Abstract

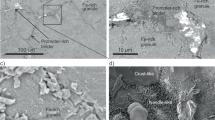

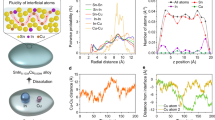

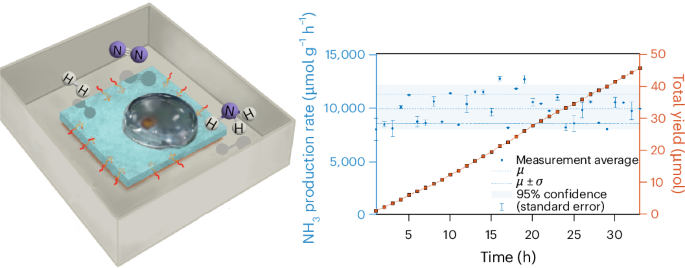

The outlook for sustainable economic and ecological growth projects an ammonia economy as a key enabler to the energy transition landscape. The predominance of the Haber–Bosch process, however, as the current industrial process for producing ammonia subdues the sustainability of establishing an energy route predicated on ammonia. Here we capitalize on the inherent atomic structure of liquid metal alloys and the ability to modulate the electronic and geometric structures of liquid metal catalysts to drive the thermocatalytic synthesis of ammonia. By exploiting the mobility of the metal atoms in the liquid metal configuration and purposefully designing disordered metal catalysts, we provide insights into designing future transition metal-based catalysts that produce ammonia from gaseous nitrogen and hydrogen under mild operating conditions. The use of a molten Cu–Ga catalyst offers a dynamic metal complex with synergistic advantages that lift the activity of its constituent elements, exceeding the activity of a control Ru-based catalyst.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$32.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data supporting the findings of this study are available in the paper and Supplementary Information or from the corresponding authors on reasonable request. The MD trajectories are available in Supplementary Data.

References

Fu, X. et al. Continuous-flow electrosynthesis of ammonia by nitrogen reduction and hydrogen oxidation. Science 379, 707–712 (2023).

Salmon, N. & Bañares-Alcántara, R. Offshore green ammonia synthesis. Nat. Synth. 2, 604–611 (2023).

Lee, B. et al. Pathways to a green ammonia future. ACS Energy Lett. 7, 3032–3038 (2022).

Wang, Q. et al. Ternary ruthenium complex hydrides for ammonia synthesis via the associative mechanism. Nat. Catal. 4, 959–967 (2021).

Lin, B. et al. Ammonia synthesis activity of alumina-supported ruthenium catalyst enhanced by alumina phase transformation. ACS Catal. 9, 1635–1644 (2019).

Ye, T.-N. et al. Vacancy-enabled N2 activation for ammonia synthesis on an Ni-loaded catalyst. Nature 583, 391–395 (2020).

Gao, W. et al. Production of ammonia via a chemical looping process based on metal imides as nitrogen carriers. Nat. Energy 3, 1067–1075 (2018).

Zuraiqi, K. et al. Liquid metals in catalysis for energy applications. Joule 4, 2290–2321 (2020).

Daeneke, T. et al. Liquid metals: fundamentals and applications in chemistry. Chem. Soc. Rev. 47, 4073–4111 (2018).

Upham, D. C. et al. Catalytic molten metals for the direct conversion of methane to hydrogen and separable carbon. Science 358, 917 (2017).

Taccardi, N. et al. Gallium-rich Pd–Ga phases as supported liquid metal catalysts. Nat. Chem. 9, 862–867 (2017).

Palmer, C. et al. Dry reforming of methane catalysed by molten metal alloys. Nat. Catal. 3, 83–89 (2020).

Zuraiqi, K. et al. Direct conversion of CO2 to solid carbon by Ga-based liquid metals. Energy Environ. Sci. 15, 595–600 (2022).

Esrafilzadeh, D. et al. Room temperature CO2 reduction to solid carbon species on liquid metals featuring atomically thin ceria interfaces. Nat. Commun. 10, 865 (2019).

Kawamura, F. & Taniguchi, T. Synthesis of ammonia using sodium melt. Sci. Rep. 7, 11578 (2017).

Tang, Z., Meng, X., Shi, Y. & Guan, X. Lithium-based loop for ambient-pressure ammonia synthesis in a liquid alloy-salt catalytic system. ChemSusChem 14, 4697–4707 (2021).

Hagen, S. et al. Ammonia synthesis with barium-promoted iron–cobalt alloys supported on carbon. J. Catal. 214, 327–335 (2003).

Rosowski, F. et al. Ruthenium catalysts for ammonia synthesis at high pressures: preparation, characterization, and power-law kinetics. Appl. Catal. A 151, 443–460 (1997).

Bosch, C. & Mittasch, A. Patent number US1128843A (Google Patents, 1915).

Martín, A. J., Mitchell, S., Mondelli, C., Jaydev, S. & Pérez-Ramírez, J. Unifying views on catalyst deactivation. Nat. Catal. 5, 854–866 (2022).

Rivera Rocabado, D. S., Aizawa, M., Noguchi, T. G., Yamauchi, M. & Ishimoto, T. Uncovering the mechanism of the hydrogen poisoning on Ru nanoparticles via density functional theory calculations. Catal. 12, 331 (2022).

Wang, Y. et al. Shielding protection by mesoporous catalysts for improving plasma-catalytic ambient ammonia synthesis. J. Am. Chem. Soc. 144, 12020–12031 (2022).

Wang, F. et al. Insights into the activation effect of H2 pretreatment on Ag/Al2O3 catalyst for the selective oxidation of ammonia. ACS Catal. 9, 1437–1445 (2019).

Sayan, Ş., Kantcheva, M., Suzer, S. & Uner, D. O. FTIR characterization of Ru/SiO2 catalyst for ammonia synthesis. J. Mol. Struct. 480-481, 241–245 (1999).

Mao, C. et al. Beyond the thermal equilibrium limit of ammonia synthesis with dual temperature zone catalyst powered by solar light. Chem 5, 2702–2717 (2019).

Tang, X. et al. Facile fabrication of nanosheet-assembled MnCoOx hollow flower-like microspheres as highly effective catalysts for the low-temperature selective catalytic reduction of NOx by NH3. Environ. Sci. Pollut. Res. 26, 35846–35859 (2019).

Monier, G. et al. DFT and experimental FTIR investigations of early stages of (001) and (111)B GaAs surface nitridation. Appl. Surf. Sci. 465, 787–794 (2019).

Lou, H. et al. Negative expansions of interatomic distances in metallic melts. Proc. Natl Acad. Sci. USA 110, 10068–10072 (2013).

Ruffman, C., Lambie, S., Steenbergen, K. G. & Gaston, N. Structural and electronic changes in Ga–In and Ga–Sn alloys on melting. Phys. Chem. Chem. Phys. 25, 1236–1247 (2023).

Kim, M., Biswas, S., Nava, G., Wong, B. M. & Mangolini, L. Reduced energy cost of ammonia synthesis Via RF plasma pulsing. ACS Sustainable Chem. Eng. 10, 15135–15147 (2022).

Yamijala, S. S. R. K. C. et al. Harnessing plasma environments for ammonia catalysis: mechanistic insights from experiments and large-scale ab initio molecular dynamics. J. Phys. Chem. Lett. 11, 10469–10475 (2020).

Rahim, M. A. et al. Low-temperature liquid platinum catalyst. Nat. Chem. 14, 935–941 (2022).

Tang, J. et al. Oscillatory bifurcation patterns initiated by seeded surface solidification of liquid metals. Nat. Synth. 1, 158–169 (2022).

Tang, J. et al. Unique surface patterns emerging during solidification of liquid metal alloys. Nat. Nanotechnol. 16, 431–439 (2021).

Wang, Q., Guo, J. & Chen, P. Recent progress towards mild-condition ammonia synthesis. J. Energy Chem. 36, 25–36 (2019).

Li, X., Zhang, X., Everitt, H. O. & Liu, J. Light-induced thermal gradients in ruthenium catalysts significantly enhance ammonia production. Nano Lett. 19, 1706–1711 (2019).

Hodgetts, R. Y. et al. Refining universal procedures for ammonium quantification via Rapid 1H NMR analysis for dinitrogen reduction studies. ACS Energy Lett. 5, 736–741 (2020).

Chen, L.-W. et al. Metal–organic framework membranes encapsulating gold nanoparticles for direct plasmonic photocatalytic nitrogen fixation. J. Am. Chem. Soc. 143, 5727–5736 (2021).

Andersen, S. Z. et al. A rigorous electrochemical ammonia synthesis protocol with quantitative isotope measurements. Nature 570, 504–508 (2019).

Zhao, Y. et al. Revealing ammonia quantification minefield in photo/electrocatalysis. Angew. Chem. Int. Ed. 60, 21728–21731 (2021).

Zhao, Y. et al. Ammonia detection methods in photocatalytic and electrocatalytic experiments: how to improve the reliability of NH3 production RATES? Adv. Sci. 6, 1802109 (2019).

Choi, J. et al. Identification and elimination of false positives in electrochemical nitrogen reduction studies. Nat. Commun. 11, 5546 (2020).

Izelaar, B. et al. Identification, quantification, and elimination of NOx and NH3 impurities for aqueous and li-mediated nitrogen reduction experiments. ACS Energy Lett. 8, 3614–3620 (2023).

Ravel, B. & Newville, M. ATHENA, ARTEMIS, HEPHAESTUS: data analysis for X-ray absorption spectroscopy using IFEFFIT. J. Synchrotron Radiat. 12, 537–541 (2005).

Bearden, J. A. & Burr, A. F. Reevaluation of X-ray atomic energy levels. Rev. Mod. Phys. 39, 125–142 (1967).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Tang, W., Sanville, E. & Henkelman, G. A grid-based Bader analysis algorithm without lattice bias. J. Phys. Condens. Matter 21, 084204 (2009).

Humphrey, W., Dalke, A. & Schulten, K. VMD: visual molecular dynamics. J. Mol. Graph. 14, 33–38 (1996).

Giorgino, T. Computing diffusion coefficients in macromolecular simulations: the Diffusion Coefficient Tool for VMD. J. Open Source Soft. 4, 1698 (2019).

Acknowledgements

T.D. acknowledges support from the Australian Research Council (ARC) via the ARC DECRA initiative (DE190100100) and the ARC Discovery Project scheme (DP220101923). T.D. and C.J.P. acknowledge the ARC Centre of Excellence in future low-energy electronics technology via CE170100039. S.S. acknowledges support from the ARC via the ARC DECRA initiative (DE190101450). S.P.R. and N.M. acknowledge the support of the ARC under the Centre of Excellence scheme (project no. CE170100026). K.Z., T.D., J.M. and R.H. acknowledge that this research was undertaken on the XAS beamline at the Australian Synchrotron, part of ANSTO. This research was undertaken with the assistance of supercomputing resources from the National Computational Infrastructure, which is supported by the Australian Government, under the National Computational Merit Allocation Scheme (Project kl59). This research was undertaken with the assistance from QUT’s Central Analytical Research Facility supported by QUT’s Research Portfolio.

Author information

Authors and Affiliations

Contributions

K.Z., K.C., S.S. and T.D. initiated, designed and led the work. Y.J., K.Z., R.H., T.D., S.S., L.W., H.Y.Z. and J.H. developed and contributed to discussion on the methodology. Y.J., K.Z., C.J.P., J.M. and R.H. carried out the experimental work and characterization. K.Z. and Y.J. developed the visualization of the work. A.C., N.M., S.P.R. and M.J.S.S. performed the computational studies and consulted on the MD calculations. K.Z. prepared the initial manuscript. All authors revised and contributed to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

Patent protection is being sought for the invention described in this paper (provisional Australia patent 2022903994).

Peer review

Peer review information

Nature Catalysis thanks Xiaofei Guan and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–34 and Table 1.

Supplementary Data 1

MD electronic structures.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zuraiqi, K., Jin, Y., Parker, C.J. et al. Unveiling metal mobility in a liquid Cu–Ga catalyst for ammonia synthesis. Nat Catal 7, 1044–1052 (2024). https://doi.org/10.1038/s41929-024-01219-z

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s41929-024-01219-z

This article is cited by

-

A colloidal approach for the synthesis of catalytically active solid–liquid–solid nanoparticles

Nature Synthesis (2025)

-

Liquid metal catalyst for ammonia synthesis at low pressure

Science China Materials (2025)

-

Preparation of the LiGa Intermetallic Alloy by Electrochemical or Thermal Method for Ammonia Synthesis

Journal of Sustainable Metallurgy (2025)

-

Without that crystalline touch

Nature Catalysis (2024)