Abstract

The shield tail brush loss elasticity is the key reason for the failure of shield tail seal. However, due to the limitation of test equipment, there is little research on the elastic properties of tail brush. In this research, a tail brush elastic test device was developed. Through this device, the tail brush is tested for elasticity. In this test, the grease filling layer number, tail brush mass, tail clearance, pressing number and pressing time were taken as the influencing factors, and the elastic coefficient and resilience force were taken as the response values. Single-factor test was carried out for each factor, then based on the Plackett-Burmanf theory and Box-Behnken response surface design theory, the ANOVA method was used to find out the significant degree of each factor’s influence on the quantitative index. The prediction model of elastic coefficient and resilience force was fitted based on RSM theory, and the verification group was added to verify the reliability of the prediction model. The results showed that the significance of influencing factors on the elasticity coefficient was ranked as follows: tail clearance > pressing number > pressing time > grease filling layer number. The significance of influencing factors on brush resilience F was ranked as follows: tailclearance > grease filling layer number > pressing time > pressing number. The accuracy of elastic coefficient regression model is 94.1%. The accuracy of the resilience force regression model is 99.56%, and the accuracy of the prediction model is high, which can be used to predict the elasticity coefficient and resilience force. Finally, the elastoplastic development mechanism of tail brush is discussed, and the safety standard of tail brush is proposed, which provides a basis for the selection of tail brush in practical construction.

Similar content being viewed by others

Introduction

In recent years, underwater tunnels in China have entered a period of rapid development. Compared with bridges, underwater tunnels demonstrate greater resilience to natural disasters, significantly contributing to regional economic growth1,2. Globally, numerous cross-river and cross-sea tunnels have been constructed, such as the Green Heart Railway Tunnel in the Netherlands3, the Great Belt Fixed Link in Denmark4, the Taiwan Strait Undersea Railway Tunnel5, and the Wuhan Yangtze River Tunnel6. In China, several ultra-high water pressure underwater tunnels, such as the Shantou Bay Submarine Tunnel (with water pressure up to 0.97 MPa), are under construction. This trend reflects a shift towards larger diameters and higher water pressures in underwater tunnel projects.

Existing shield tunneling technology generally considers water pressures above 0.5 MPa as high and those exceeding 0.8 MPa as ultra-high7. The highest water pressure recorded in an international shield tunnel project is 1.5 MPa (Lake Mead Intake Tunnel in the United States)8, while the highest domestic record is 1.05 MPa (Xiaolangdi Yellow River Diversion Project Shield Tunnel)9. The planned Qiongzhou Strait Tunnel will face ultra-high water pressures of up to 2.0 MPa, as illustrated in Fig. 110,11,12,13.

A reliable tail seal is a critical prerequisite for the smooth construction of underwater tunnels and has long been one of the major technical challenges in shield tunneling14,15. If the tail seal fails, external slurry can flood into the shield machine, posing severe threats to the safety of construction personnel. For instance, during the construction of the Hangzhou Qingchun Road Tunnel crossing the Qiantang River, the shield machine experienced significant upward tilting, resulting in uneven distribution of the tail gap and misalignment between the shield axis and the tunnel segment axis. By the time the shield machine reached the 124th ring, excessive slurry ingress occurred, as shown in Fig. 2, leading to near-complete failure of the tail seal and halting of the tunneling process16,17,18.

In the 1970s, Japanese researchers were the first to apply brush seals in shield tail sealing systems. Brush seals, a type of flexible contact dynamic seal, are capable of adapting to the dynamically varying tail gaps, as illustrated in Fig. 319. The tail brush is a critical component of the tail sealing system, forming the tail seal chamber together with the segment lining and the shield body. If the number of tail brushes is denoted as N, the number of tail seal chambers is N-1. The number of tail brushes required varies with the water-soil pressure conditions: for P < 3 bar, three tail brushes are used; for 3 bar ≤ P < 6 bar, four tail brushes are employed; and for 6 bar ≤ P < 10 bar, five tail brushes are recommended20,21.

During shield tunneling, the bristle ends of the tail brush must remain firmly pressed against the outer surface of the segment lining. The pressure exerted by an individual tail brush on the segment lining is defined as the tail brush rebound force. Insufficient resilience of the shield tail brush will lead to the formation of leakage channels at the free end of the brush body and the contact surface of the tube sheet, resulting in the failure of the shield tail seal, therefore, the resilience of the shield tail brush is one of the important factors affecting the performance of shield tail sealing system22.

Researchers have conducted preliminary studies on the sealing and mechanical properties of tail brushes. Wei Chunlin et al.23 performed failure tests on tail brushes using a loading test bench and observed that under identical external loads, the ultimate load capacity of the tail brush increases as the tail gap decreases, indicating a significant influence of the tail gap on the load-bearing capacity of the tail brush. Maidl24 improved the structure of tail brushes by enhancing their stiffness, thereby increasing their adaptability to variations in the tail gap and ensuring the sealing performance. Guanlin Ye et al.25 investigated the impact of tail brush rebound force on segment alignment and compared the rebound forces of wire brushes and steel plate brushes. Chao Yu et al.26 analyzed the causes of tail seal failure in the Foshan Metro Line 2 and summarized four failure modes of tail brushes, providing a preliminary structural analysis of the tail brush. Shen Guili et al.27 designed a test device for tail brush elasticity and wear resistance, though no experimental results were reported. Zhong Xiaochun et al.28,29,30 conducted more in-depth research, using indicators such as rebound force and stiffness coefficient to evaluate tail brush performance, they performed elasticity tests on tail brushes, conducted numerical simulations using Midas GTS to analyze elasticity, and developed a tail sealing unit test apparatus to measure the critical sealing pressure. However, the elasticity tests on tail brushes did not account for the influence of tail grease, and their modeling of tail brushes omitted the explicit simulation of bristle structures.

In summary, there are currently no national or international standards related to the testing and evaluation of shield tail brushes. While researchers have tested theresilience force of the shield tail brush, further refinement of testing methods is needed. On one hand, the shield tail brush is filled with viscous tail grease during operation, and the influence of the tail grease on the resilience force and elasticity coefficient of the brush requires further investigation. On the other hand, the brush is deformed due to compression by the tunnel segment, and the steps on the bristles enhance the radial support between adjacent bristles. Changes in the shield tail clearance can cause variations in the deformation of the brush and the radial support state between adjacent bristles, leading to changes in the resilience force of the brush, which ultimately affects the sealing performance of the tail brush. Therefore, studying the elastic deformation behavior of the shield tail brush is of significant engineering importance. Based on this, this study proposes a shield tail brush elasticity testing device and testing scheme, and conducts elasticity experiments on the shield tail brush, aiming to provide a scientific basis for predicting the resilience force of the brush and controlling the shield tail clearance.

Tail brush and device

At present, in the construction of shield tunnel, the selection of shield tail brush is selected according to the engineering experience. Domestic shield engineering commonly used tail brush brands are Shandong East, Shanghai Xiangdun, Shanghai Lancheng, China Railway Tunnel Croupco and Henan Suidun. In the elasticity test of tail brush, this study considered the effects of tail grease filling amount, tailskin clearance, pressing time, pressing number and tail brush mass on the elasticity of the tail brush, and the test data were more significant.

Shield tail brush structure

When a full-face tunnel boring machine operates under high water pressure, the shield tail sealing system isolates the external slurry and the grout mixture behind the lining from the interior of the shield, ensuring construction safety. The shield tail seal is located in the gap between the shield shell and the segment lining, comprising shield tail brushes and shield tail grease. The shield tail brushes are welded to the inner wall of the shield shell, with overlapping connections between adjacent brushes. Together with the shield tail grease, they effectively isolate external slurry. The real products and size of the tail brush are shown in Fig. 4.

The type of tail brush to be tested is W150-25-130-205(185), which is widely used in engineering. The initial height of the shield tail brush is 150 mm, which is composed of five parts: wire cluster, upper cover plate, lower cover plate, front protection plate, back protection plate, pin and stainless steel mesh. The thickness of the wire cluster is 20 mm, and it is superimposed in the sandwich between the front and back protection plate in a step shape. Two layers of wire mesh are added to the contact surface of the middle two layers of stainless steel mesh. The front protection plate is composed of 2 pieces of 110 mm×195 mm×1 mm manganese steel plate superimposed, the back protection plate is composed of 2 pieces of 205 mm×315 mm×1 mm manganese steel plate superimposed and 1 piece of 100 mm×195 mm×2 mm manganese steel plate superimposed, the upper cover plate and the lower cover plate are 8 mm thick manganese steel plate. The initial Angle between the back protection plate and the lower cover plate is 50°.

Device and operation procedure

Test device

According to the test object, in order to quantitatively characterize the elastic properties of the tail brush and explore the elastoplastic development trend of the tail brush under different working conditions, a set of tail brush elastic test device was developed to monitor the change of resilience of the tail brush during deformation. The overall height of the tail brush elastic test device is 1000 mm, and the width is 500 mm. It mainly includes: a hydraulic cylinder, frame, displacement sensor, tension-compression sensor, linear bearing, guiding axle, pressing plate, holddown groove, cover plate, etc.

The tail brush to be tested requires frequent replacement during the test. To facilitate flexible disassembly and assembly, the position of the holddown groove is optimized. The holddown groove is welded to the bottom of the upper panel of the test device, and the tail brush is inserted into this groove. The guiding axle is positioned at the four corners of the frame, with a linear bearing mounted on each axle. The linear bearings are bolted to the pressing plate, which simulates the outer wall of the segment. The cover plate is used to simulate the inner wall of the shield shell. The resilience force of the tail brush is measured by the tension-compression sensor, while the tailskin clearance is measured by the displacement sensor. The tailskin clearance can be adjusted by controlling the expansion and retraction of the hydraulic cylinder’s piston rod, causing the pressing plate to rise and fall along the guiding axle. The tail brush elasticity test device is shown in Fig. 5.

Operation procedure

At present, there is no corresponding elastic test standard for tail brush. To ensure the repeatability of test results, the following operation steps are adopted to carry out the test, and the operation process is illustrated in Supplementary Fig. S1.

STEP 1: Set test parameters. Enter the tailskin clearance, pressing number and pressing time. The tailskin clearance can be adjusted in the range of 25–200 mm, pressing time is 0–50 h, and pressing number is 0-400 times;

STEP 2: Fill the tail grease. Fill the bottom of the tail brush with tail grease so that the tail grease covers the wire cluster until a small amount spills. In this experiment, CRIA grease of China Railway Construction South China High-tech Industry Co., LTD., which was used in the Pearl River Tunnel of Guangzhou Metro Line 22 in June 2019, with a river crossing distance of 1000 m, and no leakage occurred, and its sealing performance was reliable;

STEP 3: Install the tail brush. The lower cover plate of the tail brush is to be upwards and insert the tail brush into the holddown groove;

STEP 4: Tighten the bolts. Tighten the bolts of the Holddown groove so that the lower cover plate of the tail brush is close to the Holddown groove of the test device to simulate the state of the tail brush welded on the shield shell;

STEP 5: Press the tail brush. Start the motor of the hydraulic system, operate the piston rod of the hydraulic cylinder to extend, push the pressing plate to press the tail brush, and obtain the change of the tailskin clearance through the displacement sensor;

STEP 6: Measure the resilience force of the tail brush. When the tailskin clearance reaches the set value, the piston rod will automatically stop, stand for some time (this time is the press time set in STEP 1), measure the resilience force of the tail brush during the rest, after the measurement is completed, the piston rod will be withdrawn, and the press action will be repeated according to the pressing time set in STEP 1.

In the above operation process, the test can be carried out by changing the grease filling layer number, tailskin clearance, pressing number, pressing time and tail brush mass.

Evaluation index of elastic properties

Residual coefficient

The elastic property of the tail is the ability of the tail brush to recover its original shape and mechanical properties after being deformed by external forces. During tunneling, the tail brush is deformed, and the resilience force of the tail brush under different deformation conditions is measured through the press test of the tail brush. After the test, the piston rod is retracted to separate the pressing plate from the tail brush, the tail brush is left for 1 min, the height of the front protection plate and the back protection plate are measured, and the residual height of the tail brush is recorded by summing and averaging. As shown in Fig. 6.

Initial height H is calculated according to Eq. (1):

Where \(\:{H}_{1}\) is the height of the front protection plate in the initial state(mm); \(\:{H}_{2}\) indicates the height of the back protection plate in the initial state(mm).

Residual height h is calculated according to Eq. (2):

Where \(\:{h}_{1}\) is the height of the front protection plate after the test(mm); \(\:{h}_{2}\) is the height of the back protection plate after the test(mm).

Residual coefficient \(\varphi\) is calculated according to Eq. (3):

Where H is the initial height of the tail brush (mm); h is the residual height of the tail brush (mm).

Elastic coefficient

A single tail brush is an elastic component that is always close to the inner wall of the shield shell during the construction process. When the tailskin clearance changes, the compression amount of the tail brush also changes. After long-term and repeated compression, the elastic performance of the tail brush has changed. The difference between the residual height of the tail brush and the tailskin clearance between the tail brush is used as the effective height L to generate the rebound force of the tail brush. The effective height is calculated according to Eq. (4):

Where h is the residual height of the tail brush (mm); E is tailskin clearance(mm).

With the same type of tail brush, tailskin clearance and the grease filling layer number, the resilience force of the tail brush may be different if the pressing time and pressing number are different. To objectively evaluate the elastic properties of the tail brush, the ratio of the resilience force of tail brush to the effective height of tail brush is taken as the elastic coefficient of tail brush, in the unit of N/mm. The larger \(\:k\) is, the greater the resilience force of the tail brush provided by the unit effective height is, the smaller the elastic loss of the tail brush is, and conversely, the greater the elastic loss of the tail brush is.

Elastic coefficient k is calculated according to Eq. (5):

Where F is the elastic coefficient of the tail brush (N).

Resilience force

To form a reliable seal at the contact surface between the tail brush and the segment, the tail brush should provide enough resilience force of the tail brush under press. The greater the resilience force of the tail brush, the closer the tail brush is to the segment; otherwise, the more relaxed the tail brush is to the segment. By analyzing Eq. (5), it can be seen that the resilience force of tail brush is positively correlated with the elastic coefficient.

Design and analysis of tail brush elasticity test

Single factor testing and analysis

Single factor test desgin

To investigate the influence of key factors on the elastic behavior of tail brushes, five groups of single-factor experiments were conducted, targeting grease filling layer number, tail brush mass, tail clearance, pressing cycles, and pressing duration. In each group, only one parameter was varied while all other conditions were held constant. Specifically, six grease layer levels (0–5), five brush mass configurations, seven tail clearance values (40–100 mm), ten pressing cycle levels (1–400), and eleven pressing durations (0–50 h) were tested. Each condition was repeated three times to ensure statistical robustness and assess data reproducibility. Mean values and 95% confidence intervals were subsequently calculated based on the three replicated datasets.

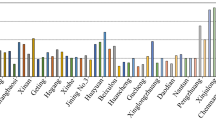

The influence of tail brush mass

Different brands of W150-25-130-205(185) type tail brush appearance is similar, all use 65Mn steel plate and φ0.35 mm SUS202 stainless steel wire, but different manufacturers use steel plate size and steel wire density are different, so different brands of tail brush quality is different. The tail brush sold by Shandong East (SDYST), Shanghai Xiangdun (SHXD), Shanghai Lancheng (SHLC), China Railway Tunnel Croupco (CRTG), Henan Suidun (HNSD) were weighed. The specifications of each brand of tail brush are shown in Table 1. Among them, SDYST and CRTG have larger mass, while the other three brands have lower mass.

In the test in this section, the tail brush mass was taken as the influencing factor, the tailskin clearance was set to 50 mm, the pressing number was fifty times, the grease was not filled, and the resilience force and residual height of the tail brush were monitored. The test results are shown in Table 2. The analysis of Table 2 shows that the minimum and maximum elastic coefficients of the tail brush are 19.848 N /mm and 20.980 N /mm, and the elastic coefficients can be approximately equal. The minimum residual height is 115.3 mm, the maximum is 124.0 mm; The minimum resilience force is 1370.3 N, and the maximum resilience force is 1479.6 N. The resilience force and residual height of the tail brush are obviously different when the mass is different.

The test results of resilience force, residual height and elastic coefficient of different tail brush mass are shown in Fig. 7. The analysis of Fig. 7 shows that when the tailskin clearance is 50 mm, the resilience force generated by the tail brush with larger mass under pressing is 109.3 N larger than that of the tail brush with smaller mass, and the residual height is 5.4 mm higher than that of the tail brush with smaller mass. According to the test results, when the tail brush material is the same, the ability of the large mass tail brush to recover to the state before press deformation is better than that of the small mass tail brush.

The influence of grease filling layer number

Tail grease is a yellow paste primarily composed of oil, with the addition of fibers, thickeners, and fillers. Its shear stress has a nonlinear relationship with the shear strain rate, classifying it as a non-Newtonian fluid. In the tail grease filling test, CRIA-P1 tail grease produced by China Railway South China Construction was used. The tail grease filling was categorized into six levels (as shown in Fig. 8): 0 layers, 1 layer, 2 layers, 3 layers, 4 layers, and 5 layers. In this classification, 0 layers means no tail grease is filled, while 5 layers indicates that tail grease is filled in all the interlayers of the steel wire.

In the preparation phase of the test, the tail grease was filled into the steel sandwich of the SDYST tail brush according to the preset number of tail grease filling layers until the tail grease spilled a small amount from the top of the tail brush. After the test began, the shield tailskin clearance was set to 50 mm, and then the filled tail brush was pressed 50 times to make the tail grease fully filled into the gap between the steel wire. The pressure sensor value at the 50th time of pressing was taken as the resilience of the tail brush, and the residual height was measured after compression. The test results are shown in Table 3.

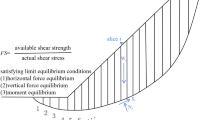

According to Fig. 9, after the tailskin clearance is set to 50 mm, press the tail brush 50 times. As the number of layers filled with tail grease increases from 0 to 5, the resilience of the tail brush decreases from 1465.9 N to 1267.3 N, decrease of 198.6 N, and the residual height decreases from 123.7 mm to 108.0 mm. The reasons for this phenomenon are: The tail brush wire is a stainless steel wire with uniform steps. The presence of the steps increases the friction coefficient of the steel wire in contact with each other when sliding axially, thus increasing the axial holding force between the steel wire31. When the tail brush is under pressure, the resilience of the steel plate and the resilience of the steel wire together form the resilience of the tail brush, and the axial holding force and the radial supporting force between the adjacent steel wires together form the resilience of the tail brush. As shown in Fig. 8.

After the tail grease is filled, the tail brush is pressed, and the tail grease filled in the gap between the steel wires has a lubricating effect, which reduces the friction coefficient of axial sliding relative to the adjacent steel wire, reduces the axial holding force of the steel wire, slides between the adjacent steel wires, and reduces the radial support force between the steel wire steps. The final performance is reduced the rebound force of the shield tail brush. After pressing, due to the large viscous force of the tail grease between the steel wire and its strong resistance to shear deformation, the steel wire cannot fully rebound. Therefore, the residual height of the tail brush decreases with the increase of the filling layers of the tail grease, and the quarter-on-quarter attenuation rate of the residual height exceeds the quarter-on-quarter attenuation rate of the elastic coefficient of the tail brush. This results in a small increase in the elastic coefficient in the range of 19.269–21.863 N/mm.

The influence of Tailskin clearance

In actual shield engineering, the change of tail attitude will lead to the change of tailskin clearance, and the tailskin clearance can be maintained in the range of 40–100 mm, and the resilience force of tail brush generated under different tailskin clearance is different.

When discussing the correlation between the tailskin clearance and the resilience force of the tail brush, the tailskin clearance is divided into 7 levels: 100 mm, 90 mm, 80 mm, 70 mm, 60 mm, 50 mm, 40 mm, fill all steel wire interlayers of SDYST tail brush with CRIA-P1 tail grease, press the measuring tail brush once, stop pressing after reaching the set tail gap, record the rebound force of the tail brush at this time, and make the press plate drop. Measure the residual height h of the tail brush and calculate the elastic coefficient of the tail brush according to Eq. (5). The test results are shown in Table 4.

After the tail brush is filled with grease, the resilience force and elastic coefficient of the tail brush change with the tail clearance, as shown in Fig. 10.

When the tail brush is pressed once, the resilience force and elastic coefficient of the tail brush increase as the tailskin clearance decreases, which is consistent with the practice. When the tailskin clearance is reduced from 100 m to 70 mm, the elastic coefficient of the tail brush shows an increasing trend. This is because when the tailskin clearance is 100 mm, the front protection plate contacts the segment and only slightly deforms. At this time, the resilience force of the tail brush is mainly provided by the rear protection plate and part of the steel wire. When the tailskin clearance is less than 70 mm, the elastic coefficient of the tail brush fluctuates around 14.5 N/mm, and the pressure of the tail brush increases linearly with the decrease of the tailskin clearance, because at this time, the front protection plate, the rear protection plate and the steel wire brush are fully compressed and deformed, and the compound action of the three forms an elastic component, so the elastic coefficient tends to be stable. When tunneling, the steel wire clusters of the tail brush and the front and rear protection plates should be kept close to the outer wall of the tube to prevent external impurities such as mud and water from polluting the sealing cavity. It is recommended that the shield tailskin clearance should not be greater than 70 mm, and the tail brush should be fully pressurized, so that the elastic coefficient and resilience force can be kept stable.

The influence of pressing time

When the shield machine is driving, the tailskin clearance is generally controlled between 50 and 70 mm. According to the test results of the tailskin clearance of 40–100 mm (see Table 4), when the tailskin clearance is 50 mm, the tail brush is fully compressed and deformed. Therefore, to study the elastoplastic development of the tail brush after continuous pressure, the tailskin clearance is set at 50 mm. The continuous pressing time is divided into the following 11 levels: At 0 h, 5 h, 10 h, 15 h, 20 h, 25 h, 30 h, 35 h, 40 h, 45 h, 50 h, the shield brush (SDYST_1) not filled with the shield oil and the shield brush (SDYST_2) filled with CRIA-P1 tail oil were pressed. The resilience force and residual height at each level were recorded, and the test results are shown in Table 5.

According to Table 5, when the tailskin clearance is 50 mm, the tail brush is under continuous pressure, and its residual height and generated resilience decrease with the compression time. After compression for 50 h, the residual height of SDYST_1 decreases from 151.0 mm to 115.7 mm, the resilience decreases from 1561.8 N to 1340.9 N, and the elastic coefficient increases from 15.468 N/mm to 20.421 N/mm. The residual height of SDYST_2 decreases from 144.0 mm to 108.3 mm, the resilience decreases from 1328.6 N to 1203.6 N, and the elastic coefficient increases from 14.139 N/mm to 20.650 N/mm.

The irreversible deformation of the front and rear steel plates of the tail brush after continuous pressure includes plastic deformation and creep, among which plastic deformation is the main one, and only plastic deformation is considered in this test. The press test results of SDYST_1 and SDYST_2 are shown in Fig. 11.

It can be seen from Fig. 11 that the changes of resilience force, residual height and elastic coefficient of SDYST_1 and SDYST_2 mainly occurred before 40 h. During the continuous pressing stage from 1 h to 40 h, the tail brush remained in a plastic yield state, and the plastic development was slow. At this stage, the resilience force and residual height of SDYST_2 are always smaller than that of SDYST_1. When the pressing time exceeds 40 h, the elastic coefficient of SDYST_2 gradually becomes the same as that of SDYST_1.

The resilience force and residual height of SDYST_2 are always smaller than that of SDYST_1 for the following two reasons:

-

(1)

The tail grease filled inside SDYST_2 reduces the axial holding force and radial support force between the steel wires, resulting in a decrease in the resilience of the tail brush. At the same time, the tail grease is a viscous non-Newtonian fluid with a coning degree of 230–240 × 0.1 mm and strong shear deformation resistance, which will prevent the rebound after it is filled into the gap of the tail brush wire. It will also lead to a decrease in the resilience of the tail brush.

-

(2)

When the tail brush is under pressure, plastic deformation occurs, resulting in reduced resilience and residual height.

The influence of pressing number

In order to study the change of resilience force and elastoplastic development of the tail brush after repeated pressure, the tailskin clearance was set to 50 mm, and the pressing number was divided into the following 10 levels: Press tests were carried out on SDYST_3 which was not filled with tail grease and SDYST_4 which was filled with CRIA-P1 tail grease for 1, 10, 50, 100, 150, 200, 250, 300, 350 and 400 times, respectively. The resilience force of the tail brush was recorded by the console sensor, and the residual height of the tail brush under the corresponding pressing number was recorded by manual measurement. The test results are shown in Table 6.

The analysis of Table 6 shows that after 400 times of compression, the resilience force of SDYST_3 decreases from 1565.3 N to 1386.1 N, the residual height decreases from 151.0 mm to 113.0 mm, and the elastic coefficient increases from 15.498 N /mm to 22.011 N/mm. The resilience force of SDYST_4 decreases from 1339.8 N to 1239.8 N, the residual height decreases from 143.7 mm to 103.0 mm, and the elastic coefficient increases from 14.309 N/mm to 23.261 N/mm. 8.952.

According to the analysis of test data, the stress value of SDYST_3 and SDYST_4 in the process of repeated compression and deformation exceeds the equivalent yield strength of the tail brush for many times. Therefore, with the increase of pressing number, the tail brush will produce plastic deformation, resulting in a decrease in the resilience force and residual height of the tail brush. Figure 12 shows that this trend is more obvious before the 300th pressing. During the period of 1-300 presses, the change rates of the resilience force, residual height and elastic coefficient of the tail brush decrease rapidly, and the elastic coefficients of SDYST_3 is stable at about 22.0 N/mm, and that of SDYST_4 is stable at about 23.0 N/mm.

The test results show that during the 1st to 300th compression, the elasticity of the tail brush varies in the following two stages, and the proportion of the change of variables in each stage to the total change is shown in Table 7.

STAGE 1: During the 1st to 50th press, the changes of resilience force, residual height and elastic coefficient of SDYST_3 without grease filling are − 121.9 N, -28 mm and + 4.283 N/mm, respectively, and the changes of resilience force, residual height and elastic coefficient of SDYST_4 with grease filling are − 57.2 N, respectively. -32.7 mm, + 7.516 N/mm.

STAGE 2: In the 51–300 times of press, the changes of resilience force, residual height and elastic coefficient of SDYST_3 without oil were − 67.2 N, -10.3 mm and + 2.179 N /mm, respectively. The changes of resilience force, residual height and elastic coefficient of SDYST_4 were − 43.9 N, -8.0 mm and + 2.350 N /mm, respectively.

Plackett-Burman testing and analysis

Plackett-Burman test design

The Plackett-Burman factorial test can screen factors that have a significant impact on the evaluation index and provide a basis for the selection of factors and levels in the Box-Behnken test design32. The test consumables include CRIA-P1 type tail grease and CRTG and SHLC brand tail brush, as illustrated in Supplementary Fig. S2.

According to the Plackett-Burman test design, five possible influencing factors (A-tail brush mass, B-grease filling layer number, C-tail clearance, D-pressing time, E-pressing number) and six blank factors (F, G, H, J, K, L) were selected, each with two levels. Using the elasticity coefficient(R1) and resilience force(R2) of tail brush as evaluation indices, a total of 12 tests group were designed. To ensure data reliability and assess reproducibility, each test was repeated twice under identical conditions, and the mean values of the replicates were used for analysis. The test factors and levels are listed in Table 8.

Analysis and discussion of Plackett-Burman test results

The results of the Plackett-Burman factorial test are shown in Table 9.

According to the variance analysis results in Tables 10 and 11, it can be seen that the grease filling layer number, the tail clearance, the pressing time, and the pressing number have significant effects on the elastic coefficient(R1) and the resilience force(R2). The order of the significance of the influence on the elastic coefficient (R1) is C > D > B > E, and the influence of A on the elastic coefficient (R1) is not significant; The order of significance of the influence on the resilience force (R2) of tail brush was C > B > D > E, and the effect of A on the resilience of tail brush (R2) was not significant.

Therefore, B-grease filling layer number, C-tail gap, D-pressing time and E-pressing number were selected as the influencing factors to beinvestigated in the design of the Box-Behnken experiment.

Box-Behnken testing and analysis

Box-Behnken test desgin

In the Box-Behnken test, the SDYST tail brush with a mass of 4.2 kg was used. According to the screening sequence results of the Plackett-Burman test, four influencing factors should be selected (A- grease filling layer number, B-tail clearance, C- pressing time, D-pressing number), and three levels of -1, 0, and 1 should be set for each factor. A total of 29 experimental runs were conducted, consisting of 24 factorial points and 5 center points. To estimate experimental variability and ensure statistical reliability, the center point was replicated five times under identical conditions. Specific factors and levels are shown in Table 12.

It should be noted that the meaning of layer 2.5 for factor A is: fill two layers of tailgrease into the tail brush first, so that these two layers of tail grease overflow from the top of the tail brush in a small amount; when filling the third layer of tail grease, fill only half of the tail brush, so that the tail grease overflow from the top half of the tail brush.

Analysis and discussion of Box-Behnken test results

With the elastic coefficient and the resilience force of tail brush as response values, the specific test results are shown in Table 13.

The relationship between the influencing factors and the elastic coefficient(R1) and resilience force(R2) is non-linear. According to the data samples identified in Table 13, the quadratic polynomial regression model of the elastic coefficient(R1) and resilience force(R2) is obtained by using the multiple regression method and considering the interaction between the two factors, as shown in Eq. (6) and Eq. (7).

Where, R1 is the elastic coefficient; R2 is the resilience force; A is grease filling layer number, B is tail clearance, C is pressing time, and D is pressing number.

The significance test of the regression model was carried out, and the test result was represented by p: when p ≤ 0.05, the regression model was significant and had statistical significance; When p ≤ 0.01, the model is verysignificant33. Equation (6) is the elastic coefficient regression model, and the variance analysis results of this regression model are shown in Table 14. According to the results of variance analysis, the influence of A is not significant, C is significant, and B and D are extremely significant. In the second term, B has a significant effect, and D has a significant effect. The interaction between B and D is significant. The influence of influencing factors on the elastic coefficient(R1) is in the order of B > D > C > A from large to small.

As can be seen from Table 14, the regression model has significance(p < 0.0001), the model missing item is not significant(p = 0.2317 > 0.05), no missing factor exists, and the model’s complex correlation coefficient R-Squared = 0.9274, indicating that the model can explain 92.74% of the response value change, and themodel has a high degree of fit with the actual test. The resulting experimental error is small, the Adj R-Squared = 0.8547 > 0.80, and the C.V.=7.36%, indicating that only 14.53% of the variation exceeds the explanatory range of the model, which further proves that the model has a good fit and can be used for preliminary analysis and prediction of the elastic coefficient(R1).

With B and D as influencing factors and elastic coefficient (R1) as response, RSM response surface diagram was drawn, as shown in Fig. 13.According to the analysis of Fig. 13, the contour lines of B and A are elliptical, which indicates that the interaction between the two factors is significant, and the density of contour lines along the B direction is significantly greater, indicating that B has a more significant impact on the elastic coefficient (R1), which is consistent with the results of ANOVA. When B decreases from 80 mm to 40 mm, the elastic coefficient (R1) increases with the increase of D. When B decreases and D increases simultaneously, the elastic coefficient (R1) increases the fastest.

Equation (7) is the resilience force regression model, and the variance analysis results of this regression model are shown in Table 15. According to the results of variance analysis, factors A, B, C and D have significant effects. In the second term, A and B have significant effects, while C and D have significant effects. The interaction terms among the factors were not significant.

As can be seen from Table 15, the regression model has significance (p < 0.0001), the lack of fit is not significant (p = 0.2654 > 0.05), no missing factor exists, and the model’s complex correlation coefficient R-Squared = 0.9908, indicating that the model can explain 99.08% of the response value change, and the model has a high degree of fit with the actual test. The resulting experimental error is small, the Adj R-Squared = 0.9816 > 0.80, and the C.V.=3.48%, indicating that only 1.84% of the variation exceeds the explanatory range of the regression model, which further proves that the tail brush resilience force prediction model is relatively reliable.

With A and B as influencing factors and shield tail brush resilience force (R2) as response, the RSM response surface diagram was drawn, as shown in Fig. 14. For the response surface curves of the ratio A and B directions, it is found that: compared with the A direction, the response surface curve in the B direction is steeper, and the contour density in the B direction is significantly higher than that in the A direction, indicating that B contributes more to the resilience force of tail brush (R2). Therefore, the influencing factors on the resilience force of tail brush (R2) are as follows: B > A > C > D in descending order.

Verification

Based on the above regression model, taking the maximum of elastic coefficient (R1) and resilience force (R2) as the optimization objectives, and considering the feasibility of actual operation, the optimal combination of influencing factors obtained is as follows: A-grease filling layer number is 0 layers, B-tail clearance is 45 mm, C- pressing time is 50 h, and D-pressing number is 399 times. Under this combination, the predicted values of elasticity coefficient (R1) and resilience force (R2) were 25.6 N/mm and 1436.7 N, respectively.

To verify the prediction accuracy of the regression model, three tests were repeated under the optimal combination of influencing factors, and the average value of the results was taken, as shown in Fig. 15. The results show that the mean value of the elastic coefficient (R1) is 24.1 N/mm, and the error rate with the predicted value is 5.9%. The mean value of the brush resilience force (R2) was 1443.0 N, and the error rate from the predicted value was 0.44%. the error rate was low, indicating that the regression model can be used to calculate the elastic coefficient (R1) and the brush resilience force (R2).

Elastic-plastic development law and safety standard of tail brush

During shield tunneling, it is necessary to monitor and control shield tail clearance. Too small shield tail clearance will lead to abnormally large resilience force of tail brush acting on segments, accelerate tail brush wear, and seriously cause hard friction between segments and tail brush during tunneling, reducing tunneling speed and damaging segments. If the tail clearance is too large, it will lead to the seal failure of the tail shield, leakage of slurry, and harm the personal safety of workers. Therefore, in shield engineering, the tail clearance is strictly controlled within the range of the ideal tail clearance, which is generally 50 ± 10 mm.

To make the research content reference to the actual project, the grease filling layer number was uniformly set to 5 layers, the pressing number was set to 399 times, and the tail clearance was set to 5 levels: 40 mm, 45 mm, 50 mm, 55 mm, 60 mm. The changes of elastic coefficient and resilience force with the pressing time were calculated, and the results were shown in Table 16.

A comprehensive analysis of Fig. 16 shows that in the process of applying continuous press to the tail brush that has been repeatedly pressed, the elastic coefficient changes slightly over time, which is consistent with the test results of the pressing number.

At this stage, the resilience force of the tail brush decreases with time, and the main reasons for this phenomenon are:

-

(1)

The tail brush is a non-Newtonian fluid. When the tail grease is standing, the shear rate is small, the shear deformation resistance is stronger, and the test time of continuous pressing is longer, which reduces the water content of the tail grease and increases the viscosity, inhibits the rebound of the tail brush, andreduces the resilience force of the tail brush.

-

(2)

During the press process, the tail brush steel wire and the steel plate produce plastic deformation.

According to the data in Table 16, when the tail clearance is 40 mm, the mean elastic coefficient is 22.1 N/mm and the variance is 0.0346. When the tail clearance is 60 mm, the mean elastic coefficient is also 22.1 N/mm and the variance is 0.0307. When the tail clearance is 50 mm, the mean elastic coefficient is 23.4 N/mm, the sample variance is only 0.0047, the dispersion of the elastic coefficient is the lowest, and the stability is the best. When the tail clearance increases or decreases with the base of 50 mm, the sample variance increases, the elastic coefficient dispersion increases, and the stability deteriorates. When the tail clearance is different, the deformation of steel wire and steel plate of shield tail brush is different, and the axial holding force and radial support force between steel wire and steel wire are different, the application point and stability are also different, which is the main reason for the change of elastic coefficient of the tail brush.

Further analysis of the resilience force data shows that: when the tail clearance is 40 mm, the mean resilience force is 1364 N, the variance is 423, and the resilience force dispersion is the lowest, and the data stability is the best. When the tail clearance increases, the deformation of the tail brush decreases, and the resilience force of the tail brush decreases. When the tail clearance increases, the variance of the resilience force increases significantly, and the data stability deteriorates. To make the tail brush form a reliable seal when the tail clearance is constantly changing and reduce the risk of shield tail seal failure, first of all, the tail clearance should be strictly controlled to be less than 60 mm. Secondly, the elasticity test should be conducted for the shield tail brush, and the grease filling layer number should be set to 5 layers and the pressing number should be set to 399 times. The tail brush should meet the safety standards in Table 17.

Conclusions

During shield tunneling, the shield tail brush is deformed by the shield shell and tube sheet extrusion, the whole ring of shield tail brush separates the shield tail seal into multiple grease chambers, which can separate the external grout from the grease chambers, and the ability to maintain reversible elastic deformation and irreversible plastic deformation during the deformation process of the shield tail brush has become a concern for some researchers. To solve this problem, a tail brush elastic test device was developed and the evaluation index of tail brush elastic properties was proposed. The following conclusions were derived.

-

(1)

The device fully meets the requirements for testing the elasticity of the tail brush. It can simulate a range of tailskin clearances, with the maximum simulated clearance reaching 200 mm. The device is capable of monitoring both tailskin clearance and tail brush resilience force, and it can perform elastic tests on multiple brands of tail brushes. A standard test protocol for tail brush elasticity has been established, ensuring the feasibility of the tests.

-

(2)

The evaluation index provides a basis for the quantitative analysis of the elastoplasticity of the shield tail brush. Specifically, the smaller the residual coefficient, the less plastic deformation the tail brush undergoes; the larger the elastic coefficient, the greater the resilience force the tail brush can provide for unit deformation, indicating that the tail brush adheres more closely to the segment. After the test, the data for the residual coefficient, elastic coefficient, and resilience force of the tail brush are analyzed to explore the elastoplastic development behavior of the tail brush.

-

(3)

When the tail brush filled with grease is pressed and deformed, the grease plays a lubricating role, which reduces the axial holding force and radial support force between the stepped steel wire. After the pressing, the grease is very viscous and has strong resistance to shear deformation, which hinders the rebound of the steel wire. In the end, the resilience force and residual height of the tail brush decreased with the increase of the grease filling layer number. In addition, when the tailskin clearance is less than 70 mm, the front and back protection plates and steel wire clusters of the tail brush are fully compressed and deformed close to the outer wall of the segment. At this time, the three compound effects form a stable elastic body, so it is recommended that the tailskin clearance is always less than 70 mm in practical engineering.

-

(4)

Taking the tail brush as the research object, the Plackett-Burman test and Box-Behnken test methods were used to determine that the shield tailskin clearance has the most significant influence on the elastic properties of the tail brush. A regression model of tailskin clearance and the resilience of the tail brush with high accuracy was proposed. Therefore, in engineering, it is necessary to control the tailskin clearance within a reasonable range of 40–60 mm, perform an elastic test on the tail brush, and select a tail brush that meets the safety standards in Table 17.

It is worth noting that shield tail brush resilience force and elastic coefficient can be obtained experimentally and can be accurately predicted using Box-Behnken Response Surface Design Theory, which is applicable to common shield tail brushes on the market.

Data availability

All data generated or analysed during this study are included in the original manuscriptof this submission.

References

Chen, X. S. Research on combined construction technology for Cross-Subway tunnels in underground spaces. Engineering 4, 103–111. https://doi.org/10.1016/j.eng.2017.08.001 (2018).

Xiang, Y. Y. & Song, W. J. Upper-Bound limit analysis of shield tunnel stability in undrained clays using complex variable solutions for different Ground-Loss scenarios. Int. J. Geomech. 17, 04017057. https://doi.org/10.1061/(ASCE)GM.1943-5622.0000946 (2017).

Yuan, D. J., Wu, J., Shen, X., Jin, D. L. & Li, X. G. Engineering safety of Cross-River or Cross-sea Long-distance Large-diameter shield tunneling under superhigh water pressure. China J. Highw Transp. 33, 26–45. https://doi.org/10.19721/j.cnki.1001-7372.2020.12.003 (2020).

Yang, W. W. Development of underwater Shield-bored tunnels. Tunn. Constr. 29, 145–151 (2009).

Wang, M. S. Current developments and technical issues of underwater traffic tunnel-discussion on construction scheme of Taiwan Strait undersea railway tunnel. Chin. J. Rock. Mech. Eng. 27, 2161–2172 (2008).

Editorial Department of China Journal of Highway and Transport. An Academic Research Summary on China Highway and Transport. China J. Highw. Transp. 25, 2–50. https://doi.org/10.19721/j.cnki.1001-7372.2012.03.002 (2012).

Xiao, M. Q. Representative projects and development trend of underwater shield tunnels in China. Tunn. Constr. 38, 360–367 (2018).

Rinaldl, G., Cuppone, P. & Turl, A. Eurasia Tunnel-Construction features of a tunnel under severe pressure conditions in high seismic area. Tunnels Undergr. Cities Eng. Innov. Meet Archaeol. Archit. Art. 2930–2939. https://doi.org/10.1201/9780429424441-310 (2019).

Schuerch, R., Perazzelli, P. & Nickerson, J. C. CimiottiG. & Anagnostou. Lake Mead Intake No. 3-The TBM tunneling experience. World Tunnel Congress San Francisco, CA, USA. April 22–28, 2752–2761 (2016).

Hong, K. R. Typical underwater tunnels in the Mainland of China and related tunneling technologies. Engineering 03, 871–879. https://doi.org/10.1016/j.eng.2017.12.007 (2017).

Jiang, B. L., Liang, B. & Wu, S. S. Feasibility study on the submerged floating tunnel in Qiongzhou Strait. China Pol. Marit Res. 25, 4–11. https://doi.org/10.2478/pomr-2018-0066 (2018).

Chen, A., Tao, W. M., Zhu, Y. & Fan, L. Study on key technology of Qiongzhou Strait tunnel. Railway Standard Des. 66, 101–106. https://doi.org/10.13238/j.issn.1004-2954.202101210009 (2022).

Qu, C. Q. The new comprehensive evaluation system for subsea tunnel site selection: A case study of the Qiongzhou Strait, China. Mar. Georesour Geotechnol. 41, 895–911. https://doi.org/10.1080/1064119X.2022.2108357 (2022).

Xiao, M. Q. Design technology of underwater tunnels. China Railway Publishing House Co. Ltd. (2016).

Yang, C., Shen, S. L., Hou, D. W., Liao, S. M. & Yuan, D. J. Material properties of the seal gasket for shield tunnels: A review. Constr. Build. Mater. 191, 877–890. https://doi.org/10.1016/j.conbuildmat.2018.10.021 (2018).

Shen, X. Study on the dynamic interaction mechanism of Machine-Soil in shield tunneling. Beijing Jiaotong Univ. (2020).

Zeng, L. et al. A novel real-time monitoring system for the measurement of the annular Grout thickness during simultaneous backfill Grouting. Tunn. Undergr. Sp Technol. 105, 103567. https://doi.org/10.1016/j.tust.2020.103567 (2020).

Oh, J. Y. & Ziegler, M. Investigation on influence of tail void grouting on the surface settlements during shield tunneling using a stress-pore pressure coupled analysis. KSCE J. Civ. Eng. 18, 803–811. https://doi.org/10.1007/s12205-014-1383-8 (2014).

Hong, K. N. & Feng, H. H. Development trends and views of highway tunnels in China over the past decade. China J. Highw Transp. 33, 62–76. https://doi.org/10.19721/j.cnki.1001-7372.2020.12.005 (2020).

Wang, Q. et al. Use of deep learning, denoising technic and cross-correlation analysis for the prediction of the shield machine slurry pressure in mixed ground conditions. Automat Constr. 128, 103741. https://doi.org/10.1016/j.autcon.2021.103741 (2021).

Hu, M., Liu, J., Zhou, W. B., Xu, W. & Wu, Z. Y. A multistage model for rapid identification of geological features in shield tunnelling. Sci. Rep. 13, 1799–1799. https://doi.org/10.1038/s41598-023-28243-6 (2023).

Wang, X. Y., Yuan, D. J., Jin, D. L. & Su, W. L. Thermal and mechanical response of soil and tunnel during replacement of shield tail brush by freezing method. KSCE J. Civ. Eng. 24, 1632–1640. https://doi.org/10.1007/s12205-020-1591-z (2020).

Wei, L. C. Experimental study on mechanical behavior of wire brushes on shield tail. Tunn. Constr. 41, 206–211 (2021).

Maidl, B. et al. Mechanised shield tunnelling. 2nd ed. Berlin: Ernst Sohn 87–99 (2012).

Ye, G. L., Han, L., Yadav, S. K., Bao, X. H. & Liao, C. C. Investigation on the tail brush induced loads upon segmental lining of a shield tunnel with small overburden. Tunn. Undergr. Sp Technol. 97, 103283–103283. https://doi.org/10.1016/j.tust.2020.103283 (2020).

Yu, C., Zhou, A. N., Chen, J., Arulrajah, A. & Horpibulsuket, S. Analysis of a tunnel failure caused by leakage of the shield tail seal system. Undergr. Space. 5, 105–114. https://doi.org/10.1016/j.undsp.2018.11.003 (2020).

Shen, G. L. et al. Design of and study on tail brush experimental platform. Tunn. Constr. 35, 851–854 (2015).

Zhong, X. C., Zhong, J. L., Zhu, W. B., Wan, J. C. & Zhu, N. W. Numerical simulation and elastic performance evaluation of shield tail brush under compression. J. Undergr. Space Eng. 19, 1115–1124 (2023).

Zhong, X. C. et al. Analysis of sealing performance of shield tail brush based on compression and grease escape test. J. Southwest. Jiaotong Univ. 58, 125–132 (2023).

Zhong, X. C. et al. Unit test on shield tail brush annular sealing system and its watertightness mechanism. Chin. J. Geotech. 45, 354–361. https://doi.org/10.11779/CJGE20211464 (2023).

Zuo, Q., Wu, H. W., Wang, C. H. & Du, J. J. Effect of yarn Struction on tensile properties of Ramie staple yarn reinforced composites. Text. Res. J. 44, 81–89. https://doi.org/10.13475/j.fzxb.20220804801 (2023).

Sanaz, A. S., Mirhassan, R. S., Abass, S. & Mohsen,B. Aspergillus Niger as an eco-friendly agent for potassium release from K- bearing minerals: isolation, screening and culture medium optimization using Plackett-Burman design and response surface methodology. Heliyon 1, e29117. https://doi.org/10.1016/j.heliyon.2024.e29117 (2024).

Amine, D., Abdeltif, A., Tounsia, A. & Naima, B. Correction to: characterization of Cardinal vine shoot waste as new resource of lignocellulosic biomass and valorization into value–added chemical using Plackett–Burman and box Behnken. Biomass Convers. Bior. 13, 17283–17283. https://doi.org/10.1007/s13399-021-01717-1 (2023).

Acknowledgements

The work was financially supported in part by the National Key Research and Development Program of China (Granted No. 2020YFB1709504), Hebei Province doctoral graduate student innovation ability training funding project (Granted No. CXZZBS2024145) and S&T Program of Hebei (Granted No. 23567602 H). The financial support is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Author contributions: J.L., J.G., S.Y. and M.H. wrote the main manuscript text and prepared Figs. 1, 2, 3, 4, 7, 8 and 10. S. Y. processed the test data. J.L., Z.Z. and Z.R. prepared Figs. 9, 10, 11, 12 and 16. J.G. and J.L. prepared Figs. 13, 14 and 15. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Li, J., Guo, J., Yang, S. et al. Development and application of tail brush elastic test device. Sci Rep 15, 14507 (2025). https://doi.org/10.1038/s41598-025-99089-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-99089-3