Abstract

Localized electrochemically grown porous platinum layers on 2D and 3D microstructured materials enable a wide range of applications from electrocatalysis to optoelectronics. These layers exhibit a thickness gradient and surface corner overloading due to electric charge accumulation at the sharp corners. On one hand, these effects can be applied to create ultra-large surface area catalysts or electrocatalysts. On the other hand, they can be mitigated by guiding the electric field at the nanoscale. Here, we show that porous platinum grown on rough conductive silicon synergistically catalyses the electroreduction of CO2 in a humid gaseous atmosphere, overcoming the disadvantage of CO2´s low water solubility. In addition, using template-directed growth of porous platinum, we tuned the optical response of an infrared (IR) metamaterial fabricated by micropatterning on Si/NiCr/Ti substrates and constructed a broad absorber on potential IR-functional microcomponents.

Similar content being viewed by others

Introduction

The chemothermal stability in air of platinum empowers exclusive applications in metrology1, catalysis2 and optoelectronics3. The porous platinum thin layer of ultra-large surface area and good electrical conductivity enables its use as an efficient electrode material for electrocatalysis due to its excellent cycling and recovering performances. Moreover, by applying this porous platinum layer to economical materials such as silicon, silicon dioxide or carbon, one mitigates the issue of cost-effective precious metals while the heterogeneous catalytic activity and noble surface are safeguarded. For example, the heterogenous catalytic activity of the SiO2-supported Pt nanoparticles4, of Au‑M/SiO2 (M = Rh, Pd, Ir, Pt)5, of intermetallic platinum–cobalt electrocatalysts6, of platinum catalyst coupled with transition metal/metal oxide7 have been already demonstrated. Elaborated methods for covering porous metals other than platinum with layers of platinum are comprehensively described in literature8,9. In addition, the applications in optoelectronics and quantum devices require along to the material intrinsic characteristics, a nanoscale precision and accuracy, to prevent instabilities in electronic properties. Porous platinum layers-based optoelectronics have been progressively driven towards nanoscale, where infinite-small structural fluctuations can cause huge undesired deviations in properties. In this regard, controlling the relationship structure - properties is a critical technical request. The geometric properties of the porous platinum nanolayers play an important role in determining their optical properties. Therefore, structural tuning of porous nanolayers by judiciously designing the nanopore´s shape, size, periodicity and their edge geometry remain nowadays an intriguing challenge. Moreover, the insertion of the optical components into the microelectronics mostly requires a non-aqueous media for operation and a possibility of material nanostructuring. We developed the growth of porous platinum nanolayers in non-aqueous media using microelectrochemistry on highly localized areas, enabling a large pallet of applications (Fig. 1). Among them, in the following, we present the applications of electrochemically grown porous platinum´s that ranges from conversion of CO2 to tuning the metamaterial‘s optical properties and further to high absorption of infrared radiation when targeting certain microstructures with potential in thermal sensors. These applications are divided in the following three categories:

-

1.

synergistic electrocatalyst to CO2 conversion by growing porous platinum on raw electrically conductive silicon;

-

2.

adjuster of metamaterial´s optical properties by templated growth of porous platinum;

-

3.

nanoscale localized absorber by electro-engineered porous platinum growth.

The structural and optical characteristics of the electrochemically produced porous platinum layers were examined by the following methods: Scanning Electron Microscopy (SEM), Focus Ion Beam (FIB) coupled with SEM, Atomic Force Microscopy (AFM), X-ray Diffraction (XRD), Energy dispersive X-ray analysis (EDX) and Fourier Transform Infrared Spectroscopy (FTIR) operated under the linearly polarized light.

Results and Discussions

For almost a decade, we have experimentally observed how the electrochemically grown porous platinum layers exhibit surface gradient and surface corner crowding as a result of the uneven distribution and accumulation of electrical charge at the edges and sharp corners of the surface. On the one hand, one can use this effect by creating a large-area catalyst/electrocatalyst (Figs. 2–4) which prove the electrocatalytic activity for CO2 reduction (Fig. 5), on the other hand, one can weaken this effect by finely grating the surface, rounding the edges, and guiding the electric field at the nanoscale to tune the optical properties of the localized platinum layers on 2D -, 3D-microstructured materials (Figs. 6–9). These approaches have enabled us to achieve broad and even divergent applications for porous platinum, which we summarize here and divide into three categories.

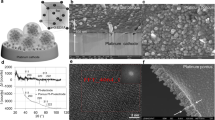

A–C SEM of the porous platinum on platinum (A), on rough conductive silicon (B) and on Cu wire (C); (D) SEM of Cu wire. E–H Corresponding EDX of the electrodes indicated in (A–D). The spectra were recorded at 15 keV or 20 keV, so that Pt-La,b lines are excited. The spectrum (F) was recorded at 10 kV to avoid Si large peak in the spectrum. The Pt-L lines are not excited and are therefore missing. I–L Corresponding raw FTIR transmittance spectra of the CO2 electrohemical conversion recorded on the electrodes indicated in (A–D) at 2 V potential difference between the anode and cathode at an interval of 10 s between the spectra a (red), b (blue), c (greem), d (light greem), respectively.

A–L SEM images at different magnifications of the electrocatalysts: porous platinum on platinum (A–D), porous platinum on conductive silicon (E–H), porous platinum on copper (I–L). The electrocatalyst nanostructure´s mean size extracted from the SEM images: porous platinum on platinum of 92 ± 10 nm, porous platinum on rough conductive silicon 77 ± 10 nm; porous platinum on copper 96 ± 11 nm.

A–C SEM images of the silicon void of porous platinum (A) and of porous platinum on silicon (B, C). D Spectroelectro-chemical setup for CO2 conversion. 1- chambers with humidity of 80–90%; 2- porous platinum grown on rough silicon electrodes; 3-direct current (DC) voltage source; 4-ampermeter; 5- oxygen impermeable membrane connected to CO2 inlet; 6- taps, 7-UV lamp for faciliting CO2 dissociation of 235 nm, 8–100 mL gas chamber equipped with KBr windows and taps, 9-spectrometer. E Photo of the FTIR-gas chamber equipped with KBr windows. F Transmittance spectra of the methanol, ethanol, isopropanol in the gaseous form. G The schematic representation of the carbon dioxide molecule, (ΔGf°=−394.39 kJ/mol) 22. H Transmittance spectra of the evacuated chamber (black line) and of the gas containing CO2 after applying ΔU = 2 V at 0 s (light blue line), 10 s (blue line) at 20 s (green line).

A–D Evolution of cyclic voltammetry (CV) recorded at 0.1 V/s, between +1 V and −1 V, in humid CO2 (A–C) compared with the cyclic voltammetry recorded on indicated electrodes in humid Ar (D). The amplified CV starts at +1 V. The diagrams (A–C) show the CO2 electroreduction activity of porous platinum on platinum (A), porous platinum on rough conductive silicon (B), copper (C), porous platinum on copper (C), respectively, as working electrode, Pt-counter electrode, Reference: Ag/AgCl.

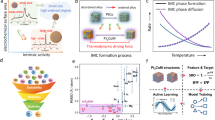

A, B Scanning electron microscopy of the samples before (A) and after (B) growing porous platinum on them; (C, D) FTIR relative reflectance spectra of the samples indicated in (A, B) recorded under 0° and 90° polarization. The spectra demonstrate the polarization dependent response of the resist (R) itself (C) and of the resist (R) polymer microstructured in square-cavity-microarray without/with porous Pt (D). Square cavity microarray are of 16 µm, 8 µm and 4 µm square ‘side, respectively.

A–D Scanning electron microscopy images of the FIB cut samples before (A, B) and after (C, D) growing porous platinum on them. E Top view SEM images in both backscattered (up) and secondary electron (down) contrast modes of the area EDX mapped in (F). F EDX mapping analysis of the porous platinum templated grown in the square array and the corresponding EDX diagram. G FTIR relative reflectance spectra of the samples indicated in (A–D) recorded in the absence of polarizator. Square cavity microarray are of 16 µm, 8 µm and 4 µm square’side, respectively.

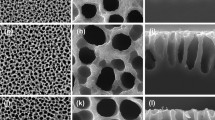

A–F Porous platinum grown at three different electrolysis times (t1 = 60 s, t2 = 90 s, t3 = 160 s), photos (A–C) and SEM images (D–F). G, H The FTIR total reflectance (specular + diffuse reflectance) (G) and specular reflectance (H) spectra of the samples indicated in (A–C). I–K The sketch of total reflectance (I) and diffuse reflectance (J) and the photograph of the integrating sphere (K) used for this experiment; (L). Vacuum transmittance spectra of the pellet of composition indicated in diagram. M–O Photo on pellets of KBr (M) of KBr with porous platinum collected from the cathodes at the ratios of 1 g KBr:\(\frac{1}{200}\) g porous platinum (N) and 1 g KBr:\(\frac{1}{100}\) g porous platinum (O).

A Scheme of the electrochemical setup (EC):1-working electrode (cathode) consist of Si chips (preferably of 1.5 cm × 1.5 cm) modified with 110 nm Pt layer (optional masked), 2-Counter electrode (anode), 3-reference electrode (Platinum quasi-reference); 4-electrical conductors and connectors; 5- programmable source of current; 6-ampermeter; 7-voltmeter; 8-electrochemical cell recipient for the bath made of glass, 9-conector to thermostat for temperature control; 10-thermostat. B Rounding the margins to make the charge do not stop at the margins but to flow under the surface. SEM images of the AFM cantilevers with the rounded and not rounded margins. C Gridding the surface to disrupt the flow of the charge at the edge; SEM images of the gridded samples and a zoom at the grid cross. D Photographs and the SEM images of the gridded samples before and after porous platinum locally grown and used as broad-band absorber in the mid infrared wavelength region. The electrochemical growth is “EC” abbreviated. E, F FTIR reflectance spectra of the porous platinum electrochemically locally grown on square-shaped areas (E) and disc-shaped areas of 500 µm in diameter (F). The insets show the examined squares Q 8, Q 16, Q 24, Q 32, Q 40, Q 48, Q 56 in the photo of the square array as well as the photos of the disk areas on the chip.

Application of porous platinum grown on conductive rough silicon as electrocatalyst

Platinum is renowned for its catalytical performance; however, the high cost impedes it large use. By growing thin layers of porous platinum on economical materials such as silicon or silicon dioxide one increases the catalytic active area of noble metal guarantying the efficiency while mitigating the cost-effective. Reported here is the growth of localized porous platinum nanolayers on electroconductive shaped surfaces such as rough electrically conductive silicon to catalyze the simultaneous and separate production from water of O2 and H2 and further conversion of CO2 to beneficial chemicals.

Porous platinum/Si/SiO2 synergistic electrocatalytic effect for CO2 conversion

The continued increase in atmospheric concentrations of CO2, which in 2024 attained 37.4 billion metric tons10, motivates creatives to develop methods to mitigate its excess by conversion of CO2 in useful chemicals. The products of CO2 conversion as fuels or precursors for the production of more complex chemicals are now in the scientific focus. The low solubility in water of the CO211,12 of 0.1449 grams CO2 per 100 ml H2O at 25 °C12 caused by the small polarization degree of the molecule, coupled with the high dissociation energy of CO bond in CO2 of 191 kcal.mol−1 = 799.144 kJ mol−112 make the CO2 conversion at room temperature and atmospheric pressure a scientific issue nowadays. The stability of CO2 molecule is assured by the electronic distribution in the orbital architecture (Fig. 4G), a linear centrosymmetric structure of two similar C = O bonds. The central carbon participates in the CO2 molecule with two sp-hybridized orbitals and two p orbitals, where each orbital of them is occupied by one decoupled electron. Instead, oxygen participates in the CO2 molecule with one p orbital occupied by two coupled electrons and three sp2 orbitals, two of them occupied by four coupled electrons and the remaining sp2 orbital with an uncoupled electron (Fig. 4G). The orbitals occupied by the uncoupled electrons join together to form pi and sigma bonds, respectively, sigma bonds confer to the whole molecule a pronounced s-character, while the pi bound confer rigidity. In the typically sp² organic compounds, the dissociation energy of carbonyl bound C = O is 178 kcal mol−1 = 744.752 kJ mol−113 while in CO2, the dissociation energy of CO bond is 799.144 kJ mol−114. Despite of CO2 stability, the plants easily use the energy of the sunlight to photosynthesize glucose from water and CO2 absorbed from the air (Eq.1) at no high pressure and no high temperature.

This natural achievement is possible by using the light-driven electrochemical processes at the biological membranes15. The transfer of electrons in photosynthesis are assigned to be an electrochemical process, the oxidation of excited chlorophyll at an electron acceptor complex, which has the role of electrode. The membrane-bound electron transfer molecules play an active role in oxidizing an electron-donor molecule on one membrane side and reduce an electron-acceptor molecule at the reverse side. The structure of energy transducing membranes as a result of the organization of biological electron transfer molecules are key tools for facilitation of the photosynthetic reaction15. Mimicking the nature, experiments conducted under light irradiation showed the splitting of CO216,17,18,19. The work carried out under the ultra violet (UV) light radiation demonstrated the CO2 photodissociation reactions (Eq 2. Eq 3):

Equation 2 at 5.45 eV corresponding to 227.49 nm with the dissociation limit at 7.42 eV corresponding to 167.09 nm16 and Eq. 3 at 11.4 eV corresponding to 108.76 nm16,17,19. Furthermore, dissociation of carbon dioxide at room temperature upon the irradiation with a light at 213 nm and 266 nm has been reported19. An interesting approach infrared spectroscopically assisted of photocatalytic reduction of CO2 in aqueous electrolyte on SiO2/Fe2O3/Reduced Graphene Oxide (RGO) attained high conversion yields18. Furthermore, experiments with chemical20 or electrochemical21 routes conducted in aqueous electrolytes with catalytic materials from platinum to copper that facilitate adsorption, coupling, and hydrogenation via proton-coupled electron transfer processes demonstrated the reduction of CO2 into the valuable chemicals (i.e. methanol, ethanol). Because the standard Gibbs free energy formation of gaseous CO2 (ΔGf° = −394.39 kJ mol−1)22 shows a spontaneous redox reaction [C] + 2[O] = CO2, reducing CO2 requires an amount of energy equal to the standard Gibbs free energy. The standard Gibbs free energy is in a relationship with the potential of an electrochemical cell as follows in Eq. 4:

where n is the number of the transferred electrons, F-Faraday number 96,485 J V−1(mol e−)−1. E°cell-standard potential of the electrochemical cell (V).

The standard potential of CO2 reduction to CH3OH is very small 16 mV versus reversible hydrogen electrode (RHE) and 20 mV versus standard hydrogen electrode (SHE)23 (Eq. 5)) while for the reduction of CO2 to CO it is 103 mV versus SHE24 (6)

Despite of this small values, there are three major inconveniences connected to the CO2 electroreduction in aqueous electrolytes: 1) high overpotential which bring to a reduction process that overlaps the H2 electro-reduced evolution. 2) the low solubility of CO2 in water, 3) low selectivity in products. Therefore, there is a continued effort to find a highly active and efficient catalyst towards selective electroreduction of CO223,24,25,26,27,28,29,30,31,32,33,34 since 1870, when the first electrocatalytic reduction of CO2 to formic acid was reported33. Products, such as monoxide carbon (CO)26,35, formic acid/formiate (HCOOH/HCOO−)31,33, formaldehyde (HCHO)31, methane (CH4)29,30, ethylene (C2H4)28,30, methanol (CH3OH)23,24,25,26,27,28,29,30,31,32,33,34,35,36 or ethanol (CH3CH2OH)37 were achieved. The reported work resumes at the electrocatalytic conversion of CO2 in aqueous electrolytes, nevertheless, recently it was demonstrated the advantage of inserting gaseous phase adjacent to the electrode35 or even to use vapor at 220 °C38 to increase the efficiency of electrocatalysis. Here we show a gaseous process at room temperature, UV light activated electro catalytical conversion of CO2 to CH3OH. In this direction, here, we compare the electro catalytical activity of the established electrocatalysts such as porous platinum on platinum, porous platinum on copper and copper void of platinum with the proposed one: porous platinum electrochemically grown on conductive rough silicon. Both morphological and composition analysis of the electrodes are presented in the Figs. 2,3. Figure 2A–D and Fig. 3A–O show the SEM images, while Fig. 2E–H shows the EDX of the used electrodes. By in situ FTIR analysis of the species produced at the electrocatalysts in a gas chamber equipped with KBr windows (Fig. 2I–L) there was observed a durable synergistic effect on the selective conversion of CO2 to the formation of methanol on porous platinum grown on the conductive silicon electrocatalysts (Fig. 2J, Fig. 4H).

The established electrodes such as copper, porous platinum and porous platinum/copper showed an expected electrocatalytic effect towards CO2 conversion (Fig. 2I–L, Fig. 5). Moreover, we demonstrate here that a high roughness electrode of porous platinum grown on conductive silicon synergistically works to convert CO2 to methanol. In addition, this method using the gaseous CO2 and micro-sized H2O droplets overcomes the drawback of low water solubility of CO2 and advantageously, can be in perspective connected with the silicon based green energy producer. We explain our finding by a three-microphase mechanism, the electrocatalytic reduction of CO2 takes place at the interface of solid catalyst with liquid water-droplet and gaseous CO2. This approach uses a 254 nm-UV line for stimulating the dissociation of CO2 coupled to an electrocatalytic process conducted into gas chamber under 80-90% humidity, for reducing CO2 to CH3OH. The electrochemical setup (Fig. 4D) connected to the spectrometer ´s gaseous chamber (Fig. 4E) equipped with KBr windows uses a composite cathode prepared by growing porous platinum on rough conductive silicon (Fig. 4A–C) (§Methods). The SEM image in Fig. 4B, C shows how abundantly grown porous platinum on rough silicon leaving blank certain areas of Si/SiO2, The EDX analysis has proven the presence of the following chemical elements: platinum, silicon, oxygen and copper (Fig. 2F). The mechanisms of CO2 electroreduction depend on several factors, among which the crucial roles are taken by the material type, morphology, temperature, electrolyte composition and their synergistic effects. We observed that SiO2 alone shows no catalytic effect on the conversion of CO2 to CH3OH at room temperature, however porous platinum grown on Si/SiO2 shows good efficiency to this reaction. Jiang et al. demonstrated that SiO2 support promotes a synergistic effect upon the bimetallic catalyst Pd/Cu at the CO2 conversion to methanol36. Moreover, to prove the role of SiO2 support in the global catalytic activity, Kusama et al. 37 reported the synergetic role of Rh-Li/SiO2 catalyst for CO2 conversion to ethanol/methanol via CO intermediate(s). Ton this basis, the following possible reactions can take place at the cathode:

while at the anode, the micro sized particles of water are oxidized to oxygen molecules:

To prove the electrocatalytic activity of the investigated electrodes, cyclic voltammetry of humid CO2 compared with the cyclic voltammetry in humid Ar were recorded and displayed in the Fig. 5. The diagrams indicate the evolution of cyclic voltammetry in humid CO2 (Fig. 5A–C) compared with the cyclic voltammetry recorded on indicated electrodes in humid Ar (Fig. 5D). The analysis of cyclic voltammetry shows that the CO2 reduction vs. Ag/AgCl at around −0.5 V on porous platinum/Pt, −0.4 V on porous platinum on conductive silicon or on both copper and porous platinum/copper (Fig. 4A–C). Practically, the electrolysis of CO2 using two electrode electrolysis in humid gaseous atmosphere requires a start difference of potential of 2 V. This experimental observation is supported by the electrolysis in the gaseous atmosphere at 160 °C achieved by Fischer et al. 38 at a difference of potential of 3 V–4 V on porous composite electrodes incorporating metallic particles of tin, bismuth, indium lead, respectively.

This work investigates the porous platinum grown on rough silicon ability to work as an efficient electrocatalyst. The electrochemical conversion of CO2 that occurs at the electrode/water/CO2 interface was demonstrated here using FTIR, as the difference between the gaseous chemicals can be detected by their infrared fingerprints. As reference spectra, the FTIR transmittance peaks of the gaseous methanol, ethanol and isopropanol in the gas chamber of the spectrometer, were respectively recorded, (Fig. 4F). With these references, the spectra of the conversion products were compared (Fig. 4H). FTIR transmission mode spectra shows the CO2 vibrational modes at 667 cm−1 (torsion vibration mode), 2341 cm−1 (C-O symmetric stretching modes), 2361 cm−1(C-O anti-symmetric stretching modes) before applying the electrical potential. After applying the potential difference of 2 V between the electrodes at a current density of 0.1 A/cm2 the CO2 conversion starts and is proven by the decreasing of corresponding intensity peaks while apparition of the additional peaks at 1033 cm−1, 1075 cm−1, 1145 cm−1, 1233 cm−1, 1450 cm−1, 1470 cm−1, 2844 cm−1, 2970 cm−1, 3000 cm−1 3080 cm−1. The vibrational modes correspond most probably to methanol39,40 because they match to the methanol peaks assigned as follows: v1 O-H stretch 3681 cm−1, v2 C-H anti-symmetric stretch (A’) 2999 cm−1, v3 C-H parallel symmetric stretch (A’) 2844 cm−1, v4 C-H in-plane anti symmetric bend 1477 cm−1, v5 C-H in-plane symmetric bend 1454 cm−1, v6 O-H bend (A’) 1340 cm−1, v7 CH3 rock (A’) 1074 cm−1, v8 C-O stretch (A’) 1033 cm−1, v9 C-H anti symmetric stretch (A”) 2970 cm−1, v10 C-H out of plane anti symmetric bend 1465 cm−1, v11 CH3 rock (A”) 1145 cm−1, v12 torsion 270 cm−141. The vibrational mode O-H stretch at 3681 cm−1 of the methanol is not clear visible in our spectra because of the overlapping with the OH stretch bands of the water. These absorption bands are broadened by the intermolecular hydrogen bonding interactions between the hydroxyl groups causing a wider range of O-H stretching vibrations42. The steep distinctive peak at 1033 cm−1 in the products spectra, which is specific for methanol, indicates the presence of methanol in the gaseous products rather than ethanol or propanol. The faradaic efficiency (§Methods) shown as a ratio of peak intensity CO2 per CH3OH divided by the charge traverses the cell in time. The electrochemical approach connected to the FTIR demonstrates the efficiency of porous platinum grown on conductive silicon cathode (Fig. 2B) in wet gaseous media, for CO2 conversion (Fig. 2J). compared to the established electrocatalyst such as platinum (Fig. 2I)., copper/copper oxide (Fig. 2L). Table 1 summarizes a comparison of this work with the literature´s reported data on the CO2 electrocatalytic conversion to CH3OH, CO, HCOOH. in aqueous media23,24,25,26,27,35 and in vapor at 220 °C36.

Application of porous platinum to tune optical properties of IR metamaterial

Transformation of materials from visible to invisible state and vice versa is a perpetual desire of humanity. At the beginning of the 20th, the Maxwell equations43 gave optimism to this desire and predicted that the light can be differently than usual propagated into a certain material, called metamaterial, for the frequencies where electric permittivity (ε) and magnetic permeability (µ) of the material are negative44,45. Since that moment on, several investigations made steps of progress in finding particular conditions of anisotropy to fulfil the Maxwell equation of negative permittivity and permeability44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63. The desired surface plasmon polariton resonances depend on the intrinsic properties of the material and the geometry of the nanostructures. Such materials were created by structuring arrays of metallic shapes such as square61, prism54, wires56, coil piles47,55 and rod pair58,62 into the dielectric medium. The first experimental demonstrations of such behaviour in the optical visible range were accomplished, nearly at the same time, for pairs of metal rods into the dielectric material53,58,62 and of pairs of dielectric cavities in metal51. Later on, negative epsilon material was achieved in visible range (514 nm, 501 nm, 496 nm, 488 nm, 476 nm) with the use of a prism shaped ultrathin Au-Si3N4-Ag waveguide sustaining a surface plasmon polariton mode with antiparallel group and phase velocities54. Yao constructed Ag vertical organised nanowires (60-nm wire diameter and 110 nm center-to-center distance) in dielectric medium of Al2O3, which exhibit negative epsilon at the wavelengths of 660 nm and 780 nm58. For microwave frequencies of 8 to 12 GHz Shelby constructed unconventional material that consists of discrete scattering elements, that may be approximated as an effective medium for wavelengths that are larger than the unit cell size dimension of 5 mm47. Grady has demonstrated ultrathin terahertz polarization converters that are capable of rotating a linear polarization state into its orthogonal one58. On the basis of these results, structures of negative epsilon at 1.4 THz corresponding to the wavelength of 214 µm have been created. The gold cut-wire (length 82 µm and width 10 µm) array and the gold ground plane are 200 nm thick, and they are separated by a polyimide dielectric spacer with thickness ts=33 µm at the periodicity of 68 µm. The incidence angle of 25°, and the incident electric field E0 linearly polarized in the x direction (s-polarized), with an angle a = 45° with respect to the cut-wire orientation assure the atypical terahertz refraction. Under an incidence of a femtosecond laser pulses at 1.5 µm wavelength Dolling obtained a negative epsilon material using a squared structured solid of thicknesses of 85 nm, the square lattice with lattice constant a = 600 nm51. Yu reported negative refraction of the collimated quantum cascade laser (λ0 = 8 µm) using plasmonic interfaces, consisting of an array of “V”-shaped-antennas that convey abrupt phase shifts in the optical path57. This breaks the constraint of standard optical components, which rely on gradual phase accumulation along the optical path to change the wave front of propagating light that the phase velocity can be negative and that group velocity can also be negative simultaneously. For attaining simultaneously negative ε and µ two separate resonances for these parameters in the refracting materials are required. Pendry55 circumvented this condition by introducing the idea of “resonant dipoles into a chiral medium” that splits the resonant transverse bands and results in a range of frequencies below w0 in which negative refraction can be seen for one of the polarizations. All the properties predicted for an isotropic nonchiral medium with ε < 0, and µ < 0 will be reproduced in this medium but only for one of the polarizations. This previews a huge resolution progress ability to focus the near fields and hence reproduce an image with resolution unlimited by wavelength. Inspired from the large amount of reports on this topic in visible range and motivated by the small amount of reports in IR range, we planned to show the capability of templated electrochemically grown porous platinum to tune optical properties of IR-metamaterial. For preparing the IR-metamaterial, we used the procedure described in §Methods. The cathodes which consist of Si/NiCr/Ti/ microstructured resist were prepared using sputtering and lithography as described in the § Methods. The thicknesses of the substrates: Ti (Supplementary Figs. 1, 2) and NiCr (Supplementary Figs. 3, 4) were evaluated using XRR. The templated electrochemically grown nanoporous platinum layer was analysed using scanning electron microscopy (SEM) and Fourier Transform Infrared Spectroscopy (FTIR) operated under linearly polarized light. In the control experiments, we observed that the resist ARP6200.13, which consists of a mixture of two polymers: polymethyl-alpha-chloracrylate and poly (alpha-methylstyrene) presents itself a polarization dependent behaviour in the wavelength regions 15–17 µm (Fig. 6). By structuring this resist polymer, a polarization-dependent optical response appeared in a wavelength region of 2.5–3.5 µm (Figs. 6,7). By filling the cavities with porous platinum, the spectral shape is significantly changed while the polarization-dependent optical response is preserved.

Application of porous platinum as defined localized optical IR absorber

Specific sensing and filtering optical signals make use of various absorber configurations. The applications of optical absorbers in nanotechnologies where the dimension is an issue, demand modifications to the conventional absorber configurations. Nanoporous platinum layers has driven interest in nanotechnological optics due to its unique chemo-mechanical stability and broadband absorption. We opted for the noble material because it confers long term chemical stability and robustness. Moreover, due to a very small concentration of PtCl4 salt the method is also cost effective. Indeed, there are useful scientific reports of ultrathin layer absorbers64,65,66,67,68 prepared by doping an ultrathin silicon film64 or by combining noble nanostructures with established oxides such as indium-tin-oxide67, or by exploiting the in-plane birefringence of α-MoO368 or even from polymers such as poly methylmethacrylate (PMMA)65,66. All these approaches attained subwavelength thickness (~nm) into a bi- or multilayer architectures. Our approach of one-step electrochemical fabrication of the thin films requires a small amount of noble salt, which also enables a relatively accessible, low-cost process. Therefore, porous platinum remains attractive compared to other materials in terms of both manufacturing costs and optical performance and stability. Organic absorbers are interesting from an optical point of view, but they are unstable at high temperatures, whereas platinum has good thermal and chemical stability in air. Figure 8A–C shows the photographs of porous platinum films grown on highly reflective platinum nanolayer (Supplementary Figs. 5, 6) at three different electrolysis times. The XRD analysis of the porous platinum confirm the crystalline nature of it (Supplementary Fig. 7). Figure 8D–F shows the corresponding SEM images, and Fig. 8G, H shows their low reflectivity. The integrating sphere experiments (Fig. 8I-K) proved that the low reflectance is rather due to absorption than to diffuse reflectance. Furthermore, the vacuum-transmittance spectra (Fig. 8L) of the porous platinum entrapped into the KBr pellets (photos in Fig. 8M–O) show accentuated absorption of the IR light. This method can be extended to other metals. Porous noble metals other than platinum can also be prepared electrochemically from a water-free solution as broadband absorber layers. Electrochemistry is possible in anhydrous solvent, if the solvent is electrically conductive after the salt addition (e.g. 0.05–1.0 g/g % metallic salts of Pt, Au, Pd, Ru, Rh, Os, Ir, Ag, Hg and Ti in solvent). The electric conductivity of the anhydrous solvent e.g. alcohol (ethanol, isopropanol), amines (ethylenediamines), aromatic amines (aniline), carboxylic acids (formic acid, propionic acid), esters (butyl acetate, ethyl acetate), sulfoxides (dimethyl sulfoxide), ketones (acetone), increases by the addition of certain metallic salts. In this way, we demonstrated that the metal salt increases the electrical conductivity of the low conductivity solvent such as isopropanol69,70,71 and can meet the condition of electrochemical production of noble metal black. Noble metal black72,73,74 represents an appreciated optical absorber material with the potential for use as a thin layer in optical sensors. In most cases, the insertion of the optical absorber in the construction of microelectronics requires a non-aqueous media for operation and a prospective that the material can be brought into a thin-layer. Therefore, an in-situ electro-deposition of optical absorbers on the constitutive microcomponents of the optical sensor (i.e. on metallic multi-junction), in non-aqueous media is of practical interest. Optimizing existing thermoelectric sensors to achieve desired higher absorption of infrared radiation and stability is an ongoing process. Currently, optical absorbers in the wavelength range from 0.4 µm to 20 µm are based on silver black75,76. However, silver black exhibits undesirable chemical reactivity toward air components75,76, affecting its long-term stability and performance, important properties for microelectronics technology. Our solution is to utilize porous noble metals69,70,71, to achieve the following advantages: 1) Synthesis in non-aqueous media; 2) high localization using in situ electrodeposition; 3) wide absorption and low reflection from ultraviolet to infrared range; 4) chemical stability in air; 5) mechanical stability and robustness; 6) grown on 2D and 3D conductive materials such as: NiCr8020, NiCr5050, Ti/Ni, Indium-tin oxide, tin-copper alloy, aluminum, copper, gold, platinum, silver70; 7) controlled thickness from 100 to 600 nm. The Fig. 9 shows the electrochemical controlled growth of porous platinum using the setup from panel (A) on engineered surfaces such as rounded corner cantilever (B) or gridded surfaces (C) as well as the highly localized electrochemically growth of porous platinum layers on inside of the square-cavity-array (D) made in resist on highly reflecting platinum nanolayer. The square array made in resist, a mixture of two polymers: polymethyl-alpha-chloracrylate and poly (alpha-methylstyrene), which can be lithographically microstructured (https://www.allresist.com/wpcontent/uploads/sites/2/2016/12/allresist_produktinfos_ar-p6200_englisch.pdf; http://www.lithoguru.com/scientist/lithobasics.html) (§Method). The high absorbance optical achievement of the porous platinum localized growth was investigated by FTIR. On one chip of 1.5 cm x 1.5 cm there are 56 square-cavities. The square cavity of 800 µm x 800 µm is electrochemically filled with porous platinum. The squares on one chip are counted from the left-up side (square1 named Q1) to the right down side (square 56 named Q 56). The Fig. 9E shows the FTIR spectra of the samples Q 8, Q 16, Q 24, Q 32, Q 40, Q 48, which achieved reproducible reflectance drops of 85% in the reciprocal wavenumber range 500-3500 cm−1 and 85–75% in the reciprocal wavenumber range 3500–6000 cm−1; Sample Q 56 showed higher reflectance drops 87-90% in the reciprocal wavenumber range 500–3500 cm−1. Moreover, Fig. 9F shows the FTIR reflectance spectra of the porous platinum electrochemically locally grown on disc-shaped areas on the chip. These results pave the way towards to the application of porous platinum as wideband absorbers on micro-structured/nano-structured surfaces, on miniaturized sensor components, respectively. If the resist is removed the meta-activity is changed while keeping the photoresist filled with porous platinum, the polarization dependence optical response can be utilized in the fabrication of the selective meta active optical sensors.

Conclusions

We presented here three application categories of the localized electrochemically grown porous platinum in non-aqueous media. 1) We made use of the electrochemical corners overloading effect to grow porous platinum on conductive rough silicon. This porous platinum-Si/SiO2 composite material proved to be a synergistic, efficient, selective and economical electrocatalyst for CO2 conversion as well as for acidified water conversion in H2 and O2. The approach of CO2 conversion from humid air has potential for being efficiently coupled to the silicon based solar cell for green energy producing in parallel with the mitigation of CO2 pollution. 2) The optical response of the IR-metamaterial prepared by shaping the resist on Si/NiCr/Ti substrates into a square-cavity-array was transformed by filling electrochemically the cavity-array with porous platinum. 3) We used the templated growth of the localized porous platinum layers on micro-structured areas to locally tune their optical properties.

Methods

Sputtering method

Platinum nanolayer on Si substrates

Pt nanolayers of 100 nm thicknesses were deposited on silicon wafer substrates by the mean of sputtering method (BesTech Jena Sputtering System II, Jena, Germany) in the clean room at the Leibniz Institute of Photonic Technology Jena. Si wafer has been cleaned by Ar ions before Pt deposition.

NiCr/Ti nanolayers on Si substrate

Sputtering instrument (BesTech Jena Sputtering System II, Jena, Germany) in the clean room at the Leibniz Institute of Photonic Technology Jena was used to grow NiCr 50:50 nanolayers of 102 nm (Supplementary Figs. 3, 4) thickness and Ti nanolayers of 8 nm thickness (Supplementary Figs. 1, 2) on silicon wafer substrates. Prior deposition, Si wafer has been cleaned by Ar ions.

The AFM probes were previously covered with a layer of NiCr:5050 by sputtering before electrochemical deposition of porous platinum.

Conductive silicon substrate

Rough silicon substrates measuring 1.5 cm x 1.5 cm each with a resistance of 290 ohms were prepared at Leibniz-Institute of Photonic Technology Jena.

Lithography

Si substrate/NiCr/Ti multilayers were covered by spin coating with resist (positive E-Beam resists AR-P 6200.13) (https://www.allresist.com/wp-content/uploads/sites/2/2016/12/allresist_produktinfos_ar-p6200_englisch.pdf) while reflecting layers of platinum on Si was similarly covered with AZ1505 photoresist and afterwards lithographically micro-structured (http://www.lithoguru.com/scientist/lithobasics.html) in a clean room at the Leibniz Institute of Photonic Technology, Jena, Germany. The wafer previously covered with resist was heated and then exposed to an E-beam in the case of E-beam resist and to a UV light in the case of photoresist.

Localized electrochemical growth of porous platinum

99% PtCl4 (MW 336.89 g/mol; Article number CC22008) was supplied by Carbolution Chemicals GmbH, St. Ingbert, Germany. Pb(CH3COO)2 (Article number 1073750250) was supplied by Merck, Darmstadt, Germany. Localized electrochemical growth of porous platinum thin layer was achieved using a water-free electrochemical reduction of platinum ions on cathodes. To synthesize localized porous platinum layers, 0.05% PtCl4 in isopropanol was used as main component of the electrolytic bath. 0.001% Pb(CH3COO)2 or 0.001%Cu(CH3COO)2 in isopropanol was used as additive69,70,71. Platinum plate serves as the anode. The cathodes were: electrically conductive silicon, platinum, copper or micro-structured SiNiCrTi-resist in form of 4 µm x 4 µm square array, 8 µm x 8 µm square array, 16 µm x 16 µm square array substrates and also Si/Pt/resist 800 µm x 800 µm square array. The resist was not removed after the electrochemical deposition of porous platinum. Porous Pt does not grow on the resist (Fig. 7C, D).

FTIR spectroscopy

The FTIR spectra in transmission mode or in reflection mode were recorded in a FTIR-Spectrometer (Vertex 80vBruker Instrument) at a resolution of 2 cm−1 as an average of 32 spectra in the spectral range 7500–500 cm−1. The samples were irradiated with a MIR silicon carbide light source of 6 mm aperture through a KBr-beam splitter. The spectra were collected with a standard FTIR detector with Mercury Cadmium Telluride (MCT) diode (D*: > 2 × 1010 cm Hz1/2W−1) liquid nitrogen cooled at 20kHz- mirror frequency or with Deuterated L-alanine Triglycine Sulphate (DLaTGS) room temperature operated (D*: > 2.7 × 108 cm Hz1/2W−1). at 10 kHz- mirror frequency, 3 mm sample aperture. The measurements were conducted in vacuum at 4 hPa where not otherwise specified. For the total reflection and diffuse reflection measurements, the spectrometer was equipped with a gold coated integrating sphere of 150 mm diameter (type A562, Bruker Instrument) mounted on a QuickLock (QL) base plate. The IR beam impinges on the sample with an incidence angle of 13°. The diffusely and the specularly reflected light is detected by an opening sleeve of 7 mm with an MCT detector. For the polarization dependence investigation, the spectrometer was equipped with a reflection grazing unit of 80° incidence (type A518/Q, Bruker Instruments) mounted on a QuickLock (QL) base plate and a MIR polarizer (type I7590 ECL, Bruker Instruments). The spectro-electrochemistry investigations in transmission mode used a 100 mL gas chamber equipped with two taps and KBr windows mounted on a QuickLock (QL) base plate. For recording localized FTIR spectra on microstructures of square-array or disc-array were collected from an area of 300 µmx300 µm using a Hyperion Microscope with 15x objective Ser. 918 17425 (NA = 0.4) connected to Bruker Vertex80v Spectrometer operated in reflection mode, detector MCT-N2 spectral resolution 2 cm−1, mirror frequency 20 kHz, 32 spectra/sample. Data analysis were done using OPUS software and displayed with the OriginLab software.

Scanning Electron Microscopy (SEM)

A JSM-6700F field emission microscope (JEOL, Tokyo, Japan) and FEI Helios NanoLab G3 UC (ThermoFisher, Netherlands) were used for most SEM measurements. Some of the micrographs were taken with a table tilt of 45°. The system is equipped with secondary electron detectors (SEI) of the InLens and Everhart-Thornley types, as well as detectors based on semiconductors and yttrium aluminum garnet (abbreviated as YAG type) for backscattered electrons.

Focused ion beam (FIB)

The dual-beam instrument FEI-Helios NanoLab G3 UC (Thermo Fisher Scientific, Eindhoven, Netherlands) was used for the cross sections and direct imaging of the layers. The instrument combines a focused ion beam column (FIB, Ga+ ions, ion energy = 30 keV) with a high-resolution field emission scanning electron microscope (SEM) (Schottky Thermal Field Emitter). This device enables BSE imaging with high-contrast backscattered electrons using retractable detectors.

Energy-dispersive X-ray spectrometry (EDX)

All energy dispersive X-ray analyses were done using a state of the art 30 mm2 silicon drift detector (SDD) by BRUKER (BRUKER Nano GmbH, Berlin, Germany) and the Esprit spectra evaluation software package. The specified energy resolution of the detector at 5.9 keV (Mn-Kα) is 129 eV.

X-ray diffraction (XRD) and X ray reflectometry (XRR)

The XRD analysis has been performed with an X′pert Pro MPD Instrument theta-theta diffractometer (PANanalytical, Almelo, Netherlands) using Cu-Kα1,2 radiation. Used optics were a parallelmirror equipped with 1/8° divergence slit, 10 mm mask, 0.04 rad Sollerslit and 1.4 mm antiscatterslit. On the diffracted beam side, a 0.18° parallel plate collimator was used with a Panalytical PIXCEL1D detector in 0D mode with 255 channels. The samples were measured with gracing incidence XRD, fixed omega angle = 1.5°, 2theta range from 10° to 90° with 0.026° steps. Total measuring time was 7 h to 10 h. For phase identification software Malvern Panalytical HighScore Plus V.4.9 was used with databases ICDD, ICSD and COD. The Scherrer equation was used for the determination of the crystallite sizes. Supplementary Fig. 7 shows the XRD data of the electrochemically grown porous platinum.

The XRR thickness measurements were done with the diffractometer used also for XRD. For Ti-NiCr double-layer system the used optics was a parallelmirror (PM) (equipped with 1/8° divergence slit, 10 mm mask, 0.04 rad sollerslit, 1.4 mm antiscatterslit - Cu Ka1-radiation) or a Hybridmonochromator (HM) (equipped with 1/2° divergence slit and 2 mm mask – monochromatic Cu Ka1-radiation) on the incoming beam and a 0.18° parallel plate collimator with 0.1 mm receivingslit, PIXCEL1D detector in 0D mode with 5 or 3 channels for the highly reflecting Pt layer. The scan were omega-theta-scans from 0.04° to 5°(PM) or 0.04° to 3° (HM) omega with 0.05°-steps. Total scan time 1h40min (PM) or 30 min (HM). For thickness calculation software Malvern Panalytical AMASS V 1.1 was used.

Ti layer thickness XRR evaluation

Ti layer thickness 8.0 nm (Fourier) – 9.0 nm (4 Frings)

The Fourier analysis of the reflectogram (Supplementary Figs. 1, 2) shows 3 peaks at 4.2 nm, 8 nm and 12.2 nm. Peak 1 (8 nm) comes from the Ti layer, peaks 2 and 3 are sum or difference peaks of an approximate 4 nm thick layer, presumably the SiO2 layer on the Si substrate.

NiCr layer thickness XRR evaluation

NiCr layer thickness 102.3 nm (Fourier) – 102.9 nm (20 Frings)

The “small” frings were evaluated to determine the NiCr layer thickness (Supplementary Figs. 3, 4). In the reflectograms there are clearly visible frings in the 2nd and 3rd “large” frings (1/8° divergence slot, 1 h 40 min measuring time). Critical angle (deg): 0.3227 First fringe angle (deg): 0.7634 Second fringe angle (deg): 1.5826. Calculated Thickness (nm): 5.1469* 20 frings = 102.9 nm

Highly reflecting Pt nanolayer thickness XRR evaluation

Reflectogram of the Pt nanolayer (Supplementary Fig. 5) enables an evaluation of the fringes thickness (nm): 6.3083 x 20 Frings = 126.2 nm. The Fourier plot (Supplementary Fig. 6) from the corresponding reflectogram indicates a Fourier Plot:Critical angle (deg): 0.5229, a Fourier start angle (deg): 0.0425 and a Fourier end angle (deg): 2.9975.

Light microscopy

The micrographs of the electrodes were recorded with a Zeiss Axio light microscope using a 2.5NEOFLUAR objective.

Ultraviolet (UV) irradiation

UV irradiation was performed using a Faust lamp (Sartorius lab Instruments, Switzerland) with an irradiation wavelength of 254 nm.

Electrochemistry

Most of the electrochemical measurements were performed using a computer-assisted AUTOLAB Metrohm Potentiostat 302 N with FRA32M-module for impedance measurements equipped with customized electrodes. The CO2 reduction measurements were performed under ambient temperature and UV light exposure on cathode in an airtight electrochemical cell connected to a FTIR gas cell of 100 mL (Fig. 4G) equipped with KBr windows and mounted into a Bruker Vertex 80 V spectrometer. The cathode compartment consists of working electrode, while the anode compartment consists of platinum/Cu plate. The cathode was one by one: copper/copper oxide wire, porous platinum copper wire, porous platinum on rough conductive silicon, porous platinum on Pt plate. Each of the compartments loaded humid CO2 from ice-CO2. Between electrode compartments there is a humid Nafion proton exchange membrane, impermeable to oxygen. The electrochemical measurements were carried out under a difference of 2 V between electrodes under 0.1 A/cm2 while recording the spectra with a Bruker Vertex 80 V spectrometer.

Electrocatalytic water electrolysis

With the setup from Scheme 1 the electrolysis of water is carried out. 0.1% H2SO4 is introduced into the electrolyzer and the circuit is closed. During the reaction, taps 6 must be closed to monitor the gases released in the two burettes. The reaction equations from the electrodes are:

The solution also holds sulfate ions SO42−, which, due to the high potential required for discharge, remain not reduced. By measuring the intensity of the electric current through the circuit (approximately 0.3 A), respectively, the volumes of gases released in 10 min at the electrodes, one calculates the electrolysis yield:

Moreover, the calculation of faradaic efficiency uses the following relations: for CH3OH,

for H2, where F is the Faraday constant, nCH3OH is the moles of produced CH3OH, and nH2 for the produced H2:

Data availability

The datasets generated and analyzed during the current study are available from the corresponding authors on reasonable request.

References

Taylor, B. N. & Thompson, A. (Eds) [1–96] (The International System of Units, National Institutes of Standards and Technology Special Publication 330, United States, Washington, 2008) https://physics.nist.gov/Pubs/SP330/sp330.pdf.

Bond, G. C. The mechanism of catalytic hydrogenation and related reactions. Q. Rev. Chem. Soc. 8, 279–307 (1954).

Irrgang, K. (Hrsg.): Temperaturmesspraxis mit Widerstandsthermometern und Thermoelementen (Temperature measurement practice with resistance thermometers and thermocouples). Vulkan, 2004, S. 100

Kim, T.-S., O’Connor, C. R. & Reece, C. Interrogating site dependent kinetics over SiO2-supported Pt nanoparticles. Nat. Commun. 15, 2074–12 (2024).

Hao, J., Liu, B., Maenosono, S. & Yang, J. One‑pot synthesis of Au‑M@SiO2 (M = Rh, Pd, Ir, Pt) core–shell nanoparticles as highly efficient catalysts for the reduction of 4‑nitrophenol. Sci. Rep. 12, 7615 (2022).

Wu, R. et al. Intermetallic synergy in platinum–cobalt electrocatalysts for selective C–O bond cleavage. Nat. Catal. 7, 702–718 (2024).

Zhou, K. L. et al. Platinum single-atom catalyst coupled with transition metal/metal oxide heterostructure for accelerating alkaline hydrogen evolution reaction. Nat. Commun. 12, 3783 (2021).

Kloke, A., von Stetten, F., Zengerle, R. & Kerzenmache, S. Strategies for the Fabrication of Porous Platinum Electrodes. Adv. Mater. 23, 4976–5008 https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.201102182 (2011).

Wang, R., Wang, C., Cai, W.-B. & Ding, Y. Ultralow-Platinum-Loading High-Performance Nanoporous Electrocatalysts with Nanoengineered Surface Structures. Adv. Mater. 22, 1845–1848 (2010).

https://www.statista.com/statistics/276629/global-co2-emissions/ visited on 22.1.2025. Annual carbon dioxide (CO2) emissions worldwide from 1940 to 2024.

Wiebe R. & Gaddy, V. L. The Solubility of Carbon Dioxide in Water at Various Temperatures from 12 to 40°and at Pressures to 500 Atmospheres. Critical Phenomena, Contribution from the Bureau of Agricultural Chemistry and Engineering, U. S. Department ofAgriculture, Washington, D. C. 1940, pp. 815-817

https://bionumbers.hms.harvard.edu/bionumber.aspx?id=106207 visited on 29.08.2024, 11:36 a.m. Solubility of carbon dioxide in water at 25˚C and 1 atm partial pressure.

Song, R. B. et al. Electrode Materials Engineering in Electrocatalytic CO2 Reduction: Energy Input and Conversion Efficiency. Adv. Mater. 32, 1903796 (2020).

McMurry, J., Ballantine, D. S., Hoeger, C. A. & Peterson, V. E. Fundamentals of General, Organic, and Biological Chemistry 2012, Prentice Hall, 783, p.186.

Tributsch, H. Application of electrochemical kinetics to photosynthesis and oxidative phosphorylation: The redox element hypothesis and the principle of parametric energy coupling. J. Bioenerg. Biomembr. 2, 249–273 (1971).

Inn, E. C. Y., Shafer & Heimerl, J. M. The Photolysis of CO2 at Wavelengths Exceeding 1740 Å. J. Atmos. Sci. 28, 838–841 (1971).

Mellinger, A. & Vidal, C. R. Laser-reduced fluorescence detection of carbon monoxide npσ (n = 5–8) triplet Rydberg states. Chem. Phys. Lett. 238, 31–36 (1995).

Kasimayan, U. et al. In-situ DRIFT investigation of photocatalytic reduction and oxidation properties of SiO2@α-Fe2O3 core-shell decorated RGO nanocomposite. Sci. Rep. 10, 2128 (2020).

Fukuda, T. et al. Dissociation of carbon dioxide and creation of carbon particles and films at room temperature. N. J. Phys. 9, 321 (2007).

Porosoff, M. D. et al. Catalytic reduction of CO2 by H2 for synthesis of CO, methanol and hydrocarbons: challenges and opportunities. Energy Environ. Sci. 9, 62–73 (2016).

García de Arquer, F. P. et al. CO2 electrolysis to multicarbon products at activities greater than 1 A cm−2. Science 367, 661–666 (2020).

https://en.wikipedia.org/wiki/Standard_Gibbs_free_energy_of_formation vizited on 31.08.2024 14:58. Standard Gibbs free energy of formation.

Zhao, S. et al. Achieving electroreduction of CO2 to CH3OH with high selectivity using a pyrite–nickel sulfide nanocomposite,. RSC Adv. 7, 1376–1381 (2017).

Le, M. et al. Electrochemical reduction of CO2 to CH3OH at copper oxide surfaces. J. Electrochem. Soc. 158, E45 (2011).

Li, C. W. & Kanan, K. W. CO2 Reduction at Low Overpotential on Cu Electrodes Resulting from the Reduction of Thick Cu2O Films. J. Am. Chem. Soc. 134, 7231–7234 (2012).

Hori, Y., Murata, A., Kikuchi, K. & Suzuki, S. Electrochemical Reduction of Carbon Dioxide to Carbon Monoxide at a Gold Electrode in Aqueous Potassium Hydrogen Carbonat. J. Chem. Soc., Chem. Commun. 1412, 728–729 (1987).

DeWulf, D. W., Jin, T. & Bard, A. J. Electrochemical and Surface Studies of Carbon Dioxide Reduction to Methane and Ethylene at Copper Electrodes in Aqueous Solutions. J. Electrochem. Soc. 136, 1686–1691 (1989).

Hori, Y., Murata, A. & Yoshinami, Y. Adsorption of CO, intermediately formed in electrochemical reduction of CO2, at a copper electrode. J. Chem. Soc., Faraday Trans. 87, 125–128 (1991).

Hori, Y., KiKuchi, K. & Suzuki, S. Production of CO and CH4 in electrochemical reduction of CO2 at metal electrodes in aqueous hydrogencarbonate solution. Chem. Lett. 14, 1695–1698 (1985).

Hori, Y., Kikuchi, K., Murata, A. & Suzuki, S. Production of methane and ethylene in electrochemical reduction of carbon dioxide at copper electrode in aqueous hydrogencarbonate solution. Chem. Lett. 15, 897–898 (1986).

Russell, P. G. et al. The Electrochemical Reduction of Carbon Dioxide, Formic Acid, and Formaldehyde. J. Electrochem. Sci. Technol. I24, 1330–1338 (1977).

Royer, E. Reduction of Carbonic Acid into Formic Acid. Cr. Acad. Acids. 70, 731–735 (1870).

Cohen, A. & Jahn, S. Electrolytic Reduction of carbon dioxide. Ber. der Dtsch. Chemischen Ges. (Ber. Dtsch. Chem. Ges.) 37, 2836 (1904).

Royer, M. E. C. r hebd Séanc. Acad. Sci. Paris 70, 731–732 (1870).

Monteiro, M. C. O., Philips, M. F., Schouten, K. J. P. & Koper, M. T. M. Efficiency and selectivity of CO2 reduction to CO on gold gas diffusion electrodes in acidic media. Nat. Commun. 12, 4943 (2021).

Jiang, X., Koizumi, N., Guo, X. & Song, C., Bimetallic Pd–Cu catalysts for selective CO2 hydrogenation to methanol. Appl. Catal. B: Environ. 170, 173–185 (2015).

Kusama, H., Okabe, K., Sayama, K. & Arakawa, H. CO2 hydrogenation to ethanol over promoted Rh/SiO2 catalysts. Catal. Today 28, 261–266 (1996).

Fischer, B., Pasquier, D. & Fecant, A., Method for producing formic acid, WO2014202855A1, (24.12 2014).

https://vpl.astro.washington.edu/spectra/methanol.htm visited on 28.08.2024 at 1:10 p.m. Methanol (CH3OH) infrared spectra details.

Luna, R. et al. Densities, infrared band strengths, and optical constants of solid methanol. Astron. Astrophys. 617, A116 (2018).

https://vpl.astro.washington.edu/spectra/c2h5ohpnnlimages.htm visited on 29.08.2024 7:44 a.m. VPL Molecular Spectroscopic Database.

Dai, F., Zhuang, Q., Huang, G., Deng, H. & Zhang, X. Infrared Spectrum Characteristics and Quantification of OH Groups in Coal. ACS Omega 8, 17064–17076 (2023).

Maxwell, J. C. A General Equations of the Electromagnetic Field. Proc. R. Soc. Lond. 13, 531–536 (1864).

Veselago, V. G. The electrodynamics of substances with simultaneously negatively values ε, µ Sov. Phys. Usp. 10, 509–514 (1968).

Paquin, R. A. Optical and physical properties of materials Ch. 35 pp 1-78 Properties of metals, University of Arizona, Tucson (1993).

Linden, S. et al. Magnetic response of metamaterials at 100 terahertz. Science 306, 1351–1353 (2004).

Shelby, R. A., Smith, D. R. & Schultz, S. Experimental verification of a negative index of refraction. Science 292, 77–79 (2001).

Pendry, J. B. A chiral route to negative refraction. Science 306, 1353–1355 (2004).

Smith, D. R., Pendry, J. B. & Wiltshire, M. C. K. Metamaterials and negative refractive index. Science 305, 788–792 (2004).

Zhang, S. et al. Experimental demonstration of near-infrared negative-index metamaterials. Phys. Rev. Lett. 95, 137404 (2005).

Dolling, G., Enkrich, C., Wegener, M., Soukoulis, C. M. & Linden, S. Simultaneous negative phase and group velocity of light in a metamaterial. Science 312, 892–894 (2006).

Schurig, D. et al. Metamaterial electromagnetic cloak at microwave frequencies. Science 314, 977–980 (2006).

Shalaev, V. M. Optical negative-index metamaterials. Nat. Photonics 1, 41–48 (2006).

Lezec, H. J., Dionne, J. A. & Atwater, H. A. Negative refraction at visible frequencies. Science 316, 430–432 (2007).

Pendry, J. B. Time reversal and negative refraction. Science 322, 71–73 (2008).

Yao, J. et al. Optical negative refraction in bulk metamaterials of nanowires. Science 321, 930 (2008).

Yu, N. et al. Light propagation with phase discontinuities: generalization laws of reflection and refraction. Science 334, 333–337 (2011).

Grady, N. K. et al. Terahertz metamaterials for linear polarization conversion and anomalous refraction. Science 340, 1304–1306 (2013).

Shalev, M. V. et al. Negative index of refraction in optical metamaterials. Opt. Lett. 30, 3356–3358 (2005).

Kildishev, A. V. et al. Negative refractive index in optics of metal–dielectric composites. J. Opt. Soc. Am. B 23, 423–433 (2006).

Smith, D. R. & Schultz, S. Determination of effective permittivity and permeability of metamaterials from reflection and transmission coefficients. Phys. Rev. B 65, 195104 (2002).

Podolskiy, V., Sarychev, A. K. & Shalaev, V. M. Plasmon modes in metal nanowires and left-handed materials. J. Nonlinear Optical Phys. Mater. 11, 65–74 (2002).

Podolskiy, V., Sarychev, A. K. & Shalaev, V. M. Plasmon modes and negative refraction in metal nanowire composites. Opt. Express 11, 735–745 (2003).

Pu, M. et al. Ultrathin broadband nearly perfect absorber with symmetrical coherent illumination. Opt. Express 20, 2246–2254 (2012).

Lateef, O. S. et al. Polarization-insensitive Archimedes’-spiral-shaped ultrathin metamaterial absorbers for microwave sensing application. Sci. Rep. 13, 19445 (2023).

Landy, N. I., Sajuyigbe, S., Mock, J. J., Smith, D. R. & Padilla, W. J. Perfect metamaterial absorber. Phys. Rev. Lett. 100, 207402 (2008).

Yang, C. S. et al. THz conductivities of indium-tin-oxide nanowhiskers as a graded-refractive-index structure. Opt. Express 20, A441–A451 (2012).

Zhu, H. et al. Ultrathin High Quality-Factor Planar Absorbers/Emitters Based on Uniaxial/Biaxial Anisotropic van der Waals Polar Crystals. Adv. Optical Mater. 9, 2100645 (2021).

Stanca, S. E. et al. Electro-architected porous platinum on metallic multijunction nanolayers to optimize their optical properties for infrared sensor application. Nanotechnology 29, 115601 (2018).

Stanca, S. E. et al. Electrochemical growth mechanism of nanoporous platinum layers. Commun. Chem. 4, 1–13 (2021).

Stanca, S. E., Ihring, A., Hänschke, F., Zieger, G. & Schmidt, H. Method for producing very precisely localized broadband absorbers for 2D- and 3D surfaces WIPO PCT International Patent WO2022253385A, 18.December 2022.

Hedayati, M. K., Faupel, F. & Elbahri, M. Review of Plasmonic Nanocomposite Metamaterial Absorber. Materials 7, 1221–1248 (2014).

Tan, F. et al. Rough gold films as broadband absorbers for plasmonic enhancement of TiO2 photocurrent over 400–800 nm. Sci. Rep. 6, 33049 (2016).

Zhou, S., Wang, Z. & Feng, Y. Optimal Design of Wideband Microwave Absorber Consisting of Resistive Meta-Surface Layers. J. Electromagn. Anal. Appl. 4, 187–191 (2012).

Paussa, L., Guzman, L., Marin, E., Isomaki, N. & Fedrizzi, L. Protection of silver surfaces against tarnishing by means of alumina/titania-nanolayers. Surf. Coat. Technol. 206, 976–980 (2011).

Nagiri, R., Kumar, K. J. & Subrahmanyam, A. Physical properties of silver oxide thin films by pulsed laser deposition: effect of oxygen pressure during growth. J. Phys. D: Appl. Phys. 42, 135411 (2009).

Acknowledgements

Financial support from the International Research Training Group (IRTG) 2675 “META-ACTIVE” and from the Federal Ministry for Economic Affairs and Climate Action (BMWK) on the basis of a decision by the German Bundestag (ZF4006822BR9) is gratefully acknowledged. The X.R.D. and E.D.X. equipment are partially supported by European Fond for Regional Development (EFRE) under the Project No. FKZ 2023 HSB 0025. We thank Franka Jahn for some SEM images and Andrea Dellith for F.I.B.-S.E.M.; We also thank Jens Heinze for sputtering the metallic layers of Pt on Si wafers, Silke Neuhaus for dividing the wafer in chips of 1.5 cm x 1.5 cm squares and Susanne Bock and Christian Kranhold for KBr pellets.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

S.E.S. conceptualized and made the porous platinum layers on gridded/not gridded highly reflecting metallic nanolayers using an electrochemical water free method. J.D. and his team recorded the S.E.M., X.R.D., E.D.X., F.I.B.; M.D recorded X.R.D. and X.R.R.; U.H. recorded the lithography. AI recorded xyz. S.E.S. recorded the FTIR, Ulbricht sphere MIR spectra. H.K., G.Z. provided funding, materials and laboratory. S.E.S. wrote the article with contributions to experimental details and results from the co-authors. All authors have given approval to the final version of the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Chemistry thanks Fa Yang and the other, anonymous, reviewers for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Stanca, SE., Diegel, M., Dellith, J. et al. Electrochemically grown porous platinum for electrocatalysis and optical applications. Commun Chem 8, 93 (2025). https://doi.org/10.1038/s42004-025-01476-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-025-01476-4