Abstract

The sustainable separation of hydrocarbons from crude oil is critical for reducing energy consumption and carbon emissions in the chemical industry. Current methods are energy intensive and do not allow for isolation of specific hydrocarbons due to overlapping physicochemical properties and molecular complexities in crude oil. Here we introduce an energy-efficient molecular sieving strategy using cucurbit[7]uril (CB[7]) aqueous solution to directly extract cyclohexane (CH) from crude oil. CB[7] enables efficient CH separation under ambient and harsh conditions through shape- and size-selective binding with an ultrahigh affinity (2.5 × 109 M−1). Industrial validation shows >99% CH purity from azeotropic benzene mixtures and crude distillates and achieves 57.4–82.4% energy savings compared with current industrial methods. By demonstrating the scalability and robustness of CB[7]-based separations, this work highlights the potential of molecular sieves for sustainable, cost-effective hydrocarbon recovery from crude oil, paving the way for large-scale, sustainable hydrocarbon purification.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available within the paper and its Supplementary Information. The X-ray crystallographic coordinates for structures reported in this study have been deposited at the Cambridge Crystallographic Data Centre (CCDC), under deposition numbers 2099397-2099400. These data can be obtained free of charge from The Cambridge Crystallographic Data Centre via www.ccdc.cam.ac.uk/data_request/cif. Source data are provided with this paper.

References

Van der Hoeven, M., Kobayashi, Y. & Diercks, R. Technology Roadmap: Energy and GHG Reductions in the Chemical Industry via Catalytic Processes (International Energy Agency, 2013).

Abergel, T. et al. Energy Technology Perspectives 2017: Catalysing Energy Technology Transformations (OECD Publishing, 2017).

Levi, P. G. & Cullen, J. M. Mapping global flows of chemicals: from fossil fuel feedstocks to chemical products. Environ. Sci. Technol. 52, 1725–1734 (2018).

Sholl, D. S. & Lively, R. P. Seven chemical separations to change the world. Nature 532, 435–437 (2016).

Yadav, V. G., Yadav, G. D. & Patankar, S. C. The production of fuels and chemicals in the new world: critical analysis of the choice between crude oil and biomass vis-à-vis sustainability and the environment. Clean. Technol. Environ. Policy 22, 1757–1774 (2020).

Tullo, A. H. Why the future of oil is in chemicals, not fuels. Chem. Eng. News 97, 26–29 (2019).

Thompson, K. A. et al. N-Aryl–linked spirocyclic polymers for membrane separations of complex hydrocarbon mixtures. Science 369, 310–315 (2020).

Chisca, S. et al. Polytriazole membranes with ultrathin tunable selective layer for crude oil fractionation. Science 376, 1105–1110 (2022).

Li, S. et al. Hydrophobic polyamide nanofilms provide rapid transport for crude oil separation. Science 377, 1555–1561 (2022).

Li, J.-R., Sculley, J. & Zhou, H.-C. Metal–organic frameworks for separations. Chem. Rev. 112, 869–932 (2012).

Zhao, X., Wang, Y., Li, D. S., Bu, X. & Feng, P. Metal–organic frameworks for separation. Adv. Mater. 30, 1705189 (2018).

Bloch, E. D. et al. Hydrocarbon separations in a metal–organic framework with open iron (II) coordination sites. Science 335, 1606–1610 (2012).

Liao, P.-Q. et al. Controlling guest conformation for efficient purification of butadiene. Science 356, 1193–1196 (2017).

Cadiau, A., Adil, K., Bhatt, P., Belmabkhout, Y. & Eddaoudi, M. A metal-organic framework–based splitter for separating propylene from propane. Science 353, 137–140 (2016).

Cui, J. et al. A molecular sieve with ultrafast adsorption kinetics for propylene separation. Science 383, 179–183 (2024).

Chen, G. et al. Solid-solvent processing of ultrathin, highly loaded mixed-matrix membrane for gas separation. Science 381, 1350–1356 (2023).

Tan, X. et al. Truly combining the advantages of polymeric and zeolite membranes for gas separations. Science 378, 1189–1194 (2022).

Xu, L.-H. et al. Highly flexible and superhydrophobic MOF nanosheet membrane for ultrafast alcohol-water separation. Science 378, 308–313 (2022).

Lai, H. W. et al. Hydrocarbon ladder polymers with ultrahigh permselectivity for membrane gas separations. Science 375, 1390–1392 (2022).

Chen, K.-J. et al. Synergistic sorbent separation for one-step ethylene purification from a four-component mixture. Science 366, 241–246 (2019).

Li, L. et al. Ethane/ethylene separation in a metal-organic framework with iron-peroxo sites. Science 362, 443–446 (2018).

Chai, Y. et al. Control of zeolite pore interior for chemoselective alkyne/olefin separations. Science 368, 1002–1006 (2020).

Lin, J. Y. Molecular sieves for gas separation. Science 353, 121–122 (2016).

Wang, H. et al. Large cages of zeolitic imidazolate frameworks. Acc. Chem. Res. 55, 707–721 (2022).

Liu, M. et al. Barely porous organic cages for hydrogen isotope separation. Science 366, 613–620 (2019).

Idrees, K. B. et al. Robust carborane-based metal–organic frameworks for hexane separation. J. Am. Chem. Soc. 145, 23433–23441 (2023).

Li, J.-H., Chen, J.-X., Lin, R.-B. & Chen, X.-M. Recent progresses on metal–organic frameworks for separation of gaseous hydrocarbons. Mater. Chem. Front. 7, 5693–5730 (2023).

Xie, F., Yu, L., Wang, H. & Li, J. Metal–organic frameworks for C6 alkane separation. Angew. Chem. 135, e202300722 (2023).

Wang, Y., Ban, Y., Hu, Z. & Yang, W. Energy-efficient extraction of linear alkanes from various isomers using structured metal–organic framework membrane. Nat. Commun. 14, 6617 (2023).

Katsoulidis, A. P. et al. Chemical control of structure and guest uptake by a conformationally mobile porous material. Nature 565, 213–217 (2019).

Yang, L. et al. Energy-efficient separation alternatives: metal–organic frameworks and membranes for hydrocarbon separation. Chem. Soc. Rev. 49, 5359–5406 (2020).

Cui, W. G., Hu, T. L. & Bu, X. H. Metal–organic framework materials for the separation and purification of light hydrocarbons. Adv. Mater. 32, 1806445 (2020).

Zhang, Z. et al. Metal-organic frameworks for C6–C8 hydrocarbon separations. EnergyChem 3, 100057 (2021).

Zeng, H. et al. Orthogonal-array dynamic molecular sieving of propylene/propane mixtures. Nature 595, 542–548 (2021).

Zhu, X. et al. Selective molecular sieving of chloro and bromotoluene isomers by trianglimine macrocycle. Chem. Mater. 35, 9160–9166 (2023).

Zhang, G. et al. Adsorptive molecular sieving of aromatic hydrocarbons over cyclic aliphatic hydrocarbons via an intrinsic/extrinsic approach. J. Mater. Chem. A 12, 6875–6879 (2024).

Moosa, B. et al. A polymorphic azobenzene cage for energy-efficient and highly selective p-xylene separation. Angew. Chem. Int. Ed. 59, 21367–21371 (2020).

Zhang, G. et al. Intrinsically porous molecular materials (IPMs) for natural gas and benzene derivatives separation. Acc. Chem. Res. 54, 155–168 (2021).

Jasra, R. & Bhat, S. Thermal desorption of normal paraffins from zeolite 5A. Zeolites 7, 127–130 (1987).

Lu, X. & Isaacs, L. Uptake of hydrocarbons in aqueous solution by encapsulation in acyclic cucurbit [n] uril‐type molecular containers. Angew. Chem. Int. Ed. 55, 8076–8080 (2016).

Sharma, M., Sharma, P. & Kim, J. N. Solvent extraction of aromatic components from petroleum derived fuels: a perspective review. RSC Adv. 3, 10103–10126 (2013).

Balogh, K., Szaniszló, N. & H-Otta, K. Can cyclodextrins really improve the selectivity of extraction of BTEX compounds? J. Incl. Phenom. Macrocycl. Chem. 57, 457–462 (2007).

Lee, J. W., Samal, S., Selvapalam, N., Kim, H.-J. & Kim, K. Cucurbituril homologues and derivatives: new opportunities in supramolecular chemistry. Acc. Chem. Res. 36, 621–630 (2003).

Barrow, S. J. et al. Cucurbituril-based molecular recognition. Chem. Rev. 115, 12320–12406 (2015).

Zhang, G. et al. Shape-induced selective separation of ortho-substituted benzene isomers enabled by cucurbit [7] uril host macrocycles. Chem 6, 1082–1096 (2020).

Florea, M. & Nau, W. M. Strong binding of hydrocarbons to cucurbituril probed by fluorescent dye displacement: a supramolecular gas-sensing ensemble. Angew. Chem. Int. Ed. 40, 9338–9342 (2011).

Assaf, K. I. et al. Hydrophobe challenge: a joint experimental and computational study on the host–guest binding of hydrocarbons to cucurbiturils, allowing explicit evaluation of guest hydration free-energy contributions. J. Phys. Chem. B 121, 11144–11162 (2017).

Grand View Research. Cyclohexane Market Analysis by Application (Adipic Acid, Caprolactam), by End-Use (Nylon 6, Nylon 66), Competitive Landscape, and Segment Forecasts, 2018–2025 (Grand View Research, 2017).

Cui, P.-F. et al. Highly selective separation of benzene and cyclohexane in a spatially confined carborane metallacage. J. Am. Chem. Soc. 144, 6558–6565 (2022).

Garcia Villaluenga, J. P. & Tabe-Mohammadi, A. A. Review on the separation of benzene/cyclohexane mixtures by pervaporation processes. J. Membr. Sci. 169, 159–174 (2000).

Mukherjee, S. et al. Advances in adsorptive separation of benzene and cyclohexane by metal-organic framework adsorbents. Coord. Chem. Rev. 437, 213852 (2021).

Moosa, B. et al. Fluorine‐boosted kinetic and selective molecular sieving of C6 derivatives. Angew. Chem. Int. Ed. 62, e202311555 (2023).

Yao, H. et al. Adsorptive separation of benzene, cyclohexene, and cyclohexane by amorphous nonporous amide naphthotube solids. Angew. Chem. 132, 20117–20122 (2020).

Han, Y. et al. Control of the pore chemistry in metal-organic frameworks for efficient adsorption of benzene and separation of benzene/cyclohexane. Chem 9, 739–754 (2023).

Natraj, A. et al. Single-crystalline imine-linked two-dimensional covalent organic frameworks separate benzene and cyclohexane efficiently. J. Am. Chem. Soc. 144, 19813–19824 (2022).

Yang, W. et al. Tiara [5] arenes: synthesis, solid‐state conformational studies, host–guest properties, and application as nonporous adaptive crystals. Angew. Chem. Int. Ed. 59, 3994–3999 (2020).

Macreadie, L. K. et al. Enhancing multicomponent metal–organic frameworks for low pressure liquid organic hydrogen carrier separations. Angew. Chem. Int. Ed. 59, 6090–6098 (2020).

Chen, C. et al. A noncovalent π‐stacked porous organic molecular framework for selective separation of aromatics and cyclic aliphatics. Angew. Chem. Int. Ed. 61, e202201646 (2022).

Zhao, X. et al. One‐pot and shape‐controlled synthesis of organic cages. Angew. Chem. Int. Ed. 60, 17904–17909 (2021).

Xie, F. & Li, J. Complete separation of benzene–cyclohexene–cyclohexane mixtures via temperature-dependent molecular sieving by a flexible chain-like coordination polymer. Nat. Commun. 15, 2240 (2024).

Nurunnabi, M. Transformation from an oil-based economy to a knowledge-based economy in Saudi Arabia: the direction of Saudi vision 2030. J. Knowl. Econ. 8, 536–564 (2017).

Lagona, J., Mukhopadhyay, P., Chakrabarti, S. & Isaacs, L. The cucurbit[n]uril family. Angew. Chem. Int. Ed. 44, 4844–4870 (2005).

Cier, H. & Waddell, M. Producing high purity cyclohexane. Ind. Eng. Chem. 51, 259–261 (1959).

Tripathi, R. P., Sagar, J. M. & Gulati, I. B. High purity cyclohexane from petroleum streams by extractive distillation. J. Appl. Chem. Biotechnol. 23, 581–588 (1973).

Day, A. et al. Controlling factors in the synthesis of cucurbituril and its homologues. J. Org. Chem. 66, 8094–8100 (2001).

Zhang, G. et al. Industrial separation challenges: how does supramolecular chemistry help? J. Am. Chem. Soc. 145, 19143–19163 (2023).

Wang, Z. et al. Efficient liquid–liquid extraction of benzene from its mixture with cyclohexane by utilizing hyperbranched polymeric ammoniums salts. Ind. Eng. Chem. Res. 58, 15321–15331 (2019).

Marongiu, B. et al. A comparative study of thermodynamic properties of binary mixtures containing dimethylsulfoxide. J. Therm. Anal. Calorim. 90, 909–922 (2007).

Liu, Z., Liu, S. & Li, Z. Benzene selective hydrogenation thermodynamics, heterogeneous catalytic kinetics catalysis mechanism and scientific essence. In Catalytic Technology for Selective Hydrogenation of Benzene to Cyclohexene 33–57 (Springer, 2020).

Mecozzi, S. & Rebek, J. Jr The 55% solution: a formula for molecular recognition in the liquid state. Chem. Eur. J. 4, 1016–1022 (1998).

Biedermann, F. et al. Release of high-energy water as an essential driving force for the high-affinity binding of cucurbit [n] urils. J. Am. Chem. Soc. 134, 15318–15323 (2012).

Raeva, V. M., Anisimov, A. V. & Ryzhkin, D. A. Calculation of vaporization enthalpies of a benzene–cyclohexane system. Russ. Chem. Bull. 70, 715–721 (2021).

Ponce, G. H. S. F. et al. Using an internally heat-integrated distillation column for ethanol–water separation for fuel applications. Chem. Eng. Res. Des. 95, 55–63 (2015).

Acknowledgements

N.M.K. acknowledges support from the King Abdullah University of Science and Technology (KAUST; grant OSR-2019-CRG8-4032). G.Z. acknowledges support from the Jiangsu Specially Appointed Professor Program. K.K. acknowledges support from the Institute for Basic Science (IBS-R007-D1).

Author information

Authors and Affiliations

Contributions

G.Z. and N.M.K. conceived and designed the research project. G.Z. performed separation experiments, NMR analysis, 1D GC-MS characterization and host–guest complexation studies. I.K. conducted crystallization experiments and single-crystal X-ray diffraction (SCXRD) analysis. D.R.B. synthesized the cucurbituril homologues. L.O.A. analysed the crystallographic data. W.L. performed molecular dynamics simulations. A.C. conducted the GC-MS measurements. V.G.S. carried out the 2D GC × GC analysis. A.-H.E. performed NMR characterization. K.K. supervised crystallographic studies and molecular design. All authors discussed the results and contributed to manuscript preparation. G.Z. wrote the original draft. B.A.M., R.D.M., W.L., N.M.K. and K.K. reviewed and edited the manuscript. N.M.K. acquired funding and supervised the project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Razi Epsztein, Jian-Rong Li and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–51, Tables 1–4 and Discussion.

Source data

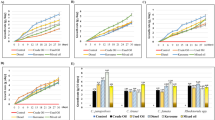

Source Data Fig. 2

Unprocessed NMR data, GC-MS and separation results.

Source Data Fig. 3

Separation results and energy cost calculation results.

Source Data Fig. 4

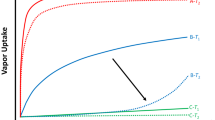

Binding constant results.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, G., Kim, I., Alimi, L.O. et al. Selective and sustainable separation of hydrocarbons from crude oil via molecular sieve. Nat Sustain 8, 784–792 (2025). https://doi.org/10.1038/s41893-025-01563-3

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41893-025-01563-3

This article is cited by

-

Selective extraction of valuable hydrocarbons

Nature Sustainability (2025)