Abstract

Substituting fiber-reinforced plastics (FRP) with wood-based materials significantly increases the sustainability of fiber-metal laminates (FML). Therefore, the present work compares the three-point bending behavior of simple wood laminates with that of hybrid aluminum-wood laminates. Wood laminates consisting of four layers of 1-mm-thick birch veneers were adhesive-bonded with a single 1-mm-thick sheet of commercial aluminum alloy EN AW-6016-T4. Longitudinal, transverse, and bidirectional orientations of the wood fibers were considered. Prior to three-point bending, the laminates were exposed to different moistures and temperatures. The bending behavior was analyzed in terms of (i) the maximum bending force, (ii) the bending angle at maximum bending force, and (iii) the strains monitored on the side surface of the laminates during each bending test. The simulation software LS-DYNA was used to create a finite element (FE) model of the bending procedure, which considered the experimentally determined material properties. In general, the hybrid aluminum-wood laminates showed a larger bending angle at maximum bending force than simple wood laminates. The maximum bending force of the laminates gradually decreased with increasing moisture content. The FE model was able to predict the bending behavior at different moisture and temperature conditions.

Similar content being viewed by others

Introduction

In recent years, the automotive industry has been facing challenges to meet demands on safety, comfort, and performance. Without any additional measures, vehicle weight and thus fuel consumption and CO2 emissions would also increase1,2,3. To address this discrepancy, vehicle manufacturers are striving to replace heavy materials by more lightweight alternatives. In particular, lightweight aluminum alloys have already been used to produce various automotive components, such as cast engine blocks or cylinder heads, extruded structural frame parts, and deep-drawn body panels4,5. Because of their outstanding strength-to-weight ratio, composites including fiber-metal laminates (FML) have emerged as alternative lightweight materials6,7. Multi-layered FML typically consist of alternating layers of composites (e.g., fiber-reinforced plastics, FRP) and light metals (e.g., aluminum alloys or high-strength steels, HSS)7,8. Research on FML has demonstrated their high potential for improving impact resistance, fatigue performance, and damage tolerance in various technical applications8,9,10,11. The formability of FML not only depends on the deformation behaviors of both metal and FRP layers, but also on their interfacial bonding. Delamination is a typical defect that may occur during forming of FML12.

Bellini et al.13 prepared samples consisting of alternating layers of carbon fiber-reinforced plastic (CFRP) and commercially pure aluminum using different numbers of layers and different adhesives. They concluded that laminates featuring a single EN AW-1100 aluminum alloy sheet bonded with sole prepreg resin yielded the highest bending strength, whereas laminates featuring two EN AW-1100 aluminum alloy sheets bonded with structural adhesive exhibited the lowest bending strength. Gupta et al.14 investigated the influence of the surface treatment of an EN AW-2024-T3 aluminum alloy sheet inside an FML structure. They found out that bending strength is influenced by the stacking sequence and by the adhesion between the aluminum alloy and the CFRP. Anodizing and grinding of the EN AW-2024-T3 aluminum alloy sheet enhanced bonding and, thus, improved the bending strength and modulus of the FML. Khalili et al.15 stated that FML have greater impact damage tolerance and superior bending behavior compared with simple glass fiber-reinforced plastics (GFRP).

With growing environmental concerns and regulations16, the need for sustainable and cost-efficient alternatives to CFRP and GFRP has been rising, as they are relatively costly and raise environmental concerns. The production of carbon fibers requires approximately 14-times more energy than the production of conventional steel, and producing fiber-reinforced plastics (FRP) generates polluting emissions and hazardous by-products such as NOx17,18,19. Furthermore, suitable recycling technologies with both low cost and low global warming potential (GWP) are still lacking20. Using natural fiber reinforcements such as flax, kenaf or sisal21,22,23,24, or wood-based materials25,26,27 offers advantages in terms of sustainability and recyclability of FML. Additionally, the costs can be reduced to one third of the costs of glass fibers23. In the automotive industry, natural fiber-reinforced composites (NFRC) have shown promising potential. They are being used in car interior parts such as seat backs24 and also for exterior body parts28,29 due to their beneficial properties, including low density and good vibration damping ability30. However, for wider use in automotive applications challenges such as poor resistance against moisture and lack of sufficient interfacial adhesion between the fibers and the polymer matrix must be addressed31. Using wood laminates instead of embedding natural fibers into a polymer matrix would solve this issue and could reduce manufacturing costs, as the production of natural fibers demands significant energy input30.

Despite the high potential of renewable wood-based materials for producing FML, investigations on this topic are rare. Kohl et al.25,32 investigated the dynamic impact stress and the three-point bending behavior on laminates consisting of alternating layers of wood veneers reinforced either by an aramid fabric or by a stainless steel foil. Samples exposed to extreme climate conditions (e.g., kiln-dried or water-stored samples) had considerably lower tensile shear strength and maximum force in dart drop tests. The reinforcing effect of the aramid fabric and of the stainless steel foil was evident. Combinations of different wood species (namely, khaya, beech, cedar, and pine), adhesive types (i.e. urea formaldehyde (UF) and 1-component polyurethane (1CP)), and layer structures (namely, one layer in transverse wood fiber orientation or two layers in transverse fiber orientation) were investigated. Beech and pine demonstrated better bending properties and 1CP showed better bonding between layers. Moreover, Silvayeh et al.33 and Domitner et al.34 studied hybrid screw-bonded joints of wood laminates and aluminum alloy sheets. They concluded that the adhesive has a major influence on the lap shear strength of the joints under quasi-static and cyclic load conditions, whereas screws contribute only little.

Fiber-reinforced materials typically exhibit a distinctly anisotropic behavior with different strength parallel and transverse to the fiber orientation35. Compared with conventional FRP, where length and alignment of the fibers can be adapted to the specific requirements, the high anisotropy and variability of the wood properties between different wood species36, and even within the same species, complicates industrial use. Graf et al.27 demonstrated that moisture and temperature considerably influence mechanical properties not only for simple wood plates, but also for hybrid aluminum-wood plates. They concluded that increasing the moisture content (MC) by 1 wt% at constant temperature the bending strength of the plates for longitudinal wood fiber orientations decreases by approximately 1%.

Finite element (FE) simulations have become essential for investigating the processing and performance of FML. Reliable FE simulations of wood-based composites include constitutive laws that describe the complex characteristic mechanical behavior of wood, such as ductile compression behavior perpendicular to the grain, brittle tensile failure, and compressive failure with softening parallel to the grain37. Notable progress has been made in the development of FE models, including experimentally determined material data, which allow for calculating the deformation behavior of wood37,38,39,40. Oudjene et al.37 developed a constitutive model for wood. They specifically modified a previous model to include anisotropic plasticity and densification effects, which occur when wood undergoes large compressive deformations and brittle failure. Müller et al.38 used the *MAT_054 material model implemented in the LS-DYNA FE software to simulate tension, compression, and bending of clear and laminated wood. Baumann et al.39 compared the feasibility of using the *MAT_143 and *MAT_058 material models for describing the mechanical behavior of birch wood. Despite facing some numerical issues, they concluded that the *MAT_058 model is basically suitable for describing tensile and compression behavior. Both studies concluded that composite material models can be employed for modeling wood-based materials. This was confirmed by Zerbst et al.40, who demonstrated the application of the *MAT_058 model for simulating automotive interior trim parts of ash wood veneers.

FE simulations have mainly been used for investigating clear wood or timber beams in construction applications, where elastic properties play a key role. Graf et al.27 investigated the bending behavior of aluminum-wood plates consisting of solid birch wood plates that were adhesive-bonded with EN AW-6016-T4 aluminum alloy sheets at different moisture contents. They highlighted the importance of moisture-dependent material properties for achieving accurate results of the simulations. While their study provided valuable basic insights into the bending behavior of hybrid aluminum-wood plates, research on this topic is still scarce, especially with the focus on bending behavior beyond the elastic deformation limit.

The present study is based on the findings of Graf et al.27, who identified great challenges with respect to debonding/delamination, localized strain zones in the bending area, and high scattering of bending properties. Therefore, this study combines experimental and numerical methods to investigate the three-point bending behavior of FML consisting of birch veneers with different fiber orientations and of an EN AW-6016-T4 aluminum alloy sheet under various moisture and temperature conditions. The layered structure of the FML is intended to improve the bending property by reducing the inherent characteristic scatter of the wood properties. Moreover, using FML with tailored orientations of the veneer layers allows for improving bending properties.

Materials and methods

Table 1 provides an overview of the key terms used in this work for describing the sample configurations investigated.

Sample preparation

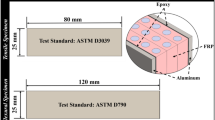

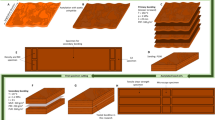

To prepare the wood laminates, four layers of rotary-cut birch wood veneer with dimensions of 300 mm × 300 mm × 1 mm were adhesive-bonded. For each of the layers, 200–300 g/m2 of commercial liquid single-component polyurethane-(PUR)-based adhesive was used. For producing the hybrid aluminum-wood laminates, EN AW-6016-T4 aluminum alloy sheets with dimensions of 250 mm × 60 mm × 1 mm were adhesive-bonded with the wood laminate using the identical type of adhesive. The stacked laminates were compressed at room temperature for 4–5 h with about 0.5 N/mm2 of contact pressure using an OTT 3013 veneer panel press. After the adhesive was cured, the laminates were cut into samples with dimensions of 250 mm × 60 mm × d. The thickness d of the simple wood laminate and of the hybrid aluminum-wood laminate was about 4.1 ± 0.1 mm and 5.2 ± 0.1 mm, respectively. Moreover, the bending behavior of 2 mm- and 4 mm-thick simple EN AW-6016-T4 aluminum alloy sheets was compared. The weights of the 2 mm-thick aluminum alloy sheets and of the hybrid aluminum-wood laminates were 80.8 ± 0.3 g and 85.5 ± 2.0 g, respectively, and the weight of the 4 mm-thick aluminum alloy weight was 160.4 ± 0.3 mm. The density of the aluminum alloy sheet and of the simple wood laminate consisting of veneers and adhesive layers in air-dried condition was 2.7 g/cm3 and about 0.7 g/cm3, respectively. As schematically illustrated in Fig. 1, samples with different orientations of the wood fibers were considered.

Schematic illustration of different sample configurations and wood fiber orientations: (a,c,e) simple wood laminates and (b,d,f) hybrid aluminum-wood laminates with (a,b) longitudinal (L), (c,d) transverse (T), and (e,f) bidirectional (B) fiber orientations. The dashed arrows indicate the rolling direction of the aluminum alloy sheet and the continuous lines indicate the fiber orientations of the wood veneers.

The three-point bending tests were performed immediately after conditioning the samples. Four different conditions were considered:

-

Heated condition: Before the bending tests, the samples were heated for 5 min inside a Siemens HT5HB33 furnace at 140 ± 5 °C. The samples reached this temperature after the exposure time of 11 min. This comparatively low temperature prevents irreversible thermal degradation of wood, which typically starts for birch wood with the decomposition of hemicellulose at temperatures of around 150 °C41,42,43.

-

Air-dried condition: The samples were tested as received without any additional treatment.

-

Moistened condition: Before bending, a predefined mass of water (15 g) was applied to the surface of the wood laminate. After the exposure time of 45 min, the residual water was wiped off. The mass of water and the exposure time were based on previous studies on the impact of different liquids such as water or acetone on wood laminate properties44,45.

-

Water-stored condition: Before the bending tests, the samples were stored at room temperature (20 °C) for 120 min in a water bath.

Determining the moisture content (MC) and the temperature of the samples

The procedure for measuring the MC of wood according to the ÖNORM EN 13183-1 standard46 was adapted to determine the gradient of moisture through the thickness of the samples. For this purpose, pieces of each wood veneer were manually extracted from the samples by using a conventional chisel, as shown in Fig. 2a. The initial mass \({m}_{0}\) of each extracted piece was measured using a Kern PNS digital precision balance. The pieces were dried inside a Siemens HT5HB33 oven at a temperature of 100 ± 5 °C. After 60 min of heating, the actual mass \({m}_{1}\) of the extracted piece was measured. If the decrease of \({m}_{1}\) was less than 0.002 g within 120 min of heating, the wood veneer was reasonably considered dry and the MC in wt% was calculated as \(MC=100({m}_{0}-{m}_{1})/{m}_{1}\).

For measuring the temperature of the samples during heating and also during testing, conventional thermowires connected to type K thermocouples were embedded into the adhesive layer between each wood veneer and between the wood veneer and the aluminum alloy sheet, as illustrated in Fig. 2b. The temperature signals were recorded using a Calex Excelog 6 data logger.

Three-point bending tests

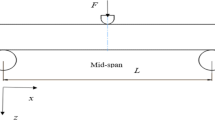

A Zwick/Roell Z100 uniaxial testing machine equipped with a 100 kN load cell was used for the three-point bending tests, and the testXpert III software was used for recording the bending force–displacement curves. The relative error of the load cell meets class 1 (± 1%) for forces between 0.2 and 1.0 kN and class 0.5 (± 0.5%) for forces above 1.0 kN. Given that the investigated force range lies mainly within these ranges, the measurement accuracy is sufficient to detect reliable results and valid trends. The test setup is illustrated in Fig. 3. The testing speed was 10 mm/min, and the testing was stopped when the max. punch force decreased by 20%. Each sample type was tested three times. The calculation of the bending angle in the software is based on ÖNORM EN ISO 7438:2021-03-1547 and considers geometries of the test setup, the sample, and the recorded punch displacement. The samples have a length of 250 mm and a width of 60 mm. A previous study on the three-point bending behavior of hybrid plates consisting of aluminum alloy sheets and massive wood plates has shown that the critical tensile strain typically occurs on the outer bending radius27. Hence, to avoid any tension-induced fracture of the wood laminate during bending, the aluminum alloy sheet was placed at the outer bending radius, i.e., next to the support rolls, as illustrated in Fig. 3a.

For optical measurement of the strains of air-dried hybrid aluminum-wood samples, the GOM ARAMIS 3D camera system with a measuring volume of 150 mm × 120 mm × 90 mm was used. The side face of the sample was sprayed with a white base coating followed by a pattern of stochastically distributed black speckles to enable strain monitoring. The strain field was calculated based on the displacements of the speckles during three-point bending using the GOM ARAMIS Professional 2018 software for digital image correlation (DIC).

The Minitab statistical software (version 22.0) was used for statistical analysis. Regression analyses with a confidence interval of 95% were performed to evaluate the influence of wood fiber orientation, MC and temperature on the max. bending force and on the bending angle at max. bending force.

Numerical modeling

Three-point bending of hybrid adhesive-bonded aluminum-wood laminates was modeled using the LS-DYNA R1310 finite element (FE) software. The created FE model was a modification of the model presented by Graf et al.27 for investigating three-point bending of hybrid adhesive-bonded aluminum-wood plates. The following description also includes the keywords used in the LS-DYNA software48.

Model geometry, mesh, and boundary conditions

Figure 4 shows the three-dimensional model of the setup used for three-point bending. The interaction between the hybrid aluminum-wood sample, the support rolls, and the punch of the three-point bending setup were modeled using the *CONTACT_AUTOMATIC_SURFACE_TO_SURFACE condition. This keyword represents the state of the art in LS-DYNA contact modeling and defines the contact between a set of shell elements and solid elements48. Several studies have proven the suitability of this contact condition for three-point bending simulations49,50,51. To consider possible self-contact of the sample during bending deformation, the *CONTACT_AUTOMATIC_SINGLE_SURFACE condition was applied. The linear punch displacement was defined using the *BOUNDARY_PRESCRIBED_MOTION_RIGID condition.

The dimensions of the sample in the model were 250 mm × 60 mm × 5.2 mm (the thickness of the wood laminate and of the aluminum alloy sheet was 4.2 mm and 1.0 mm, respectively), which was in accordance with the dimensions of samples used in the three-point bending tests. The model was created using solid elements (ELFORM = − 1), with dimensions of 2 mm × 2 mm × 0.52 mm for the wood veneer layers and 2 mm × 2 mm × 0.33 mm for the aluminum alloy sheet. The wood laminate was divided into four sections (SECTION_SOLID), resulting in one section with two element rows for each veneer layer, as illustrated in the detail of Fig. 4. As most of the samples did not show any delamination/debonding, perfect bonding conditions between the veneer layers and the aluminum alloy sheet were modeled using a rigid tie contact. The very thin adhesive layers can be reasonably supposed to have just minor influence, whereas the properties of the comparatively thick veneers and of the aluminum alloy sheet dominate the bending behavior52. Therefore, the adhesive layers were not explicitly modeled.

Material definitions

Table 2 presents the input parameters that were used for creating the FE model. The input parameters were determined by previous studies on the material properties of birch wood at different conditions53,54 and of aluminum alloy EN AW-6016-T4 at room temperature55 using uniaxial compression and/or tensile testing. The material properties of each of the four layers were dependent on the MC and on the temperature of the layer. The MC 1–4 of the individual veneer layers 1–4 were defined according to the MC measurements. The temperature of the four layers was constant in each of the models. The material axes option (AOPT) settings in the software were used for considering the orientation of the individual veneer layers.

The punch and the support rolls were treated as rigid using the MAT_RIGID (*MAT_020) material model. The isotropic plastic behavior of the aluminum alloy was described using the MAT_PIECEWISE_LINEAR_PLASTICITY (*MAT_024) material model. The orthotropic behavior of wood was described using the *MAT_LAMINATED_COMPOSITE_FABRIC (*MAT_058) material model, which allows for describing non-symmetric tension and compression. The model considers quasi-brittle tensile behavior and ideal plastic compression behavior40, and its feasibility for modeling wood was already confirmed27,39,40,56. The channel filter class (CFC) 60 was used for smoothing the bending force–bending angle curves calculated in the simulations.

Results and discussion

Variation of the moisture content

Figure 5 illustrates the variation of the MC under different conditions. Both simple wood and hybrid aluminum-wood laminates exhibit a MC of approximately 5 wt% (air-dried condition), which decreases to about 1 wt% when heating the samples to 140 °C (heated condition). Because of direct water exposure (moistened condition), the MC of veneer layer 1 of simple wood and hybrid aluminum-wood laminates with longitudinal and with bidirectional fiber orientations approaches the fiber saturation point (FSP). However, veneer layers 2–4 in these configurations show a lower MC of about 7–15 wt%. In contrast, the MC of each veneer layer of hybrid aluminum-wood laminates with transverse fiber orientation decreased by about 50% due to swelling and distortion of the wood, which favored run-off of water from the top veneer layer. Water-stored simple wood laminates maintain a MC close to the FSP, particularly at the outer veneer layers, whereas the MC of the inner veneer layers is lower, as the adhesive may act as a diffusion barrier57. A gradient of the MC is observed in hybrid aluminum-wood laminates. The MC decreases from the outer veneer layer toward the layer next to the aluminum alloy sheet, as the sheet next to layer 4 is a barrier that prevents water diffusion into the inner veneer layers.

Figure 6 presents the bending force–bending angle curves recorded in the three-point bending tests for different conditions of the wood laminates. The hybrid aluminum-wood laminates generally showed higher max. bending force than the simple wood laminates, which was due to the reinforcement effect of the aluminum alloy sheet. Moreover, wood laminates with longitudinal fiber orientation exhibited higher max. bending forces than those with transverse fiber orientation, which is consistent with observations for simple wood plates and hybrid aluminum-wood plates27. Wood laminates with bidirectional fiber orientation exhibit max. bending forces between those with longitudinal or transverse fiber orientation. The bending force–bending angle curves of solid wood plates show great scatter, which is mainly due to characteristic wood features (e.g., knots and branches). However, the layered structure of the wood laminates used in the present study reduces the influence of such features that typically affect mechanical properties35,58.

Bending force–bending angle curves of simple wood laminates and of hybrid aluminum-wood laminates with longitudinal (L), transverse (T), and bidirectional (B) fiber orientations for (a) heated, (b) air-dried, (c) moistened, and (d) water-stored conditions. The bending force–bending angle curves of 2 mm- and 4 mm-thick aluminum alloy sheets are also included in (b).

Failure of the laminates was typically initiated at the max. bending force. After failure initiation, the bending force steadily decreased, as failure of the wood laminate continued. Fracture of the aluminum alloy sheet was not observed in any of the three-point bending tests.

For comparison, Fig. 6b contains the bending force–bending angle curves of 2 mm-thick EN AW-6016-T4 aluminum alloy sheets of similar weight (80.8 ± 2.0 g) as the hybrid aluminum-wood laminate (85.5 ± 0.3 g), and the bending force-bending angle curves of 4 mm-thick EN AW-6016-T4 aluminum alloy sheets. The bending behavior of hybrid aluminum-wood laminates with transverse fiber orientation was quite similar to the bending behavior of 2 mm-thick aluminum alloy sheets, as the max. bending force was 383 ± 40 N and 405 ± 3 N, respectively. Hybrid aluminum-wood laminates with longitudinal and bidirectional fiber orientations showed significantly greater bending force, which also indicates superior energy absorption. In contrast, the max. bending force achieved with the 4 mm-thick aluminum alloy sheets was four times greater; however, one has to consider that this sheet was twice as heavy. These results demonstrate that hybrid aluminum-wood laminates are a promising lightweight alternative to conventional aluminum alloys.

The bending stiffness of each sample configuration was calculated based on the linear slopes of the bending force-bending displacement curves shown in Fig. 6. As the general trend of the stiffness is quite identical in all conditions tested, Table 3 exemplarily compares the stiffness of samples in air-dried condition. A higher bending stiffness basically indicates greater resistance to elastic deformation. As early failure occurred in simple wood laminates, the high bending stiffness of samples with longitudinal fiber orientation was associated with rather low bending angles at max. bending force, whereas the low bending stiffness of samples with transverse fiber orientation was associated with rather high bending angles at max. bending force. Samples with bidirectional fiber orientations exhibited the highest bending angle at max. bending force, which was due to the relatively low bending stiffness and to the delayed failure, resulting from the combination of transverse and longitudinal fiber orientations. Compared to simple wood laminates, hybrid aluminum-wood laminates generally showed not only higher max. bending forces, but also higher bending stiffness, which was due to the reinforcing effect of the aluminum alloy sheet. However, compared to simple aluminum-wood laminates the bending angle at max. bending force significantly increased only for unidirectional, but not for bidirectional hybrid aluminum-wood laminates, as the bending angle of simple aluminum-wood laminates was already high. Therefore, the beneficial reinforcing effect of the aluminum sheet was rather low in bidirectional aluminum-wood laminates.

Figure 7 illustrates the Pareto diagrams of the standardized effects achieved from the regression analyses. The coefficient of determination, R2, the predictive coefficient of determination, R2(pred), and the significance level, α, are included in the respective diagrams. Wood fiber orientation and MC significantly influence the max. bending force and the bending angle at max. bending force for both hybrid aluminum-wood and simple wood laminates (p-value < 0.05). The temperature only shows an influence on the bending force for hybrid aluminum-wood laminates.

Influence of fiber orientation

Longitudinal fiber orientation

If the major tensile stresses were oriented parallel to the wood fibers, failure of the simple wood laminates independent of their condition started at the tensile zone at the outer bending radius, as exemplarily shown in Fig. 8a. However, in simple wood laminates, fracture of the wood fibers along the sample thickness stopped earlier than in simple wood plates27. Beyond the force max., the decrease of bending force was less pronounced for simple wood laminate than for simple wood plates. This is likely attributable to the adhesive layer between the wood veneers, which hindered or even prevented the progress of fiber fracture. As indicated by the max. bending force, fracture of the simple wood plate27 and of the simple wood laminate was initiated at a bending angle of about 19° and 15°, respectively.

Typical failure modes of samples with longitudinal fiber orientation: (a) fracture of fibers of simple wood laminates in air-dried condition at the tension zone at the outer bending radius, (b) crushed fibers at the compression zone of hybrid aluminum-wood laminates in heated condition, and (c) surface roughening at the compression zone of hybrid aluminum-wood laminates in water-stored condition.

In contrast to the simple wood laminates, which exclusively failed by fracture of the wood fibers at the outer bending radius, failure of the hybrid aluminum-wood laminates started at the compression zone located at the inner bending radius. This failure behavior was basically independent of the condition of the samples. As exemplarily demonstrated in Fig. 8, especially for heated and air-dried hybrid aluminum-wood laminates, crushing of the wood fibers was observed, whereas for moistened and water-stored hybrid aluminum-wood laminates, surface roughening was detected. In contrast, fiber buckling was observed for air-dried hybrid aluminum-wood plates in the compression zone27. Therefore, increasing the MC reduces the buckling and crushing susceptibility of the fibers within the compression zone, and moisture generally tends to increase the ductility of wood fibers58. Compared with samples in heated condition, samples in water-stored condition show significantly lower failure due to higher ductility of the wood fibers, as demonstrated in Fig. 9. Several failure modes such as local debonding/delamination, wood fracture in the laminate, and fiber crushing were observed in heated condition. Liu et al.59 demonstrated that the bonding strength depends on both the adhesive type and the temperature at which wood pyrolysis occurs. They indicate that pyrolysis on larch wood occurs between 150 and 300 °C. Additionally, Frangi et al.60 demonstrated that a significant loss in the bonding capability of PUR adhesives occurs at 150 °C. Based on this, it can be supposed that some weakening of the adhesive may start at 140 °C, which causes local delamination and wood fracture, as indicated in Fig. 9b.

Transverse fiber orientation

As shown in Fig. 10a, simple wood laminates in air-dried condition suffered from early brittle interfiber fracture, which started at the tensile zone at the outer bending radius at the average bending angle of about 23°. This agrees with observations on the fracture behavior of simple wood plates27; however, the laminates reduce the susceptibility of complete interfiber fracture. Two out of three tested samples only exhibit partial interfiber fracture over the sample thickness, as demonstrated by the left sample shown in Fig. 10a.

Increasing the temperature or the MC did not reduce the tendency to interfiber fracture in simple wood laminates, although increasing the MC decreased the susceptibility to interfiber fracture in simple wood plates. Therefore, the bending angles achieved with simple wood laminates in moistened and water-stored conditions were only about half of the bending angles achieved with simple wood plates with identical preparation conditions27. The adhesive layer between each wood veneer reduces the water absorption of the sample, which decreased the influence of the molecular binding forces61. This was confirmed by the measured MC of the wood layers illustrated in Fig. 5, which were significantly lower than the MC of hybrid aluminum-wood plates consisting of solid wood instead of adhesive-bonded wood veneers27.

At small bending angles, simple wood laminates were sensitive to interfiber fracture; however, as demonstrated in Figs. 10b and 11a, even at high MC, hybrid aluminum-wood laminates did not show any failure at the forming zone. It is evident that the aluminum alloy sheet was able to withstand the tensile stresses during bending, which agrees with observations on hybrid aluminum-wood plates27. Although hybrid aluminum-wood laminates with longitudinal fiber orientation show failures in the compression zone, for hybrid aluminum-wood laminates with transverse fiber orientation no failure was observed. Furthermore, no significant failure was observed for samples in heated condition, as illustrated in Fig. 11b.

The anisotropic nature of wood with its direction-dependent alignment of cellulose fibers in the hemicellulose and lignin matrix obviously influences the failure modes. The Young’s modulus (modulus of elasticity, MOE) of cellulose fibers in longitudinal orientation is more than 10 times higher than the modulus in transverse orientation, which indicates that the fibers dominate the stiffness. If major compression stresses are applied parallel to the fibers (i.e., in longitudinal fiber orientation), the wood cells are deformed along their longitudinal axis. The more ductile matrix, that enables better compressibility in form of cell cavities collapse, if high compression stresses are applied perpendicular to the fibers (i.e., in transverse fiber orientation)62,63.

Bidirectional fiber orientation

In contrast to simple wood laminates with transverse fiber orientation, none of the simple wood laminates with bidirectional fiber orientation exhibited complete interfibre fracture. Nevertheless, an onset of interfiber fracture was also observed at the tensile zone located at the bottom veneer layer with transverse fiber orientation, as demonstrated in Fig. 12a. If the growing crack reached the next veneer layer with longitudinal orientation, it was deflected and propagated parallel to the fibers through the thickness of the veneer. Crack growth was stopped if the crack reached the next layer with transverse fiber orientation.

Typical failure modes of samples with bidirectional fiber orientation: (a) crack initiation and propagation at the tensile zone of simple wood laminates in air-dried condition, (b) crushing of wood fibers of hybrid aluminum-wood laminates in heated condition, and (c) buckling of wood fibers of hybrid aluminum-wood laminates in air-dried condition.

Hybrid aluminum-wood laminates with bidirectional fiber orientation showed an increase of surface roughness, crushing, and buckling of fibers at the compression zone located at the top layer with longitudinal fiber orientation. As shown in Fig. 12b, samples in heated condition showed crushing of fibers, but as shown in Fig. 12c, samples in air-dried condition showed buckling of fibers and surface roughening of the upper wood veneer. However, samples in moistened and water-stored conditions only showed surface roughening, as observed in laminates with unidirectional longitudinal fiber orientation. Increasing the MC decreased the crushing and buckling susceptibility of fibers, as discussed for hybrid aluminum-wood laminates with longitudinal fiber orientation (Section “Longitudinal fiber orientation”) and for hybrid aluminum-wood plates27.

In general, debonding/delamination between the aluminum alloy and the wood in water-stored conditions was not observed, as illustrated in Fig. 13a. However, the abrupt decrease beyond the max. bending force is related to microscopic fracture phenomena or to local debonding/delamination mechanisms in the sample, as confirmed by the LOM image of the hybrid aluminum-wood laminate in heated condition shown in Fig. 13b.

Max. bending force

Figure 14 illustrates the dependency of max. bending force on the mean MC determined across all veneer layers 1–4 measured on reference samples. In general, simple wood plates27 show higher max. bending forces than simple wood laminates for each sample type and each condition.

Influence of temperature

At constant MC, the Young’s modulus and the bending strength of wood both decrease with increasing temperature, as confirmed in previous studies64,65,66. However, one has to consider that increasing the temperature to 140 °C also reduced the MC from about 5 wt% to about 1 wt%. Typically, at elevated temperatures the MC of wood decreases, which influences mechanical properties67. As illustrated in Fig. 14, decreasing the MC tends to increase the max. bending force, which counteracts the effect of the elevated temperature described in literature. Hence, the max. bending force in heated condition can be similar or even higher than in air-dried condition. Only for hybrid aluminum-wood laminates, the temperature has a statistically significant effect (p-value = 0.003) on the max. bending force as shown in Fig. 7a. This is reasonable, as the mechanical properties of EN AW-6016-T4 are temperature-dependent68. Exposing this alloy to elevated temperatures even for a few minutes reduces the strength, as Mg–Si clusters dissolute in the microstructure. This negative effect has also been observed during the first few minutes of artificial aging69,70,71. However, this influence can be considered as relatively weak, as R2 and R2(prog) decrease by only 2% if the model excludes temperature. Nevertheless, to visualize the effect of temperature, contour plots for hybrid aluminum-wood laminates are shown in Fig. 15. The regression equations in Fig. 14 demonstrate that the temperature term stays constant for all three fiber orientations. The contour plot illustrates that highest max. bending forces generally occur at low temperatures and low MC. As both temperature and MC increase, the max. bending force decreases. For a given MC the max. bending force decreases as the temperature increases.

Influence of moisture content

Gerhards64 summarized several studies on the influence of MC on the bending behavior of wood. For MC in the range of 5–22 wt%, bending strength was found to decrease linearly at a constant temperature of 20 °C. This linear decrease is also evident in Fig. 14, as the max. bending force tends to decrease from the air-dried condition (MC of 5 wt%) to the water-stored condition (MC of 20–25 wt%) for each of the six sample configurations. The negative values predicted by the regression line for simple wood laminates with transverse fiber orientation are due to the low max. bending force measured at high MC. It can be assumed that max. bending forces are close to zero for MC beyond about 18 wt%. Increasing the MC by 1 wt% at constant temperature decreases the bending force by about 1–2% for hybrid and simple wood laminates with longitudinal and bidirectional fiber. Hence, the absolute bending force of hybrid aluminum-wood laminates decreases more steeply with increasing MC, as the bending force achieved in air-dried condition at low MC is already high. High R2 > 92% indicates a strong fit of the regression model to the data, which confirms a linear dependency. Furthermore, high R2(prog) > 90% confirms that the model is reliable for predicting the bending behavior of hybrid aluminum-wood laminates and of simple wood laminates, even if only the MC is considered as variable.

Bending angle at max. bending force

Figure 16 illustrates the dependency of the bending angle that was evaluated at the max. bending force on the MC. In general, the application of an aluminum alloy sheet significantly increased the bending angle of hybrid aluminum-wood laminates with both longitudinal (L) and transverse (T) fiber orientations, as illustrated in Fig. 16a,b. Macroscopic debonding/delamination of the aluminum alloy sheet from the wood veneer did not occur at the bending zone, except for the hybrid aluminum-wood laminates in heated condition, which confirms that the adhesive was basically suitable for bonding of aluminum with wood, even if the bonding is subsequently exposed to deformation. For simple wood laminates with transverse (T) fiber orientation, bending angle at max. bending force is limited by brittle interfiber fracture (Sect. “Transverse fiber orientation”). The aluminum alloy sheet used in the hybrid aluminum-wood laminate prevented the interfiber fracture, which improved significantly the bendability, as illustrated in Fig. 16b.

Influence of temperature

As confirmed by the statistical insignificance, no clear influence of temperature on the bending angle at max. bending force was observed. Consequently, bending angles at max. bending force were lower, similar or even higher in heated condition compared with the air-dried condition for both hybrid aluminum-wood laminates and simple wood laminates. As shown in Fig. 16c, heating of both hybrid aluminum-wood laminates and of simple wood laminates with bidirectional fiber orientation decreased the bending angles at max. bending forces for all samples tested. This decrease can be attributed to complex failure modes in the wood laminate, as well as to intense crushing of fibers in the compression zone of hybrid aluminum-wood laminates.

Influence of moisture content

As shown in Fig. 16, the bending angle at max. bending force tended to increase with increasing MC. Unidirectional (L,T) aluminum-wood laminates exhibited significantly higher bending angles at max. bending force than the unidirectional (L,T) simple wood laminates. In contrast, the bending angles at max. bending force of bidirectional (B) laminates were comparable for both simple wood laminates and hybrid aluminum-wood laminates. This indicates that just a minimal influence of the aluminum alloy sheet exists for the bidirectional fiber orientation, as previously discussed. R2 > 81% indicates a good fit between the model and the data and it confirms a linear dependency between the bending angle at max. bending force and the MC. The predictive accuracy of R2(prog) > 74% further confirms the reliability of the model.

Simulation of bending behavior

Figure 17 compares the bending force-bending angle curves from experiments and FE simulations for different MC. In general, the simulation was able to predict the bending behavior of different sample tpand conditions. However, for samples with longitudinal fiber orientation, the difference between the curves increases with increasing MC. This could be attributed to the natural characteristics of wood including, e.g., knots, fiber misorientation, variation of the MC, or moisture-induced swelling, which may influence mechanical properties72, but which have not yet been fully considered in the model. Fiber angle deviations are more dominant in samples with longitudinal fiber orientation than in samples with transverse fiber orientation. Despite the basically good match between simulations and experiments, the curves determined for the hybrid aluminum-wood laminates with bidirectional fiber orientation differ considerably in heated condition, Fig. 17a. The bending force that was monitored in the experiments notably decreased at small bending angles, which indicates possible failures such as microscopic fracture phenomena and local debonding of layers or more complex failure of the veneer layers, as observed particularly for wood laminates with bidirectional fiber orientation in Fig. 13b.

Experimental and numerical bending force–bending angle curves of aluminum-wood laminates in different fiber orientations in (a) heated, (b) air-dried, (c) moistened, and (d) water-stored condition, with (a) at elevated temperatures and (b–d) at room temperature. The continuous lines represent the experimental results of the bending tests and the dashed lines represent the results of the FE simulations.

Both MC and temperature not only influence the mechanical properties of the wood veneer layers, but also the properties of the adhesive between these layers73,74,75. Hence, differences between simulations and experiments may be due to varying bonding conditions and delamination caused by, e.g., different local MC or temperatures. However, considering the adhesive layer in the model would require material data that are usually obtained through elaborate testing of the adhesive at different conditions. Despite these limitations, the created FE model can be reasonably considered suitable for simulating wood and wood-metal composites (i.e., wood-based fiber-metal laminates).

Figure 18 shows strain fields in horizontal direction on the surface of air-dried hybrid aluminum-wood laminates with longitudinal, transverse, and bidirectional fiber orientations at the max. bending angles of 44°, 83°, and 80°, respectively. Zones of tensile strain (red) are observed at the outer bending radius and zones of compressive strain (blue) are detected at the inner bending radius. The strain fields indicate that the unstressed region, and thus the neutral bending axis (green), shifts toward the aluminum alloy sheet, which has a greater Young’s modulus than the wood laminate. This mechanism has also been identified for wood beams reinforced with carbon fiber-reinforced plastics (CFRP)76 or with steel using flexible shear connectors77.

Comparison of strain fields determined (a,c,e) by DIC measurement and (b,d,f) by FE simulation at specific bending angles of hybrid aluminum-wood laminates in air-dried condition for (a,b) the wood laminate with longitudinal fiber orientation, (c,d) the wood laminate with transverse fiber orientation, and (e,f) the wood laminate with bidirectional fiber orientation. Positive and negative strain values illustrate tensile zones (red) and compressive zones (blue), respectively.

The compressive strain of laminates with longitudinal fiber orientation (i.e., the major stresses are parallel to the fibers of all veneer layers) and with bidirectional fiber orientation (i.e., the major stresses are parallel to the fibers of the upper veneer layer) is rather concentrated at the inner bending radius. In contrast, the compressive strain of the laminate with transverse fiber orientation (i.e., the major stresses are perpendicular to the fibers of all veneer layers) is more evenly distributed over the inner bending radius. Compared with the strain field in three-point bending of hybrid aluminum-wood plates27, the strains in three-point bending of hybrid aluminum-wood laminates are less concentrated. The more homogeneous strain field was likely the reason why hybrid aluminum-wood laminates did not show any macroscopic debonding/delamination between the aluminum alloy sheet and the wood laminate at the bending zone. Moreover, this confirms that the adhesive used in this study was suitable for bonding wood with aluminum.

In both simulations and experiments the strain of hybrid metal-wood laminates with longitudinal fiber orientation is concentrated at the bending radius, whereas the strain of hybrid metal-wood laminates with transverse fiber orientation is more evenly distributed along the bending radius. In particular, the high compressive strain at the inner bending radius indicates local densification of wood fibers. Moreover, the FE model enabled identifying regions of high tensile strain at the outer bending radius. In these critical regions, wood failure and/or adhesive failure may cause delamination between the metal sheet and wood layers, as observed for hybrid aluminum-wood plates27.

Moreover, the results of the simulation indicate that the strain distribution in hybrid aluminum-wood laminates with bidirectional fiber orientation is more complex than the distribution in laminates with unidirectional fiber orientation, as additional zones of compressive strain parallel to veneer layers were predicted. Because of the limitation of the optical strain measuring system, capturing these thin zones in the bending tests was impossible.

Summary and conclusions

This work investigates the bending behavior of simple wood laminates and of hybrid aluminum-wood laminates at different temperatures and moisture contents (MC), as these laminates offer a great lightweight potential. Based on the results of three-point bending experiments and of finite element (FE) simulations, the following conclusions can be drawn:

-

(1)

Simple wood laminates and hybrid aluminum-wood laminates show significantly less variation of bending properties (max. bending force and bending angle at max. force) than simple wood plates and hybrid aluminum-wood plates with identical dimensions. Moreover, bending of simple wood laminates and of hybrid aluminum-wood laminates requires less force than bending of simple wood plates and of hybrid aluminum-wood plates. Hence, the properties of the laminates are generally superior to the properties of the plates.

-

(2)

The aluminum alloy sheet in hybrid aluminum-wood laminates is able to bear critical tensile stresses and to prevent fracture of fibers in longitudinal orientation and interfiber fracture in transverse orientation. Thus, the bendability of hybrid aluminum-wood laminates with unidirectional (longitudinal or transverse) fiber orientation is greater than the bendability of simple wood laminates. Hybrid aluminum-wood laminates with longitudinal and bidirectional fibers even show a higher bending force, which indicates that their energy absorption is also greater than that of aluminum plates of similar weight.

-

(3)

Decreasing the MC of the laminates increases the max. bending force and enhances the tendency to brittle fracture, as indicated by the decreasing bending angle at max. bending force. Because increasing the temperature to 140 °C decreased the MC to about 1 wt%, the max. bending force of simple wood laminates and of hybrid aluminum-wood laminates in heated condition was similar to or even higher than the max. bending force in air-dried condition. Hence, maintaining a certain MC is required for achieving good bendability.

-

(4)

Using an aluminum alloy sheet which absorbs tensile strains in critical zones and prevents brittle interfiber fracture of wood laminates significantly improves the bendability. Increasing the MC basically enhances the ductility of wood fibers, but the bendability of the laminates also depends on the fiber orientation. Using wood laminates with the MC of approximately 13 wt% is supposed to improve the ductility and to prevent brittle fracture of the wood fibers.

-

(5)

An FE model for predicting the bending force and the deformation (bending strain) of hybrid aluminum-wood laminates was successfully created. The predictive ability of the model tends to decrease once the MC and/or the temperature of the wood laminates increases, since the material properties of wood strongly depend on both properties. Introducing the wood characteristics (e.g., fiber misalignment), the exact local moisture/temperature distributions, and the elastoplastic properties as well failure criteria of the adhesive layers would improve the predictive quality of the model.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Brooker, A. D., Ward, J. & Wang, L. Lightweighting impacts on fuel economy, cost, and component losses. SAE Technical Paper 2013-01-0381 (2013).

Joost, W. J. Reducing vehicle weight and improving U.S. energy efficiency using integrated computational materials engineering. JOM 64(9), 1032–1038 (2012).

Lutsey, N. & Sperling, D. Energy efficiency, fuel economy, and policy implications. Transp. Res. Record J. Transp. Res. Board 1941, 8–17 (2005).

Miller, W. et al. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 280(1), 37–49 (2000).

Fentahun, M. A. & Savs, M. A. Materials used in automotive manufacture and material selection using ashby charts. Int. J. Mater. Eng. 8(3), 1032–1038 (2018).

Zhang, W. & Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 221, 110994 (2022).

Asundi, A. & Choi, A. Y. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 63, 384–394 (1997).

He, W. et al. On impact behavior of fiber metal laminate (FML) structures: A state-of-the-art review. Thin-Walled Struct. 167, 108026 (2021).

Sasso, M., Mancini, E., Dhaliwal, G., Newaz, G. & Amodio, D. Investigation of the mechanical behavior of CARALL FML at high strain rate. Compos. Struct. 222, 110922 (2019).

Yao, L., Yu, H., Wang, C. & He, W. Numerical and experimental investigation on the oblique successive impact behavior and accumulated damage characteristics of fiber metal laminates. Thin-Walled Struct. 166, 108033 (2021).

Giallanza, A., Parrinello, F., Ruggiero, V. & Marannano, G. Fatigue crack growth of new FML composites for light ship buildings under predominant mode II loading condition. Int. J. Interact. Des. Manuf. 14, 77–87 (2020).

Ding, Z., Wang, H., Luo, J. & Li, N. A review on forming technologies of fibre metal laminates. Int. J. Lightweight Mater. Manuf. 4, 110–126 (2021).

Bellini, C., Di Cocco, V., Iacoviello, F. & Sorrentino, L. Performance evaluation of CFRP/Al fibre metal laminates with different structural characteristics. Compos. Struct. 225, 111117 (2019).

Gupta, R. K., Mahato, A. & Bhattacharya, A. Strength and failure behavior of carbon fiber reinforced aluminum laminates under flexural loading. Mech. Adv. Mater. Struct. 29(5), 662–676 (2022).

Khalili, S., Mittal, R. & GharibiKalibar, S. A study of the mechanical properties of steel/aluminium/GRP laminates. Mater. Sci. Eng. A 412, 137–140 (2005).

European Union. Regulation (EU) 2019/631 of the European Parliament and of the Council of 17 April 2019 Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing Regulations (EC) No 443/2009 and (EU) No 510/201. (Official Journal of the European Union, 2019).

Sakamoto, K., Kawajiri, K., Hatori, H. & Tahara, K. Impact of the manufacturing processes of aromatic-polymer-based carbon fiber on life cycle greenhouse gas emissions. Sustainability 14(6), 3541 (2022).

Joshi, S., Drzal, L., Mohanty, A. & Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A 35, 371–376 (2004).

Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 16(3), 268–282. https://doi.org/10.1007/s11367-011-0264-z (2011).

Vo Dong, P. A. & Azzaro-Pantel, C. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 133, 63–75 (2018).

Thwe, M. M. & Liao, K. Durability of bamboo-glass fiber reinforced polymer matrix hybrid composites. Compos. Sci. Technol. 63, 375–387 (2003).

Wu, Y., Xia, C., Cai, L., Garcia, A. C. & Shi, S. Q. Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J. Clean. Prod. 184, 92–100 (2018).

Faruk, O., Bledzki, A. K., Fink, H.-P. & Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 299, 9–26 (2014).

Mohammed, L., Ansari, M., Pua, G., Jawaid, M. & Islam, M. S. A review on natural fiber reinforced polymer composite and its applications. Int. J. Polym. Sci. 2015(2), 243947 (2015).

Kohl, D., von Boyneburgk, C., Feldmann, M., Heim, H.-P. & Böhm, S. Characterization of wood-based multi-material systems under dynamic impact stress. Wood Mat. Sci. Eng. 15(3), 130–139 (2020).

Heyner, D. et al. Innovative concepts for the usage of veneer-based hybrid materials in vehicle structures. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 235, 1302–1311 (2021).

Graf, E. et al. Experimental and numerical analysis of the three-point bending behavior of hybrid adhesive-bonded aluminum-wood plates. J. Mater. Eng. Perform. 33, 6387–6397 (2024).

Pickering, K. L., Aruan Efendy, M. G. & Le, T. M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 83, 98–112. https://doi.org/10.1016/j.compositesa.2015.08.038 (2016).

Koronis, G., Silva, A. & Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 44(1), 120–127. https://doi.org/10.1016/j.compositesb.2012.07.004 (2013).

Hristian, L., Ostafe, M., Manea, L. & Leon, A. The study about the use of the natural fibres in composite materials. IOP Conf. Ser. Mater. Sci. Eng. 145(3), 032004 (2016).

Graupner, N., Herrmann, A. S. & Müssig, J. Natural and man-made cellulose fibre-reinforced poly(lactic acid) (PLA) composites: An overview about mechanical characteristics and application areas. Compos. Part A Appl. Sci. Manuf. 40(6–7), 810–821. https://doi.org/10.1016/j.compositesa.2009.04.003 (2009).

Kohl, D., Long, T. H. & Böhrm, S. Wood-based multi-material systems for technical applications –compatibility of wood from emerging and developing countries. Proced. Manuf. 8, 611–618 (2017).

Silvayeh, Z. et al. Mechanical performance of hybrid joints of aluminum sheets. Proced. Struct. Integr. 51, 141–144 (2023).

Domitner, J. et al. Mechanical performance and failure behavior of screw-bonded joints of aluminum sheets and cross-laminated birch veneer plates. Eng. Fail. Anal. 146, 107074 (2023).

Jakob, M. et al. The strength and stiffness of oriented wood and cellulose-fibre materials: A review. Prog. Mater Sci. 125, 100916 (2022).

Arriaga, F. et al. Mechanical properties of wood: A review. Forests 14, 1202 (2023).

Oudjene, M. & Khelifa, M. Finite element modelling of wooden structures at large deformations and brittle failure prediction M. Mater. Des. 30, 4081–4087 (2009).

Müller, U. et al. Crash simulation of wood and composite wood for future automotive engineering. Wood Mat. Sci. Eng. 15(5), 312–324 (2020).

Baumann, G., Hartmann, S., Müller, U., Kurzböck, C. & Feist, F. Comparison of the two material models 58, 143 in LS Dyna for modelling solid birch wood. in Proceedings of the 12th European LS-DYNA Conference (2019).

Zerbst, D., Liebold, C., Gereke, T., Clauß, S. & Cherif, C. Numerical simulation of the forming process of veneer laminates. J. Compos. Sci. 5(6), 150 (2021).

Hill, C., Altgen, M. & Rautkari, L. Thermal modification of wood—a review: Chemical changes and hygroscopicity. J. Mater. Sci. 56(11), 6581–6614 (2021).

Yildiz, S., Gezer, E. D. & Yildiz, U. C. Mechanical and chemical behavior of spruce wood modified by heat. Build. Environ. 41, 1762–1766 (2006).

Antons, A., Cirule, D., Verovkins, A. & Kuka, E. Effect of thermal treatment on physical and mechanical properties of birch and pine wood. Res. Rural Dev. 1, 78–85 (2018).

Joeressen, J. et al. Chemical resistance of acetylated radiata pine sliced veneers. Wood Mat. Sci. Eng. 18(4), 1467–1477 (2022).

Wurm, S. et al. Chemical resistance of modified wood veneers in sustainable load bearing elements. ACS Omega 9(48), 47690–47698 (2024).

Austrian Standards International. ÖNORM EN 1383-1:2019-10-01: Timber - Drying of sawn timber and bamboo - Part 1: General guidance on drying procedure (2019).

Austrian Standards International. ÖNORM EN ISO 7438:2020 Metallische Werkstoffe - Biegeversuch (2021).

Livermore, LS-Dyna R13.0 Keywords user’s manual Vol. II (2021).

Fu, X. & Zhang, X. Three-point bending of thin-walled arched beams with square sections. Thin-Walled Struct. 182, 110201 (2023).

Dou, S. S., Xia, J. S., Qiu, X. L. & Al-Bahrani, M. Investigation of bending behavior for slotted sandwich panels made with ABS and PLA along with aluminum cores. J. Braz. Soc. Mech. Sci. Eng. 45, 106 (2023).

Hampaiyan Miandowab, H., Rahmani, R. & Saeidi Googarchin, H. Bending characteristics of partially reinforced aluminum/CFRP hybrid hat-section beam structures with an adhesively bonded joint: An experimental, numerical, and analytical study. Polym. Compos. 45, 8949–8969 (2024).

Bodig, J. & Jayne, B. A. Mechanics of Wood and Wood Composites 1st edn. (Van Nostrand Reinhold, 1982).

Al-musawi, H. et al. The compressive behaviour of beech and birch at different moisture and temperature conditions along the grain. Eng. Fail. Anal. 159, 108017 (2024).

Al-musawi, H. et al. Compressive strength of beech and birch at different moisture contents and temperatures. J. Mater. Sci. 58, 13994–14008 (2023).

Hodžić, E. et al. Influence of alloy composition and lubrication on the formability of Al-Mg-Si alloy blanks. J. Manuf. Processes 85, 109–121. https://doi.org/10.1016/j.jmapro.2022.11.029 (2023).

Zerbst, D. et al. Modelling inhomogeneity of veneer laminates with a finite element mapping method based on arbitrary grayscale images. Materials 13, 2993 (2020).

Afshari, Z. & Malek, S. Moisture transport in laminated wood and bamboo composites bonded with thin adhesive layers – A numerical study. Constr. Build. Mater. 340, 127597 (2022).

Niemz, P. & Sonderegger, W. U. Holzphysik Eigenschaften, Prüfung und Kennwerte 2nd edn. (Carl Hanser Verlag, 2021).

Liu, J. et al. Bonding performance of melamine-urea–formaldehyde and phenol-resorcinol–formaldehyde adhesive glulams at elevated temperatures. Int. J. Adhes. Adhes. 98, 102500 (2020).

Frangi, A., Fontana, M. & Mischler, A. Shear behaviour of bond lines in glued laminated timber beams at high temperatures. Wood Sci. Technol. 38, 119–126 (2004).

Li, W. et al. Impact of internal structure on water-resistance of plywood studied using neutron radiography and X-ray tomography. Constr. Build. Mater. 73, 171–179 (2014).

Sun, J., Zhao, R., Zhong, Y. & Chen, Y. Compressive mechanical properties of larch wood in different grain orientations. Polymers 14, 3771 (2022).

Yuan, Q., Liu, Z., Zheng K. & Ma, C. Chapter 5 – Wood. in Civil Engineering Materials: From Theory to Practice 239–259 (Elsevier, 2021).

Gerhards, C. Effect of moisture content and temperature on the mechanical properties of wood: an analysis of immediate effects. Wood Fiber 14(1), 4–36 (1982).

Zhou, J. et al. Effects of temperature on the bending performance of wood-based panels. BioResources 7(3), 3597–3606 (2012).

Sulzberger, P. The effect of temperature on the strength of wood, plywood and glued joints. Aeronaut. Res. Consult. Comm. Rep. 16, 1–44 (1953).

Yue, K., Wu, J., Wang, F., Chen, Z. & Lu, W. Mechanical properties of douglas fir wood at elevated temperatures under nitrogen conditions. J. Mater. Civil Eng. 34(2), 04021434 (2021).

Yang, Z. & Banhart, J. Natural and artificial ageing in aluminium alloys – the role of excess vacancies. Acta Mater. 215, 117014 (2021).

Banhart, J., Chang, C. S. T., Liang, Z., Wanderka, N., Lay, M. D. H. & Hill, A.J. The Kinetics of natural ageing in 6000 alloys – a multi-method approach. Proceedings of the 12th International Conference on Aluminium Alloys 381–388 (2010).

Engler, O., Marioara, C. D., Aruga, Y., Kozuka, M. & Myhr, O. R. Effect of natural ageing or pre-ageing on the evolution of precipitate structure and strength during age hardening of Al-Mg-Si alloy AA 6016. Mater. Sci. Eng. A 759, 520–529 (2019).

Yu, W., He, H., Zhang, W., Li, L. & Sun, C. Modulation of the natural aging effect on subsequent artificial aging in Al-Mg-Si aluminum alloys with alloying content ~ 1 wt% through temperature tuning. J. Alloy Compd. 814, 152277 (2020).

Forest Products Laboratory, Wood Handbook - Wood as an Engineering Material. General Technical Report FPL-GTR-282 (Forest Products Laboratory, United States Departement of Agriculture Forest Service, 2021).

Galvez, P., Lopez de Armentia, S., Abenojar, J. & Martinez, M. A. Effect of moisture and temperature on thermal and mechanical properties of structural polyurethane adhesive joints. Compos. Struct. 247, 112443 (2020).

Na, J., Fan, Y., Tan, W., Guo, S. & Mu, W. Mechanical behavior of polyurethane adhesive bonded joints as a function of temperature and humidity. J. Adhes. Sci. Technol. 32(5), 457–472 (2018).

Borges, C. et al. Review on the effect of moisture and contamination on the interfacial properties of adhesive joints. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 235(3), 527–549 (2021).

Borri, A., Corradi, M. & Grazini, A. A method for flexural reinforcement. Compos. Part B Eng. 36, 143–153 (2005).

Burdzik, W. & Skorpen, S. Experimental and analytical timber beams with flexible of composite steel-reinforced investigation into the stiffness shear connectors. J. S. Afr. Inst. Eng. 58(4), 11–20 (2016).

Acknowledgements

The authors are grateful for research funding from the Federal Ministries BMK and BMAW as well as the Province of Styria within the COMET—Competence Centers for Excellent Technologies program, and for funding from the companies ACstyria Mobilitätscluster GmbH, BASF SE, BASF Polyurethanes GmbH, DYNAmore Gesellschaft für FEM Ingenieurdienstleistungen mbH, evon GmbH, Fill Gesellschaft m.b.H, Forst-Holz-Papier, Indorama Ventures Schoeller Wool Austria GmbH, Holzcluster Steiermark GmbH, IB STEINER, Klumpp Coatings GmbH, LEAN Management Consulting GmbH, Pfeifer Holding GmbH, Volkswagen AG und Weitzer Woodsolutions GmbH. The COMET program is handled by the Austrian Research Promotion Agency (FFG, 882509) and the Styrian Business Promotion Agency (SFG, 1000065896). Publishing was supported by TU Graz Open Access Publishing Fund. The authors thank Sebastian Fritsche for his help with the statistical analysis in Minitab.

Author information

Authors and Affiliations

Contributions

Peter Auer: Methodology, Investigation. Josef Domitner: Conceptualization, Formal analysis, Methodology, Project administration, Resources, Validation, Writing – Review & Editing, Supervision. Eva Graf: Conceptualization, Formal analysis, Investigation, Validation, Visualization, Writing – Original draft. Philipp Matz: Formal analysis, Software, Validation. Johannes Painer: Resources, Validation. Christof Sommitsch: Formal analysis, Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Graf, E., Matz, P., Auer, P. et al. Bending behavior of hybrid laminates made of aluminum and wood for sustainable lightweight structures. Sci Rep 15, 16495 (2025). https://doi.org/10.1038/s41598-025-99234-y

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-99234-y