Abstract

Environmental problems are worsening due to the complexity in managing plastic waste. Chemical recycling emerges as a pivotal technology that can suppress carbon introduction into the carbon cycle and provide petroleum alternatives for current petrochemical processes. The utilization of zeolites can reduce energy consumption by lowering the operation temperature for pyrolysis. Here, we demonstrate low-temperature catalytic cracking of polyethylene (PE) utilizing an open-batch reactor configuration and *BEA-type zeolite catalysts. With the optimized open-batch setup and zeolites, high PE conversion (~80%) and liquid selectivity (~70%) were achieved at 330 °C. We systematically explored the effects of aluminum (Al) site density and crystal size, revealing that zeolite crystal size is another critical factor determining the liquid production. This work not only demonstrates that an effective combination and optimization of reactor and catalysts can enhance the overall catalytic activity but also offers insights into designing catalysis systems for effective recycling of polyolefin wastes.

Similar content being viewed by others

Introduction

Plastics have emerged as pivotal materials that buttress current human civilizations, assuming an irreplaceable role in maintaining human well-being. Consequently, the production of plastics has been experiencing substantial global growth, primarily driven by the versatility and extensive applicability of polymer-based products across various sectors of industry, encompassing automotive, construction, electronics, aerospace, and packaging1. As a result, in 2015, an estimated 6300 MT of plastic waste had been generated, posing a formidable environmental challenge these days2,3,4. Additionally, the utilization and subsequent disposal of single-use plastics contribute to the prospection of additional carbons for make-up inputs, primarily from oil reserves. Within this context, plastic recycling assumes considerable importance, as it serves not only to mitigate immediate environmental threats but also plays a crucial role in achieving carbon neutrality by curbing additional fossils into the carbon cycle. Chemical recycling, comprising both conventional and innovative technologies aimed at converting plastic waste into value-added chemicals, encompassing monomers, aromatics, and olefins, has attracted substantial interest from the scientific and engineering communities. This interest majorly stems from its capability to leverage existing chemical processes, keeping the carbon quantity in circulation5,6,7.

Polyolefin wastes, including polyethylene (PE) and polypropylene (PP), have gained substantial attention in the field of chemical recycling of plastic waste due to their prevalence, comprising over 50% of the global plastic waste stream8. The polyolefin polymer backbone comprises of C-C bonds, necessitating controlled cleavage to yield liquid hydrocarbons suitable for use as feedstocks in downstream processes. These subsequent processes may encompass traditional processes, such as the fluidized catalytic cracking preceded by hydrotreatment, as well as innovative technologies such as the plasma gasification, which yields ethylene and acetylene under arc discharge9. In this context, it is essential to prioritize the optimization of liquid hydrocarbon yield with controlled selectivity distribution to meet the downstream process requirements, thereby enhancing overall operational efficiency. Many technologies have been developed and utilized for the conversion of polyolefin waste into a spectrum of hydrocarbons, spanning from light olefins to wax10,11,12. Pyrolysis, conducted at high temperatures ranging from 450 to 600 °C in an inert atmosphere, entails thermal cleavage of the main backbone of polyolefins13. Although the pyrolysis process has the highest technological maturity, it presents several challenges, including high energy consumption resulting from high temperature conditions14,15,16. To tackle these challenges, hydrogenolysis17,18,19,20 and alkane tandem metathesis21,22 at low temperature (200–250 °C) have been suggested and widely studied as alternative processes. However, the cost viability of these approaches is hindered by the requirement for high-pressure hydrogen and/or the utilization of platinum group metal catalysts like Pt or Ru.

Catalytic cracking process efficiently decomposes polyolefins at lower temperatures than pyrolysis, employing a solid acid catalyst. Extensive research has focused on reducing energy consumption and carbon deposition in the reactor23,24,25,26,27. Zeolites, common microporous solid acid catalysts, reduce the activation energy necessary for breaking C-C bond chains of polyolefins through mechanisms such as the ß-scission and protonolysis over their Brønsted acid sites28. The final distribution of products is primarily determined by the shape selectivity of the micropore structures of zeolites28,29,30,31. Among various commercialized zeolites, zeolite beta, with 12-membered-ring (12MR) micropores measuring 7–8 Å in pore opening and interconnected channels in three dimensions, is recognized for its high selectivity in producing liquid products (C5–30) in the catalytic cracking of polyolefin32,33,34. Furthermore, zeolite beta serves as an ideal platform for investigating the correlation between catalytic performance and intrinsic properties of zeolites, including crystal sizes and Si/Al ratios, as modification of these properties through hydrothermal synthesis has extensively studied35,36.

While zeolite have been commonly considered as capable of reducing the operation temperature of pyrolysis under non-hydrogen conditions, the catalytic cracking of polyolefins using zeolites has primarily been investigated within a temperature range exceeding 380 °C8,33,37,38. Although there is a systematic study reporting the decomposition behavior of PE by ZSM-5 zeolite at temperatures below 300 °C39, it indicates that the liquid products, which are of primary interest in the polyolefins valorization processes, are scarcely produced. Furthermore, existing studies using zeolite have rarely reported optimization from the perspective of process variables rather than zeolite structures and properties8,37,38. In this study, we demonstrate the potential to further reduce the operating temperature of catalytic cracking of PE (namely, 330 °C) while maintaining polyolefin conversion above 80% and liquid selectivity exceeding 70%, through appropriate control of the intrinsic properties of zeolite beta, in conjunction with the optimization of reactor design and associated process parameters. A series of zeolite beta catalyst samples were synthesized, with independent control over parameters including Si/Al ratio and crystal size, specifically the external surface area. Under the optimized condition at 330 °C, the correlation between catalytic performance and intrinsic properties of zeolites were established, demonstrating that decreased particle size and increased external surface area enhances liquid selectivity, thereby providing a direction for catalyst design for polyolefin conversion processes. Figure 1 presents schematic illustrations that encapsulate the central concept of this study.

Results and discussions

Catalytic cracking process optimization

The structure and operation modes of batch reactors containing a PE/catalyst slurry during catalytic contact are crucial for improving the conversion and product distribution in low-temperature PE catalytic cracking. The reactor used for this work could operate in either closed-batch or open-batch mode by simply closing or opening the downstream valve that connects to the condenser/collector units as shown in Fig. 1a and Supplementary Fig. 3. The primary purpose of catalytic decomposition of PE is to obtain liquid hydrocarbon products suitable for further processing in downstream processes. Typically, an improved liquid selectivity can be achieved by minimizing excessive contact between zeolite and hydrocarbon species (Fig. 1b). This approach helps to prevent irreversible coke formation and evolution of gas species from over-cracking, as demonstrated by a recent hydrogenolysis study using a supported Pt catalyst40. Indeed, employing a selected *BEA-type zeolite catalyst (S-BEA-30, see below for the sample information), an open-batch configuration at 330 °C resulted in higher conversion and liquid selectivity (45.1% and 62.3%, respectively) than the conventional closed-batch configuration (38.3% and 44.9%, respectively), by allowing the evaporated products to escape the reactor (Fig. 2a). The formation of uncrackable solid phase that deactivates the catalysis, is considerably reduced in an open-batch configuration compared to a closed-batch configuration as shown in Supplementary Fig. 4.

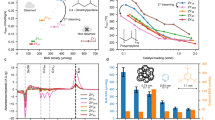

a PE conversion, liquid selectivity, and b liquid product selectivity distributions with varied open-batch reactor configurations. c PE conversion, liquid selectivity, and d liquid product selectivity distributions with varied operation temperatures. e PE conversion, liquid selectivity, and f liquid product selectivity distributions from various commercial zeolites. Polyethylene to catalyst ratio denoted as PE/Cat ratio.

The inert-gas flow rate is a crucial parameter influencing the conversion and liquid selectivity in the open-batch catalytic cracking of PE. Figure 2b demonstrates that increasing the inert-gas flow rate shifts the selectivity distribution towards heavier products, suggesting fewer catalytic scissions in PE chains due to reduced contact time. The PE conversion increases monotonously with the inert-gas flow rate, while liquid selectivity showed an optimum at 10 mL/min in our reactor setup, which was adopted as the standard reaction condition for subsequent experiments. Increasing the flow rate up to 30 mL/min decreased the liquid selectivity, presumably due to insufficient condensation in the condenser assembly, an issue that could be mitigated with improved design. These results highlight the significance of the reactor design and operation modes in the catalytic PE decomposition into liquid hydrocarbons. Obviously, temperature is a key parameter affecting the rate of catalytic scissions of the main backbone of PE chains. At the optimized inert-gas flow rate of 10 mL/min with the selected zeolite catalyst (S-BEA-30), the conversion of PE is dramatically influenced by the operation temperature as depicted in Fig. 2c. A high conversion of 98.3% was observed at 390 °C, near the typical temperature range of the conventional pyrolysis process. Conversely, at the low limit of 260 °C, the conversion was low, under 20%, even with the zeolite catalyst. The selectivity towards light C5 and C6 liquid hydrocarbons was noticeably low at 260 °C, implying sluggish scission of C-C backbones of linear hydrocarbons (Fig. 2d). In this work, we evaluated various zeolite catalysts at 330 °C, achieving acceptably high conversion and high liquid selectivity, highlighting disparities among samples.

The use of zeolites greatly enhances the conversion of PE at low temperatures by accelerating C-C bond scission, catalyzed by Brønsted acid sites that promote the carbenium or carbonium mechanisms28. In absence of zeolites, just a 0.2 % PE conversion was observed at 330 °C. To evaluate the effect of zeolite topologies, several commercially available zeolites, including ZSM-5 (MFI), zeolite beta (*BEA), and zeolite Y (FAU) were examined (Supplementary Fig. 5). These zeolites achieved PE conversions ranging from 20% to 80% at the same temperature. Details on the tested commercial zeolites are provided in the Supplementary Figs. 1, 2 and Supplementary Table 1. All zeolites demonstrated notable isomerization, as indicated by the complexity of the resulting gas chromatograph (GC) profiles (see Supplementary Figs. 6, 7). Among the tested commercial zeolites, ZSM-5 having micropores limited by 10MR pore openings, exhibited the highest conversion, but its liquid selectivity was lower than that of zeolite beta due to its high gas selectivity as depicted in Fig. 2e, which originated from its narrow pore system. ZSM-5 also tended to produce lighter liquid products than the other two frameworks (Fig. 2f). The 1H and 13C NMR spectra for the same liquid product mixtures are also presented in Supplementary Fig. 8. The 1H NMR spectra indicate that the products contain the most olefinic sp2 C-H in the order of ZSM-5 > zeolite beta > zeolite Y. This matches the order of PE conversion (Fig. 2e), presumably due to the high frequency of chain scission via the ß-scission occurred over ZSM-5. Conversely, the lowest PE conversion and olefinic proton content observed in the zeolite Y samples are likely due to their relatively weak acid sites41. The zeolite beta sample of 12MR pore openings achieved a PE conversion comparable to ZSM-5 with the highest liquid selectivity. In this work, the effects of the intrinsic properties of zeolite on the *BEA framework were investigated. The synthesis of *BEA-type zeolites, which has been extensively studied for decades35,42,43, offers great synthetic flexibility in terms of Si/Al ratios and crystal sizes.

Intrinsic properties-controlled beta zeolite catalytic cracking of LDPE

*BEA-type zeolites can be crystallized with a wide synthetic window of hydrothermal synthesis using tetraethylammonium hydroxide (TEAOH) as the organic structure-directing agent (OSDA)35. It has been observed that the crystal size of the resulting *BEA-type zeolite crystals is strongly correlated with the Al content in the hydrothermal *BEA-crystallizing systems35. As the Si/Al ratio of the system increases, the crystal size also increases, thereby reducing the relative contribution of acid sites in on external surfaces compared to those within micropores. To decouple the Si/Al ratio from the crystal size, we employed three different hydrothermal methods from the literature and modified them to prepare three series of *BEA-type zeolites, denoted as L-, M-, and S-series. For the preparation of large crystals (L-series, 0.65–1.7 µm), fluoride was used as the mineralizer, known to stabilize small composite building unites of the *BEA framework42,44. The medium- and small-sized *BEA-type zeolites (M- and S-series, 130–170 nm and 30–140 nm, respectively) were obtained using conventional hydroxide media36,43. The S-series were synthesized at a low crystallization temperature of 100 °C, much below the conventional temperature (140 °C) for *BEA synthesis. As noted above, trends observed here indicate that reducing the Al content generally led to larger crystal sizes (Fig. 3a). The scanning electron micrographs (SEMs) of three representative samples from the three series are shown in Fig. 3b–d. In this work, samples are denoted as “X-BEA-y,” where X represents the series code (L, M, or S) and y indicates the approximate Si/Al ratio of the zeolites, as characterized by the energy dispersive spectroscopy (EDS). The sample information is summarized in Table 1. Their synthetic details and additional characterization results are provided in the Supplementary Table 2 and Supplementary Figs. 9–12.

a Schematic summary of intrinsic properties-controlled beta zeolite, scanning electron microscope images of synthesized beta zeolite with Si/Al 10: b L-BEA-10, c M-BEA-10, and d S-BEA-10. Each data was provided with an error bar which was calculated via standard deviation of 10 parallel data. Large, Medium, Small crystal sized zeolite beta with y (Si/Al) denoted as L-, M-, S-BEA-y.

The catalytic cracking of PE using the prepared *BEA-type zeolites was tested in an open-batch configuration under optimal conditions (10 mL N2/min, 330 °C, 2 h) as previously discussed. Figure 4a–c show the conversion and liquid selectivity, achieved with the *BEA-type zeolites listed in Table 1. The justification for comparing the cracking behavior of zeolite beta sample series synthesized through different methods is supported by the independent 1,3,5-triisopropylbenzene (TIPB) cracking results provided in Supplementary Fig. 14. The framework Al sites primarily act as Brønsted acid sites in zeolites, serving as active sites for the catalytic cracking of long-chain hydrocarbons28. Thus, the decrease in Si/Al ratios led to an increase in the PE conversion across all sample series, indicating enhanced apparent catalytic activity. Crystal size also played a crucial role in the PE conversion. The S-series samples, with higher specific external surface area values (Table 1), showed higher PE conversions than the L-series samples. A similar trend was observed in liquid selectivity (Fig. 4b). Al sites can be located within either the micropores or external surfaces of the zeolite samples. The catalytic conversion of PE over *BEA-type zeolites may occur in two steps: bulky molecule scission at the external surface acid sites, followed by additional scission of smaller molecules within the micropores. We think that the molecular weight distribution of liquid products primarily depends on the spatial distributions of these acid sites as shown in Fig. 4e. The S-BEA-10 sample having the most Al sites and the highest external surface area showed a high PE conversion (~80%) and liquid selectivity (~70%) at a low temperature of 330 °C. This result offers experimental evidence that reducing crystal size also meaningfully enhances the PE conversion and liquid selectivity by facilitating the external scission process of polymer chains. Moreover, the increase in mesopore volume associated with decreasing crystal size suggests an improvement in mass transfer efficiency, which may contribute to the observed enhancement in catalytic performance. Further analysis on the conversion and liquid selectivity is provided in the Supplementary Figs. 13–21.

a Conversion, b liquid selectivity, c liquid selectivity by conversion, d hydrocarbon distribution in liquid products, and e schematic description for the relation between acid site distribution and liquid product molecular weight. Large, Medium, Small crystal sized zeolite beta with y (Si/Al) denoted as L-, M-, S-BEA-y.

The simulated distillation (SIMDIS) results confirmed that over 99% of the liquid portion comprises hydrocarbons in the range from C5 to C30 (Supplementary Figs. 22, 23 and Table 3). Figure 4d illustrates the hydrocarbon distribution in liquid products from the catalytic cracking of PE over L-BEA-10, M-BEA-10, and S-BEA-10, which have similar Si/Al ratios but vary in crystal sizes. L-BEA-10 and M-BEA-10 predominantly yielded hydrocarbons in the gasoline (C5–10) range, whereas S-BEA-10 yielded heavier products under the same reaction conditions. Considering the total number of Al sites is similar across the three samples, it suggests that L-BEA-10 and M-BEA-10 have more micropore Al sites than S-BEA-10, providing a greater extent of secondary scission to lighter products. This serves as an example of the reactant shape selectivity.

The spent catalysts were recovered as entangled chunks mixed with residues, including deposited coke species. The SIMDIS analysis of the Soxhlet extract, using toluene as the solvent, revealed a minimal composition of remaining product-range (C5–C30) hydrocarbons in the solid phase (Supplementary Fig. 15 and Table 3). The spent catalysts should be recoverable and reusable from the remaining solid phase. However, mechanical separation of inorganic catalyst components from the mixture was unsuccessful due to the polymeric organic components remaining in the solid phase, showing a sturdy texture at room temperature. To assess catalyst reusability, a new PE feed of the same amount was directly added to the spent mixture for a second run. The conversion and liquid selectivity in the second run decreased compared to the first, from 78% to 67% and from 68% to 54%, respectively (Fig. 5a). However, the product distribution of the liquid product within the range from C5 to C15 remained almost unchanged, as shown in Fig. 5b, indicating that coke-induced deactivation primarily influenced the external surfaces of zeolite rather than the micropores. The zeolite catalysts could be separated by removing the residue through air calcination at 580 °C for 6 h. The regenerated catalyst was found to have physical properties very similar to those of the virgin catalyst, as confirmed by PXRD, SEM, EDS, and BET analyses (Supplementary Fig. 24). Consequently, in the catalytic cracking of PE using the regenerated catalyst, both the conversion and liquid selectivity were almost identical (Fig. 5c, d). Finally, the optimized 330 °C open-batch reaction conditions were applied to an actual post-consumer PE waste sample collected from a local recycling center, and it was compared to two model virgin PEs with different molecular weights (4 kDa and 204 kDa), confirming that the resulting PE conversion and liquid selectivity were similar to those observed with the virgin PE model feed with heavier molecular weight, as illustrated in Supplementary Fig. 25.

a Conversion and liquid selectivity, b hydrocarbon distribution in liquid products; show the regenerated zeolite beta catalytic cracking compared to the virgin zeolite beta, namely c conversion, d hydrocarbon distribution in liquid products. Small crystal sized zeolite beta with y (Si/Al) denoted as S-BEA-y.

Conventionally, the catalytic cracking of polyolefins using zeolite catalysts have adopted operation temperatures higher than 380 °C (Supplementary Fig. 26)33,45,46. This work demonstrates the temperature can be greatly reduced to 330 °C while maintaining high PE conversion and liquid selectivity, provided the reactor configuration and catalysts are adequately optimized. The open-batch configuration effectively prevents over-cracking or excess coke formation by properly regulating the contact between the feed molecules and the zeolites, removing the distillates to the gas phase. Proper selection of inert-gas flow rate, which further regulates the contact time, can further enhance the PE conversion and liquid selectivity. Among the tested commercial zeolites, zeolite beta having the *BEA topology exhibited excellent acid site strength, ensuring high conversion of PE even at low temperature and an adequate shape selectivity towards aliphatic liquid products. Along with the Al content of zeolites, the crystal size was confirmed as a crucial factor determining the PE conversion and liquid phase selectivity. Reducing the crystal size ensures high liquid selectivity regardless of the Al content by enhancing the chain scission on the external surfaces of zeolites. This work not only highlights the potential for the low-temperature catalytic cracking of PE using zeolite catalysts but also provides insights into other plastic waste chemical recycling technologies in terms of selection of catalysts47.

Methods

Synthesis of *BEA-type zeolites

All *BEA-type zeolites presented in this work were synthesized using conventional hydrothermal methods, recipes that are modifications of the previously reported methods in the literature36,42,43. Initially, Al sources, OSDA(TEAOH), mineralizers, and water were mixed to achieve a desired gel composition in 40 mL PTFE liners. Subsequently, Si sources were added, ensuring complete dispersion and homogenization by subsequent stirring. The general gel composition can described as 1.0 SiO2: x Al: y TEAOH: z (NH4F or NaOH): w H2O. x determines the Al content, while y, z, and w depend on the different sample series yielding different crystal sizes. Additional aging steps can be added depending on the sample series. The PTFE liners charged with gels were clad in steel autoclaves and transferred to a convection oven preheated to the desired temperature, which could be rotating or static. The progress of crystallization was tracked by analyzing PXRD patterns of aliquots collected every 3–7 days. Following crystallization, the products were thoroughly rinsed with distilled water and acetone and calcined at 580 °C for 6 h. The resultant *BEA-type zeolites were then converted into their H-forms through ion exchange with ammonium nitrate (NH4NO3) and subsequent calcination at 580 °C for 6 h. The details of the preparations of the three series of samples (L-, M-, and S-series), including specified gel compositions, are provided in the Supplementary Information, together with the characterizations of the resulting zeolites.

Open-batch catalytic cracking process of PE

Polyolefin catalytic cracking was conducted using open-batch reactive distillation setup in a stirring batch reactor (CheMReSys, R-201) with custom modifications to allow an inert gas flow. Initially, 1 g of zeolite catalyst and 10 g of model feed PE (LDPE, melt index 25 g/10 min at 190 °C/2.16 kg, average Mw ~204 kDa by GPC, Sigma-Aldrich) were placed in a 75 mL stainless steel liner and sealed within the stirring reactor. The stainless tubing and fitting connected to the reactor were heated to 330 °C during the operation with heating tapes to minimize condensation and residue within the tubing and fitting. The reaction was performed for 2 h at a bulk temperature of 330 °C with stirring at 200 rpm using an impeller-type stirrer. Simultaneously, inert gas (N2) flowed at a desired rate. The liquid product was collected via a condensation device connected to a cold constant-temperature circulation column set at −15 °C, comprising two stages to minimize the process loss. The gaseous product was collected in a gas sampling bag connected to the end of the reactive distillation setup and analyzed using a GC-FID. The details of quantification methods and reactor structure/operation modes are provided in the Supplementary Information.

Characterizations

Powder X-ray diffraction (XRD) patterns were obtained with a SMARTLAB instrument (Rigaku, Japan). Scanning electron microscopy (SEM) images and elemental compositions of the zeolites were analyzed using a JSM-7800F Prime microscope equipped with an energy-dispersive spectroscopy (EDS) unit, specifically SDD type with active area of 80 mm2. EDS was standardized using Certified Reference Materials (CRMs) to ensure accuracy by JEOL Ltd. N2 physisorption (77 K) isotherms were measured using a BELSORP MINI X sorption analyzer. Prior to measurements, samples underwent a 3-h degassing step at 300 °C using a BELPREP VAC II instrument (MicrotracBEL, Japan). Raman spectra of solid samples were recorded with a DXR2xi instrument (Thermo Fisher Scientific, USA). The selectivity distributions of liquid products were determined using a ChroZen gas chromatography-flame ionization detector (GC-FID, Youngin, Korea), and product identification was carried out with a TSQ 3000 Evo gas chromatography-mass spectrometry (GC-MS) system (Thermo Fisher Scientific, USA) based on the NIST library.

Data availability

The data used in this study are available from the corresponding author upon reasonable request.

References

Chang, C.-F. & Rangarajan, S. Machine learning and informatics based elucidation of reaction pathways for upcycling model polyolefin to aromatics. J. Phys. Chem. A 127, 2958–2966 (2023).

Cressey, D. Bottles, bags, ropes and toothbrushes: the struggle to track ocean plastics. Nature 536, 263–265 (2016).

Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Sci. Adv. 3, e1700782 (2017).

Joshi, C., Browning, S. & Seay, J. Combating plastic waste via Trash to Tank. Nat. Rev. Earth Environ. 1, 142–142 (2020).

Alonso, J. A., Aguado, J. & Serrano, D. P. Feedstock recycling of plastic wastes (Royal society of chemistry, 1999).

Jiang, J. et al. From plastic waste to wealth using chemical recycling: a review. J. Environ. Chem. Eng. 10, 106867 (2022).

Klemeš, J. J., Fan, Y. V. & Jiang, P. Plastics: friends or foes? The circularity and plastic waste footprint. Energy Sources A Recov. Util. Environ. Eff. 43, 1549–1565 (2021).

Wang, Y. et al. Elucidating the structure-performance relationship of typical commercial zeolites in catalytic cracking of low-density polyethylene. Catal. Today 405-406, 135–143 (2022).

Ma, W. et al. Characterization of tar evolution during DC thermal plasma steam gasification from biomass and plastic mixtures: parametric optimization via response surface methodology. Energy Convers. Manage. 225, 113407 (2020).

Wang, N. M. et al. Chemical recycling of polyethylene by tandem catalytic conversion to propylene. JACS 144, 18526–18531 (2022).

Conk, R. J. et al. Catalytic deconstruction of waste polyethylene with ethylene to form propylene. Science 377, 1561–1566 (2022).

Aguado, R., Olazar, M., San José, M. J., Gaisán, B. & Bilbao, J. Wax formation in the pyrolysis of polyolefins in a conical spouted bed reactor. Energy Fuels 16, 1429–1437 (2002).

Anuar Sharuddin, S. D., Abnisa, F., Wan Daud, W. M. A. & Aroua, M. K. A review on pyrolysis of plastic wastes. Energy Convers. Manage. 115, 308–326 (2016).

Pandey, D. S., Katsaros, G., Lindfors, C., Leahy, J. J. & Tassou, S. A. Fast pyrolysis of poultry litter in a bubbling fluidised bed reactor: energy and nutrient recovery. Sustainability 11, 2533 (2019).

Songip, A. R., Masuda, T., Kuwahara, H. & Hashimoto, K. Test to screen catalysts for reforming heavy oil from waste plastics. Appl. Catal. B 2, 153–164 (1993).

Ng, S. H., Seoud, H., Stanciulescu, M. & Sugimoto, Y. Conversion of polyethylene to transportation fuels through pyrolysis and catalytic cracking. Energy Fuels 9, 735–742 (1995).

Rorrer, J. E., Troyano-Valls, C., Beckham, G. T. & Román-Leshkov, Y. Hydrogenolysis of polypropylene and mixed polyolefin plastic waste over Ru/C to produce liquid alkanes. ACS Sustain. Chem. Eng. 9, 11661–11666 (2021).

Bin Jumah, A., Anbumuthu, V., Tedstone, A. A. & Garforth, A. A. Catalyzing the hydrocracking of low density polyethylene. Ind. Eng. Chem. Res. 58, 20601–20609 (2019).

Liu, S., Kots, P. A., Vance, B. C., Danielson, A. & Vlachos, D. G. Plastic waste to fuels by hydrocracking at mild conditions. Sci. Adv. 7, eabf8283 (2021).

Rorrer, J. E., Beckham, G. T. & Román-Leshkov, Y. Conversion of polyolefin waste to liquid alkanes with Ru-based catalysts under mild conditions. JACS Au 1, 8–12 (2020).

Kim, D. et al. Metathesis, molecular redistribution of alkanes, and the chemical upgrading of low-density polyethylene. Appl. Catal. B 318, 121873 (2022).

Ellis, L. D. et al. Tandem heterogeneous catalysis for polyethylene depolymerization via an olefin-intermediate process. ACS Sustain. Chem. Eng. 9, 623–628 (2021).

Okonsky, S. T., Krishna, J. J. & Toraman, H. E. Catalytic co-pyrolysis of LDPE and PET with HZSM-5, H-beta, and HY: experiments and kinetic modelling. React. Chem. Eng. 7, 2175–2191 (2022).

Figueiredo, A. L. et al. Catalytic cracking of LDPE over nanocrystalline HZSM-5 zeolite prepared by seed-assisted synthesis from an organic-template-free system. J. Anal. Appl. Pyrolysis 117, 132–140 (2016).

Uemichi, Y., Kashiwaya, Y., Tsukidate, M., Ayame, A. & Kanoh, H. Product distribution in degradation of polypropylene over silica-alumina and CaX zeolite catalysts. Bull. Chem. Soc. Jpn. 56, 2768–2773 (1983).

Audisio, G., Bertini, F., Beltrame, P. L. & Carniti, P. Catalytic degradation of polyolefins. Makromol. Chem. Marcromol. Symp. 57, 191–209 (1992).

You, Y. S., Shim, J.-S., Kim, J.-H. & Seo, G. Liquid-phase degradation of polyethylene wax over mordenite catalysts with different Si/Al molar ratios. Catal. Lett. 59, 221–227 (1999).

Corma, A., Planelles, J., Sanchez-Marin, J. & Tomas, F. The role of different types of acid site in the cracking of alkanes on zeolite catalysts. J. Catal. 93, 30–37 (1985).

Kissin, Y. V. Chemical mechanisms of catalytic cracking over solid acidic catalysts: alkanes and alkenes. Catal. Rev. 43, 85–146 (2001).

Amin, A. M., Croiset, E. & Epling, W. Review of methane catalytic cracking for hydrogen production. Int. J. Hydrogen Energy 36, 2904–2935 (2011).

Lin, Q.-F. et al. A stable aluminosilicate zeolite with intersecting three-dimensional extra-large pores. Science 374, 1605–1608 (2021).

Gaca, P., Drzewiecka, M., Kaleta, W., Kozubek, H. & Nowińska, K. Catalytic degradation of polyethylene over mesoporous molecular Sieve MCM-41 modified with heteropoly compounds. Pol. J. Environ. Stud. 17, 25–31 (2008).

Serrano, D. P., Aguado, J. & Escola, J. M. Catalytic cracking of a polyolefin mixture over different acid solid catalysts. Ind. Eng. Chem. Res. 39, 1177–1184 (2000).

Park, J. W., Kim, J.-H. & Seo, G. The effect of pore shape on the catalytic performance of zeolites in the liquid-phase degradation of HDPE. Polym. Degrad. Stab. 76, 495–501 (2002).

Camblor, M., Mifsud, A. & Pérez-Pariente, J. Influence of the synthesis conditions on the crystallization of zeolite Beta. Zeolites 11, 792–797 (1991).

Mintova, S. et al. Variation of the Si/Al ratio in nanosized zeolite Beta crystals. Microporous Mesoporous Mater. 90, 237–245 (2006).

Caldeira, V. P. et al. Properties of hierarchical Beta zeolites prepared from protozeolitic nanounits for the catalytic cracking of high density polyethylene. Appl. Catal. A Gen. 531, 187–196 (2017).

Peral, A. et al. Bidimensional ZSM-5 zeolites probed as catalysts for polyethylene cracking. Catal. Sci. Technol. 6, 2754–2765 (2016).

Hittinger, J. P. & Shantz, D. F. Systematic study of low temperature cracking of low-density polyethylene with ZSM-5. Microporous Mesoporous Mater. 343, 112170 (2022).

Wang, Y.-Y. et al. Catalytic hydrogenolysis of polyethylene under reactive separation. ACS Catal. 14, 2084–2094 (2024).

Sandoval-Díaz, L.-E., González-Amaya, J.-A. & Trujillo, C.-A. General aspects of zeolite acidity characterization. Microporous Mesoporous Mater. 215, 229–243 (2015).

Jon, H., Lu, B., Oumi, Y., Itabashi, K. & Sano, T. Synthesis and thermal stability of beta zeolite using ammonium fluoride. Microporous Mesoporous Mater. 89, 88–95 (2006).

Xie, B. et al. Organotemplate-free and fast route for synthesizing beta zeolite. Chem. Mater. 20, 4533–4535 (2008).

Xia, Q.-H., Shen, S.-C., Song, J., Kawi, S. & Hidajat, K. Structure, morphology, and catalytic activity of β zeolite synthesized in a fluoride medium for asymmetric hydrogenation. J. Catal. 219, 74–84 (2003).

López, A., de Marco, I., Caballero, B. M., Adrados, A. & Laresgoiti, M. F. Deactivation and regeneration of ZSM-5 zeolite in catalytic pyrolysis of plastic wastes. Waste Manage. 31, 1852–1858 (2011).

Williams, P. T. & Brindle, A. J. Catalytic pyrolysis of tyres: influence of catalyst temperature. Fuel 81, 2425–2434 (2002).

Rorrer, J. E. et al. Role of Bifunctional Ru/Acid catalysts in the selective hydrocracking of polyethylene and polypropylene waste to liquid hydrocarbons. ACS Catal. 12, 13969–13979 (2022).

Acknowledgements

This research was supported by Korea Institute of Industrial Technology (KITECH) through the Korea Environmental Industry & Technology Institute (KEITI) funded by the Ministry of Environment (ARQ202209004001).

Author information

Authors and Affiliations

Contributions

H.K. contributed to zeolite synthesis, catalytic cracking, data collection, and drafting the original manuscript. J.Y. contributed to zeolite synthesis, reactor design, and data collection. D.J. contributed to TIPB cracking data collection. K.H.K. contributed to SIMDIS data collection. K.H.K., I.R., and S.J. contributed to developing ideas for experimental designs. S.J. contributed to funding acquisition, project administration, and procuring post-consumer PE waste. J.H.K. contributed to reactor design, supervision, and both writing and reviewing the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interest.

Peer review

Peer review information

Communications Engineering thanks Makenna Pennel and the other, anonymous, reviewers for their contribution to the peer review of this work. Peer review reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Kang, H., Yoon, J., Jun, D. et al. Optimization of low-temperature catalytic cracking of polyolefin waste in open-batch reactors using zeolite beta with controlled intrinsic properties. Commun Eng 4, 57 (2025). https://doi.org/10.1038/s44172-025-00392-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44172-025-00392-8