Abstract

China’s booming truck industry has led to a rapid rise in end-of-life trucks, yet only one-third are formally recycled. Here we estimate the resource, economic, and decarbonization potential of end-of-life trucks in China through 2050 using a dynamic population balance model. Our analysis shows the annual amount of end-of-life trucks will increase nine-fold to 53 million metric tons by 2050. The economic benefit from these materials is projected to reach 44 billion United States dollars, adjusted for inflation. Furthermore, urban mining of aluminum, iron, and copper can reduce carbon emissions by up to 58 million metric tons in 2050 compared to primary production. These findings provide quantitative support for urban mining policies to advance decarbonization, particularly in economies with fossil fuel-dominated power grids.

Similar content being viewed by others

Introduction

The world has reached a consensus on the need to bolster the circular economy to achieve sustainable development1,2,3,4. In recent years, major economies have put circular economy policies into action to tackle resource and energy-related and environmental challenges5,6,7. A key approach in the circular economy is urban mining8,9, which focuses on extracting or recycling secondary materials from waste or end-of-life products for new demands during the urbanization and industrialization process10,11,12,13. As such, urban mining has garnered considerable attention due to its potential to enhance resource and energy security and yield environmental benefits14,15.

The development of China’s road freight transportation (e.g., for a massive amount of bulk material use) has driven the truck industry’s rapid growth16,17,18,19. Consequently, the end-of-life generation of trucks has soared in China20. Trucks are resource-intensive products containing substantial amounts of steel, non-ferrous metals, plastics, glass, etc., in each unit21. The long-chain production of new or virgin materials is energy-intensive and results in a large amount of carbon emissions under a thermal power-dominated power grid22,23. On the other hand, the short-chain production of secondary materials is, in general, less resource and energy-intensive regarding the total material requirement and processing 24,25,26,27. Efficient recycling of end-of-life trucks (ELTs)—defined in this study as the process of recovering the maximum feasible proportion of recyclable materials from ELTs with high material recovery rates, economic viability, and minimal environmental impact—can alleviate resource scarcity, reinforce industrial economic chains downstream, and reduce energy consumption and carbon emissions28,29,30. On the contrary, inefficient recycling of ELTs may severely impact the environment, causing water-soil pollution and human health damage if waste liquids and toxic compounds are released into the environment31,32,33,34.

China, being one of the world’s biggest automobile markets, has put in place laws and regulations to boost the recycling industry for end-of-life vehicles (ELVs)31,35,36. For example, the 14th Five-Year Plan (2021–2025) for the Development of Circular Economy addresses an objective to improve the standardization of management and environmental oversight of vehicle recyclers37. This initiative is anchored in a national framework encompassing both regulatory and technical process standards. Key examples include the State Council’s revised Measures for the Management of End-of-Life Motor Vehicle Recycling, which establishes legal requirements for company qualifications and operations, and the national standard, Technical Specification for End-of-life Vehicle Recycling and Dismantling Enterprise (GB 22128), which outlines specific technical protocols for dismantling, pollution control, and material recovery rates. Nevertheless, only about 40% of ELVs currently enter formal recycling channels38. Two-thirds of these ELVs are left in open spaces or end up in the grey market for informal and uncontrolled recycling39. Trucks are a major vehicle type. Globally, heavy-duty vehicles account for only 10% of the total vehicle stock but are responsible for over 35% of the total material used in road transportation16. It is crucial to accurately estimate the number of trucks in use and their potential for urban mining40,41.

However, existing studies primarily only focus on recycling end-of-life passenger vehicles40,42,43,44,45. For example, Li et al.46 estimated China’s future ELV quantity and resource recovery potential from 2021 to 2030; Tan et al.47 conducted a spatiotemporal analysis of end-of-life electric vehicles and retried traction batteries in different provinces in China; Liu et al.48 provided a carbon emission reduction analysis on metal recycling in China’s end-of-life passenger vehicles, which finds that the recycling process can reduce 3816 kg of CO2eq per vehicle compared to primary production in 2020. There remains a knowledge gap regarding the recycling potential of trucks.

Understanding the current and future amount and distribution pattern of ELTs is a fundamental prerequisite for effective management. Accordingly, we conducted a forecast study on how secondary resources will be generated with ELTs by 2050. We also assessed the economic and environmental advantages of urban mining, with a focus on carbon emission reduction. We used a dynamic stocks-driven population balance model based on historical stocks, material contents, commodity prices, and energy use and carbon emission factors (Fig. 1). The study provides physical and economic data for recyclers to prepare and improve recycling technologies and schemes. The results serve as vital decision-making references for the government in managing resource efficiency, formulating environment-concerning policies, and promoting sustainable development of road transportation.

Results

Shift of in-use and end-of-life trucks

This study analyzes the trend of stock changes of various truck types. The results show that the stock of trucks in China will increase year by year with economic growth and continuous urbanization from 16 million units in 2010 to 30 million units in 2020 and to 51 million units in 2050, with an average annual growth rate of 3%, as shown in Fig. 2a. Among them, small trucks have the largest proportion of stock (Fig. 2b), from 9.1 million units in 2010 to 21 million units in 2020, and then grow slowly, reaching 37 million units in 2050. Heavy trucks follow small trucks, with stock increasing from 4.0 million units in 2010 to 8.4 million units in 2020 and stabilizing after 2035 at about 13 million units until 2050. The stock of medium trucks accounts for a relatively small proportion, decreasing from 2.7 million units in 2010 to 1.1 million units in 2020 and is expected to fall to less than 1 thousand units by 2050. Mini trucks have the most minor proportion of all trucks and have been on a downward trend, which was 23 thousand units in 2021. The reason for the growth of overall truck stock is the expansion of China’s public transportation network and large-scale urbanization of infrastructure after 2000, resulting in a surge in demand for trucks in transportation. Due to changes in China’s economic structure in recent years, trucks have increasingly served the logistics industry.

a Stock number and number share; b stock weight; c end-of-life number; d end-of-life weight and weight share. The forecast shows a slight wave-like increase, as the sum of the historical data for the four truck types follows this pattern, which is also the same for Fig. 3. Uncertainty caused by the weight range of trucks is provided in Supplementary Fig. 1 and discussed in the sensitivity and uncertainty analysis section. NT signifies mini truck, MT signifies medium truck, HT signifies heavy truck, and ST signifies small truck.

We estimated the number of ELTs in China as the basis of the following economic and carbon reduction potential assessments. Figure 2c, d show the evolution of the end-of-life number and weight of various types of trucks. In 2010, the total end-of-life weight of trucks was 5.9 Mt, but it will reach 28 Mt in 2030 and 40 Mt in 2050, with an annual growth rate of 5% (Supplementary Fig. 1). In 2010, medium trucks had the largest end-of-life weight, with an end-of-life weight of 3.2 Mt (322.74 thousand units), accounting for 55% of the total end-of-life weight, followed by small trucks, with an end-of-life weight of 2.3 Mt (663.69 thousand units), accounting for 38% of the total end-of-life weight. Heavy trucks had a relatively low end-of-life weight, with an end-of-life weight of 0.3 Mt (17.31 thousand units), accounting for 5% of the total. Mini trucks had the lowest end-of-life weight, with an end-of-life weight of 0.1 Mt (15.71 thousand units), accounting for only 2% of the total end-of-life weight. By 2050, small trucks will have the most considerable end-of-life weight, accounting for 57% of the total, while heavy trucks will increase by 62 times to 42% compared to 2010, and medium trucks will drop to below 1% after 2032. Mini trucks’ end-of-life weight share will stay less than 1%. The above analysis indicates that medium trucks may pose greater pressure and challenges to the government and recycling enterprises after scrapping.

Evolution of valuable resources in ELTs

Many valuable resources are locked in the truck when it reaches the end-of-life stage. From 2010 to 2050, the basic material and metal resources show a consistent trend of increase (Fig. 3a, b). Among them, the weight of rubber, plastic, and glass will increase from 0.3 Mt, 0.4 Mt, and 0.2 Mt in 2010 to 2.7 Mt, 3.7 Mt, and 1.6 Mt in 2050. In addition, the mineral resources of Fe, Al, Cu, Mg, Pb, Zn, Sn, Co, and W in 2010 were about 4.0 Mt, 0.3 Mt, 106 kt, 30 kt, 47 kt, 3.0 kt, 89 kt, 37 kt, and 156 t, and these materials’ resources will generally increase about nine times by 2050. Of these, Fe (73%) and Al (5%) have the largest share of mineral resources of all the base materials and are perhaps the primary targets for recovery.

The rising trend of rare earths is similar to other metals (Fig. 3c), which will increase from 62 t in 2010 to 524 t in 2050. In 2010, the recoverable weight of Dy, Nd, and La was 2.3 t, 21 t, and 39 t, respectively, and then increased to 20 t, 180 t, and 325 t by 2050, respectively. The recoverable weight of precious metals has also shown an upward trend. From 2010 to 2050, their mineral resources will increase from 4.6 t to 40 t (Fig. 3d). In 2010, the mineral resources of Au, Pt, Pd, Rh, and Ag were 1.2 t, 1.3 t, 1 t, 0.3 t, and 0.8 t respectively, but they will rise to 10.5 t, 10.9 t, 8.7 t, 2.4 t, and 7 t respectively by 2050. However, empirical knowledge suggests that informal recycling is a major concern for ELT recycling and management in developing and industrialized countries.

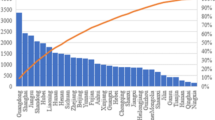

Economic potential of ELT urban mining

From an economic perspective, the materials sequestered in ELTs have great economic potential if they are effectively recycled, as shown in Fig. 4. Within a specific range of market values, the average economic potential of these materials will increase from 2.6 billion US$ in 2010 to 15 billion US$ in 2030 and 23 billion US$ in 2050 (Supplementary Fig. 2). For example, in 2023, in the evolution of the recycling potential, basic materials account for 96% of the economic potential (Supplementary Fig. 3), with Cu and Al having the highest monetary value, both about 2.71 billion US$, followed by Fe (1.92 billion US$) and plastics (1.47 billion US$). Precious metals account for 3% of the economic potential. The economic value of all the precious metals, ranked in descending order, is Au (220 million US$), Pd (77 million US$), Pt (16 million US$), Ag (3.1 million US$), and Rh (2.2 million US$). Since the content of rare metals and rare earths in trucks is extremely low, they account for only 1% of the economic potential, which is about 16 million US$. The above analysis shows that basic materials are currently the main recycling targets. The relevant recycling enterprises should focus on these metals when planning capacity allocation.

Carbon reduction potential of ELT urban mining

Due to the limited collection of energy demand data and carbon footprint data samples, to ensure the study’s comprehensiveness, this study set up a ± 20% range for energy use and carbon emission factors (Table 1). Figure 5 shows the potential energy and carbon reduction if all Fe, Al, and Cu in ELT are urban mined as secondary resources. For example, in 2023, for energy use reduction (Fig. 5a–c), the maximum reduction potential of Al is averagely 53 GJ (the distribution under the low and high ranges is 41 GJ and 64 GJ, respectively), which is because the primary production of Al consumes much more energy than the secondary production, and the energy reduction potential of Fe and Cu after recycling is 144 GJ (ranging 83–205 GJ) and 4.5 GJ (ranging 2.5–6.5 GJ), respectively (Supplementary Fig. 4). By the year 2050, the maximum potential for energy use reductions from Fe, Al, and Cu will be 322 GJ (ranging 186–458 GJ), 117 GJ (ranging 91–143 GJ), and 10 GJ (ranging 5.6–14 GJ), respectively. Due to the low metal recycling rate in ELTs, the substantial environmental benefits mentioned above have not yet been achieved. However, circular economy policies and ELT recycling technology are indeed rapidly advancing and will substantially improve the recycling rate in the future.

a Energy demand for Fe production; b Energy demand for Al production; c Energy demand for Cu production; d Carbon emissions from Fe production; e Carbon emissions from Al production; f Carbon emissions from Cu production. Subfigures 5d-5f show the trends in carbon emissions from primary production and recycling of target metals under both fixed factors (bright color) and decreasing factors (dim color). The shaded areas represent the uncertainty range (±20%) of the energy use and carbon emission factors.

In terms of carbon reduction (Fig. 5d–f), in 2023, Fe can reduce carbon emissions by an average of 15 Mt (ranging 7.9–23 Mt, note that all carbon emissions hereafter are in carbon dioxide equivalent (CO₂eq)) after recycling, far exceeding the other two metals. It is worth noting that Fe has such high carbon reduction benefits not because of its high emission coefficient but because of the large amount of Fe that makes up vehicles. Secondly, Al can reduce carbon emissions by about 10 Mt (ranging 7.9–12 Mt) after recycling, while Cu can reduce carbon emissions by about 344 kt (ranging 200–487 kt) after recycling (Supplementary Fig. 4). By 2050, the maximum potential for carbon emission reductions from Fe, Al, and Cu under a fixed emission factor scenario is projected to be 35 Mt for Fe (with a range of 18–52 Mt), 22 Mt for Al (with a range of 18–27 Mt), and 767 kt for Cu (with a range of 447–1087 kt), with a total 58 Mt potential. In contrast, under a scenario where the emission factors decrease annually, carbon emissions are expected to peak between 2030 and 2035 and subsequently decline until 2050. In such a scenario, the reductions are anticipated to be 10 Mt for Fe (ranging 4.9–14 Mt), 6.2 Mt for Al (ranging 4.9–7.5 Mt), and 213 kt for Cu (ranging 124–302 kt) in 2050. Optimizing the carbon emission factor will partially mitigate the carbon reduction effect of truck recycling. However, it is important to note that improvements in the emission factor are not achieved overnight; it is a gradual process. For example, under the decreasing carbon emission factor scenario, Al recycling was projected to generate a cumulative carbon emission reduction of 277 Mt compared to primary production between 2025 and 2050. Under the fixed carbon emission factor scenario, this benefit is even greater, at 471 Mt.

Sensitivity and uncertainty analysis

Sensitivity analysis of changes in the useful life of trucks is necessary because of possible product substitutions that can affect the lifespan of trucks. As shown in Fig. 6, the results show that in estimating the end-of-life weight of trucks in 2010, one year of longer life could reduce the end-of-life weight by 19.9%, while one year of shorter life could increase the end-of-life weight by 20.7%. This indicates that the effect of short-term estimation is pronounced, but in the long run, the lifespan of trucks will not unduly affect the end-of-life weight of trucks (Fig. 6a). It is also critical to consider economic factors when assessing the ELT recycling potential. There is a 41% error in the market value of the materials sequestered in the trucks, considering economic fluctuations (Supplementary Fig. 2). In addition, the weight range of trucks, such as deregistered trucks, sometimes with only the truck unit and sometimes with both the truck unit and the trailer unit, can also affect the estimation. The deviation in end-of-life weight was estimated to fluctuate around 11% after 2021. Furthermore, the vehicle weight range is mainly caused by whether the truck is equipped with a trailer unit. The main components of the trailer are basic materials (Fe, Al, plastic, rubber, etc.). Therefore, vehicle weight has a larger impact on basic materials and less impact on other metals (precious metals, rare earths, etc., as they are concentrated in the truck unit). Here, we performed uncertainty calculations for the end-of-life weight of trucks (Fig. 6b–e). The simulated distributions can well reflect the weight of ELTs in 2010, 2020, 2030, and 2050, and all the uncertainty analyses can verify and validate the accuracy and robustness of the above estimation and study results.

Discussion

The automobile industry in China is expanding rapidly. Indeed, China just overtook Japan in 2023, becoming the world’s No. 1 automobile exporter with 5.3 million units of exports49. Yet it still is grappling with the issue of high end-of-life rates and insufficient recycling50,51. At present, the Chinese vehicle population is swelling at an average yearly growth rate of 12%, and the annual end-of-life rate of vehicles in China is hovering around 1.0–1.4%48. The surge in the total number will unavoidably lead to a further rise in the yearly volume of ELVs in the near future. For trucks, the cumulative weight of ELTs was 6 Mt in 2010, and it’s projected to escalate to 53 Mt by 2050 (Fig. 2d), which is an approximately 9-fold increase. Given the substantial rise in the amount and the potential environmental hazards associated with ELTs, it is imperative for policymakers to oversee formal recycling initiatives while encouraging active involvement from various stakeholders, including recyclers and consumers52.

The total economic value of recyclable resources is expected to rise substantially from 2.6 billion US$ in 2010 to 23 billion US$ in 2050 (Fig. 4). Taking an inflation rate of 2% per year into account, the value in 2050 will increase more to 44 billion US$. Among them, Cu, Al, Fe, and plastics contribute about 96% of the economic value. Urban mining materials from trucks can create more jobs and income for the waste recycling industry 53. At the same time, a formal and controlled recycling system can also improve the working standards and social welfare of the workers54. Economic potential data can provide guidance for cost control. The system is self-sustainable when the overall recovery cost is lower than the economic potential55. Although metal recycling has improved in recent years, the status quo is still far from a circular economy56,57. Except for Fe, Al, Cu, and Pb, materials like plastics, rubbers, Mg, and Zn are facing technical challenges. Additionally, truck electrification is expected to increase the demand for battery materials, such as lithium (Li) in LiFePO4 batteries, the most popular battery type in China. We recommend that future research also consider the impact of truck electrification. To encourage urban mining, from an economic viewpoint, financial subsidies and tax incentives for developing technologies or creating new utilization applications for low-quality recyclables should be provided58.

The compositional shift within China’s truck fleet, as identified by our model, has profound implications for both the economic and environmental outcomes of ELT recycling. The decline of medium trucks and the concurrent rise of small trucks and, particularly, heavy trucks reshape the future waste stream. Heavy trucks, being substantially heavier and containing a higher proportion of Fe and Al per unit, will become the primary drivers of the total volume of recoverable base metals. This trend directly amplifies the future economic potential (Fig. 4), as the value is concentrated in these materials. Similarly, the environmental impact is magnified; since the carbon reduction potential is a function of material mass (Fig. 5), the growing prevalence of material-intensive heavy trucks means that each recycled truck will, on average, yield greater carbon savings, particularly for Fe. Therefore, future recycling policies and infrastructure planning must be tailored to the specific material composition and dismantling requirements of small trucks and heavy trucks to fully capitalize on these evolving economic and environmental opportunities.

The production of Fe, Al, and Cu is highly energy-intensive, accounting for about 10% of global manufacturing energy use59. Urban mining of these metals from ELTs can reduce both material demand and processing requirements, thereby lowering energy consumption and associated carbon emissions60,61,62,63. Al, the second most abundant metal in trucks64, exemplifies this potential: recycling Al through shredding, separation, melting, and casting can save up to over 95% of the energy compared with primary production from bauxite65, leading to CO₂ reductions of around 10 Mt in 2023 (ranging 7.9–12.2 Mt), as shown in Fig. 5. However, the calculated carbon reduction benefits of urban mining are strongly influenced by the carbon intensity of China’s electricity grid. Under the current coal-dominated energy mix, recycling offers substantial decarbonization benefits by avoiding the high emissions of primary production, especially for Al. As the grid transitions toward renewables, the relative carbon advantage of recycling will narrow, though its absolute energy savings and strategic role in resource efficiency and energy security will remain crucial for advancing a circular economy.

In 2020, the Fe and Al consumption of China’s automobile industry was 30 Mt and 4 Mt, respectively66. Assuming the overall industrial collection and recycling rate of Fe and Al from trucks is 70%, we estimated that 10 Mt and 0.7 Mt of recycled Fe and Al returned to the market in 2020, which can theoretically satisfy the Chinese automobile market 33% and 18% of Fe and Al demand67. However, due to downcycling (recycled Fe and Al mainly flow to the construction industry), the actual proportion in that year should be lower than the theoretical value. Currently, China’s ELV recycling industry is in development, with the number of formal recycling enterprises increasing from 653 in 2016 to 748 in 201848. The lifting of the ban on selling the Five Major Assemblies—a regulatory term in China referring to the engine, transmission, steering gear, front and rear axles, and frame—has gradually led many manufacturers’ processing factories to accept remanufactured assemblies, a critical step for promoting higher-value circular economy activities68. We expect that the number of scrapped trucks in China will reach its highest level around 2040. This also indicates that the potential of China’s truck recycling system is enormous, and China should accelerate the construction of a standardized recycling system before the scrap peak arrives. Therefore, we believe that the ELT recycling industry should be developed more in China. Additional discussion about improvement recommendations from viewpoints of financial support, education, and information technologies are provided in Supplementary Discussion.

Conclusions

This study employed a dynamic stock-driven population balance model to forecast the resource, economic, and carbon benefits of ELT urban mining in China through 2050. Our model reveals a major structural shift in the vehicle fleet, projecting that the total weight of ELTs will increase nine-fold, from 6 Mt in 2010 to 53 Mt by 2050. A key finding is the changing composition of this waste stream, with medium trucks declining while heavy trucks and small trucks become dominant, altering the profile of available secondary materials.

The key findings derived from our analysis are threefold. First, the total stock of recyclable materials, particularly Fe, Al, and Cu, is projected to grow substantially, presenting a major opportunity for resource security. Second, this material stock translates into a substantial economic potential, estimated to rise from 2.6 billion US$ in 2010 to 23 billion US$ or 44 billion US$ (2% annual inflation rate) by 2050, driven primarily by the value of base metals. Third, urban mining offers substantial environmental co-benefits; recycling just Fe, Al, and Cu from ELTs could have reduced carbon emissions by averagely 26 Mt in 2023 alone compared to primary production.

These findings lead to direct policy and industrial implications. The projected surge in ELT volume, particularly from heavy trucks and small trucks, necessitates proactive development of specialized, high-capacity recycling infrastructure. Given that economic viability is heavily reliant on a few base metals, policies should incentivize the recovery of less profitable but critical materials, such as rare earths, to foster a more comprehensive circular economy. Furthermore, as the carbon reduction benefits are contingent on China’s current energy mix, continued investment in ELT recycling represents a robust, no-regrets strategy for industrial decarbonization, delivering substantial energy and resource savings regardless of the future pace of grid decarbonization.

Methods

Research framework and data sources

The research roadmap of this study is presented in Fig. 1. First, future truck stocks were projected from historical data using a logistic-based extrapolation model. Second, ELTs were estimated by integrating the Weibull distribution with a population balance model. Third, the potential weight of recyclable resources was calculated based on truck material composition, and their economic value was assessed using prevailing market prices. Finally, the carbon reduction potential was evaluated with reference to energy consumption and emission factors reported in the literature. Our analysis integrates multiple data sources, including historical truck stocks, material composition of trucks, truck lifespans, material commodity prices, and energy and emission factors for primary and secondary material production. The historical stocks were obtained from the National Bureau of Statistics of China69. The material composition and lifespan parameters were primarily drawn from the literature and validated by senior engineers (co-authors) from the China National Heavy Duty Truck Group Co., Ltd20,70. The commodity prices were sourced from the London Metal Exchange71. The energy consumption and emission factors were compiled from academic literature72. The detailed sources for each data item are provided in Supplementary Table 1, and the content for each is presented in Supplementary Tables 2–6.

Forecasting in-use truck stocks

The stock of trucks is the number of in-use trucks at a specific time node within the system boundary73. This study considers four truck types: heavy truck (HT), medium truck (MT), small truck (ST), and mini truck (NT). Because we focus on the Chinese domestic market, imported trucks overseas are considered, while exported trucks from China are excluded. The stock of trucks can be divided into historical (2002–2021) and future (2022–2050) periods. Based on the historical stock from statistics, the future stock was projected by the logistic-based stock extrapolation. This study estimates resource potential by a stock-driven model; second-hand use is included in the stock. Previously, Verhulst proposed the logistic function model to study population growth problems74. The logistic function’s growth can be divided into four stages: initial introduction, rapid growth, saturation, and decline, and its curve can be used to reflect the accumulation of durable goods in the world75. To date, the logistic function model has been examined to forecast the stock of e-waste and ELVs in society76. Here, we used the logistic function to forecast future truck stocks, as shown in Eq. 1. The fitting diagram is shown in Supplementary Fig. 5.

where \({S}_{t}\) represents the stock of trucks in year \(t\), \(a\) represents the saturation value of the stock, \(k\) represents the logistic growth, and \({t}_{c}\) represents the intermediate year of the stock saturation year.

Estimating ELT generation

The ELT generation refers to the number of trucks that are deregistered from the administration and are sometimes also called scrap trucks73. Methods, such as the time series model (output-driven)77, market supply method/Stanford method (input-driven)78, and dynamic material flow analysis method (system-based)79, can be used to estimate the end-of-life number. However, it is suggested that stock data and their changing patterns are stable for estimating the ELT generation80. Meanwhile, the method selection also largely depends on the data availability and robustness81. Based on our primary data sources (i.e., truck ownership statistics), this study employed a stock-driven population balance model for estimating the ELT. “Stock-driven” means specifying the expected stock path (e.g., truck stock forecasts)82. This model enforces number balance between the in-use stocks, inflows, and outflows, where time is discretized (e.g., yearly) in the model, and each flow through the system is tracked as an age cohort with a probabilistic lifespan83. Equations 2 and 3 show calculations between a system’s stocks, inflows, and outflows. Previously, this method has been widely used in the building sectors to examine the metabolic consequences of diffusion processes of durable capital stocks84,85. Its strength lies in its inherent stock–flow consistency and transparent representation of age cohorts and lifetimes. It can also link material use and waste generation, making it particularly suitable for policy testing (e.g., scenarios of recycling targets)86,87.

where \({S}_{t}\) represents the stock of trucks in year \(t\). \({F}_{t}^{{in}}\) and \({F}_{t}^{{out}}\) represent the number of inflows and outflows, respectively. \(l\) signifies the maximum lifespan of trucks. \(k\) signifies a truck’s use age (i.e., 1, 2, 3, and so on); thus, \(t-k\) is the production year (e.g., 2020, 2021, and 2023). \(\varphi \left(k\right)\) represents the scrap rate of such a truck produced in year \(t-k\) in year \(t\).

The end-of-life rate of trucks can be obtained from the lifespan distribution pattern. Common life distributions include the Weibull distribution, lognormal distribution, and normal distribution88. Among them, the Weibull distribution is often used due to its advantages of convenient equation processing and high data fit. It is widely used in studying the end-of-life generation of passenger vehicles, typically to fit the vehicle’s lifespan distribution89. Equations 4 and 5 show the probability density and cumulative distribution functions. In this study, the term “lifespan” refers to the period of truck use from its initial registration until final deregistration. As a change of ownership within China does not alter the original registration year or extend the official deregistration date, the resale of second-hand trucks, therefore, does not affect the statistical estimation of their lifespan or end-of-life flows. Additionally, China currently does not allow the import of second-hand trucks due to the intense restriction of the Chinese laws on banning foreign waste. The export of second-hand trucks is also subject to stringent regulations in China, including one-batch-one-license approval, limited to a maximum of 20 units per permit, and an explicit prohibition on exporting scrapped, mortgaged, or illegally sourced trucks. These legal restrictions mean that China’s truck stock operates mainly as a closed system with respect to second-hand trade. Therefore, our model implicitly accounts for second-hand trucks within the total in-use stock, without requiring a separate parameter for their trade. The shape parameter and scale parameter data can be found in Supplementary Table 4.

where \(\varphi (k)\) represents the probability density function, and the cumulative distribution function \(\varnothing \left(k\right)\) is obtained after integrating \(\varphi (k)\); \(\beta\) is the shape parameter (\(\beta\)>0), reflecting the shape of the function image; \(\eta\) is the scale parameter (\(\eta\)>0), reflecting the dispersion of the data.

Evaluating resource circulation and economic potential

Trucks contain a considerable number of metals, rubbers, and plastics. For example, the vehicle body consists of ferrous and non-ferrous metals, and the off-gas catalytic converter contains precious metals such as Pt, Pd, and Rh90,91. These metals are of high economic value92. Following the quantification of ELT numbers, we estimated the number of secondary resources contained in ELTs based on the trucks’ material composition data; we also evaluated the economic value of these resources based on resources’ commodity prices (considering a 2% annual inflation rate), as shown in Eqs. 6 and 782. The average material contents were adopted as an appropriate value in this study. We assumed that materials are not lost during a truck’s service life. In addition, tractor and cargo trucks are commonly sold with only truck units (customers configure trailers themselves), while dump and tank trucks are usually sold with both truck units and trailer units. In this study, we assumed that each ELT has one truck unit and trailer, and we set weight ranges to show the possible deviation of recycler only receiving truck unit, or both truck and trailer units.

where \({V}_{j}\) is the weight of materials \(j\) within \(n\) categories of ELT; \(i\) is the type of ELT; \({W}_{i}\left(t\right)\) is the total weight of the \(i\) type of ELT that is wasted in the year \(t\); \({e}_{{ij}}\) is the proportion of materials \(j\) contained in \(i\) type of ELT (Supplementary Table 5). \({T}_{{avg}}\) is the total average market value of all materials, and \({p}_{j\left({avg}\right)}\) is the market price per ton of materials \(j\) within a given period (Supplementary Table 6).

Assessing carbon reduction potential

Truck production uses enormous amounts of materials. The primary resource mining and production processes consume a lot of energy and consequently emit a large quantity of greenhouse gases. In contrast, secondary metal urban mining requires less energy and emits fewer greenhouse gases (Supplementary Fig. 6)30. Since Fe, Al, and Cu account for about 75% of the weight share, based on the life cycle thinking, we assessed the carbon emissions of Fe, Al, and Cu recycling processes and their primary production processes48. For example, primary production of Al involves extracting bauxite ore, smelting it into alumina, and then using electrolysis processes to refine it into Al metal using a large amount of electricity, mostly from thermal power generation in China. Recycling of Al, on the other hand, involves melting down the scrap metal and casting it into new shapes, which excludes electrolysis processes, thereby using only about 5–10% of the energy required for primary production93. Similarly, recycling Fe avoids iron ore extraction and replaces blast and basic oxygen furnaces with electric arc furnaces, saving tremendous energy 94. Compared with primary production, the energy reduction and carbon reduction in specific years can be calculated using Eqs. 8 and 9. Energy use and carbon emission factors are provided in Table 1.

where, \({E}^{{red}}\) represents energy reduction, \({e}_{p}\) represents the unit energy demand during the primary production of materials, \({e}_{s}\) represents the unit energy demand during the secondary production of materials; \({C}^{{red}}\) represents CO2 reduction, \({c}_{p}\) represents the carbon emission factor during the primary production of materials, \({c}_{s}\) represents the carbon emission factor during the secondary production of materials.

Sensitivity and uncertainty analysis

Sensitivity analysis is a method that modifies one input parameter at a time and observes the effect of changes in the model inputs on the output95. We also assessed the model output’s precision and accuracy by observing changes in one or more input data to identify the possible uncertainty. This study considers lifetime distribution to be the main factor influencing the forecasting results of the ELT number. Therefore, we chose the truck lifespan as a sensitivity analysis parameter. Another parameter is the truck weight. This study performed Monte Carlo simulations (105 iterations) to obtain the final estimates of flows and their uncertainties. Oracle’s Crystal Ball was employed for the simulation to indicate the uncertainty 96.

Reporting summary

Further information on research design is available in the Nature Portfolio Reporting Summary linked to this article.

Data availability

All data from this study is accessible free of charge in the ZENODO database under: https://zenodo.org/uploads/17122049.

References

Lorek, S. & Spangenberg, J. H. Sustainable consumption within a sustainable economy–beyond green growth and green economies. J. Clean. Prod. 63, 33–44 (2014).

Rogelj, J. et al. Paris Agreement climate proposals need a boost to keep warming well below 2 C. Nature 534, 631–639 (2016).

Sachs, J. D., Schmidt-Traub, G., Mazzucato, M., Messner, D. & Nakicenovic, N. Rockström J. Six transformations to achieve the sustainable development goals. Nat. Sustain. 2, 805–814 (2019).

Enhancing circular economy as a contribution to achieving sustainable consumption and production. UNEP (2022).

Friant, M. C., Vermeulen, W. J. & Salomone, R. Analysing European Union circular economy policies: words versus actions. Sustain. Prod. Consum. 27, 337–353 (2021).

Zhu, J., Fan, C., Shi, H. & Shi, L. Efforts for a circular economy in China: A comprehensive review of policies. J. Ind. Ecol. 23, 110–118 (2019).

Herrador, M., De Jong, W., Nasu, K. & Granrath, L. Circular economy and zero-carbon strategies between Japan and South Korea: A comparative study. Sci. Total Environ. 820, 153274 (2022).

Xiong, X., Zhao, L., Xu, G. & Zeng, X. The Evolution of Neodymium Cycle, Urban Minerals, and Trade in China. Journal of Sustainability 1, 1–16 (2025).

Zeng, X. & Xiong, X. Economic Performance of Urban Mining for Future Resource Supply. In: The Oxford Handbook on the Greening of Economic Development. (Oxford University Press, 2025).

Zeng, X., Mathews, J. A. & Li, J. Urban mining of e-waste is becoming more cost-effective than virgin mining. Environ. Sci. Technol. 52, 4835–4841 (2018).

Arora, M., Raspall, F., Fearnley, L. & Silva, A. Urban mining in buildings for a circular economy: Planning, process and feasibility prospects. Resour. Conserv. Recycl. 174, 105754 (2021).

Boxall, N. J. et al. Urban mining of lithium-ion batteries in Australia: Current state and future trends. Miner. Eng. 128, 45–55 (2018).

Funari, V., Toller, S., Vitale, L., Santos, R. M. & Gomes, H. I. Urban mining of municipal solid waste incineration (MSWI) residues with emphasis on bioleaching technologies: a critical review. Environ. Sci. Pollut. Res. 30, 59128–59150 (2023).

Zhang, L., Zhong, Y. & Geng, Y. A bibliometric and visual study on urban mining. J. Clean. Prod. 239, 118067 (2019).

Xue, Y., Bressers, H. & Wen, Z. A massive urban symbiosis: a preliminary review of the urban mining pilot base programme in China. Towards Zero Waste: Circular Economy Boost, Waste to Resources, 121–143 (2018).

Hao, H. et al. Impact of transport electrification on critical metal sustainability with a focus on the heavy-duty segment. Nat. Commun. 10, 5398 (2019).

Xu, X., Chase, N. & Peng, T. Economic structural change and freight transport demand in China. Energy Policy 158, 112567 (2021).

Hao, H., Geng, Y., Li, W. & Guo, B. Energy consumption and GHG emissions from China’s freight transport sector: scenarios through 2050. Energy Policy 85, 94–101 (2015).

Song, L. et al. China’s bulk material loops can be closed but deep decarbonization requires demand reduction. Nat. Clim. Change 13, 1136–1143 (2023).

Zeng, X., Ali, S. H., Tian, J. & Li, J. Mapping anthropogenic mineral generation in China and its implications for a circular economy. Nat. Commun. 11, 1544 (2020).

De Oliveira Neto, G. C., Vendrametto, O., Naas, I. A., Palmeri, N. L. & Lucato, W. C. Environmental impact reduction as a result of cleaner production implementation: a case study in the truck industry. J. Clean. Prod. 129, 681–692 (2016).

Toktarova, A., Walter, V., Göransson, L. & Johnsson, F. Interaction between electrified steel production and the north European electricity system. Appl. Energy 310, 118584 (2022).

Shao, S., Liu, J., Geng, Y., Miao, Z. & Yang, Y. Uncovering driving factors of carbon emissions from China’s mining sector. Appl. Energy 166, 220–238 (2016).

Reck, B. K. & Graedel, T. E. Challenges in metal recycling. Science 337, 690–695 (2012).

Dunn, J. B., Gaines, L., Sullivan, J. & Wang, M. Q. Impact of recycling on cradle-to-gate energy consumption and greenhouse gas emissions of automotive lithium-ion batteries. Environ. Sci. Technol. 46, 12704–12710 (2012).

Bringezu, S., Schütz, H., Steger, S. & Baudisch, J. International comparison of resource use and its relation to economic growth: The development of total material requirement, direct material inputs and hidden flows and the structure of TMR. Ecol. Econ. 51, 97–124 (2004).

Kosai, S. & Yamasue, E. Global warming potential and total material requirement in metal production: Identification of changes in environmental impact through metal substitution. Sci. Total Environ. 651, 1764–1775 (2019).

Henckens, M., Driessen, P. & Worrell, E. Metal scarcity and sustainability, analyzing the necessity to reduce the extraction of scarce metals. Resour. Conserv. Recycl. 93, 1–8 (2014).

Nag, U., Sharma, S. K. & Govindan, K. Investigating drivers of circular supply chain with product-service system in automotive firms of an emerging economy. J. Clean. Prod. 319, 128629 (2021).

Hertwich, E. G. et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—a review. Environ. Res. Lett. 14, 043004 (2019).

Zhang, L. et al. Collaborative approach for environmental and economic optimization based on life cycle assessment of end-of-life vehicles’ dismantling in China. J. Clean. Prod. 276, 124288 (2020).

Raimi, M. O. et al. Leaving no one behind: impact of soil pollution on biodiversity in the global south: a global call for action. In: Biodiversity in Africa: potentials, threats and conservation. Springer (2022).

Sakai, S. et al. An international comparative study of end-of-life vehicle (ELV) recycling systems. J. Mater. Cycles Waste Manag. 16, 1–20 (2014).

Sato, F. E. K., Furubayashi, T. & Nakata, T. Application of energy and CO2 reduction assessments for end-of-life vehicles recycling in Japan. Appl. Energy 237, 779–794 (2019).

Yu, Z., Tianshan, M., Rehman, S. A., Sharif, A. & Janjua, L. Evolutionary game of end-of-life vehicle recycling groups under government regulation. Clean Technol. Environ. Policy 25, 1473–1484 (2023).

Karagoz, S., Aydin, N. & Simic, V. End-of-life vehicle management: A comprehensive review. J. Mater. Cycles Waste Manag. 22, 416–442 (2020).

Sun, J. & Xiao, Z. Channel selection for automotive parts remanufacturer under government replacement-subsidy. Eur. J. Ind. Eng. 12, 808–831 (2018).

Gan, J. & Luo, L. Using DEMATEL and intuitionistic fuzzy sets to identify critical factors influencing the recycling rate of end-of-life vehicles in China. Sustainability 9, 1873 (2017).

Zhou, F., Lim, M. K., He, Y., Lin, Y. & Chen, S. End-of-life vehicle (ELV) recycling management: Improving performance using an ISM approach. J. Clean. Prod. 228, 231–243 (2019).

Qiao, D., Wang, G., Gao, T., Wen, B. & Dai, T. Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Sci. Total Environ. 764, 142835 (2021).

Li, Y. et al. The potential and trend of end-of-life passenger vehicles recycling in China. Sustainability 12, 1455 (2020).

Ohno, H. et al. Optimal recycling of steel scrap and alloying elements: input-output based linear programming method with its application to end-of-life vehicles in Japan. Environ. Sci. Technol. 51, 13086–13094 (2017).

Xu, G., Yano, J. & Sakai, S. Recycling potentials of precious metals from end-of-life vehicle parts by selective dismantling. Environ. Sci. Technol. 53, 733–742 (2018).

Restrepo, E. et al. Stocks, flows, and distribution of critical metals in embedded electronics in passenger vehicles. Environ. Sci. Technol. 51, 1129–1139 (2017).

Andersson, M., Söderman, M. L. & Sandén, B. A. Are scarce metals in cars functionally recycled? Waste Manag 60, 407–416 (2017).

Li, Y., Liu, Y., Chen, Y., Huang, S. & Ju, Y. Projection of end-of-life vehicle population and recyclable metal resources: Provincial-level gaps in China. Sustain. Prod. Consum. 31, 818–827 (2022).

Tan, Q., Li, J., Yang, L. & Xu, G. Cascade use potential of retired traction batteries for renewable energy storage in China under carbon peak vision. J. Clean. Prod. 412, 137379 (2023).

Liu, M. et al. End-of-life passenger vehicles recycling decision system in China based on dynamic material flow analysis and life cycle assessment. Waste Manag 117, 81–92 (2020).

China is ‘certain’ to have overtaken Japan as the world’s top auto exporter in 2023. In: CNN (2024).

Li, J., Yu, K. & Gao, P. Recycling and pollution control of the End of Life Vehicles in China. J. Mater. Cycles Waste Manag. 16, 31–38 (2014).

Wang, J. et al. Institutional, technology, and policies of end-of-life vehicle recycling industry and its indication on the circular economy-comparative analysis between China and Japan. Front. Sustain. 2, 645843 (2021).

Eheliyagoda, D., Xiong, X. & Zeng, X. The Position of China in Neodymium Utilization: Trend and Challenges. ACS Sustainable Resour. Manage. 1, 2621–2629 (2024).

Qiao, Q., Zhao, F., Liu, Z. & Hao, H. Electric vehicle recycling in China: Economic and environmental benefits. Resour. Conserv. Recycl. 140, 45–53 (2019).

Fatimah, Y. A., Govindan, K., Murniningsih, R. & Setiawan, A. Industry 4.0 based sustainable circular economy approach for smart waste management system to achieve sustainable development goals: A case study of Indonesia. J. Clean. Prod. 269, 122263 (2020).

Safder, U., Tariq, S. & Yoo, C. Multilevel optimization framework to support self-sustainability of industrial processes for energy/material recovery using circular integration concept. Appl. Energy 324, 119685 (2022).

Graedel, T. E. et al. What do we know about metal recycling rates? J. Ind. Ecol. 15, 355–366 (2011).

Zhang, L. & Xu, Z. A critical review of material flow, recycling technologies, challenges and future strategy for scattered metals from minerals to wastes. J. Clean. Prod. 202, 1001–1025 (2018).

Bui, T. D., Tseng, J. W., Tseng, M. L. & Lim, M. K. Opportunities and challenges for solid waste reuse and recycling in emerging economies: A hybrid analysis. Resour. Conserv. Recycl. 177, 105968 (2022).

Nuss, P. & Eckelman, M. J. Life cycle assessment of metals: a scientific synthesis. PloS one 9, e101298 (2014).

Sun, Z., Xiao, Y., Agterhuis, H., Sietsma, J. & Yang, Y. Recycling of metals from urban mines–a strategic evaluation. J. Clean. Prod. 112, 2977–2987 (2016).

Vélez-Henao, J. A. & Pauliuk, S. Material requirements of decent living standards. Environ. Sci. Technol. 57, 14206–14217 (2023).

Kosai, S., Matsui, K., Matsubae, K., Yamasue, E. & Nagasaka, T. Natural resource use of gasoline, hybrid, electric and fuel cell vehicles considering land disturbances. Resour. Conserv. Recycl. 166, 105256 (2021).

Dong, H. et al. Achieving carbon emission reduction through industrial & urban symbiosis: A case of Kawasaki. Energy 64, 277–286 (2014).

Mallick P. K. Materials, design and manufacturing for lightweight vehicles. Woodhead publishing (2020).

Jirang, C. & Roven, H. J. Recycling of automotive aluminum. Transactions of Nonferrous Metals Society of China 20, 2057–2063 (2010).

Assessment of Aluminium Usage in China’s Automobile Industry 2016-2030. IAI (2019).

Ou, S. et al. China’s vehicle electrification impacts on sales, fuel use, and battery material demand through 2050: Optimizing consumer and industry decisions. Iscience 24, (2021).

Saidani, M., Yannou, B., Leroy, Y. & Cluzel, F. Dismantling, remanufacturing and recovering heavy vehicles in a circular economy—Technico-economic and organisational lessons learnt from an industrial pilot study. Resour. Conserv. Recycl. 156, 104684 (2020).

China. National Bureau of Statistics. https://data.stats.gov.cn/easyquery.htm?cn=C01.

Zeng, X., Ali, S. H. & Li, J. Estimation of waste outflows for multiple product types in China from 2010–2050. Scientific Data 8, 15 (2021).

London Metal Exchange https://www.lme.com.

Asmatulu, E., Twomey, J. & Overcash, M. Evaluation of recycling efforts of aircraft companies in Wichita. Resour. Conserv. Recycl. 80, 36–45 (2013).

Song, L. & Chen, W. Stocks and flows of steel in automobiles, vessels and household appliances in China. Nat. Resour. J. 35, 895–907 (2020).

Cramer J. S. The origins of logistic regression. Tinbergen Institute discussion paper (2002).

Nakatani, J. & Moriguchi, Y. Time-series product and substance flow analyses of end-of-life electrical and electronic equipment in China. Waste Manag 34, 489–497 (2014).

Kuong, I. H., Li, J., Zhang, J. & Zeng, X. Estimating the evolution of urban mining resources in Hong Kong, up to the year 2050. Environ. Sci. Technol. 53, 1394–1403 (2019).

Araujo, M. G., Magrini, A., Mahler, C. F. & Bilitewski, B. A model for estimation of potential generation of waste electrical and electronic equipment in Brazil. Waste Manag 32, 335–342 (2012).

Mmereki, D., Li, B. & Wang, L. Estimation of waste electronic and electrical equipment arising in Botswana-A case study of Gaborone City. Int. J. Environ. Sci. 3, 441–452 (2012).

Yedla, S. Development of a methodology for electronic waste estimation: A material flow analysis-based SYE-Waste Model. Waste Manag. Res. 34, 81–86 (2016).

Wang, F., Huisman, J., Stevels, A. & Baldé, C. P. Enhancing e-waste estimates: Improving data quality by multivariate Input–Output Analysis. Waste Manag 33, 2397–2407 (2013).

Zhang, L., Lu, Q., Yuan, W., Jiang, S. & Wu, H. Characterizing end-of-life household vehicles’ generations in China: Spatial-temporal patterns and resource potentials. Resour. Conserv. Recycl. 177, 105979 (2022).

Gómez, M. et al. Navigating the future: China’s photovoltaic roadmap challenges. Sci. Bull. 68, 2491–2494 (2023).

Ramkrishna, D. & Mahoney, A. W. Population balance modeling. Promise for the future. Chem. Eng. Sci. 57, 595–606 (2002).

Müller, D. B. Stock dynamics for forecasting material flows—Case study for housing in The Netherlands. Ecol. Econ. 59, 142–156 (2006).

Sartori, I., Sandberg, N. H. & Brattebø, H. Dynamic building stock modelling: General algorithm and exemplification for Norway. Energy and Buildings 132, 13–25 (2016).

Wiedenhofer, D., Fishman, T., Lauk, C., Haas, W. & Krausmann, F. Integrating material stock dynamics into economy-wide material flow accounting: concepts, modelling, and global application for 1900–2050. Ecol. Econ. 156, 121–133 (2019).

Lauinger, D., Billy, R. G., Vásquez, F. & Müller, D. B. A general framework for stock dynamics of populations and built and natural environments. J. Ind. Ecol. 25, 1136–1146 (2021).

Lin, M. et al. Response to the upcoming emerging waste: necessity and feasibility analysis of photovoltaic waste recovery in China. Environ. Sci. Technol. 56, 17396–17409 (2022).

Nakamoto, Y., Tokito, S. & Kito, M. Impact of vehicle electrification on global supply chains and emission transfer. Environ. Res. Lett. 18, 054021 (2023).

Yao, P. et al. The role of nickel recycling from nickel-bearing batteries on alleviating demand-supply gap in China’s industry of new energy vehicles. Resour. Conserv. Recycl. 170, 105612 (2021).

Ziemann, S., Müller, D. B., Schebek, L. & Weil, M. Modeling the potential impact of lithium recycling from EV batteries on lithium demand: A dynamic MFA approach. Resour. Conserv. Recycl. 133, 76–85 (2018).

Li, W., Bai, H., Yin, J. & Xu, H. Life cycle assessment of end-of-life vehicle recycling processes in China—take Corolla taxis for example. J. Clean. Prod. 117, 176–187 (2016).

Quinkertz, R., Rombach, G. & Liebig, D. A scenario to optimise the energy demand of aluminium production depending on the recycling quota. Resour. Conserv. Recycl. 33, 217–234 (2001).

Watari, T., Cabrera Serrenho, A., Gast, L., Cullen, J. & Allwood, J. Feasible supply of steel and cement within a carbon budget is likely to fall short of expected global demand. Nat. Commun. 14, 7895 (2023).

Xiong, X. et al. China’s recycling potential of large-scale public transport vehicles and its implications. Comm. Eng. 2, 56 (2023).

Islam, M. T. & Huda, N. Assessing the recycling potential of “unregulated” e-waste in Australia. Resour. Conserv. Recycl. 152, 104526 (2020).

Acknowledgements

Guochang Xu’s primary affiliation is the Material Cycles Division, National Institute for Environmental Studies (NIES); Guochang Xu conceived the research idea during a visiting period at the School of Sustainable Energy and Resources, Nanjing University, with Xin Xiong. This work was supported by the JSPS KAKENHI (grant number 22K18433), the NIES Young Researcher Fund (grant number 2425AV002), the Postgraduate Research & Practice Innovation Program of Jiangsu Province (grant number KYCX25_0345), and the National Natural Science Foundation of China (grant number 72504160).

Author information

Authors and Affiliations

Contributions

Xin Xiong is the primary contact for this paper. Guochang Xu: conceived the idea, wrote the manuscript, contributed to revisions, and funding acquisition; Xin Xiong: conceived the idea, collected and analyzed data, wrote the manuscript, and funding acquisition; Wei Liu: revising the manuscript and supervised the study, funding acquisition; Shuo Yang: contributed to revising the manuscript; Youping Miao: collected and analyzed the data; Fei Liu: contributed to revising the manuscript; Heping Liu: contributed to revising the manuscript; Yikun Feng: collected and analyzed the data; Xiaoming Liang: collected and analyzed the data; Ziyan He: contributed to revising the manuscript; Kenichi Nakajima: contributed to revising the manuscript, supervised the study, and funding acquisition. All authors discussed the results and commented on the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Earth and Environment thanks Joanna Kulczycka and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: [Mengze Li] and [Nandita Basu]. [A peer review file is available].

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Xu, G., Xiong, X., Liu, W. et al. Resource, economic, and carbon benefits of end-of-life trucks’ urban mining in China. Commun Earth Environ 6, 805 (2025). https://doi.org/10.1038/s43247-025-02832-x

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s43247-025-02832-x