Abstract

Hot cracking remains a significant challenge in the fusion welding of high-strength aluminum alloys, particularly AA6061, which is highly susceptible to solidification cracking in the fusion zone (FZ). This study investigates the efficacy of friction stir processing (FSP) as a pre-weld treatment to enhance the weldability of AA6061 by engineering the base metal microstructure. We demonstrate that FSP transforms AA6061 from a material highly prone to solidification cracking into one with remarkable crack resistance during fusion welding. By applying multi-pass FSP to AA6061-T6, we achieved a base metal with ultra-fine grains, which facilitated the epitaxial growth of fine grains during subsequent fusion welding. The refined grain structure in the FZ, combined with reduced dendrite arm spacing, significantly mitigated solidification cracking by improving grain coalescence and strain accommodation during solidification. Post-weld T6 heat treatment resulted in a joint efficiency of 0.95 in tensile strength, outperforming conventional fusion welding and friction stir welding. This work highlights the potential of FSP as a pre-weld treatment to convert crack-prone aluminum alloys into viable candidates for high-integrity, lightweight structural applications.

Similar content being viewed by others

Introduction

Welding is a crucial enabling technology in manufacturing. Enhancing the weldability of high-strength aluminum alloys presents a significant challenge for their widespread application in lightweight structures. This challenge serves as a driving force behind the growing research interest in the welding of aluminum alloys1,2,3,4,5,6,7,8,9. Hot cracking is a detrimental phenomenon for weldability of alloys. This issue, which encompasses both solidification cracking and liquation cracking10,11,12, occurs during the fusion welding of certain susceptible Al alloys13, particularly those belonging to high strength grades (i.e., 2xxx, 6xxx, and 7xxx series)14,15. Among these, the Al alloy 6061 is particularly prone to solidification cracking, with reports indicating its sensitivity surpasses that of alloys 2024 and 707516. A key factor influencing solidification cracking is the grain size within the fusion zone (FZ)17,18,19. For instance, it has been shown that the introduction of Ti in the weld pool and the formation of in-situ inoculants successfully grained refined the weld metal and mitigated the solidification cracking in aluminum alloys20. More recently, it is shown that the addition of nanoparticles to Al alloy can effectively eliminate solidification cracking by refining the grain structure in the FZ21. The susceptibility to liquation cracking is highly governed by the initial microstructure of the base metal. The extent of liquation is influenced by the grain size, second phase characteristics (i.e., nature, size and volume fraction) in the initial microstructure of the base material22,23.

Friction stir processing (FSP) is an effective method for locally altering the microstructure of alloys, thereby improving their localized properties24,25,26,27. Mousavizade et al.28 proposed the use of FSP as a pre-weld treatment prior to fusion welding, providing a viable solution to reduce liquation cracking in the IN738 nickel-based superalloy by developing a liquation-resistant microstructure within the partially melted zone (PMZ). This technique has since been applied to enhance the weldability of various nickel-based superalloys29, as well as aluminum30,31 and magnesium alloys32. For instance, Pirjamadi et al.30 explored the influence of FSP pre-weld treatment on cracking during the fusion welding of AA7075 alloy. They discovered that the hot-rolled base metal of AA7075, characterized by large, elongated pancake-shaped grains, is particularly prone to severe liquation cracking during fusion welding, which can subsequently lead to solidification cracks. However, with the application of FSP pre-weld treatment, the microstructure of the PMZ was significantly enhanced, resulting in a crack-free weld. Fusion welding on fine-grained base metal that has undergone FSP reduces the thickness of the liquid film, thereby decreasing susceptibility to liquation cracking and mitigating solidification cracks. Beiranvand et al.31 demonstrated that applying FSP as a pre-weld treatment significantly reduced liquation cracking in AA2024 aluminum alloy during laser welding. This improvement was attributed to grain refinement in the base metal. Moreover, they reported that higher resistance to liquation cracking in the base metal could also decrease the tendency for solidification cracking in the fusion zone. This occurs because liquation cracks in the partially melted zone (PMZ) can act as preferential initiation sites for solidification cracks.

Most previous studies have demonstrated that FSP can serve as a pre-treatment before fusion welding to refine grain size in the PMZ, thus eliminating the risk of liquation cracking. However, less attention has been given to the impact of FSP pre-weld treatment on solidification cracking. Given that FSP-treated samples exhibit a refined grain structure in both the heat-affected zone (HAZ) and PMZ, and considering the role of epitaxial growth in autogenous welds, this process also influences grain size in the fusion zone (FZ), thereby affecting solidification cracking. Rule et al.29 indicated that FSP pre-weld treatment can reduce grain size in the fusion zone of IN600 nickel-based superalloy; however, the effect on solidification cracking was not addressed.

The objective of this study is to examine the influence of FSP pre-weld treatment on the cracking phenomena during arc fusion welding of AA6061. This alloy is notably susceptible to solidification cracking but less so to liquation cracking compared to other high-strength aluminum alloys. The findings of the present study suggest that FSP pre-weld treatment enhances resistance to solidification cracking during fusion welding of AA6061.

Materials and methods

The material under investigation in this study is a commercial AA6061-T6 sheet with a thickness of 3 mm. The chemical composition (measured by spark emission spectroscopy) and mechanical properties (determined via tensile testing) of the AA6061-T6 alloy are presented in Table 1. Test plates measuring 100 × 120 × 3 mm, were cut from the base plate sheets. A copper-based backing plate was utilized to enhance the heat sink during the welding process.

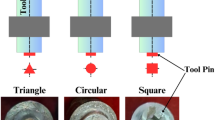

Welding was performed under two different scenarios, namely, on the untreated and FSP-treated AA6061-T6 base materials. For the first scenario, bead-on-plate welding was conducted using autogenous tungsten inert gas (TIG) welding on the as-received AA6061-T6. The welding parameters were chosen to achieve a full penetration weld. These included a welding speed of 2 mm/s, a voltage of 10 V, a current of 120 A, and a gas flow rate of 14 L/min. For the second scenario, the wrought AA6061-T6 base material was pre-treated using FSP with an H13 tool steel. The tool had a shoulder diameter of 18 mm, pin diameter of 6 mm, and probe length of 2.8 mm. The FSP parameters were adjusted to create a desired SZ depth of 2.8 mm, with a tool rotational speed of 400 rpm, tool travel speed of 200 mm/min, and a tool tilt angle of 3°. To ensure the entire weld area was placed inside a sufficient SZ with fine grains, a multi-parallel pass FSP approach was employed, featuring a 30% overlap between adjacent passes. Subsequently, bead-on-plate fusion welding was conducted on the FSP-treated samples, which were prepared using abrasive papers to achieve smoothness. The TIG welding was performed under conditions similar to those used for the untreated material. This welding strategy, which combines friction stir processing (FSP) as a pre-weld treatment followed by TIG welding, is referred to as FTIG (see Fig. 1a).

For optical microscopy, samples were sectioned perpendicular to the welding direction and subjected to standard metallographic preparation procedures to achieve a mirror finish surface. The specimens were then etched with Barker’s reagent for optical microscopy examination. The grain size within the fusion zone (FZ) was measured using the intercept method, under the ASTM E112-10 standard. For field emission scanning electron microscopy (SEM) analysis, the samples were etched with a 10% NaOH solution to enhance microstructural visibility. The fractured surfaces of the cracks and tensile-tested specimens were also investigated using SEM. Finally, the samples were subjected to electron backscatter diffraction (EBSD) analysis to study the grain structure, and grain boundary character. For this purpose, an FEI Versa-3D FESEM equipped with an EBSD detector was utilized. The EBSD analysis was carried out with an accelerating voltage of 20 keV, and a tilt angle of 70°. The EBSD data were collected using TSL OIM 7 software and subsequently analyzed using MTEX toolbox and ATEX software.

The mechanical properties of the macro-crack free welds were assessed using transverse tensile testing in both as-weld and T6 heat treated conditions. The heat treatment process involved solutionizing the samples at 480 °C for 1 h, followed by water quenching at 25 °C. Subsequently, the samples were aged at 160 °C for 18 h and then air-cooled. The tensile specimens of sub-size dimensions were prepared perpendicular to the welding direction in accordance with the ASTM E8/E8M-16a standard using a CNC machine, followed by surface grinding, as illustrated in Fig. 1b. Tensile test was conducted at a constant traverse speed of 1 mm/min using a 100 kN universal testing machine. The tensile properties of the as-received AA6061-T6 base material was also determined. The reported mechanical property values represent the average of three test samples.

Results and discussion

Fusion welding on un-treated AA6061: high susceptibility to solidification cracking

Figure 2a shows the overview of the fusion weld made on the un-treated AA6061 indicating a macroscale centerline cracking within the fusion zone. According to Fig. 2b, the etched top cross-sectional view of the weld, some porosities were also detected in the FZ. Figure 2c shows the higher magnification light optical micrograph (LOM) of the region designated by a blue rectangle in Fig. 2b, hinting that the grain structure is significantly coarser at the fusion boundary/within the FZ in comparison to that of the heat affected zone (HAZ). Figure 2d shows the non-etched top cross-sectional view of the weld, where in addition to the large centerline macro-crack, a copious number of micro-cracks are also perceptible within the weld. The fractography results of the centerline crack are shown in Fig. 2e–f. The dendritic morphology of the fracture surface implies the presence of the liquid during fracture, suggesting that the cracks have originated from solidification cracking.

Welding on un-treated on AA6061-T6: (a) Overview of the weld, bead-on-plate weld exhibiting showing a prominent longitudinal crack. The schematic highlights the transverse metallographic cross-sections (indicated by green arrows) and the fracture surface (indicated by blue arrows). (b–c) Light optical microscopy (LOM) images of the weld cross-section. (d) LOM micrographs revealing macro/micro-cracks and porosity. (e–f) SEM fractography of the crack surface.

According to Kou’s model33 for solidification cracking, AA6061 possesses high crack susceptibility index, │dT/d(fS)0.5│ near (fS)0.5 = 1 where fS is the solid fraction during solidification of the alloy, which indicates a slow transverse growth rate for the grains in the mushy zone to bond together and resist cracking due to tensile stresses induced by solidification shrinkage33. One of the key factors that affect the resistance of the mushy zone to tolerate the tensile stresses is the grain size of the FZ6,8. Figure 3a shows EBSD analysis of the grain structure around the fusion boundary, encompassing a part of the FZ and HAZ. Adjacent to the fusion boundary within the FZ, the average solidification grain size is ~ 41 µm, with a maximum size of 312 µm (Fig. 3b), whereas the average grain size within the HAZ is ~ 22 µm (Fig. 3c).

It is interesting to note that no liquation cracks were found in the PMZ. The susceptibility of liquation is a function of grain size and secondary phase characteristics (i.e., nature, size and volume fraction)22,23. In the present case, it is believed that the combination of fine grain size of the as-received base plate and the presence of fine secondary phase precipitates with low volume fraction make the as-received BM resistance to liquation cracking.

In summary, fusion welding of AA6061 using conventional strategy is highly prone to solidification cracking. In the following section, the effect of FSP pre-weld thermo-mechanical treatment on the microstructure and cracking behavior of the AA6061 weld is investigated. The new approach involved using multi-parallel pass FSP as a pre-treatment, aimed at creating a wide stirring zone. Subsequently, a bead-on-plate weld pool is created autogenously using GTAW process on the FSP-treated AA6061 plate. The fusion zone was entirely contained within the SZ.

Fusion welding on FSP-treated AA6061: crack mitigation

Figure 4a shows the overview of the fusion weld performed on FSP-treated AA6061, demonstrating the absence of macroscale cracks in the weld metal. This shows that the FSP pre-weld thermomechanical treatment effectively eliminates macro-solidification cracks in AA6061 welds. It is worth mentioning that the disparity between the morphology/size of the grains within the FZ and HAZ was also observed in the FSP-treated AA6061, as shown in Fig. 4b–c. Upon higher magnification examination of the weld cross section in non-etched condition (Fig. 4d), micro-cracks (and some porosities) were occasionally observed within the FZ. But nevertheless, even the observed micro-cracks were remarkably less prevalent compared to the untreated AA6061 scenario. The elimination of macro-solidification cracks and sharp reduction of micro-cracks lead to production of a strong weld on AA6061 which can be used in structural applications.

The elimination of solidification macro-cracks, along with the mitigation of solidification micro-cracks during fusion welding of FSP-treated AA6061, can be attributed to the influence of FSP pre-weld thermomechanical treatment on the microstructure of the fusion zone (FZ).

-

(i)

Role of grain size: Grain refinement within the FZ is widely recognized as a critical strategy for enhancing resistance to hot cracking. Kou 19 demonstrated that when the grain size is reduced by a factor of n, the cracking-susceptibility index is also reduced by a factor of n. Figure 5a presents EBSD micrographs illustrating the grain structure near the FZ/HAZ interface, while Fig. 5b and c depicts the grain size distribution within the FZ and HAZ, respectively. The grain structure adjacent to the fusion boundary is predominantly influenced by epitaxial growth, resulting in an average solidification grain size of 28 µm and a maximum grain size of 97 µm. Importantly, the average grain size in this region is approximately 32% smaller than that produced by the initial welding strategy, indicating significant microstructural refinement at the fusion boundary. In the absence of nucleating agents or nanoparticles during fusion welding, microstructural evolution is primarily governed by epitaxial growth of the FZ grains from the HAZ grains. In welds produced on untreated base material, epitaxial growth originates from a microstructure characterized by an initial grain size averaging 20 µm, as depicted in Fig. 6a, with grains in the HAZ averaging 22 µm, as shown in Fig. 3c. Conversely, in welds performed on FSP-treated base metal, epitaxial growth initiates from a refined microstructure with an average grain size of 6 µm (Fig. 6b) and a smaller HAZ grain size of 13 µm (Fig. 5c). Consequently, the final microstructure of the FZ in untreated base material (Fig. 6c) is relatively coarse due to the limited growth sites, leading to a reduced resistance to solidification cracking, as evidenced by macro-crack (Fig. 2a) and micro-cracks (Fig. 6c) in the FZ. In contrast, the finer initial grain structure in FSP-treated samples provides more potential growth sites for epitaxial grain growth at the fusion boundary and promotes the development of finer microstructures in the FZ, as illustrated in Fig. 6d, thereby enhancing resistance to solidification cracking. Fine grains in FZ are better equipped to accommodate local strains during solidification, thereby reducing stress on the remaining liquid and significantly enhancing resistance to hot cracking19.

-

(ii)

Role of dendrite arm spacing: As explained by Kou19, finer dendrites possess a greater surface area per unit volume for coalescence, which enhances their ability to resist cracking compared to coarser dendrites. Kou19 demonstrated that when the dendrite size is reduced by a factor of n, the cracking-susceptibility index is also reduced by a factor of n. As illustrated in Fig. 6e, the FZ produced on untreated BM exhibited coarse dendrites with primary dendrite arm spacing (PDAS) values of 49.3 ± 11.4 µm. In contrast, the FZ produced on FSP-treated BM displayed finer, closely packed dendrites with a smaller PDAS of 27.9 ± 3.9 µm (Fig. 6f), representing a 55% reduction. Therefore, the finer dendrite structure of the welds produced on the FSP-treated BM can reduce the cracking-susceptibility index compared to the welds made on the un-treated BM. The finer dendritic structure observed in the fusion welds of the FSP-treated BM can be attributed to the finer grain structure of the substrate (i.e., BM). This correlation is supported by the phase-field modeling study of Nabavizadeh et al.34, which established a direct relationship between dendrite arm spacing and the initial grain size of the pre-existing substrate (i.e., base metal in fusion welding).

Effect of base metal grain structure on the fusion zone microstructure: (a) LOM micrograph showing the un-treated BM grain structure, (b) LOM micrograph and EBSD image (inset) showing the FSP-treated BM grain structure and (c) EBSD image showing the FZ grain structure of the weld made on the un-treated BM (d) EBSD image showing the FZ grain structure of the weld generated on the FSP-treated BM, (e) LOM micrograph showing the dendritic structure of the FZ of the weld made on the un-treated BM and (f) LOM micrograph showing the dendritic structure of the FZ of the weld made on the FSP-treated BM.

Enhanced tensile strength

Figure 7a displays the stress–strain curve of transverse tensile testing of the macrocrack-free weld performed on FSP-treated AA6061 BM in both as-weld (FTIG-AW) and T6 solution aged condition (FTIG-T6). For comparison, the stress–strain curve of the un-treated AA6061-T6 BM is also superimposed. The welds made on FSP-treated BM achieved tensile strengths of 193 MPa in the as-welded condition and 307 MPa after T6 heat treatment, compared to 315 MPa for the untreated AA6061-T6 BM. Figure 7b presents a comparison of the tensile strength of FTIG welds with previously reported values for FSW solid-state welds35,36,37,38,39 and fusion welds utilizing 4043 filler metal40,41,42,43 and 5356 filler metal44,45,46,47, all evaluated in the T6 condition. The average joint efficiencies for fusion welding of AA6061 using 4043 and 5356 filler metals in the T6 condition are 0.70 and 0.83, respectively. In contrast, the average joint efficiency for solid-state FSW under the same conditions is 0.87. Notably, the joint efficiency achieved with the FTIG technique is 0.95, significantly surpassing those reported for conventional fusion welds with 4043 and 5356 filler metals, as well as for FSW solid-state welds. It is of note that fusion welding using 4043 and 5356 filler metals mitigate solidification cracking in AA6061. However, due to limited response of their FZ to the subsequent T6 aging, the joint efficiency is limited. In the present work, by refining the base metal microstructure, promoting finer microstructure in terms of grain size, and dendrite arm spacing in the fusion zone, and mitigating the solidification cracks, FSP pre-weld treatment enables the production of high-strength fusion weld, offering a significant advancement over traditional welding methods.

Mechanical properties of welds made on FSP-treated AA6061-T6: (a) engineering stress–strain curves of the welds at as-weld and T6 conditions. The stress–strain curve of AA6061-T6 base metal is also superimposed. (b) the ultimate tensile strength of the welds made on FSP-treated AA6061-T6, compared to the welds produced using conventional methods including friction stir welding35,36,37,38,39, fusion welding using 5356 filler metal40,41,42,43 and fusion welding using 4043 filler metal44,45,46,47, (c) SEM fractography of AA6061-T6 base metal after tensile test, (d) SEM fractography of AA6061-T6 welds made on FSP-treated AA6061 base metal. The arrows indicate micro-pores and micro-cracks.

Figure 7c and d present the SEM micrographs of the fracture surfaces of the BM-T6 and FTIG-T6 samples, respectively. Both samples exhibit a dimple-like ductile fracture morphology. However, micro-cracks and pores are visible on the fracture surface, as indicated by the arrows in Fig. 7d. The presence of micro-cracks, porosities, and coarser grains in the weld zone negatively impacts its ductility and strength compared to the BM. Therefore, enhancing the ductility of the FZ necessitates the complete elimination of micro-cracks and the promotion of finer grain formation within the weld zone.

Conclusions

This study establishes friction stir processing (FSP) as a transformative pre-weld treatment for overcoming the persistent challenge of hot cracking in AA6061-T6 fusion welds. By refining the grain structure of the base material, FSP promoted epitaxial growth of fine grains in the fusion zone, reduced dendrite arm spacing, and eliminated macro-solidification cracks. The resultant welds achieved 95% of the tensile strength of the base material after T6 aging, outperforming conventional fusion welding with filler metals and solid-state friction stir welding. This approach unlocks new opportunities for deploying AA6061 in critical applications requiring high-strength, crack-resistant joints, advancing sustainable lightweight manufacturing.

Data availability

The data will be made available upon request. Correspondence and requests for materials should be addressed to M.P.

References

Hu, Y. et al. Inhibiting weld cracking in high-strength aluminium alloys. Nat. Commun. 13(1), 5816 (2022).

Jin, J. et al. High-strength and crack-free welding of 2024 aluminium alloy via Zr-core-Al-shell wire. Nat. Commun. 15(1), 1748 (2024).

Chen, Y. et al. In situ observation and reduction of hot-cracks in laser additive manufacturing. Commun. Mater. 5(1), 84 (2024).

Aucott, L. et al. Initiation and growth kinetics of solidification cracking during welding of steel. Sci. Rep. 7(1), 40255 (2017).

Fouad, R. A. et al. The influence of various welding wires on microstructure, and mechanical characteristics of AA7075 Al-alloy welded by TIG process. Sci. Rep. 14(1), 19023 (2024).

Gadallah, E. A., El Aal, M. I. A., Mohamed, A. Y. & El-Fahhar, H. H. Effects of filler on the microstructure and corrosion of similar and dissimilar gas inert tungsten arc welding aluminum alloys joints. Sci. Rep. 13(1), 19011 (2023).

Azar, A. S. et al. Corrosion performance and degradation mechanism of a bi-metallic aluminum structure processed by wire-arc additive manufacturing. NPJ Mater. Degradation 5(1), 26 (2021).

Chi, J. et al. Effect of double-pulse frequency and post-weld heat treatment on microstructure and mechanical properties of metal-inert gas welded Al–Mg–Si alloy joints. Mater. Sci. Eng. A 913, 147029 (2024).

Soundararajan, R., Ramkumar, K. R., Sivasankaran, S. & Kim, H. S. Enhancement of tensile strength in AA 6061–T6 plates joined by gas tungsten arc welding using high entropy alloy filler sheet. Mater. Sci. Eng. A 832, 142481 (2022).

Pouranvari, M. Critical review on fusion welding of magnesium alloys: metallurgical challenges and opportunities. Sci. Technol. Weld. Joining 26(8), 559–580 (2021).

Kou, S. Welding Metallurgy 3rd edn. (John Wiley, 2020).

Wall, A. & Benoit, M. J. A review of existing solidification crack tests and analysis of their transferability to additive manufacturing. J. Mater. Process. Technol. 320, 118090 (2023).

Liu, J. & Kou, S. Crack susceptibility of binary aluminum alloys during solidification. Acta Mater. 110, 84–94 (2016).

Soysal, T. & Kou, S. Effect of filler metals on solidification cracking susceptibility of Al alloys 2024 and 6061. J. Mater. Process. Technol. 266, 421–428 (2019).

Liu, J., Zeng, P. & Kou, S. Solidification cracking susceptibility of quaternary aluminium alloys. Sci. Technol. Weld. Joining 26(3), 244–257 (2021).

Kou, S. Predicting susceptibility to solidification cracking and liquation cracking by calphad. Metals 11(9), 1442 (2021).

Coniglio, N. & Cross, C. E. Initiation and growth mechanisms for weld solidification cracking. Int. Mater. Rev. 58(7), 375–397 (2013).

Jiang, P. et al. Fine grains reduce cracking susceptibility during solidification: insights from phase-field simulations. JOM 71, 3223–3229 (2019).

Kou, S. Grain refining and cracking during solidification. Metall. Mater. Trans. A, pp.1–13 (2024).

Schempp, P. et al. Solidification of GTA aluminum weld metal: Part 1—Grain morphology dependent upon alloy composition and grain refiner content. Weld. J 93(2), 53s–59s (2014).

Sokoluk, M., Cao, C., Pan, S. & Li, X. Nanoparticle-enabled phase control for arc welding of unweldable aluminum alloy 7075. Nat. Commun. 10(1), 98 (2019).

Lippold, J. C. Welding metallurgy and weldability (John Wiley & Sons, 2014).

Radhakrishnan, B. & Thompson, R. G. A model for the formation and solidification of grain boundary liquid in the heat-affected zone (HAZ) of welds. Metall. Trans. A. 23, 1783–1799 (1992).

Heidarzadeh, A. et al. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater Sci. 117, 100752 (2021).

Ma, Z. Y. Friction stir processing technology: A review. Metall. Mater. Trans. A. 39, 642–658 (2008).

Gupta, A., Alluri, P., Thool, K. & Choi, S. H. Uncovering the microstructural and precipitate evolution in the cryogenic temperature-Friction stir processed AA6xxx sheets. Mater. Charact. 219, 114619 (2025).

Sharahi, H. J., Pouranvari, M. & Movahedi, M. Strengthening and ductilization mechanisms of friction stir processed cast Mg–Al–Zn alloy. Mater. Sci. Eng. A 781, 139249 (2020).

Mousavizade, S. M., Ghaini, F. M., Torkamany, M. J., Sabbaghzadeh, J. & Abdollah-Zadeh, A. Effect of severe plastic deformation on grain boundary liquation of a nickel–base superalloy. Scripta Mater. 60, 244–247 (2009).

Rule, J. R., Rodelas, J. M. & Lippold, J. C. Application of friction stir processing as a pretreatment to fusion welding. Weld. J. 92, 283s–290s (2013).

Pirjamadi, A., Movahedi, M., Ghasemi, A., Peng, Z. & Pouranvari, M. Overcoming liquation cracking in AA7075 welds via friction stir processing pre-weld treatment: A microstructural approach. Metall. Mater. Trans. A. 55(9), 3290–3301 (2024).

Malekshahi Beiranvand, Z., Malek Ghaini, F., Sheikhi, M. & Abdollah-Zadeh, A. Effect of severe plastic deformation on hot cracking of wrought aluminium alloy in pulsed laser welding. Sci. Technol. Weld. Joining 18, 473–477 (2013).

Sharahi, H. J., Pouranvari, M. & Movahedi, M. Enhanced resistance to liquation cracking during fusion welding of cast magnesium alloys: Microstructure tailoring via friction stir processing pre-weld treatment. Mater. Sci. Eng. A 798, 140142 (2020).

Kou, S. A criterion for cracking during solidification. Acta Mater. 88, 366–374 (2015).

Nabavizadeh, S. A., Eshraghi, M. & Felicelli, S. D. Three-dimensional phase field modeling of columnar to equiaxed transition in directional solidification of Inconel 718 alloy. J. Cryst. Growth 549, 125879 (2020).

Elangovan, K. & Balasubramanian, V. Influences of post-weld heat treatment on tensile properties of friction stir-welded AA6061 aluminum alloy joints. Mater. Charact. 59(9), 1168–1177 (2008).

Baghdadi, A. H., Rajabi, A., Selamat, N. F. M., Sajuri, Z. & Omar, M. Z. Effect of post-weld heat treatment on the mechanical behavior and dislocation density of friction stir welded Al6061. Mater. Sci. Eng. A 754, 728–734 (2019).

Baghdadi, A. H., Sajuri, Z., Omar, M. Z. & Rajabi, A. Friction stir welding parameters: Impact of abnormal grain growth during post-weld heat treatment on mechanical properties of Al–Mg–Si welded joints. Metals (Basel) 10(12), 1607 (2020).

Madhusudhan Reddy, G., Mastanaiah, P., Sata Prasad, K. & Mohandas, T. Microstructure and mechanical property correlations in AA 6061 aluminium alloy friction stir welds. Trans. Indian Inst. Met. 62, 49–58 (2009).

Huarez, J. C. V., Hernandez, R. G., Almaraz, G. M. D. & López, J. J. V. Effect of pre and post weld heat treatment on the mechanical properties of friction stir welded AA6061-T6 joint. Int. J. Automot. Mech. Eng. 17(2), 7882–7889 (2020).

Wang, J., Chen, X., Yang, L. & Zhang, G. Effect of preheat & post-weld heat treatment on the microstructure and mechanical properties of 6061–T6 aluminum alloy welded sheets. Mater. Sci. Eng. A 841, 143081 (2022).

Jie, Y. I., Guan, W., Li, S., Liu, Z. & Gong, Y. Effect of post-weld heat treatment on microstructure and mechanical properties of welded joints of 6061–T6 aluminum alloy. Trans. Nonferrous Met. Soc. China 29(10), 2035–2046 (2019).

Fadaeifard, F., Matori, K. A., Garavi, F., Al-Falahi, M. & Sarrigani, G. V. Effect of post weld heat treatment on microstructure and mechanical properties of gas tungsten arc welded AA6061-T6 alloy”. Trans. Nonferrous Met. Soc. China 26(12), 3102–3114 (2016).

Wang, H., Liu, X. & Liu, L. Research on laser-TIG hybrid welding of 6061–T6 aluminum alloys joint and post heat treatment. Metals (Basel) 10(1), 130 (2020).

Ramaswamy, A., Malarvizhi, S. & Balasubramanian, V. Influence of post weld heat treatment on tensile properties of cold metal transfer (CMT) arc welded AA6061-T6 aluminium alloy joints. J. Mech. Behav. Mater. 28(1), 135–145 (2019).

Ramaswamy, A., Malarvizhi, S. & Balasubramanian, V. Post-weld heat treatment effects on the tensile properties of cold metal arc welded AA 6061–T6 aluminum joints. Mater. Test. 62(1), 69–76 (2020).

Dewan, M. W., Wahab, M. A. & Okeil, A. M. Influence of weld defects and postweld heat treatment of gas tungsten arc-welded AA-6061-T651 aluminum alloy. J. Manufct. Sci. Eng. 137(5), 51027 (2015).

Dewan, M., Liang, J., Wahab, M. & Okeil, A. Post-weld residual stresses and heat treatments of gas tungsten arc welded aluminum alloy AA6061-T651. World J. Eng. 10(1), 11–22 (2013).

Author information

Authors and Affiliations

Contributions

A. J. performed the experiments, analyzed the data, and wrote the original draft. A. G. conducted the EBSD analysis and contributed to writing the paper. M. T. K. analyzed the EBSD data, and S. L. S. performed the EBSD experiments. M. P. supervised the work and contributed to writing the paper. All authors reviewed and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Jalili, A., Ghasemi, A., Kafshgari, M.T. et al. Pre-weld friction stir processing mitigates hot cracking and strengthens AA6061 fusion welds. Sci Rep 15, 15618 (2025). https://doi.org/10.1038/s41598-025-99424-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-025-99424-8

Keywords

This article is cited by

-

Abnormal Grain Growth Limits Weldability of Friction Stir-Processed Alloys

Metallurgical and Materials Transactions A (2025)