Abstract

Doping of luminescent materials by rare-earth ions is common practice to achieve desired emission properties for a large variety of applications. As several rare-earths ions are frequently combined, it is subsequently difficult to effectively detect and control their homogeneous distribution within the host material. Here, we present a simple, rapid, large scale and precise method of rare-earth mapping using a commercial UV-Vis scanner. We discuss the influence of rare-earth distribution on the physical, optical and luminescent properties with no observable qualitative effect on photoluminescent properties and optical anisotropy. On the contrary, rare-earth-rich areas exhibit significantly higher values of refractive index and optical absorption, which allowed for their identification by the commercial scanner device. The presented method thus provides fast and accurate information about the rare-earth distribution in the material volume with high resolution (≈2.7 µm) and low limit of concentration difference detection (≈0.014 at.%) compared to other techniques, which makes it a promising candidate for high throughput measurements.

Similar content being viewed by others

Introduction

Nowadays, research on new types of advanced optical materials for high-tech applications, especially in photonics and optics, is still a part of cutting-edge research in material science. As an example, one can mention the development of inorganic crystals for scintillators and radiation detectors1, medical imaging2, solid state lasers3,4 or light emitting diodes3,4 and quantum information processing5. Rapid and precise detection of luminescence/optically active impurities or/and dopant distribution is therefore crucial step in material fabrication and qualitative control as the non-uniformity of distribution is a limitation for majority of application. Despite this, it is still a challenge to provide fast and accurate measurements of the rare-earth ions distribution within the large area/volume, as the common methods are based on inspection using optical microscopy techniques with relatively small field of view6,7. Contrary, the scanning optical techniques such as transient absorption microscopy or transmission spectroscopy8 suffer from long acquisition and scanning times. Energy dispersive X-ray spectroscopy (EDX)6,9, inductively coupled plasma atomic emission spectrometry (ICP-AES)7, and other techniques can be used as well, however they are less suitable for industry applications due to their complicated operations, and time and cost demands. This leads to situations when one has to choose between a relatively small area of interest, reasonable detection time and achievable resolution. Therefore, none of above-mentioned experimental techniques, which are standards in laboratory environment, provide wide field, fast and high throughput inspection tool applicable for industry requirements. Here, we present a novel and simple approach for fast and large area mapping of RE doping homogeneity suitable for both, laboratory and industrial environments based on commercial UV-Vis scanner. To demonstrate the functionality of this approach, we have chosen commonly used luminescent materials, such as yttrium and lutetium garnets of type RE3Al5O12 (where RE is an ion of the lanthanide series from La3+ to Lu3+ or Y3+) and especially those that are doped with luminescently active trivalent rare-earth ions. Doped Y3Al5O12 (YAG) and Lu3Al5O12(LuAG) single crystals are widely used for active media in solid state lasers3,4, scintillators1, telecommunications and in equally important cases such in white light emitting diode (LED) technology, which offers a number of advantages over conventional lighting methods, such as higher efficiency, longer lifetime, reliability and less demands on operational dimensions10. White light LEDs usually employ Ce3+-doped YAG/LuAG materials for light conversion. However, the resulting spectral characteristics are not ideal due to high color temperature as the result of missing red spectral part11. To achieve proper luminescence conversion from driving GaN diode, the substitution of structural Y3+ by some larger ions (e.g. Gd3+ or La3+)12,13,14 is usually applied. This increases the crystal field splitting and moderate the Ce3+ emission towards the longer wavelengths as has been shown in several previous works12,14,15,16. However, the possibility of doping both YAG/LuAG host materials with high concentrations of rare-earth ions brings above mentioned difficulties17 in the form of their non-uniform distribution during the growth process, especially with large ions like Gd3+ 14,16. This non-uniformity may then strongly affect the optical and emission properties18,19. Therefore doped YAG and LuAG garnets are ideal model material systems to test the inspection approach of RE doping homogeneity.

Scanner-derived lateral diagrams allowed us to study the effect of increasing Gd3+ concentration on the reduction of the central rare-earth-rich area or to study the difference between the unequal distribution of Ce atoms in Ce-doped YAG and LuAG crystals. These diagrams were systematically correlated with optical and magneto-optical (MO) response of the materials characterized by optical transmission, spectroscopic ellipsometry (SE), emission spectroscopy and photoluminescence (PL) kinetics, and magneto-optical Faraday rotation experiments. The correlation has proven the rare-earth origin of the laterally resolved structures in scanner diagrams showing this approach as simple, rapid and precise method of lateral scanning for industrial application.

Results

Selected samples of Ce/Gd doped YAG and LuAG single crystals were prepared according to a stoichiometric ratio of [(Y or Lu) + Ce]:Al = 3:5 for Ce(Y,Lu)AG and (Y + Gd + Ce):Al = 3:5 for CeYAG:Gd crystals. Prepared samples are listed in Table 1 with denoted concentrations of both Ce3+ and Gd3+ ions derived from X-ray fluorescence (XRF) spectroscopy measurements. Wafers were then prepared for optical analysis and diced to the pieces of phosphors with dimensions of approximately 10 × 10 mm (see Fig. 1). Samples were firstly inspected using a polarizing microscope (with crossed polarizers) that showed good sample quality and excluded the presence of mechanical stresses and facet formations in the samples (Fig. 2B, C). From the polarization microscope, we also did not observe any presence of ingrown core in our samples as is shown on the example of CeYAG as the only detectable impurities/defects can be attributed to surface scratches and remaining dust on the sample surface (highlighted by red circles in Fig. 2B, C).

The example sections were investigated using UV-Vis commercial scanner (A), polarization microscope (B) and optical microscope (C). Displayed images correspond to the size of square segment of about 10 × 10 mm. Investigated positions within CeYAG wafer are highlighted in Fig. 1 using a red dashed line. The detected impurities/defects highlighted by red circles represent surface scratches and remaining dust on the sample surface.

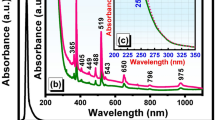

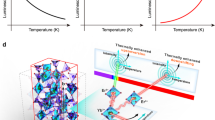

Due to the expected inhomogeneous lateral distribution of rare-earth ions, selected sections were studied across the both side polished wafers by transmission spectroscopy to identify the position and intensity of absorption maxima. The optical absorption spectra were performed in wavelength range from ultraviolet to near infrared (200–900 nm) region and exhibit two characteristic spectral bands A1: λA1 = 460 nm and A2: λA2 = 340 nm attributed to allowed optical transitions of 4f electrons from the ground state 2F5/2 to the 5d1 and 5d2 empty orbitals of Ce3+ ions and one intra-4f optical transition (A3: λA3 = 275 nm) of Gd3+ ions from the ground state 8S to the excited state 6I (Figs. 3, 4)20. Note, that observed 4f →4f’ transitions can only be observed for Gd-doped materials, as these are forbidden transitions in the case of isolated ions. The absorption in YAG and LuAG crystals between 275 nm and 200 nm may be ascribed to the trace impurities in the samples of the order of units to ten of ppm coming from chemicals, crucible, furnace, or possible residual color centers, c.f. also refs. 21,22. Note that the position of 5d of Ce3+ ions is split into five 5d1−5 states in the surrounding dodecahedral crystal field and the remaining three high-energy transitions are centered approximately at 5d5: 210 nm (5.9 eV), 5d4: 230 nm (5.39 eV) and 5d3: 265 nm (4.68 eV)20,23,24 respectively, which are represented using black arrows in Figs. 3, 4. However, in the case of the examined samples, these high-energy bands are reliably overlaid by absorption on the above-mentioned impurities and colour centres. Using the known position of the first absorption maxima at approximately 445–460 nm, the high resolution and large area lateral mapping has been recorded across the whole plane disc using the commercial UV-Vis scanner device CanoScan 9000F. The whole investigated wafer was inserted into the scanning device and measured in one single step in the transmission mode. Obtained high resolution image was then split to separated red, green and blue (RGB) channels, when the blue one was later used for investigation of RE lateral distribution due to spectral overlap with characteristic absorption band of Ce3+ ions. This data processing and evaluation is schematically depicted in Fig. 5 and described in details in Materials and Methods section. From Fig. 1 is then visible clear separation between the central part and external region in CeYAG:Gd single crystals. Observed change can be with certainty connected with different concentration of absorption centers as the presence of mechanical stresses, facet formations or/and defects was excluded previously using the polarization microscopy measurements (Fig. 2). In accordance with observations made from measurements of optical absorption spectra, darker patterns follow the increasing concentration of Ce3+ atoms in the host material. Applying the same principle, for the CeLuAG samples were observed even more unorganized distribution within the central part of the wafer. Observed pattern may be then correlated with the lateral distribution of RE ions (most probably Ce3+) within the wafer. Commercial scanner can be therefore used for direct large area mapping of RE distribution with high resolution up to (≈2.7 µm) by selection a suitable scanner setting (DPI from 75 up to 9600), light source or wavelength range. To further demonstrate the versatility of the presented method, a second commonly used scanner LaserJet Pro M1132 MFP was used for scanning of selected samples in reflection mode (see Fig. S2) with similar qualitative results.

Reference spectrum of undoped YAG single crystal has been taken from ref. 22.

Reference spectrum of undoped YAG/LuAG single crystal has been taken from ref. 22.

With the known lateral position of the central pattern, conventional transmission spectra has been recorded for selected areas in the external (marked as EX) as well as in the central (CX) part of the discs to estimate the concentration difference of RE ions. The exact positions are marked in Fig. 1 using the proper scale. Presented results then verify that investigated YAG discs may be divided into two parts with approximately constant absorption and thus similar concentration of dopants as the measured differences in the absorption across one external or central region are within the experimental error. Moreover it was observed that the addition of Gd ions leads to a more uniform lateral distribution of RE ions as the concentration change (estimated from λA1 maximum) is decreasing between external and central region (Table 1). Increasing Gd content also caused a gradual shrinking of the central pattern (see Fig. 1). A different situation occurred for CeLuAG material, where the level of inhomogeneity is more visible and the evolution of absorption coefficient in central part is more significant (see Fig. 4). The absolute differences in absorption coefficients between the central and external part derived from Figs. 3, 4 accompanied by the spectral positions of corresponding peak maxima may be seen in Table 1. These observations suggest a good agreement between the complementary techniques used to measure optical absorption and lateral scanning using commercial scanners. However, it should be mentioned that the use of commercial scanners allows fast, precise and simple measurements of large areas with relatively high accuracy of RE ion concentration determination and lateral resolution. The combination of conventional two-beam UV-Vis spectroscopy and lateral scanning thus gives us a simple and precise tool for the estimation of concentrations and RE ion distribution.

Redistribution of RE ions during growth does not affect only quantitative properties (such as absorption strength) but also influences the qualitative nature of emission spectra and their kinetics. The non-uniform distribution can enhance/suppress the processes of energy transfer mechanisms, non-linear processes of photoluminescence upconversion, cross-relaxations, etc. which are strongly influenced by the mutual distance between RE ions and their spatial arrangement, and thus directly affecting emission kinetics and spectral features. The qualitative effect of RE ions concentration on photoluminescence emission has been studied for both external and central parts of Ce/Gd-doped YAG and LuAG samples (see Figs. 3, 4). Investigated samples exhibit emission centered at 513–548 nm resuling from the 5d to 4f transitions of Ce3+ ions, which can be decomposed into two electronic transitions from the lowest 5d state: 5d1 → 2F5/2 and 5d1 → 2F7/2. Observed Stokes emission had a significant dependence on RE element concentration as well as used host YAG/LuAG matrix. As is visible from Table 1, the observed photoluminescence maximum (λE) is blue-shifted by approximately 25 nm for CeLuAG compared to the CeYAG single crystals. On the contrary, the increasing Gd content led to a red shift12 of the maximum towards higher wavelengths by ≈10 nm. For doped YAG samples were thus observed a slight increase in the spectral distance (∆λ) between the measured absorption (λA1) and emission (λE) maxima. On the other hand, the noticeable narrowing of ∆λ has been observed for CeLuAG samples compared to the CeYAG (see Table 1). However, no significant qualitative difference between the emission spectra for the central and outer regions was observed for any of the investigated samples as the difference is on the edge of experimental uncertainty (≈1 nm).

In addition, the role of impurities and other possible quenching processes in photoluminescence emission has been studied using the PL decay kinetics (Fig. 6a). Decay curves were measured by single photon counting method under the excitation of λk,exc = 482 nm and the PL Ce3+ emission was collected at corresponding emission maximum. Resulting from detailed inspections of Ce decay curves for two samples with and without gadolinium content, a certain degree of non-linearity was observed for samples containing gadolinium as an additive. In this case, a two-exponential fit provides the best correspondence between the model and measured data and contains a weaker decay time short component τ ≈20 ns together with the main decay time component τ ≈60 ns. The main decay time very well corresponds to values obtained in high purity single crystals prepared by Czochralski method24. In samples with Gd content, PL decay curves contains also a weaker component what refers a non-radiative transfer of part of energy between Ce3+ and impurity ions or/and defect states24. Integration of decay curves indicates that about 2% of energy was lost from the excited states due to this nonradiative transitions. From this it may be assumed that the addition of gadolinium caused additional defects in the crystal structure. However, the lateral distribution of RE ions for a given composition shows no change in PL decay curves between the central and outer parts as can be seen in Fig. 6a.

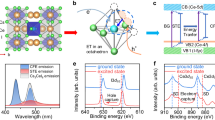

The effect of dopant concentration was also studied with respect to their magneto-optical properties. The MO spectra measured at selected central and external parts of CeYAG:Gd and CeLuAG crystals are displayed in Fig. 6b. The detected bands originated from Ce3+ ions in CeYAG crystals were observed and centered at ≈453 nm (2.73 eV) and ≈336 nm (3.69 eV) accompanied by a single band attributed to the gadolinium transition at ≈275 nm (4.5 eV). In LuAG host matrix, a narrowing of the separation between the two Ce3+-originated maxima was observed similarly as in the optical absorption measurements. Based on the measured spectra, the same tendency was observed for both doped YAG/LuAG host matrices as in the case of optical absorption. The central region then exhibits a noticeably higher amplitude of MO effect compared to the outer part with a factor of about ≈1.2 for band centered at 453 nm (YAG) or 443 nm (LuAG) respectively. Because of the paramagnetic nature of this Ce3+: 2F5/2 → 2D transition25,26 a linear dependence of the MO amplitude on the dopant concentration may be assumed and thus MO measurements can be used to detect RE ions distribution following the evolution of Faraday rotation maxima.

Another established method how to precisely estimate the distribution of RE ions is the sensitive measurement of refractive index. Obtained ellipsometric spectra were fitted according to our previous work22 using the Woollam CompleteEase software with integrated modified Sellmeier model (Eq. 1)

where n is the refractive index, AE, BE and CE are the parameters derived from the ellipsometric model, ϵ(∞) term represents the sum of one plus the contribution to the dielectric function from high-energy excitations and λ (μm) is the wavelength of the incident light. Note, that the last term which contains CE parameter describes low frequency excitations, i.e. the phonons contribution, and approximates the effective resonance frequency of the lattice vibrations at zero frequency. The model structure consisted of a semi-infinite bulk material and a layer of surface roughness approximated by effective medium approach27. The presented model was used because it describes well the spectral dependence of the refractive index near the optical-band-gap energy and at lower energies in the infrared region. To maintain consistency, the data were also fitted using the classical two-pole Sellmeier model with a similar qualitative output. The results for this second Sellmeier model are included in the Supplementary section (Supplementary Table 1, Figs. 3, 4).

The spectra of refractive indices were recorded in the center of selected RE-doped YAG and LuAG samples. Deduced line of refractive index investigation leads from and to the external part across the central part of the disc and uses the notation of spots from 1 to 5 as is shown in Fig. 7–8 with denoted proper scale beam position. The observed change in refractive index between the central and outer part takes place at the third decimal place, where the RE rich central part of CeYAG:Gd has larger refractive index value by approximately ≈0.006 (0% Gd), ≈0.001 (5% Gd) and ≈0.002 (13% Gd) at λ = 193 nm. These values correspond with the difference between the denoted positions 1 and 3 in Fig. 7 for the respective Gd3+ concentration. The difference between the minimum (outer part) and maximum value of refractive index for CeLuAG sample has been found as ≈0.005 at λ = 193 nm (see Fig. 8). The Sellmeier coefficients AE, BE, CE, ϵ(∞) and the surface roughness for the previously mentioned positions are summarized in Table 2.

Compared to other involved methods, the lateral mapping using commercial scanning devices, such as CanoScan 9000F or similar, offers solid and variable alternatives for rapid and precise analysis of doping homogeneity in macroscopic luminescent materials with a resolution of up to ≈2.7µm depending on the selected configuration. From the provided mutual comparison between characterization techniques it is then evident, that measurement of photoluminescent emission as well as the PL kinetics is not feasible for tracking of such small concentration differences in large area luminescent material, as these methods are extremely sensitive to measurement geometry, light source time stability or temperature variation. Moreover, other applied methods within this study (SE with CCD detector, UV-Vis-NIR spectrophotometer, XRF), as well as other commonly used methods of compositional analysis such as Energy-dispersive X-ray (EDX) analysis, suffer from several major disadvantages compared to the presented method, including poor lateral resolution (UV-Vis-NIR or FTIR spectrophotometer, conventional SE or XRF analysis), long or unrealistic acquisition times for evaluation of large area samples (EDX, µ-XRF, SE) and last but not least high acquisition costs commonly in the high tens or even high hundreds of thousands of US dollars (see Table 3). It should also be noted that most of these characterization techniques are not capable of analysing large macroscopic samples without any special modification or must provide point-by-point analysis and thus they are not suitable for potential industrial or semi-industrial applications. On the contrary, performed lateral scans can be provided in one step (lasting several minutes) for selected cropped section or extended to the maximum measurement area of 21 × 29.7 cm2 (Reflection configuration) or 7.5 × 24.2 cm2 (Transmission configuration) using various preset DPI settings resulting in 339−42.3 μm (Reflection configuration) or 84.7−2.65 μm (Transmission configuration) lateral resolution. As can be seen from Fig. 9, the image quality of the transmission mode is higher compared to the reflection mode, however, the qualitative information is unchanged. This means, that each commercially available home scanner can be in principle used for described homogeneity mapping.

Regarding the observed changes in absorption coefficient derived from the measurement of optical transmission (see Table 1), clearly detectable change between a brighter and darker region in performed lateral scans may be assigned with the 6% concentration difference of Ce atoms. Based on the known Ce atom concentration in CeYAG: Gd 13% (0.24 at.% Ce), the minimal detectable difference using the presented scanning method is estimated to be approximately 0.014 at.%. This value may be regarded as the minimum observable threshold and was estimated from the observed absorption peak maximum A1 ratio, A1: αC /αE (see Table 1), as the optical absorption is linearly proportional to the concentration of Ce3+ ions concerning the validity of Lambert-Beer law. Using the knowledge of the Ce concentration in the CeYAG Gd 13% material (0.24 at.%) and the estimated value of experimentally recognizable relative difference, the presented method is then capable of tracking concentration differences on the level of approximately 0.014 at.% Ce in the case of Ce3+-doped materials. However, considering the sufficient contrast observed between the external and central regions (see Fig. 1.), it is plausible that the actual minimum detectable concentration and the minimum detectable difference may be lower than the estimated threshold. These detection limits surpass those achievable with EDX analysis (≈0.1 at.%) and are comparable to those obtained with XRF analysis (≈0.01 at.%). However we have to note here that presented technique is providing the information only about the qualitative concentration difference and not its absolute values. A comparison of the relevant parameters for these techniques is provided in Table 3.

Conclusion

We have provided a complex optical, magneto-optical and luminescence characterization of Ce3+/Gd3+-doped YAG and LuAG single crystals with respect to the lateral distribution of RE ions within the crystal. From that is evident, that RE ions are inhomogeneously distributed within the crystals without any significant effect on optical anisotropy and thus the undetectable by using a polarization microscopy method. The inhomogeneity of the rare-earth ions arrangement has also no significant qualitative effect on emission spectra as well as the observed decay time curves. On the contrary, investigation of optical absorption or Faraday rotation naturally followed the change in RE concentration as well as the involvement of spectroscopic ellipsometry method. The disadvantages such as, low lateral resolution, high acquisition price, long scanning time, etc., of aforementioned techniques for mapping large areas was subsequently eliminated with the use of commercial scanners, which provided accurate and fast information about the distribution of RE ions in the material volume with high resolution up to ≈2.7 µm. Combination of conventional techniques (such as optical absorption) and lateral scanning thus gives us a simple and precise tool for the determination of concentrations and RE ion distribution which can been used for quality control of prepared wafers and study of RE ion distribution behaviour in transparent materials. This was also illustrated on the example of CeYAG samples with different Gd content, where the Gd ions increase the uniform lateral distribution of Ce atoms within the wafer and led to the reduction of the central pattern or the observed absence of any arrangement in the central part in case of CeLuAG crystals. The presented method can be further optimized for other rare-earth ions or phosphors by applying the methodological approach described in this study, utilizing a suitable combination of one or more red, green, or blue channels with the characteristic absorption bands of the luminophores in a transparent host matrix determined by UV-Vis-NIR spectrophotometer. Generally, this method can be used to track the lateral distribution of areas of different optical transmission/absorption. To obtain proper information about lateral distribution, the measured material has to fulfill following: (i) The difference in the absorbance must have the same sign (i.e. the absorbance of one region must be lower/higher than of the other one) in the whole color channel window (ii) the material has to absorb in the detection spectral range of the scanner CCD and the emission spectral range of the scanner light source. This somewhat limits the potential for materials with several doping elements where the absorption bands can be very close to each other in wavelength/energy. Such difficulty can be overcame using a proper bandpas filter placed on top of the measured sample. The filter than defines the spectral characteristic of the incident light, allowing for acquisition of only one absorption band. Note that the presented values of lateral resolution remain unchanged, whereas the observable thresholds and contrast may vary depending on the luminophore or host matrix used.

Methods

Raw materials Lu2O3, Y2O3, Al2O3, CeO2 and Gd2O3 as powders of the best commercially available (5N) oxides purity were mixed according to a stoichiometric ratio of [(Y or Lu) + Ce]:Al = 3:5 for Ce(Y,Lu)AG and (Y + Gd + Ce):Al = 3:5 for CeYAG:Gd crystals, where Ce content was set as 0.2 at.% and Gd concentration as 5 at.% and 13 at.% respectively. These are mixed and melted at high temperature above 2000 °C. The single crystals were grown from the melt with the method Czochralski or Kyropoulos in the orientation < 111 >. Prepared samples are listed in Table 1 with denoted concentrations of both Ce3+ and Gd3+ ions, which were determined by the XRF spectroscopy with estimated precision of 0.01 at.%. The single crystals were cropped and sliced to the wafers and tempered in oxygen atmosphere for 24 h at temperature above 1000 °C. The surfaces of sliced wafers were treated to the double-side polished (Ra ≈ 2 nm) or top grounded (Ra 0.5–1.6 µm)/bottom polished and to the resulting thickness of 0.2 mm. Wafers were diced to the pieces of phosphors with dimensions of approximately 10 × 10 mm (see Fig. 1). Inspection in a polarizing microscope showed good sample quality and no mechanical stress was observed in the samples (see Fig. 2). Ellipsometry measurements were carried out on single-sided polished samples using the variable angle Mueller matrix spectroscopic ellipsometer (SE) J.A. Woollam Co. RC2 in the spectral range 0.73 to 6.42 (193–1700 nm) and angle of incidence from 55°–65° with 5° steps.

SE measurements were performed laterally point-by-point using the standard beam size (diameter ≈ 4 mm) or with focusing probes (diameter ≈ 200 µm). Measurements were provided in the centre of each sliced segment. Similar samples were used to perform steady-state photoluminescence spectra using a FluoroMax-3 HORIBA spectrofluorometer with a xenon lamp and excitation wavelength at corresponding absorption maxima. The photoluminescence decay kinetics were measured by single photon method with 50 ps resolution under 482 nm excitation at corresponding emission maxima. Transmission spectra were recorded point-by-point on a double-beam Shimadzu UV-Vis 2600 spectrophotometer at room temperature over the wavelength region from 200 to 900 nm. Where possible, the real beam sizes/investigated areas are displayed (see Figs. 1, 3, 4, and 7) Lateral scan was performed using conventional scanner CanoScan 9000F with CCD 12-line color sensor and second HP LaserJet M1132. The CanoScan 9000F operates in both transmission and reflection mode using various DPI settings with derived lateral resolutions from 84.7–2.65 µm (300, 600, 1200, 2400, 4800 and 9600 DPI in Transmission mode) and from 339–42.3 µm (75, 100, 150, 200, 300, 400 and 600 DPI in Reflection mode), whereas the HP LaserJet M1132 operates only in reflection regime with maximum lateral resolution of ≈20 µm while using 1200 DPI setting. Obtained high resolution images in .tif format were open in free-to-use Java-based image processing software ImageJ 1.54g and split to separate red, green and blue channels (Procedure: Image upload→Image→Color→Split channels). Due to the presence of characteristic absorption band assigned to Ce3+ ions centered at 446−458 nm, only the blue part of RGB model has been used for data evaluation by applying the gray-scale mask on the blue channel output (Procedure: Image→Lookup Tables→Grays) with later final adjustment of Brightness/Contrast. Described process is schematically illustrated in Fig. 5. The Faraday rotation was measured at room temperature in applied magnetic field 0.7 T and using the rotation analyzer modulation in wavelength range 1.2–6.2 eV (200–1200 nm).

Data availability

The data that support the findings of this study are included within the article and attached supplementary material and are also available from the corresponding author upon reasonable request.

References

Diening, A. & Kuck, S. Spectroscopy and diode-pumped laser oscillation of Yb3+,Ho3+-doped yttrium scandium gallium garnet. J. Appl. Phys. 87, 4063–4068 (2000).

Zhao, W. et al. Evidence of the inhomogeneous Ce3+ distribution across grain boundaries in transparent polycrystalline Ce3+-doped (Gd,Y)3Al5O12 garnet optical ceramics. Jpn. J. Appl. Phys. 49, 022602 (2010).

Beil, K. et al. Thermal and laser properties of Yb:LuAG for kW thin disk lasers. Opt. Express 18, 20712–20722 (2010).

Lupei, V. & Lupei, A. Nd:YAG at its 50th anniversary: still to learn. J. Lumin. 169, 426–439 (2016).

Kunkel, N. & Goldner, P. Recent advances in Rare-Earth doped inorganic crystalline materials for quantum information processing. Z. Anorg. Allg. Chem. 644, 66–76 (2018).

Azrakantsyan, M., Albach, D., Ananyan, N., Gevorgyan, V. & Chanteloup, J.-C. Yb3+:YAG crystal growth with controlled doping distribution. Opt. Mater. Express 2, 20–30 (2012).

Chen, J.-C. et al. Fluorescence mapping of oxidation states of Cr ions in YAG crystal fibers. J. Cryst. Growth 274, 522–529 (2005).

Zhu, Y. & Cheng, J. Transient absorption microscopy: technological innovations and applications in materials science and life science. J. Chem. Phys. 152, 020901 (2020).

Epicier, T. et al. Spatial distribution of the Yb3+ rare earth ions in Y3Al5O12 and Y2O3 optical ceramics as analyzed by TEM. J. Mater. Chem. 22, 18221–18229 (2012).

Voronko, Y. & Sobol, A. Local inhomogeneity of garnet crystals doped with rare-earth ions. Phys. Stat. Sol. (a) 27, 657–663 (1975).

Kottaisamy, M., Thiyagarajan, P., Mishra, J. & Ramachandra Rao, M. Color tuning of Y3Al5O12:Ce phosphor and their blend for white LEDs, Mater. Res. Bull. 43, 1657–1663 (2008).

Shi, H. et al. Luminescence properties of YAG:Ce, Gd phosphors synthesized under vacuum condition and their white LED performances, Opt. Mater. Express 4, 649–655 (2014).

Pan, Y., Wu, M. & Su, Q. Tailored photoluminescence of YAG:Ce phosphor through various methods. J. Phys. Chem. Solids 65, 845–850 (2004).

Shao, Q. et al. Temperature-dependent photoluminescence studies on Y2.93-xLnxAl5O12:Ce0.07 (Ln=Gd, La) phosphors for white LEDs application,. J. Alloy. Compd. 498, 199–202 (2010).

Yang, H., Lee, D.-K. & Kim, Y.-S. Spectral variations of nano-sized Y3Al5O12:Ce phosphors via codoping/substitution and their white LED characteristics. Mater. Chem. Phys. 114, 665–669 (2009).

Wu, L., Gundiah, G. & Cheetham, A. Structure–property correlations in Ce-doped garnet phosphors for use in solid state lighting. Chem. Phys. Lett. 441, 250–254 (2007).

Saleh, M., Kakkireni, S., McCloy, J. & Lynn, K. Improved Nd distribution in Czochralski grown YAG crystals by implementation of the accelerated crucible rotation technique. Opt. Mater. Express 10, 632–644 (2020).

Xu, X. et al. Comparison of Yb:YAG crystals grown by CZ and TGT method. J. Cryst. Growth 257, 297–300 (2003).

Zhao, W. et al. Ce3+ dopant segregation in Y3Al5O12 optical ceramics. Opt. Mater. 33, 684–687 (2011).

Ueda, J. & Tanabe, S. Review of luminescent properties of Ce3+-doped garnet phosphors: New insight into the effect of crystal and electronic structure. Opt. Mater. X 1, 100018 (2019).

Slack, G., Oliver, D., Chrenko, R. & Roberts, S. Optical absorption of Y3Al5O12 from 10 to 55,000 cm−1 wavenumbers. Phys. Rev. 177, 1308–1314 (1969).

Hrabovsky, J., Kucera, M., Palousova, L., Bi, L. & Veis, M. Optical characterization of Y3Al5O12 and Lu3Al5O12 single crystals. Opt. Mater. Express 11, 1218–1223 (2021).

Tomiki, T. et al. Ce3+ centres in Y3Al5O12 (YAG) single crystals. J. Phys. Soc. Jpn. 60, 2437–2445 (1991).

Kucera, M. et al. Ce-doped YAG and LuAG epitaxial films for scintillation detectors. IEEE Trans. Nucl. Sci. 55, 1201–1205 (2008).

Kucera, M. & Hakenova, J. Strong faraday effect in Ce3+: YAG. J. Magn. Magn. Mater. 104–107, 439–440 (1992).

Jacobs, R., Krupke, W. & Weber, M. Measurement of excited-state-absorption loss for Ce3+ in Y3Al5O12 and implications for tunable 5d→4f rare-earth lasers. Appl. Phys. Lett. 33, 410–412 (1978).

Bruggeman, D. Berechnung verschiedener physikalischer konstanten von heterogenen substanzen. I. Dielektrizitätskonstanten und leitfähigkeiten der mischkörper aus isotropen substanzen. Ann. Der Phys. 416, 636–664 (1935).

Acknowledgements

The authors acknowledge the Czech Ministry of Education, Youth and Sports for financial support (grant No. LTACH19023). This work was supported by the Charles University grant SVV–2024–260720 and European Union and the state budget of the Czech republic under the project (project SenDiSo: CZ.02.01.01/00/22008/ project FERRMION: CZ.02.01.01/00/22008/0004591).

Author information

Authors and Affiliations

Contributions

J.H. conducted the UV-Vis-NIR, Faraday Rotation, Spectroscopic ellipsometry, emission spectroscopy and lateral scanning measurements, and co-wrote the manuscript. L.P. and J.K. participated in crystal growth, polishing, XRF spectroscopy and lateral scanning measurement. M.K. provided the photoluminescence decay curves measurements and co-wrote. J.Z. and L.B. provided comments and suggestions on the optical and magneto-optical properties of investigated materials. M.V. planned and guided the study, co-wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Daniel Franta, Scott E. Crawford and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Jet-Sing Lee.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Hrabovsky, J., Kucera, M., Palousova, L. et al. Rapid and precise large area mapping of rare-earth doping homogeneity in luminescent materials. Commun Mater 5, 251 (2024). https://doi.org/10.1038/s43246-024-00679-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s43246-024-00679-x