Abstract

The increasing focus on sustainable manufacturing has brought about interest in the bio-based cutting fluids where the mineral oils are being replaced. In the paper, the rice bran oil (RBO) as a renewable and environmentally harmless lubricant is reinforced with copper (Cu) nanoparticles (NPs) to improve its thermophysical and tribological properties when used in machining processes by using waste materials of rice processing. The reinforcement of 0.5 vol.% of Cu-NPs into base oil enhanced thermal conductivity by 51% and the viscosity by 25.7% as compared to unreinforced oil. The tribological measures showed reduced coefficient of friction by 48.9% at 0.5 vol.% of Cu-NPs as compared to rice bran oil (0 vol.% of Cu-NPs). The obtained RBO-Cu nanofluid demonstrated a high dispersion stability and sustainable lubricating properties during the prolonged use. These results imply that the reinforced RBO cutting fluids using Cu can potentially present a sustainable, high-performance solution to precision machining operations that can be sustainable and have a high process efficiency.

Similar content being viewed by others

Introduction

A lot of machine operations such as turning1, milling2,3, drilling4, and grinding5,6 use cutting fluids. Their primary functions are cooling, lubricating, chip removal and corrosion protection. Combined, these items decrease cutting temperatures, reduce tool wear, increase tool life, and enhance surface polish of machined parts7,8,9. It is possible to significantly increase the performance of the cutting fluid during the machining process by adding oil rather than merely water. This not only yields improved results compared to dry machining, but it also reduces the amount of tool wear, cutting forces, and surface roughness associated with the operation10. Oil may be mineral, synthetic or vegetable. The cutting fluids produced in the world are about 85 percent of mineral oils, which are derived in petroleum. Cutting fluids that are made using mineral oils contain a high number of various chemicals and once they are applied, they leave behind oil mist thereby increasing the chances of bacteria and other microbes developing. This may lead to skin and allergy complications in the machine shop workers, and this poses a significant health hazard11,12,13. Approximately 80 percent of the occupational diseases that are recorded around the metalworking regions are associated with extended periods of skin exposure to metalworking fluids14,15. Additionally, when machines are utilized, the elevated temperature that accompanies these processes may transform mineral oils, which are not environmentally friendly, such as disposing of them or treating it16,17.

The cutting fluids made of vegetables are gaining a foothold in the contemporary manufacturing industry as they are biodegradable, renewable and exhibit a lesser impact on the environment as compared to mineral-based oils18,19. Manikanta et al.20 reported enhanced turning performance of stainless steel (SS 304) with vegetable oil as compared to conventional cutting fluid and dry condition. One of the most attractive vegetable oils is rice bran oil (RBO), which is the byproduct of rice milling that is naturally slippery, oxidatively stable, and has an appealing fatty acid composition21,22. Naturally, vegetable oils generate a polar boundary film on metal surfaces, and this increases the ease with which machining becomes simpler23. Their low thermal conducting property however limits their performance at high speed. One of the possible methods to overcome such issues is the addition of metallic nanoparticles to the base oil to form nanofluids. The addition of nanoparticles (NPs) to cutting oils to enhance the performance and tribological properties of minimum quantity lubrication (MQL) systems has elicited a lot of interest24. When nanofluids (NFs) are adopted in the heat transfer processes, their thermophysical properties play a significant role in the heat transfer coefficient (HTC). Thermal conductivity, the ability of the material to transfer heat, dynamic viscosity, the ability of a pump to pump efficiently and the amount of pressure material loses, and specific heat, the ability of a material to trap and give up the heat of the higher part of the material25. A large variety of nanoparticles have been investigated, including metallics like copper (Cu), zinc (Zn), silver (Ag), nickel (Ni), gold (Au), and metal oxides like copper oxide (CuO), titanium oxide (TiO2), iron oxide (Fe2O3), silicon oxide (SiO2), aluminum oxide (Al2O3) particles, as well as carbon-based (graphene, carbon nanotubes (CNTs), multi-walled CNTs, diamond) particles. Nanofluids are frequently stabilized with the help of surfactants, enhanced in terms of physical capabilities, and made more hydrophilic26.

Adding nanoparticles to oil makes it easier for heat to escape, slows down film boiling, and encourages droplets to spread while keeping the viscosity low enough for spray delivery27. When the tool and chip touch, the nanoparticles make a hybrid tribo-film of metal oxides and oil-derived species. This film acts as a sacrificial, low-shear layer, stops adhesion and built-up edges, fills in surface valleys, and cuts down on wear. These particles also smooth out rough spots by polishing or rolling them lightly. This lowers the cutting forces and temperature while improving the surface finish and tool life28. The combination of RBO’s chemisorbed molecules and the nanoparticles layer creates a long-lasting interfacial film that can withstand shear and oxidation. This changes wear mechanism from harsh adhesive or abrasive modes to milder tribo-chemical mechanism29.

Cu-nanoparticles can greatly improve heat transfer, lower the temperature in the cutting zone, reduce tool wear, and improve the finish of the surface during machining30. Thus, this study focuses on the development of a sustainable and high-performance cutting fluid based on rice bran oil (RBO) reinforced with highly conductive and lubricative copper (Cu) nanoparticles. While several studies have reported the use of Cu nanoparticles in combination with other vegetable oils, their interaction with rice bran oil remains largely unexplored. There is not much research on the thermophysical properties of RBO-reinforced Cu nanoparticles. There is also no research on how the rheology of RBO–Cu nanofluids with volume fraction of nanoparticles affects tribological performance. This study aims to enhance the thermophysical properties of rice bran oil by incorporating Cu nanoparticles and to create an environmentally friendly alternative to regular lubricants that work just as well or better in terms of cooling, lubrication, and tribological behavior when machining is difficult.

Materials and methods

Formulation of nano-cutting fluid

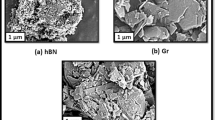

The method for making nanofluid from rice bran oil (RBO) and copper nanoparticles (Cu NPs) involves heating, chemical, and mechanical dispersion steps in that order to make sure that the suspensions are stable and homogeneous and have better thermophysical and tribological performance. To get rid of moisture and light volatiles that have stuck to the surface of Cu nanoparticles (see Fig. 1), they are heated to 80–90 °C. To make the dried particles more compatible with oil and less likely to clump together, they are stirred with a small amount of solvent (RBO, which itself contains oleic acid as a surface modifier/surfactant) for 30 min at 800 rpm. The coated nanoparticles (0.1–0.5 Vol.%) are then mixed into refined RBO using a probe sonication method that uses pulsed sonication (2 s ON/2 s OFF) at a frequency of 20 kHz for a total of 30 min of ON time. Ice bath is maintained on the sample to ensure it does not disintegrate due to heat. High-intensity cavitation is employed to disaggregate clusters into primary or near prime particles in this step. A further procedure, which involves sonication in an ultrasonic bath (30 min at room temperature), removes any remaining microbubbles in the dispersion and further increases the stability of the dispersion. Lastly, the ready nano fluid is transferred into amber glass bottles with minimal headspaces and stored in the dark room temperature in order to preserve the quality of the dispersion. Every step in the procedure is highly significant: Thermal drying prevents oxidation by moisture, coating the nanoparticles with oleic acids facilitates their wetting and dispersal in nonpolar media, probe sonication provides the nanoparticles with the appropriate degree of shear needed to deagglomerate, and gentle bath sonication ensures that the nanoparticles are not broken. Figure 2 shows a detailed schematic diagram for making nanofluid.

Characterization and measurement of nanofluid’s properties

Nanoparticle Tracking Analyzer (NTA, NanoSight 300) was used to look at nanoparticle agglomeration, which is a sign of the nanofluid’s physical stability. Fourier Transform Infrared Spectroscopy (FTIR, Nicolet IS-50) was used to check chemical stability. A thermal conductivity tester (DTC-300) was used to measure thermal conductivity, and a rheometer (ARES-G2) was used to measure viscosity.

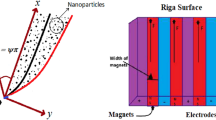

Tribological testing

To determine the coefficient of friction, a series of reciprocating tribological tests was conducted using a Rtec multipurpose tribometer (see Fig. 3a). For the tribological pair, a polished flat disc of alloy 925 and a tungsten carbide ball were used. To maintain a total sliding distance of 100 m, as specified in the ASTM G133 standard, a 21-min testing duration was performed at a frequency of 20 Hz and a stroke length of 2 mm, using a 25 N load. A schematic diagram for tribological reciprocating testing is shown in Fig. 3b.

Results and discussion

Physical stability

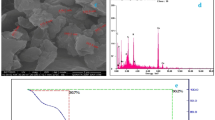

Figure 4 shows the average size distribution of the nanofluids’ hydrodynamic particles, which contain 0.1–0.5 vol% Cu nanoparticles. For concentrations of 0.1, 0.2, 0.3, 0.4, and 0.5 vol%, the average particle sizes were 86.52 nm, 121.93 nm, 147.10 nm, 154.36 nm, and 162.85 nm, respectively. The results show a clear pattern: as the concentration of nanoparticles goes up, the size of the particles goes up as well. This is because of more particles interacting with each other and clumping together when the volume concentration is higher31. At 0.1 vol%, the average particle size was about the same as the manufacturer’s reported primary particle size (80 nm). This means that there was not much agglomeration and the dispersion was stable. However, as the concentration rose above 0.2 vol%, there was a slow rise in particle size, which meant that agglomeration was starting because van der Waals attractive forces were stronger than steric or electrostatic repulsive forces.

The average particle sizes remained below 200 nm despite the higher concentrations (0.4–0.5 vol%), indicating that the nanofluid maintained good colloidal stability. This is due to effective pre-treatment32 and dispersion techniques24 that prevented the formation of complex agglomerates, such as heating nanoparticles, magnetic stirring, and simultaneously using a bath sonicator and a probe. The NTA results show that the Cu nanofluids we made are physically stable overall, with only a small increase in particle size across the range of concentrations we tested. This kind of stability makes sure that the thermophysical and tribological properties stay the same during machining.

Chemical stability

The spectra of Fourier Transform Infrared Spectroscopy (FTIR) for base fluid and nanofluids is shown in Fig. 5. The absorption bands in the spectra of base fluid (RBO) and RBO-based Cu nanofluids are very similar. This shows that the basic chemical structure of the base fluid stayed the same after the nanoparticles were added. The strong peaks between 2920 and 2850 cm−1 are due to C–H stretching vibrations of the –CH2 and –CH3 groups. The band near 1740 cm−1 is due to the C = O stretching vibration of triglyceride esters, which are a major part of RBO. Also, the absorptions between 1450 and 1370 cm−1 are C–H bending vibrations, and the peaks between 1200 and 1000 cm−1 are C–O–C stretching of ester linkages.

The spectra of Cu nanofluids do not have any extra peaks or big peak shifts compared to pure RBO. Therefore, nothing altered or reacted during the nanofluid’s formation. Light reflecting off the scattered nanoparticles is what causes minor changes in peak intensity at higher nanoparticle concentrations33. FTIR analysis, which demonstrates that the addition of Cu nanoparticles has no effect on the chemical structure of RBO, supports this. In other words, these nanofluids continue to be chemically stable. It is important to ensure that the thermophysical properties of the base fluid do not alter during storage or machining.

Thermal conductivity

Figure 6 shows the results of testing Cu nanofluids made from rice bran oil for thermal conductivity at 30 °C. As more Cu nanoparticles were added, thermal conductivity kept rising. Pure rice bran oil had the lowest value, and the sample with the most copper had the biggest jump. At comparatively low concentrations (0.2% or less), thermal conductivity increased in a nearly straight line. This suggests that the nanoparticles stayed scattered and did not clump much. The growth curve started to slightly bend after that range, indicating even better heat transfer as the particles interacted more. A similar result with increase of volume fraction of nanoparticles was reported by Manikanta et al.20. In essence, the numbers rise as more copper, phonon, and electron transport are absorbed. The primary cause of this increase is copper’s inherent 400 W/m–K heat conductivity. The oil becomes a better heat highway as a result. Additionally, the continuous motion of these minuscule particles causes micro-level disturbances that accelerate the movement of heat. However, if it continues to add more, the oil thickens, and the nanoparticles begin to group together. The gains slow down because it is more difficult for heat to spread. As a result, adding Cu nanoparticles to rice bran oil greatly increases its thermal conductivity. Because of this, these nanofluids are an excellent choice for advanced heat handling techniques such as minimum quantity lubrication (MQL) machining.

Viscosity

Figure 7 clearly shows that increasing the number of nanoparticles in rice bran oil–based Cu nanofluid results in higher viscosity. That matters a lot in machining because viscosity tells you how well a cutting fluid can cool and lubricate. When nanoparticles are added, the increase in viscosity allows the fluid to support greater weight and creates a stronger film between the tool and the chip, as well as between the tool and the workpiece34. That is a good thing, it keeps the lubricating film stable, cuts down on direct metal-to-metal contact, and helps reduce friction and adhesive wear while cutting. The entire structure is made denser by stronger interactions between the particles and the fluid, as well as between the particles themselves. The scattered Cu nanoparticles roll around, reduce friction, and improve the oil’s ability to dissipate heat, much like tiny ball bearings. Temperatures drop when you create a cutting zone that loses heat more quickly, improving the surface finish. In conclusion, the viscosity of rice bran oil is considerably changed by the addition of copper nanoparticles. This finding is consistent with what is commonly seen in metallic nanofluids: shear-thickening happens as additional particles are added.

Integrated consideration of nano fluid properties

The coolants that include nanoparticles and contain nanoparticles are known as nanofluids, and researchers have strived to enhance the heat transfer characteristics of the nanofluids. The problem is that it is not sufficient to enhance their heat conductivity. The whole scenario should be considered since the addition of nanoparticles not only influences thermal conductivity. It changes the viscosity, stability, and even the capacity of the fluid to lubricate surfaces. These adverse effects are enormous. They affect the ability of the fluid to conduct heat and the energy cost to conduct the heat. In order to make nanofluids functional and yet not expensive, there is a necessity to balance between enhancing heat transfer and retaining fluid viscosity that is not difficult to pump. Here, the ratio of relative thermal conductivity (\(k_{r}\)) to relative viscosity (\(\mu_{r}\)) is very important. The ratio is what is used to evaluate the overall performance of a nanofluid. It tracks how this \({\raise0.7ex\hbox{${k_{r} }$} \!\mathord{\left/ {\vphantom {{k_{r} } {\mu_{r} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${\mu_{r} }$}}\) ratio changes (see Fig. 8) as more nanoparticles are added. The ratio continues to rise as the concentration increases, indicating improved heat transfer compared to the rise in viscosity. In other words, efficiency climbs. Focusing on \({\raise0.7ex\hbox{${k_{r} }$} \!\mathord{\left/ {\vphantom {{k_{r} } {\mu_{r} }}}\right.\kern-0pt} \!\lower0.7ex\hbox{${\mu_{r} }$}}\) provides a straightforward method for measuring performance, considering both the enhanced heat transfer and the increased flow resistance. The findings clearly indicate an optimal quantity of nanoparticles that enhance thermal conductivity without making the fluid excessively difficult to pump.

Tribological performance of formulated sustainable cutting fluid

Figure 9 shows how the coefficient of friction (COF) of Cu nanofluids based on rice bran oil changes with different nanoparticle volume fractions. As the concentration of nanoparticles increased, the coefficient of friction clearly went down. The base fluid, which was pure rice bran oil, had the highest COF of 0.1626. This means that the sliding surfaces had more frictional resistance. When Cu nanoparticles were added, the COF went down by a lot—about 10.95%, 22.39%, 32.35%, 39.73%, and 48.95% at 0.1%, 0.2%, 0.3%, 0.4%, and 0.5% volume fractions, respectively, compared to the base oil.

Nano fluids are functional in tribology due to several reasons that are interrelated. Much like micro-mechanics, they make things smoother and friction-reducing by rolling and smoothing rough surfaces to prevent the grinding of rough surfaces against other rough surfaces28. They also eliminate wear and ensure the stability of the system even as it slides past to form a thin layer of protection at points of convergence of surfaces. Also, these nanofluids ensure that the lubricating layer does not settle and prevent overheating of the surface by better spreading the heat out of the point of contact. Overall, the addition of Cu nanoparticles to rice bran oil enhances its wear and friction reduction properties significantly. The rice bran oil-based nano fluids that have been produced in the form of nano fluids are indeed very promising in being environmentally friendly lubricants in heavy-duty and long-lasting uses.

Lubrication mechanisms and anticipated machining performance of rice bran oil–based Cu nanofluid

The coefficient of friction is significantly decreased with the addition of Cu nanoparticles to the rice bran oil-based nanofluid. This is improved in the form of lubrication and anti-wear performance. These adjustments are especially important to machining operations such as drilling, turning, and milling, where heat and friction between the tool and the workpiece may have a significant impact on the quality of the surface and the life of tools. A well-established lubrication mechanism for different mediums has been shown in Fig. 10. In the absence of any lubricant (dry condition), direct contact occurs between the micron-scale surface asperities (Fig. 10a), leading to severe rubbing and consequently high friction. When a lubricating medium such as oil is introduced, a thin film formed by hydrocarbon chains develops between the contacting surfaces (Fig. 10b). This film partially separates the surfaces, thereby reducing direct asperity contact and lowering the coefficient of friction. With the use of a nanofluid, the lubrication mechanism is further enhanced. Dispersed nanoparticles facilitate relative motion by inducing a micro-rolling or ball-bearing effect between the contacting surfaces (Fig. 10c). Moreover, the nanoparticles penetrate and fill surface cavities, forming an additional protective tribo-layer in conjunction with the hydrocarbon film. This synergistic effect significantly minimizes surface interaction and results in a substantial reduction in the coefficient of friction between the contacting surfaces30.

The copper nanoparticles assist in the generation of a thin lubricating coating that is durable in the area of contact. This decreases the loss of energy as friction generates heat since one can stick less between the tool and the workpiece. This makes cutting less difficult, and the tool will undergo less wear and tear35. Cu nanoparticles are more effective in heat removal from the cutting area due to the high thermal conductivity of the particles. This helps to keep the tool-chip interface hidden and cold to ensure that the tool does not become soft or wear off prematurely. Temperature control has another benefit, which is the maintenance of the part size and surface characteristics36.

The Cu nanoparticles are easy to disperse in the oil, enabling the tool and the workpiece to pass on to each other easily. This reduces the abrasion and adhesive effects of materials. The protective layer of particles of Cu acts as a solid lubricant, thus preventing the metals from coming in contact with each other30. Furthermore, built-up edge (BUE), a common problem that affects tool shape and surface finish during prolonged machining runs, is prevented by this film. Tools move more smoothly, and ploughing has less impact on the workpiece surface due to the reduced coefficient of friction. Therefore, the surface roughness (Ra) of the machined part should significantly decrease. Improved lubrication ensures smooth chip flow, reduced tool vibration, and a more uniform cutting zone, all of which contribute to improved surface quality23. Rice bran oil-based Cu nanofluids not only work better, but they are also a biodegradable and non-toxic alternative to regular cutting fluids that are made from petroleum. Their better tribological and thermal properties can help reduce the amount of fluid used, making them an eco-friendly choice for modern machining industries that want to go green12,31.

Conclusion

The proposed research was able to demonstrate the development and evaluation of a high-performance, sustainable, and high-performance cutter of a rice bran oil (RBO)-based cutter dispersed in copper nanoparticles (Cu-NPs). The study has shown that the addition of Cu nanoparticles to RBO significantly enhances its thermophysical and tribological characteristics, making it an appropriate and easy-to-use, eco-friendly lubricant alternative to conventional mineral-oil-based lubricants. Based on the tests, the analysis revealed that Cu nanoparticles were uniformly dispersed in the base oil and did not alter its chemical structure. Consequently, it causes the suspension to remain stable over a long period. The thermal conductivity of the nanofluid also increases exponentially with an increase in the number of nanoparticles. This is attributed to the increased micro-convection due to the Brownian motion, as well as the ability of the copper particles to create more effective channels of heat transfer. It enhances the tool-chip interface, strengthening its capacity to bear load, and is beneficial in lubrication and minimizing wear, despite a slight rise in viscosity. The performance ratio (k/m) ensures that it is evident that the higher the viscosity, the more effective the transfer of heat. The cooperation between the RBO polar molecules that occur naturally and the Cu nanoparticles regarding the creation of this stable tribo-film derives. Such a combination maintains lower temperatures and decreases wear and friction. In general, Cu-RBO nanofluid is superior to conventional cutting fluids. It freezes faster, oils more efficiently, and is more eco-friendly, all of which align with the green manufacturing and the circular economy. The findings indicate that reinforced bran oil nanofluids made of Cu can drastically transform sustainable machining and precision. This has ensured that the biodegradable nanofluid lubricants can be applied in the industry in the future.

Data availability

Most of the data is included in this manuscript itself and other required data will be provided by corresponding author (Walle Tilahun) based on authorized request and need.

References

Wang, X. et al. Tribology of enhanced turning using biolubricants: A comparative assessment. Tribol. Int. https://doi.org/10.1016/j.triboint.2022.107766 (2022).

Liu, D. et al. Kinematics and improved surface roughness model in milling. Int. J. Adv. Manuf. Technol. 131, 2087–2108 (2024).

Duan, Z. et al. Mechanical behavior and semiempirical force model of aerospace aluminum alloy milling using nano biological lubricant. Front. Mech. Eng. 18, 4 (2023).

Pal, A., Chatha, S. S. & Sidhu, H. S. Performance evaluation of the minimum quantity lubrication with Al2O3- mixed vegetable-oil-based cutting fluid in drilling of AISI 321 stainless steel. J. Manuf. Process. 66, 238–249 (2021).

Cui, X. et al. Comparative assessment of force, temperature, and wheel wear in sustainable grinding aerospace alloy using biolubricant. Front. Mech. Eng. https://doi.org/10.1007/s11465-022-0719-x (2023).

Liu, M. et al. Analysis of grain tribology and improved grinding temperature model based on discrete heat source. Tribol. Int. 180, 108196 (2023).

Jia, D. et al. Lubrication-enhanced mechanisms of titanium alloy grinding using lecithin biolubricant. Tribol. Int. 169, 107461 (2022).

Xu, W. et al. Electrostatic atomization minimum quantity lubrication machining: From mechanism to application. Int. J. Extreme Manufact. https://doi.org/10.1088/2631-7990/ac9652 (2022).

Manikanta, J. E., Khalad, A., Santosh, S., Gurajala, N. K. & Prasad, C. Employing artificial neural networks and grey-based taguchi approach for optimization of sustainable turning of SS304 alloy. Int. J. Interact. Design Manufact. https://doi.org/10.1007/s12008-025-02344-0 (2025).

Manikanta, J. E., Raju, B. N., Prasad, C. & Sankar, B. S. S. P. Machining performance on SS304 using nontoxic, biodegradable vegetable-based cutting fluids. Chem. Data Collect. 42, 100961 (2022).

Yuan, S., Hou, X., Wang, L. & Chen, B. Experimental investigation on the compatibility of nanoparticles with vegetable oils for nanofluid minimum quantity lubrication machining. Tribol. Lett. 66, 106 (2018).

Sen, B., Mia, M., Krolczyk, G. M., Mandal, U. K. & Mondal, S. P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precision Eng. Manufact. - Green Technol. https://doi.org/10.1007/s40684-019-00158-6 (2021).

Manikanta, J. E., Abdullah, M., Ambhore, N. & Kotteda, T. K. Analysis of machining performance in turning with trihybrid nanofluids and minimum quantity lubrication. Sci. Rep. 15, 12194 (2025).

Khanna, N., Shah, P., de Lacalle, L. N. L., Rodríguez, A. & Pereira, O. In pursuit of sustainable cutting fluid strategy for machining Ti-6Al-4V using life cycle analysis. Sustain. Mater. Technol. 29, e00301 (2021).

Rasep, Z., Muhammad Yazid, M. N. A. W. & Samion, S. Lubrication of textured journal bearing by using vegetable oil: A review of approaches, challenges, and opportunities. Renew. Sustain. Energy Rev. https://doi.org/10.1016/j.rser.2021.111191 (2021).

Wu, X. et al. Circulating purification of cutting fluid: An overview. Int. J. Adv. Manufact. Technol. 117(9), 2565–2600 (2021).

Tang, L. et al. Biological stability of water-based cutting fluids: Progress and application. Chinese J. Mech. Eng. (English Edition) https://doi.org/10.1186/s10033-021-00667-z (2022).

Luo, X. et al. Sustainable development of cutting fluids: The comprehensive review of vegetable oil. J. Clean. Prod. 473, 143544 (2024).

Wang, W. et al. Formulation, characterization, mechanism, and application of vegetable oil-based nano-cutting fluids. Int. J. Adv. Manuf. Technol. 136, 909–923 (2025).

Manikanta, J. E., Ambhore, N., Nikhare, C., Gurajala, N. K. & Ch, H. K. Sustainable machining: enhancing performance with vegetable oil-based nano cutting fluids. Discov. Mater. 5, 1–11 (2025).

Edla, S. et al. Formulation of rice bran oil-based green cutting fluid with holy basil oil and clove oil as bio-additives. Biomass Convers. Biorefin. 13, 16877–16886 (2023).

Rahmania, H. et al. Revealing the thermal oxidation stability and its mechanism of rice bran oil. Sci. Rep. 10, 14091 (2020).

Yadav, S. K., Ghosh, S. & Sivanandam, A. Surfactant free enhancement to thermophysical and tribological performance of bio-degradable lubricant with nano-friction modifier for sustainable end milling of Incoloy 925. J. Clean. Prod. 428, 139456 (2023).

Manikanta, J. E., Nikhare, C., Gurajala, N. K., Ambhore, N. & Mohan, R. R. A review on hybrid nanofluids: Preparation methods, thermo physical properties and applications. Iranian J. Sci. Technol. Trans. Mech. Eng. 49, 67–79. https://doi.org/10.1007/s40997-024-00772-z (2025).

Lyu, Z., Asadi, A., Alarifi, I. M., Ali, V. & Foong, L. K. Thermal and fluid dynamics performance of MWCNT-water nanofluid based on thermophysical properties: An experimental and theoretical study. Sci. Rep. 10, 5185 (2020).

Anandan, V., Naresh Babu, M., Vetrivel Sezhian, M., Yildirim, C. V. & Dinesh Babu, M. Influence of graphene nanofluid on various environmental factors during turning of M42 steel. J. Manuf. Process. 68, 90–103 (2021).

Dennison, M. S., Jebabalan, S. K. & Barik, D. Applicability of nano-cutting fluids for enhanced cooling, low tool wear, and high tribological performance during machining: A review. Discover Appl. Sci. https://doi.org/10.1007/s42452-024-06398-9 (2024).

Ross, N. S., Mashinini, P. M., Rai, R. & Gupta, M. K. Carbon nano dots mixed rice bran oil as a cutting fluid for enhanced lubrication/cooling in milling of additively manufactured 316 stainless steel. J. Mol. Liq. 391, 123200 (2023).

Li, Y.-S., Bhuiyan, F. H., Lee, J., Martini, A. & Kim, S. H. Elucidating tribochemical reaction mechanisms: insights into tribofilm formation from hydrocarbon adsorbates coupled with tribochemical substrate wear. RSC Mechanochemistry 1, 328–341 (2024).

Yadav, S. K., Ghosh, S. & Sivanandam, A. Investigating the wear mechanism of TiAlN/TiN PVD-coated WC inserts in end milling of incoloy 925 under synergy of bio-degradable fatty acids and nano-metallic solid lubricant. J. Tribol. 146, 084201 (2024).

Yadav, S. K., Ghosh, S. & Sivanandam, A. Application of a potential novel hybrid nano-lubricant by simultaneous dispersion of ceramic and metallic NPs in plant oil for eco-benign end milling of Incoloy 925. Int. J. Adv. Manuf. Technol. 139, 399–429 (2025).

Duan, Z. et al. Tribological and micro-milling performance of surfactant-free microwave plasma-modified Al2O3 nanoparticles biodegradable lubricants. J. Clean. Prod. 493, 144969 (2025).

Sikdar, S., Rahman, M. H. & Menezes, P. L. Synergistic study of solid lubricant nano-additives incorporated in canola oil for enhancing energy efficiency and sustainability. Sustainability 14, 290 (2022).

Tiwari, S., Amarnath, M. & Gupta, M. K. Synthesis, characterization, and application of Al2O3/coconut oil-based nanofluids in sustainable machining of AISI 1040 steel. J. Mol. Liq. 386, 122465 (2023).

Duan, Z. et al. Tool wear in enhanced minimum quantity lubrication assisted milling: from mechanism to application. Chinese J. Aeronautics 103597 (2025) https://doi.org/10.1016/j.cja.2025.103597.

Singh, R. & Sharma, V. Machining induced surface integrity behavior of nickel-based superalloy: Effect of lubricating environments. J. Mater. Process. Technol. 307, 117701 (2022).

Acknowledgements

The authors extend their gratitude to the Department of Mechanical Engineering and Central Research Facility (CRF) of IIT Delhi, for providing experimental and characterization facilities.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Shravan Kumar Yadav: Conceptualization, methodology, analysis, investigation, writing- original draft, and discussion; K. Rajesh Kannan: writing-review and editing; Walle Tilahun: introduction, conclusion, and references.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Yadav, S.K., Kannan, K.R. & Tilahun, W. Development of a sustainable Cu-nano-cutting fluid based on rice bran oil for superior heat management and wear reduction. Sci Rep 16, 7248 (2026). https://doi.org/10.1038/s41598-026-38520-9

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s41598-026-38520-9