Abstract

Advancing the mechanical properties of naturally weak clayey soils is crucial in geotechnical engineering and is often achieved through targeted stabilization techniques. This research focuses on reinforcing clayey soil by integrating inert material, specifically aeolian sand collected from roadside deposits, in varying proportions from 2.5 to 30%. An experimental approach is adopted to analyze the improvement in geotechnical properties resulting from the addition of aeolian sand to clay through a series of geotechnical tests. These tests include the methylene blue test (MBV), the determination of Atterberg limits (LL, PL, PI), compaction characteristics (MDD and OMC), direct shear testing (C and ϕ), and oedometer tests (Cc and Cs). Furthermore, an optimization approach based on response surface methodology (RSM) and a central composite design (CCD) is implemented to determine the optimal mixture composition and accurately predict the evolution of the geotechnical properties of the soil. The experimental findings demonstrate significant improvements in the mechanical characteristics of the soil following the incorporation of aeolian sand, with the best performance achieved at a 30% sand content. The MBV decreased by 34.98%, the LL decreased by 39.62%, the PL decreased by 37.50%, and the PI decreased by 45.45%. In contrast, the MDD increased by 12.25%, enhancing the compaction and load-bearing capacity of the soil. A reduction of approximately 7.59% in the OMC was observed, lowering the water demand. The internal friction angle (ϕ) increased significantly by up to 233.33%, improving the shear strength, whereas the cohesion decreased by 49.78%. Additionally, the Cc and Cs decreased by 16.15 and 54.45%, respectively, which reduced the sensitivity of the soil to volume changes. Mathematical models are developed and statistically validated using the clay and aeolian sand contents as predictive variables, while key parameters such as the maximum dry density (MDD), cohesion (C), internal friction angle (ϕ), compressibility coefficient (Cc), and swelling coefficient (Cs) serve as response metrics. By applying analysis of variance (ANOVA) and refining the quadratic model via RSM, the study demonstrated significant results, with a coefficient of determination (R2) exceeding 0.97 for all the responses. The alignment between R2 and adjusted R2, along with the observed P values for critical parameters, highlights the robustness of the model. These findings pave the way for practical applications in foundation and road infrastructure projects, particularly in arid regions where water management and soil stability are critical concerns. The integration of 30% sand proves to be an effective and sustainable solution for enhancing the strength and stability of clayey soils in moisture-sensitive environments.

Similar content being viewed by others

Introduction

Geotechnical engineers around the globe often face the challenge of dealing with poor-quality soils during large-scale development and infrastructure projects. These problematic soils consistently pose significant hurdles during both the construction and postconstruction phases. Key issues include low load-bearing capacity, weak structural integrity, high swelling potential, and excessive compressibility1. As available land becomes scarcer, civil engineering projects are more frequently constructed on weak or vulnerable substrates. This trend underscores the need for advanced ground improvement methods, with soil stabilization and reinforcement techniques being among the most critical2. In the field of soil engineering, fine-grained soils have long been recognized as some of the most challenging soils globally. These soils, often referred to as “expansive soils,” are notorious for their significant volumetric changes when used as foundations for structures. Clays play a crucial role in construction projects involving soil because of their prominence and impact3. The unique swelling and shrinking behavior of expansive soils is caused by the presence of swelling clay minerals. These minerals expand when they absorb water and contract when they dry out, creating large voids in the soil matrix. Fine-grained soils are typically characterized by low shear strength and reduced bearing capacity4. Although damage caused by expansive clays occurs gradually and is less dramatic than that caused by natural disasters such as hurricanes, earthquakes, or infrastructure failures, it still results in significant economic costs annually3. According to Nelson and Miller (1997)5, the financial impact of expansive soils exceeds that of earthquakes or floods. This highlights the need to thoroughly understand expansive soils to develop effective strategies for mitigating their negative effects on civil infrastructure. In situations with poor soil conditions, the cost of constructing safe buildings increases significantly, making soil improvement techniques necessary. Although these soil improvement projects are costly, they often lead to overall savings in construction costs by reducing the need for extensive repairs and maintenance3.

Natural soils, especially clay, frequently display suboptimal mechanical and geotechnical characteristics6 and are problematic in geotechnical engineering practice, as they undergo dramatic volume changes by absorbing or losing water due to seasonal moisture variations, resulting in their substantially low shear strength and overall bearing capacity7. Consequently, they require interventions to achieve acceptable geotechnical standards6. Numerous approaches have been suggested to mitigate the problem of soil swelling. These methods include chemical, mechanical, and physical stabilization methods8. A plethora of scholarly endeavors have delved into enhancing the physical and mechanical attributes of cohesive soils, frequently involving the incorporation of diverse materials into fine-grained soil matrices to achieve this objective. The partial replacement of conventional stabilizers with environmentally friendly and sustainable materials has recently become a common approach for enhancing the strength and stiffness properties of earthen materials9. Chemical and mechanical treatments have emerged as prominent approaches to mitigate swelling, with a notable avenue being the utilization of waste materials. This approach serves two purposes: stabilizing waste and ameliorating clayey soil conditions10. Chemical stabilization methods involve the application of an array of additives, such as lime, cement, lime–cement blends, lime–fly ash combinations, lime–rice husk–cement–fly ash blends, gypsum, enzymes, cement dust, marble dust, granite dust, and lime-zeolite7. Another treatment technique used in recent years involves the use of expanded polystyrene (EPS), which is a polymeric material known for its low density and high strength‒density ratio. This makes it widely recognized as a lightweight geosynthetic material in embankments and retaining structures to improve slope stability and reduce lateral earth pressure. Additionally, owing to its low thermal conductivity and flexibility, it is well suited for use as a thermal and sound insulator in building construction11. Examples include EPS beads12,13,14,15,16, expanded polystyrene (EPS) beads16, sand-EPS geofoam14, glass beads and EPS beads17. Various other chemicals are aimed at improving expansive soil properties18,19, and cemented soils are used as a worldwide soil stabilization practice in all geotechnical engineering applications; however, the high energy consumption and cost of cement are important20. Furthermore, since lime and Portland cement production is costly and highly contributes to CO2 emissions, many alternatives have been proposed in the literature to be partially replaced with the corresponding conventional stabilizers in the treatment process. These alternatives not only address such geoenvironmental constraints but also lead to considerable enhancements in the strength properties and brittleness of treated soils7. Therefore, various types of binders have been proposed to partially or even totally supplant cement20. Mechanical soil stabilization techniques, which preserve chemical properties and encompass measures such as compaction control, prewetting, sand admixture, removal and replacement with nonswelling soil, the use of expanded polystyrene (EPS) geofoam, soil reinforcement through geosynthetics, and the incorporation of polypropylene fibers and disposable face mask fibers21, are used to improve the mechanical properties of cement-stabilized soils. Overall, the combination of cementation and fiber reinforcement has demonstrated a significant synergistic effect, resulting in notable improvements in the mechanical properties of fine sands21, all of which have demonstrated efficacy in the treatment of expansive soils22,23. Some research endeavors advocate the addition of inert materials to swelling soil as a means of stabilization21. Below, we provide concise explanations of select investigations exploring these methodologies. Cai et al.2 explored the influence of different ratios of lime and polypropylene fibers on the geotechnical characteristics of clayey soils. Through comprehensive direct shear, unconfined compression, shrinkage, and swelling tests on nine unique soil mixtures, their study revealed notable results. Increasing the lime content initially led to an increase, followed by a subsequent decrease in the cohesion, friction angle, and unconfined compressive strength of the clayey soil. Additionally, adding fibers to the clay matrix improved the shrinkage and strength properties, although it increased the swelling potential2. Khajeh et al.24 used zeolite as an additive to reduce lime consumption in the treatment of problematic clays and to further enhance the soil stabilization process in the pavement base and subbase courses. An exhaustive literature survey25,26,27 examining the application of marble dust for stabilizing expansive soils has provided convincing evidence of its effectiveness. Significant improvements in the engineering properties of expansive soils were noted, primarily due to a marked reduction in soil plasticity caused by the replacement of clay particles with coarser, nonplastic aggregates. Additionally, there was a notable increase in the maximum dry density (MDD), resulting from a lower void ratio and improved soil gradation. This increase in soil strength followed a consistent trend with the addition of marble dust, peaking at a 20% dosage before declining. Hence, the optimal marble dust content for enhancing soil strength is 20%, although this value is subject to the intrinsic properties of the soil28. Kaushik and Ramasamy and Ramasasany (2006)29 meticulously scrutinized the attributes of coal ash to determine its feasibility as a construction material for geotechnical purposes. They reported that while fly ash exhibited strong compaction strength, it presented poor shear strength when saturated. Furthermore, Chauhan et al. (2008)30 reported that increasing the proportion of fly ash in silty sand led to a notable increase in the optimal moisture content and a decrease in the maximum dry density. Cokca Erdal (2001)31 added Soma fly ash and Tuncbilek fly ash to expansive soil at 0–25%. The optimum content of fly ash to reduce the swell potential was found to be 20%. Jirathanathworn and Chantawarangul (2003)32 reported that by using fly ash mixed with a small amount of lime, the engineering properties of clayey soil, such as strength and hydraulic conductivity, improved. Another treatment process for low- and high-plasticity clays with different concentrations ranging from 2 to 10 mol/L, along with binary solutions with NaAlO2/NaOH mass ratios of 1 and 0.75, was studied by Nouhi et al.33 to develop alkaline activation that is useful in geotechnical engineering practices for a variety of field applications in terms of both safety and performance because not only are natural clays used as the sole precursors but also a relatively low alkali concentration has contributed to the optimum improvement of the composite material33. Mohammadi et al.34 studied the recycling of industrial alkaline solutions for soil stabilization via low-concentration fly ash-based alkali cements34 to improve the strength and stiffness of clayey soils. Building on the findings of previous studies, further research into enhancing the mechanical properties of clay soils has proven to be essential. This includes investigating the use of alternative materials for soil treatment. In this context, the present study explores the potential of sand as a novel treatment material.

Sand, renowned for its soil stabilizing qualities, plays a crucial role in mitigating clay shrinkage and preventing expansion, thereby increasing the density of composite soil blends and improving the California bearing ratio (CBR)35. Extensive research has highlighted the positive influence of sand on expansive soils, with studies examining its effects on soil behavior. For example, investigations in Medan by Aswar et al. (2012)36 demonstrated the effectiveness of river sand in strengthening lower foundation materials35. Similarly, Darma (2003)37 combined sea and mountain sands and emphasized the pivotal role of sand in reinforcing soil matrices for lower foundations26. Roy (2013)38 explored how sand alters plasticity, compaction, and strength in cohesive soil mixtures.

Khan et al. (2014)39 investigated clay‒sand blends with various sand contents (0%, 20%, 40%) through standard Proctor tests. Their findings confirmed earlier research, which revealed a direct relationship between the sand content, maximum dry density (MDD), and reduced optimum moisture content (OMC)39. Endaryanta and Wibowo (2020)26 reported significant improvements in the CBR and reduced swelling values when beach sand was mixed with clay, particularly with an optimal sand content of 85%. Furthermore, Alnmr and Ray (2024)40 provided empirical equations for predicting soil properties on the basis of sand content, highlighting the potential of sand as a beneficial soil amendment. Bahia Louafi and Bahar (2012)41 highlighted significant improvements in soil stability through sand integration, effectively reducing swelling tendencies and addressing structural uplift concerns. Using ultrasonic devices, changes in clay porosity were detected via variations in ultrasonic pulse propagation velocities following sand incorporation. Additionally, Orabi et al. (2018)42 reported a decrease in the liquid limit and plasticity index with increasing sand concentration, alongside an increase in the soil permeability coefficient and angle of internal friction. Notably, the introduction of a 20% sand mixture distinctly reinforced the engineering characteristics of the cohesive soil compositions, leading to a notable increase in shear strength.

Response surface methodology (RSM) serves as a powerful statistical tool that enables the exploration of complex relationships among various process parameters by intricately modeling response variables1,34. By utilizing quantitative data from experimental designs, regression model analyses, and real-world scenarios, the RSM facilitates enhanced performance results2. Many academic investigations have utilized the RSM to design experiments, develop predictive models, and optimize key variables4,43,44,45,46. Boukhatem et al. (2024)46 explored the use of waste marble powder (WMP) and lime (LM) as solutions for improving clayey soils in Bouzaroura El Bouni, Algeria, which face issues such as low load-bearing capacity, poor permeability, and erosion susceptibility. The effects of varying the clay content, LM, and WMP on the soil properties were investigated via response surface methodology (RSM) Box–Behnken design. Statistical analysis and numerical optimization reveal optimal mixtures with high desirability, highlighting the potential of LM and WMP to enhance soil characteristics for both environmental sustainability and engineering applications. While incorporating sand into expansive soils for enhancement purposes is both effective and economically viable, the literature notably lacks a focus on investigating how sand affects the physical characteristics of soils, especially through the application of response surface methodology to optimize geotechnical parameters in clay‒sand treatments19.

This study aims to evaluate the experimental results and characterize the behavior of cohesive clayey soil with poor geotechnical properties treated with aeolian sand as an innovative stabilization solution. The aeolian sand collected along the national roads in the coastal areas of Annaba, Algeria, was incorporated into the soil in varying proportions ranging from 2.5 to 30%, with increments of 2.5%. This study focuses on the evolution of key parameters and how the clay–aeolian sand combination affects the soil properties. Two complementary approaches were adopted.

The first approach was an experimental methodology based on a rigorous protocol to measure the physical and mechanical properties of the treated soil, including the methylene blue value (MBV), Atterberg limits (LL, PL, and PI), compaction characteristics (MDD and OMC), direct shear test parameters (C and ϕ), and oedometer test parameters (Cc and Cs). Significant geotechnical improvements were observed in the soil treated with an optimal mixture containing 30% aeolian sand. Specifically, the MBV decreased by 34.98%, whereas the LL and PL decreased by 39.62% and 37.50%, respectively, resulting in a 45.45% reduction in the PI. Moreover, the MDD increased by 12.25%, whereas the OMC decreased by approximately 7.59%, reducing the water demand. ϕ substantially increased to 233.33%, enhancing the shear strength, although the cohesion (C) decreased by 49.78%. Additionally, (Cc) and (Cs) decreased by 16.15% and 54.45%, respectively.

The second approach focused on optimizing the key geotechnical parameters via response surface methodology (RSM). A central composite design, including 13 experiments conducted via Design Expert V13 software, was employed to optimize the maximum dry density (MDD), cohesion (C), internal friction angle (ϕ), compressibility coefficient (Cc), and swelling coefficient (Cs). A second-order polynomial model was developed through statistical analysis, and its fit quality was assessed via analysis of variance (ANOVA), the coefficient of determination (R²), and adjusted and predicted R² values. This approach provides a deeper understanding of the interaction mechanisms between clayey soil and aeolian sand, allowing better control and enhancement of the geotechnical properties of the treated soil.

Materials and protocols

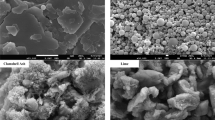

Clay soil

The soil sample used in this study was obtained near the eastern outskirts of Oued Anebcity, approximately 24 kilometers north of Annaba, the capital city of Algeria. The geographic coordinates of the sampling site were determined to be latitude 36° 52’ 50” N and longitude 7° 29’ 22” E. Clay soil, characterized by its brownish-red color, originates from the weathering and metamorphic transformation of Micaschists, a crystalline metamorphic rock dating back to the Cambrian‒Ordovician period. Initially, the clay was stored outside without any plant debris or other foreign matter and then dried in an oven at 105 °C for 24 h. Afterward, the desiccated soil was sieved to ensure uniformity and further dried in the oven to achieve complete desiccation, preventing any heat-induced alterations47. Finally, the dried clay was passed through a 4.75 mm sieve to achieve consistent granulometry. Following the stipulations delineated in the standard NF P 94 − 06848, a methylene blue assay was conducted to ascertain the specific surface area of the fines present within the clay. The empirical relationship denoted by the equation SSt = 21 × VB (0/2 µm) was employed to correlate methylene blue adsorption values with specific surface area measurements, with the outcomes tabulated in (Table 1). Notably, the liquid limit and plastic limit of the clay were determined to be 53 and 32%, respectively, thereby yielding a plasticity index of 21%, thereby situating it within the highly plastic clay classification according to the Casagrande plasticity chart. Furthermore, the clay underwent a standard Proctor compaction test, revealing a maximum dry density of 1.55 t/m³ and an optimal moisture content of 15.80%. Comprehensive details pertaining to the mechanical properties of the untreated clay are presented in (Table 1). Figure 1 shows a graph depicting the grain size distribution curve for the clay sample and aeolian sand.

According to the granulometric analysis of the clay depicted in the particle size curve, a substantial portion, ranging from 40 to 80%, comprises fine particles with diameters less than 80 μm. This situates the material within the intermediary realm between silt and clay in terms of textural classification. While silt falls under the technical classification of clay, the graph in (Fig. 1) highlights the nuanced nature of this fine, borderline texture. The elucidation of this grain size distribution curve is closely related to sedimentometry, a pivotal technique instrumental in discerning over 80% of the grains represented therein. Through granulometry, a myriad of values for parameters such as the coefficient of curvature (Cc) and the coefficient of uniformity (Cu) were derived, facilitating the determination of the proportion of particles with diameters below 2 μm and exceeding 80 μm. Notably, the Hazen coefficient Cu is equal to 1, whereas the curvature coefficient Cc is equal to 1. These values indicate a well-dispersed and well-graded distribution in the grain size spectrum.

Additive sand

The sand used in this study is an aeolian sand collected along national roads in coastal areas, where it was transported by the wind and deposited at the edge of the tracks in Algeria. The sand equivalent is 93%, and the amount of methylene blue solution (10 g/L) used in the test is shown in (Table 2).

The aeolian sand exhibited a specific gravity (Gs) of 2.63, coupled with a maximum void ratio (emax) of 0.815 and a minimum void ratio (emin) of 0.613. A meticulous sieving analysis was performed to delineate the grading attributes of the aeolian sand, revealing Dmax to be 0.6 mm, D50 to be 0.46 mm, the coefficient of uniformity (Cu) to stand at 1.44, and the coefficient of curvature (Cc) at 0.96. These parameters collectively categorize aeolian sand as poorly graded, reflecting a relatively even dispersion of particle sizes.

Methods and testing procedures

Numerous laboratory investigations have been undertaken to elucidate the inherent characteristics of clay, adhering rigorously to the guidelines set forth by the French Standardization Association (AFNOR). The study embraced a methodical approach, incorporating a judicious blending ratio derived from previous scholarly endeavors, with untreated samples (0%) serving as the baseline for comparative analysis. The stabilization of the clay soil was achieved through the incremental addition of aeolian sand ranging from 2.5 to 30% by the dry weight of the clayey substrate. This process involved 12 repetitions, each involving 12 distinct increments of sand (2.5, 5, 7.5, 10, 12.5, 15, 17.5, 20, 22.5, 25, 27.5, and 30%, respectively). The amalgamation of pulverized clay and aeolian sand was meticulously executed in a spacious tray, ensuring uniformity of distribution to mitigate potential discrepancies in mixing. A battery of laboratory assessments, including specific gravity tests for density (NF-P94–053)49, methylene blue tests (NF P94–068)48, Atterberg limit tests (NF P94–051)50, compaction tests (NF P94–093)51, direct shear tests (NF P94–071–1)52, and oedometric tests (XP P94–091)53, which were conducted on both untreated and sand-treated clay samples, were performed. The initial procedures involved Atterberg limit tests conforming to the NF P 94–051 standards50, wherein liquid limit tests were conducted via the Casagrande method as stipulated by established protocols19, followed by the determination of plastic limits for the soil samples19. Subsequent specific gravity tests were executed in accordance with NF-P94-05338, followed by standard probe tests following the NF-P94-093 guidelines40, aimed at ascertaining the optimum water content for prepared clay–sand mixtures. Moisture content, a pivotal parameter, was gauged in adherence to NF-P94-05054, maintaining a 2% interval in moisture content variation for consistency. Compaction, a fundamental practice in soil engineering, involves the consolidation of soil through applied force, thereby reducing air voids and increasing density. This process, which is influenced by moisture levels, aims to minimize soil porosity10. Direct shear tests were subsequently conducted in accordance with the NF P94-071-1 standards52 to assess shear properties under different soil conditions, including natural clay and clay–sand mixtures, at the optimal moisture content (OMC). These evaluations provide essential data for designing earthen structures and determining the soil foundation bearing capacity6 by using samples prepared directly in shear boxes. The tests, which were conducted under varying normal loads, aimed to clarify shear parameters such as cohesion (C) and the internal friction angle (ϕ)6.

Experimental design using the RSM

The RSM technique is a robust statistical tool crucial for optimizing stochastic experimental procedures44,45,46,55. It offers a structured methodology to explore the complex quantitative links between independent and response variables. By constructing a response surface model and carefully selecting an appropriate empirical model, researchers can pinpoint optimal experimental conditions and protocols43,44,45,55,56. Central composite design (CCD) stands out as a widely adopted approach in response surface methodology (RSM), representing a fractional factorial design well known for its effectiveness43,45. Leveraging CCD, researchers delve into unraveling the intricate nexus between independent variables and response variables, steering the determination of an apt experimental configuration [45; 56]. Figure 2 shows a tripartite layout exemplifying a three-factor CCD, delineating a geometric construct akin to a cube embellished with axial points adorning the face centers. The total number of experimental samples can be delineated by the formula (2k + 2k + n), where ‘k’ signifies the number of factors and ‘n’ denotes the number of center points.

The investigation employed Design Expert software, specifically version 13, to harness the potential of a full factorial design paradigm in crafting design matrices. Subsequent to this phase, Design-Expert software, which includes the powerful toolset of response surface methodology (RSM), was employed for the discerning tasks of statistical analysis and the generation of regression models. The two independent variables under scrutiny encompassed the clay soil content, abbreviated as CLAY, and the aeolian sand content, abbreviated as Sand. Encapsulated within Table 3 are the two independent factors, each delineated across two experimental tiers, with coded levels denoting their normalized manifestations. Notably, “−1” and “+1” represent the low and high echelons of the independent factors, respectively.

In our current study, we explored the effects of substituting different proportions of aeolian sand for the dry weight of clay on the geotechnical properties of composite mixtures. We carefully selected these parameters because of their significant influence on soil behavior. Our investigation focused on critical metrics such as dry density (maximum dry density, MDD), cohesion (C), the internal friction angle (φ), the compressibility coefficient (Cc), and the swelling coefficient (Cs). Various combinations were considered for each parameter within specific groups. To analyze the impact of these variables on the outcomes thoroughly, we employed design expert software (version 13). The meticulously gathered data were then utilized in design of experiments (DOE) software to establish the model equation. The reliability of these models was further validated via a comprehensive array of statistical techniques, including analysis of variance (ANOVA), regression analysis, and assessment of normal residual plots. The precise mathematical expressions elucidating the anticipated outcomes in relation to the chosen parameters were methodically crafted through the utilization of multiple regression analysis on the empirical dataset. The comprehensive quadratic equation framework, outlined by43,44,45,46,56,57, stands as a fundamental tool for comprehending the intricate relationships among the specified variables and the consequent geotechnical reactions.

where Y represents the responses (dependent variables); \(\:{\beta\:}_{O}\) is the constant coefficient; \(\:{\beta\:}_{i},\:{\beta\:}_{ii}\) and \(\:{\beta\:}_{iii\:}\) are coefficients for the linear, quadratic, and interaction effects, respectively; and \(\:{x}_{i}\) and \(\:{x}_{j}\) are factors (independent variables)57.

Table 4 delineates the experimental framework comprising two input variables and five associated responses. The objective of this setup is to employ it in response surface methodology (RSM) analysis and refine the compositional data for Clay_ aeolian sand. This iterative process aims to establish the empirical relationship between the output model and input variables, a relationship subject to statistical validation through analysis of variance (ANOVA). ANOVA scrutinizes the statistical significance of interaction, linear, and quadratic coefficients. Employing a central composite design (CCD) characterized by two factors at two levels, a total of 13 experimental permutations were executed. These permutations encompassed various levels of the testing variables, including the alteration of specific percentages of clay soil (clay) and aeolian sand (sand). Each term within the model underwent statistical scrutiny to assess its fit to the data, considering a significance level of p < 0.05 and evaluating the F value against the critical F value. Furthermore, the R-squared (R²), predictive accuracy, predicted R-squared (R²), and adjusted R-squared (R²) values were determined to ascertain the validity of the proposed polynomial model. To illustrate the input‒output dynamics, both response surface and contour maps were constructed43,56,58.

Results and discussion

Effects of aeolian sand additives on the methylene blue value (MBV)

The results of the methylene blue value (MBV) assay revealed a discernible decrease in chromatic intensity compared with that of the untreated control upon the introduction of aeolian sand, with reductions of 1.95, 3.30, 4.95, 9.90, 11.86, 18.32, 19.97, 20.27, 21.17, 26.42, 24.47, 32.73, and 34.98%, respectively, relative to the untreated clay’s baseline of 6.66%. Notably, the extent of argillosity, as gauged by the methylene blue valuation within various clay-aeolian sand amalgams, is negatively correlated with the augmentation of aeolian sand constituents, as illustrated in (Fig. 3).

The decrease in VBS (volumetric base swelling) values can be attributed to the inherent cationic attributes of the methylene blue value (MBV) dye, which manifests a positive charge. Conversely, clay particles that ensconced within the matrix presented a negative charge. Upon the introduction of methylene blue dye into the clay medium, electrostatic attraction occurs, drawing the dye molecules toward the negatively charged clay particles. The magnitude of this interaction is contingent upon the surface area of the clay particles, wherein a larger surface area augments the adsorption capacity for methylene blue dye. With respect to the aeolian sand additive renowned for its proficient adsorption properties, upon its introduction into a solution containing methylene blue, it stands poised to adsorb dye molecules onto its surface. This adsorption process potentially leads to a decrease in the concentration of methylene blue within the clay–aqueous sand solution matrix. These findings corroborate the research of Mohamed El-Habacha59, Laoufi and Bahar (2012)41 and H. AitHmeid60.

Effects of the addition of aeolian sand on the consistency limits

Determining the consistency of clay is crucial for predicting its swelling behavior. Exploring how aeolian sand affects the consistency limits of clay involves examining the Atterberg limits in clay–eolian sand mixtures. These limitations provide insights into the clay content in the substrate5. The plasticity characteristics of both natural and treated clays are defined via parameters such as the liquid limit (LL), plastic limit (PL), and plasticity index (PI)6. After adding aeolian sand to the dried clay, the liquid limit (LL) and plastic limit (PL) were re-evaluated on the modified substrate. The changes in LL, PL, and PI with varying proportions of aeolian sand are visually depicted in (Fig. 4). An appreciable reduction in LL was observed upon the addition of aeolian sand, manifesting as a decrease of 3.77–39.62% relative to that of the untreated clay with an initial LL of 53%. Conversely, the PL values decreased in the aeolian sand-treated clay, decreasing by 6.25–37.50% compared with the natural state PL of 32% in the untreated clay. The plasticity index (PI) consistently decreases from 22% in untreated clay to 12% in clay with a 30% aeolian sand content, and a decrease of 45.45% was recorded, diverging from that of natural untreated clay6. The decreases in LL and PI also indicate a decrease in the expansiveness of the soil, which reduces the risk of deformation according to humidity variations. This strengthens the foundations and reduces maintenance-related expenses, especially in regions exposed to freeze‒thaw cycles and humidity fluctuations. Thus, these results play an essential role in ensuring the sustainability and stability of infrastructure.

These results corroborate the literature on solid waste materials, suggesting a negative correlation between the plasticity index and the incorporation of additive materials (Fig. 4). A decrease in LL signifies a decrease in the swelling propensity of the clay, whereas an increase in PL may be attributed to a decrease in the diffused double layer thickness of the clay particles, subsequently augmenting the shearing resistance. The concurrent alterations in LL and PL contribute to a reduction in soil PI with increasing aeolian sand concentration, with a more pronounced decrease observed at higher sand concentrations. This decrease in the PI suggests potential deformation of the clay during sand stabilization1,6. Similar results were demonstrated by Okagbue61, who described advantageous alterations in engineering properties owing to cation exchange, clay flocculation, agglomeration, and pozzolanic reactions. These trends parallel those induced by lime, rice husk ash, and cement treatments50. Additionally, these findings align with studies conducted by32,38,40,41,62,63, in which a sand content exceeding 50% was utilized to ameliorate the properties of high-plasticity soils.

Effects of the addition of aeolian sand on the optimal moisture content and maximum dry density

The conventional Proctor compaction test was employed to ascertain the maximum dry density (MDD) at the optimum moisture content (OMC) across all samples. These assessments were conducted on meticulously prepared stabilized clay soil samples, each incorporating varying proportions of the aeolian sand additive, as illustrated in (Figs. 5 and 6).

A comprehensive examination of the moisture content and maximum dry (MDD) unit weight pertaining to the incorporation of aeolian sand revealed that unmodified clay soil yielded the highest dry unit weight, reaching a magnitude of 1.55 t/m³. However, upon the addition of 30% sand, the dry unit weight increased to a value of MDD = 1.74 t/m³, surpassing that of the untreated clay, thus exhibiting a notable increase of 12.25%. These findings highlight the significant impact of aeolian sand additives on the dry unit weight and optimal moisture content (OMC) of clay soils. These authors demonstrated that adding up to 30% aeolian sand leads to an increase in the maximum dry density (MDD), which enhances the bearing capacity of the soil and is an essential factor for road subgrades and foundations. A higher density reduces settlement and improves structural stability. Moreover, a decrease in the optimal moisture content (OMC) reduces the water demand. For unstabilized clay, the OMC is 15.80%, whereas the addition of 30% aeolian sand reduces it to 14.60%, representing an approximate reduction of 7.59%, which is particularly advantageous in arid environments or in projects that require accelerated drying, thereby accelerating construction processes. This modification is both efficient and beneficial for geotechnical applications, especially in soil stabilization and concrete foundations. As such, these findings are critical for enhancing the durability and reliability of infrastructure, ensuring its long-term performance under varying environmental conditions. The current experimental investigation delves into the compaction dynamics of clay‒ aeolian sand blends, culminating in clear conclusions drawn from the obtained results. Increasing the percentage of sand in the mixture clearly led to a corresponding increase in the MDD and a proportional decrease in the OMC content. This phenomenon is attributed to the inherent properties of the aeolian sand particles, which are coarser and have a smaller surface area than the clay particles do. Coarser soils require less moisture content to achieve maximum dry density because of this property.

Conversely, the increase in MDD results from the improved packing efficiency of both clay and sand particles, creating a well-graded composite structure and increasing the specific gravity of the sand. Furthermore, the observed increase in the MDD in clay stabilized with varying proportions of aeolian sand can be attributed to agglomeration and flocculation processes among clay particles. These processes promote rapid cation exchange within the clay–aeolian sand matrix, enhancing compaction characteristics. Importantly, these findings align with those of previous studies, particularly those cited in the literature32,38,39,40,64, thereby reinforcing the consistency and reliability of the current results.

Effects of the addition of aeolian sand on the shear strength parameters

The relationship between cohesion (c) and friction angle (φ) vis-à-vis varying proportions of sand content is depicted in (Fig. 7). Laboratory experiments, such as direct shear tests, are crucial for revealing the inherent frictional properties and cohesive behavior of soil.

These tests involve the application of carefully controlled forces and shear stresses to soil samples, from which deformation data are collected to determine key parameters that govern the soil response. This study subaims to assess the mechanical properties of a composite material made of clay and sand through direct shear testing under consistent loading conditions. Direct shear experiments were conducted on twelve different clay‒ aeolian sand compositions to elucidate their mechanical behavior. This methodology facilitates the construction of the shear strength envelope for the studied soil and enables the determination of crucial parameters such as the internal friction angle (φ) and cohesion (C). The findings revealed a progressive increase in the internal friction angle of the mixture with increasing aeolian sand content, resulting in a notable increase in the internal friction angle (φ) of the composite, with increases of 105.56, 111.11, 127.77, 133.20, 144.42, 155.55, 188.88, 200, 205.55, 211.11, 222.09, and 233.33%, respectively, in comparison with those of the untreated clay with φ = 9°. This phenomenon can be attributed to the coarse surface texture of the sand particles, facilitating their interlocking and augmenting resistance against shear stresses. Conversely, clay particles, characterized by smoother surfaces, exhibit less effective interlocking, thereby resulting in lower internal friction angles in clay-rich mixtures than in those abundant in sand. These observations are consistent with the conclusions drawn by Orabi et al. (2018)42. With respect to the cohesive properties of clay– aeolian sand amalgamations, the study revealed a decrease in cohesion (c) with the incorporation of aeolian sand additives, with reductions of 2.90, 11.83, 18.30, 24.11, 29.69, 34.15, 34.82, 35.27, 43.08, 47.54, 48.88, and 49.78%, respectively, relative to the untreated clay with C = 44.8 kN/m². This phenomenon can be explained by the inherent deficiency of sand in forming robust interparticle bonds, hence serving predominantly as an inert filler that diminishes the cohesive contribution of clay particles and lowers the overall cohesion of the mixture. The introduction of aeolian sand perturbs the formation of robust interparticle bonds within the clay matrix, resulting in a reduction in the packing density and dilution of the cohesive effect of the clay particles, thereby resulting in a substantial decrease in the cohesion of the clay‒ aeolian sand composite. This shows that despite the loss of cohesion in the soil, marked by a decrease, and the increase in the internal friction angle, the soil becomes more stable under loading, particularly in unsaturated soils. By increasing the friction angle, the bearing capacity increases, which reduces the risk of differential settlement in foundations, especially in loose and sandy soils.

Effects of the addition of aeolian sand on the consolidation characteristics

Figure 8 illustrates the effects of the addition of aeolian sand on the consolidation characteristics- the compressibility index (Cc) and the swelling coefficient (Cs). The principal aim of this work is to examine the consolidation properties of clay soil samples under incremental vertical loading conditions. The experimental protocol adheres to vertical drainage conditions, with sample confinement within a rigid casing as stipulated by the standard (XP P 94–091)53.

Figure 8 graphically depicts the fluctuations in the compressibility index (Cc) and swelling coefficient (Cs) in relation to varying aeolian sand content percentages. The compressibility index (Cc) gradually decreases, with values of 0.62, 2.48, 4.97, 6.21, 8.07%, 9.94, 11.80, 11.80, 13.04, 14.29, 14.90, and 16.15%, respectively, in comparison with the untreated clay’s Cc value of 0.161. An analysis of the decline in soil compressibility (Cc) resulting from sand treatment revealed a significant reduction, albeit to a lesser degree. The introduction of aeolian sand results in a dilution of the clay content, thereby mitigating overall compressibility. However, the bonding affinity between individual aeolian sand particles and clay is not robust, implying that the resulting mixture might still be prone to compaction under pressure. This observed decrease in the compressibility index suggests the possibility of heightened product formation within soil pore spaces due to physicochemical alterations62. Conversely, the graphical representation in Fig. 9 indicates a marked decrease in the swelling potential (Cs). The depicted curves visually capture this trend, wherein the reduction in Cs generally follows a sequence of 3.63, 9.09, 12.72, 18.18, 21.81, 27.27, 30.90, 38.18, 45.45, 50.90, and 54.45%, respectively, compared with untreated clay with Cs ≈ 0.055.

Results of the analysis of variance (ANOVA)

The aim of the analysis of variance (ANOVA) was to assess the statistical significance of the independent variables, namely, the proportions of clay and aeolian sand additives, as well as their interactions, concerning various response variables, including dry density (MDD), cohesion (C), the internal friction angle (φ), the compressibility coefficient (Cc), and the swelling coefficient (Cs). Table 5 presents the ANOVA results along with the statistics derived from the fitting analysis. Within this context, several pertinent terms, such as the standard deviation, mean, coefficient of determination (R2), predicted R2, model F, P values, and adjusted R2, were derived through the RSM for the parameters MDD, C, φ, Cc, and Cs.

Selection of a suitable model

In the context of designing and analyzing experimental assays via the composite central design (CCD) methodology, understanding how the choice of model impacts the results of analysis of variance (ANOVA) is crucial. To explore this, we evaluated different models: linear polynomials, two-factor interaction (2FI) polynomials, and quadratic polynomials. Each model was assessed via various metrics, such as the coefficient of determination (R²), adjusted coefficient of determination (Adj. R²), precision adequacy, Fisher’s F test value, and the associated probability (p value) are pivotal in determining the model’s suitability across different responses. These findings are summarized in (Table 5). On the basis of these results, the quadratic regression model emerged as the preferred option owing to its higher and statistically significant R² and F value metrics. This finding indicates that the model effectively explains a significant portion of the variability in the dependent variable and fits the dataset well. This conclusion aligns with insights from45,46,47,65, which support the widespread use of second-order polynomial equations in response surface methodology (RSM). These equations are valued for their flexibility in representing various functional forms, making them adept at approximating the true response surface. Additionally, the ease of parameter estimation (β) and empirical evidence further bolster the effectiveness of the second-order model in addressing real-world response surface challenges65.

The mean squared error (MSE) represents the average of the squared differences between the observed and predicted values. It is calculated by summing the squared deviations between each observed and predicted value and then dividing by the total number of observations. A lower MSE indicates higher model accuracy44,45,46. In addition, the coefficient of determination (R²) represents the proportion of the total variance in the dependent variable that is explained by the model. It ranges from 0 to 1, with a value closer to 1 indicating that the model effectively explains the variability in the data. R² is calculated by subtracting the ratio of the residual sum of squares to the total sum of squares from 1; a low MSE and a high R² suggest that the model fits the data well, minimizing errors and explaining a large portion of the variance44,45,46.

For the current study and after selecting a quadratic model, the R2 values are 0.9979, 0.9869, 0.9775, 0.9789, and 0.9988 for the MDD, C, φ, Cc, and Cg, respectively. The significance of the model can be observed through the discrepancy between the adjusted R2 and R2 values. A diminished disparity suggests heightened import of the model, whereas R2 values nearing unity denote a robust model endowed with exceptional predictive ability, a trait conspicuously shown in the present investigation across all response factors. The significance of the model is further validated by P values, with all response variables exhibiting values less than 0.05; notably, MDD, C, φ, Cc, and Cs show values even lower than 0.0001, underscoring the model’s considerable significance. Moreover, it can be concluded that the model holds considerable significance.

Development of a mathematical model

The investigation employed central composite design (CCD) methodology to scrutinize the impact of diverse geotechnical parameters on the remediation of clayey soil through the incorporation of various proportions of aeolian sand, ranging from 2.5 to 30%, at incremental intervals of 2.5%. These parameters included dry density (MDD), cohesion (C), the internal friction angle (φ), the compressibility coefficient (Cc), and the swelling coefficient (Cs). Coded expressions were subsequently deduced for the MDD, C, φ, Cc, and Cs via response surface methodology (RSM). The utilization of the generalized quadratic polynomial equation (Eq. 2) enabled the anticipation of response values with enhanced prognostic accuracy.

These equations are utilized to estimate the responses at specified locations across the five parameters. To evaluate the differences between the experimental results and the values predicted from the RSM models, specific comparisons are essential. Through the error histogram, which represents the distribution of residuals and the differences between the observed and predicted values, it is possible to assess whether the errors follow a normal distribution and identify any systematic biases in the model44,45,46. Figure 9 illustrates the disparities in the MDD, C, φ, Cc, and Cs between the experimental and predicted responses via the RSM models.

The results presented here highlight how well the proposed methods reveal the geotechnical properties specific to aeolian sand-amended soil. The findings from this study confirm that the predicted values for key metrics, such as the maximum dry density (MDD), cohesion (C), angle of internal friction (φ), compression index (Cc), and swelling index (Cs), derived from quadratic models via central composite design (CCD), closely match real-world data. This alignment suggests that the models effectively capture the soil’s behavior under given conditions, bolstering our trust in their predictive accuracy. In essence, these findings buttress the dependability of the models in elucidating the intricate dynamics inherent to aeolian sand-amended soil, thereby augmenting their practical applicability within the realm of geotechnical engineering. By showing a robust concordance between forecasted and experimental metrics spanning various parameters, this inquiry underscores the resilience and relevance of the proposed methodology in predicting soil behavior, a facet indispensable for judicious decision-making across diverse engineering domains.

Normal probability plot of residuals

Figure 10a–e delineate normal probability plot illustrating residuals for various conditions: (a) MDD, (b) CC, (c) Cs, (d) C, and (e) φ.

The utilization of a normal probability plot (NPP) for the assessment of data adherence to a Gaussian distribution is a pivotal graphical technique65. A robust regression model is expected to comprehensively encapsulate the variability inherent in the dependent variable across the sample. NPPs serve as a visual tool for illustrating the residuals juxtaposed with their anticipated values, assuming a normal distribution. The residuals signify the dissonance between the observed and predicted response values. Ideally, these residuals should follow a Gaussian distribution. Notably, in cases where the experimental design is well balanced or nearly balanced or when dealing with datasets of considerable magnitude, minor deviations from normality tend to exert negligible influence on the overall outcome. As discernible from the aforementioned figure, the residuals exhibit dispersion closely aligned with a linear trend, suggesting adherence to a Gaussian distribution. Therefore, it can be deduced that the assumption of normality remains valid for the five response variables scrutinized within this inquiry. Consequently, there is no discernible evidence of nonnormality, skewness, outliers, or latent variables, eluding identification.

Response surface plot for the MDD, C, Φ, Cc and Cs as a function of the percentage of clay and sand

The response surface method (RSM) elucidates the intricate interplay between dependent and independent variables within an experimental framework45,46,66. Figure 11 shows three-dimensional representations of response surfaces derived from regression model equations, which effectively visualize the outcomes of simulations via isovalue plots, employing the response surface method (RSM).

These plots intricately demonstrate the interactive effects of two variables on the geotechnical characteristics of aeolian sand-amended clay, concurrently identifying optimal conditions through the application of statistical methodologies to a diverse array of combinations. The gradation of colors observed on the surfaces in (Fig. 11), as well as their corresponding contour plots, delineates the extremities of the response variables, with red hues signifying maximum values and blue hues representing minimum values. Within the contour plots, the smallest ellipse denotes the maximum predicted response58. The parameters, including dry density (MDD), cohesion (C), internal friction angle (φ), compressibility coefficient (Cc), and swelling coefficient (Cs), predominantly demonstrate a pronounced susceptibility to variations in sand content, as evidenced by their highly significant linear relationships at a significance level of p < 0.01.

Methodology for optimization based on desirability

Using numerical optimization techniques employing response surface methodology (RSM) within Design Expert 13 software, the investigation discerned optimal parameter configurations that adhere to predefined criteria. The principal objective of this optimization endeavor was to maximize response variables while concurrently ensuring adherence to all designated parameter specifications. As per the theoretical framework of the desirability function methodology67, each response variable is transformed into a desirability function of exponential nature. The underlying principle of this approach entails the conversion of the ith response quality (y∗) into the ith desirability (di), subsequently amalgamating all desirability values into a unified desirability function (D). The attainment of the target response leads to a desirability value of unity, whereas deviations are reflected otherwise. Each desirability function is categorized into three types on the basis of user-defined preferences, namely, smaller-the-best, higher-the-best, and normal-the-best68. The culmination of individual response desirability values yields an overall desirability index, denoted as D, which serves as a singular quality metric. This index is ascertained by allotting weight factors to distinguish quality responses, contingent upon their respective priorities or customer requisites. The computation of the composite desirability index is articulated as follows67:

In the realm of optimization, the overarching desirability index, denoted as D, is derived from the weighted aggregation of individual response factors, symbolized as wi. Manifesting mathematical elegance, D attains unity when each di, representative of a distinct response, achieves the same value; otherwise, D is rendered null in the presence of any di equating to zero. Should the aspiration entail the attainment of a predetermined target value, Ti, the desirability, di, is meticulously calculated according to the prescriptive formulations outlined in reference67.

In the pursuit of optimizing a desired outcome, the desirability function emerges as a pivotal tool, as expounded upon by reference67.

In the pursuit of mitigating a response, the desirability function is articulated as per the citation provided59.

Yi represents the achieved outcome of the ith output within the optimization procedures, with Lowi denoting the minimum values and Highi indicating the maximum values of the corresponding dataset. It is advisable to pursue desirability levels nearing unity for enhanced results, as elucidated in prior research69. The optimization procedure adhered to the specified parameters outlined in (Table 6). The resulting refined values are illustrated in (Fig. 12). The amalgamation of various responses and factors culminates in the formulation of a singular desirability function, as elucidated by69. This analytical approach delineates the desirability associated with each individual factor and response, in addition to presenting an aggregate measure of desirability. Notably, this methodology highlights specific data points, encapsulating both the precise numerical values of the factors or responses and the degree to which the overarching goals are achieved69,70.

In Fig. 12, a ramp plot is depicted, showing a desirability score of 0.967, thereby substantiating the feasibility of optimizing multiple responses concurrently69,70. The resulting parameters include a clay content of 71.482%, augmented by the inclusion of an aeolian sand content constituting 30% as an additive. Moreover, the achieved values encompass a maximum dry density (MDD) of 1.73 g/cm2, a compressibility coefficient (Cc) of 0.136, a swelling coefficient (Cs) of 0.027, a cohesion (C) of 43.774 kN/m2, and an internal friction angle (φ) of 9°. An attainment of a desirability value of 0.967 signifies the efficacious optimization of the quintet of responses. Through the optimization process, a specific mixture composition was discerned, culminating in the realization of these optimal property indices. This blend predominantly comprised 71.482% clay, augmented with 30% aeolian sand.

As delineated in (Table 7), this accomplishment is underscored by the corresponding peak values attained for the maximum dry density (MDD), compressibility coefficient (Cc), swelling coefficient (Cs), cohesion (C), and internal friction angle (φ), which are 1.73 g/cm2, 0.136, 0.027, 43.774 kN/m2, and 9°, respectively. Table 7 also provides detailed insights into the four most auspicious solutions (mixtures) identified during this optimization endeavor.

Conclusion

In the realm of civil engineering, the utilization of clayey soils necessitates careful consideration of their properties to ensure structural integrity. Recently, sand has emerged as a valuable supplement for increasing the quality of clayey soils. This study endeavors to scrutinize the ramifications of varying eolian sand collected along national roads in coastal areas, where it was transported and deposited by wind at the roadside. Owing to its specific origin, this eolian sand possesses unique properties that ensure optimal compatibility with clayey soil. The outcomes of an empirical inquiry and optimization employing response surface methodology (RSM) concerning the behavior of clayey soil amalgamated with diverse aeolian: sand ratios served as the foundation for establishing correlations and advocating optimal practices. These methodologies include evaluations such as the liquid limit, plastic limit, plasticity index, maximum dry density, optimal moisture content, consolidation traits, and shear strength parameters extrapolated through a quadratic model based on the central composite design (CCD) technique. Considering the findings of this study, the following conclusions can be drawn:

-

1.

The novelty of this study lies in its systematic integration of aeolian sand with precisely controlled increments as small as 2.5%. While seemingly minor, these increments were deliberately chosen to capture subtle yet critical modifications in soil behavior. This precise approach enables a detailed understanding of the interactions between clay and sand, leading to measurable and reproducible results.

-

2.

The addition of 30% aeolian sand resulted in a significant reduction in key soil parameters, with the methylene blue value (MBV) decreasing by 34.98%, the liquid limit (LL) by 39.62%, and the plastic limit (PL) by 37.50%, leading to a 45.45% reduction in the plasticity index (PI). These changes substantially reduce the expansiveness and shrinkage potential of the soil, thereby improving the stability of infrastructures such as highways and buildings constructed on clayey subgrades.

-

3.

An increase in eolian sand content up to 30% resulted in a reduction in soil cohesion (49.78%) alongside a substantial increase in the internal friction angle (ϕ) (233.33%). This shift contributes to an overall improvement in shear strength, reinforcing the ability of the soil to withstand applied loads in foundation and pavement applications.

-

4.

These results indicate that at 30% eolian sand, the MDD increased by 12.25%, improving the compaction and load-bearing capacity of the soil. Additionally, the OMC decreased by approximately 7.59%, reducing the soil water demand, which contributed to more efficient and cost-effective stabilization.

-

5.

Moreover, at the same proportion of 30% aeolian sand, the compressibility (Cc) and swelling potential (Cs) were reduced by 16.15 and 54.45%, respectively, resulting in lower sensitivity to volume changes.

-

6.

RSM, specifically the central composite design (CCD), is instrumental in pinpointing an optimal soil composition. This approach also ensures results that are applicable to real-world scenarios, where significant changes must be carefully managed to optimize performance. The findings of this study reveal that a mixture of 70% clay and 30% aeolian sand provides the best overall properties, with a maximum dry density of 1.74 g/cm³, reduced compressibility (Cc = 0.135), decreased swelling (Cs = 0.0265), cohesion of 22.5 kN/m², and an internal friction angle of 21°. These improvements are crucial for ensuring soil stability in moisture-sensitive environments, making this method applicable to real-world engineering challenges.

This study presents a rigorous and innovative approach to optimizing clayey soil properties through a meticulous selection of materials, a structured experimental strategy, and advanced statistical modeling. Leveraging RSM provides valuable insights into the influence of eolian sand content on soil behavior, offering a reliable and sustainable solution for clay stabilization. The practical implications of this research extend to critical geotechnical applications, particularly in the construction of resilient foundations and road infrastructure, where improved soil performance is essential for stability and environmental protection.

A 30% eolian sand content enhances the geotechnical properties of clayey soil by increasing cohesion, reducing plasticity, improving compaction, and strengthening mechanical resistance. It also promotes drainage, minimizing the risks of swelling and shrinkage. However, large-scale implementation poses challenges, including the difficulty of ensuring uniform mixing across extensive areas, leading to potential variations in density and strength. Additionally, logistical, economic, and technical constraints must be addressed for effective application. Future research should focus on large-scale field trials and durability analyses to validate the long-term performance of eolian sand‒clay mixtures under real conditions.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on request.

References

James, J. Strength benefit of sawdust/wood Ash amendment in cement stabilization of an expansive soil. RevistaFacultad de Ingeniería 28 (50), 44–61. https://doi.org/10.19053/01211129.v28.n50.2019.8790 (2019).

Cai, Y., Shi, B., Ng, C. W. W. & Tang, C. S. Effect of polypropylene fibre and lime admixture on engineering properties of clayey soil. Eng. Geol. 87, 3–4 https://doi.org/10.1016/j.enggeo.2006.07.007 (2006).

Hunar, F. H. A. & Mohammed, A. S. Modeling the effect of chemical additives on clay soil plasticity: novel analysis of oxide contributions in fly Ash and cement treatments. Model. Earth Syst. Environ. https://doi.org/10.1007/s40808-024-02154-5 (2024).

Ikeagwuani, C. C. & Nwonu, D. C. Emerging trends in expansive soil stabilisation: A review. J. Rock Mech. Geotech. Eng. 11, 423e440. https://doi.org/10.1016/j.jrmge.2018.08.013 (2019).

Nelson, J. & Miller, D. J. Expansive Soils: Problems and Practice in Foundation and Pavement Engineering. Books.google.com (Wiley, 1997).

Munirwan, R. P., Taha, M. R., Mohd Taib, A. & Munirwansyah, M. Shear strength improvement of clay soil stabilized by coffee husk Ash. Appl. Sci. 12, 5542. https://doi.org/10.3390/app12115542 (2022).

Khajeh, A., Reza Jamshidi Chenari, R., Payan, M. & MolaAbasi., M. Assessing the effect of lime-zeolite on geotechnical properties and microstructure of reconstituted clay used as a subgrade soil. Phys. Chem. Earth Parts A/B/C. 132, 103501. https://doi.org/10.1016/j.pce.2023.103501 (2023).

Smaida, A., Mekerta, B. & Gueddouda, M. K. Physico-mechanical stabilization of a high swelling clay. Constr. Building Mater. Volume. 289, 123197 (2021).

Khajeh, A. et al. Application of expanded polystyrene beads inclusion in lightening lime-zeolite treated clays: strength and stiffness assessment. Environ. Dev. Sustain. 26, 21369–21397. https://doi.org/10.1007/s10668-023-03535-z (2024).

Mutman, U. Clay improvement with burned Olive waste Ash. Sci. World J. https://doi.org/10.1155/2013/127031 (2013).

Kazempour, S., Jamshidi Chenari, R., Ahmadi, H., Payan, M. & Senetakis, K. Assessment of the compression characteristics and coefficient of lateral Earth pressure of aggregate-expanded polystyrene beads composite fill-backfill using large oedometer experiments. Constr. Build. Mater. 302, 124145. https://doi.org/10.1016/j.conbuildmat.2021.124145 (2024).

Khajeh, A., Ebrahimi, S. A., Mola Abasi, J., Chenari, R. & Payan, M. Effect of EPS beads in lightening a typical zeolite and cement-treated sand. Bull. Eng. Geol. Environ. 80, 8615–8632. https://doi.org/10.1007/s10064-021-02458-1 (2021).

Khajeh, A., Ebrahimi, S. A., Molaabasi, H. & Payan, M. Effect of EPS beads in lightening a typical zeolite and cement-treated sand. Bull. Eng. Geol. Environ. 80 (11), 8615–8632. https://doi.org/10.1007/s10064-021-02458-1

Payan, M., Jamshidi Chenari, R., Hakimi Basti, T. & Senetakis, K. Monotonic, Cyclic and post-cyclic shearing behavior of sand-EPS geofoam interface. Geosynth. Int. 28 (3), 259–278. https://doi.org/10.1680/jgein.20.00041 (2020).

Kazempour, S., Jamshidi Chenari, R., Ahmadi, H., Payan, M. & Senetakis, K. Assessment of the hydraulic characteristics of aggregate-expanded polystyrene beads composite using enhanced standard proctor compaction test configuration. Iran. J. Sci. Technol. Trans. Civil Eng. 47 (1), 627–637. https://doi.org/10.1016/j.conbuildmat.2021.124145 (2021).

Bekranbehesht, B., Jamshidi Chenari, R., Rezvani, R. & Payan, M. Nondestructive shear stiffness evaluation of EPS-sand composites using quartz and calcareous aggregates. J. Mater. Civ. Eng. 35 (7), 04023174. https://doi.org/10.1061/jmcee7.mteng-15189 (2023).

Khorrami, R., MoshfeghniaTochaee, M., Payan, M. & Jamshidi Chenari, R. Deformation characteristics and creep behaviour of rigid particulates-EPS beads composites. Geosynth. Int. 1–18. https://doi.org/10.1680/jgein.23.00145 (2024).

Estabragh, A. R., Rafatjo, H. & Javadi, A. A. Treatment of an expansive soil by mechanical and chemical techniques. Geosynth. Int. 21 (3), 233–243 (2014).

AbdEllatief, M., Mahmoud, M. & Abdo, H. Effect of bagasse ash on the behavior of expansive clay in ELSalheya area, Qena, Egypt. In Proceedings of the International Conference on Advances in Structural and Geotechnical Engineering (2017).

Khajeh, A., Jamshidi Chenari, R. & Payan, M. A simple review of cemented non-conventional materials: soil composites. Geotech. Geol. Eng. 38, 1019–1040. https://doi.org/10.1007/s10706-019-01090-x (2020).

Molaabasi, H., Jamshidi Chenari, R. & Payan, M. An experimental study on the effect of disposable COVID-19 face masks on the mechanical properties of cement-stabilized sand. Environ. Dev. Sustain. 1–21. https://doi.org/10.1007/s10668-024-04519-3 (2024).

Sridharan, A. Swelling behavior of compacted fine-grained soils. Eng. Geol. 72 (1–2), 9–18 (2004).

Hussein, H. Effect of sand and sand-lime piles on the behavior of expansive clay soil. Hindawi Adv. Civil Eng. 201, https://doi.org/10.1155/2021/4927078 (2021).

Khajeh, A., Jamshidi Chenari, R., Molaabasi, H. & Payan, M. An experimental investigation on geotechnical properties of a clayey soil stabilised with lime and zeolite in base and subbase courses. Road. Mater. Pavement Des. 23 (12), 2924–2941. https://doi.org/10.1080/14680629.2021.1997789 (2024).

Saxena, D. Effects of marble powder and Fie sand on properties of expansive soil. Int. J. Eng. Trends Technol. 52 (1), 12–16 (2017).

Puspitasari, P., Yuwanda, V. & Dika, J. The properties of eggshell powders with the variation of sintering duration. In IOP Conference Series: Materials Science and Engineering. (IOP Publishing, 2019).

Anand, D., Sharma, R. K. & Sharma, A. Improving swelling and strength behavior of black cotton soil using lime and quarry dust. Sustain. Dev. Through Eng. Innovat. 601–609. (2021).

Zada, U. et al. Recent advances in expansive soil stabilization using admixtures: current challenges and opportunities. Case Stud. Construct. Mater. https://doi.org/10.1016/j.cscm.2023.e01985 (2023).

Kaushik, N. P. & Ramasamy, G. Strength characteristics of compacted coal ash. Unpublished thesis, Department of Civil Engineering, Engineering College Kota.

Chauhan, S., Mittal, S. & Mohanty, B. Performance evaluation of silty sand subgrade reinforced with fly Ash and fibre. Geotext. Geomembr. 26 (5), 429–435. https://doi.org/10.1016/j.geotexmem.2008.02.001 (2008).

Cokca, E. Use of class C fly ashes for the stabilization—Of an expansive soildz. J. Geotech. Geoenviron. Eng. 127, 568–573. (2001).

Jirathanathworn, T. S., Nontananandh, S. & Chantawarangul, K. Stabilization of clayey sand using fly ash mixed with small amount of lime. Proc. of the 9th National Convention on Civil Engg. Engineering institute of Thailand and Thammasat University 2, 93–98. (2003).

Khaksar Najafi, S. N. E., Ranjbar, P. Z. & Jamshidi Chenari, R. Geotechnical performance of alkali-activated uncalcined clayey soils with hydroxide- and aluminate-based activators. J. Mater. Civil Eng.. 36 https://doi.org/10.1061/JMCEE7.MTENG-16746 (2024).

Mohammadi, E. L. et al. Recycling industrial alkaline solutions for soil stabilization by low-concentrated fly ash-based alkali cements. Constr. Build. Mater. 393, 132083. https://doi.org/10.1016/j.conbuildmat.2023.132083 (2023).

Endaryanta, M. R. & Wibowo, D. E. Strengthening and supporting efforts to reduce swelling of soil by using beach sands through CBR test. J. Phys: Conf. Ser. 1625, 012008. https://doi.org/10.1088/1742-6596/1625/1/012008 (2020).

Aswar, Y. A. P. & Reza, M. CBR improvement study lower base layer material due to sand addition. J. Civil Des. 1 (1), 41–49 (2012).

Darma, P. The Performance of the Lapis Foundation and Lower Foundation Laboratory with Sea Sand as Substitute Material for some of its Fine Aggregates (Bandung Institute of Technology, 2003).

Roy, T. K. Infuence of sand on strength characteristics of cohesive soil for using as subgrade of road. Procedia Soc. Behav. Sci. 104, 218–224. https://doi.org/10.1016/j.sbspro.2013.11.114 (2013).

Khan, F. S., Azam, S., Raghunandan, M. E. & Clark, R. Compressive strength of compacted clay-sand mixes. Adv. Mater. Sci. Eng. 1–6. https://doi.org/10.1155/2014/ (2014).

Alnmr, A. & Ray., R. Investigating the impact of varying sand content on the physical characteristics of expansive clay soils from Syria. Geotech. Geol. Eng. https://doi.org/10.1007/s10706-023-02698-w (2024).

Louafi, B. & Bahar, R. SAND: an additive for stabilzation of swelling clay soils. Int. J. Geosci. https://doi.org/10.4236/ijg.2012.34072 (2012).

Al Rawi, O. S., Assaf, M. N. & Hussein, N. M. Effect of sand additives on the engineering properties of fine grained soils. ARPN J. Eng. Appl. Sci. 13, 9 (2018).

Fathipour, H., Javankhoshdel, S., Abolfazlzadeh, Y., Payan, M. & Jamshidi Chenari, R. Probabilistic assessment of seismic bearing capacity of strip footings seated on heterogeneous slopes using finite element limit analysis (FELA) and response surface method (RSM). Proceedings of the TMIC 2022 Slope Stability Conference (TMIC 2022) https://doi.org/10.2991/978-94-6463-104-3_18 (2022).

Aidoud, A., Bencheikh, M., Boukour, S., Bahloul, O. & Widiane Qatr Ennada, Z. Enhancement of the mechanical characteristics of a green mortar under extreme conditions: experimental study and optimization analysis. Iran. J. Sci. Technol. Trans. Civil Eng. https://doi.org/10.1007/s40996-024-01612-5(2024) (2024).

Boudermine, H., Boumaaza, M., Belaadi, A., Bourchak, M. & Bencheikh, M. Performance analysis of Biochar and W. Robusta palm waste reinforced green mortar using response surface methodology and machine learning methods. Constr. Build. Mater. 438, 137214. https://doi.org/10.1016/j.conbuildmat.2024.137214 (2024).

Boukhatem, G. et al. Optimizing properties of clayey soil using lime and waste marble powder: a sustainable approach for engineering applications. Front. Mater. 11, 1392875. https://doi.org/10.3389/fmats.2024.1392875 (2024).

Wahab, N. A. et al. Strength and durability of cement-treated lateritic soil. Sustainability 13, 6430 (2021).

NF P 94 – 068. Investigation and testing—Measurement of the Adsorption Capacity of Methylene Blue in Soil or Rock Material. Determination of the methylene blue value of soil or rock material using the spot test.

NF P 94 – 053. Investigation and Testing—Measurement of bulk density.

NF P 94 – 051. Determination of Atterberg limits—Liquid limit by the cup method—Plastic limit by the rolling method.

NF P 94 – 093. Investigation and testing—Determination of compaction references for a material—Standard proctor test—Modified proctor test.

NF P 94-071-1. Soils: Investigation and testing—Straight shear box test—Part 1: Direct shear.

XP P94-091. Investigation and testing—Compressibility test using the oedometer.

NF P 94 – 050. Investigation and testing—Determination of the gravimetric water content of materials—Oven-drying method.

Boutahir Born Bencheikh, M. et al. Recent Tendencies in the Use of the Response Surface Method in the Stability of a Synthetic Retaining Wall 3 Geotech. Eng. J. SEAGS & AGSSEA (2023).

Jamshidi Chenari, M., Payan, M., Jamshidi Chenari, R., Dastpak, P. S. M. A. S. C. E. & pand Rita, Sousa, L. Probabilistic assessment of bearing capacity of strip footings seated on geosynthetic reinforced soil deposits using finite element limit analysis (FELA) and response surface method (RSM). Geo-Congress 40–50 https://doi.org/10.1061/9780784484692.005 (2023).

Khor, C. P., Jaafar, M. & Ramakrishnan, S. Optimization of conductive thin film epoxy composites properties using desirability optimization methodology. Hindawi Publish. Corp. J. Optim. https://doi.org/10.1155/2016/1652928 (2016).

Belaadi, A. et al. Water uptake of HDPE reinforced with WashingtoniaFibreBiocomposites: mathematical modelling using artificial neural network, response surface methodology and genetic algorithm. Adv. Mater. Process. Technol. https://doi.org/10.1080/2374068X.2023.2198828 (2023).

El-Habacha, M. et al. Methylene blue dye’s adsorption on a natural clay surface from Southeast Morocco: modeling and experimental equilibrium studies. https://doi.org/10.21203/rs.3.rs-2306837/v1 (2022).

AitHmeid, H. et al. .L. Adsorption of a basic dye, methylene Blue, in aqueous solution on bentonite. Moroccan J. Chem. 3, 416–433 (2021).

Okagbue, C. O. Stabilization of clay using woodash. J. Mater. Civil Eng. 19 (1), 14–18 https://doi.org/10.1061/(ASCE)0899-1561 (2007).

Bayshakhi, D. N., Grytan, S., Siddiqua, S., Rokunuzzaman, M. D. & Rafiqul, I. Geotechnical properties of wood ash-based composite fine-grained soil. Hindawi Adv. Civil Eng. https://doi.org/10.1155/2018/9456019 (2018).

Srikanth, V. & Mishra, A. K. Atterberg limits of sand-bentonite mixes and the infuence of sand composition. Geotech. Charact. Geoenviron. Eng. https://doi.org/10.1007/978-981-13-0899-4_17 (2019).

Gupta, C. & Sharma, R. K. Infuence of marble dust, Fy Ash and Beas sand on sub grade characteristics of expansive soil. J. Mech. Civ. Eng. 13, 13–18 (2014).

El-Sesy, M. E. & Ibrahim, S. Application of central composite design approach for optimization nitrate removal from aqueous solution by immobilized Pseudomonas putida. Water Sci. Technol. http://iwaponline.com/wst/article-pdf/83/12/2931/906194/wst083122931.pdf (2021).

Arachchige, T., Meetiyagoda, O. K., Takahashi, T. & Fujino, T. Response surface optimization of chemical coagulation for solid–liquid separation of dairy manure slurry through Box–Behnken design with desirability function. Heliyon 9, e17632. https://doi.org/10.1016/j.heliyon.2023.e17632 (2023).

Lafifi, L., Rouaiguia, A. & Boumazza, N. Optimization of geotechnical parameters using Taguchi’s design of experiment (DOE), RSM and desirability function. Innovative Infrastructure Solutions. 4, 35. https://doi.org/10.1007/s41062-019-0218-z (2019).

Tran, N. T., Chau, N. L. & Dao, T. P. A hybrid computational method of desirability, fuzzy logic, ANFIS, and LAPO algorithm for multiobjectiveoptimization design of Scott Russell compliant mechanism. Hindawi Math. Probl. Eng. Doi. https://doi.org/10.1155/2020/3418904 (2020).

Šoštarić, T. et al. Structural changes of waste biomass induced by alkaline treatment: the effect on crystallinity and thermal properties. Biomass Conv. Bioref. 12, 2377–2387. https://doi.org/10.1007/s13399-020-00766-2 (2022).

Handel, N. et al. Microstructural characterization andmulti-objective optimization of concrete containing recycled gravel and crystallized slag: A box-behnken design methodology. Iran. J. Sci. Technol. Trans. Civ. Eng. https://doi.org/10.1007/s40996-024-01718-w (2025).

Author information

Authors and Affiliations

Contributions

Conceptualization, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Data curation, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Analysis and Validation, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Formal analysis, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B; Investigation, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Methodology, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Project administration, K.R and MS. K. Resources, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Software, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B., Supervision, K. R and MS. K.; Validation, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Visualization, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B.; Writing—original draft, M. B, ME. B, G. B, MS. K, N. N, K. S and SR. B., Data Visualization, Editing and Rewriting, M. B, ME. B, G. B, MS. K, N. N, K. S, SR. B and R. S.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions