Abstract

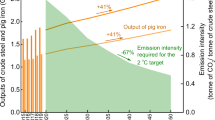

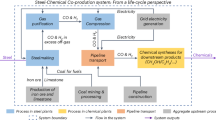

Improving the sustainability of the steel industry requires decarbonization strategies that are both technically and economically viable. The recovery of both material and heat on site is a promising approach but largely unexplored. Here we propose a scheme integrating heat recovery, carbon mineralization and the use of slag in cement production, along with the blast-furnace injection of hydrogen from off-gas. The proposed scheme, based on the synergistic use of coke oven gas and slag, can reduce CO2 emissions by 48% compared to the conventional approach. When coupled with an external gas supply from coal gasification or biomass pyrolysis, CO2 emissions can drop by 63% and 92%, respectively. The cost of avoiding CO2 emissions could be less than half the cost of conventional industrial capture and could be offset by the projected carbon price by 2030. For the steel industry in China, we find that the scheme is applicable to over 46% of existing steel mills, resulting in 16 provinces meeting the 2 °C target and 19 provinces surpassing the 50% national mitigation target. Overall, we have shown how a minor reconfiguration of the steel production process could substantially improve the sustainability of the steel industry.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data and parameters used for this study are provided in the Supplementary Information.

References

Wang, P. et al. Efficiency stagnation in global steel production urges joint supply-and demand-side mitigation efforts. Nat. Commun. 12, 2066 (2021).

Climate Change and the Production of Steel (World Steel Association, 2021); https://worldsteel.org/wp-content/uploads/Climate-change-production-of-iron-and-steel-2021.pdf

National Bureau of Statistics of the People’s Republic of China. https://data.stats.gov.cn/ (2021).

Sustainable Steel (World Steel Association, 2021); https://worldsteel.org/wp-content/uploads/Sustainable-steel.pdf

Wei, R. et al. Current status and potential of biomass utilization in ferrous metallurgical industry. Renew. Sustain. Energy Rev. 68, 511–524 (2017).

Razzaq, R., Li, C. & Zhang, S. Coke oven gas: availability, properties, purification, and utilization in China. Fuel 113, 287–299 (2013).

Bermúdez, J. M., Arenillas, A., Luque, R. & Menéndez, J. A. An overview of novel technologies to valorise coke oven gas surplus. Fuel Process. Technol. 110, 150–159 (2013).

Guo, Y. et al. Co-production of steel and chemicals to mitigate hard-to-abate carbon emissions. Nat. Chem. Eng. 1, 365–375 (2024).

Lee, J. et al. Molar-scale formate production via enzymatic hydration of industrial off-gases. Nat. Chem. Eng. 1, 354–364 (2024).

Mochizuki, Y., Tsubouchi, N. & Akiyama, T. Investigation of strength and reduction reactivity during heat treatment in simulated-experimental blast furnace of carbon-containing pellet prepared by vapor deposition of tar to cold-bonded pellet with large particle size. Fuel Process. Technol. 176, 21–32 (2018).

Zhang, X., Jiao, K., Zhang, J. & Guo, Z. A review on low carbon emissions projects of steel industry in the World. J. Clean. Prod. 306, 127259 (2021).

Yilmaz, C., Wendelstorf, J. & Turek, T. Modeling and simulation of hydrogen injection into a blast furnace to reduce carbon dioxide emissions. J. Clean. Prod. 154, 488–501 (2017).

Yilmaz, C. & Turek, T. Modeling and simulation of the use of direct reduced iron in a blast furnace to reduce carbon dioxide emissions. J. Clean. Prod. 164, 1519–1530 (2017).

Sun, Y. et al. Decarbonising the iron and steel sector for a 2 °C target using inherent waste streams. Nat. Commun. 13, 297 (2022).

Kuramochi, T., Ramírez, A., Turkenburg, W. & Faaij, A. Comparative assessment of CO2 capture technologies for carbon-intensive industrial processes. Prog. Energy Combust. Sci. 38, 87–112 (2012).

Chen, Z., Cang, Z., Yang, F., Zhang, J. & Zhang, L. Carbonation of steelmaking slag presents an opportunity for carbon neutral: a review. J. CO2 Util. 54, 101738 (2021).

Zhou, C., Tremain, P., Doroodchi, E., Moghtaderi, B. & Shah, K. A novel slag carbon arrestor process for energy recovery in steelmaking industry. Fuel Process. Technol. 155, 124–133 (2017).

Wu, J. et al. Centrifugal-granulation-assisted thermal energy recovery towards low-carbon blast furnace slag treatment: state of the art and future challenges. Appl. Energy 325, 119835 (2022).

Rashad, A. M. A synopsis manual about recycling steel slag as a cementitious material. J. Mater. Res. Technol. 8, 4940–4955 (2019).

Sun, Y., Zhang, Z., Liu, L. & Wang, X. Integrated carbon dioxide/sludge gasification using waste heat from hot slags: syngas production and sulfur dioxide fixation. Bioresource Technol. 181, 174–182 (2015).

Zhang, H. et al. A review of waste heat recovery technologies towards molten slag in steel industry. Appl. Energy 112, 956–966 (2013).

Barati, M., Esfahani, S. & Utigard, T. A. Energy recovery from high temperature slags. Energy 36, 5440–5449 (2011).

Proctor, D. et al. Physical and chemical characteristics of blast furnace, basic oxygen furnace, and electric arc furnace steel industry slags. Environ. Sci. Technol. 34, 1576–1582 (2000).

Chen, J. et al. Application of iron and steel slags in mitigating greenhouse gas emissions: a review. Sci. Total Environ. 844, 157041 (2022).

Pan, S. et al. CO2 mineralization and utilization by alkaline solid wastes for potential carbon reduction. Nat. Sustain. 3, 399–405 (2020).

Pickering, S. J., Hay, N., Roylance, T. F. & Thomas, G. H. New process for dry granulation and heat recovery from molten blast-furnace slag. Ironmak. Steelmak. 12, 14–21 (1985).

Ökvist, L. S. High temperature properties of BOF slag and its behaviour in the blast furnace. Steel Res. Int. 75, 792–799 (2004).

Buelens, L. C., Galvita, V. V., Poelman, H., Detavernier, C. & Marin, G. B. Super-dry reforming of methane intensifies CO2 utilization via Le Chatelier’s principle. Science 354, 449–452 (2016).

Manzolini, G. et al. Techno-economic assessment of SEWGS technology when applied to integrated steel-plant for CO2 emission mitigation. Int. J. Greenh. Gas Control 94, 102935 (2020).

Ding, J., Wang, Y., Gu, R., Wang, W. & Lu, J. Thermochemical storage performance of methane reforming with carbon dioxide using high temperature slag. Appl. Energy 250, 1270–1279 (2019).

Tian, S., Jiang, J., Yan, F., Li, K. & Chen, X. Synthesis of highly efficient CaO-based, self-stabilizing CO2 sorbents via structure-reforming of steel slag. Energy Convers. Manag. 49, 7464–7472 (2015).

Zhu, T., Liu, X., Wang, X. & He, H. Technical development and prospect for collaborative reduction of pollution and carbon emissions from iron and steel industry in China. Engineering 31, 37–49 (2023).

Tian, S., Jiang, J., Zhang, Z. & Manovic, V. Inherent potential of steelmaking to contribute to decarbonisation targets via industrial carbon capture and storage. Nat. Commun. 9, 4422 (2018).

Suopajärvi, H. et al. Use of biomass in integrated steelmaking–status quo, future needs and comparison to other low-CO2 steel production technologies. Appl. Energy 213, 384–407 (2018).

Safarian, S. To what extent could biochar replace coal and coke in steel industries? Fuel 339, 127401 (2023).

Yu, S., Lehne, J., Blahut, N. & Charles, M. 1.5 °C Steel: Decarbonizing the Steel Sector in Paris-compatible Pathways (Pacific Northwest National Laboratory, 2021).

Fan, Z. & Friedmann, S. J. Low-carbon production of iron and steel: technology options, economic assessment, and policy. Joule 5, 829–862 (2021).

Gong, M. et al. Coke oven gas to methanol process integrated with CO2 recycle for high energy efficiency, economic benefits and low emissions. Energy Convers. Manag. 133, 318–331 (2017).

Zhai, Y., Wang, S., Wang, Z., Zhang, T. & Ji, C. Experimental and numerical study on laminar combustion characteristics of by-product hydrogen coke oven gas. Energy 278, 127766 (2023).

Mousa, E., Wang, C., Riesbeck, J. & Larsson, M. Biomass applications in iron and steel industry: an overview of challenges and opportunities. Renew. Sustain. Energy Rev. 65, 1247–1266 (2016).

Xie, H. et al. Sorption-enhanced reforming of raw COG and its adaptability to hydrogen metallurgy: thermodynamic analysis. Int. J. Hydrogen Energy 49, 837–848 (2024).

Xia, L. et al. Integrated biochar solutions can achieve carbon-neutral staple crop production. Nat. Food 4, 236–246 (2023).

Global Iron and Steel Tracker. Global Energy Monitor https://globalenergymonitor.org/projects/global-iron-and-steel-tracker/ (2021).

Cement. www.ccement.com/qiye/list-10-610000-0.html (2024).

Yan, P. et al. Biomass energy in China’s terrestrial ecosystems: insights into the nation’s sustainable energy supply. Renew. Sustain. Energy Rev. 127, 109857 (2020).

Ying, J., Eimer, D. A., Mathisen, A., Brakstad, F. & Haugen, H. A. Ultrasound intensify CO2 desorption from pressurized loaded monoethanolamine solutions. II. Optimization and cost estimation. Energy 173, 218–228 (2019).

Gielen, D. CO2 removal in the iron and steel industry. Energy Convers. Manag. 44, 1027–1037 (2003).

Xu, X. China’s multi-year provincial administrative division boundary data. The Resource and Environment Science and Data Center, Institute of Geographic Sciences and Natural Resources Research, Chinese Academy of Sciences https://doi.org/10.12078/2023010103 (2023).

Acknowledgements

This work was financially supported by the National Nature Science Foundation of China (grant no. U21A20321 to F.C. and grant no. 72025401 to X.L.). We thank the National Key Research and Development Program of China (grant no. 2024YFC3909301 to Z.D. and F.C.), the Carbon Neutrality and Energy System Transformation Program (X.L.) and the Research Project Supported by Shanxi Scholarship Council of China (grant no. 2022-018 to Z.D.) for their support.

Author information

Authors and Affiliations

Contributions

Z.D., X.L. and F.C. designed the research. Z.D., Y.W., C.C. and H.S. performed the comprehensive model simulation and data compiling processes. F.C. gave important guidance on the scenario selection and analyses. Z.D. and X.L. wrote the article. All authors contributed to the discussions and paper revision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Sustainability thanks Lei Zhu and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–8, Figs. 1–9 and Tables 1–27.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Di, Z., Wang, Y., Chang, C. et al. Synergistic gas–slag scheme to mitigate CO2 emissions from the steel industry. Nat Sustain 8, 763–772 (2025). https://doi.org/10.1038/s41893-025-01572-2

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s41893-025-01572-2

This article is cited by

-

Research on cloud-edge-end distributed collaborative computing based on deep reinforcement learning

Scientific Reports (2025)