Abstract

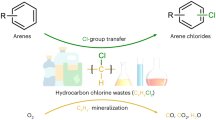

To achieve sustainable resource circulation, preparation of reactive species from stable compounds is unavoidable. Chlorine chemistry is an eco-friendly methodology to address this demand. Chlorine is industrially produced from sodium chloride (NaCl), an abundant natural resource in oceans. Chlorine provides various chemical products, including polymers, through chlorination and subsequent conversion reactions. In these reactions, the byproducts are usually hydrogen chloride, which is commercially utilized as hydrochloric acid and is finally neutralized to NaCl after use. Therefore, chlorine chemistry enables fine chemical production from NaCl with almost no wastage. This review provides an overview of the synthesis of fine chemicals and polymers using chlorine chemistry and discusses them from the perspective of sustainability.

Similar content being viewed by others

Introduction

Chlorine is a typical element that is abundant in seawater, and organisms on Earth, including humans, use organic chlorine compounds to perform life functions1. However, chlorine and organic chlorides are highly toxic, and some have been confirmed to be highly carcinogenic2. Given this background, readers may believe that the chlorine industry is the polar opposite of green chemistry and sustainable development. However, the strong toxicity of organic chlorides is inextricably linked to their excellent reactivity of organic chlorides. Organic chlorides are important synthetic intermediates in polymers, pharmaceuticals, and pesticides. In this review, we discuss how the excellent reactivity of organic chlorides contributes to resource circulation and sustainability. For example, improving the reactivity of naturally occurring stable compounds is necessary to prepare fine chemicals from biomass. Similarly, recovery of chemical potential is required for resource circulation from the final products in the chemical industry, such as plastics. In this context, chlorination and functionalization using organic chlorides are effective tools. To consider the potential of chlorine chemistry in the sustainable chemical industry, we first describe the industrial production of chlorine and explain it from the viewpoint of green chemistry.

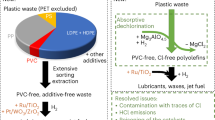

According to the World Chlorine Council, the production of chlorine in the world was 89 Mt in 20183. The common procedure for chlorine production is electrolysis of a NaCl aqueous solution from sea, which is called the chlor-alkali process. The chlor-alkali process is operated using a mercury cell, diaphragm cell, and membrane cell. Membrane cell electrolysis is currently the most popular process owing to its low toxicity and high energy efficiency. 35% of the chlorine produced is used in vinyl chloride resins, and 10% is used in bleach, drinking water disinfection, and inorganic chemicals4. On the other hand, 25% is used as a raw material for resins, such as propylene oxide, epichlorohydrin, and diisocyanate, and as chlorinated intermediates for pharmaceuticals and agricultural chemicals. In this review, we focus on the production and conversion of organic chlorides into functional chemicals.

Although significant efforts have been made5,6, chlorine production still consumes significant amounts of electricity. Therefore, chlorine chemistry may not be considered eco-friendly. However, this perception is not always accurate. Japan has the Fuji River, which is a rapid stream that flows around Mt. Fuji to Suruga Bay (Fig. 1). Taking advantage of this topography, six hydroelectric power plants with a total output of 145 MW of Nippon Light Metal were built in the basin, and most of the electricity required for chlorine production is provided by this renewable energy source7. Large-scale hydroelectric power generation requires the construction of dams, which may impact the environment and cause water resource problems in river basins. On the other hand, the Fuji River, of which total length is less than 130 km, is a raging river that is listed as one of Japan’s three most rapid rivers. Thus, flood control projects have been carried out historically. Currently, the small-scale hydroelectric power plants mentioned above do not simply produce electricity but also contribute to reducing flood damage. Consequently, chlorine production at this plant is a unique business that takes advantage of the characteristics of the local topography, and the issues that are generally discussed on a global scale do not necessarily apply. The chlorine produced is transported by pipeline to the Iharanikkei Chemical Industry Co., Ltd. plant, where it is converted into various functional chemical products8. Furthermore, the by-product, hydrochloric acid, produced in these processes is also used commercially as basic chemical product. Although hydrochloric acid has various demands, including neutralization, cleaning, washing, and acid catalysis in organic reactions, it is ultimately neutralized with a base and processed into sodium or potassium salts. Hence, the chlorine chemistry in this plant guarantees resource circulation. The chemical industry, which takes advantage of these regional characteristics, is important in ensuring sustainability. Therefore, within this complex, chlorine chemistry is an ideal means of adding high value to organic compounds using renewable energy and natural resources, with almost no waste. However, we must refer that surplus hydrogen chloride production has become a problem on a global scale. Thus, chlorine regeneration from hydrogen chloride has attracted attention9. In the next section, we introduce a method to produce functional chemical products from chlorine. Sodium hypochlorite (NaClO), another product of the chlorine industry, is a useful reagent for organic synthesis. For more details, please refer to our previous review10.

Synthesis of organic chlorides from chlorine

Chlorination using chlorine

Electrophilic aromatic substitutions11 and photochlorination12 are important elementary reactions in the organic chlorine industry. The electrophilic aromatic substitution of toluene (1) is not regioselective and affords a mixture of ortho- and para-isomers 2 and 3 (Fig. 2A). As these isomers are useful raw materials for fine chemicals, they must be separated by distillation. Because the difference between the boiling points is only 3 °C at normal pressure, Iharanikkei Chemical Industry purifies these isomers using a distillation column with more than 300 theoretical plates. In contrast, the photochlorination is regioselective. Because the reaction proceeds via a radical mechanism, it occurs regioselectively at certain positions to afford stable radicals. For example, the photochlorination of toluene occurs at the benzyl position (Fig. 2B). However, photochlorination is a chain reaction in which a mixture of mono-, di-, and tri-substituted toluenes 4, 5, and 6 is generated. These compounds are separated using a distillation column with more than 30–40 theoretical plates.

Di- and tri-chlorotoluene derivatives

The products of toluene photochlorination can be converted to other functional chemicals via further modification. 4 is majorly used as a benzylation reagent in organic chemical industry. The hydrolysis of α,α-dichlorotoluene (5), known as benzal chloride, affords benzaldehyde 713. For example, a patent of performing hydrolysis at 70–75 °C in the presence of a zinc hydroxide catalyst was reported14. This is a typical industrial process for the preparation of aromatic aldehydes (Fig. 2C). Similarly, the hydrolysis of α,α,α-trichlorotoluene (6), also known as benzotrichloride, results in benzoyl chloride (8) (Fig. 2D). This reaction can proceed simply by adding water and heating; however, the hydrolysis of 8 also proceeds to afford benzoic acid if excess water is added15. Therefore, water must be added gradually to suppress excessive reactions. Industrially, a catalyst should be added to increase the reaction rate, and catalyst residues should also be considered. ZrO2‧nH2O16, FeCl317, and ZnCl218 have been reported as suitable catalysts. Moreover, the chlorine–oxygen exchange reaction between 6 and aromatic carboxylic acid 9 affords two aromatic acyl chlorides, 10 and 8 (Fig. 2E). In contrast to the hydrolysis of 8, which may afford benzoic acid via an excessive reaction, the chlorine-oxygen exchange does not accompany such side reactions. Therefore, it has been widely studied industrially, and many related patents using ZnCl219 and FeCl320 catalysts have been filed.

The combination of the elementary reactions described in Fig. 2 enables the synthesis of various organic chlorides with higher values. For example, toluene is converted to p-chlorobenzaldehyde (12), an intermediate of pharmaceuticals and agricultural chemicals, via an electrophilic aromatic substitution reaction, followed by photochlorination and hydrolysis (Fig. 3A)21. Terephthaloyl chloride (16), a monomer of polyesters and polyamides, is prepared from p-xylene via photochlorination and a chlorine–oxygen exchange reaction (Fig. 3B)22. This protocol is also effective for the synthesis of 1,4-cyclohexane dicarbonyl chloride (18), a promising monomer for bio-based polyesters (Fig. 3C)23. Isomerization from the cis isomer to the trans isomer occurs in the chlorine–oxygen exchange reaction between 17 and 6. Nevertheless, because the melting points of 18 T and 18 C are significantly different, separation by filtration resulted in high purity of each isomer24.

Phthaloyl chloride

As described later in this section, phthaloyl chloride (24) is a convenient reagent for chlorination and oxidation. Because 16 was prepared from 13 (Fig. 3B), a similar procedure seems effective for the preparation of 24. However, the photochlorination of o-xylene (19) does not afford the hexa-substituted product because the steric hindrance of penta-substituted product 20 prevents further photochlorination (Fig. 4A)25. Therefore, a multistep reaction is required to obtain 2426. The hydrolysis of 20 resulted in aldehyde 21, which is in a tautomerization with lactone 22. Photochlorination of 22 affords 23, which is a tautomer of 24. This multistep synthesis is inefficient, and other routes to 24 are desirable.

Treatment of phthalic anhydride (25) with common chlorination reagents, such as PCl5 and SOCl2, yielded 24, although unreacted 25 remained in the reaction system (Fig. 4B)27,28. Unfortunately, the boiling point of 24 (276 °C) is close to that of 25 (284 °C), and purification by distillation is not practical. Thus, quantitative chlorination was necessary to obtain 24 with high purity. Some patents claim that phosgene is effective in addressing this demand, although its use should be avoided in industrial applications owing to its toxicity27, 29, 30. Kyrides reported the chlorination of 25 using benzotrichloride 6 in the presence of ZnCl2 (Fig. 4C)31. Technical issues include the requirement of a large amount of catalyst (10 mol%) for the reaction at 120 °C and inadequate purity (< 95%) due to the remaining unreacted 25. We discovered that ZrCl4 was a more active catalyst than ZnCl232. A small amount (0.1 mol%) of ZrCl4 was sufficient even at 160 °C, resulting in 24 with very high purity (>99%). ZnO was also found effective, although the activity was lower than ZrCl433.

24 functions an excellent chlorination reagent for carboxylic acids (Fig. 4D)34, 35. Chlorination does not require catalysts. In fact, the treatment of methacrylic acid (26) with 24 resulted in 27 with a high purity (> 99%)36. Such high-purity acyl chlorides are useful for precise polymerization chemistry37. 24 functions as a precursor of the Vilsmeier-Haack (V-H) reagent (Fig. 4E). For example, the treatment of 24 with N,N-dimethylformamide (DMF) in a low-polarity solvent such as toluene, o-chlorotoluene, or 1,4-dioxane at ambient temperature resulted in the precipitation of the V-H reagent 2838. Filtration of the reaction mixture afforded 28 as a colorless solid, and the reaction with carboxylic acid afforded the corresponding acyl chloride. For example, the reaction of 28 and 29 in 1,4-dioxane at 70 °C afforded 30 in a high yield (86%). Note that 30 was insoluble in 1,4-dioxane and DMF at 25 °C, and colorless precipitation was observed after cooling the reaction mixture. Thus, 30 was obtained by filtration. 28 was also effective for the chlorination of primary and secondary alcohols38 (Fig. 4F) and formylation of aromatic rings38, 39 (Fig. 4G).

Sustainable polymers using monomers derived via chlorine chemistry

As mentioned above, chlorine chemistry provides aromatic aldehydes and acyl chlorides with almost no waste. Historically, dialdehydes have been applied to polyaddition via imine formation40,41 and the Morita-Baylis-Hillman reaction42,43, whereas divalent acyl chlorides are common monomers of polyesters and nylons. On the other hand, monomers derived via chlorine chemistry, including dialdehydes and divalent acyl chlorides, have gained researchers’ attention from a viewpoint of sustainability. This section introduces the new trends in the field of polymer chemistry.

Bio-based divalent acyl chlorides

2,5-furandicarboxy chloride

The production of plastics has been supported by the petrochemical industry, although a shift to bio-based materials is desirable. 2,5-Furandicarboxylic acid, derived from glucose or fructose44, is one of the top value-added chemicals in biomass, as defined by the US Department of Energy45. Therefore, the corresponding acyl chloride 35 is important as a monomer with higher electrophilicity.

Wu and coworkers prepared a bio-based polyester 38 via acyclic diene metathesis (ADMET) polymerization of diene 37, derived from 35, followed by hydrogeneration (Fig. 5A)46. Notably, the physical properties of 38 were similar to those of polyethylene. The ring-opening polymerization of cyclic oligoester 40 prepared from 35 and diol 39 has also been reported (Fig. 5B)47. As the direct polycondensation of divalent carboxylic acids and diols does not afford a high-molar-mass polymer48, such a two-step process is often preferred. Recently, Arai et al. reported the synthesis of polyamide 43 from 35 and bifuran diamine 4249. This is a fully furan-based polymer with a high glass transition temperature (Tg) of 193 °C (Fig. 5C). Kanetaka et al. prepared poly(ether ketone) 47 from 35 (Fig. 5D)50. 47 exhibited a 5% weight loss temperature (Td5), melting point (Tm), and Tg of 414, 337, and 143 °C, respectively, suggesting its performance as an engineering plastic, although the content of bio-based moieties was not high.

Epoxy resins account for the majority in the thermosetting resin market and are used in a variety of applications, including coatings and fiber-reinforced plastics, because of their thermal stability, mechanical strength, and chemical resistance. It is desirable to replace monomers with biomass-derived products without sacrificing their excellent properties. Miao et al. reported a new epoxy resin prepared from 35, eugenol, and methyl hexahydrophthalic anhydride51. Although almost all moieties of this epoxy resin were composed of bio-based moiety, it exhibited excellent mechanical performance and heat resistance comparable to a common petroleum-derived epoxy resin. Recently, Wu et al. reported a bio-based and chemically recyclable epoxy resin (Fig. 5E)52. Diepoxide 48, prepared from 35, and bio-based diamine 49 were reacted to form a network polymer 50. Epoxy resin 50 exhibited a Tg of 170 °C, a storage modulus (E′) of 1.2 GPa, and chemical resistance alcohols except methanol. Remarkably, the alcoholysis of 50 using methanol at 70 °C resulted in the recovery of diester 51 and alcoholic residues, which could be converted to 49 and glycidol, the raw materials of 50. Therefore, this resin was evaluated to be chemically recyclable.

Itaconyl chloride

Itaconic acid53 (56) is another dicarboxylic acid listed in the top value-added chemicals in biomass by the US Department of Energy45. Its derivatives have also been recognized as bio-based acryl monomers for radical polymerization54,55,56. However, the corresponding acyl chloride (58) was difficult to synthesize using common chlorination reagents such as SOCl2 and PCl5 in high yield and purity, because the chlorination of 56 afforded a stable intermediate, itaconyl anhydride (57)57. Because polycondensation is sensitive to monomer purity, a synthetic procedure to prepare 58 with a high purity (>99%) is desirable.

Dichloromethyl alkyl ethers function as strong chlorination reagents for carboxyl acids and esters in the presence of Lewis acid catalysts, such as ZnCl2. Because dichloromethyl alkyl ethers with short (C1–C3) alkyl groups have low boiling points, butyl ether 55 was prepared via the reaction of butyl formate and oxalyl chloride (Fig. 5F)58,59. The DMF catalyst was not effective, probably because of the poor solubility of the corresponding intermediate, V-H reagent 28. In contrast, N-methyl-N-phenyl formamide (54) was effective in producing 55. The treatment of 56 or 57 with 55 in the presence of ZnCl2 or ZnO resulted in a high purity (>99%) and quantitative yield of 5860. In the polycondensation of 56 and its esters with diols, the thermal polymerization of acryl moieties via a radical mechanism must be avoided to obtain linear polymers. Thus, the high reactivity of 58 was effective for achieving polycondensation at lower temperatures.

Chemically recyclable monomers derived via chlorine chemistry

Phthalaldehydes

As mentioned at the beginning of this section, polyaddition of dialdehydes and diamines are reversible reaction, and the resulting polyimines, also known as “dynamers,” have a potential to chemical recycling40. Recently, Xiao et al. reported polycondensation using the Hooz reaction, a three-component condensation of divalent diazocarbonyl compounds 59, dialdehydes 60, and trialkylborons 61 (Fig. 6A)61. Although the main chain was composed of a carbon skeleton, the retro-aldol reaction using potassium hydroxide resulted in a recovery of 60. Thus, this polymer was partially recyclable.

Phthalaldehyde (63b) affords polyacetals via cationic polymerization, although the ceiling temperature (Tc) is low (−36 °C)62. Therefore, the activation of the chain end immediately causes depolymerization at ambient temperature, and this feature is applied to chemically amplified photoresists63 and self-immolative polymers64, that is, polymers that undergo depolymerization triggered by the removal of specific groups usually located in chain ends or pendant groups65,66. In contrast, the cyclic polymer 64 was relatively stable because of the absence of chain ends (Fig. 6B). Lutz et al. investigated the effects of the aromatic substituents of 63 on their Tc67. Notably, the degradation temperature (Td) exhibited a linear relationship with Tc, and the monomer with a perfluoro aromatic ring (63e) exhibited thermal stability up to ca. 200 °C. Therefore, stability and recyclability can be tuned by modifying the aromatic substituents.

Cyclic viny esters

Cyclic vinyl esters are another category of monomers derived by chlorine chemistry. For example, cyclic ketene acetal ester 66 was obtained via the chlorination of acetylsalicylic acid (72) by V-H reagent 28 followed by intramolecular esterification (Fig. 6C)68. Kazama et al. reported radical polymerization of 66 using 2,2′-azobis(isobutyronitrile) (AIBN)69,70. Notably, hydrolysis of the resulting polymer 67 in dimethyl sulfoxide (DMSO) using HCl aq or NaOH aq afforded acetic acid (68) and salicylic acid (69). The reaction mechanism was explained by the hydrolysis of each component consisting of 67, that is, esters, acetals, and 1,3-dicarbonyl skeletons. Because 68 and 69 are the raw materials of 72, polymers 67 and 71 are principally chemically recyclable. In practice, the reuse of 68 is not realistically effective; it is not worth reusing 68 because of the hassle of isolation and purification. The true value of these results is that 69 was used as a platform to construct a polymerization-active vinylidene group using acetic acid. 69 was recovered by extraction of hydrolysis products of 67. Thus, the resynthesis of 72 was possible using the recovered 69 and the renewable reagent, acetic anhydride. In this meaning, 67 could be evaluated as a chemically recyclable vinyl polymer. Recently, Goto et al. reported similar cyclic ketene acetal esters as recyclable vinyl monomers71. Kazama et al. also reported that the cationic polymerization of 66 using BF3‧OEt2 as an initiator also afforded 6770. In contrast, the use of a binary initiator of 70 and EtAlCl2 below 0 °C resulted in poly(ester ketone) 71 by ring-opening polymerization (ROP) via cation isomerization. 71 was also degraded by NaOH aq to yield 68 and 69 via the hydrolysis of esters and 1,3-dicarbonyl skeleton, respectively. Therefore, 66 is a recyclable two-role monomer for vinyl polymerization and ROP.

Cyclic vinyl ester 76, which was prepared from 25 and malonic acid (73), is another recyclable vinyl monomer (Fig. 6D)72. Herein, 25 and 53 are products of chlorine chemistry. Radical polymerization of 76 resulted in the corresponding vinyl polymer 7773,74. The hydrolysis of 77 causes the ring-opening of lactone moieties to enhance the steric repulsion of pendant groups, leading to chain scission and depolymerization to afford monomer precursors 74 and 75 as a mixture of tautomers72.

Covalent adaptable networks

Molecular strategies that utilize reversible covalent bond formation are known as dynamic covalent chemistry (DCC)75. DCC is attractive for achieving reversible polymer synthesis/degradation76; the dynamers40 and polyacetals described in 3.2.1 are typical examples. Similarly, DCC has been applied to the reversible crosslinking of polymers77. Historically, the aim has been to completely decrosslink network polymers and recycle recovered linear polymers. In recent years, attention has shifted from decrosslinking to the reconstruction of crosslinked structures. If the exchange of the crosslinked points is sufficiently fast, the reformation of the crosslinked structures follows deformation. Thus, the crosslinked resin becomes processable, even though the crosslinked structure is not removed. Such resins are known as covalent adaptable networks (CANs)78,79. CANs, whose crosslinked structure is reformed via bond exchange by an addition–elimination mechanism (associative bond exchange), are specifically defined as vitrimers because of their unique rheological properties80. In addition to processability, CANs are chemically recyclable via decrosslinking. Therefore, CANs are expected to contribute to sustainability as an alternative to conventional thermosetting resins.

Condensation between amines and aldehydes, that is, imine formation, is a reversible reaction. Importantly, the imide exchange reaction, which is typically promoted by heat and polar solvents, proceeds even in the absence of catalysts. Therefore, imine bonds are convenient for application in CANs. Terephthalaldehyde (60a), a product of α,α,α′,α′-tetrachloroxylene hydrolysis, is often used for imine formation in CANs. For example, Ling et al. prepared CANs (vitrimers) by crosslinking poly(amide imine) 80 with amine ends using triester 81 (Fig. 7A)81. The resulting network polymer 82 exhibited stress relaxation and processability, suggesting the reconstruction of the network structure by an imine exchange reaction. The tensile strength was up to 47 MPa, and the creep resistance was improved compared with that of typical imine-based CANs. These properties were attributed to the hydrogen bonds formed in the amide groups.

Recently, Deng et al. reported CANs prepared from acylhydrazine 83 and di- or tri-aldehydes 60a and 84 (Fig. 7B)82. In this study, the 1,2-dithiolane moieties of 83 were incorporated into ROP to construct the backbone. Resin 85 exhibits both processability and mechanical toughness owing to the imine exchange reaction and hydrogen bonds. In addition, depolymerization of the backbone polymer occurred in dimethyl sulfoxide (DMSO). Additional experiments suggested that depolymerization was promoted in polar solvents, such as DMSO and DMF, and the free acylhydrazine groups functioned as initiators of depolymerization. Therefore, the combination of DMSO for depolymerization and hydrazine for decrosslinking of imine bonds afforded 83, indicating partial chemical recycling.

Aromatic aldehydes are good reactants for Knoevenagel condensation. Thus, Wang et al. used aromatic aldehydes as good reactants for the Knoevenagel condensation of 60a and triarm α-cyanoacetate 8683. Model reactions using small molecules suggested bond exchange between the Knoevenagel adducts. Network polymer 87 exhibited malleability and reprocessability, suggesting its performance as a CANs. Typically, CANs have poorer mechanical properties, particularly creep resistance, than conventional thermosetting resins. To improve them, hydrogen bonds were incorporated in the previously described examples 82 and 85. In contrast, 87 exhibited excellent mechanical properties despite the absence of hydrogen bonds. The Young’s modulus and tensile strength were 3.8 GPa and 102 MPa, respectively, while the coefficient of thermal expansion from 30 to 80 °C was 82 ppm K–1. These excellent properties were attributed to the long conjugated system of Knoevenagel adducts. Furthermore, the treatment of 87 with sodium hydroxide resulted in the recovery of 60a.

Outlook

This review provides an overview of the production of chlorine and organic chlorides and their applications in sustainable polymers. Since chlorine gas is rarely used in a laboratory, researchers may have an impression of its toxicity and corrosivity to chlorine and organic chlorides. We hope to improve the evaluation of chlorine chemistry through this review. The benefits of chlorine chemistry can be summarized as follows:

1. Chlorine is an abundant naturally derived resource. Chlorine is an abundant, naturally derived resource that can be obtained through the electrolysis of seawater. The power consumption problem can be almost completely solved by hydroelectric power generation using rapids. A chemical industry that takes advantage of regional characteristics is important to promote SDGs.

2. A clean chemical industry with almost no waste is produced. Aromatic aldehydes and acyl chlorides are produced from toluene derivatives, chlorine, water, and ultraviolet (UV) light. Acyl chloride can be converted into other acyl chlorides via oxygen-chlorine exchange reactions. The hydrochloric acid produced as a byproduct also has commercial value.

3. Chlorine chemistry enables the use of bio-based compounds and resource circulation. Acyl chloride, aldehyde, hydrochloric acid, and sodium hydroxide, produced by chlorine chemistry, are highly reactive reagents. These reagents are effective for chemical modification and activation of stable and unreactive biomass-derived compounds. In addition, resource recycling through synthesis/degradation using these reagents has been studied in cutting-edge polymer chemistry.

We believe that chlorine chemistry will lead to green chemistry and the development of sustainable polymer materials. However, acyl chlorides are easily hydrolyzed to generate hydrogen chloride during transportation and storage, which poses the problem of corroding metal products. To address this issue, we examined acyl-1,2,4-triazole 89, derived from the corresponding acyl chloride 88 and 1,2,4-triazole (Fig. 8)84. In the presence of 4-(N,N-dimethylamino)pyridine (DMAP), 89 converted alcohols to esters at a rate comparable to that of 88. The byproduct was 1,2,4-triazole, which is water-soluble and has low toxicity. Bulk polycondensation using divalent acyl-1,2,4-triazole 91 and diol 92 at 80 °C afforded polyester 9385,86.

Sustainable use of organic chlorides requires safe and convenient alternatives that can be easily derived from organic chlorides. Furthermore, the huge amount of electricity consumed during chlorine production is a significant issue, even though it is managed by hydroelectric power. Improvements in chlorine production methods remain an important research topic. We look forward to the day when chlorine chemistry can overcome these issues and truly contribute to the SDGs.

References

Winterton, N. Chlorine: the only green element—towards a wider acceptance of its role in natural cycles. Green. Chem. 2, 173–225 (2000).

Huang, B., Lei, C., Wei, C. & Zeng, G. Chlorinated volatile organic compounds (Cl-VOCs) in environment—sources, potential human health impacts, and current remediation technologies. Environ. Int. 71, 118–138 (2014).

World Chlorine Council. Sustainability Progress Report. https://worldchlorine.org/wp-content/uploads/2020/09/2020-WCC-Sustainability-Report.pdf (2024).

Chlorine-Sodium Hydroxide (Chlor-Alkali). https://www.spglobal.com/commodityinsights/en/ci/products/chlorine-sodium-chemical-economics-handbook.html (2024).

Wang, Y., Liu, Y., Wiley, D., Zhao, S. & Tang, Z. Recent advances in electrocatalytic chloride oxidation for chlorine gas production. J. Mater. Chem. A Mater. Energy Sustain. 9, 18974–18993 (2021).

Karlsson, R. K. B. & Cornell, A. Selectivity between oxygen and chlorine evolution in the chlor-alkali and chlorate processes. Chem. Rev. 116, 2982–3028 (2016).

Kambara Complex|Nippon light metal company, ltd. https://www.nikkeikin.com/company/seizou/ (2024).

Iharanikkei’s Strengths. Iharanikkei chemical industry co., ltd. https://www.iharanikkei.net/company/solution.html (2024).

Pérez-Ramírez, J. et al. Sustainable chlorine recycling via catalysed HCl oxidation: from fundamentals to implementation. Energy Environ. Sci. 4, 4786–4799 (2011).

Kirihara, M. et al. Sodium hypochlorite pentahydrate crystals (NaOCl·5H2O): a convenient and environmentally benign oxidant for organic synthesis. Org. Process Res. Dev. 21, 1925–1937 (2017).

Aromatic Substitution, Electrophilic. In March’s Advanced Organic Chemistry pp. 657–751 (John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007).

Tournier, A., Deglise, X. & André, J. C. Industrial photochemistry V: modelling and trial runs of a reactor with separate photochemical and thermal steps. J. Photochem. 22, 313–332 (1983).

Davies, W. & Perkin, W. H. CCLXIV.—the chlorination and bromination of the toluic acids and the preparation of the phthalaldehydic acids. J. Chem. Soc. Trans. 121, 2202–2215 (1922).

Sato, S., Watanabe, O., Ichikawa, J., Production of benzaldehyde compound. JP:S60248640:A, December 9, 1985. JP: H04061862B (1992).

Xiong, W., Shi, Q. & Liu, W. H. Simple and practical conversion of benzoic acids to phenols at room temperature. J. Am. Chem. Soc. 144, 15894–15902 (2022).

Tomita, K. Production of benzenecarbonyl chloride derivative. JP:H09-067302:A (1997).

Nakano, T., Ohkawa, K., Matsumoto, H. & Nagai, Y. Synthesis of aroyl chlorides from substituted benzotrichlorides. Org. Prep. Proc. Inter. 10, 291–293 (1978).

Li, Q., Li, F., Chen, S., Liu, J., Wu, Q. Preparation of mebendazole. CN113956205A (2022).

Chen, Q. & Li, K. A Kind of Preparation Technology of Benzoyl chloride. CN103787874B (2015).

Freidlin, E. G., Shcherbik, L. K., Palei, B. A., Krasil’nikova, G. S. & Shadrova, N. N. Study of the reaction of substituted benzoic acids and potassium benzoate with benzotrichloride. Zhur. Org. Khim. 16, 1040–1043 (1980).

McEwen, W. L. Org. Synth. 12, 12 (1932).

Alex, H. Improvements in or relating to benzne dicarboxylic acid dichlorides. DE 1170928B (1959).

Yoon, W. J. et al. Advanced polymerization and properties of biobased high Tg polyester of isosorbide and 1,4-cyclohexanedicarboxylic acid through in situ acetylation. Macromolecules 46, 2930–2940 (2013).

Kimura, Y., Yamaoka, T. Method of obtaining trans-cyclohexane-1,4-dicarboxylic acid dichloride. JP:2014047201:A (2014).

Bhatt, M. V., El Ashry, S. H. & Somayaji, V. Indian J. Chem. 19B, 473–486 (1980).

Hara, S. Preparation method of aromatic polycarboxilic acid chlorides. JP:S47-027949:A, October 30th, 1972. JP: S52020464B (1977).

Rohde, T., Henkelmann, J. Method for the Production of Phthalic Dichloride. WO2006056436:A1 (2006).

Ott, E. Symmetrical and unsymmetrical o-phthalyl chlorides. Org. Synth. 11, 88 (1931).

Job, A. D. Process for the preparation of phthaloyl chloride. US: 7154003B (2006).

Nagata, T., Tamaoki, A., Wada, M. Preparation of carboxylic acid chloride. JP:S56103131:A, August 18, 1981. JP: S63032775B (1988).

Kyrides, L. P. Phthalyl chloride. J. Am. Chem. Soc. 59, 206–208 (1937).

Kimura, Y., Takao, Y., Sugiyama, T., Hanawa, T., Ito, H. Method for producing phthalic dichloride compound and catalyst used in the production method. JP:5649288:B2 (2014).

Kimura, Y., Takao, Y., Sugiyama, T., Hanawa, T., Ito, H. Method for producing high-purity raw material containing phthalic dichloride compound. JP:5438946:B2 (2013).

van Dorp, W. A. & van Dorp, G. C. A. Sur Les Chlorures Des Acides Fumarique et Maléique et Sur Quelques-Uns de Leurs Dérivés. Recl. Trav. Chim. Pays-Bas Belg. 25, 96–103 (1906).

Yamazaki, T., Ichige, T. & Kitazume, T. Convenient preparation of 2-phenylethyl-3,3-difluoro-2-methylpropionate. Collect Czech Chem. Commun. 67, 1479–1485 (2002).

Kimura, Y., Wada, N., Takaya, K. Method for producing high-purity methacrylic acid chloride. JP:2012082176:A, April 26, 2012. JP5788657B (2015).

Kohsaka, Y. & Nagatsuka, N. End-reactive poly(tetrahydrofuran) for functionalization and graft copolymer synthesis via a conjugate substitution reaction. Polym. J. 52, 75–81 (2020).

Kimura, Y., Matsuura, D., Hanawa, T. & Kobayashi, Y. New preparation method for Vilsmeier reagent and related imidoyl chlorides. Tetrahedron Lett. 53, 1116–1118 (2012).

Warashina, T. et al. Regioselective formylation of pyrrole-2-carboxylate: crystalline Vilsmeier reagent vs dichloromethyl alkyl ether. Org. Process Res. Dev. 23, 614–618 (2019).

Fukuda, K., Shimoda, M., Sukegawa, M., Nobori, T. & Lehn, J.-M. Doubly degradable dynamers: dynamic covalent polymers based on reversible imine connections and biodegradable polyester units. Green. Chem. 14, 2907–2911 (2012).

Hui, Z. & Gandini, A. Polymeric Schiff bases bearing furan moieties. Eur. Polym. J. 28, 1461–1469 (1992).

Ji, S., Bruchmann, B. & Klok, H.-A. Synthesis of side-chain functional polyesters via Baylis–Hillman polymerization. Macromolecules 44, 5218–5226 (2011).

Ji, S. H., Bruchmann, B. & Klok, H. A. Exploring the scope of the Baylis-Hillman reaction for the synthesis of side-chain functional polyesters. Macromol. Chem. Phys. 212, 2612–2618 (2011).

Cai, J., Li, K. & Wu, S. Recent advances in catalytic conversion of biomass derived 5-hydroxymethylfurfural into 2,5-furandicarboxylic acid. Biomass. Bioenergy 158, 106358 (2022).

Werpy, T., Petersen, G. Top Value Added Chemicals from Biomass: Volume I -- Results of Screening for Potential Candidates from Sugars and Synthesis Gas; Office of Scientific and Technical Information (OSTI). https://doi.org/10.2172/15008859 (2004).

Wu, Q. et al. Recyclable biomass-derived polyethylene-like materials as functional coatings for commercial fabrics: toward upcycling of waste textiles. ACS Sustain. Chem. Eng. 10, 17187–17197 (2022).

Pfister, D., Storti, G., Tancini, F., Costa, L. I. & Morbidelli, M. Synthesis and ring-opening polymerization of cyclic butylene 2,5-furandicarboxylate. Macromol. Chem. Phys. 216, 2141–2146 (2015).

Kricheldorf, H. R., Langanke, D., Spickermann, J. & Schmidt, M. Macrocycles. 10. macrocyclic poly(1,4-butanediol−ester)s by polycondensation of 2-stanna-1,3-dioxepane with dicarboxylic acid chlorides. Macromolecules 32, 3559–3564 (1999).

Arai, K. et al. Synthesis of biobased polyamides containing a bifuran moiety and comparison of their properties with those of polyamides based on a single furan ring. ACS Appl. Polym. Mater. 5, 3866–3874 (2023).

Kanetaka, Y., Yamazaki, S. & Kimura, K. Preparation of poly(ether ketone)s derived from 2,5-furandicarboxylic acid via nucleophilic aromatic substitution polymerization. J. Polym. Sci. A Polym. Chem. 54, 3094–3101 (2016).

Miao, J.-T., Yuan, L., Guan, Q., Liang, G. & Gu, A. Biobased heat resistant epoxy resin with extremely high biomass content from 2,5-furandicarboxylic acid and eugenol. ACS Sustain. Chem. Eng. 5, 7003–7011 (2017).

Wu, X. et al. Closed-loop recyclability of a biomass-derived epoxy-amine thermoset by methanolysis. Science 384, adj9989 (2024).

Robert, T. & Friebel, S. Itaconic acid—a versatile building block for renewable polyesters with enhanced functionality. Green. Chem. 18, 2922–2934 (2016).

Winkler, M., Lacerda, T. M., Mack, F. & Meier, M. A. R. Renewable polymers from itaconic acid by polycondensation and ring-opening-metathesis polymerization. Macromolecules 48, 1398–1403 (2015).

Watanabe, H., Matsumoto, A. & Otsu, T. Polymerization of N-alkyl-substituted Itaconimides and N-(Alkyl-substituted Phenyl)itaconimides and characterization of the resulting polymers. J. Polym. Sci. A Polym. Chem. 32, 2073–2083 (1994).

Ohtake, T., Ito, H., Horiba, K., Toyoda, N. & Kohsaka, Y. Polymeric surfactants bearing divalent carboxy pendants for stable color dispersions with high redispersibility. ACS Appl. Polym. Mater. 5, 4901–4909 (2023).

Feuer, H. & Pier, S. M. Itaconyl chloride. Org. Synth. 33, 41 (1953).

Warashina, T., Matsuura, D. & Kimura, Y. Efficient preparation of dichloromethyl alkyl ethers and their application in the formylation of aromatic compounds: scope and limitations. Tetrahedron 75, 608–616 (2019).

Kimura, Y. & Warashina, T. Convenient preparation of dichloromethyl alkyl ethers. Tetrahedron Lett. 58, 4598–4599 (2017).

Kawatani, R., Aoki, Y., Tezuka, S., Kimura, Y. & Kohsaka, Y. Synthesis of itaconyl dichloride with high purity and its application to polycondensation. Tetrahedron 161, 134071 (2024).

Xiao, Y., Zhou, Q., Fu, Z., Yu, L. & Wang, J. Synthesis of poly(β-hydroxyketone)s with three-component polymerization of diazocarbonyl compounds, triethylboron, and aldehydes. Macromolecules 55, 2424–2432 (2022).

Kaitz, J. A. & Moore, J. S. Copolymerization of o-phthalaldehyde and ethyl glyoxylate: cyclic macromolecules with alternating sequence and tunable thermal properties. Macromolecules 47, 5509–5513 (2014).

Coulembier, O. et al. Probe-based nanolithography: self-amplified depolymerization media for dry lithography. Macromolecules 43, 572–574 (2010).

Seo, W. & Phillips, S. T. Patterned plastics that change physical structure in response to applied chemical signals. J. Am. Chem. Soc. 132, 9234–9235 (2010).

Shelef, O., Gnaim, S. & Shabat, D. Self-immolative polymers: an emerging class of degradable materials with distinct disassembly profiles. J. Am. Chem. Soc. 143, 21177–21188 (2021).

Yardley, R. E., Kenaree, A. R. & Gillies, E. R. Triggering depolymerization: progress and opportunities for self-immolative polymers. Macromolecules 52, 6342–6360 (2019).

Lutz, J. P. et al. Functionalized and degradable polyphthalaldehyde derivatives. J. Am. Chem. Soc. 141, 14544–14548 (2019).

Babin, P. & Bennetau, B. 2-alkylidene-benzo[1,3]dioxin-4-ones: a new class of compounds. Tetrahedron Lett. 42, 5231–5233 (2001).

Kazama, A. & Kohsaka, Y. Radical polymerization of “dehydroaspirin” with the formation of a hemiacetal ester skeleton: a hint for recyclable vinyl polymers. Polym. Chem. 10, 2764–2768 (2019).

Kazama, A., Kohsaka, Y. Diverse chemically recyclable polymers obtained by cationic vinyl and ring-opening polymerizations of the cyclic ketene acetal ester “dehydroaspirin.” Polym. Chem. https://doi.org/10.1039/d2py01181f.

Oh, X. Y., Ge, Y. & Goto, A. Synthesis of degradable and chemically recyclable polymers using 4,4-disubstituted five-membered cyclic ketene hemiacetal ester (CKHE) monomers. Chem. Sci. 12, 13546–13556 (2021).

Chiba, Y., Kawatani, R. & Kohsaka, Y. Chemically recyclable vinyl polymers by free radical polymerization of cyclic styrene derivatives. ACS Macro Lett. 12, 1672–1676 (2023).

Ito, H. & Ueda, M. Syntheses of acetophenone enol ester polymers and their conversion to poly(phenylacetylenes). Macromolecules 23, 2885–2894 (1990).

Ito, H., Ueda, M. & Ito, T. Positive deep UV Resist Based on Poly(α-acetoxystyrene). J. Photopolym. Sci. Technol. 3, 335–345 (1990).

Rowan, S. J., Cantrill, S. J., Cousins, G. R. L., Sanders, J. K. M. & Stoddart, J. F. Dynamic covalent chemistry. Angew. Chem. Int. Ed. Engl. 41, 898–952 (2002).

Maeda, T., Otsuka, H. & Takahara, A. Dynamic covalent polymers: reorganizable polymers with dynamic covalent bonds. Prog. Polym. Sci. 34, 581–604 (2009).

Engle, L. P. A review of thermally controlled covalent bond formation in polymer chemistry. J. Macromol. Sci. Part A Pure Appl. Chem. 33, 239–257 (1993).

Scheutz, G. M., Lessard, J. J., Sims, M. B. & Sumerlin, B. S. Adaptable crosslinks in polymeric materials: resolving the intersection of thermoplastics and thermosets. J. Am. Chem. Soc. 141, 16181–16196 (2019).

Kloxin, C. J., Scott, T. F., Adzima, B. J. & Bowman, C. N. Covalent Adaptable Networks (CANs): a unique paradigm in crosslinked polymers. Macromolecules 43, 2643–2653 (2010).

Denissen, W., Winne, J. M. & Du Prez, F. E. Vitrimers: permanent organic networks with glass-like fluidity. Chem. Sci. 7, 30–38 (2016).

Liang, K. et al. Malleable, recyclable, and robust poly(amide–imine) vitrimers prepared through a green polymerization process. ACS Sustain. Chem. Eng. 9, 5673–5683 (2021).

Deng, Y., Zhang, Q., Qu, D.-H., Tian, H. & Feringa, B. L. A chemically recyclable crosslinked polymer network enabled by orthogonal dynamic covalent chemistry. Angew. Chem. Int. Ed. Engl. 61, e202209100 (2022).

Wang, S. et al. Recyclable, malleable, and strong thermosets enabled by Knoevenagel adducts. J. Am. Chem. Soc. 146, 9920–9927 (2024).

Kohsaka, Y., Homma, K., Sugiyama, S. & Kimura, Y. Esterification with aromatic acyl-1,2,4-triazole catalyzed by weak base at the rate comparable to acyl chloride. Chem. Lett. 47, 100–102 (2018).

Kohsaka, Y., Homma, K., Mori, I., Sugiyama, S. & Kimura, Y. Bifunctional acyl-1,2,4-triazole: an alternative monomer of dicarbonyl chloride for metal- and halogen-free polyester synthesis. Chem. Lett. 47, 221–224 (2018).

Kohsaka, Y. et al. Synthesis of polyarylates and aliphatic polyesters by divalent acyl-1,2,4-triazole: a route to metal-free synthesis at low temperature. Polym. J. 53, 887–893 (2021).

Acknowledgements

The authors thank to Ms. Shiori Sato to provide information on a chlorine market.

Author information

Authors and Affiliations

Contributions

Y.Ko. defined the scope of the review, wrote sections, prepared figures, edited, and proofread. D.M. provided information on a chlorine market. Y.Ki. provided information on chlorine chemistry and industry, and contributed proofreading.

Corresponding authors

Ethics declarations

Competing interests

Y.Ki. and D.M. report a relationship with Iharanikkei Chemical Industry Co., Ltd. that includes: employment. Y.Ko. declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Peer review

Peer review information

Communications Chemistry thanks Vânia G. Zuin and the other, anonymous, reviewer for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kohsaka, Y., Matsuura, D. & Kimura, Y. Sustainable synthesis of fine chemicals and polymers using industrial chlorine chemistry. Commun Chem 7, 265 (2024). https://doi.org/10.1038/s42004-024-01345-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-024-01345-6