Abstract

A key issue of all-solid-state rechargeable lithium batteries is the formation of a low-resistive electrode‒solid electrolyte interface. Since this problem begins with undesirable side reactions during the electrode‒solid electrolyte interface bonding process, the basic guidelines for suppressing side reactions need to be clarified. Here, we combine a typical Li+-conductive amorphous solid electrolyte, lithium phosphate, which exhibits various Li chemical potentials depending on the Li/P atomic ratio on the film surface, with c-axis oriented LiCoO2 thin films. The lowest interfacial resistances of less than 10 Ω cm2 are achieved within a certain range of Li/P atomic ratios. We clarify that interface bonding is classified as Li-insertion or Li-extraction types on the electrodes. The formation of appropriate ranges of Li-inserted or Li-extracted electrode states at the bonding interface is a major factor for attaining low-resistivity electrode–solid electrolyte interfaces and determining their appropriate combinations.

Similar content being viewed by others

Introduction

All-solid-state lithium batteries (SSBs) are promising power sources for advanced electric vehicles, satellites, and surface-mounted semiconductor devices because of their high-power density, liquid-free system, and enhanced safety and thermal stability features1,2. Two critical issues in enhancing the performance of SSBs are as follows: the solid electrolyte (SE) and the interface. The former issue is related to the development of solid electrolytes (SEs) with high lithium-ion (Li+) conductivity. Research aimed at discovering highly Li+ conductive SEs has been conducted based on experimental and theoretical approaches3,4,5,6. Researchers have discovered sulfide3, oxyhalide4, and composite5 SEs that achieve Li+ conductivities of approximately 10 mS cm−1 or higher at room temperature and have proposed design principles for these superionic conductors6. The Li+ transference number of SEs is unity; thus, practical Li+ conductivity is comparable to or even exceeds that of the organic electrolytes used in commercial lithium-ion batteries7.

The latter issue is related to the formation of low-resistivity and highly stable electrode–SE interfaces. Challenges in achieving low-resistivity interface begin with the interface bonding process, and their stability during charge‒discharge reactions depends on the potential window of the SEs8,9 and (electro)chemical and/or mechanical factors10,11. During the interface bonding process, resistive side reactions often occur around the interface12,13,14,15 because both electrodes and SEs are composed of different elements and concentrations; this leads to mutual diffusion driven by the chemical potential differences of the constituent elements. A typical example is the case of SSBs using oxide-based SEs where high-temperature sintering is applied, and this process can facilitate the diffusion of various constituent elements. However, the most mobile element during the interface bonding process is Li because both materials are designed with Li+ conductive properties. When the Li chemical potential (\({\mu }_{{{{\rm{Li}}}}}\)) aligns at the interface, the Li concentration also varies around the interface. This nonstoichiometric Li region triggers side reactions that occur during the sintering process16,17 and during the charging reactions of SSBs18,19. Thus, understanding how the alignment of \({\mu }_{{{{\rm{Li}}}}}\) influences the low-resistivity electrode–SE interface is important.

Problems associated with the formation of a low-resistivity electrode–SE interface during the interface bonding process have been examined by using various electrode–SE combinations, and numerous approaches have been proposed, such as coating layer formation20, in-situ interlayer formation21,22, and low-temperature bonding processes23,24. Among these approaches, several factors have been identified from the fundamental aspects of thin-film SSBs using amorphous lithium phosphorus oxynitride glass electrolytes (LiPONs, typically Li3+xPO4−xNx)25. The anodic potential window of LiPON has been estimated to be ca. 4 V in theoretical calculations8,9. Thin-film SSBs typically employ Li metal anodes, and stable charge‒discharge reactions have been ensured for tens of thousands of cycles26. The Li+ conductivity of LiPON is approximately 10−6 S cm¹ at room temperature, and LiPON is generally prepared by radio frequency (RF) magnetron sputtering. Factors contributing to high interfacial resistance during the formation of LiPON on electrodes have been discussed in terms of chemical potential differences27, Fermi energy differences28, and damaging effects during interface formation29. Chemical potential differences are related to element diffusion during the interface bonding process, as mentioned above. For example, when LiCoO₂ (LCO) is combined with LiPON, both Li and O from LCO diffuse into LiPON, forming resistive lithium compounds such as LiNO₂ and reducing Co on the LCO side27. Fermi energy differences pertain to the electron transfer; since the Fermi energy of LiPON is higher than that of LCO, electrons flow from LiPON to LCO upon bonding, reducing LCO28. This leads to Co reduction and structural degradation of LCO. The damage layer effect involves the structural degradation of LCO during the deposition of LiPON. When LiPON is formed on an LCO film by sputtering under an N₂ atmosphere, ion bombardment with negatively charged N ions damages the LCO structure, and the interfacial resistance is subsequently increased29. Consequently, the interfacial resistance of LCO/LiPON at 4.0 V (25 °C) can be reduced to as low as 8.6 Ω cm² by a less damaging sputtering position30. All these factors are related to the reduction in the interfacial resistance. However, LiPON is an amorphous material with various Li compositions related to \({\mu }_{{Li}}\). Additionally, the Fermi energy varies depending on the Li/P atomic ratio31. Furthermore, the sputtering conditions, including their positions, differ from those used by other researchers. Thus, how each factor and its interactions contribute to the reduction in interfacial resistance remains unclear.

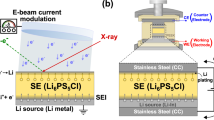

In this study, we prepared amorphous lithium phosphate thin films (LPOs) with low amounts of nitrogen (approximately 1% versus oxygen), which have different Li/P atomic ratios (2 to 9) on the film surface. The LPO films were fabricated using bias-induced RF magnetron sputtering at substrate temperatures less than 80 °C. These LPO films were deposited onto c-axis oriented lithium cobalt oxide (LiCoO2: LCO) thin-film electrodes, and their electrochemical properties were evaluated. We demonstrate that interface bonding is classified into two types, namely, lithium-insertion bonding and lithium-extraction bonding; the type depends on the Li/P atomic ratio. Furthermore, a strong correlation is observed between the Li/P atomic ratio and the LCO/LPO interfacial resistance. An optimal Li/P atomic ratio range achieves the lowest interfacial resistance of less than 10 Ω cm2 at 4.0 V and 25 °C. Once the Li/P atomic ratio increases beyond this range, reductive degradation of LCO occurs because of excess Li insertion into LCO. Alternatively, when the Li/P atomic ratio decrease beyond this range, kinetically less reversible phase formation occurs because too much Li is extracted from LCO. Both these cases result in increased interfacial resistances.

Results and discussion

Figure 1a and b show the cross-sectional SEM images of the LPO films deposited under 0 V substrate bias on Pt/Ti/Si substrates at substrate temperatures less than −80 °C (CL film) or at room temperature (RT film). The film thicknesses of the CL and RT films were 1.7 μm and 1.5 μm, respectively, and did not significantly depend on the substrate temperature. However, the CL film exhibited uniform contrast, whereas the RT film contained granular contrasts within the film. Figure 1c shows the XRD patterns of the CL film, RT film, and substrate. The CL film showed a halo pattern at approximately 20°, in addition to the diffraction peaks from the substrate; however, the RT film contained other diffraction peaks (*), although they did not match the diffraction patterns from the typical impurity materials such as LiPO3, Li4P2O7, Li3PO4, Li2CO3, and Li2O. These results indicate that the CL film is completely formed in an amorphous state, whereas the RT film is partially crystallized. Figure 1d and e show the electrochemical impedance spectroscopy (EIS) of the CL and RT films measured at 3.0 V using Li/LPO/Pt/Ti/Si cells (S-cells). Each spectrum exhibited a single semicircle in the higher frequency region and followed a divergent line to the real axis in the lower frequency region. The diameter of the semicircle is assigned to the resistance of Li+ conduction in the LPO films, and the Li+ conductivities at 25 °C (σLi+) were estimated to be 4.7 × 10−7 S cm−1 for the CL film and 1.3 × 10−7 S cm−1 for the RT film. The CL films are uniformly formed in amorphous states and have higher σLi+. Thus, we selected to prepare various LPO films under substrate cooling conditions in later discussions.

Cross-sectional SEM image of an LPO prepared at a cooling condition (CL) and b at room temperature (RT). c XRD patterns of LPOs prepared under CL and RT conditions in addition to reference peaks. EIS plots of the S-cells using LPOs prepared under d CL and at e RT conditions. f Summary of the oxygen chemical bonding state of LP-xs (x = 2.20, 2.63, 5.24, and 8.78) prepared under CL conditions; here, bridging oxygen (red): Ob, nonbridging oxygen (green): Onb, and Li2O (gray). g Ionic conductivities of LP-xs at 25 °C.

Supplementary Table 1 summarizes the Li/P, O/P, and N/O atomic ratios of the series of the LPO films prepared in this work. All LPO films were deposited at a substrate bias of 0 V to −6 V under substrate cooling (CL conditions). These atomic ratios were determined by the XPS measurements on each film surface. The Li/P atomic ratio varied from 1.75-8.78 depending on the substrate bias, whereas the N/O atomic ratio remained constant at 0.01–0.03. Both the Li/P and O/P atomic ratios tended to increase with increasing negative bias. Hereafter, the LPO films with a Li/P atomic ratio of x are denoted LP-x. Figure 1f shows the proportions of the bridging oxygen (Ob), nonbridging oxygen (Onb), and Li2O derived from O 1 s for LP-2.20, LP-2.63, LP-5.24, and LP-8.78. The increased Li/P atomic ratio resulted in an increase in the proportion of Li2O31. Cross-sectional SEM images of these LP-xs (Supplementary Fig. 1a–d) showed uniform contrast as with Fig. 1a and their EISs measured at 3.0 V using S-cells (Supplementary Fig. 1e–h) were resembled with those in Fig. 1d. Figure 1g shows a summary of the σLi+ of the LP-xs. σLi+ was obtained in the range of 3-5 × 10−7 S cm−1 regardless of x. These σLi+ values are approximately 1/7 to 1/4 of the typical σLi+ of LiPON (ca. 2 × 10−6 S cm−1) because of the lower nitrogen substitution (N/P < 0.03) in our LPO films than in general LiPON (N/P~0.1)32,33.

Figure 2a shows the open circuit voltages (OCVs) of the S-cells using the LP-2.20, LP-2.63, LP-5.24, and LP-8.78. OCV depends on the Li/P atomic ratio, and a higher Li/P atomic ratio tends to decrease the OCV. The OCV of the S-cell is the difference in \({\mu }_{{{{\rm{Li}}}}}\) at the Li/LP-x interface (\({{{{\rm{\mu }}}}}_{{{{\rm{Li}}}}}^{{{{\rm{Li}}}}/{{{\rm{LP}}}}{{ \mbox{-} }}{{{\rm{x}}}}}\)) and Pt/LP-x interface (\({\mu }_{{{{\rm{Li}}}}}^{{{{\rm{Pt}}}}/{{{\rm{LP}}}}{{ \mbox{-} }}{{{\rm{x}}}}}\)), as illustrated in the inset of Fig. 2a.

a OCV variations of the S-cells using the LP-xs (x = 2.20, 2.63, 5.24, and 8.78; 1–2 μm in thickness) and the L-cells using the LP-xs (x = 1.75, 2.60, and 4.23; 10 nm in thickness) at 25 °C. Inset shows the schematic image of the L-cell and observed OCV in the S-cell. b Schematic distribution images of \({\eta }_{{{{\rm{Li}}}}}\), \({\mu }_{{{{\rm{Li}}}}}\), and \({\varPhi }_{{{{\rm{Li}}}}}\) in the LP-xs during the deposition at substrate bias of 0 to −6 V against earth.

Here, the conduction band minimum (CBM) of LPO is lower than the work function of Li31. LPOs then react with Li to form a stable interface, similar to a LiPON film15,24. Therefore, \({{{{\rm{\mu }}}}}_{{{{\rm{Li}}}}}^{{{{\rm{Li}}}}/{{{\rm{LP}}}}{{ \mbox{-} }}{{{\rm{x}}}}}\) is fixed regardless of the Li/P atomic ratio. The variations in the OCV are then reflected by the difference in \({\mu }_{{{{\rm{Li}}}}}^{{{{\rm{Pt}}}}/{{{\rm{LP}}}}{{ \mbox{-} }}{{{\rm{x}}}}}\) across each cell. Bias-induced RF sputtering has been applied to alter the atomic ratios of LiPON films34,35, and a mismatch of the Li/P atomic ratios at the surface and inside the bulk has been reported35. We measured the average Li/P atomic ratios of LP-2.20, 2.86, and 5.73 using the inductively coupled plasma (ICP) and atomic absorption spectrometry, and the Li/P ratios were determined to be 2.78-2.79 in these films. Additionally, we measured the depth profiles of both the Li/P and O/P atomic ratios in those films using nuclear reaction analysis (NRA) and Rutherford backscattering spectrometry (RBS), and the values were 2.80–2.81 and 3.15, respectively, with uniform distributions throughout the films (Supplementary Fig. 2). These results indicate that the surface composition varies with the substrate voltage, whereas the bulk composition is similar in these films. This situation reasonably explains the attainment of nearly the same \({\sigma }_{{{{{\rm{Li}}}}}^{+}}\) for the LP-xs samples regardless of the Li/P atomic ratio (Fig. 1g). Here, to determine the relationship between the Li/P atomic ratio around the Pt/LP-xs and \({\mu }_{{{{\rm{Li}}}}}^{{{{\rm{Pt}}}}/{{{\rm{LP}}}}{{ \mbox{-} }}{{{\rm{x}}}}}\), we prepared 10 nm-thick LP-1.75, 2.60, and 4.23 layers on the Pt/Ti/Si substrates as quasi-uniform interface layers around the Pt/LP-xs. We then measured their OCVs through an organic liquid electrolyte, with the Li metals as reference and counter electrodes (L-cells). As shown in Fig. 2a, the OCV of the L-cells almost followed the variations in the S-cells. These results indicate that the Li/P atomic ratio around the Pt/LP-xs changes in relation to the surface Li/P atomic ratio.

A schematic image of LP-x prepared at different substrate biases is shown in Fig. 2b. When the substrate bias is set to a negative voltage, Li is preferably deposited on the LP-x surface, increasing the Li/P atomic ratio at the LP-x surface. LP-xs maintain uniform Li/P and P/O atomic ratios in the bulk, whereas the Li/P atomic ratio around the Pt/LP-x interface varies in relation to the surface Li/P atomic ratio. We speculate this behaviour occur by following mechanism. Both the LP-x surface and substrate holder are exposed to plasma with electron conduction during sputtering. Since LP-xs are Li+ conductive materials with negligible electronic conductivity36, this short-circuited state aligns \({\mu }_{{{{\rm{Li}}}}}^{{{{\rm{Pt}}}}/{{{\rm{LP}}}}{{ \mbox{-} }}{{{\rm{x}}}}}\) with \({\mu }_{{{{\rm{Li}}}}}\) on the LP-xs surface during the deposition of LP-xs and will result in a total alignment of the electrochemical Li+ potential (\({\eta }_{{{{\rm{Li}}}}}\)). However, further experimental studies are needed to support this mechanism.

Figure 3a–j show the cyclic voltammograms (CVs) at 25 °C of thin-film batteries (TFB; Li/LP-x/LCO; 1.98 ≤ x ≤ 8.78). The OCV of each TFB is indicated by a red circle in each CV. The CVs were initially swept from the OCV to 3.0 V (OCV-sweep), followed by three cycles at 3.0–4.0 V (1st-3rd CVs). Two cycles were subsequently conducted at 3.0–4.2 V (4th-5th CVs). Both the 1st CV and the 4th CV overlapped with the 2nd CV and the 5th CV, respectively, with the exception of the TFBs using the LP-5.73 and LP-8.78. For the TFBs with LP-x values of 2.27 ≤ x ≤ 3.52 (Fig. 3c–g), a couple of redox peak due to the two-phase reaction of LCO at 3.9 V and two pairs of redox peaks at 4.1 V and 4.2 V corresponding to the order‒disorder phase transition was observed37. For the TFB with LP-5.24 (Fig. 3h), an additional oxidation peak appeared at 2.0–2.7 V during the OCV-sweep, indicating the formation of spinel-phase LCO38,39. For the TFBs with LP-x values of 5.73 ≤ x (Fig. 3h–j), the spinel-phase oxidation peak further increased with increasing x, whereas the two-phase reaction peak decreased and became broader. On the other hand, for the TFBs with LP-x values of x ≤ 2.20 (Fig. 3a, b), the two-phase reaction peak weakened with decreasing x. These results clarify that the charge‒discharge reactions of the TFBs are strongly influenced by the range of x. Figure 3k–t show the EISs of the TFBs (Li/LP-x/LCO; 1.98 ≤ x ≤ 8.78) measured at 3.0 V after OCV-sweep and at 4.0 V during the 3rd CV. In the TFBs with LP-x values of 2.27 ≤ x ≤ 3.52 (Fig. 3m–q), one semicircular arc was observed in the higher frequency region at both voltages, and the interfacial resistance at 4.0 V (Rint) was too small to detect as a separated semicircular arc in the middle frequency region (Supplementary Fig. 3). In the TFB with LP-5.24 (Fig. 3r), Rint was distinguished in the middle frequency region and further increased in the TFBs with LP-5.73 (Fig. 3s) and LP-8.78 (Fig. 3t). Additionally, in the TFBs with LP-2.20 (Fig. 3l) and LP-1.98 (Fig. 3k), a semicircular arc visibly appeared in the middle-frequency region assigned to Rint.

The variations of CV (a–j) and EIS (k–t) of the TFBs using LP-1.98 (a and k), LP-2.20 (b and l), LP-2.27(c and m), LP-2.40(d and n), LP-2.52 (e and o), LP-2.86 (f and p), LP-3.52 (g and q), LP-5.24 (h and r), LP-5.73 (i and s), and LP-8.78 (j and t) measured at 25 °C. Each TFB shows a different OCV, which is shown as a red circle in each CV. OCV-sweep (black) means the initial CV from the OCV to 3.0 V. CVs were then repeated at 3.0–4.0 V (red) for two cycles, and the EIS was measured at the 3rd cycle. Later, two cycles were carried out at 3.0–4.2 V (blue). The 1st CV is denoted as 1 in the CV using the LP-5.73 and LP-8.78. EISs were measured at 3.0 V (black) after the OCV-sweep and 4.0 V (red) during the 3rd CV. In the cases of TFBs using LP-5.73 and LP-8.78, EISs were also measured at 2.5 V during the OCV-sweep to check the operations. The numbers in the EIS plots are the data measured at 10n Hz. u Summary of the OCVs and the Rint depending on the LP-xs.

Figure 3u show a summary of both the OCV and the Rint against x in LP-x for the TFBs. The pristine LCO film showed two Raman bands (A1g and Eg) characteristic of the layered structure of LCO40, and both the OCV and the Rint were 3.33 V (vs. Li/Li+) and 110 Ω cm2 in an organic liquid electrolyte, respectively (Supplementary Fig. 4). On the other hand, the OCVs of the TFBs depended on x and tended to decrease with increasing x; these results were similar to those using the S-cells. The estimated Rint values of the TFBs obtained via LP-x (2.27 ≤ x ≤ 3.52) were less than 10 Ω cm², with value of 1.4 Ω cm2 (LP-2.27), 5.7 Ω cm2 (LP-2.40), 1.4 Ω cm2 (LP-2.52), 4.3 Ω cm2 (LP-2.86), and 7.1 Ω cm2 (LP-3.52), as shown in the Supplementary Fig. 3. The Rint for the TFB using the LP-5.24 increased to 140 Ω cm2 and further increased to thousand Ω cm2 for the TFBs using the LP-5.73 and LP-8.78. Additionally, the Rint for the TFB using the LP-2.20 and LP-1.98 exceeded 800 Ω cm2. Supplementary Table 2 summarizes both the OCVs and the Rints against LP-xs. The Rint reached a minimum in the range of 2.27 ≤ x ≤ 3.52 and then increased once the xs exceeded this range.

Figure 4a shows the XRD patterns of LP-1.98, LP-2.40, LP-2.52, LP-2.86, LP-3.52, and LP-5.73 deposited on the LCO films. The XRD patterns of the LCO film without LP-x (bare LCO) and the Pt/Ti/Si substrate are also shown as references. Both the peak intensities and diffraction angles are normalized using Pt (111) at 2θ = 39.90° from each substrate. The diffraction peaks from the bare LCO film were observed at 18.97° for (003) and 38.50° for (006), and the c-axis lattice constant (caxis) was determined to be 14.03 Å nearly consistent with a previous report of LCO40. Figure 4b shows a magnified image around the diffraction peak at 19° in Fig. 4a. The LCO film covered with LP-2.86 had the same caxis of 14.03 Å with maintaining (003) diffraction intensity of the bare LCO film. The LCO film covered with LP-x (3.52 ≤ x) decreased (003) diffraction intensity with increasing x. Alternatively, the LCO films covered with LP-x (x ≤ 2.52) shifted the (003) peak depending on x. The LCO with LP-2.40 (OCV in TFB; 4.37 V) shifted (003) peak to a lower angle, and the caxis of the LCO film expanded to 14.36 Å; this value was nearly consistent with the expected caxis at 4.4 V for LCO41. Additionally, the LCO with LP-1.98 (OCV in TFB; 4.62 V) shifted (003) peak to higher angle, and the caxis shrink to 13.62 Å; this value was in agreement with expected caxis at 4.6 V for LCO42. These results clarify that the LCO structure changes depending on x during the interface bonding process.

a XRD patterns of a pristine LCO film (orange) and the LCO films after depositing LP-1.98 (gray), LP-2.40 (light blue), LP-2.52 (brown), LP-2.86 (blue), LP-3.52 (green), and LP-5.73 (purple). b Magnified XRD pattern (17-22°) of a. Cross-sectional STEM images of LCO/LP-xs (c–f) and Co L-edge EELS spectra measured at A-D areas in STEM (g–j) for bare LCO (c and g), LCO/LP-3.52 (d and h), LCO/LP-2.40 (e and i), and LCO/LP-5.73 (f and j). k Summary of Co L3-edge energy loss measured at A-D areas in bare LCO (black), LCO/LP-3.52 (green), LCO/LP-5.73 (blue), and LCO/LP-2.40 (red).

To further investigate the structural changes in the LCO films covered with LP-xs, STEM-EELS measurements were performed. Figure 4c–f show the cross-sectional STEM images of the bare LCO (Fig. 4c) and the LCO films covered with LP-3.52 (Fig. 4d), LP-2.40 (Fig. 4e), and LP-5.73 (Fig. 4f). EELS spectra around the Co L-edge (770-800 eV; Fig. 4g–j) and O K-edge (520–550 eV; Supplementary Fig. 5a–d) were measured in the A-D areas of each STEM image for the bare LCO film (Fig. 4g and Supplementary Fig. 5a) and LCO films covered with LP-3.52 (Fig. 4h and Supplementary Fig. 5b), LP-2.40 (Fig. 4i and Supplementary Fig. 5c), and LP-5.73 (Fig. 4j and Supplementary Fig. 5d). Here, the oxidation states inside LCO were estimated based on the energy loss of the Co L2-edge (~795 eV) and Co L3-edge (~780 eV) peaks. The values of the Co L3-edge energy in the A-D areas inside the LCO films are plotted in Fig. 4k. The Co L3-edge shifted to lower energy with increasing x, indicating that Co is reduced state in this order, and this trend explains decreasing OCV variations. The oxidation states of the LCO film were also estimated from the pre-edge peak of the O K-edge (~530 eV); this corresponds to the transition of O 1s states to O 2p states hybridized with Co 3d states (Supplementary Fig. 5). The pre-edge peak intensity is related to the oxidation state, and the pre-edge peak intensity from LCO with LP-2.40 is stronger than those from bare LCO and LCO with LP-3.52; these results indicate that LCO with LP-2.40 is in a more oxidized state43. In the case of LCO with LP-2.40, Co L3-edge peak energy is flat inside the film, indicating that delithiated LCO is uniformly formed in the film. Because this Li extraction corresponds to the charging reaction of LCO within an acceptable voltage range and then proceeds smoothly, Li is extracted evenly across the film. On the other hand, in the case of LCO with LP-5.73, the pre-edge peak of the O K-edge gradually decreased from the substrate to the surface, and the pre-edge peak intensity nearly disappeared both in the D and C area (ca. 20 nm away from the interface); these results indicate that LCO has a reductively degraded region from the interface to the substrate44. Excess Li insertion induces an irreversible structural transformation, and such transformation rate will be much slower than that of Li diffusion within an acceptable voltage range. This provides the formation of gradually degraded region from the interface. In the case of LCO with LP-3.52, the Co L3-edge showed a lower energy shift near to the interface (D position) compared with the bulk, but this trend is also observed in the bare LCO. Thus, LCO film is totally reduced state, but the interface structure will be almost maintained as with the bare LCO.

Figure 5 shows a schematic image of the LCO/LP-x interface during interface bonding depending on x in LP-x. Once the LCO films are combined with LP-xs, the LCO films are formed at charged or discharged states depending on x, and provide different OCVs. This situation arises from the alignment of \({\mu }_{{{{\rm{Li}}}}}\) at the LCO/LP-x interface during interface bonding. The LP-x with a lower \({\mu }_{{{{\rm{Li}}}}}\) around the interface aligns with LCO by extracting Li from the LCO film, whereas the LP-xs with a higher \({\mu }_{{{{\rm{Li}}}}}\) around the interface align with LCO by inserting Li into the LCO film. When these Li extracted or inserted states of LCO are within an acceptable range (2.27 ≤ x ≤ 3.52), the LCO/LP-xs interfaces are formed in a low-resistive interface state. When x becomes greater than the acceptable range, extra Li insertion reductively decomposes LCO as suggested by a weaker (003) diffraction peak and forms a resistive spinel phase38. This reduced region preferentially forms around the interface according to the EELS analyses (Fig. 4). On the other hand, when x becomes lower than the acceptable range, too much Li is extracted from LCO, and a kinetically less reversible phase transition (H1-3/O1 phase) occurs, and another resistive region forms45. LCO with LP-1.98 has a broad shoulder X-ray diffraction peak at approximately 20.8° (caxis~13.00 Å), and this peak is basically consistent with perfectly delithiated CoO2 (caxis = 12.88 Å); consequently, the Li-extracted region will also form a gradient state in the thickness direction. Li-extraction type bonding has been observed in the case of LCO-Li1+xAlxTi2−x(PO4)316, and Li-insertion type bonding has been reported in the case of Li0.5CoO2-Li6.4La3Zr1.4Ta0.6O1217. Thus, systematic variations in LCO-LP-x depending on x are not special cases but are common phenomena in all-solid-state batteries at the interface bonding process depending on the difference in \({\mu }_{{{{\rm{Li}}}}}\) between the electrode and SE.

The OCVs of the TFBs depend on the LP-xs and LP-2.86 shows nearly the same OCV as that measured in liquid electrolyte. Then, this \({\mu }_{{{{\rm{Li}}}}}\) is nearly the same as that of pristine LCO. Once the x decreases below 2.86, \({\mu }_{{{{\rm{Li}}}}}\) in the LP-xs becomes lower than that of LCO; here, the interface is then formed with the Li-extraction, and the charged LCO is also formed. Highly Li-extracted LCO provides a kinetically less reversible H1-3/O1 phase or decomposes the structure, leading to an increase of Rint. On the other hand, when x becomes larger than 2.86, \({\mu }_{{{{\rm{Li}}}}}\) in the LP-xs becomes higher than that of LCO; here, an interface is formed as Li-insertion states, and discharged LCOs are also formed. Highly Li-inserted states (5.73 ≤ x) reductively decompose the LCO structure, leading to the increase of Rint.

The alignment of \({\mu }_{{{{\rm{Li}}}}}\) at the LCO/LP-x interface occurs during the charge‒discharge reactions. Thus, we can reproduce the above degradations by electrochemical methods. Here, we selected the TFBs using LP-2.27 or LP-3.52 with Rint values less than 10 Ω cm2 and investigated the effects of the lower or higher cut-off voltages on the CVs (Fig. 6a, b, g, and h) and EISs (Fig. 6c–f and i–l). Figure 6a and b show the CVs of a TFB using LP-2.27 at 1.2–4.0 V and at 1.0–4.0 V, respectively. The voltage was initially swept from the OCV (4.01 V) to 3.0 V, and then the voltage was swept from 3.0 V to 1.2 V, 4.0 V, and 3.0 V at the 1st CV. Then, the 2nd CV was carried out at 3.0–4.0 V for EIS measurements at 3.0 V and 4.0 V. The 3rd CV was carried out as with the 1st CV and held at 1.2 V for 15 h, and then the EISs were measured at 3.0 V and 4.0 V during the 4th CV as with the 2nd CV. Later, the same measurements were conducted by changing the lowest cut-off voltage from 1.2 V to 1.0 V. The CVs measured at 1.2–4.0 V (Fig. 6a) showed two-phase reaction peaks at 3.9 V, and the corresponding EISs at 3.0 V and 4.0 V at the 2nd and the 4th CVs (Fig. 6c and d) almost overlapped with small Rint, as shown in Fig. 3m–q. When CVs were conducted by changing the lowest cut-off voltage to 1.0 V (Fig. 6b), an irreversible reductive current flowed at 1.0 V in the 1st CV and generated oxidation peaks at 2.0–2.7 V, whereas the two-phase reaction peak decreased. The EIS at 4.0 V measured during the 2nd CV (Fig. 6e) and the 4th CV (Fig. 6f) generated a tilted capacitive line to the real axis in the low-frequency region. These characteristic variations in the CVs and EISs are observed in the TFBs using LP-5.73 (Fig. 3i and s) and LP-8.78 (Fig. 3j and t). The effects of higher cut-off voltages on the electrochemical performance of a TFB were investigated in the same manner. Figure 6g and h show the CVs of a TFB using LP-3.52 at 3.0–5.0 V and at 3.0–5.2 V, respectively. The voltage was initially swept from the OCV (1.78 V) to 3.0 V, and then the CVs were measured at 3.0–5.0 V at the 1st CV. Then, the 2nd CV was carried out at 3.0–4.0 V for the EIS measurements at 3.0 V and 4.0 V. The 3rd CV was carried out as with the 1st CV and held at 5.0 V for 15 h, and then the EIS was measured at 3.0 V and 4.0 V during the 4th CV. Later, the same measurements were conducted by changing the higher cut-off voltage from 5.0 V to 5.2 V. The 1st CV measured at 3.0–5.0 V (Fig. 6g) showed almost reversible redox peaks due to the two-phase reaction at 3.9 V, the order-disorder reaction at 4.1–4.2 V, the O3/H1-3 phase transition reaction at 4.5 V, and the H1-3/O1 phase transition reaction at 4.6 V44. The 3rd CV peak appeared as a broad two-phase reaction peak during the cathodic scan, and both the O3/H1-3 and H1-3/O1 reaction peaks also disappeared. The Rint measured at the 2nd CV (Fig. 6i) was estimated to be 7.1 Ω cm2; this value was slightly increased to 20 Ω cm2 at the 4th CV (Fig. 6j). When the cut-off voltage increased to 5.2 V, the two-phase reaction current peak further decreased and broadened (Fig. 6h), and Rint increased to 128 Ω cm2 at the 2nd CV (Fig. 6k) and further to 1280 Ω cm2 at the 4th CV (Fig. 6l). A broad reductive current at approximately 3.9 V (Fig. 6h) was observed at the OCV-sweep of the TFB using LP-1.95 (Fig. 3a) and LP-2.20 (Fig. 3b), and Rint visibly increased in the same manner (Fig. 3k and l). At these higher cut-off voltages, Rint increase because of kinetically less reversible H1-3/O1 phase formation45.

CVs (a and b) and EISs (c–f) of TFBs using LP-2.27 were measured from 1.2 V (or 1.0 V) to 4.0 V. After the OCV-sweep, the 1st CV (black) was scanned between 1.2 V and 4.0 V. EIS measurements (Fig. 4c) were then taken at 3.0 V (black) and 4.0 V (red) during the 2nd CV. The 3rd CV repeated the 1st scan, but the voltage was held at 1.2 V for 15 hours. Subsequently, EISs (Fig. 4d) were measured at 3.0 V (black) and 4.0 V (red) during the 4th CV. After this series of electrochemical measurements, additional CVs (b) and EISs (e during the 2nd CV and f during the 4th CV) were similarly conducted, with the lower cut-off voltage changed to 1.0 V. To investigate the effects of a higher cut-off voltage, CVs (g and h) and EISs (i–l) of TFBs using LP-3.52 were measured in the same manner at 3.0V-5.0 V (g and i during the 2nd CV, and j during the 4th CV) and at 3.0V–5.2 V (h and k during the 2nd CV, and l during the 4th CV). All CVs were conducted at a scan rate of 0.5 mV s−1, and EIS measurements ranged from 100 mHz to 200 kHz. The numbers in all the EIS are data points measured at 10n Hz. All electrochemical measurements were performed at 25 °C.

The reductive decomposition of LCO during the interface bonding process with LiPON has been reported to occur by electron transfer from LiPON to LCO, which is driven by the difference in the Fermi energy (ΔEF) between LCO and LiPON28. We investigated the band structure of LP-xs (x = 2.35, 2.82, 3.77, and 4.05) using UPS and LEIPS31. The VBM depends on the Li/P atomic ratio, where the VBMs are approximately 8.8 eV for Li/P atomic ratios less than 3, and the values decrease to 7.0 eV for Li/P atomic ratios greater than 3. The CBM is nearly independent of the Li/P atomic ratio, and the values are 3.4–3.7 eV. Here, the EF of LP-2.35 is 4.5 eV greater than that of LCO (5.3 eV)46, and that of LP-3.77 is 5.3 eV comparable with that of LCO. From the difference in ΔEF, LCOs are expected to be reduced by the combination with LP-2.35 and to be nearly unchanged by the combination with LP-3.77. However, LP-2.35 is expected to oxidize LCO, whereas LP-3.77 is expected to reduce LCO during the bonding process, as shown in Fig. 3u. Thus, the difference in ΔEF is not sufficient to explain the trend of the oxidative/reductive trends of LCO depending on x. Sputtering damage to the LCO structure during the deposition of LPO has been reported to influence Rint29. Our LP-xs are prepared with the same sputtering dimensions (on-axis), but the values of Rint are strongly related to the Li/P ratios. Thus, the sputtering damage is not directly related to the degradation of LCO in our systems. However, sputtering damage may influence the resistance in another way. We prepared LP-2.79 on an LCO film and a Pt/Ti/Si substrate at RT (LP-2.79 (RT)), where the LP-x is within the range that provides a low-resistive Rint, as shown in Fig. 3u. The OCV of TFB using LP-2.79 (RT) was 4.40 V; this value was higher than that prepared under substrate cooling conditions. The CV plot showed the typical redox peaks of LCO (Supplementary Fig. 6a). The EIS data of the S-cell of Li/LP-2.79/Pt/Ti/Si (OCV: 3.01 V) revealed one semicircular arc at 3.0 V, as shown in Fig. 1d. On the other hand, the TFB using LP-2.79 (RT) presented an extra semicircular arc in the higher frequency region (Supplementary Fig. 6b), whereas Rint was low, and the EIS data measured at 3.0 V and 4.0 V nearly overlapped. Because the higher-frequency semicircular arc observed in TFB was independent of the voltage, we speculate that some Co2+ may diffuse into the LPO because of the effect of sputtering damage, and that a smaller Li+ conductive region is formed because of the reduced Li+ carrier density around the LCO/LP-2.79 (RT) interface. The structural stability of charged or discharged LCO depends on the temperature. Thus, when the substrate is not sufficiently cooled, the thermal decomposition of Li-extracted or Li-inserted LCO will provide other resistive compounds depending on the preparation conditions30.

Finally, we investigated the cycle stability of TFB using LP-2.27 for 10000 cycles at 3.0–4.2 V and 25 °C at 100 C rate. Supplementary Fig. 7a shows the charge‒discharge curves of the TFB. The TFB delivered 2.30 μAh cm−2 during the initial discharge reaction, and the capacity was basically maintained after 10000 cycles, with a degradation ratio per cycle of 0.002% (Supplementary Fig. 7b). Although the initial discharge capacity at 100 C was ca. 63% of the theoretical capacity of the LCO film (ca. 50 nm in thickness, 3.8 μAh cm−2), this capacity increased to 3.32 μAh cm−2 at 1 C rate and accounted for ca. 87% of the theoretical capacity (Supplementary Fig. 7a). This means that our LCO film is an c-axis oriented film, and Li diffusion inside the LCO film is retarded at higher C rates, which is different from that observed on epitaxial LCO films47. EISs were measured after the 1st, 1000th, 2000th, 5000th, and 10,000th cycles (Supplementary Fig. 7c–g). Each EIS showed one semicircular arc in the high-frequency region followed by a straight line to the real axis. The Rint slightly increased from 1.4 Ω cm2 (Supplementary Fig. 7h) to 15.6 Ω cm2 (Supplementary Fig. 7i) after 10,000 cycles, and a stable interface was maintained. Of course, these stabilities will depend also on other factors such as mechanical strength, higher temperature aging, which will be addressed in future work.

Conclusions

LCO thin films with c-axis orientations were combined with amorphous lithium phosphate glass electrolyte films, LPO, with different \({\mu }_{{{{\rm{Li}}}}}\) around the LCO/LPO interfaces. The correlations among the surface Li/P ratio, open-circuit voltage (OCV), and interfacial resistance between LCO and LPO were investigated. The \({\mu }_{{{{\rm{Li}}}}}\) is aligned during the bonding of LCO with LPO, and the bonding type is classified into two categories: Li-insertion type and Li-extraction type. An optimal range of Li/P ratios provide acceptable Li-inserted or Li-extracted states of LCO and maintain the crystal structure of LCO; this leads to a reduced interfacial resistance as low as 1.4 Ω cm2. Once the Li/P atomic ratio exceed this optimal range, excess lithiated or delithiated LCOs are generated. These situations cause reductive decomposition of LCO or kinetically less reversible phase transitions (H1-3/O1 phase), leading to an increase in the interfacial resistance. These situations were reproduced using electrochemical overcharging or over-discharging states. During the electrode-solid electrolyte interface bonding process, the difference in \({\mu }_{{{{\rm{Li}}}}}\) plays an important role to supress side reactions. Thus, appropriate control of \({\mu }_{{{{\rm{Li}}}}}\) and/or desirable electrode‒solid electrolyte combinations is crucial for suppressing the side reactions during the interface bonding process. The findings of this study could be extended to other electrode materials, such as LiFePO₄ and LiNixCoyMnzO₂ (x + y + z = 1). However, because the thermal and structural stability of electrodes in their lithiated and/or delithiated states depend on each electrode material, optimized ranges will also depend on the electrode species.

Methods

Materials synthesis

The substrates used in this study were prepared by initially depositing a Ti thin film (thickness (t)~2 nm) and then a Pt thin film (t~60 nm) as a current collector via radiofrequency (RF) magnetron sputtering onto the entire surface of a Si(001) wafer (10 mm in square, t = 0.5 mm) with a naturally oxidized thin layer (SiO2). The resulting substrates are denoted as Pt/Ti/Si substrates. Polycrystalline LiCoO2 (LCO) thin films (ϕ = 6 mm, t~50 nm) were prepared on the Pt/Ti/Si substrates using pulsed laser deposition (PLD). The laser source was a 4th harmonic YAG laser, and the laser was focused on a Li1.4CoOx sintered target (Toshima Manufacturing Co., Ltd., Japan) with a laser energy of 0.25 J cm−2 on the target at 10 Hz. The LCO films were fabricated at 600 °C on Pt/Ti/Si substrates under an O2 partial pressure of 27 Pa for 1 h. The resulting LCO films were transferred to an RF magnetron sputtering system without being exposed to air. A series of LP-x thin films were deposited on the LCO films on Pt/Ti/Si substrates using bias-controlled RF magnetron sputtering with a substate cooling system31. A commercially available sintered Li3PO4 target (ϕ = 75 mm, t = 5 mm; Kojundo Kagaku, Japan) was used as a target, and indium was used as a bonding metal. The substrate temperature was decreased to less than 80 °C during the deposition, where liquid nitrogen was added to the upper side of the substrate holder. The LP-x films were deposited at 120 W under a N2 + O2 (4:1 in volume) partial pressure of 1.5 Pa for 15 h. The resulting multilayers were then transferred into an Ar-filled glove box using a transfer vessel. The Li films (ϕ = 3 mm, t~10 μm) were deposited on the LP-x/LCO multilayers to form TFBs (Li/LP-x/LCO/Pt/Ti/Si) or S-cells (Li/LP-x/Pt/Ti/Si) using vacuum evaporation and assembled in an Ar-filled glove box.

Characterization methods for the LPO films

XPS and FE-SEM

Before depositing Li, the S-cells were transferred from the abovementioned Ar-filled groove box to the XPS instrument via an airtight sample holder. XPS measurements of the Li 1s, P 2p, O 1s, C 1s, N 1s, and Pt 4f peaks were collected using an XPS instrument (PHI5000 Versa Probe III, ULVAC-PHI). The X-ray source (Al Kα:1486.6 eV) was radiated to a sample surface with a spot size of 100 μm in square, a take-off angle of 80°, and a pass energy of 27 eV. The depth resolution is a few nm. All LP-x compositions described in this study were calculated using PHI MultiPak, a data analysis software installed in PHI5000. The Shirley method was used for baseline correction, and each spectrum was fitted using a Gaussian-Lorentzian function. The area of each fitted peak was then divided by corrected relative sensitivity factors of each element for the equipment provided within the software to determine the elemental composition. Each O 1 s spectrum was deconvoluted using CASA XPS software.

Both the thickness and morphology of the LP-xs were observed by field emission-scanning electron microscopy (FE-SEM; SU8030, Hitachi). Initially, a thin Au film was deposited on the surface of the samples via RF magnetron sputtering at room temperature without exposing the samples to air. The gold-coated samples were transferred into FE-SEM by an airtight sample holder. The FE‒SEM images were collected at an accelerating voltage of 10 kV.

RBS/NRA & ICP‒AES

The element distributions of P and O in addition to those of C, Si, Pt, Ti, and Cl in the LP-xs on Pt/Ti/Si were analysed by Retherford backscattering spectroscopy (RBS, National Electrostatics Corporation, Pelletron at Toray Research Centre, Inc.), and the element distribution of Li was analysed using nuclear reaction analysis (NRA). RBS was measured using a high-resolution RBS analyser; the ion beam current and size on the sample were approximately 13 nA and ϕ = 2 mm, respectively. The same apparatus was used for NRA; here, NRA was used to analyse the depth of the Li composition. The 7Li (p, α)4He reaction was used for the NRA measurements, with H+ (1500 keV) as the incident ion, and the beam current and current on the sample were 3 nA and ϕ = 2 mm, respectively. The average bulk compositions of the LP-xs were estimated using atomic absorption spectrometry (AAS; ZA 3300, Hitachi) and inductively coupled plasma spectrometry (ICP; PS3520VDDII, Hitachi). The samples measured by RBS and NRA were dissolved in dilute nitric acid and then distilled with water to prepare sample solutions. After the thin film was dissolved, the substrates were dissolved in sulfuric acid, nitric acid, hydrochloric acid, and hydrofluoric acid and then dissolved in diluted nitric acid to obtain a sample solution. The Li composition of these solutions was measured via AAS, the P composition was measured via ICP, and the amount of each element in each sample was determined and then converted to atomic ratios.

Characterization methods for the LCO films

XRD and Raman spectroscopy

The crystal structures of the LCO thin films were analysed using X-ray diffraction (XRD: Ultima IV, Rigaku) with a CuKα source. Scan mode of the XRD measurements was carried out at θ-2θ scans in air at room temperature in the range of 2θ = 15° to 60° with a sampling width of 0.01° and a scan speed of 2° min−1. Both the diffraction peak intensities and angles were normalized to the Pt (111) peak intensity and diffraction position observed at 2θ = 39.90°. Raman spectroscopy (NRS-5100M, Jasco) was used to analyse a pristine LCO film in air at room temperature with a green laser (532 nm in wavelength).

STEM-EELS

The sample thinning for the STEM observations was carried out using a focused ion beam (FIB) coupled with SEM (FIB-SEM, NB5000, Hitachi High-Tech). A Ga-ion beam was radiated to the samples at an acceleration voltage of 40 kV at −160 °C, and the damage layer was removed at 10–5 kV using Ar gas. The electron energy-loss spectra (EELS) were collected using a 200 kV transmission electron microscope (JEM-2400FCS, JEOL Ltd.) equipped with a Gatan Continuum ERS imaging filter (Gatan Inc.). The acceleration voltage, probe current, pixel size, and resolution were 200 kV, 46 pA, 2 nm/pixel, and 48 × 40 pixels, respectively. The resulting spectral energy positions were normalized to zero-loss energy, and their intensities were normalized to the peak intensity of the Co L3-edge (~780 eV) and the pre-edge peak of the O K-edge (~530 eV) measured in the A area in Fig. 4c–f, respectively.

Electrochemical measurements

Electrochemical measurements of the TFBs were carried out via a potentio-galvanostat (VMP3, Biologic) in an Ar-filled glove box at 25 °C, where the TFBs were pressed ca. a few tens of kPa to prevent mechanical short circuit. CV measurements were carried out at 0.5 mV s−1 in any case. EIS measurements were carried out with an alternating current (AC) amplitude of 10 mV at a given voltage from 100 MHz to 200 kHz. In both cells, the smallest electrode area is Li metal; thus, both the current density (mA cm2) in the CVs and the interface resistivity (Rint, Ω cm2) were calculated from the electrode area of Li metal (ϕ = 3 mm, 0.071 cm2). For comparison, the electrochemical properties of a pristine LCO film were measured in an organic liquid electrolyte. A three-electrode cell was fabricated in an Ar-filled glove box using an LCO film as the working electrode, Li metal as the reference and counter electrodes, and 1 mol dm−3 LiClO4 dissolved in propylene carbonate as the organic liquid electrolyte.

Charge‒discharge reactions of TFBs using LP-2.27 were carried out by constant current‒constant voltage methods at a 1 C rate for 5 cycles and at a 100 C rate for 10,000 cycles. The reactions were conducted at 25 °C between 3.0 V and 4.2 V at 3.38 μA cm−2 for the 1 C rate and 338 μA cm−2 for the 100 C rate, where the TFBs were maintained at each cut-off voltage for 10 minutes. All these measurements were carried out in an Ar-filled glove box.

Data availability

All data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Sun, Y. K. Promising all-solid-state batteries for future electric vehicles. ACS Energy Lett. 5, 3221–3223 (2020).

Janek, J. & Zeier, W. G. Challenges in speeding up solid-state battery development. Nat. Energy 8, 230–240 (2023).

Li, Y. et al. A lithium superionic conductor for millimeter-thick battery electrode. Science 381, 50–53 (2023).

Tanaka, Y. et al. New oxyhalide solid electrolytes with high lithium ionic conductivity >10 mS cm−1 for all‐solid‐state batteries. Angew. Chem. Int. Ed. 62, e202217581 (2023).

Ohta, S. et al. Fast ionic conduction achieved through the design and synthesis of ceramic heterointerfaces. Joule 9, 101789 (2024).

Wang, Y. et al. Design principles for solid-state lithium superionic conductors. Nat. Mater. 14, 1026–1031 (2015).

Liu, M. et al. Reviewing recent progress of liquid electrolyte chemistry for mitigating thermal runaway in lithium‒ion batteries. Energy Storage Mater. 65, 103133 (2024).

Zhu, Y., He, X. & Mo, Y. Origin of outstanding stability in the lithium solid electrolyte materials: insights from thermodynamic analyses based on first-principles calculations. ACS Appl. Mater. Interfaces 7, 23685–23693 (2015).

Schwietert, T. K., Vasileiadis, A. & Wagemaker, M. First-principles prediction of the electrochemical stability and reaction mechanisms of solid-state electrolytes. JACS Au 1, 1488–1496 (2021).

Zhao, Y. et al. A review on modeling of electro-chemo-mechanics in lithium-ion batteries. J. Power Sources 413, 259–283 (2019).

Wang, M. J., Kazyak, E., Dasgupta, N. P. & Sakamoto, J. Transitioning solid-state batteries from lab to market: linking electro-chemo-mechanics with practical considerations. Joule 5, 1371–1390 (2021).

Kim, K. H. et al. Characterization of the interface between LiCoO2 and Li7La3Zr2O12 in an all-solid-state rechargeable lithium battery. J. Power Sources 196, 764–767 (2011).

Kato, T. et al. Effects of sintering temperature on interfacial structure and interfacial resistance for all-solid-state rechargeable lithium batteries. J. Power Sources 325, 584–590 (2016).

Wang, Z. et al. In situ TEM-EELS observation of nanoscale interfacial phenomena in all-solid-state batteries. Nano Lett. 16, 3760–3767 (2016).

Schwöbel, A., Hausbrand, R. & Jaegermann, W. Interface reactions between LiPON and lithium studied by in-situ X-ray photoemission. Solid State Ion-. 273, 51–54 (2015).

Tian, H. K. et al. Electron and ion transfer across interfaces of the NASICON-type LATP solid electrolyte with electrodes in all-solid-state batteries: a density functional theory study via an explicit interface model. ACS Appl. Mater. Interfaces 12, 54752–54762 (2020).

Onoue, K. et al. Trigger of the highly resistive layer formation at the cathode–electrolyte interface in all-solid-state lithium batteries using a garnet-type lithium-ion conductor. ACS Appl. Mater. Interfaces 15, 52333–52341 (2023).

Yoshikawa, K. et al. Origin of O2 generation in sulfide-based all-solid-state batteries and its impact on high energy density. Adv. Sci. 11, e2402528 (2024).

Cheng, D. et al. Unveiling the stable nature of the solid electrolyte interphase between lithium metal and LiPON via cryogenic electron microscopy. Joule 4, 2484–2500 (2020).

Sakuda, A., Hayashi, A. & Tatsumisago, M. Interfacial observation between LiCoO2 electrode and Li2S−P2S5 solid electrolytes of all-solid-state lithium secondary batteries using transmission electron microscopy. Chem. Mater. 22, 949–956 (2010).

Kato, T. et al. In-situ Li7La3Zr2O12/LiCoO2 interface modification for advanced all-solid-state battery. J. Power Sources 260, 292–298 (2014).

Duan, H. et al. In situ constructed 3D lithium anodes for long‐cycling all‐solid‐state batteries. Adv. Energy Mater. 13, 2300815 (2023).

Ohta, S. et al. All-solid-state lithium-ion battery using garnet-type oxide and Li3BO3 solid electrolytes fabricated by screen-printing. J. Power Sources 238, 53–56 (2013).

Iwasaki, S. et al. Preparation of thick-film LiNi1/3Co1/3MnO2 electrodes by aerosol deposition and its application to all-solid-state batteries. J. Power Sources 272, 1086–1090 (2014).

Yu, X., Bates, J. B., Jellison, G. E. & Hart, F. X. A stable thin‐film lithium electrolyte: lithium phosphorus oxynitride. J. Electrochem. Soc. 144, 524–532 (1997).

Wang, B. et al. Characterization of thin‐film rechargeable lithium batteries with lithium cobalt oxide cathodes. J. Electrochem. Soc. 143, 3203–3213 (1996).

Fingerle, M., Buchheit, R., Sicolo, S., Albe, K. & Hausbrand, R. Reaction and space charge layer formation at the LiCoO2–LiPON interface: insights on defect formation and ion energy level alignment by a combined surface science–simulation approach. Chem. Mater. 29, 7675–7685 (2017).

Iida, S. I. et al. Characterization of cathode-electrolyte interface in all-solid-state batteries using TOF-SIMS, XPS, and UPS/LEIPS. J. Vac. Sci. Technol. B 39, 044001 (2021).

Haruta, M. et al. Negligible “negative space-charge layer effects” at oxide-electrolyte/electrode interfaces of thin-film batteries. Nano Lett. 15, 1498–1502 (2015).

Shiraki, S. et al. Atomically well-ordered structure at solid electrolyte and electrode interface reduces the interfacial resistance. ACS Appl. Mater. Interfaces 10, 41732–41737 (2018).

Nakayama, F. et al. Electronic properties of lithium-ion conductive amorphous lithium phosphorus oxynitride. Chem. Commun. 58, 13262–13265 (2022).

Lacivita, V., Artrith, N. & Ceder, G. Structural and compositional factors that control the Li-Ion conductivity in LiPON electrolytes. Chem. Mater. 30, 7077–7090 (2018).

Su, Y. et al. LiPON thin films with high nitrogen content for application in lithium batteries and electrochromic devices prepared by RF magnetron sputtering. Solid State Ion-. 282, 63–69 (2015).

Jouybari, Y. H., Berkemeier, F., Schäfer, A. & Schmitz, G. The influence of sputter conditions on the properties of LiPON and its interfaces. J. Power Sources 394, 160–169 (2018).

Mani, P. D. et al. Ionic conductivity of bias sputtered lithium phosphorus oxy-nitride thin films. Solid State Ion-. 287, 48–59 (2016).

Shao, B., Huang, Y. & Han, F. Electronic conductivity of lithium solid electrolytes. Adv. Energy Mater. 13, 2204098 (2023).

Reimers, J. N. & Dahn, J. R. Electrochemical and in situ X‐ray diffraction studies of lithium intercalation in Lix CoO2. J. Electrochem. Soc. 139, 2091–2097 (1992).

Shu, J. et al. A new look at lithium cobalt oxide in a broad voltage range for lithium-ion batteries. J. Phys. Chem. C. 114, 3323–3328 (2010).

Kobayashi, S. et al. Protons inside the LiCoO2 electrode largely increase electrolyte–electrode interface resistance in all-solid-state Li batteries. J. Phys. Chem. C. 127, 4684–4688 (2023).

Inaba, M., Iriyama, Y., Ogumi, Z., Todzuka, Y. & Tasaka, A. Raman study of layered rock-salt LiCoO2 and its electrochemical lithium deintercalation. J. Raman Spectrosc. 28, 613–617 (1997).

Amatucci, G. G., Tarascon, J. M. & Klein, L. C. CoO2, The end member of the Lix CoO2 solid solution. J. Electrochem. Soc. 143, 1114–1123 (1996).

Wu, Z. et al. Unveiling the evolution of LiCoO2 beyond 4.6 V. ACS Energy Lett. 8, 4806–4817 (2023).

Li, S. et al. Structural distortion-induced charge gradient distribution of Co ions in delithiated LiCoO2 cathode. J. Phys. Chem. Lett. 10, 7537–7546 (2019).

Sharifi-Asl, S. et al. Facet-dependent thermal instability in LiCoO2. Nano Lett. 17, 2165–2171 (2017).

Ohnishi, T., Mitsuishi, K. & Takada, K. In situ X-ray diffraction of LiCoO2 in thin-film batteries under high-voltage charging. ACS Appl. Energy Mater. 4, 14372–14379 (2021).

Swift, M. W. & Qi, Y. First-principles prediction of potentials and space-charge layers in all-solid-state batteries. Phys. Rev. Lett. 122, 167701 (2019).

Kawashima, K., Ohnishi, T. & Takada, K. High-rate capability of LiCoO2 cathodes. ACS Appl. Energy Mater. 3, 11803–11810 (2021).

Acknowledgements

This work was financially supported by JSPS KAKENHI “Interface IONICS” JP19H05813 and JST GteX (JPMJGX23S2).

Author information

Authors and Affiliations

Contributions

T. O. and Y. I. contributed equally to this work. M.M. conducted the data curation, investigation, writing of the original draft, and electrochemical measurements and analysis of the TFBs, S-cells, and L-cells. F. N. assisted with the UPS-LEIPS observations, analysis of the LP-xs, and the electrochemical measurements and analysis of the TFBs, S-cells, and L-cells. Y. S. prepared the LCO thin films and characterized them. M.S. conducted the SEM observations. Y.N. and K.H. conducted the STEM-EELS measurements. K.Y. advised on the EELS data analysis. T.O. provided the discussion on bias induced by the substrate cooling RF magnetron system and modified the original draft. T.Y. assisted with the XRD measurements and their analyses. Y.I. supervised and conceptualized the research and assisted in manuscript writing and editing. All authors participated in discussions during the manuscript writing and editing process and have given approval to the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Materials thanks Yu Qiao and the other anonymous reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: Jet-Sing Lee. A peer review file is available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Maruno, M., Nakayama, F., Suzuki, Y. et al. Chemical design rules for low-resistivity electrode–electrolyte interfaces in all-solid-state lithium batteries. Commun Mater 6, 144 (2025). https://doi.org/10.1038/s43246-025-00870-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s43246-025-00870-8