Abstract

Fiber wall element model which considers cumulative damage effect of material is set up by introducing cumulative damage index to the fiber wall element hysteretic models of reinforcement and concrete. A numerical simulation of the cyclic loading test of the short-limb shear wall is conducted by using the fiber wall element model, alongside a corresponding pseudo-static test. Results demonstrate that energy dissipation capacity and ductility of T-shaped short-limb shear wall are good. All the specimens failed under a flexural-dominant behavior, and the damage was mainly concentrated in the boundary element of the web. Special attention should be paid to the design of the web boundary. The model exhibits a high level of numerical stability and computational efficiency for all specimens investigated. Comparisons of experimental and analytical results demonstrate that the proposed fiber wall element model with good accuracy, providing an important reference to the seismic performance assessment of RC shear wall.

Similar content being viewed by others

Introduction

The seismic performance of structures is closely related to low-cycle fatigue damage. Under the action of earthquake, structures will suffer from low cycle fatigue damage, which is manifested as material damage on the microscopic level, and elastic–plastic deformation of structure on the macroscopic level. The macro damage of structures is actually caused by the cumulative damage effect of materials. The current nonlinear numerical simulation analysis of short-limb shear walls rarely considers the cumulative damage effect of material, it is unscientific. So far, analytical modeling of the nonlinear response of structural walls can be conducted by using either microscopic (e.g., finite element) or macroscopic models1,2. Macroscopic modeling approaches available in the literature, with the so-called fiber-based models being more common3,4,5,6. Due to their simple formulations, macro-models are computationally less intensive that are easy to implement, and many have been shown to be efficient and accurate in predicting important hysteretic response characteristics of RC walls7,8,9,10,11. However, it also has the inherent disadvantage caused by simplified calculation and analysis. In order to simulate the whole process of seismic damage and failure of RC walls, micro models are more precise, but their large degrees of freedom will bring huge amount of calculation, which is difficult to be popularized and applied in practical projects. Combining the advantages of the two models, a new fiber wall element model of short-limb shear wall is proposed in this paper, which considers the continuous cumulative damage effect of concrete and reinforcement.

China’s “code for seismic design of buildings” does not involve the cumulative damage effect of materials under large earthquakes. Even if the structure meets the requirements of elastic–plastic deformation, it may not be able to ensure that it will not collapse under large earthquakes. Cumulative damage effect of material is the main reason that affects the normal use function of structures and finally leads to structural failure, More and more domestic and foreign scholars choose to introduce damage index and use damage analysis to evaluate seismic performance of structures. The existing seismic damage evaluation models are mainly defined from four aspects: degradation12,13,14,15,16, deformation17,18,19,20,21, energy22,23, and combination of deformation and energy24. Most of the damage evaluation models mentioned above are posterior models, which cannot directly consider the deterioration of structural mechanical properties caused by cumulative damage effect of materials. In this paper, the cumulative damage index of concrete and reinforcement is introduced into the wall element hysteretic model, and a new fiber wall element model of short-limb shear wall considering the cumulative damage effect of concrete and reinforcement is established. Based on the fiber wall element model, the corresponding program is compiled, and the hysteretic performance of the short-limb shear wall is analyzed through numerical simulation analysis. Nonlinear numerical simulation analysis of pseudo static test of T-shaped short-limb shear wall is carried out. The results of nonlinear numerical simulation analysis are close to the pseudo static test results, proving that the method proposed in this paper is reasonable and feasible.

New fiber wall element model

Cumulative damage index of material

The damage variable of materials under earthquake is related to the maximum elastic–plastic deformation and the accumulated elastic–plastic deformation of material during earthquake. In this paper, the cumulative damage index of concrete under uniaxial tension compression cycle is defined as follows21:

where, Dci is the cumulative damage index of concrete in the wall element; dmax respectively takes the maximum value of positive and negative displacement amplitude in all loading cycles; di is the absolute value of displacement amplitude in both positive and negative directions in each loading cycle; du is the extreme displacement value of the member when it is destroyeded under monotonic loading. For ordinary concrete, \(\alpha = 1.0,\,\beta = 0.5\) 25.

For reinforcement, this article uses plastic strain to calculate cumulative damage index26:

where, Dsi is the cumulative damage index of reinforcement in the wall element; N is the number of half cycles of plastic deformation of steel; \(\varepsilon_{i}^{p}\) is the plastic strain of the steel in the first half cycle; \(\varepsilon_{u}^{p}\) is the ultimate plastic strain of steel measured from the uniaxial tensile test; \(\varepsilon_{m}^{p}\) is the maximum plastic strain during the cycle. The cumulative damage assessment model of component is calculated by the following formula:

where, D is the damage index of short-limb shear wall specimen; Aci is the concrete area of the wall element; Asi is the reinforcement area of the wall element; γ is a calibration parameter, and the value of it is 6 as proposed by Mehanny21.

Because the mechanical properties of reinforcement and concrete are different, this paper considers reinforcement and concrete separately in the wall element, and establishes the concrete and reinforcement wall element hysteretic model considering the cumulative damage effect of concrete and reinforcement respectively. According to the cross-sectional area of the reinforcement and concrete of the wall element, the material stress–strain hysteretic relationship can be transformed into the corresponding hysteretic relationship between the force and deformation of the wall element. The degradation of wall element strength and stiffness is considered from the perspective of cumulative damage effect of materials. For example, in the hysteretic model of concrete element (shown in Fig. 1)25, when the skeleton curve does not enter the descending stage, the unloading stiffness is still KCO, but the strength degraded. After the skeleton curve entering the descending stage, the strength and stiffness degradation caused by cumulative damage effect of concrete are considered respectively.

where, Dci is the cumulative damage index of fiber wall element of concrete after the i-th loading cycle. \(\zeta_{kc}\) is the damage parameter of stiffness degradation, which is determined by the constant amplitude loading test, and the value of \(\zeta_{kc}\) is 0.15; \(\zeta_{pc}\) is the damage parameter of strength degradation, which is determined by cyclic potest with equal amplitude, and the value of \(\zeta_{pc}\) is 0.2725. The hysteretic model of fiber wall element of reinforcement considering the cumulative damage effect can be established with the same idea by referring to the Takeda model27 selected by Lai.

Calculation model and basic assumption

The short-limb shear wall is divided into longitudinal wall strips along the longitudinal direction, as shown in Fig. 2(b). Each longitudinal wall strip consists of three parts, namely the plastic part at both ends and the elastic part in the middle, as shown in Fig. 2(a). It can be considered that the plastic elements at both ends of the wall are composed of a set of finite length of steel bars and concrete springs, which concentrate the deformation of the steel bars and concrete within the imaginary plastic domain length \(\eta\) H of the wall element, where H is the height of the whole wall and the value of \(\eta\) is 0.2, referring to Zhang28.

The bar element is discretized into several cross-sections along the longitudinal direction, and each cross-section is further discretized into many reinforcement and concrete fibers along the horizontal direction, as shown in Fig. 3. Discretization of Section Fiber is shown in Fig. 4. The calculation module flow of fiber wall element model of shortlimb shear wall is shown in Fig. 5. It is assumed that reinforcement and concrete works together to bear the shear force, so the shear stiffness is provided by the concrete fiber. Because most of the short-limb shear walls are high shear wall in the engineering design, and the bending failure mode is the main mode. Therefore, the shear stiffness of the wall element can be determined by considering only the different axial tension and compression states of the wall element and then according to the magnitude of the compressive strain value and the tensile strain value of the fiber material. The shear stiffness of the wall element can be calculated according to the shear stiffness calculation method of the multi vertical bar model29. Freedom of element node is shown in Fig. 1(c). The cross-sectional displacement model can be expressed as:

where \(\omega\) is the displacement of the centroid position in the direction of the wall axis; \(v\) is the displacement of the shear center position in the axial direction, and θ is the average rotation angle of the section around the x-axis.

The element end force vector is:

The element end displacement vector is

The horizontal displacement caused by shear deformation in the \(i\) end and \(j\) end is defined as \(\overline{v}_{i}\) and \(\overline{v}_{j}\), respectively:

where \(r\) represents rotational height to height of wall, the value of \(r\) is 0.5 proposed by Lu et al.30.

Constitutive relation of material

Steel constitutive model proposed by Hoeher and Stanton31 is selected as shown in Fig. 6. Conctete constitutive model proposed by Hoshikuma32 is used and concrete hysteretic rule proposed by Mander33 is selected as shown in Fig. 7.

Pseudo static test of short-limb shear wall and demonstration of fiber wall element model

Specimen design and loading system

Six T-shaped RC short-limb shear wall specimens with wall height of 1.4 m and section thickness of 100 mm are made according to the scale of 1/2. The design parameters of short-limb shear wall members are shown in Table 1. The design axial load ratio n for shear wall specimens is calculated by Eq. (13):

where N is the design axial load, fc is the design compressive strength of concrete, A is the gross area of the wall.

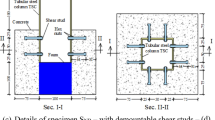

Section size and reinforcements details fare shown in Fig. 8. The specimen is made of concrete with the strength grade of C40, and the average cube compressive strength of concrete is 47.2 Mpa. The stirrup is made of high-strength steel rebars with a diameter of 4 mm; the diameter of the distributed and longitudinal rebar is 8 mm and 12 mm respectively; the mechanical properties of reinforcements are shown in Table 2.

All specimens were tested under combined constant axial load and increasing lateral load. A hydraulic jack was used to provide axial load on each specimen. The jack was connected to the rigid top-beam. An actuator was used to provide the increasing lateral load at the top of the specimen, as shown in Fig. 9. The loading-control method was used before specimens yielding; after that, specimens were loaded with multiple of yielding displacement. Detailed loading device and specific loading system can be found in the literature written by Zhang30.

Failure process and damage development of specimens

All six specimens exhibited the same flexural-dominant behavior, with crushing of concrete and tensile failure of longitudinal reinforcement in the free web boundary zone. The typical specimen T500-1 was taken to illustrate the failure process and damage evolution of short-limb shear wall. Figure 10 shows the crack patterns and failure modes of specimen T500-1; Fig. 11 shows the damage evolution of all specimens. Minor horizontal cracks appeared at the bottom of the web when the positive load reached 60kN with a damage index value of 0.15 (Fig. 12). When the positive load reached 70kN, the horizontal crack of the web was increased to 0.2 mm with a damage index value of 0.20; at this time, the specimen was slightly damaged. When the positive load reached 95kN, oblique cracks appeared in the middle of the web, and specimen yielded in the positive direction. When the negative load reached 100kN, multiple diagonal cracks appeared at the flange and web-flange junction. When the negative load reached 135kN, specimen yielded in the negative direction with a damage index value of 0.60; at this time, the specimen was moderately damaged. Afterwards, displacement control loading mode was adopted. As the loading displacement increased to a drift level of 1.5%, severe crushing and spalling of concrete cover were observed, with a damage index of 0.85; at this time, the specimen was seriously damaged. Lastly, as the loading displacement increased to a drift level of 2.0%, major crushing of web concrete occurred, and the outermost longitudinal reinforcing bars started to buckle (Fig. 10b), with a damage index value of 0.99; at this time, the specimen was destroyed. No vertical splitting and concrete spalling occurred at the flange or web–flange junction (Fig. 10c); therefore, the seismic design requirements for web-flange junction can be appropriately relaxed, but special attention should be paid to the seismic design of the web boundary.

Hysteresis performance analysis

The hysteresis curves of specimens recorded in the test are shown in Fig. 13. As shown in Fig. 13, the hysteretic behavior of T-shaped short-limb walls in the positive and negative loading direction is quite different:

The hysteretic curves are plumper and the walls has big energy dissipation capacity and ductility, when web is in tension (positive loading direction); However, the hysteretic curves pinche obviously and the energy dissipation capacity and ductility are very poor, when web is in compression (negative loading direction); But when web is in compression, the load-bearing capacity of specimens is significantly higher than that of when web is in tension. Obviously, the free web boundary is the weakest part of T-shaped walls. Thus, high-strength or closer spaced stirrup and high strength longitudinal reinforcement should be used in the free web boundary to prevent premature crushing of concrete or tensile failure of longitudinal reinforcement.

Comparison of calculation and test results

This paper uses the idea of modular programming to program. Because each module of the modular program is relatively independent, it can be debugged separately during the preparation process, which is easy to expose problems more clearly and reduce the complexity of program debugging. Modules are connected through interfaces. Thus, different calculation modules can be accessed according to different calculation needs, such as calculation methods, element types, constitutive relations, etc. Thus, different calculation functions can be completed without changing the main body of the program, providing a wider space for the application of the program. The program is divided into four modules: namely, structure level module, unit level module, section level module and fiber level module. In the element level module (as shown in Fig. 5), the calculation module of the fiber wall element model of short-limb shear wall based on the cumulative damage effect of material derived by this article is compiled, and the section level module is established on the basis of the fiber wall element model. The fiber layer module includes the constitutive relations of concrete and reinforcement. Using Finite element analysis program (FEAP) as software development platform34, the corresponding program was compiled based on the fiber wall element model. Numerical analysis of T-shaped shear wall specimens was carried out to obtain the hysteresis curves. Satisfactory agreement between analytical and experimental results can be seen in Fig. 14, indicating that the fiber wall element model proposed in this paper are reasonable and feasible.

Conclusions and recommendations

In this paper, cyclic loading test of T-shaped RC short-limb shear wall specimens and the corresponding nonlinear finite element analysis is conducted to propose a new fiber wall element model which considers cumulative damage effect of material. The main conclusions and suggestions are as follows:

-

1.

RC short-limb shear wall specimens mainly exhibited flexural-dominant behavior, with crushing of concrete and tensile failure of longitudinal reinforcement in the free web boundary zone. The free web boundary is the weakest part of T-shaped walls. Thus, high-strength or closer spaced stirrup and high strength longitudinal reinforcement should be used in the free web boundary to prevent premature crushing of concrete or tensile failure of longitudinal reinforcement. No vertical splitting and concrete spalling occurred in the flange and web–flange junction; therefore, the seismic design requirements for web-flange junction can be appropriately relaxed.

-

2.

The new fiber wall element model of short-limb shear wall is established by introducing the cumulative damage index to the hysteretic model of fiber wall element of reinforcement and concrete, which can considers the cumulative damage effect of materials as well as coupling effect between bending and axial force.

-

3.

The model exhibits a high level of numerical stability and computational efficiency for all specimens investigated. Comparisons of experimental and analytical results demonstrate that the proposed fiber wall element model with good accuracy, providing an important reference to the seismic performance assessment of RC short-limb shear wall.

Data availability

Data available on request from the corresponding author.

References

Gullu, M. F., Orakcal, K. & Kolozvari, K. The fixed-strut-angle finite element (FSAFE) model for reinforced concrete structural walls. Bull. Earthq. Eng. 17, 6463–6489 (2019).

Kolozvari, K. et al. State-of-the-art in nonlinear finite element modeling of isolated planar reinforced concrete walls. Eng. Struct. 194, 46–65 (2019).

Xinzheng, Lu., Tian, Y., Cen, S., Xie, H. G. L. & Wang, L. A high-performance quadrilateral flat shell element for seismic collapse simulation of tall buildings and its implementation in OpenSees. J. Earthq. Eng. 22(9), 1662–1682 (2018).

Ding, R., Tao, M. X. & Nie, X. Analytical model for seismic simulation of reinforced concrete coupled shear walls. Eng. Struct. 168, 819–837 (2018).

Rezapour, M. & Ghassemieh, M. Macroscopic modelling of coupled concrete shear wall. Eng. Struct. 169, 37–54 (2018).

Wu, Y. T., Lan, T. Q. & Xiao, Y. Macro-modeling of reinforced concrete structural walls: State-of-the-art. J. Earthq. Eng. 21(4), 652–678 (2017).

Kolozvari, K., Gullu, M. F. & Orakcal, K. Finite element modeling of reinforced concrete walls under uni-and multi-directional loading using Opensees. J. Earthq. Eng. 26(12), 6524–6547 (2022).

Kolozvari, K., Kalbasi, K., Orakcal, K. & Wallace, J. Three-dimensional modelfor nonlinear analysis of slender flanged reinforced concrete walls. Eng. Struct. 236, 112105 (2021).

Kolozvari, K., Kalbasi, K., Orakcal, K., Massone, L. M. & Wallace, J. Shear-flexure-interaction models for planar and flanged reinforced concrete walls. Bull. Earthq. Eng. 17, 6391–6417 (2019).

Kolozvari, K. et al. Comparative study of state-of-the-art macroscopic models for planar reinforced concrete walls. ACI Struct. J. 115(6), 1637–1657 (2018).

Gullu, M. F. & Orakcal, K. Nonlinear finite element modeling of reinforced concrete walls with varying aspect ratios. J. Earthq. Eng. 25(10), 2033–2064 (2021).

Powell, G. H. & Allahabadi, R. Seismic damage prediction by deterministic methods: Concept and procedures. Earthq. Eng. Struct. Dyn. 16(5), 719–734 (1988).

Roufaiel, M. S. L. Analytical modeling of hysteretic behavior of R/C frames. J. Struct. Eng. 113(3), 429–444 (1987).

Hearn, G. & Testa, R. B. Model analysis for damage detection in structures. J. Struct. Eng. 117(10), 3042–3063 (1991).

Lemaitre, J. A continuous damage mechanics model for ductile fracture. J. Eng. Mater. Technol. 107(3), 83–89 (1998).

Kawinkler, H. & Zohei, M. Cumulative damage in steel structures subjected to earthquake ground motions. Comput. Struct. 16(14), 531–541 (1983).

Chung, Y. S., Meyer, C. & Shinozuka, M. Modeling of concrete damage. ACI Struct. J. 86(3), 259–271 (1988).

Banon, H., Biggs, J. M. & Irvine, H. M. Seismic damage in reinforced concrete frames. J. Struct. Eng. ASCE 107(9), 1713–1729 (1981).

Stephen, J. E. & Yao, J. T. P. Damage assessment using response measurement. J. Struct. Eng. ASCE 113(4), 787–801 (1987).

Wang, M. L., Shan, S. P. & Yao, J. T. P. Reinforce concrete hysteretic model based on the damage concept. Earthq. Eng. Struct. Dyn. 15(8), 993–1003 (1987).

Mehanny, S. S. F. & Deierlein, G. G. Seismic damage and collapse assessment of composite moment frames. J. Struct. Eng. 127(9), 1045–1053 (2001).

Chai, Y. H., Romstad, K. M. & Bird, S. M. Energy-based linear damage model for high-intensity seismic loading. J. Struct. Eng. 121(5), 857–864 (1995).

Khashaee, P. Energy-Based Seismic Design and Damage Assessment for Structures (Southern Methodist University, 2004).

Park, Y. J. & Ang, A.H.-S. Mechanistic seismic damage model for reinforced concrete. J. Struct. Eng. ASCE 111(4), 722–739 (1985).

Xiangling, G., Qinghua, H. & Zhoucai, W. Analysis of load-displacement relationship for RC columns under reversed load considering accumulative damage. Earthq. Eng. Eng. Vib. 26(4), 68–74 (2006) ((in Chinese)).

Zuyan, S. & Bao, D. An experiment-based cumulative damage mechanics model of steel under cyclic loading. Adv. Struct. Eng. 1(1), 39–46 (1997).

Lai, S. S. Post-yield hysteretic biaxial models for reinforced concrete members. ACI Struct. J. 84(3), 235–245 (1987).

Zhang, P. L. & Li, Q. L. Cyclic loading test of T-shaped mid-rise shear wall. Struct. Des. Tall Spec. Build. 22(10), 759–769 (2013).

Li, B., Li, H. & Chen, X. Analysis of macroscopic finite unit models for R/C shear wall. J. Shenyang Arch. Civil Eng. Univ. (Nat. Sci.) 18(2), 101–104 (2002) ((in Chinese)).

Lu, X. L. & Lu, W. S. Application of fiber wall element model in nonlinear analysis of shear wall structures. Chin. Q. Mech. 26(1), 72–80 (2005) ((in Chinese)).

Hoehler, M. S. & Stanton, J. F. Simple phenomenological model for reinforcing steel under arbitrary load. J. Struct. Eng. 132(7), 1061–1069 (2006).

Hoshikuma, J. & Kawashina, K. Stress-strain model for confined reinforced concrete in bridge piers. J. Struct. Eng. 123(5), 624–633 (1997).

Mander, J. B., Priestley, M. J. N. & Park, R. Theoretical stress-strain model for confined concrete. J. Struct. Eng. 114(8), 1804–1826 (1988).

Lin, D. S. & Xu, X. Nonlinear Finite Element and Program (Zhejiang University Press, 2004).

Acknowledgements

The research was funded by the National Natural Science Foundation of China (Grant no: 52168069, 51568028). The writers wish to express their sincere gratitude to the sponsor.

Author information

Authors and Affiliations

Contributions

Conceptualization, ZHANG Pinle. and Gao Junfang ; Validation, Deng Rang ; Formal analysis, Zhang Pinle and Gao Junfang.; All authors have read and agreed to the published version of the manuscript. Zhang Pinle and Gao Junfang wrote the main manuscript text and Deng Rang prepared all test datas.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhang, P., Rang, D. & Junfang, G. Study on a new fiber wall element model of RC short-limb shear wall. Sci Rep 15, 17778 (2025). https://doi.org/10.1038/s41598-025-99519-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-025-99519-2