in metamorphic rocks, notably the formation of oligocrystalline structures with a range of grain sizes and shapes. (A-F) Microstructures with increasing polydispersity showcase the transition from predominantly equiaxed grains to the emergence of larger, abnormally grown grains. (G) The Polydispersity index quantifies the variation in grain size within each microstructure. (H) Misorientation angle distribution indicates the relative crystallographic orientations between neighboring grains.

Figure 1A-F shows stress-free in-silico polydisperse grains characterized according to the elastic energies associated with the perimeter and area of the grains53. These microstructures reach a mean grain diameter of 20 \(\mu\)m, with a Log-normal grain size distribution, but with a non-uniform shape collection (the reader is referred to Fig. S1 in the Supplementary Materials for extended characterization), parametrized following the American Society for Testing and Materials (ASTM) E122-113 standard. Our previously developed oligocrystalline elastic modified Potts free energy functional (OEMP)52 encodes the microstructure’s elastic properties and considers long- and short-range interactions between the grain ensemble. Through this rationale, we generate microstructures composed of equidimensional crystals with shapes of euhedral crystals and fully developed faces (a polygonal structure). However, controlling the speed of the secondary recrystallization process makes it possible to control the emergence of abnormal grains. Figures between 1B and E show abnormal grains whose density of occurrence decreases towards (F). To characterize the microstructures even further, we include the grain-size polydispersity in Figure 1G, which increases from A to F (the reader is referred to Fig. S2 in the Supplementary Materials for extended characterization). By modifying the Lagrange multipliers of the harmonic shaping functions within the functional, our OEMP functional and TIMC minimization scheme reproduces the secondary recrystallization phenomenon in which certain energetically favorable grains overgrow in a matrix of finer grains, resulting in a bimodal grain-size distribution.

Figure 1H illustrates the symmetry of euhedral crystals through the smallest misorientation angle, \(\theta _{m}\), and determines that the relative orientations between grains describe a cubic system. For our system, composed of mixed oligocrystalline and polycrystalline structures with random orientations, the maximum value of \(\theta _{m}\) is 62.8\(^\circ\) and a mean value of \(\sim\)45\(^\circ\), indicating that the structure has polygonal shapes intersecting at triple boundaries (the reader is referred to Fig. S3 in the Supplementary Materials for extended characterization). In this context, the maximum misorientation and frequency indicate a single phase in cubic crystal symmetries54. Last, the distribution of the number of sides of the grains for all simulated structures resulted in an average of six sides in the grain local neighborhood, following the Euler-Poincaré relationship for polygonal aggregates55. Results in Fig. 1A-F indicate that our model reproduces the physical conditions for reproducing oligocrystalline microstructures from a local balance of the interfacial tension at the GBs, where the total surface area is greater than the total grain boundary area. Also, it provides a processing route capable of achieving single-crystal-like properties but with much less stringent processing restrictions on material volume and shape, and at a much lower processing cost. Our approach is the first theoretical methodology able to reproduce oligocrystalline microstructures in good agreement with experimental results in metamorphic rocks (please refer to an extended discussion in the Supplementary Information).

Seriated-amoeboid shapes foster abnormal growth

Grain morphology and recrystallization dynamics. Figure highlights the transition from partially recrystallized aggregates with amoeboid grain boundaries to completely recrystallized aggregates with more defined, polygonal shapes. Changes in grain size distribution, morphology, and the Feret shape factor characterize this transition. (A) Microstructural evolution during recrystallization, showing the gradual change in grain morphology. (B) Quantitative grain shape and topology analysis uses the Feret factor to assess grain boundary irregularity and the number of grain sides to describe the topological evolution.

The physical description of a microstructure necessitates characterizing the complete spatial and geometrical arrangement of all its components. This includes texture, grain structure, and misorientation distributions, which must be homogeneously distributed throughout the bulk56,57. For AGG cases, solid-state diffusional transformations can yield relatively large single crystals. This phenomenon arises because the nucleation and initial growth of new grains are inhibited by small grains exhibiting high surface free energy, rendering them less stable than their larger grains15,58. This metastable state can be overcome at discrete sites characterized by morphological irregularities, preferential locations for grain nucleation and growth. These irregularities are a critical determinant of microstructural evolution and constitute a central focus of this research59,60. The abundance of suitable nucleation sites dictates the resulting grain size distribution. A high density of such sites promotes the formation of numerous small grains, whereas a sparse distribution favors the development of isolated, large porphyroblasts20,61. However, it was found that multiple nuclei formed simultaneously produce a growing amoeba-like shape, to coalesce later to a single crystal with a constant radial growth rate, regardless of size62,63,64,65. These crystalline structures are central for analyzing foliation processes, enabling the determination of the shear direction and minimum shear strain required to induce brittle failure. This analysis hinges on understanding the activation of crystal rotation mechanisms relative to specific reference frames66.

Figure 2A presents the dynamic recrystallization during solid-state transformation. We distinguish two characteristic microstructures: partially recrystallized aggregates and completely recrystallized aggregates. These microstructures show a bimodal grain size distribution, distinct in partially recrystallized aggregates (please refer to the Supplementary Information for more details), with small granoblastic grains of uniform size between grains with undulate rotation. This evolution process can be described through bulging recrystallization, where grains can have patchy rotations, kinks, deformation lamellae, and evidence for brittle fracturing, caused by grain boundaries irregular and globoid with lobes on the scale of the small grains67. New grains nucleate preferentially at pre-existing grain boundaries, consuming the parent grains and forming small, equiaxed grain aggregates.68,69. Figure 2A (first line) shows a mosaic of approximately equidimensional subhedral or anhedral grains with strongly curved and lobate interlocking grain boundaries (with an amoeba-like shape), with a complete fine-to-coarse-grained gradation. The growth process reproduces an inequigranular aggregate, with large grains growing during solid-state transformation and embedded in a finer-grained matrix. Figure 2A (center line) depicts a polygonal aggregate with straight grain boundaries consisting of anhedral or subhedral grains and gradational distribution of different grain sizes, and figure 2A (bottom line) begins with anhedral crystalline shapes, less common euhedral shapes, and partially developed crystal faces, until achieving, at the final stage of the process, individual grains with subhedral morphology and irregular crystal form but some well-developed crystal faces. In the equilibrium stage, the shape of grain aggregates produces polygonal structures with straight grain boundaries consisting of anhedral or subhedral grains and equigranular size distribution (the reader is referred to Figure S4 in the Supplementary Materials for extended characterization).

Figure 2B provides a compelling visual representation of the grain shape distribution, using the Feret factor, and a topological description (inset) through grain sides evolution70. These factors quantify the irregularity of the grain boundary and define the ratio of the actual length of a grain boundary divided by the size of the outline of the grain projection71. A Feret factor of one means that the grain is a smooth round structure, and values are progressively lower for interlobate to amoeboid grain72. For distributions E and F in Figure 2B, the recrystallization transition from old to new grain is less abrupt due to the possibility of subgrain rotation. The sides of the grains are flattened, showing sweeping rotation, and the size of the new grains is similar to the old ones, through transitions in orientation from subgrains to new grains occur26. Also, subgrain boundaries can be seen to change laterally into grain boundaries73. Samples A to E exhibit bulk recrystallization characterized by a heterogeneous distribution of dislocation density within the grains. On the other hand, sample F displays a homogeneous dislocation density across the recrystallized grains22,74,75.

While some state-of-the-art studies suggest that recrystallized aggregates may develop specific lattice-preferred orientations, potentially leading to large, fully recrystallized grains originating from single-parent grains, our research revealed no such preferential orientation. Instead, grain boundary diffusion was the sole mechanism driving the observed microstructural evolution25,73,76,77. Nevertheless, differentiating between normal and abnormal grain growth, particularly concerning the distinction between pre-existing and newly formed grains, proves challenging in high-temperature grain boundary migration recrystallization. For instance, in a metamorphic rock, features like large new grains that interlobate to amoeboid grain boundaries and are internally subdivided into smaller subgrains indicate the transition process24. In practice, characteristic features of different recrystallization mechanisms can be found together in one sample since temperatures or deformation conditions may change78,79. In Figure 2B, the E-curve describes the aggregate as a collection of small, dynamically recrystallized grains around a big crystal core along its rim. In some instances, a fully recrystallized aggregate exhibits sufficient complexity to differentiate it from a non-recrystallized, equiaxed sample. This complexity stems from intracrystalline deformation, a lattice-preferred orientation, or a non-uniform grain size distribution within the aggregate, features typically absent in non-recrystallized microstructures.80. However, it is important to note that such microstructural distinctions are often subtle and may be overlooked when relying solely on macroscopic observations, which are prevalent in the current literature.

Shape-dependent mechanical response in oligocrystalline microstructures

The microstructural relationships between abnormal grains and the surrounding matrix are crucial in controlling the final microstructural pattern in oligocrystalline structures. Yet, these relationships remain poorly understood and warrant further investigation. The depth of this understanding is further highlighted by the complexity of the two mechanical processes operating during porphyroblast growth, which form the basic framework for the discussion in this paper. The first and most important arises from the elementary consideration that a growing porphyroblast has to make room for itself, and, in most cases, the volume it finally occupies was once occupied by pre-existing matrix grains81. The second mechanical process arises from the fact that, in general, a porphyroblast will have a compressibility different from that of its surrounding matrix82. In the vicinity of a growing grain (where creep deformation is observed), the deformation process will advance with porphyroblast boundary evolution83. Although the microstructural changes due to such creep will be negligible for any fixed position of the porphyroblast-matrix boundary, the cumulative effect on grains swept along an advancing grain face may be appreciable84. This deformation process involves grain rotation due to transport ahead of the advancing porphyroblast margin and further rotations and minor translations in response to the local deviatoric stress field85.

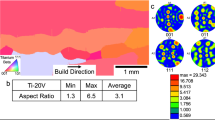

Stress distribution and texture evolution under deformation. Abnormal grain growth and microstructural heterogeneity impact the mechanical response of aggregates under deformation. The von Mises stress distribution (Top) reveals stress concentrations around smaller grains and stress relaxation within larger, abnormally grown grains. Grain orientations before and after deformation (Middle) illustrate how crystal lattices reorient in response to applied stress. Pole figures (Bottom) visualize the overall texture evolution, indicating the development of preferred crystallographic orientations.

The macroscopic response of the aggregate strongly depends on grain neighborhood hardening and the evolution of crystallographic orientations86. During an elastic response, applied stress promotes GB migration and boosts texture evolution (large segments of grains with similar orientations), which fosters the mechanisms for energy dissipation during the plastic response87. To assess the influence of an external load on the transition between normal and abnormal microstructures, we applied a constant deformation along the y-axis to all structures, employing periodic boundary conditions in the x-direction. The displacement was 1\(\mu\)m at each boundary to guarantee that the microstructure is still under elastic conditions; i.e., mean von Mises stress \(<\sigma _\text {VM}>\) is below the yield stress \(\sigma _\text {Y} = 750\) MPa (please see details behind the model parametrization in the Supplementary Materials). Although we consider it a constant strain, our method can be used for constant stress. After the deformation is imposed on the system, the OEMP free energy functional is minimized using the TIMC scheme. Figure 3 summarizes the most relevant observations after applying a single deformation event to all microstructures. The figure includes contour plots of von Mises stress, grain orientations (before and after energy minimization), and pole figures to determine the collective behavior after deformation.

A remarkable feature in Figure 3(A to F) is the high-stress anisotropy, which refers to the directional dependence of a material’s mechanical properties, driven by the orientation mismatch between each grain and the strain direction. Macroscopically, the yield stress demarcates the transition from elastic to plastic deformation. Microscopically, grain boundary (GB) migration can either decrease or increase the yield point. This phenomenon is observed in large grains, whereas dislocation motion is significantly hindered in small grains, leading to increased local hardening7,26. The presence of abnormally grown grains induces localized softening, concurrent with hardening processes in the adjacent regions36,88. In addition, for the aggregates, the elastic limit also depends on the shape of the GB because its geometry influences the curvature-driven GB diffusion, enhancing the emergence of stress hot spots (SHS). Therefore, an increase in the orientational anisotropy of the constituent grains or the presence of localized abnormal grain growth leads to a heterogeneous elastic response in nominally identical aggregates. To incorporate this behavior into our model, we employed a stiffness tensor that varies with the orientation of each grain.

As illustrated in the first line of Figure 3, our model predicts stress concentrations within smaller grains surrounding abnormally grown crystals, while larger grains exhibit enhanced stress relaxation. Despite all samples possessing the same average grain size, the degree of polydispersity contributes to a generalized increase in stress levels, culminating in sample F, which exhibits the highest polydispersity index. This behavior is consistent with classical dislocation theory, which posits that decreasing grain size diminishes the mobility of dislocations and grain boundaries (GBs)89. This reduction in mobility occurs primarily through strain hardening associated with grain refinement. The practical implications of this phenomenon have motivated the use of mean grain size as an engineering parameter to enhance the strength of polycrystalline solids, a topic of considerable interest to materials scientists and engineers. The middle line of Figure 3 shows the misorientation of the polygonal aggregates before and after the deformation process. Furthermore, the absence of a preferential texture indicates that the formation of oligocrystals occurs solely through grain boundary (GB) migration. Aggregate lineations can develop by elongating equiaxed grain aggregates or deforming large single crystals followed by recrystallization. As depicted in the bottom panel of Figure 3, all crystal axes, except those parallel or normal to the traction direction, rotate towards that direction. Axes parallel to the traction direction may undergo deformation via kinking or twinning, accompanied by segment rotation. This mechanism indicates a non-random, systematic crystal lattice-preferred orientation (LPO) arrangement. However, for samples A and F, characterized by equant grain shapes, dislocation creep appears to be the dominant mechanism responsible for the formation and rotation of the LPO relative to the instantaneous stretching axes80,90,91.

Tailored control of foliation patterns

Foliation patterns and microstructural control. (A-F) Iso-stress contours and foliation planes are depicted for microstructures with varying degrees of abnormal grain growth, providing a visual representation of how the orientation and curvature of these features evolve in response to microstructural changes and the complexity of the deformation process. Microstructure D exhibits the most well-defined and pervasive foliation pattern among the microstructures analyzed. (G) The polydispersity index is tracked for microstructures (A-F) after deformation, revealing a consistent trend of polydispersity reduction due to grain alignment with the deformation lines. (H) Mean von Mises stress for each microstructure, demonstrating a monotonic increase from (A-F), with microstructure (D) uniquely exhibiting the lowest density of stress hotspots. (I) The relationship between mean von Mises stress and the Feret factor reveals that controlled abnormal grain growth enables the formation of near ”iso-stressed” microstructures, effectively mimicking the stress distribution observed in metamorphic rocks.

The term “foliation” is employed here to denote any pervasive planar feature within a polycrystalline aggregate. This study will demonstrate that various elements can define foliations, including spatial variations in grain size, a preferred orientation of elongated grains or aggregates, or a combination thereof92. Primary layering in sediments arises from discontinuous processes, resulting in considerable variability in the thickness and composition of individual beds or layers, with low symmetry about planes parallel to the layering. Conversely, secondary layering develops through differentiation processes within a stress field, producing a more monotonous bimodal structure with a symmetry plane parallel to the layering. This category encompasses cleavage, schistosity, differentiated compositional layering, and mylonitic foliation92. Elevated temperatures without deformation, such as those encountered in contact aureoles, typically diminish foliation intensity. This reduction results from the nucleation and growth of new grains with random orientations over the pre-existing foliated structure. Figure 4 presents a morphological description of foliation patterns that develop during porphyroblast interactions, along with a discussion of the primary processes involved in their formation. This analysis is grounded in the descriptive classifications of foliation patterns established by Powell93 and Borradaile et al.94, focusing exclusively on morphological features.

Results in Figure 4A-F reveal a novel finding: a continuous foliation pattern characterized by a non-layered, homogeneous distribution of grains exhibiting a non-preferred orientation. These bands predominantly form within grains experiencing higher hydrostatic stress, where only a single slip system can operate under energy relaxation conditions. Sigmoid foliation patterns, another novel aspect, arise from deformation and grain boundary migration. This migration modulates local stress relaxation within abnormal grains and strain-hardening in the surrounding matrix. Furthermore, crystalline reorientation processes, such as dislocation creep or solid-state diffusion, aid in developing this sigmoid pattern. This pattern may explain why some grains within a deformed aggregate exhibit significantly less deformation than others. However, substantial grain shape and preferential growth differences also play a crucial role in this behavior. While this process may contribute to developing a grain shape-preferred orientation, its significance remains uncertain as the number of active slip systems increases with temperature. Notably, the iso-stress contours (white lines) in Figure 4 exhibit a predominant orientation as a function of the evolving microstructural topology. These contours display local variations and changes in sigmoidal direction, influenced by stress hotspots. Conversely, the foliation planes (red lines) demonstrate a generally non-uniform orientation, reflecting the local characteristics of the sample.

Figure 4A presents iso-stress contours with a predominant NW-SE orientation, exhibiting local variations and changes in sigmoidal direction influenced by stress hotspots. Consequently, the orientation of the stress field converges towards regions of higher stress concentration arising from microstructural heterogeneity within the sample, a consequence of complex deformation processes. Notably, the pronounced curvatures and directional changes, particularly around local planes, suggest the presence of stress concentrators near potential shear failure zones. Conversely, the foliation planes display a generally non-uniform NE-SW orientation with local variations. These planes curve around areas of stress concentration or abrupt directional changes, characteristic of ductile deformation processes. While the angle of intersection between the stress field and foliation planes varies, it typically approximates 45\(^{\circ }\). This angle is more pronounced in regions with greater stress curvature, indicating that foliation patterns develop in response to local compressive deformation. However, in areas where stress contours are straighter and parallel, the angle of intersection with foliation bands decreases, promoting slip failure. Shifting to Figure 4B, it depicts iso-stress contours with more frequent directional changes and regions where the NW-SE orientation is less defined. The general NE-SW orientation of the foliation planes persists but exhibits more pronounced undulations and directional shifts. This pattern suggests that the aggregate underwent more significant deformation via intricate mechanisms, where the influence of abnormal grains becomes increasingly apparent. Furthermore, Figure 4(C) illustrates iso-stress contours with even greater curvature than in the previous structures, characterized by sinuous trajectories and frequent directional changes, forming near-concentric patterns. These patterns arise from the more prominent abnormal structures that disrupt the mechanical response. Additionally, regions with near-parallel foliation bands intersecting at acute angles and deviating around stress hotspots are evident. In contrast, as the prevalence of abnormal grains diminishes in Figures 4D-F, the effective concentration of foliation planes decreases. This observation highlights a complex interplay of factors influencing high-temperature deformation in the aggregate, dominated by intergranular transport mechanisms. This shift promotes ductile deformation in the abnormal grains and brittle failure in the smaller neighboring grains. Under these conditions, dynamic recrystallization is highly active, with grains continuously reorienting and reorganizing, hindering the formation of well-defined foliation planes. Moreover, persistent intergranular diffusion or grain sliding processes further impede the development of planar structures like foliation, thereby modulating the aggregate’s mechanical behavior (the reader is referred to Figure S6 in the Supplementary Materials for extended characterization).

Analysis of the evolved microstructures reveals a compelling correlation between controlled abnormal grain growth, foliation patterns, and stress distribution. Figure 4G presents the polydispersity index for microstructures A to F after applying the deformation field and energy minimization. A distinct leftward shift in the curves for all microstructures except F indicates a reduction in polydispersity driven by grain alignment with the deformation lines. This alignment process, facilitated by grain rotation and growth, directly forms the observed foliation patterns. In microstructure F, where the grain growth mechanism is suppressed, grain rotation emerges as the dominant mechanism for energy minimization, as evidenced by the pronounced reorientation depicted in the inset of Figure 4G. A comparative analysis of the foliation patterns across all microstructures reveals that microstructure D exhibits the most well-defined and pervasive pattern. This observation, coupled with the preceding analyses, underscores the profound influence of controlled abnormal grain growth on the mechanical response of the aggregates, particularly in mitigating the emergence of failure planes. Further evidence for the optimized mechanical behavior of microstructure D is provided in Figure 4H, which uncovers a monotonic increase in mean von Mises stress from microstructure A to F. While all stress values remain below the yield stress of the material, microstructure D uniquely exhibits the lowest density of stress hotspots. This result unequivocally establishes microstructure D as an optimal design point for enhanced mechanical performance with its specific degree of abnormal grain growth. A deeper understanding of this optimized behavior is gained by examining the mean von Mises stress as a function of the Feret factor, as shown in the figure 4I. Remarkably, microstructure D displays a near-constant stress level across the entire range of Feret factors, indicating a highly effective stress delocalization mechanism. This behavior stems from the controlled development of abnormal grains, which enables precise grain rotation and growth dynamics regulation. The abnormal grains act as localized stress relaxation zones, while the surrounding matrix, composed of smaller grains, undergoes strain hardening. This synergistic interplay between abnormal grains and the matrix culminates in a near “iso-stressed” microstructure that effectively dissipates stress concentrations and mimics the foliation patterns observed in metamorphic rocks, known for their resilience under deformation.

Discussion

This study presents a novel approach to tailoring the mechanical properties of polycrystalline materials by strategically harnessing controlled abnormal grain growth (AGG). While experimental investigations have successfully induced AGG through cyclic heat treatments in various alloy systems, such as Fe-based shape memory alloys with titanium and chromium additions7, the fundamental physical mechanisms governing the emergence of abnormal grains remain inadequately understood. This knowledge gap is evident in the conflicting interpretations regarding the role of subgrain size and shape in driving AGG. For example, Vollmer et al. attributed the promotion or inhibition of AGG to the grain boundary migration rate induced by cyclic heat treatment, which tailors AGG rates and yields good pseudoelastic properties without requiring an additional aging step. They argued that strongly reduced subgrain sizes and acicular shapes result in a higher driving force for AGG. However, our findings contradict this assertion, demonstrating that grain boundary diffusion, strongly influenced by grain curvature, is the primary driver of AGG. Our model reveals that localized diffusion in amoeboid regions promotes AGG, allowing us to study the evolutionary mechanisms in a controlled manner. Conversely, studies on ultra-large single crystals grown via AGG26 elucidated that repeated low-temperature cycles accelerate grain boundary migration by increasing sub-boundary energy, thereby promoting further AGG and enabling continuous growth of large grains after each heat treatment cycle.

In alignment with our results, Kusama et al.26 emphasized the role of boundary energy, dependent on grain shape and orientation, in driving abnormal grain growth. Regions with higher boundary energy exhibit an increased driving force for grain boundary migration, thus promoting abnormal growth. Furthermore, investigations into abnormal grain growth mediated by fractal boundary migration at the nanoscale have revealed that grains develop complex, convoluted morphologies describable by a fractional dimension, indicating a fractal nature of the grain boundaries88. This suggests that abnormal grains fill space akin to fractal objects rather than traditional geometric shapes, a process influenced by microstructural details at the nanoscale, where grain rotation and coalescence play significant roles in microstructural evolution. This fractal description could explain the results of traditional models that rely on curvature-driven migration. However, despite these advancements, establishing definitive correlations between grain boundary shape and the degree of dynamic recrystallization remains experimentally challenging due to the inherent complexities of experimental observations95. This dynamic recrystallization process, influenced by grain boundary orientation, local kinematics, stretching direction, and cavitation along specific boundaries, acts as a principal control mechanism for modulating the mechanical response of the aggregate. Significantly, our numerical results comprehensively explain the diverse experimental observations reported in the state-of-the-art, elucidating the intricate interplay of grain boundary diffusion, curvature, and dynamic recrystallization in the emergence and evolution of abnormal grain growth.

A growing field of application is the design and manufacture of shape memory alloys and heat-resistant alloys96,97. These materials present exceptional characteristics due to their monocrystalline structure98. However, their application is limited to specific contexts due to the high manufacturing costs99,100,101. Conventionally, the fabrication of single crystals is achieved through technical processes such as those of Bridgman and Czochralski102,103,104. One of the most prominent techniques is the strain annealing method, which involves inducing a cold deformation followed by a thermal annealing process105. Thus, alternative approaches for synthesizing single crystals through solid-state techniques, which promote abnormal grain growth, are in growth106. For example, during cyclic heat treatment processes between 500 and 900\(^\circ\)C, in a Cu-Al-Mn shape memory alloy, the \(\beta\)-BCC phase was transformed into the \(\beta / \beta + \alpha\)-FCC phase by controlled abnormal grain growth. This technique shows competitive advantages for obtaining single crystals25,33. In the thermomechanical field, abnormal grain instabilities influence the development of foliation planes, modulating the material’s response during deformation107,108. For example, when there is a high contrast between domains that differ in grain size and shape, this leads to the nucleation of shear microbands109. These shear bands are crucial, as they define the compositional layering of the material, resulting in different mechanical properties depending on the domain spacing110. In this sense, grain size and shape are crucial in defining foliation patterns, generating potential points of pronounced foliation111. This behavior is particularly relevant in high-cycle creep or fatigue processes, where the interaction between grain size and shape can give rise to distinctive foliation features112. Additionally, following the works of25,33, achieving a sequence of heat treatments to obtain the growth of abnormal crystals is possible. The procedure is a sequence of cyclic heat treatment, in combination with high-temperature cycles (between 900 and 500\(^\circ\)C) and low-temperature cycles (740 and 500\(^\circ\)C ), with posterior water quenching, required to achieve single crystal growth in Cu-Al-Mn bars (Please refer to the supplemental figure S5, for a detailed graphical representation of sequence of heat treatment).

Controlled abnormal grain growth and sigmoidal foliation patterns are critical factors in enhancing the mechanical performance of polycrystalline materials. By mimicking the stress distributions observed in metamorphic rocks, these microstructural features facilitate stress relaxation and matrix hardening, optimizing the material’s resistance to deformation. This level of microstructural control presents significant opportunities for improving metallic alloys and lays the groundwork for innovative heat treatment techniques. Furthermore, we can design alloys with tailored microstructures through computational modeling of these processes, allowing for the precise manipulation of mechanical properties for high-performance applications. This modeling approach represents a powerful advancement, heralding a new era in computational alloy design in advanced materials engineering.

Materials and methods

Free energy functional and theoretically-informed Monte Carlo

Two fundamental contributions define our free energy functional: (i) due to oligocrystalline structure through a modified Potts model, \({\mathscr {H}}_\text {PM}\), and (ii) through the elastic density that includes the external deformation field and grain boundaries evolution, \({\mathscr {H}}_{E}\). We call this free energy functional an oligocrystalline elastic modified Potts model (OEMP), and it is written as follows:

where N is the number of lattice points of the system, \(\Gamma _{i}\) are the neighbors of each lattice, and \(N_g\) is the number of individual grains of the microstructure. The \({\mathscr {H}}_\text {PM}\), first bracket, comprises three energy densities due to the preferred orientation, perimeter, and area of each grain, which gives control over the shape and size of each grain. The free energy penalization over the grain orientation is done through the \(\gamma _{ij}\) parameter and the Kronecker-delta function \(\delta _{ij}\), which is one if two neighbor lattices have the same crystallographic orientation and zero otherwise. Here, harmonic energy densities are used to set the area and perimeter of the grains to a prefixed size and shape, where the Lagrange multipliers, \(\lambda (s_{k})\) and \(\sigma (v_{k})\), make possible these requirements through by fulfilling the Avrami equations113,114, and \(S_T\) and \(V_T\) are the targeted grain perimeter and area, respectively.

Our simulations are performed in two-dimensional polycrystalline structures of 500 \(\mu\)m x 500 \(\mu\)m. We use a coarse-grained description of the aggregate, where the microstructure is discretized using a square lattice. The resolution of the mesh is determined according to the ratio between the minimum and maximum length scale of the desired microstructure115. In this work, we selected cubic polycrystalline structures for metamorphic rocks (syntectonic porphyroblasts) with grains between 5 to 100 \(\mu\)m covering nearly 1 mm length scales. We performed consistency and stability analyses and found that around 160,000 lattice points were sufficient to resolve the system. Each lattice point represents \(10^{10}\) atoms for this case. The TIMC free energy minimizations were carried out in five independent simulations. Every simulation started from a randomly generated polycrystalline structure with over 40,000 grains. The grain size was defined according to: (i) a circle of equivalent radius, \(r = (A_{grain}/\pi )^{1/2}\), (ii) using the ASTM E112-13, and (iii) an averaged grain diameter (\(\langle d \rangle\)) through the arithmetic mean value of Feret-axis in the grain. The grain shape was defined according to Feret’s diameter ratio, which measures the longest and minimum distance between any two points along the selection boundary; this measurement includes the angle between the Feret’s diameter and a line parallel to the x-axis of the image (0-180 degrees). Through the Feret aspect ratio, the degree of circularity of each grain can be defined as \(4\pi (A_{grain})/P^2\) (where \(A_{grain}\) is the grain area, and P is its perimeter). A value of 1.0 indicates a perfect circle116. As the value approaches 0.0, it means an increasingly elongated shape. Also, it was possible to define the roundness as \(4(A_{grain})/(\pi (Feret^2))\).

The polydispersity index, which characterizes the differences in size for the constituent grains and can be described by the cumulative fractional volume or grain size distribution (GSD), which has been shown to influence the packing properties of the aggregate strongly, is modeled as a truncated power law that can be characterized by its shape (exponent, \(\eta\)) and its size span (ratio of the largest to the smallest particle size, \(\lambda\)) and is defined as:

where \(d_{min}\) (\(d_{max}\)) is the minimum (maximum) Feret diameter in the sample, and \(\Theta\) is the fraction of volume occupied by grains of diameter smaller than d. The optimal packing with the densest state could be obtained with an exponent of \(\eta \simeq 0.5\)117,118. Our theoretically informed Monte Carlo method is remarkably adaptable to different stress conditions. It begins with a Metropolis scheme to generate a Markov chain. Random trial updates of the local preferred orientation and rotations are proposed and accepted according to the Metropolis criteria. We established the grain rotation (with a maximum value of 2 degrees per trial) and the probability of re-orientation of a selected lattice following a Gaussian probability distribution to guarantee detailed balance119,120. For deformation conditions, the likelihood of change in preferred orientation is driven by the local hydrostatic stress, increasing the probability of re-orientation in tensile zones while allowing stagnation in compressive zones. This evolution follows the mechanisms established by Stress-assisted diffusion121,122,123. We constructed a Markov chain of these configurations by proposing transitions between an old configuration and a new one with probability \(P(\text {old} \rightarrow \text {new}) = \text {min}\left[ 1,\text {exp}(-\beta \Delta {\mathscr {H}}) \right]\) (where \(\beta ^{-1} = k_B T\), \(\Delta {\mathscr {H}} = {\mathscr {H}}_\text {new} - {\mathscr {H}}_\text {old}\), T is the temperature and \(k_B\) is Boltzmann constant). To guarantee the energy minimization without local entrapment, we included rotation-coalescence mechanisms into the Markov chain: (i) a grain k is selected randomly and a slight rotation in every Euler’s angle is proposed; if the CO of the \(k^{th}\) grain matches with some neighboring grain, the probability of coalescence increases, (ii) grain k and grain l are selected randomly. A slight rotation is performed for every CO, and the neighborhood of each grain will be checked to verify the coalescence between adjacent grains (2 or more). Free energy functional minimizations required \(10^3\) MC steps, where each step is defined as N-lattice random trials. Deformed structures were minimized by an additional 1000 MC steps (For a more detailed representation of our deformation scheme, we refer the reader to supplemental information).

Data availability

The paper and/or the Materials contain all the data needed to evaluate the conclusions. The authors may provide additional data related to this paper upon request.

References

Pollock, T. Alloy design for aircraft engines. Nat. Mater. 15, 809–815 (2016).

Shibuta, Y. et al. Heterogeneity in homogeneous nucleation from billion-atom molecular dynamics simulation of solidification of pure metal. Nat. Commun. 8, 1–9 (2017).

Li, J. et al. Grain-orientation-engineered multilayer ceramic capacitors for energy storage applications. Nat. Mater. 19, 999–1005 (2020).

Tian, H.-K., Liu, Z., Ji, Y., Chen, L.-Q. & Qi, Y. Interfacial electronic properties dictate li dendrite growth in solid electrolytes. Chem. Mater. 31, 7351–7359 (2019).

Cha, J., Zhou, C., Lee, Y., Cho, S.-P., Chung, I. High thermoelectric performance in n-type polycrystalline snse via dual incorporation of cl and pbse and dense nanostructures. ACS Appl. Mater. Interfaces (2019).

Padture, N., Gell, M. & Jordan, E. Thermal barrier coatings for gas-turbine engine applications. Science 296, 280–284 (2002).

Vollmer, M., Arold, T., Kriegel, M., Klemm, V., Degener, S., Freudenberger, J., Niendorf, T. Promoting abnormal grain growth in fe-based shape memory alloys through compositional adjustments. Nat. Commun. 10 (2019).

Aydin, E. et al. Scaled deposition of ti3c2tx mxene on complex surfaces: Application assessment as rear electrodes for silicon heterojunction solar cells. ACS Nano 16, 2419–2428 (2022).

Sun, L., Xu, Z., Peng, L., Lai, X. Effect of grain size on the ductile-brittle fracture behavior of commercially pure titanium sheet metals. Mater. Sci. Eng. A 822 (2021).

Panda, D., Sabat, R., Suwas, S., Hiwarkar, V. & Sahoo, S. Texture weakening in pure magnesium during grain growth. Philos. Mag. 99, 1362–1385 (2019).

Zeng, X. et al. Role of deformation mechanisms and grain growth in microstructure evolution during recrystallization of Mg-Nd based alloys. Scr. Mater. 166, 53–57 (2019).

Noell, P. & Taleff, E. Subgrains, texture evolution, and dynamic abnormal grain growth in a mo rod material. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 50, 4608–4619 (2019).

Liu, W., Liu, Y., Cheng, Y., Chen, L., Yu, L., Yi, X., Duan, H. Unified model for size-dependent to size-independent transition in yield strength of crystalline metallic materials. Phys. Rev. Lett. 124 (2020).

Wang, X., Zheng, S., Shinzato, S., Fang, Z., He, Y., Zhong, L., Wang, C., Ogata, S., Mao, S. Atomistic processes of surface-diffusion-induced abnormal softening in nanoscale metallic crystals. Nat. Commun. 12 (2021).

Ueland, S., Chen, Y. & Schuh, C. Oligocrystalline shape memory alloys. Adv. Funct. Mater. 22, 2094–2099 (2012).

Tanaka, Y. et al. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 327, 1488–1490 (2010).

Omori, T. et al. Superelastic effect in polycrystalline ferrous alloys. Science 333, 68–71 (2011).

Dake, J., Oddershede, J., Sorensen, H., Werz, T., Shatto, J., Uesugi, K., Schmidt, S., Krill, I., C.E., Direct observation of grain rotations during coarsening of a semisolid al-cu alloy. In Proceedings of the National Academy of Sciences of the United States of America. Vol. 113. E5998-E6006 (2016).

Meiners, T., Frolov, T., Rudd, R., Dehm, G. & Liebscher, C. Observations of grain-boundary phase transformations in an elemental metal. Nature 579, 375–378 (2020).

Mezger, J. Mimicking syntectonic growth: Cordierite overgrowth of earlier rotated staurolite porphyroblasts, strain caps and deflected foliation. J. Struct. Geol. 32, 703–708 (2010).

Jin, X. et al. Analysis of abnormal texture formation and strengthening mechanism in an extruded Mg-Gd-Y-Zn-Zr alloy. J. Mater. Sci. Technol. 45, 133–145 (2020).

Nie, J., Hu, C. Yan, Q. Luo, J. Discovery of electrochemically induced grain boundary transitions. Nat. Commun. 12 (2021).

Lu, N. et al. Dynamics of particle-assisted abnormal grain growth revealed through integrated three-dimensional microanalysis. Acta Mater. 195, 1–12 (2020).

Zollner, D. & Rios, P. On the topology and size advantage of potentially abnormal grains. Comput. Mater. Sci. 153, 382–391 (2018).

Omori, T. et al. Abnormal grain growth induced by cyclic heat treatment. Science 341, 1500–1502 (2013).

Kusama, T., Omori, T., Saito, T., Kise, S., Tanaka, T., Araki, Y., Kainuma, R. Ultra-large single crystals by abnormal grain growth. Nat. Commun. 8 (2017).

Williamson, A. & Delplanque, J.-P. Investigation of dynamic abnormal grain growth using the Monte Carlo Potts method. Comput. Mater. Sci. 124, 114–129 (2016).

Ciulik, J. & Taleff, E. Dynamic abnormal grain growth: A new method to produce single crystals. Scr. Mater. 61, 895–898 (2009).

Kheiri, S., Mirzadeh, H. & Naghizadeh, M. Tailoring the microstructure and mechanical properties of aisi 316l austenitic stainless steel via cold rolling and reversion annealing. Mater. Sci. Eng. A 759, 90–96 (2019).

Kalinenko, A., Vysotskii, I., Malopheyev, S., Mironov, S., Kaibyshev, R. Relationship between welding conditions, abnormal grain growth and mechanical performance in friction-stir welded 6061-t6 aluminum alloy. Mater. Sci. Eng. A 817 (2021).

Zhang, N. et al. Segregation induced hardening in annealed nanocrystalline ni-fe alloy. Mater. Sci. Eng. A 735, 354–360 (2018).

Darling, K., Tschopp, M., Roberts, A., Ligda, J. & Kecskes, L. Enhancing grain refinement in polycrystalline materials using surface mechanical attrition treatment at cryogenic temperatures. Scr. Mater. 69, 461–464 (2013).

Omori, T., Iwaizako, H. & Kainuma, R. Abnormal grain growth induced by cyclic heat treatment in fe-mn-al-ni superelastic alloy. Mater. Des. 101, 263–269 (2016).

Yang, S., Zhang, J., Chi, M., Wen, Y., Chen, X., Wang, C., Liu, X. Low-cost cu-based shape memory single crystals obtained by abnormal grain growth showing excellent superelasticity. Materialia 5 (2019).

Qin, W., Szpunar, J., Umakoshi, Y. A criterion for grain-size limit of polycrystalline materials. J. Appl. Phys. 106 (2009).

Gusak, A., Chen, K.-J., Tu, K., Chen, C. Modeling of abnormal grain growth in (111) oriented and nanotwinned copper. Sci. Rep. 11 (2021).

Taleff, E. & Pedrazas, N. A new route for growing large grains in metals. Science 341, 1461–1462 (2013).

Han, L. et al. Multifunctional high-entropy materials. Nat. Rev. Mater. 9, 846–865 (2024).

Dong, Q. et al. Abnormal crystal growth in ch3nh3pbi3-xclx using a multi-cycle solution coating process. Energy Environ. Sci. 8, 2464–2470 (2015).

Hu, J., Shi, Y., Sauvage, X., Sha, G. & Lu, K. Grain boundary stability governs hardening and softening in extremely fine nanograined metals. Science 355, 1292–1296 (2017).

Cordero, Z., Knight, B. & Schuh, C. Six decades of the hall-petch effect-a survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 61, 495–512 (2016).

Wang, Y., Chen, M., Zhou, F. & Ma, E. High tensile ductility in a nanostructured metal. Nature 419, 912–915 (2002).

SchiÃtz, J., Di Tolla, F. D. & Jacobsen, K. W. Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561–563 (1998).

Aoki, C., Ueno, T., Ohno, T. & Oikawa, K. Influence of hot-working conditions on grain growth of superalloy 718. J. Mater. Process. Technol. 267, 26–33 (2019).

Zheng, S.-X., Luo, X.-M. & Zhang, G.-P. Cumulative shear strain-induced preferential orientation during abnormal grain growth near fatigue crack tips of nanocrystalline Au films. J. Mater. Res. 35, 372–379 (2020).

Fang, Q., Li, L., Wang, X., Li, J. & Jiang, L. Abnormal grain coarsening mechanism in conical nickel. J. Alloys Compds. 768, 613–617 (2018).

Bhuiyan, M.N., Frame, L.D., Mushongera, L.T. Interfacial interactions in particle-induced abnormal grain growth. Adv. Eng. Mater. 25 (2023).

Kinoshita, T., Ohno, M. Phase-field simulation of abnormal grain growth during carburization in nb-added steel. Comput. Mater. Sci. 177 (2020).

Li, T. et al. Effects of agg on fracture toughness of tungsten carbide. Mater. Sci. Eng. A 445–446, 587–592 (2007).

Bednarczyk, W., Kawałko, J., Rutkowski, B., Watroba, M., Gao, N., Starink, M.J., Bała, P., Langdon, T.G. Abnormal grain growth in a Zn-0.8Ag alloy after processing by high-pressure torsion. Acta Mater. 207 (2021).

Kacher, J., Robertson, I., Nowell, M., Knapp, J. & Hattar, K. Study of rapid grain boundary migration in a nanocrystalline ni thin film. Mater. Sci. Eng. A 528, 1628–1635 (2011).

Ospina-Correa, J., Olaya-Munoz, D., Toro-Castrillon, J., Toro, A., Ramirez-Hernandez, A., Hernandez-Ortiz, J. Grain polydispersity and coherent crystal reorientations are features to foster stress hotspots in polycrystalline alloys under load. Sci. Adv. 7 (2021).

Wejchert, J., Weaire, D. & Kermode, J. Monte carlo simulation of the evolution of a two-dimensional soap froth. Philos. Mag. B 53, 15–24 (1986).

Thevamaran, R. et al. Dynamic martensitic phase transformation in single-crystal silver microcubes. Acta Mater. 182, 131–143 (2020).

Mackenzie, J. Second paper on statistics associated with the random disorientation of cubes. Biometrika 1, 229–240 (1958).

Li, X., Lu, L., Li, J., Zhang, X. & Gao, H. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 5, 706–723 (2020).

George, E. P., Raabe, D. & Ritchie, R. O. High-entropy alloys. Nat. Rev. Mater. 4, 515–534 (2019).

Meier, D., Ragunathan, R., Degener, S., Liehr, A., Vollmer, M., Niendorf, T., Sick, B. Reconstruction of incomplete X-ray diffraction pole figures of oligocrystalline materials using deep learning. Sci. Rep. 13 (2023).

Frost, B. R. et al. A geochemical classification for granitic rocks. J. Petrol. 42, 2033–2048 (2001).

Wang, Q. et al. Petrogenesis of adakitic porphyries in an extensional tectonic setting, Dexing, South China: Implications for the genesis of porphyry copper mineralization. J. Petrol. 47, 119–144 (2006).

Skrzypek, E., Schulmann, K., P.Š típská, Chopin, F., Lehmann, J., Lexa, O., Haloda, J. Tectono-metamorphic history recorded in garnet porphyroblasts: Insights from thermodynamic modelling and electron backscatter diffraction analysis of inclusion trails. J. Metamorphic Geol. 29, 473 - 496 (2011).

Okamoto, A. & Michibayashi, K. Misorientations of garnet aggregate within a vein: An example from Sanbagawa metamorphic belt, Japan. J. Metamorphic Geol. 24, 353–366 (2006).

Berger, A., Herwegh, M., Schwarz, J.-O. & Putlitz, B. Quantitative analysis of crystal/grain sizes and their distributions in 2D and 3D. J. Struct. Geol. 33, 1751–1763 (2011).

Engvik, A. K. & Jakob, J. Metamorphic evolution of sillimanite gneiss in the high-pressure terrane of the western Gneiss region (Norway). Eur. J. Mineral. 36, 345–360 (2024).

Groome, W. G. & Johnson, S. E. Constraining the relative strengths of high-grade metamorphic rocks using foliation refraction angles: An example from the northern New England appalachians. J. Struct. Geol. 28, 1261–1276 (2006).

Massironi, M., Bistacchi, A. & Menegon, L. Misoriented faults in exhumed metamorphic complexes: Rule or exception?. Earth Planet. Sci. Lett. 307, 233–239 (2011).

Jiang, M. et al. Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in Az31 magnesium alloy during extrusion. Acta Mater. 157, 53–71 (2018).

Han, J., Kang, S.-H., Lee, S.-J., Kawasaki, M., Lee, H.-J., Ponge, D., Raabe, D., Lee, Y.-K. Superplasticity in a lean Fe-Mn-Al steel. Nat. Commun. 8 (2017).

Tiamiyu, A. A. et al. Nanotwinning-assisted dynamic recrystallization at high strains and strain rates. Nat. Mater. 21, 786–794 (2022).

Igathinathane, C., Pordesimo, L., Columbus, E., Batchelor, W. & Methuku, S. Shape identification and particles size distribution from basic shape parameters using ImageJ. Comput. Electron. Agric. 63, 168–182 (2008).

Bürgmann, R. & Dresen, G. Rheology of the lower crust and upper mantle: Evidence from rock mechanics, geodesy, and field observations. Annu. Rev. Earth Planet. Sci. 36, 531–567 (2008).

Payton, R. L., Chiarella, D., Kingdon, A. The influence of grain shape and size on the relationship between porosity and permeability in sandstone: A digital approach. Sci. Rep. 12 (2022).

Bhattacharyya, J., Agnew, S. & Muralidharan, G. Texture enhancement during grain growth of magnesium alloy az31b. Acta Mater. 86, 80–94 (2015).

Cantwell, P. R. et al. Grain boundary complexions. Acta Mater. 62, 1–48 (2014).

Hu, T., Yang, S., Zhou, N., Zhang, Y., Luo, J. Role of disordered bipolar complexions on the sulfur embrittlement of nickel general grain boundaries. Nat. Commun. 9 (2018).

Holm, E., Miodownik, M. & Rollett, A. On abnormal subgrain growth and the origin of recrystallization nuclei. Acta Mater. 51, 2701–2716 (2003).

Kim, S. G. & Park, Y. B. Grain boundary segregation, solute drag and abnormal grain growth. Acta Mater. 56, 3739–3753 (2008).

Legros, M., Dehm, G., Arzt, E. & Balk, T. J. Observation of giant diffusivity along dislocation cores. Science 319, 1646–1649 (2008).

Jin, S. et al. Colossal grain growth yields single-crystal metal foils by contact-free annealing. Science 362, 1021–1025 (2018).

Pande, C. & Cooper, K. Nanomechanics of hall-petch relationship in nanocrystalline materials. Prog. Mater. Sci. 54, 689–706 (2009).

Stallard, A., Hickey, K. & Upton, G. Measurement and correlation of microstructures: The case of foliation intersection axes. J. Metamorph. Geol. 21, 241–252 (2003).

Enami, M., Taguchi, T., Kouketsu, Y., Michibayashi, K. & Nishiyama, T. Formation process of Al-rich calcium amphibole in quartz-bearing eclogites from the Sulu Belt, China. Am. Mineral. 107, 1582–1597 (2022).

Hirsch, D. & Carlson, W. Variations in rates of nucleation and growth of biotite porphyroblasts. Journal of Metamorphic Geology 24, 763–777 (2006).

Hartung, R.F., Simões, L.S. Trouw, R.A., Silva, A.J. Growth mechanism of garnet megaporphyroblasts of the passos nappe, southern brasília orogen, brazil. J. Metamorph. Geol. 102 (2020).

Kim, H. S. Deformation-induced garnet zoning. Gondwana Res. 10, 379–388 (2006).

Ahluwalia, R., Lookman, T. & Saxena, A. Elastic deformation of polycrystals. Phys. Rev. Lett. 91, 555011–555014 (2003).

Goswami, R., Feng, C., Qadri, S. & Pande, C. Fatigue-assisted grain growth in Al alloys. Sci. Rep. 7, 1–7 (2017).

Braun, C., Dake, J., Krill, C., Birringer, R. Abnormal grain growth mediated by fractal boundary migration at the nanoscale. Sci. Rep. 8 (2018).

Cordero, Z., Knight, B. & Schuh, C. Six decades of the hall-petch effect- A survey of grain-size strengthening studies on pure metals. Int. Mater. Rev. 61, 495–512 (2016).

Lu, L., Sui, M. & Lu, K. Superplastic extensibility of nanocrystalline copper at room temperature. Science 287, 1463–1466 (2000).

Meyers, M., Mishra, A. & Benson, D. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 51, 427–556 (2006).

Urueña, C., Andersson, J., Möller, C., Lundgren, L., Göransson, M., Lindqvist, J.-E., Åkeson, U. Variation in technical properties of granitic rocks with metamorphic conditions. Eng. Geol. 293 (2021).

Powell, C. A morphological classification of rock cleavage. Tectonophysics 58, 21–34 (1979).

Borradaile, G., Bayly, M. & Powell, C. Atlas of deformational and metamorphic rock fabrics. Atlas Deform. Metamorph. Rock Fabrics 1, 1–34 (1982).

Dobe, R., Das, A., Mukherjee, R., Gupta, S. Evaluation of grain boundaries as percolation pathways in quartz-rich continental crust using atomic force microscopy. Sci. Rep. 11 (2021).

Sutou, Y. et al. Effect of grain size and texture on pseudoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater. 53, 4121–4133 (2005).

Sutou, Y., Omori, T., Kainuma, R. & Ishida, K. Grain size dependence of pseudoelasticity in polycrystalline Cu-Al-Mn-based shape memory sheets. Acta Mater. 61, 3842–3850 (2013).

Patoor, E., Lagoudas, D. C., Entchev, P. B., Brinson, L. C. & Gao, X. Shape memory alloys, part I: General properties and modeling of single crystals. Mech. Mater. 38, 391–429 (2006).

Sozinov, A., Likhachev, A., Lanska, N. & Ullakko, K. Giant magnetic-field-induced strain in nimnga seven-layered martensitic phase. Appl. Phys. Lett. 80, 1746–1748 (2002).

Kainuma, R., Imano, Y., Ito, W., Morito, H., Sutou, Y., Oikawa, K., Fujita, A., Ishida, K., Okamoto, S., Kitakami, O., Kanomata, T. Metamagnetic shape memory effect in a Heusler-type Ni43Co7Mn39Sn11 polycrystalline alloy. Appl. Phys. Lett. 88 (2006).

Kainuma, R. et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 439, 957–960 (2006).

Mahajan, S. The role of materials science in microelectronics: Past, present and future. Progress in Materials Science 49, 487–509 (2004).

LLorca, J., Orera, V.M. Directionally solidified eutectic ceramic oxides. Prog. Mater. Sci. 51, 711 - 809 (2006).

Chen, J. et al. A review on fundamental of high entropy alloys with promising high-temperature properties. J. Alloys Compds. 760, 15–30 (2018).

Hadorn, J. P. et al. Effects of solute and second-phase particles on the texture of nd-containing mg alloys. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 43, 1363–1375 (2012).

Zahid, G., Huang, Y. & Prangnell, P. Microstructure and texture evolution during annealing a cryogenic-spd processed Al-alloy with a nanoscale lamellar HAGB grain structure. Acta Mater. 57, 3509–3521 (2009).

Hickey, K. A. & Bell, T. H. Syn-deformational grain growth: Matrix coarsening during foliation development and regional metamorphism rather than by static annealing. Eur. J. Mineral. 8, 1351–1373 (1996).

Nicchio, M. A. et al. Development of cataclastic foliation in deformation bands in Feldspar-rich conglomerates of the Rio do Peixe Basin, NE Brazil. J. Struct. Geol. 107, 132–141 (2018).

Loorents, K.-J. & Kondelchuk, D. Trends of enrichment of free mica grains in crushed rock aggregates. Bull. Eng. Geol. Environ. 68, 89–96 (2009).

Yeh, M.-W., Lin, Y.-L., Lee, T.-Y. & Ji, J.-Q. Microfabric reconstruction via quantitative digital petrographic image analysis for weakly foliated gneisses. Tectonophysics 587, 107–118 (2013).

Wilson, C. Shear zones in a pegmatite: A study of albite-mica-quartz deformation. J. Struct. Geol. 2, 203–209 (1980).

Stallard, A., Shelley, D. & Reddy, S. The initiation and development of metamorphic foliation in the Otago Schist, part 2: Evidence from quartz grain-shape data. J. Metamorph. Geol. 23, 443–459 (2005).

Mirzadeh, H., Cabrera, J., Najafizadeh, A. & Calvillo, P. Ebsd study of a hot deformed austenitic stainless steel. Mater. Sci. Eng. A 538, 236–245 (2012).

Quan, G.-Z. et al. Constitutive modeling for the dynamic recrystallization evolution of Az80 magnesium alloy based on stress-strain data. Mater. Sci. Eng. A 528, 8051–8059 (2011).

Sakai, T., Belyakov, A., Kaibyshev, R., Miura, H. & Jonas, J. J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 60, 130–207 (2014).

Ospina-Correa, J. D. et al. Process mineralogy of refractory gold ore in thiosulfate solutions. Hydrometallurgy 182, 104–113 (2018).

Mazza, F. Displacement-based seismic design of hysteretic damped braces for retrofitting in-plan irregular r.c. framed structures. Soil Dyn. Earthq. Eng. 66, 231 - 240 (2014).

Bhanja, S. & Sengupta, B. Modified water-cement ratio law for silica fume concretes. Cement Concr. Res. 33, 447–450 (2003).

Holm, E. & Foiles, S. How grain growth stops: A mechanism for grain-growth stagnation in pure materials. Science 328, 1138–1141 (2010).

Oates, A., Gorfinkiel, N., González-Gaitán, M. & Heisenberg, C. Quantitative approaches in developmental biology. Nat. Rev. Genet. 10, 517–530 (2009).

Desai, T., Millett, P. & Wolf, D. Is diffusion creep the cause for the inverse Hall-Petch effect in nanocrystalline materials?. Mater. Sci. Eng. A 493, 41–47 (2008).

Ginter, T. J. & Mohamed, F. A. Evidence for dynamic recrystallization during Harper-Dorn creep. Mater. Sci. Eng. A 322, 148–152 (2002).

Mohamed, F. A. Harper-Dorn creep: Controversy, requirements, and origin. Mater. Sci. Eng. A 463, 177–184 (2007).

Passchier, C.W. & Trouw, R.A. Microtectonics (2005).

Acknowledgements

This study was funded by the Corporación Universitaria Remington, Medellín, Colombia, for financial support (No 4000000310). J.D.O-C. is grateful to the Grupo de Investigación Ingeniar, Facultad de Ingeniería, and MinCiencias through its National Doctoral Program Scholarship. S.V-G is thankful to the Global Health Institute One-Health Colombia at Universidad Nacional de Colombia and to Politécnico Colombiano Jaime Isaza Cadavid, both located in Medellín, Colombia, for their financial support (No. 2024/00095/001). D.A.O-M is grateful to Institucion Universitaria Pascual Bravo for financial support through its Scholarship Program “Talento Pascualino” (No. VAD-1714). The work was partially supported by Universidad Nacional de Colombia at Medellín, Colombia, as a contribution to the project “Nuevos candidatos vacunales para tres enfermedades tropicales desatendidas: Zika, Chikunguña y Fiebre Amarilla (Novel vaccine candidates for three neglected tropical diseases: ZikV, ChikV, YFV) Program 93161” contract 632-2022, funded by the Ministry of Science, Technology and Innovation - MinCiencias.

Author information

Authors and Affiliations

Contributions

J.D.O-C and D.A.O-M contributed equally to this work. J.D.O-C and D.A.O-M performed the simulations and calculations included in this report. R.R-P, S.V-G, and J.P.H-O directed the discussions required to derive the model and the required computational setups. J.P.H-O conceived and guided the research. All authors contributed equally to the data analysis and manuscript preparation.

Corresponding author

Ethics declarations

Competting interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Ospina-Correa, J.D., Olaya-Muñoz, D.A., Patiño, R.R. et al. Iso-stress architecture from mineral foliation patterns. Sci Rep 15, 14158 (2025). https://doi.org/10.1038/s41598-025-99007-7

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-99007-7