Abstract

This study examines the impact of alkaline treatment on the mechanical, thermal, and morphological properties of sugar palm fiber (SPF)-reinforced thermoplastic polyurethane (TPU) composites. SPF fibers (250 μm) were treated with sodium hydroxide (NaOH) solutions of 0%, 2%, 4%, and 6% (w/w) for 90 min at room temperature. These fibers were then mixed with TPU in an extruder at 180–200 °C and molded into composite sheets using compression molding at 190 °C, 10 MPa pressure, and a 10-minute holding time. X-ray diffraction (XRD) revealed increased crystallinity in the composites, peaking at 1589 cps with 6% NaOH. Fourier transform infrared (FTIR) spectra showed improved fiber-matrix compatibility, most evident with 2% NaOH. SEM analysis indicated cleaner and rougher fiber surfaces post-treatment, though cracks were observed at higher concentrations. Energy-dispersive X-ray (EDX) confirmed increased oxygen content and sodium residue at elevated NaOH levels, reflecting lignin removal. Thermogravimetric analysis (TGA) demonstrated enhanced thermal stability, with the highest residue mass of 599.16 °C at 6% NaOH. Alkaline treatment notably enhanced SPF/TPU composites, with 2% NaOH providing optimal flexural strength and 6% NaOH maximizing impact strength and thermal stability.

Similar content being viewed by others

Introduction

Industrial practices are evolving to produce environmentally friendly products by substituting certain functions of synthetic plastics sourced from petroleum. Products derived from composites are made from natural sources, which are crucial in minimizing carbon footprints and offering readily available properties thanks to their widespread presence in nature1. The choice of natural fibers for composite reinforcements significantly impacts global environmental protection, promoting sustainable development, preserving living ecosystems, and facilitating the creation of eco-friendly products2,3,4.

Natural fibers like hemp, flax, jute, wood, and various waste cellulosic products that reinforce polymer composites have undergone extensive study as alternatives to synthetic fibers. Polymer composites reinforced with synthetic fiber presented specific environmental health concerns5. Applying natural fiber exhibits advantages such as higher load capacity, ease of modification, low cost, and density. It contributes to reduced grinding in processing equipment and is relatively harmless, biodegradable, renewable, and mechanically comparable to inorganic fibers. Additionally, it features low density, biological degradation, health and environmental protection, simple separation, accessibility, enhanced energy recovery, non-corrosive properties, cost reduction, and practical thermal and acoustic insulation attributes6,7,8,9,10.

Sugar palm is a natural fiber that contributes to sustainable composites, offering numerous benefits as a raw material for products11, such as simple biological degradation, low production costs, high density, reproducibility, non-toxicity, and wear resistance12. Sugar palm fiber exhibits a range of applications, such as in bioplastics, food packaging, separators, and seat cushions13,14,. The role of sugar palm fiber in improving composite performance is influenced by several factors, including changes to the fiber surface structure5,6, orientation, fiber distribution, and fiber composition, as well as the bond strength between the fiber and the matrix. Modified fiber demonstrates improved thermal stability. The biocomposite films made from sugar palm, wheat starch, and polyvinyl alcohol (PVA) had 24.6% more mass left over at 495 °C than the fiber that had not been treated, which was 23.3%. This indicates that employing chemical treatment improves the fiber’s resistance to thermal degradation9. A study by Radzi et al. in 2023 found that treating sugar palm fiber with 6% NaOH for three hours on sugar palm, bamboo, and kenaf with polyester hybrid biocomposites significantly decreased the amount of dirt, lignin, and hemicellulose. This process improves the bond strength between the fiber and the resin matrix while also increasing the fiber’s hydrophilicity, which ultimately results in reduced water absorption11. On the other hand, the decrease in adhesion at the fiber-matrix interface and more voids significantly contributed to the hastened failure process of the composite10.

Although sugar palm fiber (SPF) has been extensively examined as a composite reinforcement with matrices like epoxy and high-impact polystyrene15,16,17,18,19 research on the application of SPF in thermoplastic polyurethane (TPU) matrices remains quite scarce. In 2019, Afzaluddin et al. reported on sugar palm/glass fibre-reinforced thermoplastic polyurethane hybrid composites, emphasizing their physical and mechanical properties20. TPU exhibits distinctive characteristics such as high tensile strength, toughness, durability, and resistance to wear and friction, presenting significant opportunities for applications involving natural fiber-based composites21. However, the chemical treatment of SPF might change how the sugar palm fiber and TPU interact, which could influence the composite’s mechanical and thermal properties. This phenomenon requires comprehensive and extensive examination. Despite these promising attributes, several knowledge gaps remain regarding optimizing SPF/TPU composites, particularly in understanding the effects of fiber treatment on interfacial bonding, mechanical performance, and long-term stability. Additionally, challenges such as potential fiber degradation, moisture absorption, and processing compatibility need further exploration to unlock the full potential of SPF-reinforced TPU composites. This study seeks to assess the impact of alkali treatment with NaOH solution at concentrations of 0%, 2%, 4%, and 6% on the characterization, mechanical properties, and thermal properties of sugar palm fiber/polyurethane thermoplastic (SPF/TPU) composites.

Experimental setup

Material

Sugar palm fiber (SPF) used in this study was purchased from Aceh, Indonesia. The resin used was thermoplastic polyurethane (TPU) type Estane® 58,311 (Selangor, Malaysia). The chemical treatment given to the SPF used sodium hydroxide (NaOH) pellet AR media. The chemical composition of SPF under pre-treatment and post-treatment settings was derived from prior research papers, as illustrated in Table 122.

Preparation of materials

The fibers were washed with water to remove dust and impurities and then dried at atmospheric pressure and room temperature for two weeks. Afterward, they were crushed using a Retsch ZM 200 grinder (Haan, Germany) and subsequently sieved to a suitable size of 250 μm using a FRITSCH auto shaker (Idar-Oberstein, Germany) to make them ideal for the final application23.

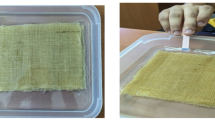

Treatment of fibre

Sugar palm fiber in composites goes through stages of cleaning and chemical treatment. First, sugar palm fibers were washed eight times using running water to remove dirt attached to the fiber surface and dry at room temperature for 30 min. The second stage is SPF going through chemical treatment using NaOH (0, 2, 4, and 6% (w/w)) to modify the fiber surface structure to increase the interfacial bond of SPF and TPU24. SPF is soaked in a plastic container containing NaOH for 90 min. After that, sugar palm fibers were washed thoroughly with distilled water to be free from dirt and residual NaOH4,15,16. Finally, sugar palm fibers were left to dry at room temperature for two weeks15.

Composites Preparation

The Thermo Scientific Eurolab 16 extruder machine from Karlsruhe, Germany, was used to make a mixture of 30% SPF and 70% TPU with a rotation speed of 40 rpm and a temperature variation of 180–200 °C23,25,26. The finished material mixture was put into a mold measuring 200 × 200 × 3 mm and compacted using hot pressing (LOTUS SCIENTIFIC) with a capacity of 25 tons. The machine was set at a pressure of 10 MPa with a temperature of 190 °C and a pressing time of 10 min, then continued with cooling until it reached a temperature of 50 °C. The result, a sheet-shaped composite, was cut according to the size of each test standard.

X-ray diffraction

The amorphous and crystalline structures of SPF/TPU composites were observed using X-ray diffraction (Rigaku Mini Flex model, Japan) with an X-ray generator tube current of 15 mA and a voltage of 30 kV. The structures formed indicate the interfacial bonding of fibers and matrices27.

Fourier transform infrared spectroscopy

The structural and functional groups of SPF/TPU composites were analyzed using Fourier Transform Infrared Spectroscopy (FTIR) type Thermo Scientific iS50 (Madison, USA). The samples consisted of TPU, composites without fiber treatment, and composites with fiber treatment, where the wave numbers identified were in the range of 4000 to 650 cm⁻¹.

Scanning Electron microscope

Scanning electron microscopy (SEM) analysis is critical in examining the distribution of fibers within the matrix and understanding the nature of the composite failure. The SEM test samples utilized in this investigation were obtained from the fractured surfaces of tensile test specimens assessed in earlier studie28. The SEM employed was the Carl Zeiss EVO model from Germany. The samples underwent a coating process involving a thin layer of platinum applied via a sputter coater, resulting in clear contrast images observable under the microscope.

Energy dispersive X-ray

The SPF/TPU composites were analyzed using energy-dispersive X-ray (EDX) with a HITACHI TM3030 Plus machine from Japan to evaluate the impact of chemical treatment on the composite’s elemental composition. The distribution of elements provides insights into the adhesion quality between the fiber and the matrix, which significantly influences their mechanical and thermal properties.

Thermogravimetric analysis

hermogravimetric analysis (TGA) was utilized to evaluate the thermal resistance of SPF/TPU composites by monitoring weight loss as the temperature increased, providing insights into the degradation mechanism of the composite. Test specimens weighing 3 g each were prepared and analyzed using a TGA Mettler Toledo (Switzerland) instrument. The testing was conducted at a heating rate of 10 °C/min over a temperature range from room temperature to 600 °C under a nitrogen atmosphere.

Differential scanning calorimetry

Analyzing the effect of fiber treatment on the thermal behavior and crystallinity level of SPF/TPU composites is a critical aspect in determining the thermal resistance of the composites. Test samples weighing 3 g were prepared in a container and tested using a Perkin Elmer DSC 800 (USA) under nitrogen atmospheric conditions with a flow rate of 10 ml/min, a heating rate of 10 °C/min, and a temperature range from room temperature to 300 °C.

Flexural testing

T The flexural test was conducted on the SPF/TPU composite to assess its ability to resist stress before structural failure and its capacity to retain deformation. The test specimens, each measuring 130 × 13 × 3 mm, were fabricated following ASTM D790 guidelines, with five samples in total. Each sample was tested using an Instron 3369Q3720 universal testing machine, employing a three-point bending setup and a crosshead speed of 2 mm/min.

Impact testing

The impact test aims to assess the ability of the SPF/TPU composite to absorb energy from a sudden load before the material breaks. The testing was performed according to ASTM D256 standards, with five specimens prepared, each measuring 63 × 13 × 3 mm. The specimens were tested using a Zwick/Roell 5113 impact tester (Ulm, Germany) with a 15 J capacity to observe the fracture surface of the material.

Results and discussion

X-ray diffraction

The X-ray diffraction (XRD) analysis for pure TPU, untreated SPF/TPU (0% NaOH), and SPF/TPU subjected to NaOH treatment at concentrations of 2%, 4%, and 6% are illustrated in Fig. 1. The XRD analysis demonstrated two prominent peaks for TPU at 19.07° and 21.95° (theta), suggesting the existence of a carbon phase. The peak observed at 21.95° theta signifies the crystalline phase of TPU, whereas the peak at 19.07° theta reflects the amorphous characteristics of TPU.

After incorporating SPF into the matrix, notable alterations were observed in the diffraction pattern. One of the three peaks in the untreated SPF/TPU composite (0% NaOH) disappeared after being treated with NaOH solution. This suggests that the chemical treatment modified the structure of the material. The fibers’ crystallinity index increased because non-cellulosic compounds like lignin and hemicellulose were removed using chemicals and machines. Additionally, the reduction of the humps following alkali treatment suggests that the amorphous chains have organized into crystalline regions. The sharpness of the peaks indicates a higher crystallinity index29. Le Troëdec et al. also evaluated the degradation of amorphous hemicellulose from the fiber surface in their study concerning the treatment of lime straw and hemp fiber30,31.

A peak intensity of about 1589 cps was seen after 6% NaOH was applied. This clearly shows that the chemical treatment significantly improved the crystallinity of the SPF/TPU composite. The observed rise may be because amorphous parts like hemicellulose and lignin were removed, making the composite material’s structure more regular. This further substantiates the hypothesis that the chemical treatment of the fibers improves the fiber-matrix interaction by eliminating amorphous barriers, leading to a composite with a more uniform structure32.

Fourier transform infrared spectroscopy

Figure 2 displays the fourier transform infrared spectroscopy (FTIR) spectra for both pure TPU and SPF/TPU composites that have been treated with varying concentrations of NaOH (0%, 2%, 4%, and 6%). The standard absorption peaks related to O–H, N–H, CH₂, CH₃, and C = O functional groups of the fibers and polymer matrix can be found in Table 2. A prominent broad band in the range of 3,420–3,200 cm⁻¹, linked to O–H stretching vibration, shows a shift from 3,326.2 cm⁻¹ in pure TPU to 3,327.55–3,328.91 cm⁻¹ in the SPF/TPU composites. This change signifies an improvement in hydrogen bonding and the compatibility between the fibre and matrix, particularly at 2% NaOH29.

The N–H peak (1,590–1,650 cm⁻¹) consistently measured around 1,596 cm⁻¹, suggesting that the treatment with NaOH did not alter the interaction of this group. The CH₂ and CH₃ stretches (3,000–2,800 cm⁻¹) had a slight change in position, going from 2,956.5 cm⁻1 in pure TPU to a range of 2,955.77–2,956.22 cm⁻³ in SPF/TPU. This shows that the interactions are stable. In pure TPU, the non-bonded C = O band (1,740 cm⁻1) moved from 1,726.9 cm⁻1 to a range of 1,726.26–1,726.43 cm⁻1. The corresponding C = O peak (1,690 cm⁻1) moved from 1,701.12 cm⁻1 to a range of 1,701.53–1,702.05 cm⁻1 33,34. This change shows that the NaOH treatment strengthened the chemical interactions between the fibers and the TPU matrix35. No new peaks emerged, indicating that the interaction observed was physical, facilitated by increased hydrogen bonds. This suggests that the primary adhesion mechanism between the fibers and the TPU matrix is dominated by physical interaction rather than chemical bonding. The peak shifts, particularly in the C = O and CH2/CH3 areas, indicate improved interfacial adhesion through enhanced hydrogen bonding. This reinforcement contributes to the composite’s improved mechanical and thermal performance, particularly at 2% NaOH treatment, by strengthening fiber-matrix compatibility without introducing new covalent interaction36,37,38,39.

Scanning electron microscopy

Figure 3 shows what the scanning electron microscopy (SEM) saw on the surface of the fiber before it was treated with 0% NaOH and after it was treated with 2, 4, and 6% NaOH. The untreated surface of the SPF, illustrated in Fig. 3a, exhibits a significant accumulation of dirt, comprising oil, wax, and various other contaminants. The SPF treated with NaOH concentrations of 2%, 4%, and 6%, as illustrated in Figs. 3b-d, exhibits a progressively cleaner and rougher surface40. This demonstrates that NaOH treatment eliminates dirt and non-cellulosic layers that obscure the fiber, including oil and wax. This process enhances the cleanliness of the fiber surface while also developing a rougher surface structure, which can improve the mechanical interaction between the fiber and the matrix in the composite4. Increasing the NaOH concentration from 2 to 4% and then to 6% results in forming a few cracks on the fiber surface, with the 6% NaOH concentration exhibiting higher cracks. Cracks may lead to fiber brittleness, influencing the dimensions and alignment of the fibers within the matrix and their capacity to withstand stress32.

The SEM observation of SPF/TPU composites treated with NaOH reveals a nuanced relationship between the quality of the fiber-matrix interface and the mechanical properties, as illustrated in Fig. 4. In 2019, Allaeddin et al. identified various failure models that may arise in composites, such as fiber-matrix debonding, fiber pull-out incidents, fiber breakage, matrix cracking, and matrix yielding41. In the sample lacking NaOH treatment (0%) depicted in Fig. 4a, there is an apparent prevalence of pull-out fibers and significant voids. The inadequate adhesion between the fiber and matrix leads to an uneven stress distribution, resulting in diminished mechanical properties during bending and impact assessments32.

At a 2% NaOH concentration (Fig. 4b), SEM shows a clear improvement in adhesion (stuck fibers), but some fibers are still pulling away. This treatment eliminates a significant portion of lignin and hemicellulose, enhancing the interaction between the fiber and the matrix. The flexural strength at this concentration shows that the fiber-matrix interface is working well to support the stress distribution42. Nonetheless, the tensile strength observed at this concentration is inferior to that of the 6% NaOH treatment (Fig. 4d), as indicated in earlier research. This may be attributed to the TPU matrix’s insufficient penetration, which has not yet reached an optimal level to cover and absorb the fibers adequately43. Consequently, this results in a diminished strengthening effect from the fibers in the tensile direction28.

Figure 4c shows a concentration of 4% NaOH. The SEM results show multiple fiber fracture phenomena that point to strong fiber-matrix adhesion. Nonetheless, the mechanical findings indicate a reduction in flexural strength relative to a concentration of 2% and the lowest impact strength observed. The observed phenomenon can be attributed to the rapid absorption of impact energy, leading to more pronounced damage to the fibers with minimal energy dissipation. The fiber fracture phenomenon happens rapidly and is not accompanied by additional energy dissipation mechanisms like matrix fracture or plastic deformation, which diminishes the material’s capacity to endure high-impact energy44.

At a concentration of 6% NaOH, the SEM analysis reveals minimal voids, a prevalence of adhered fibers, and a more uniform distribution of fibers. In 2020, Sabarinathan et al. found that the application of silane treatment to fish tail palm fibre/vinyl ester resin with compositions of 10, 20, and 30 wt% caused a decrease in void content from 2.34, 2.67, and 2.99% to 1.98, 2.10, and 2.50% 38. The earlier studies showed that this condition led to the highest tensile strength across all samples. This is because the better interfacial adhesion makes it easier for stress to move from the matrix to the fibers during tensile testing36,45. Moreover, the impact strength peaks at this concentration, as the TPU matrix demonstrates superior capability in absorbing impact energy due to robust interactions with the fibers. Nevertheless, the flexural strength was diminished compared to the 2% and 4% concentrations, likely because of fiber degradation stemming from excessive alkali treatment that influenced the fiber orientation within the matrix46.

Energy dispersive X-ray spectroscopy

The element composition on the surface of the untreated SPF/TPU composite (0% NaOH) and after NaOH treatment at concentrations of 2%, 4%, and 6% were evaluated through energy dispersive x-ray spectroscopy (EDX) analysis, as tabulated detailed in Table 3; Fig. 5. The findings indicate that the carbon element is predominant in the untreated SPF/TPU composite (0% NaOH), accounting for a weight% of 58.635%, whereas oxygen contributes 40.702%. This composition highlights the prevalence of the TPU polymer matrix and SPF fibers, which retain considerable amounts of hemicellulose and lignin content47.

Following the treatment with NaOH, notable alterations in the elemental composition were observed48. The composite subjected to 2% NaOH treatment exhibited a slight reduction in carbon content to 58.265%, alongside a decrease in oxygen content to 40.263%. The sodium content of 1.472% suggests residual NaOH solution adsorbed on the fiber surface. As the concentration of NaOH rose to 4% and 6%, the carbon content diminished further, reaching 56.982% and 55.629%, respectively. The oxygen content steadily increased, reaching 42.523% in the 6% NaOH treatment. Furthermore, the sodium content rose to 1.741% with 4% NaOH and 1.848% with 6% NaOH.

The reduction in carbon content and the rise in oxygen indicate the partial extraction of amorphous hemicellulose and lignin from the surface of SPF fibers following NaOH treatment49. The treatment with 6% NaOH led to a more significant rise in oxygen content than the 4% and 2% treatments, suggesting that new hydroxyl groups were revealed due to the breakdown of the fibers’ amorphous components. The presence of sodium residue in the NaOH-treated samples indicates that, despite the washing of the fibers, some residual NaOH solution remained on the surface. This residue may enhance the roughness of the fiber surface, potentially leading to robust mechanical interactions between the fibers and the TPU matrix within the composite. Nonetheless, elevated sodium levels may also enhance the hygroscopic properties of the composite, a factor that must be considered in real-world applications50.

Thermogravimetric analysis

The thermogravimetric analysis (TGA) results are shown in Fig. 6. It indicates that the SPF/TPU composite treated with NaOH is more thermally stable than the untreated composite and pure SPF. Table 4 displays the mass residue data at significant temperatures (26.99 °C, 303.00 °C, and 599.16 °C) for conditions lacking NaOH treatment (0%) and for NaOH treatments of 2, 4, and 6%. The test on pure TPU showed that it had a significant mass residue of 94.19% at 303.00 °C and 4.1% at 599.16 °C, showing that it is very resistant to thermal degradation. In contrast, pure SPF exhibited a residue of only 71.89% at 303.00 °C and was nearly depleted at 599.16 °C (0.0038%), attributable to the significant presence of hemicellulose and lignin, which are prone to degradation. A 0% untreated SPF/TPU composite showed better thermal stability, with a mass residue of 90.45% at 303.00 °C and 13.15% at 599.16 °C. This indicates that TPU affects the thermal properties of SPF4,51.

Applying alkali treatments using NaOH enhanced the thermal stability of the composite52. At NaOH concentrations of 2% and 4%, the residue at elevated temperatures (599.16 °C) rose to 13.84% and 17.56%, respectively. The observed increase is because wax, lignin, and hemicellulose are removed from the fiber surface. This makes the fiber less amorphous and increases the crystalline structure of cellulose. The increased crystalline cellulose enhances hydrogen bonding and optimizes the distribution of thermal energy through a more stable structure53. The treated fibers are less likely to absorb water, which makes it easier for them to stick to the TPU matrix54. At a NaOH concentration of 6%, the residue at a temperature of 599.16 °C was observed to decrease to 13.81%. This is probably a result of excessive fiber degradation, which compromises the fiber structure as a reinforcement51.

Differential scanning calorimetry

Differential Scanning Calorimetry.

The Differential Scanning Calorimetry (DSC) results show essential information about the thermal changes that happen in SPF/TPU composites, such as the crystallization temperature (Tc), melting temperature (Tm), melting energy, and crystallinity level (Fig. 7). The numbers show how changing the NaOH concentration (0, 2, 4, and 6%) affected the composite’s thermal properties and the levels of crystallinity that went with them55, as shown in Table 5.

The melting temperature of pure TPU is 208.64 °C, accompanied by a maximum crystallinity level of 20.224%. If the SPF/TPU composite was not treated with 0% NaOH, it has a slightly lower Tm of 204.61 °C and a crystallinity level of 16.992%. The observed decrease indicates SPF fibers’ influence on the TPU matrix’s crystallization process. The treatment with NaOH reveals differences in thermal properties. The composite subjected to 2% NaOH treatment exhibits a reduced Tm of 203.32 °C compared to the untreated composite. The melting energy has decreased to 32.668 J/g, with a crystallinity level of 16.599%. The observed decrease could be attributed to the partial extraction of hemicellulose and lignin, which influences the fiber and matrix interaction56.

The treatment with 4% NaOH resulted in a Tm of 200.85 °C and a crystallinity level of 15.528%. Changing the chemicals in the fiber means that increasing the concentration of NaOH might cause the TPU matrix to become less crystallized. In the case of the 6% NaOH treatment, the melting temperature (Tm) was observed to rise to 207.39 °C, while the crystallinity level attained 19.094%. The observed rise might be because the fibers are now more compatible with the matrix after being treated with NaOH. This, in turn, may make the thermal interaction within the composite stronger57. The DSC results indicated that the treatment with NaOH influenced the thermal transition of the composite 59 60–62. When Tm and crystallinity went down during the first treatment, the structure of the fibers changed. On the other hand, when they went up during later treatments, the matrix and fibers were better able to work together. This finding fits with earlier research that showed that chemical treatment could change the fibers’ size and orientation within the matrix57, changing the composite’s mechanical and thermal properties61.

Flexural properties

Figure 8 shows how the composite’s flexural strength changes with different amounts of SPF immersion media, precisely at 0%, 2%, 4%, and 6% NaOH. An observable enhancement in the flexural strength value of SPF/TPU treated with NaOH solution is noted, in contrast to the untreated SPF/TPU composite (0 wt% NaOH). The flexural strength of the composite with untreated SPF measures 4.4028 MPa. In contrast, the flexural strength of the treated composite shows an increase to 12.6, 12.46, and 11.163 MPa at NaOH concentrations of 2, 4, and 6%, respectively. This finding indicates that NaOH treatment enhances the compatibility between fibers and TPU matrices 44. Moreover, the uniformity of SPF within the matrix significantly improves flexural strength15.

The few empty spaces seen with SEM and the uniform distribution of SPF in the composite with a 2% NaOH concentration make the surface contact between SPF and the matrix stronger. This improvement allows the matrix to effectively transfer stress to the fibers, decreasing the likelihood of composite failure before fracture49. Increasing the amount of NaOH from 2 to 6%, on the other hand, lowers the flexural strength because SPF breaks down in the matrix4. Cracks start appearing on the fiber surface, making the fibers brittle and easily separate from the matrix when loaded. This causes a low and uneven stress transfer mechanism7.

Figure 9 illustrates how varying NaOH concentrations (0, 2, 4, and 6%) influence the flexural modulus of SPF/TPU composites. A flexural modulus of 97.6 MPa was found when 0% NaOH was applied to SPF. This value increased significantly after 2%, 4%, and 6% NaOH treatments, giving 340.728, 328.65, and 293.936 MPa values in that order. The treatment with NaOH effectively eliminates impurities from the fiber surface, which enhances the interfacial interaction between SPF and TPU, consequently leading to an increase in the flexural modulus of SPF/TPU composites17,36 and raising the NaOH concentration from 2 to 4% and then to 6% results in a reduction of the flexural modulus. The degradation of too short fibers leads to a disturbance in fiber orientation, which subsequently reduces the flexural modulus32,62. Additionally, SEM observations indicate that treatment with 4% and 6% NaOH leads to the formation of cracks on the fiber surface, initiating the cracking process and hastening the composite failure mechanism63.

Impact strength

The influence of NaOH treatment at concentrations of 0, 2, 4, and 6% of SPF on the impact strength value of the SPF/TPU composite is illustrated in Fig. 10. The composite exhibited an impact strength of 41.73 kJ/m² without NaOH treatment, which increased to 86.7, 85.02, and 103.4 kJ/m² after SPF was immersed in NaOH solutions of 2, 4, and 6% before the mixing and molding process. The alteration of the fiber surface can effectively eliminate the components of hemicellulose, lignin, and wax layers, enhancing moisture resistance. This process influences the fiber’s roughness and fosters a robust bond between SPF and TPU64. The implications of this are significant for improving the impact strength of the composite, given the substantial energy needed to induce fracture failure of the fiber58.

Applying 6% NaOH on SPF demonstrates a significantly higher impact strength than the 2% and 4% concentrations. This effect can be attributed to removing a more significant amount of amorphous components29, which enhances the elasticity and energy absorption capacity of the composite65. The composition of 4% NaOH exhibits a lower impact strength than 6% and 2%, likely attributed to inadequate fiber distribution and fiber brittleness within the matrix, which diminishes elastic resistance and the composite’s capacity to absorb impact energy59. Furthermore, the low impact strength value may result from the significant kinetic energy absorbed by the composite, leading to an increased likelihood of matrix cracks, fiber fractures, and more extensive permanent indentation in the impacted region66.

Conclusions

This investigation assessed the impact of alkali (NaOH) treatment at varying concentrations of 0% (control), 2%, 4%, and 6% on the mechanical, thermal, and morphological characteristics of sugar palm fiber (SPF) composites reinforced with thermoplastic polyurethane (TPU). The XRD analysis results indicated that the treatment with NaOH enhanced fiber crystallinity, achieving a peak intensity of 1589 cps at a 6% NaOH concentration, in contrast to the control sample. The FTIR spectrum demonstrated enhanced compatibility between the fiber and matrix at a 2% NaOH concentration, indicated by a shift in the O–H and C = O bands, while no new peaks appeared. SEM observations indicated that NaOH effectively altered the fiber surface to exhibit increased roughness; however, at concentrations of 4% and 6%, microcracks were observed that could potentially impact fiber orientation, composite density, and the quality of matrix-fiber adhesion. The findings were validated by EDX analysis, which revealed an increase in oxygen content and sodium residues on the fiber surface following alkali treatment. The maximum flexural strength was obtained with 2% NaOH treatment, demonstrating a 25% increase relative to the control sample. The treatment with 6% NaOH resulted in the highest impact strength, attaining a value of 12.8 kJ/m², which represents a 30% increase over the untreated sample. The treatment with 6% NaOH demonstrated optimal thermal stability, exhibiting the highest mass retention of 18.6% at a temperature of 599.16 °C, as indicated by TGA analysis. Nonetheless, elevating the NaOH concentration resulted in the degradation of lignin and hemicellulose, a factor that must be taken into account in material design for specific applications. The results indicate that a 2% NaOH concentration yields optimal performance for enhancing flexural strength, whereas a 6% NaOH concentration is preferable for applications that demand high impact strength and thermal stability. It is advisable to conduct additional studies to investigate the integration of alkali treatment with various modification techniques, including the application of coupling agents or physical treatments like plasma, to enhance fiber-matrix adhesion and thermal stability. Furthermore, an examination of additional parameters like wear characteristics, environmental durability, and resilience to extreme conditions, including heat and humidity, might be conducted to broaden the applicability of this composite across diverse industries.

Data availability

Data availabilityWe ensure that all research datas are contained within the article.

References

Ramlee, N. A., Jawaid, M., Zainudin, E. S. & Yamani, S. A. K. Modification of oil palm empty fruit bunch and sugarcane Bagasse biomass as potential reinforcement for composites panel and thermal insulation materials. J. Bionic Eng. 16, 175–188 (2019).

Ishak, M. R., Sapuan, S. M., Leman, Z., Rahman, M. Z. A. & Anwar, U. M. K. Characterization of sugar palm (Arenga pinnata) fibres: tensile and thermal properties. J. Therm. Anal. Calorim. 109, 981–989 (2012).

Vega, J., Madrigal, S. & Martınez, J. ‘Thermoplastic Polyurethanes-Fumed silica composites: influence of NCO/OH in the study of thermal and rheological properties and morphological characteristics. Thermoplastic–Composite Mater. Croatia: Intech 11–25 (2012).

El-Shekeil, Y. A., Sapuan, S. M., Khalina, A. & Zainudin, E. S. Al-Shuja’a, O. M. Effect of alkali treatment on mechanical and thermal properties of Kenaf fiber-reinforced thermoplastic polyurethane composite. J. Therm. Anal. Calorim. 109, 1435–1443 (2012).

Costanza, R. & Ruth, M. Using dynamic modeling to scope environmental problems and build consensus. Environ. Manage. 22, 183–195 (1998).

Herrera-Franco, P. J. & Valadez-Gonzalez, A. Mechanical properties of continuous natural fibre-reinforced polymer composites. Compos. Part. Appl. Sci. Manuf. 35, 339–345 (2004).

Cantero, G., Arbelaiz, A., Llano-Ponte, R. & Mondragon, I. Effects of fibre treatment on wettability and mechanical behaviour of flax/polypropylene composites. Compos. Sci. Technol. 63, 1247–1254 (2003).

Jacob, M., Thomas, S. & Varughese, K. T. Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos. Sci. Technol. 64, 955–965 (2004).

Julson, J. L., Subbarao, G., Stokke, D. D., Gieselman, H. H. & Muthukumarappan, K. Mechanical properties of biorenewable fiber/plastic composites. J. Appl. Polym. Sci. 93, 2484–2493 (2004).

Mehta, G., Mohanty, A. K., Thayer, K., Misra, M. & Drzal, L. T. Novel biocomposites sheet molding compounds for low cost housing panel applications. J. Polym. Environ. 13, 169–175 (2005).

Radzi, A. M., Sapuan, S. M., Jawaid, M. & Mansor, M. R. Water absorption, thickness swelling and thermal properties of Roselle/sugar palm fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 8, 3988–3994 (2019).

Ishak, M. R. et al. Sugar palm (Arenga pinnata): its fibres, polymers and composites. Carbohydr. Polym. 91, (2013).

Bachtiar, D., Sapuan, S. M., Zainudin, E. S., Khalina, A. & Dahlan, K. Z. M. The tensile properties of single sugar palm (Arenga pinnata) fibre. in IOP conference series: materials science and engineering vol. 11 012012IOP Publishing, (2010).

Ilyas, R. A., Sapuan, S. M., Ishak, M. R., Zainudin, E. S. & Atikah, M. S. N. Characterization of sugar palm nanocellulose and its potential for reinforcement with a starch-based composite. in Sugar Palm Biofibers, Biopolymers, and Biocomposites 189–220 (CRC, (2018).

Bachtiar, D., Sapuan, S. M. & Hamdan, M. M. The effect of alkaline treatment on tensile properties of sugar palm fibre reinforced epoxy composites. Mater. Des. 29, 1285–1290 (2008).

Bachtiar, D., Sapuan, S. M. & Hamdan, M. M. The influence of alkaline surface fibre treatment on the impact properties of sugar palm fibre-reinforced epoxy composites. Polym. Plast. Technol. Eng. 48, 379–383 (2009).

Sapuan, S. M., Hamdan, M. M. & Bachtiar, D. Flexural properties of alkaline treated sugar palm fibre reinforced epoxy composites. Int. J. Automot. Mech. Eng. 1, (2010).

Bachtiar, D., Salit, M. S., Zainuddin, E., Abdan, K. & Dahlan, K. Z. H. M. Effects of alkaline treatment and a compatibilizing agent on tensile properties of sugar palm fibre-reinforced high impact polystyrene composites. Bioresources 6, 4815–4823 (2011).

Bachtiar, D., Sapuan, S. M., Khalina, A., Zainudin, E. S. & Dahlan, K. Z. M. Flexural and impact properties of chemically treated sugar palm fiber reinforced high impact polystyrene composites. Fibers Polym. 13, 894–898 (2012).

Afzaluddin, A., Jawaid, M., Salit, M. S. & Ishak, M. R. Physical and mechanical properties of sugar palm/glass fiber reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 8, 950–959 (2019).

El-Shekeil, Y. A., Salit, M. S., Abdan, K. & Zainudin, E. S. Development of a new kenaf bast fiber-reinforced thermoplastic polyurethane composite. Bioresources 6, (2011).

Ilyas, R. A. et al. Mechanical testing of sugar palm fiber reinforced sugar palm biopolymer composites. in Advanced Processing, Properties, and Applications of Starch and Other bio-based Polymers 89–110 (Elsevier, (2020).

Mohammed, A. A., Bachtiar, D., Siregar, J. P., Rejab, M. R. M. & Hasany, S. F. Physicochemical study of eco-friendly sugar palm fiber thermoplastic polyurethane composites. Bioresources 11, 9438–9454 (2016).

Mohammed, A. A., Bachtiar, D., Rejab, M. R. M., Hasany, S. F. & Siregar, J. P. Influence of different sugar palm Fiber content on the tensile, flexural, impact, and physicochemical properties of Eco-Friendly thermoplastic polyurethane. Theor. Found. Chem. Eng. 53, (2019).

Gunatillake, P., Mayadunne, R. & Adhikari, R. Recent developments in biodegradable synthetic polymers. Biotechnol. Annu. Rev. 12, 301–347 (2006).

El-Shekeil, Y. A., Sapuan, S. M., Zainudin, E. S. & Khalina, A. Optimizing processing parameters and fiber size for Kenaf fiber reinforced thermoplastic polyurethane composite. Key Eng. Mater. 471, 297–302 (2011).

Kaushik, V. K., Kumar, A. & Kalia, S. Effect of mercerization and benzoyl peroxide treatment on morphology, thermal stability and crystallinity of Sisal fibers. Int. J. Text. Sci. 1, 101–105 (2012).

Mohammed, A. A., Bachtiar, D., Siregar, J. P. & Rejab, M. R. M. Effect of sodium hydroxide on the tensile properties of sugar palm fibre reinforced thermoplastic polyurethane composites. J. Mech. Eng. Sci. 10, (2016).

Ilyas, R. A. et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: A comprehensive approach from macro to nano scale. J. Mater. Res. Technol. 8, 2753–2766 (2019).

Le Troëdec, M. et al. Physico-chemical modifications of the interactions between hemp fibres and a lime mineral matrix: impacts on mechanical properties of mortars. in 10th International Conference of the European Ceramic Society 451–456 (Göller Verlag, (2007).

Le Troedec, M. et al. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part. Appl. Sci. Manuf. 39, 514–522 (2008).

Nurazzi, N. M., Khalina, A., Sapuan, S. M. & Ilyas, R. A. Mechanical properties of sugar palm yarn/woven glass fiber reinforced unsaturated polyester composites: effect of fiber loadings and alkaline treatment. Polimery 64, 665–675 (2019).

Ahmad, S. H. et al. Polyester-kenaf composites: effects of alkali fiber treatment and toughening of matrix using liquid natural rubber. J. Compos. Mater. 45, 203–217 (2011).

Rahmat, A. R. & Day, R. J. Curing characteristics of unsaturated polyester/aramid reinforced composite: microwave vs. thermal energy. Jurnal Teknologi (Sciences Engineering). 83, 96 (2003).

Silverstein, R. M. & Bassler, G. C. Spectrometric identification of organic compounds. J. Chem. Educ. 39, 546 (1962).

Li, X., Tabil, L. G. & Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J. Polym. Environ. 15, 25–33 (2007).

Kumar, V., Arun, A., Rajkumar, K. & Palaniyappan, S. Effect of Kigelia pinnata Biochar inclusion on mechanical and thermal properties of curtain climber fiber reinforced epoxide biocomposites. Polym. Compos. 45, 4459–4472 (2024).

Sabarinathan, P., Rajkumar, K., Annamalai, V. E. & Vishal, K. Static and dynamic behavior of micrometric agro Prunus amygdalus particulate distributed interpolymer layer-kenaf composite. Polym. Compos. 41, 3309–3321 (2020).

Vishal, K., Rajkumar, K., Sabarinathan, P. & Arun, A. Mechanical and thermal characteristics of steam-exploded silane grafted Kigelia Pinnata fruit (KPF) fiber reinforced vinyl ester polymer composites. Polym. Compos. 1, 1–17 (2023).

Norizan, M. N., Abdan, K., Salit, M. S. & Mohamed, R. The effect of alkaline treatment on the mechanical properties of treated sugar palm yarn fibre reinforced unsaturated polyester composites reinforced with different fibre loadings of sugar palm fibre. Sains Malays. 47, 699–705 (2018).

Alaaeddin, M. H., Sapuan, S. M., Zuhri, M. Y. M., Zainudin, E. S. & Al-Oqla, F. M. Physical and mechanical properties of polyvinylidene fluoride-Short sugar palm fiber nanocomposites. J. Clean. Prod. 235, 473–482 (2019).

Radzi, A. M., Sapuan, S. M., Jawaid, M. & Mansor, M. R. Mechanical performance of Roselle/sugar palm fiber hybrid reinforced polyurethane composites. Bioresources 13, 6238–6249 (2018).

Ramlee, N. A., Jawaid, M., Zainudin, E. S. & Yamani, S. A. K. Tensile, physical and morphological properties of oil palm empty fruit bunch/sugarcane Bagasse fibre reinforced phenolic hybrid composites. J. Mater. Res. Technol. 8, 3466–3474 (2019).

Mukhtar, I., Leman, Z., Zainudin, E. S. & Ishak, M. R. Hybrid and Nonhybrid Laminate Composites of Sugar Palm and Glass Fibre-Reinforced Polypropylene: Effect of Alkali and Sodium Bicarbonate Treatments. Int J Polym Sci 1230592 (2019). (2019).

Mohanty, A. K., Misra, M. & Drzal, L. T. Surface modifications of natural fibers and performance of the resulting biocomposites: an overview. Compos. Interfaces. 8, 313–343 (2001).

Ammar, I. M., Huzaifah, M. R. M., Sapuan, S. M., Leman, Z. & Ishak, M. R. Mechanical Properties of Environment-Friendly Sugar Palm Fibre Reinforced Vinyl Ester Composites at Different Fibre Arrangements. EnvironmentAsia 12, (2019).

Atiqah, A., Jawaid, M., Sapuan, S. M. & Ishak, M. R. Effect of surface treatment on the mechanical properties of sugar palm/glass fiber-reinforced thermoplastic polyurethane hybrid composites. Bioresources 13, 1174–1188 (2018).

Rashid, B., Leman, Z., Jawaid, M., Ghazali, M. J. & Ishak, M. R. Physicochemical and thermal properties of lignocellulosic fiber from sugar palm fibers: effect of treatment. Cellulose 23, 2905–2916 (2016).

Atiqah, A., Jawaid, M., Sapuan, S. M. & Ishak, M. R. Mechanical and thermal properties of sugar palm fiber reinforced thermoplastic polyurethane composites: effect of silane treatment and fiber loading. J. Renew. Mater. 6, 477–492 (2018).

Agrebi, F., Ghorbel, N., Rashid, B., Kallel, A. & Jawaid, M. Influence of treatments on the dielectric properties of sugar palm fiber reinforced phenolic composites. J. Mol. Liq. 263, 342–348 (2018).

Alvarez, V., Rodriguez, E. & Vázquez, A. Thermal degradation and decomposition of jute/vinylester composites. J. Therm. Anal. Calorim. 85, 383–389 (2006).

El-Shekeil, Y. A., Sapuan, S. M., Abdan, K. & Zainudin, E. S. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Mater. Des. 40, 299–303 (2012).

Atiqah, A. et al. Physical and thermal properties of treated sugar palm/glass fibre reinforced thermoplastic polyurethane hybrid composites. J. Mater. Res. Technol. 8, 3726–3732 (2019).

Nurazzi, N. M. et al. Thermal properties of treated sugar palm yarn/glass fiber reinforced unsaturated polyester hybrid composites. J. Mater. Res. Technol. 9, 1606–1618 (2020).

Mohammed, A. A. et al. Effects of KMnO 4 treatment on the flexural, impact, and thermal properties of sugar palm fiber-reinforced thermoplastic polyurethane composites. Jom 70, 1326–1330 (2018).

Irfai, M. A., Wulandari, D. & Marsyahyo, E. Effect of NaOH treatment on bending strength of the polyester composite reinforce by sugar palm fibers. in IOP Conference Series: Materials Science and Engineering vol. 336 012008IOP Publishing, (2018).

Radzi, A. M., Sapuan, S. M., Jawaid, M. & Mansor, M. R. Effect of alkaline treatment on mechanical, physical and thermal properties of Roselle/sugar palm fiber reinforced thermoplastic polyurethane hybrid composites. Fibers Polym. 20, 847–855 (2019).

Nguyen, T., Zavarin, E. & Barrall, E. M. Thermal analysis of lignocellulosic materials: part I. Unmodified materials. J. Macromolecular Science-Reviews Macromolecular Chem. 20, 1–65 (1981).

Awal, A., Ghosh, S. & Sain, M. Thermal properties and spectral characterization of wood pulp reinforced bio-composite fibers. J. Therm. Anal. Calorim. 99, 695–701 (2010).

Groenewoud, W. M. Characterisation of Polymers by Thermal Analysis (Elsevier, 2001).

Huzaifah, M. R. M., Sapuan, S. M., Leman, Z. & Ishak, M. R. Effect of fibre loading on the physical, mechanical and thermal properties of sugar palm fibre reinforced vinyl ester composites. Fibers Polym. 20, 1077–1084 (2019).

Mohd Nurazzi, N. et al. Effect of fiber orientation and fiber loading on the mechanical and thermal properties of sugar palm yarn fiber reinforced unsaturated polyester resin composites. Polimery 65, (2020).

Chandrasekar, M. et al. Flax and sugar palm reinforced epoxy composites: effect of hybridization on physical, mechanical, morphological and dynamic mechanical properties. Mater. Res. Express. 6, 105331 (2019).

Mwaikambo, L. Y. & Ansell, M. P. Chemical modification of hemp, Sisal, jute, and Kapok fibers by alkalization. J. Appl. Polym. Sci. 84, 2222–2234 (2002).

Ilyas, R. A. et al. Mechanical testing of sugar palm fiber reinforced sugar palm biopolymer composites. Adv. Process. Prop. Appl. Starch Other Bio-Based Polym. Adv. Process. Prop. Appl. https://doi.org/10.1016/B978-0-12-819661-8.00007-X (2020).

Safri, S. N. A., Sultan, M. T. H., Jawaid, M. & Majid, M. S. A. Analysis of dynamic mechanical, low-velocity impact and compression after impact behaviour of benzoyl treated sugar palm/glass/epoxy composites. Compos. Struct. 226, 111308 (2019).

Acknowledgements

This project was supported by Researchers Supporting Project number (RSPD2025R900) King Saud University, Riyadh, Saudi Arabia.The authors wish to thank Universitas Syiah Kuala for facilitate the finishing part of this work and Universiti Malaysia Pahang Al-Sultan Abdullah and Ministry of Education Malaysia for supporting the work financially under a project of FRGS (Fundamental Research Grant Scheme). The authors also wish to thank University of Technology Iraq for scholarship fund for one of the authors.

Author information

Authors and Affiliations

Contributions

D.B.: conceptualization, supervision; A.A.M. and S.P.: writing—original draft, investigation; A.I.I.: Writing- review and editing, validation; J.P.S: methodology, investigation; M.R.M.R.: formal analysis, data curation; S.S.: methodology, resources; T.C.: formal analysis, validation; D.F.F: formal analysis, data curation; S.A.F., M.I.A. and Q.M.: Administration, Funding, Validation. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical statement

This research study did not involve the use of animals and humans.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bachtiar, D., Mohammed, A.A., Palanisamy, S. et al. Effect of alkaline treatment on the thermal and mechanical properties of sugar palm fibre reinforced thermoplastic polyurethane composites. Sci Rep 15, 14085 (2025). https://doi.org/10.1038/s41598-025-99227-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99227-x