Abstract

Understanding how solar PV installations affect the landscape and its critical resources is crucial to achieve sustainable net-zero energy production. To enhance this understanding, we investigate the consequences of converting agricultural fields to solar photovoltaic installations, which we refer to as ‘agrisolar’ co-location. We present a food, energy, water and economic impact analysis of agricultural output offset by agrisolar co-location for 925 arrays (2.53 GWp covering 3,930 ha) spanning the California Central Valley. We find that agrisolar co-location displaces food production but increases economic security and water sustainability for farmers. Given the unprecedented pace of solar PV expansion globally, these results highlight the need for a deeper understanding of the multifaceted outcomes of agricultural and solar PV co-location decisions.

Similar content being viewed by others

Main

Climate change threatens our finite food, energy and water (FEW) resources. To address these threats by transitioning towards net-zero carbon emissions energy systems, new energy installations should be designed while considering effects on the complete FEW nexus. The rapid expansion of solar photovoltaic (PV) electricity generation is a key part of the solution that will need to grow more than tenfold in the United States (US) by 2050 to meet net-zero goals1. However, solar PV expansion presents threats to agricultural production due to its land-use intensity and potential in croplands2. A considerable portion of ground-mounted solar PV facilities in the US are installed in agricultural settings3,4,5. Yet regions with high solar breakthrough, such as the California Central Valley (CCV), are often among the most valuable and productive agricultural land in the US3,5,6. It is not yet clear how the current solar PV landscape affects agricultural security, much less under 2050 net-zero expansion. Here we quantify both the agricultural offsets of solar PV land-use change and the decision-making processes behind these transitions for existing solar PV arrays in agriculture.

Competition between solar PV and agricultural land uses has led to various co-location methods where installations are sited, designed and managed to optimize landscape productivity across a wide range of ecological and anthropogenic services7. This approach differs from conventional solar PV deployment, which is often installed and managed primarily for electricity output and reduced maintenance7. Emerging concepts such as techno-ecological synergies (TES)8 and more recently, ecovoltaics7, encompass a wide range of co-location strategies enabling renewable energy installations to serve multiple productive ecosystem services. Agricultural production and solar PV can be laterally integrated (agrisolar co-location)9 or directly share land and photons via vertical integration (agrivoltaic co-location)10,11.

Agrivoltaic co-location involves the direct integration of solar and agriculture (crops or grazing) or ecosystem services (pollinator habitat, native vegetation) within the boundaries of solar infrastructure11. The earliest technical standardization, originating from Germany, specifies that this can occur under or between system rows, but not adjacent to, while agricultural yield losses are reduced to less than one-third of reference (without solar PV) yields10. Effective agrivoltaic management can improve agricultural yield, microclimate regulation, soil moisture retention, nutrient cycling and farmer profitability, while enhancing public acceptance12,13,14,15. Thus, agrivoltaic co-location can address the agricultural competition concerns created by solar PV expansion.

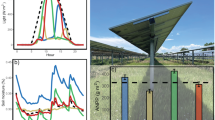

The term agrisolar is more broadly defined (modified from SolarPower Europe9), as the integration and co-management of solar photovoltaics, agriculture and ecosystem services within agroenergy landscapes, explicitly considering the trade-offs and co-benefits of agricultural, environmental and socio-economic objectives. Thus defined, agrisolar practices align with TES and ecovoltaic principles and encompass both coincident (‘agrivoltaic co-location’) and adjacent co-location where agricultural land is replaced (hereafter ‘agrisolar co-location’)11,16. However, replacing agricultural land with solar PV (‘adjacent agrisolar’) without implementing agrivoltaic management has historically been considered conventional solar and thus excluded from co-location research because agricultural production is ceased on site10. There is some evidence, however, that converting portions of agricultural fields to solar PV in water-stressed regions can also provide water and economic benefits that enhance agricultural security despite food production losses17,18. Adjacent agrisolar replacement appears to be the dominant practice, with recent work showing that there have been relatively few documented agrivoltaic installations compared to total solar PV deployment in agriculture in the CCV5,19. Because agrisolar practices are understudied relative to literature on other forms of co-location14,20, there is a need to assess regional resource outcomes for most existing solar PV installations and consequences for lost food production without agrivoltaic management. Conceptual examples of solar PV co-location are shown in Fig. 1.

Farms practicing adjacent agrisolar co-location exchange food production for enhanced energy, water and economic resource security (left). Agrivoltaic and ecovoltaic co-location provide additional benefits (non-exhaustive) to food, ecology, soil health and community acceptance (right). Credit: B. McGill under a Creative Commons license CC BY-NC-ND 4.0.

We argue that by enhancing water, energy and economic security, transitioning farm fields to solar PV installations can be considered adjacent agrisolar management in water-stressed regions. Here security is the capacity of a farmer to maintain or improve their financial well-being, operational resilience and access to essential resources, such as water and energy, while preserving the integrity and future of their agricultural practices. We assess the FEW security effects of these agrisolar PV installations across the CCV through 2018 and estimate the economic potential of those arrays throughout a 25-year operational-phase lifespan. We compute landowner cash flow including net energy metering (NEM) for commercial-scale PV installations and land leases for larger utility-scale arrays. All resource and economic effects are referenced to a counterfactual business-as-usual scenario with no solar PV installation, assuming continued agricultural production and operation on the same plot of land. The purpose of this analysis is to evaluate the lifespan FEW and economic impacts of existing agrisolar arrays in the CCV. Rather than projecting future installations or policies, we report on the existing agrisolar placement, design and policy practices to inform future practices on a per-hectare basis, tailored to regional needs. We also highlight the need for, and opportunities within, additional research into agrisolar practices.

Results

Commercial- and utility-scale agrisolar arrays in CCV

We assembled a comprehensive dataset of agriculturally co-located solar PV installations within the CCV through 2018. We identified 925 solar PV arrays installed between 2008 and 2018, with an estimated capacity of 2,524 MWp on 3,930 ha of recently converted agricultural land. The estimated array capacity of each individual array ranged from 19 kWp to 97 MWp. A temporal synthesis of the input solar PV dataset, separated by array scale, is shown in Fig. 2b,c. The smaller commercial-scale arrays are roughly twice as common, yet account for one-tenth of the installed capacity and converted land area of utility-scale arrays. Note that commercial-scale arrays are predominantly fixed axis, whereas utility-scale arrays are more frequently single-axis tracking systems. There are also notable peaks in the number of installations for both array scales in 2016, potentially in response to the NEM 2.0 legislation timeline21. While there is some spatial clustering of converted crop types (Fig. 2a), converted crops were widely distributed across the CCV.

a, Map of displaced crop groups within the CCV alluvial boundary. b,c, The array installation number, capacity, area and mount type (fixed-axis or single-axis tracking) by year for the 925 utility- (b) and commercial-scale (c) arrays assessed. Maps in a generated with Uber H3108 with CCV alluvial boundary data from the US Geological Survey59 and contiguous US shapefiles from the US Census Bureau109.

Offset food and nutritional production

The 925 agriculturally co-located arrays displaced 3,930 ha of cropland, which is ~0.10% of the CCV active agricultural land22. In the baseline scenario (Methods provide scenario details), nutritional loss was 0.16 trillion kcal (Tkcal) and 1.41 Tkcal foregone by commercial- and utility-scale arrays, respectively (Fig. 3). The total, 1.57 Tkcal, is equivalent to the caloric intake of ~86,000 people for 25 years (solar lifespan), assuming a 2,000 kcal d–1 diet. The nutritional footprint of commercial-scale arrays (−21.2 million kcal (Mkcal) ha–1 yr–1) was greater than utility-scale arrays (−15.6 Mkcal ha–1 yr–1) and the total impact was primarily composed of grain (58%), orchard crops (21%) and vegetables (10%). Utility-scale arrays displaced the nutritional value of grain (60%) hay/pasture (16%) and vegetables (10%). Note that for displaced kcal production of hay/pasture, contribution was negligible despite dominating the converted area due to inefficient caloric conversion to human nutrition for feed and silage crops. Resource footprint, total lifespan impact and crop contribution is shown in Fig. 3. Cumulative resource impacts across the region through time are available in Supplementary Fig. 1.

Scientific metric prefixes are thousands (k), millions (M), billions (G) and trillions (T). Footprints are area-weighted average values for the baseline scenario across commercial- (Comm) and utility-scale (Utility) agrisolar installations. Total impacts show the baseline scenario with worst- and best-case scenarios in parentheses, except for land area, which shows the Ong et al.110 and fire code buffer area bias estimates, respectively (Supplementary Discussion). Energy and water resources are the sum of total impacts (‘Energy’ is electricity produced and irrigation electricity offset, ‘Water’ is irrigation water use offset and O&M water use). Crop contribution is ordered by decreasing impact. Vegetables were omitted from the utility-scale economic crop contribution because their total impact was negative (6.98% of the absolute utility-scale economic budget), that is, replacing vegetable fields with utility-scale arrays reduced farm income. Artwork credit: B. McGill under a Creative Commons license CC BY-NC-ND 4.0.

Electricity production and consumption

We modelled the annual electricity generation for each array and offset irrigation electricity demand. Total cumulative electricity generation for these identified arrays by 2042 was projected to be 10 TWh for commercial-scale arrays and 113 TWh for utility-scale arrays. The potential electricity saved by not irrigating converted land was 11 GWh and 146 GWh for commercial- and utility-scale arrays, respectively. Note that this was three orders of magnitude less than the total electricity generation. For reference, the total lifespan impact of electricity production and potential irrigation electricity offset ( ~ 124 TWh) could power ~466,000 US households for 25 years (assuming 10.6 MWh yr–1 per household).

Changes in water use

Most (74%) agriculturally co-located arrays in the CCV replaced irrigated croplands. On the basis of the business-as-usual change in total water-use budget (considering irrigation water-use offset and operation and maintenance—O&M water use), we estimate that agrisolar co-location in the region would reduce water use by 5.46 thousand m3 ha–1 yr–1 (total: 42.1 million m3) and 6.02 thousand m3 ha–1 yr–1 (total: 544 million m3) over the 25-year period for commercial- and utility-scale arrays, respectively. This could supply ~27 million people with drinking water (assuming 2.4 liters per person per day) or irrigate 3,000 hectares of orchards for 25 years. O&M water use on previously irrigated land was ~eight times less than irrigated crops—if offset irrigation water were conserved rather than redistributed. Irrigated crops that contributed the most to the offset irrigation water use were orchards (29%), hay/pasture (28%) and grain (27%) for commercial-scale installations and grain (37%), hay/pasture 31%), cotton (15%) for utility-scale installations.

Agricultural landowner cash flow

Adjacent agrisolar co-location is more profitable than the baseline agriculture-only scenario, regardless of how landowners are compensated (Fig. 4). For commercial-scale arrays, agrisolar landowners experience early losses from installation expenditure (−US$53,000 ha–1 yr–1). However, the lifespan cash flow was dominated by NEM, offset electricity costs and surplus generation sold back to the grid, resulting in a net positive economic footprint of US$124,000 ha–1 yr–1, 25 times greater returns than lost food revenue (−US$4,920 ha–1 yr–1). The resulting economic payback period was 5.2 years (best- and worst-case payback in 2.9 and 8.9 years respectively; Supplementary Fig. 2).

a,b, The discounted cash flow footprint for commercial- (n = 572; a) and utility-scale (n = 353; b) agrisolar in thousand US$ ha–1 yr–1. Data are represented as the baseline area-weighted mean footprint, with vertical lines used to illustrate the range between best- and worst-case scenarios. Discounted cash flows are broken into revenues (blue), expenditures (Exp.) (orange) and net profits (green). Variable explanation in equations (9) and (10) in ‘Discounted cash flow for agrisolar co-location’.

The net economic footprint for utility-scale agrisolar landowners (US$2,690 ha–1 yr–1) was 46 times less than the commercial-scale footprint (Fig. 4b). In contrast to commercial-scale arrays, utility-scale agrisolar landowners were not responsible for installation or O&M costs but still lost food revenue (−US$3,330 ha–1 yr–1) and were only compensated by land lease (US$1,940 ha–1 yr–1) and offset operational (US$3,830 ha–1 yr–1) and irrigation water-use costs (US$220 ha–1 yr–1). In the worst-case scenario, the total budget was negative (−US$432 ha–1 yr–1), suggesting that some landowners could lose revenue. There was no payback period for utility-scale agrisolar landowners because the net economic budget was always positive (baseline and best-case scenario) or always negative (worst-case scenario). Cumulative economic impacts across the region in Supplementary Fig. 3.

On average, estimated foregone farm operation costs exceeded forgone food revenue (Fig. 4). While this may be affected by reporting differences in agricultural revenue and farm operation cost sources, agricultural margins are known to be small, or negative, for certain croplands (for example, pastureland), with margins likely to decrease further under future climate change and water availability scenarios23. For commercial-scale installations, cutting farm operation costs in half (highly conservative) resulted in a longer economic payback period of just a month. Cutting offset farm operation costs in half for utility-scale installations did not affect economic payback or the always-positive baseline and best-case budget.

Discussion

The effect of agrisolar co-location on food production

We found that displacing agricultural land with solar PV locally reduced crop production ( ~ 1.57 Tkcal), which may affect county- and state-level food flows. Fortunately, on national and global scales, food production occurs within a market where reduced production in one location creates price signals that can stimulate production elsewhere. For example, high demand and increased irrigation pumping costs in the CCV have resulted in higher prices received for specialty orchard crops. Thus, farmers have elected to switch from cereal and grain crops to specialty crops24. Solar PV is also far more energy dense per unit of land than growing crops to produce biofuels18—a practice common across large swaths of agricultural farmland in the US and elsewhere. We show that conversion of feed, silage and biofuel croplands provides high irrigation water-use offsets while minimizing nutritional impacts due to the low or non-existent caloric conversion efficiencies of these crops (Fig. 3). Though, considering food waste and a lack of crop-specific nutritional-quality knowledge, we cannot evaluate end-point impacts of reported foregone kcal (calories) on human diets and health25.

California produces 99% of many of the nation’s specialty fruit and nut orchard crops (for example, almonds, walnuts, peaches, olives)26. Fields producing these crops were commonly converted to solar PV (270 ha of orchard crops), and it may be difficult to shift production of these crops to other locations due to their intensive water footprint, climate sensitivity and time to production27,28. Altering global supply of these crops could lead to food price increases similar to biofuel land-use changes29 with agricultural markets taking time to compensate30. We found that these nutritionally dense, valuable and operationally costly crops are more commonly replaced by commercial-scale rather than utility-scale installations, resulting in a higher nutritional footprint at the site scale (Fig. 3). However, due to their smaller arrays size (Fig. 2), these arrays have a lower regional lifespan nutritional impact. The total solar PV area we consider (the area covered by panels and space between them) does not account for total cropland transformation by all solar energy infrastructure. Thus, total cropland area converted and associated caloric losses may be underestimated by up to 25%. We conducted a sensitivity analysis on this potential area bias for all area-based metrics and discuss the details of this underestimate in Supplementary Discussion.

Global food needs are projected to double by 205031,32. To meet these needs, yield per unit area must increase, agricultural land area under production must increase and/or food waste and inefficiency must be reduced. Reducing waste is feasible but requires a considerable change in dietary preferences33 and supply chain pathways34. Yield increases alone are unlikely to meet these needs31 and half of global habitable land is already agricultural35. Cultivated lands are facing additional pressures due to soil quality deterioration, aridification, water availability, urban growth and threats to global biodiversity that will be exacerbated under a changing climate36,37,38,39. Given these pressures on arable land, cropland selection for future agrisolar co-location, both commercial- and utility-scale, should be assessed at local, regional, national and international scales to maintain food availability and security.

Water security potential with agrisolar co-location

Here we show that solar PV installations preferentially displace irrigated land in the CCV (3,310 ha and 74% of co-located installations). Displacing this irrigated cropland enhances farmer cash flow while probably reducing overall water use by 5.46 and 6.02 thousand m3 ha–1 yr–1 for commercial- and utility-scale arrays, respectively. The total displaced irrigation water use was eight times the O&M use for those arrays. Thus, installing solar PV in water-scarce regions has substantial potential to reduce water use, which bolsters findings from previous studies17,18,40,41. This analysis does not incorporate the additional hydrologic effects of modifying surface energy and water budgets, including reducing evapotranspiration and the potential for increased groundwater recharge42,43.

Given that the cash flow benefits from utility-scale agrisolar co-location are relatively small, we evaluated how water-use limitations may be a factor in farmland conversion decisions. We hypothesize that fallowing land is largely a consequence of water shortages in the CCV24,40, thus fallowing land proximal to an array (within 100 metres) may indicate an emergent agrisolar practice: intentional fallowing and irrigation water-use offset adjacent to arrays supported by revenue from the array. Each array was coded by the adjacent crop type before and post installation of the array. While we cannot know what landowners would have done with the array acreage absent the installation, this analysis provides evidence of broader land-use trends that might have been driving decisions. The transition of array acreage from before proximal post-installation land use for utility-scale arrays is displayed in Fig. 5.

Note several crop types are grouped for simplicity and thus have altered colouring compared to similar groups in other figures. Transitions with total array capacity of <10 MWp were omitted for clarity but are shown in Supplementary Table 1.

Understanding how economic incentives affect the replacement of valuable cropland with solar PV is essential to inform future energy landscape models and policies. Here we examined the transition to post-solar installation fallowing in adjacent irrigated cropland (Fig. 5). We observed fallowing of adjacent irrigated cropland at 58 utility-scale installations totalling 658 MWp and 968 ha (27% of utility-scale area) composed of 410 ha of grain, 250 ha of hay and pasture, 225 of orchards, grapes and vegetables and 82 ha of cotton and other crops. The direct area of these arrays (968 ha) can be linked to a potential irrigation water-use offset of 195 million m3 over 25 years. If these arrays were on-farm plots of average size, 14,000 ha of fallowed land adjacent to these 58 arrays could displace an additional 120 million m3 of irrigation water use, each year, or 3,000 million m3 over 25 years (Supplementary Methods). Thus, if landowners choose to fallow farmland adjacent to leased land for utility-scale arrays, the water-use reductions are greatly amplified. We discuss several important limitations44 of the Cropland Data Layer (CDL) regarding this analysis in Supplementary Discussion.

Intensely irrigated cropland in the CCV is vulnerable to drought, especially in southern basins that rely heavily on surface-water deliveries due to limited groundwater availability45. The California Budget Act of 2021 provides financial support for fallowing to motivate farmers to reduce water use46. Whereas fallowing land can help mitigate some hydrological problems, removing production can also result in large agricultural revenue losses47. Converting land with solar electricity production, rather than simply fallowing could reduce risks to farmers while enhancing financial security17, especially during periods of extreme drought40. Whereas this has implications for future installations, we show that farmers already appear to be practicing solar fallowing, probably resulting in long-term irrigation water-use reductions.

We acknowledge the potential issues in assuming that foregone irrigation water use due to solar PV installations was conserved rather than redistributed. However, a portion of this potential offset is probably real given three observations: (1) utility-scale installations correlate with newly fallowed land, which was not observed for commercial-scale arrays; (2) the 2014 Sustainable Groundwater Management Act (SGMA)48 requires water-use reductions by the 2040s and (3) agriculturally co-located solar PV maintains Williamston Act Status under the Solar-Use Easement49 (which has recently been revived50), a California tax incentive common in irrigated lands highly suitable for solar51. In our dataset, 46% of utility-scale installations and 58% of commercial-scale installations were completed after SGMA was enacted (Fig. 2b,c). We also performed a sensitivity analysis where only 50% of irrigation water-use offset was conserved rather than redistributed, which still resulted in an estimated US$9 million and 246 million m3 conserved due to the regional change in water use from just direct area converted (Supplementary Discussion).

Given this potential for water-use offset, solar fallowing for water-use reduction presents an opportunity for incentivized solutions that are already of interest to landowning farmers in the region17. With suitable solar area in the CCV exceeding projected fallowing acreage to comply with SGMA51, implementing agrisolar co-location policies and incentives such as these could promote complementary land uses and enhance public support15.

Achieving economic security across return structures

Regardless of scale and related financial benefits, farmers are switching away from cultivating crops to cultivating electricity. This study empirically demonstrates that both NEM and land-lease incentive structures have been viable frameworks for PV deployment in some of the most valuable cropland in the US6. Critically, we incorporate farm-specific agricultural dynamics across a region (offset farm operation costs, irrigation costs and food revenue) into economic considerations for replacing cropland with solar.

By including these revenues and costs, this study clearly demonstrates the strong economic incentives to replace cropland with commercial-scale arrays (Fig. 4a). Under the grandfathered NEM 1.0 and 2.0 agreements, commercial-scale agrisolar landowners enhanced financial security by 25 times lost food revenue over the lifetime of the array, while simultaneously reducing water use. The resulting total net revenue, US$124,000 ha–1 yr–1, is potentially underestimated because post-lifespan module replacement, resale or continued use is likely, and property values could increase (terminal value) compared to the reference scenario. We also have not considered several programmes, credits and incentives (for example, Rural Energy for America Program) that could enhance net revenue (Supplementary Discussion). However, these returns are not unlimited due to NEM capacity limitations (<1 MWp) and requirements to size the installation below annual on-farm load21.

Renewable energy policy evolves quickly, shifting incentives for new customer generators. Whereas climate change and decreasing water availability in the coming decades23 will probably increase financial motivation to install solar in agriculture, future adoption and the co-benefits reported here will also depend on new business models for grid pricing52. Pricing structures have already and will inevitably continue to change as utilities, regulators and grid customers adapt to distributed renewable generation, avoid curtailment and avoid the utility death spiral52. Although future installations and policy are not the focus of this study, the newest policy, NEM 3.0, substantially reduces compensation for surplus generation and limits options for multiple metered connections53, probably requiring future installations to add battery storage and other measures to maintain similar profitability54. However, this study considers solar arrays that are grandfathered into their respective NEM 1.0 and 2.0 agreements. Additionally, our estimated load contributions suggest that revenue reported here mostly originates from offset demand rather than credit for surplus generation (Supplementary Notes and Supplementary Discussion). The bottom line is that owning solar PV, offsetting annual on-farm electric load and selling surplus electricity back to the utility under NEM 1.0 and 2.0 has increased economic and energy security for farmers with existing arrays and has probably promoted water-use reductions in the region. Importantly, we also assumed that all decisions were made by and returns received by landowning or partial-owning farmers. We do not have access to land-ownership data for the CCV, but nearly 40% of agricultural land in the region is rented or leased55.

Utility-scale land-lease rates alone do not offset lost agricultural revenue. However, including offset farm operation costs results in a substantially lower but still profitable agrisolar economic footprint with no major up-front capital investment (Fig. 4b). In water-scarce regions, particularly where water-use reduction is required, the smaller returns from utility-scale agrisolar practices and potentially related fallowing of land may be more attractive than continued cultivation under water-supply uncertainty17. Thus, without profitable compensation, agrivoltaic practices may not be feasible if offset operational costs and water-use reductions are driving utility-scale agrisolar decision making. We also omit some agricultural dynamics (such as the environmental benefits of carbon reduction), which could reinforce resource and economic security for both commercial- and utility-scale installation (Supplementary Discussion).

Opportunities for agrisolar research

Whereas funding and incentives for co-location research have expanded rapidly in recent years, we advocate extending these to agrisolar co-location. Adjacent agrisolar replacement with barren or unused ground cover still falls short of the full potential of ecovoltaic and agrivoltaic multifunctionality7,9,10,11. However, the regional resource and economic co-benefits of replacing irrigated land in water-stressed regions with solar PV here cannot be ignored. These findings are also immediately relevant to the Protecting Future Farmland Act of 202356, which set out a goal to better understand the multifaceted impacts of installed solar on US agricultural land. We discuss additional placement and management decisions that fall under the umbrella of agrisolar co-location in Supplementary Discussion.

We have shown that the goal of co-location, to enhance synergies between the co-production of agriculture and/or other ecosystem services and net-zero electricity production, is at least partially achievable with agrisolar co-location. Broader agrisolar research may also expose the consequences of not widely adopting agrivoltaics to retain agricultural production and protect food security. Given the ecosystem service benefits reported here, there may be an opportunity to broaden the scope of co-location research and incentives to include agrisolar co-location practices defined here.

Methods

Identifying agrisolar PV arrays across the CCV

We used remotely sensed imagery of existing solar PV arrays and geographic information system (GIS) datasets to develop a comprehensive and publicly available dataset of ground-mounted arrays co-located with agriculture in the CCV through 2018. We extracted all existing non-residential arrays from two geodatabases (Kruitwagen et al.4,57 and Stid et al.5,58) within the bounds of the CCV alluvial boundary59. We removed duplicate arrays and applied temporal segmentation methods described in Stid et al.5 to assign an installation year for Kruitwagen et al.4 arrays. We acquired Kruitwagen et al.4 panel area within array bounds by National Agriculture Imagery Program imagery pixel area with solar PV spectral index ranges suggested in Stid et al.5 and removed commissions (reported array shapes with no panels). We then removed arrays with >70% overlap with building footprints60 to retain only ground-mounted installations. Finally, overlaying historical CDL crop maps with new array shapes, we removed arrays in areas with majority non-agricultural land cover the year before installation (Supplementary Fig. 4 and Supplementary Discussion).

The resulting dataset (925 agrisolar co-located arrays) included 686 ground-mounted arrays from Stid et al.5 plus 239 from Kruitwagen et al.4. For these sites, we calculated array peak capacity (kWp) by61:

where \({\mathrm{Area}}_{\mathrm{panel}}\) is the total direct area of PV panels in m2, \(\eta\) is the average efficiency of installed PV modules during the array installation year62 (Supplementary Fig. 5) and \({G}_{\mathrm{STC}}\) is the irradiance at standard test conditions (kW m–2). Arrays were split into ‘Commercial-’ (<1 MWp) and ‘Utility-’ (≥1 MWp) scale arrays following the California Public Utility Commission NEM capacity guidelines63.

Scenario summary and assumptions

We computed annual FEW resource and economic values for each ground-mounted agrisolar PV array identified across the CCV for four scenarios: (1) reference, business as usual with no solar PV installation and continued agricultural production on the same plot of land, (2) baseline, agrisolar PV installation with moderate assumptions related to each component of the analysis, (3) worst case, PV installation with high negative and low positive effects for each component, (4) best case, similar but opposite of the worst-case scenario. We compare baseline to the reference scenario to estimate the most likely FEW and economic effects and use the differences between best- and worst-case scenarios to estimate uncertainty. Supplementary Tables 2 and 3 provide an overview of scenarios for each resource and Supplementary Tables 4 and 5 for baseline agrisolar lifespan FEW resource and economic value outcomes, respectively.

Identified arrays were installed between 2008 and 2018 and were assumed to have a 25-year lifespan for arrays due to performance, warranties, module degradation and standards for electrical equipment64,65. We assumed that land-use change effects ceased following 25 years of operation to simplify assumptions about module replacement, resale or continued use. We then summarized the FEW and economic effects of all arrays across the CCV and divided our temporal analysis into three phases: (1) addition (2008–2018) where arrays were arrays were being installed across the CCV, (2) constant (2019–2032) with no array additions but all arrays installed by 2018 are operating and maintained and (3) removal (2032–2042), where arrays are removed after 25 years of operation.

We performed several sensitivity analyses to address limitations in the available data and methods and to show how changes in future policy (NEM) could affect incentives displayed here. Sensitivity analysis included the capacity cut-off between commercial- and utility-scale (5 MW), solar PV lifespan (15 and 50 years), nominal discount rate (3%, 7% and 10%), solar PV direct area bias (proportional direct to total infrastructure area and a uniform perimeter buffer) and irrigation redistribution (assuming 50% of irrigation water-use offset is redistributed rather than conserved), all else equal (Supplementary Discussion and Supplementary Tables 6–20). We discuss additional assumptions and limitations in Supplementary Discussion.

Displaced crop and food production

Replacing fields (or portions thereof) with solar PV arrays affects crop production by (1) lost production of food, fibre and fuels and (2) reduced revenue from crop sales. We simplify the complex effects of lost production and include solely the foregone calories through both direct and indirect human consumption, which is justified because CCV crop production is largely oriented towards food crops. Future analyses could evaluate the lost fibre (primarily via cotton) or fuel (via biofuel refining) production.

We evaluated the economic and food production effects of displaced crops through a crop-specific opportunity cost assessment of land-use change, incorporating actual reported; yields, revenue, caloric density and regionally constrained caloric conversion efficiencies for feed/silage and seed oil crops. All crop type information was derived from the USDA National Agricultural Statistics Service (NASS) CDL22 for the array area in both prior- and post-installation years (Supplementary Fig. 4 and Supplementary Methods provide the adjacent fallowed land analysis). Each array was assigned a majority previous crop from the spatially weighted means of crop types within the array area for the five years before the installation.

We converted all eligible crop types to kcal (also called calorie) for human consumption after Heller et al.25. Foregone food production (\({\mathrm{Food}}_{\mathrm{Foregone}}\) in kcal) following PV installation was then defined for each array as:

where \({\mathrm{kcal}}_{\mathrm{density}}\) is in kcal kg–1, \(\mathrm{Yield}\) is in kg m–2 and \(\mathrm{Area}\) of each array in m2. Crop-specific caloric density data (kcal kg–1) were derived from the USDA FoodData Central April 2022 release66. FoodData food descriptions and nutrient data were joined and CDL specific crop groupings were made through a workflow described in Supplementary Fig. 6. Crop-specific yield data (kg m–2) were derived from the USDA NASS Agricultural Yield Surveys67. State-level (California) yield data were processed similarly, with missing crop data filled based on national average yields. We used caloric conversion efficiencies for feed, silage or oil crop to account for crop production that humans do not directly consume.

For each array, we calculated annual revenue of forgone crop production in real (inflation adjusted) dollars, calculated by:

where \({\mathrm{Price}}_{\mathrm{crop}}\) is in US$ kg–1, \(\mathrm{Yield}\) is in kg m–2 and \(\mathrm{Area}\) of each array in m2. We used the annual ‘price received’ for all crops in the USDA NASS Monthly Agricultural Prices Report for 2008 through 201868. For the baseline case, we assumed that food prices will scale directly with electricity prices through 2042 given that they respond to similar inflationary forces69. Supplementary Fig. 6 and Supplementary Methods provide a more complete workflow including best- and worst-case scenario assumptions.

Change in irrigation water use and cost savings

Irrigation water use can only be offset by agrisolar co-location if the prior land use was irrigated. The presence of irrigation was inferred from the Landsat-based Irrigation Dataset (LanID) map for the year before installation70,71 (Supplementary Fig. 4). If the array area contained irrigated pixels, then we assumed the cropland area and all respective crops within the rotation were irrigated.

We calculated the total forgone irrigation water use (\({\mathrm{IrrigWater}}_{\mathrm{Foregone}}\) in m3) by:

where \({\mathrm{IrrigDepth}}_{\mathrm{crop}}\) in m is the crop-specific irrigation depth, \({\mathrm{IrrigWater}}_{\mathrm{year}}\) in m3 is the annual county-level irrigation water-use estimate and \({\mathrm{IrrigWater}}_{\mathrm{survey}\; \mathrm{year}}\) in m3 is the county-level irrigation water-use estimate for the respective survey year irrigation depths.

We estimated annual crop-specific county-level irrigated depths from survey and climate datasets for each array. Crop-specific irrigation depths (\({\mathrm{IrrigDepth}}_{\mathrm{crop}}\)) were taken from the 2013 USDA Farm and Ranch Survey72 and 2018 Irrigation and Water Management Survey73, and logical crop groupings were applied (for example, almonds, pistachios, pecans, oranges and peaches were considered orchard crops). Because irrigation depths depend on the total precipitation in each survey year, we used multilinear regression to build annual county-level irrigation water-use estimates (\({\mathrm{IrrigWater}}_{\mathrm{year}}\)) from five-year US Geological Survey (USGS) water use74, gridMET growing season average precipitation75, with year as a dummy variable to incorporate temporal changes in irrigation technologies and practices. For the installation phase (2008 to 2018), these depths varied based on historical climate and survey data, whereas the projection phases (constant and removal) used a scenario-dependent moderate, wet (worst-case, least water savings) or dry (best case, most water savings) year estimate from the historical record (discussed in Supplementary Methods).

Assigning an economic value to water use is difficult and varies based on the temporally changing supply and demand76. We calculated the economic value of the change in water use (Water in real US$) to the farmer by:

where \({\Delta\mathrm{Water}}_{\mathrm{use}}\) (m3) is the offset irrigation water use for the co-located crop minus O&M projected water use, \({\mathrm{Irrig}}_{\mathrm{Energy}}\) (MWh m–3) is the irrigation electricity required to irrigate the co-located crop given local depth to water and drawdown estimates from McCarthy et al.77, \({\mathrm{Price}}_{\mathrm{Elec}}\) (US$ MWh–1) is the utility-specific (commercial-scale) or regional average (utility-scale) annual price of electricity based on the electricity returns and modelled electricity generation described in Supplementary Methods and \({\mathrm{Water}}_{\mathrm{right}}\) is a CCV-wide average water right contract rate of ~ US$0.03 m–3 (ref. 78). Here we assume that water (and thus energy) otherwise used for irrigation was truly foregone and not redistributed elsewhere within or outside the farm. Change in O&M water use was based on Klise et al.79 reported values, described in Supplementary Methods.

Electricity production, offset and revenue

Installing solar PV in fields has three benefits: (1) production of electricity by the newly installed solar PV array, (2) reduction in energy demand due to reduced water use and field activities and (3) revenue generation via net energy metering (NEM) or land lease. Here we assume that on-farm electricity demand is dominated by electricity used for irrigation and ignore offset energy (embodied) used for fuel.

We modelled electricity generation for each array using the pvlib python module developed by SANDIA National Laboratory80. Weather file inputs for pvlib were downloaded from the National Renewable Energy Laboratory (NREL) National Solar Radiation Database81. We also estimated annual on-farm load to differentiate offset electricity use and surplus generation. Not only is electricity generated by the arrays, but electricity consumption is foregone for each array due to not irrigating the array area. The annual change in electricity consumption due to water use (\({\mathrm{Electricity}}_{\mathrm{water}\; \mathrm{use}}\) in GWh) is calculated by:

where \({\mathrm{IrrigElec}}_{\mathrm{demand}}\) is the county-level rates for irrigation electricity demand in GWh m–3 and \({\varDelta\mathrm{Water}}_{\mathrm{use}}\) is the change in water use in m3 from equation (5). County-level electricity requirements to irrigate were calculated using irrigation electricity demand methods described in McCarthy et al.77 modified with a CCV-specific depth to water (piezometric surface) product for the spring (pre-growing season) of 201882.

Revenue from electricity generation was calculated separately for each array depending on array size and the installation year. Commercial-scale arrays (<1 MW) were assumed to operate under an NEM 1.0 if installed before 2017 and NEM 2.0 if installed later, which allows for interconnection to offset on-farm load and compensation for surplus electricity generation (Supplementary Methods and Supplementary Table 21). Thus, for commercial-scale arrays, annual cash flow from solar PV (NEM in US$) is calculated as:

where \({\mathrm{Saved}}_{\mathrm{offset}\; \mathrm{load}}\) is real US$ saved by offsetting annual on-farm electric load and \({\mathrm{Earned}}_{\mathrm{surplus}}\) is real US$ earned by surplus PV electricity generation sold to the utility under NEM guidelines. Both \({\mathrm{Saved}}_{\mathrm{offset}\; \mathrm{load}}\) and \({\mathrm{Earned}}_{\mathrm{surplus}}\) are estimated based on pvlib modelled electricity generation and valued at the historical utility-specific energy charge retail rates. Historical energy charges are available either through utility reports83,84,85 or the US Utility Rate Database via OpenEI86. We made several assumptions that resulted in omission of fixed charges including transmission and interconnection costs from the analysis. Details about electricity rates and omitted charges are summarized in Supplementary Methods.

For utility-scale arrays (≥1 MW), annual revenue from agrisolar co-location (Lease in US$) was assumed to be given by:

where Lease is the economic value estimated to be paid to the farmer by the utility for leasing their land in US$ m–2 and Area of each array in m2.

We assumed commercial-scale arrays installed before 2017 were grandfathered into NEM 1.0 guidelines for the duration of their lifespan. However, arrays installed in 2017 and 2018 fall under NEM 2.0 guidelines which include a US$0.03 kWh–1 non-bypassable charge removed from \({\mathrm{Earned}}_{\mathrm{surplus}}\)21,87,88. Annual on-farm operational load was estimated and distributed across the year based on reported California agricultural contingency profiles89 and Census of Agriculture county-level average farm sizes90,91,92 (Supplementary Figs. 7 and 8 and Supplementary Methods). With distributed hourly load estimations and modelled solar PV electricity generation, we delineated electricity and revenue contributing to annual load (\({\mathrm{Saved}}_{\mathrm{offset}\; \mathrm{load}}\)) from surplus electricity and revenue that would have been sold back to the grid and credited via NEM (\({\mathrm{Earned}}_{\mathrm{surplus}}\)).

Future electricity revenue was projected using 2018 conditions (contribution to annual load, to surplus) and energy charge rates, modelled electricity production described above (includes degradation, pre-inverter, inverter efficiency and soiling losses) and projected changes in the price of electricity. The Annual Energy Outlook report by the US Energy Information Administration (EIA) provides real electricity price projections annually between 2018 and 2050 for ‘Commercial End-Use Price’93. This annual rate of change was used to estimate projected deviations from 2018 energy charges (2018 US$ kWh–1) during the constant and removal phases (2019–2042), with projected solar PV generation including discussed losses.

We used solar land consultant and industry reports for solar land-lease (\({\mathrm{Land}}_{\mathrm{lease}}\)) rates that ranged from US$750 ha–1 yr–1 to US$4,950 ha–1 yr–1, with high-value land averaging IS$2,450 ha–1 yr–1 in the CCV94,95. Comparable lease rates (~US$2,500 to US$5,000 ha–1 yr–1) were reported by developers in the CCV region17 and used in a solar PV and biomass trade-off study in Germany18 (~US$1,000 to US$2,950 ha–1 yr–1).

Array installation and O&M costs

Historical installation costs (Installation) were taken from the commercial-scale PV installation prices reported in the Annual Tracking the Sun report where reported prices are those paid by the PV system owner before incentives62. The baseline scenario is the median installation price, whereas the best- and worst-case scenarios are the 20th and 80th percentile installation costs, respectively. These reported values are calculated using NREL’s bottom-up cost model and are national averages using average values across all states. Installation cost was not discounted, as it represents the initial investment for commercial-scale installations at day zero. All future cash flows, profits and costs are compared to this initial investment. We also included the 30% Solar Investment Tax Credit in the Installation for commercial-scale arrays96. The system bounds of this impact analysis were installation through the operational or product-use phase. We, therefore, did not assume removal expenses or altered property value (terminal value) to remove uncertainty in decision making at the end of the 25-year array lifespan.

Historically reported and modelled O&M values (pre-2020) range from US$0 kWp–1 yr–1 (best case) to US$40 kWp–1 yr–1 (worst case) with an average (baseline) of US$18 kWp–1 yr–1 (refs. 97,98). Projected O&M costs were based on modelled commercial-scale PV lifetime O&M cost to capital expenditure cost ratios from historical and industry data that provided scenarios varying on research and development differences (conservative, moderate, advanced). The annual reported values are provided from 2020 to 2050 for fixed O&M costs including: asset management, insurance products, site security, cleaning, vegetation removal and component failure and are detailed in the Annual Technology Baseline report by NREL97, which are largely derived from the annual NREL Solar PV Cost Benchmark reports.

Farm operation costs

Business-as-usual farm operation costs (Operation) were derived from the ‘Total Operating Costs Per Acre to Produce’ reported in UC Davis Agricultural and Resource Economics Cost and Return Studies99. We removed operational costs to ‘Irrigate’ from the total because we estimate that as a function of electricity requirements and water rights (described in ‘Change in irrigation water use and cost savings’) while retaining ‘Irrigation Labour’ as this was not included in our irrigation cost assessment. Best- and worst-case scenarios for farm operation costs coincided with yield scenarios described in ‘Displaced crop and food production’.

Discounted cash flow for agrisolar co-location

For each commercial-scale array in the CCV, we computed the annual real cash flow as:

and for each utility-scale array as:

where Commercial is the real return in 2018 US$ for commercial-arrays (<1 MWp) and Utility is the real return in 2018 US$ for utility-scale arrays (≥1 MWp). Each of the terms on the right-hand side of these equations are defined in the sections above.

We then computed real annual discounted cash flow (\({\mathrm{DCF}}_{\mathrm{real}}\)) for each array to estimate the total lifetime value of each array. The \({\mathrm{DCF}}_{\mathrm{real}}\) at any given year n is calculated for each array by:

where \({{\mathrm{CF}}_{n}}^{\mathrm{real}}\) is the real annual cash flow at year n (either Commercial or Utility as relevant for each array) and \({r}_{\mathrm{real}}\) is the real discount rate without an expected rate of inflation (i) from the nominal discount rate (\({r}_{\mathrm{nom}}\)) calculated using the Fisher equation100:

Vartiainen et al.101 clearly communicates this method in solar PV economic studies and discusses the importance of discount rate (in their case, weighted average cost of capital) selection. For i, we use 3%, which is roughly the average producer price index (PPI) and consumer price index (CPI) (3.4% and 2.4%, respectively) between 2000 and 2022 and comparable to other solar PV economic studies101,102. We use a 5% \({r}_{\mathrm{nom}}\)103 and perform a sensitivity analysis using 3%, 7% and 10% \({r}_{\mathrm{nom}}\) and discuss discount rates used in literature in Supplementary Discussion. Separately from the sensitivity analysis for \({r}_{\mathrm{nom}}\), we also calculated our best-case and worst-case scenarios for each array.

All prices were adjusted to 2018 US dollars for calculation of real cash flow terms in equations (11) and (9). We adjusted consumer electricity prices and installation costs for inflation to real 2018 US$ using the US Bureau of Labor Statistics Consumer Price Index for All Urban Customers104. We adjusted all production-based profits and costs (all other resources) using US Bureau of Labor Statistics Producer Price Index for All Commodities105.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

The datasets and outputs generated in the current study are publicly available via Zenodo at https://doi.org/10.5281/zenodo.10023293 (ref. 106) with all source data referenced in the published article and in its Supplementary Information files.

Code availability

The code used to generate and analyse the datasets reported here are hosted via GitHub at https://github.com/stidjaco/FEWLS_tool and are available via Zenodo at https://doi.org/10.5281/zenodo.10023281 (ref. 107).

References

Ardani, K. et al. Solar Futures Study (US DOE, 2021); https://www.energy.gov/sites/default/files/2021-09/Solar%20Futures%20Study.pdf

Adeh, E. H., Good, S. P., Calaf, M. & Higgins, C. W. Solar PV power potential is greatest over croplands. Sci Rep. 9, 11442 (2019).

Hernandez, R. R., Hoffacker, M. K., Murphy-Mariscal, M. L., Wu, G. C. & Allen, M. F. Solar energy development impacts on land cover change and protected areas. Proc. Natl Acad. Sci. USA 112, 13579–13584 (2015).

Kruitwagen, L. et al. A global inventory of photovoltaic solar energy generating units. Nature 598, 604–611 (2021).

Stid, J. T. et al. Solar array placement, electricity generation, and cropland displacement across California’s Central Valley. Sci. Total Environ. 835, 155240 (2022).

USDA Land Values 2022 Summary (NASS, 2022).

Sturchio, M. A. & Knapp, A. K. Ecovoltaic principles for a more sustainable, ecologically informed solar energy future. Nat. Ecol. Evol. 7, 1746–1749 (2023).

Hernandez, R. R. et al. Techno–ecological synergies of solar energy for global sustainability. Nat. Sustainability 2, 560–568 (2019).

Agrisolar Best Practice Guidelines Version 2 (SolarPower Europe, 2023).

Agri-Photovoltaic Systems–Requirements for Primary Agricultural Use (Deutsches Institut für Normung, 2021).

Macknick, J. et al. The 5 Cs of Agrivoltaic Success Factors in the United States: Lessons From the InSPIRE Research Study (NREL, 2022).

Barron-Gafford, G. A. et al. Agrivoltaics provide mutual benefits across the food–energy–water nexus in drylands. Nat. Sustainability 2, 848–855 (2019).

Choi, C. S. et al. Environmental co‐benefits of maintaining native vegetation with solar photovoltaic infrastructure. Earth’s Future 11, e2023EF003542 (2023).

Gomez-Casanovas, N. et al. Knowns, uncertainties, and challenges in agrivoltaics to sustainably intensify energy and food production. Cell Rep. Phys. Sci. 4, 101518 (2023).

Pascaris, A. S., Schelly, C., Rouleau, M. & Pearce, J. M. Do agrivoltaics improve public support for solar? A survey on perceptions, preferences, and priorities. Green Technol. Resilience Sustainability 2, 8 (2022).

McCall, J., Macdonald, J., Burton, R. & Macknick, J. Vegetation management cost and maintenance implications of different ground covers at utility-scale solar sites. Sustainability 15, 5895 (2023).

Biggs, N. B. et al. Landowner decisions regarding utility-scale solar energy on working lands: a qualitative case study in California. Environ. Res. Commun. 4, 055010 (2022).

Bao, K., Thrän, D. & Schröter, B. Land resource allocation between biomass and ground-mounted PV under consideration of the food–water–energy nexus framework at regional scale. Renewable Energy 203, 323–333 (2023).

Fujita, K. S. et al. Georectified polygon database of ground-mounted large-scale solar photovoltaic sites in the United States. Sci. Data 10, 760 (2023).

Knapp, A. K. & Sturchio, M. A. Ecovoltaics in an increasingly water-limited world: an ecological perspective. One Earth 7, 1705–1712 (2024).

Picker, M., Florio, M. P., Sandoval, C. J. K., Peterman, C. J. & Randolph, L. M. Decision Adopting Successor to Net Energy Metering Tariff (California Public Utilities Commission, 2016).

USDA National Agricultural Statistics Service Cropland Data Layer (USDA, 2023); https://nassgeodata.gmu.edu/CropScape/

Medellín-Azuara, J., Howitt, R. E., MacEwan, D. J. & Lund, J. R. Economic impacts of climate-related changes to California agriculture. Climatic Change 109, 387–405 (2011).

Gebremichael, M., Krishnamurthy, P. K., Ghebremichael, L. T. & Alam, S. What drives crop land use change during multi-year droughts in California’s Central Valley? Prices or concern for water? Remote Sens. 13, 650 (2021).

Heller, M. C., Keoleian, G. A. & Willett, W. C. Toward a life cycle-based, diet-level framework for food environmental impact and nutritional quality assessment: a critical review. Environ. Sci. Technol. 47, 12632–12647 (2013).

Ross, K. & Honig, M. California State Fact Sheet (USDA Farm Service Agency, 2011).

Lobell, D. B., Field, C. B., Cahill, K. N. & Bonfils, C. Impacts of future climate change on California perennial crop yields: model projections with climate and crop uncertainties. Agric. For. Meteorol. 141, 208–218 (2006).

Alam, S., Gebremichael, M. & Li, R. Remote sensing-based assessment of the crop, energy and water nexus in the Central Valley, California. Remote Sens. 11, 1701 (2019).

Wise, M., Dooley, J., Luckow, P., Calvin, K. & Kyle, P. Agriculture, land use, energy and carbon emission impacts of global biofuel mandates to mid-century. Appl. Energy 114, 763–773 (2014).

Gilbert, C. L. How to understand high food prices. J. Agric. Econ. 61, 398–425 (2010).

Ray, D. K., Mueller, N. D., West, P. C. & Foley, J. A. Yield trends are insufficient to double global crop production by 2050. PLoS ONE 8, e66428 (2013).

Tilman, D., Balzer, C., Hill, J. & Befort, B. L. Global food demand and the sustainable intensification of agriculture. Proc. Natl Acad. Sci. USA 108, 20260–20264 (2011).

Godfray, H. C. J., Poore, J. & Ritchie, H. Opportunities to produce food from substantially less land. BMC Biol. 22, 138 (2024).

Kummu, M. et al. Lost food, wasted resources: global food supply chain losses and their impacts on freshwater, cropland, and fertiliser use. Sci. Total Environ. 438, 477–489 (2012).

Ritchie, H. & Roser, M. Land Use (Our World in Data, 2013); http://ourworldindata.org/land-use

Molotoks, A. et al. Global projections of future cropland expansion to 2050 and direct impacts on biodiversity and carbon storage. Glob. Change Biol. 24, 5895–5908 (2018).

Prăvălie, R. et al. Arable lands under the pressure of multiple land degradation processes. A global perspective. Environ. Res. 194, 110697 (2021).

Elliott, J. et al. Constraints and potentials of future irrigation water availability on agricultural production under climate change. Proc. Natl Acad. Sci. USA 111, 3239–3244 (2014).

Flörke, M., Schneider, C. & McDonald, R. I. Water competition between cities and agriculture driven by climate change and urban growth. Nat. Sustainability 1, 51–58 (2018).

He, X. et al. Solar and wind energy enhances drought resilience and groundwater sustainability. Nat. Commun. 10, 4893 (2019).

Shirkey, G. et al. An environmental and societal analysis of the US electrical energy industry based on the water–energy Nexus. Energies 14, 2633 (2021).

Sturchio, M. A., Kannenberg, S. A., Pinkowitz, T. A. & Knapp, A. K. Solar arrays create novel environments that uniquely alter plant responses. Plants People Planet 6, 1522–1533 (2024).

Yavari Bajehbaj, R., Cibin, R., Duncan, J. M. & McPhillips, L. E. Quantifying soil moisture and evapotranspiration heterogeneity within a solar farm: implications for stormwater management. J. Hydrol. 638, 131474 (2024).

Lark, T. J., Mueller, R. M., Johnson, D. M. & Gibbs, H. K. Measuring land-use and land-cover change using the US. Department of Agriculture’s cropland data layer: cautions and recommendations. Int. J. Appl. Earth Obs. Geoinf. 62, 224–235 (2017).

Medellín-Azuara, J. et al. Hydro-economic analysis of groundwater pumping for irrigated agriculture in California’s Central Valley, USA. Hydrol. J. 23, 1205–1216 (2015).

Skinner, N. Budget Act of 2021 SB 170 (California Assembly, 2021).

Medellín-Azuara, J. et al. Economic Impacts of the 2021 Drought on California Agriculture Preliminary Report Prepared for The California Department of Food and Agriculture (UC Merced, 2022); http://drought.ucmerced.edu

California Water Code § 10729 (State of California, 2015).

Wolk, L. Local Government: Solar-Use Easement SB-618 (State of California, 2011).

Committee on Governance and Finance. Local Government Omnibus Act of 2022 SB-1489 (State of California, 2022).

Ayres, A. et al. Solar Energy and Groundwater in the San Joaquin Valley (Public Policy Institute of California, 2022); http://www.ppic.org/?show-pdf=true&docraptor=true&url=https%3A%2F%2Fwww.ppic.org%2Fpublication%2Fsolar-energy-and-groundwater-in-the-san-joaquin-valley%2F

Laws, N. D., Epps, B. P., Peterson, S. O., Laser, M. S. & Wanjiru, G. K. On the utility death spiral and the impact of utility rate structures on the adoption of residential solar photovoltaics and energy storage. Appl. Energy 185, 627–641 (2017).

Cooke, M. Decision Addressing Remaining Proceeding Issues (California Public Utilities Commission, 2023).

Barbose, G. One Year In: Tracking the Impacts of NEM 3.0 on California’s Residential Solar Market (Lawrence Berkeley National Laboratory, 2024); https://escholarship.org/uc/item/4st8v7j0

Bigelow, D. US Farmland Ownership, Tenure, and Transfer (USDA Economic Research Service, 2016).

Baldwin, T. & Grassley, C. Protecting Future Farmland Act of 2023 S.2931 (US Senate, 2023).

Kruitwagen, L. et al. A global inventory of solar photovoltaic generating units—dataset. Zenodo https://doi.org/10.5281/zenodo.5005868 (2021).

Stid, J. T. et al. Spatiotemporally characterized ground-mounted solar PV arrays within California’s Central Valley. Figshare https://doi.org/10.6084/m9.figshare.23629326.v1 (2023).

Faunt, C. C. Alluvial boundary of California’s Central Valley. US Geological Survey https://doi.org/10.5066/P9CQNCA9 (2012).

Heris, M. P., Foks, N., Bagstad, K. & Troy, A. A National Dataset of Rasterized Building Footprints for the U.S. (USGS, 2020); https://doi.org/10.5066/P9J2Y1WG

Martín-Chivelet, N. Photovoltaic potential and land-use estimation methodology. Energy https://doi.org/10.1016/j.energy.2015.10.108 (2016).

Barbose, G., Darghouth, N., O’shaughnessy, E. & Forrester, S. Tracking the Sun Pricing and Design Trends for Distributed Photovoltaic Systems in the United States (Lawrence Berkeley National Laboratory, 2022); http://emp.lbl.gov/publications/tracking-sun-pricing-and-design-1

Perea, H. Electricity: Natural Gas: Rates: Net Energy Metering: California Renewables Portfolio Standard Program AB-327 (State of California, 2013).

Federal Energy Management Program 10 CFR (US DOE, 2017).

Best Practices for Operation and Maintenance of Photovoltaic and Energy Storage Systems 3rd edn (NREL, 2018); http://www.nrel.gov/docs/fy19osti/73822.pdf

USDA. FoodData Central (Agriculture Research Service, 2019).

Crop Production (USDA, 2022).

Agricultural Prices (USDA, 2019); http://usda.library.cornell.edu/concern/publications/c821gj76b?locale=en

Ringler, C., Bhaduri, A. & Lawford, R. The nexus across water, energy, land and food (WELF): potential for improved resource use efficiency? Curr. Opin. Environ. Sustainability 5, 617–624 (2013).

Xie, Y., Gibbs, H. K. & Lark, T. J. Landsat-based irrigation fataset (LANID): 30 m resolution maps of irrigation distribution, frequency, and change for the US, 1997-2017. Earth Syst. Sci. Data 13, 5689–5710 (2021).

Xie, Y. & Lark, T. J. LANID-US: Landsat-based irrigation dataset for the United States. Zenodo https://doi.org/10.5281/zenodo.5548555 (2021).

Farm and Ranch Irrigation Survey (2013). (USDA, 2013); http://agcensus.library.cornell.edu/wp-content/uploads/2012-Farm-and-Ranch-Irrigation-Survey-fris13.pdf

Irrigation and Water Management Survey. USDA NASS 2018 Irrigation and Water Management Survey (2017 Census of Agriculture) (USDA, 2018); http://www.nass.usda.gov/Publications/AgCensus/2017/Online_Resources/Farm_and_Ranch_Irrigation_Survey/fris.pdf

USGS Water Use Data for California (USGS, 2015).

Abatzoglou, J. T. Development of gridded surface meteorological data for ecological applications and modelling. Int. J. Climatol. 33, 121–131 (2013).

Medellín-Azuara, J., Harou, J. J. & Howitt, R. E. Estimating economic value of agricultural water under changing conditions and the effects of spatial aggregation. Sci. Total Environ. 408, 5639–5648 (2010).

McCarthy, B. M. Energy Trends in Irrigation: A Method for Estimating Local and Large-Scale Energy Use in Agriculture (Michigan State Univ., 2021).

Baldocchi, D. D. The cost of irrigation water and urban farming. Berkeley News (2018).

Klise, G. T. et al. Water Use and Supply Concerns for Utility-Scale Solar Projects in the Southwestern United States (Sandia National Laboratories, 2013); http://www.osti.gov/servlets/purl/1090206

Holmgren, W. F., Hansen, C. W. & Mikofski, M. A. pvlib python: a python package for modeling solar energy systems. J. Open Source Software 3, 884 (2018).

Sengupta, M. et al. The National Solar Radiation Data Base (NSRDB). Renewable Sustainable Energy Rev. 89, 51–60 (2018).

California Department of Water Resources. i08 GroundwaterDepthSeasonal contours. California Natural Resources Agency Open Data Platform (2022); https://data.ca.gov/dataset/i08-groundwaterdepthseasonal-contours

Pacific Gas and Electric. Electric rates: current and historic electric rates. (PG&E, accessed 6 July 2023); https://www.pge.com/tariffs/en/rate-information/electric-rates.html

Sacramento Municipal Utility District. CEO & GM report on rates and services. (SMUD, accessed 6 July 2023); https://www.smud.org/Corporate/About-us/Company-Information/Reports-and-Statements/GM-Reports-on-Rates-and-Services

Southern California Edison. Historical Prices and Rate Schedules. (SCE, accessed 6 July 2023); https://www.sce.com/regulatory/tariff-books/historical-rates

Zimny-Schmitt, D. & Huggins, J. Utility Rate Database (URDB). OpenEI https://data.openei.org/submissions/5 (2020).

Ratemaking, Solar Value and Solar Net Energy Metering—A Primer (SEPA, 2015); https://www.energy.gov/sites/prod/files/2015/03/f20/sepa-nem-report-0713-print.pdf

Gong, A., Brown, C. & Adeyemo, S. The Financial Impact of California’s Net Energy Metering 2.0 Policy (Aurora Solar, 2017); https://www.ourenergypolicy.org/wp-content/uploads/2017/07/Aurora_NEM2_Whitepaper_v1.01__1_.pdf

Olsen, D., Sohn, M., Piette, M. A. & Kiliccote, S. Demand Response Availability Profiles for California in the Year 2020 (Lawrence Berkeley National Laboratory, 2014); http://www.osti.gov/servlets/purl/1341727/

2007 Census of Agriculture (USDA NASS, 2009); https://agcensus.library.cornell.edu/wp-content/uploads/2007-United_States-State-usv1.pdf

2012 Census of Agriculture (USDA NASS, 2014); https://agcensus.library.cornell.edu/wp-content/uploads/usv1.pdf

2017 Census of Agriculture (USDA NASS, 2019); http://www.nass.usda.gov/Publications/AgCensus/2017/Full_Report/Volume_1,_Chapter_1_US/usv1.pdf

Annual Energy Outlook 2020 with Projections to 2050 (EIA. 2020).

Lease Rates for Solar Farms: How Valuable Is My Land? SolarLandLease https://www.solarlandlease.com/lease-rates-for-solar-farms-how-valuable-is-my-land (2020).

Van Trump, K. What You Need to Know… Big Money Leasing Farmland to Solar Operators. The Van Trump Report https://www.vantrumpreport.com/what-you-need-to-know-big-money-leasing-farmland-to-solar-operators/ (2020).

Energy Policy Act of 2005 (US Congress, 2005).

2022 Annual Technology Baseline (NREL, 2022).

Ramasamy, V., Feldman, D., Desai, J. & Margolis, R. U.S. Solar Photovoltaic System and Energy Storage Cost Benchmarks: Q1 2021 (NREL, 2021); http://www.nrel.gov/docs/fy22osti/80694.pdf

Current Cost and Return Studies: Commodities (UC Davis, 2022).

Fisher, I. Appreciation and Interest (AEA Publication, 1896).

Vartiainen, E., Masson, G., Breyer, C., Moser, D. & Román Medina, E. Impact of weighted average cost of capital, capital expenditure, and other parameters on future utility‐scale PV levelized cost of electricity. Prog. Photovoltaics 28, 439–453 (2020).

Liu, X., O’Rear, E. G., Tyner, W. E. & Pekny, J. F. Purchasing vs. leasing: a benefit–cost analysis of residential solar PV panel use in California. Renewable Energy 66, 770–774 (2014).

Kelley, L. C., Gilbertson, E., Sheikh, A., Eppinger, S. D. & Dubowsky, S. On the feasibility of solar-powered irrigation. Renewable Sustainable Energy Rev. 14, 2669–2682 (2010).

Consumer Price Index (CPI) Databases (US BLS, 2023).

Producer Price Index (PPI) Databases (US BLS, 2023).

Stid, J. T. Agrisolar food, energy, and water and economic lifecycle scenario (FEWLS) tool data. Zenodo https://doi.org/10.5281/zenodo.10023293 (2025).

Stid, J. T. FEWLS tool: initial release of FEWLS tool. Zenodo https://doi.org/10.5281/zenodo.10023281 (2023).

Uber Technologies Inc. H3: hexagonal hierarchical spatial indexing. GitHub https://github.com/uber/h3 (2019).

Cartographic Boundary File (US Census Bureau, 2019); http://Census.gov

Ong, S., Campbell, C., Denholm, P., Margolis, R. & Heath, G. Land-Use Requirements for Solar Power Plants in the United States NREL/TP-6A20-56290, 1086349 (OSTI, 2013); https://doi.org/10.2172/1086349

Acknowledgements

This work was supported by the USDA National Institute of Food and Agriculture (NIFA) INFEWS grant number 2018-67003-27406. We credit additional support from the USDA NIFA Agriculture and Food Research Initiative Competitive grant number 2021-68012-35923 and the Department of Earth and Environmental Sciences at Michigan State University. Any opinions, findings and conclusions or recommendations expressed in this publication are those of the authors and do not necessarily reflect the views of the USDA or Michigan State University. We are grateful to B. McGill for bringing the vision of agrisolar co-location to life through her artistic conceptual depiction.

Author information

Authors and Affiliations

Contributions

J.T.S. led the dataset characterization, methods development, analysis, interpretation and wrote the original draft. S.S. modelled electricity generation and NEM returns. S.S. and A.A. conceptualized economic models and aided in interpretation of energy results. A.D.K. aided interpretation and along with R.A. and J.R. aided in food and water methodology conceptualization. All authors contributed to manuscript editing and revising. D.W.H., A.D.K., A.A. and R.A. acquired funding.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Greg Barron-Gafford, Paul Mwebaze and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–8, Tables 1–21, Notes, Discussion and Methods.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Stid, J.T., Shukla, S., Kendall, A.D. et al. Impacts of agrisolar co-location on the food–energy–water nexus and economic security. Nat Sustain 8, 702–713 (2025). https://doi.org/10.1038/s41893-025-01546-4

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41893-025-01546-4

This article is cited by

-

Aligning sociotechnical systems perspectives and adoption readiness levels to accelerate clean energy adoption

Nature Reviews Clean Technology (2026)

-

Coupling and coordination relationship between land use efficiency and renewable energy industry in china: spatio-temporal differentiation and interactive response

Environment, Development and Sustainability (2026)

-

Scientific frontiers of agrivoltaic cropping systems

Nature Reviews Clean Technology (2025)

-

A harmonized dataset of ground-mounted solar energy in the US with enhanced metadata

Scientific Data (2025)

-

Thermodynamic and environmental assessment of apple production in Türkiye: regional comparison and agrivoltaic integration

Scientific Reports (2025)