Abstract

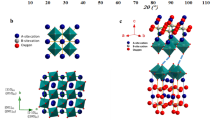

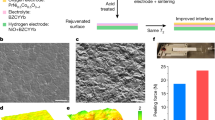

The emerging applications of steam electrolysis and electrochemical synthesis at 300–600 °C set stringent requirements on the stability of protonic ceramic cells, which cannot be met by Ce-rich electrolytes. A promising candidate is Ce-free BaZr0.8Y0.2O3−δ, but its usage has long been hindered due to the high sintering temperatures required for protonic devices. Here we resolved the issue through a co-sintering process, in which the shrinkage stress of a readily sinterable support layer helps to densify the pure BaZr0.8Y0.2O3–δ electrolyte membrane at low temperatures. This approach eliminates Ce and harmful sintering aids in the dense zirconate electrolyte membrane, thereby enhancing the Faradaic efficiency and electrochemical stability, especially under harsh operating conditions. The protonic zirconate cells have exceptional performance and demonstrate stable high-steam pressure electrolysis up to 0.7 atm steam pressure, −2 A cm−2 current density and over 800 h of dynamic operation at 600 °C. Our processing breakthrough enables stabilized protonic cells for demanding applications in future energy infrastructure.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Data supporting the findings in the present work are available in the manuscript or Supplementary Information.

References

Fabbri, E. et al. Tailoring the chemical stability of Ba(Ce0.8−xZrx)Y0.2O3−δ protonic conductors for intermediate temperature solid oxide fuel cells (IT-SOFCs). Solid State Ion. 179, 558–564 (2008).

Ding, H. et al. Self-sustainable protonic ceramic electrochemical cells using a triple conducting electrode for hydrogen and power production. Nat. Commun. 11, 1907 (2020).

Kim, J. et al. Triple‐conducting layered perovskites as cathode materials for proton‐conducting solid oxide fuel cells. ChemSusChem 7, 2811–2815 (2014).

Wachsman, E. D. & Lee, K. T. Lowering the temperature of solid oxide fuel cells. Science 334, 935–939 (2011).

Wu, W. et al. Electrochemically engineered, highly energy-efficient conversion of ethane to ethylene and hydrogen below 550 °C in a protonic ceramic electrochemical cell. ACS Catal. 11, 12194–12202 (2021).

Vøllestad, E. et al. Mixed proton and electron conducting double perovskite anodes for stable and efficient tubular proton ceramic electrolysers. Nat. Mater. 18, 752–759 (2019).

Li, M. et al. Switching of metal–oxygen hybridization for selective CO2 electrohydrogenation under mild temperature and pressure. Nat. Catal. 4, 274–283 (2021).

Virkar, A. V. Mechanism of oxygen electrode delamination in solid oxide electrolyzer cells. Int. J. Hydrog. Energy 35, 9527–9543 (2010).

Jacobsen, T. & Mogensen, M. The course of oxygen partial pressure and electric potentials across an oxide electrolyte cell. ECS Trans. 13, 259 (2008).

Dong, Y. et al. Potential jumps at transport bottlenecks cause instability of nominally ionic solid electrolytes in electrochemical cells. Acta Mater. 199, 264–277 (2020).

Yang, L. et al. Enhanced sulfur and coking tolerance of a mixed ion conductor for SOFCs: BaZr0.1Ce0.7Y0.2–xYbxO3–δ. Science 326, 126–129 (2009).

Katahira, K. et al. Protonic conduction in Zr-substituted BaCeO3. Solid State Ion. 138, 91–98 (2000).

Chen, F. et al. Chemical stability study of BaCe0.9Nd0.1O3-α high-temperature proton-conducting ceramic. J. Mater. Chem. 7, 481–485 (1997).

Bhide, S. V. & Virkar, A. V. Stability of BaCeO3‐based proton conductors in water‐containing atmospheres. J. Electrochem. Soc. 146, 2038 (1999).

Li, J. et al. Chemical stability of Y-doped Ba(Ce, Zr)O3 perovskites in H2S-containing H2. Electrochim. Acta 53, 3701–3707 (2008).

Shin, S. et al. Protonic conduction in the single crystals of SrZrO3 and SrCeO3 doped with Y2O3. Solid State Ion. 40, 910–913 (1990).

Mitsui, A., Miyayama, M. & Yanagida, H. Evaluation of the activation energy for proton conduction in perovskite-type oxides. Solid State Ion. 22, 213–217 (1987).

Takahashi, T. & Iwahara, H. Solid-state ionics: protonic conduction in perovskite type oxide solid solutions. Rev. Chim. Min. 17, 243–253 (1980).

Kreuer, K. D. Proton-conducting oxides. Annu. Rev. Mater. Res. 33, 333–359 (2003).

Ryu, K. H. & Haile, S. M. Chemical stability and proton conductivity of doped BaCeO3–BaZrO3 solid solutions. Solid State Ion. 125, 355–367 (1999).

Fabbri, E., Pergolesi, D. & Traversa, E. Materials challenges toward proton-conducting oxide fuel cells: a critical review. Chem. Soc. Rev. 39, 4355–4369 (2010).

Babilo, P., Uda, T. & Haile, S. M. Processing of yttrium-doped barium zirconate for high proton conductivity. J. Mater. Res. 22, 1322–1330 (2007).

Choi, S., Davenport, T. C. & Haile, S. M. Protonic ceramic electrochemical cells for hydrogen production and electricity generation: exceptional reversibility, stability, and demonstrated faradaic efficiency. Energy Environ. Sci. 12, 206–215 (2019).

Melekh, B.-T. et al. Structure, phase transitions and optical properties of pure and rare earth doped BaCeO3, SrCeO3 prepared by inductive melting. Solid State Ion. 97, 465–470 (1997).

Yamanaka, S. et al. Thermophysical properties of BaZrO3 and BaCeO3. J. Alloys Compd. 359, 109–113 (2003).

Arabacı, A. & Öksüzömer, M. F. Preparation and characterization of 10 mol% Gd doped CeO2 (GDC) electrolyte for SOFC applications. Ceram. Int. 38, 6509–6515 (2012).

Zhang, S. L. et al. Effect of Fe doping on the performance of suspension plasma-sprayed PrBa0.5Sr0.5Co2−xFexO5+δ cathodes for intermediate-temperature solid oxide fuel cells. Ceram. Int. 43, 11648–11655 (2017).

Zha, S. et al. GDC-based low-temperature SOFCs powered by hydrocarbon fuels. J. Electrochem. Soc. 151, A1128 (2004).

Peng, C. et al. BaZr0.8Y0.2O3−δ electrolyte with and without ZnO sintering aid: preparation and characterization. Solid State Ion. 181, 1372–1377 (2010).

Shimada, H. et al. Effect of Ni diffusion into BaZr0.1Ce0.7Y0.1Yb0.1O3−δ electrolyte during high temperature co-sintering in anode-supported solid oxide fuel cells. Ceram. Int. 44, 3134–3140 (2018).

Okuyama, Y. et al. Improvement of protonic ceramic fuel cells with thin film BCZY electrolyte. ECS Trans. 68, 2545 (2015).

Dong, Y. et al. Enhanced mobility of cations and anions in the redox state: the polaronium mechanism. Acta Mater. 232, 117941 (2022).

Han, D. et al. Proton conductive BaZr0.8−xCexY0.2O3−δ: influence of NiO sintering additive on crystal structure, hydration behavior, and conduction properties. ChemSusChem 14, 614–623 (2021).

Huang, Y., Merkle, R. & Maier, J. Effect of NiO addition on proton uptake of BaZr1−xYxO3−x/2 and BaZr1−xScxO3−x/2 electrolytes. Solid State Ion. 347, 115256 (2020).

Han, D. et al. Detrimental effect of sintering additives on conducting ceramics: yttrium‐doped barium zirconate. ChemSusChem 11, 4102–4113 (2018).

Liu, Z. et al. Enhancing sinterability and electrochemical properties of Ba(Zr0.1Ce0.7Y0.2)O3-δ proton conducting electrolyte for solid oxide fuel cells by addition of NiO. Int. J. Hydrog. Energy 43, 13501–13511 (2018).

Vera, C. Y. R. et al. A mini-review on proton conduction of BaZrO3-based perovskite electrolytes. J. Phys. Energy 3, 032019 (2021).

Dong, Y. et al. Ultra‐uniform nanocrystalline materials via two‐step sintering. Adv. Funct. Mater. 31, 2007750 (2021).

Kjølseth, C. et al. Space–charge theory applied to the grain boundary impedance of proton conducting BaZr0.9Y0.1O3−δ. Solid State Ion. 181, 268–275 (2010).

Sun, Z. et al. Electrochemical properties and intermediate‐temperature fuel cell performance of dense yttrium‐doped barium zirconate with calcium addition. J. Am. Ceram. Soc. 95, 627–635 (2012).

Sun, W., Liu, M. & Liu, W. Chemically stable yttrium and tin co‐doped barium zirconate electrolyte for next generation high performance proton‐conducting solid oxide fuel cells. Adv. Energy Mater. 3, 1041–1050 (2013).

Sun, W. et al. An easily sintered, chemically stable, barium zirconate‐based proton conductor for high‐performance proton‐conducting solid oxide fuel cells. Adv. Funct. Mater. 24, 5695–5702 (2014).

Shafi, S. P. et al. Y and Ni co-doped BaZrO3 as a proton-conducting solid oxide fuel cell electrolyte exhibiting superior power performance. J. Electrochem. Soc. 162, F1498–F1503 (2015).

Shi, N. et al. Controllable CO2 conversion in high performance proton conducting solid oxide electrolysis cells and the possible mechanisms. J. Mater. Chem. A 7, 4855–4864 (2019).

Lei, L. et al. Energy storage and hydrogen production by proton conducting solid oxide electrolysis cells with a novel heterogeneous design. Energy Convers. Manag. 218, 113044 (2020).

Dong, Y. et al. Chemical and structural origin of hole states in yttria-stabilized zirconia. Acta Mater. 203, 116487 (2021).

Kim, I.-H. et al. Determination of partial conductivities and computational analysis of the theoretical power density of BaZr0.1Ce0.7Y0.1Yb0.1O3−δ (BZCYYb1711) electrolyte under various PCFC conditions. J. Mater. Chem. A 7, 21321–21328 (2019).

Graves, C. et al. Eliminating degradation in solid oxide electrochemical cells by reversible operation. Nat. Mater. 14, 239–244 (2015).

Skafte, T. L. et al. Electrothermally balanced operation of solid oxide electrolysis cells. J. Power Sources 523, 231040 (2022).

Bian, W. et al. Revitalizing interface in protonic ceramic cells by acid etch. Nature 604, 479–485 (2022).

Sun, Z. et al. Lowering grain boundary resistance of BaZr0.8Y0.2O3−δ with LiNO3 sintering-aid improves proton conductivity for fuel cell operation. Phys. Chem. Chem. Phy. 13, 7692–7700 (2011).

Luisetto, I. et al. Electrochemical performance of spin coated dense BaZr0.80Y0.16Zn0.04O3−δ membranes. J. Power Sources 220, 280–285 (2012).

Lei, L. et al. A highly active hybrid catalyst modified (La0.60Sr0.40)0.95Co0.20Fe0.80O3−δ cathode for proton conducting solid oxide fuel cells. J. Power Sources 389, 1–7 (2018).

Duan, C. et al. Readily processed protonic ceramic fuel cells with high performance at low temperatures. Science 349, 1321–1326 (2015).

Bi, L. et al. Y-doped BaZrO3 as a chemically stable electrolyte for proton-conducting solid oxide electrolysis cells (SOECs). J. Mater. Chem. A 3, 5815–5819 (2015).

Lei, L. et al. Intermediate-temperature solid oxide electrolysis cells with thin proton-conducting electrolyte and a robust air electrode. J. Mater. Chem. A 5, 22945–22951 (2017).

Acknowledgements

This work is supported by the proton conducting solid oxide electrolysis cells (P-SOEC) lab call project and the HydroGEN Advanced Water Splitting Materials Consortium, established as part of the Energy Materials Network under the United States Department of Energy (USDOE); the Office of Energy Efficiency and Renewable Energy (EERE); and the Hydrogen and Fuel Cell Technologies Office (HFTO) under DOE Idaho Operations Office under contract no. DE-AC07-05ID14517. We would like to thank the Office of EERE and the Office of Basic Energy Sciences (BES) for support through H2LinkSc, a cross-office initiative to bring new ideas, materials, and tools from basic science to bear on applied problems. H.L. and M.Z. also would like to acknowledge funding support from National Science Foundation (OIA-2119688) and a subcontract from Idaho National Laboratory. J.L. acknowledges support by the Hydrogen in Energy and Information Sciences (HEISs), an Energy Frontier Research Center funded by the U.S. Department of Energy (DOE), Office of Science, Basic Energy Sciences (BES), under Award DE-SC0023450.

Author information

Authors and Affiliations

Contributions

Y. Dong, H.L., J.L. and D.D. conceived the project. W.T., W.B. and H.D. fabricated the cells and conducted electrochemical measurements. W.T., W.B. and Y. Dong analysed the data. Y. Ding conducted the TEM analysis. Z.Z., Q.S. and S.K. contributed to the SEM analysis and cell fabrication. Q.S., Y.W., B.X., P.D., D.C., J.Y.G., W.F., W.W. and M.Z. contributed to sample characterizations and analysis. W.T., W.B. and Y. Dong wrote the paper, with substantial inputs from H.D., H.L., J.L. and D.D. All authors discussed and contributed to the writing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Synthesis thanks Guntae Kim and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editor: Peter Seavill, in collaboration with the Nature Synthesis team.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–20.

Source data

Source Data Fig. 1

Source data for Fig. 1.

Source Data Fig. 2

Source data for Fig. 2.

Source Data Fig. 3

Source data for Fig. 3.

Source Data Fig. 4

Source data for Fig. 4.

Source Data Fig. 5

Source data for Fig. 5.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tang, W., Bian, W., Ding, H. et al. Sintering protonic zirconate cells with enhanced electrolysis stability and Faradaic efficiency. Nat. Synth 4, 592–602 (2025). https://doi.org/10.1038/s44160-025-00765-z

Received:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/s44160-025-00765-z