Abstract

Origami structures hold promising potential in space applications, such as ultra-large-area solar arrays, deployable space stations, and extra-terrestrial modular foldable buildings. However, the development of thick-panel origami structures has been limited, relying on a few typical origami patterns without a comprehensive design theory for multi-crease, multi-vertex thick-panel configurations. Additionally, realizing closed Polyhedra in thick-panel origami presents substantial challenges. Here, we introduce a design methodology inspired by origami and kirigami principles for one-degree-of-freedom (one-DOF) flat-foldable thick-panel origami-kirigami structures, including modular scalable arrays and closed polyhedral structures. The thick-panel origami-kirigami modular scalable arrays incorporate mixed four-crease vertices and (2n + 4)-crease vertices, enabling one-DOF flat-foldability and modular expansion of thick-panel units. The thick-panel origami-kirigami closed polyhedral structures, including tetrahedrons, square pyramids and triangular prisms, possess one-DOF inward-flat-foldability and structural closure after unfolding. This novel design framework for thick-panel origami-kirigami structures is capable of structural design from centimeter to meter scale, validated by kinematic analysis and prototype experiments.

Similar content being viewed by others

Introduction

The emergence of origami geometry has led to remarkable advancements in rigid origami and thick-panel origami structures, garnering widespread attention from researchers. These structures hold vast potential for applications ranging from space deployable structures1,2,3 to origami robots4,5, scalable architectural designs6,7, and origami metamaterials8,9,10. Origami structures, characterized by their high folding/unfolding ratio, flatness, and polyhedral closure, offer promising applications in space, including ultra-large-area solar arrays, solar sails, sunshades, large-caliber reflecting antennas and telescopes, air-space trans-domain morphing wings, deployable space stations, and extra-terrestrial modular foldable buildings11,12. Thick-panel origami structures for space applications possess the following attributes: (1) one-degree-of-freedom (one-DOF) mechanisms with deterministic motion, facilitating ease of actuation and control; (2) flat-foldability, allowing compact stowage; (3) deployability, enabling unfolding upon reaching orbit; and (4) modularity and scalability, permitting design flexibility to meet mission requirements.

Rigid origami patterns consist of systematically arranged vertices and creases. Typical vertices include the four-crease vertex and the six-crease vertex. Variations derived from the four-crease vertex include the Miura pattern13, eggbox pattern14, helical pattern15, twist origami pattern16, and winding origami patterns2,3,17,18. Examples of six-crease vertex arrangements include the Resch pattern19,20, waterbomb pattern21,22, diamond pattern23,24, and Kresling pattern25,26. Current origami patterns are typically designed based on a few standard multi-crease vertices, such as four-crease and six-crease vertices, lacking a comprehensive design theory for novel multi-crease, multi-vertex origami patterns. Modular origami, involving the integration of multiple origami units folded from a single sheet into two- or three-dimensional composite structures9,27,28, presents new opportunities for designing multi-crease multi-vertex origami patterns. Thick-panel origami accounts for panel thickness, as directly applying zero-thickness origami models may cause physical interference. Therefore, thick-panel origami structures often adapt zero-thickness origami patterns through thick-panel methods12,24,29,30,31,32. Combining kirigami with origami introduces novel approaches to constructing one-DOF thick-panel origami-kirigami structures28,33.

Mathematicians have demonstrated that closed polyhedral structures cannot achieve rigid folding while remaining closed34. Achieving rigid flat folding for closed polyhedral structures is a substantial challenge, with kirigami technologies offering potential solutions. Recent research has focused on the development of rigid foldable polyhedral structures by incorporating creases, slits, or flexible hinges in cubes35,36, rectangular prisms37, triangular prism38, zero-thickness tetrahedron and rhombic dodecahedron39, and cylindrical prism40. The kinematic complexity of thick-panel polyhedral structures limits the variety of available designs, particularly for configurations like tetrahedrons, quadrangular pyramids, and triangular prisms, which have yet to be realized in thick-panel origami forms. These Polyhedra provide superior stability and rigidity due to their unfolded configurations consisting primarily of triangular faces, making them ideal for space applications such as modular deployable space stations. These limitations hinder theoretical development and the broad application of origami engineering. Consequently, designing novel multi-crease, multi-vertex thick-panel arrays and polyhedral structures remains a major challenge.

Here, we introduce a novel design methodology for one-DOF flat-foldable thick-panel origami-kirigami structures, which enables the creation of modular scalable arrays and closed polyhedral structures, ranging in size from centimeters to meters. First, we introduce the concept of inward-flat-foldable origami- and origami-kirigami-based symmetrical triangular thick-panel units (STTPUs) that integrate origami and kirigami principles. The kinematic conditions required to achieve one-DOF motion in these units are rigorously derived. Second, we construct one-DOF flat-foldable origami- and origami-kirigami-based thick-panel arrays featuring mixed four-crease vertices and (2n + 4)-crease vertices, where n refers to the number of layers of STTPUs and is any non-zero integer. These arrays are modularly assembled using the proposed STTPUs, showcasing robust adaptability and scalability. Finally, we demonstrate various one-DOF inward-flat-foldable thick-panel origami-kirigami closed polyhedral structures based on the STTPUs, including tetrahedrons, square pyramids, and triangular prisms. The concept of origami-kirigami structures is validated by experiments conducted on 3D printed and metal prototypes.

Results

Origami-kirigami patterns and thick-panel units

Symmetrical triangular origami patterns (OriSTPs)

Four-crease vertices have given rise to many classic origami patterns, such as the Miura pattern, eggbox pattern, helical pattern, twist origami pattern, and winding origami pattern. Building on the four-crease vertex principle, we propose a class of one-DOF rigid foldable symmetrical triangular origami patterns (OriSTPs) capable of achieving complete inward folding. Complete inward folding means that after folding, the origami pattern occupies an area no greater than that of its largest part, with all other parts fully covered by the largest part.

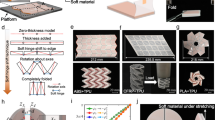

For a zero-thickness rigid plane-symmetric triangular sheet, multi-layer OriSTPs are constructed to achieve multiple inward folds by equally dividing its base angles multiple times, which results in one-layer OriSTPs (Fig. 1A and Figure S1A), two-layer OriSTPs (Fig. 1D and Fig. S1B), and three-layer OriSTPs (Fig. 1G and Fig. S1C). The specific construction procedures are detailed in Supplementary Text S1, and the folding processes of their origami sheets are demonstrated in Movie S1.

A–C One-, two- and three-layer origami patterns, origami-kirigami patterns and their symmetrical triangular thick-panel units (STTPUs). The blue solid lines represent mountain creases, the red dashed lines represent valley creases, and the green dotted line represents slit creases. D Ratio of change in thickness of STTPUs. E Ratio of change in main surface area of STTPUs. F Ratio of change in total surface area of STTPUs, when the base angles are 60 degrees. G–I The folding sequences of the 3D printed prototypes of one-, two- and three-layer origami-based STTPUs. J–O The folding sequences of the 3D printed prototypes of one-, two- and three-layer origami-kirigami-based STTPUs. The base angles are 60 degrees.

Therefore, for an n-layer rigid OriSTP, the angular bisector of the apex angle is designated as a mountain crease. The two base angles are divided equally into n + 1 parts, with the angular bisectors alternating between mountain and valley creases from top to bottom. The lines connecting the n intersections of the angular bisectors of the two base angles alternate between valley and mountain creases from top to bottom. If n is odd, the perpendicular bisector of the base is a valley crease; if n is even, the perpendicular bisector of the base is a mountain crease. These origami patterns can achieve (n + 1)-divided inward folding. Thus, based on the four-crease vertex principle and the angle bisection method, it is possible to achieve unlimited multiple inward folding and varying vertex counts in a rigid symmetrical triangular sheet.

A zero-thickness rigid sheet of one-layer OriSTPs is shown in Fig. 1A. Four creases divide the sheet into four sectors with sector angles αAOB, αBOD, αDOC, and αCOA, respectively. These angles satisfy the condition αAOB + αBOD + αDOC + αCOA = 2π. To achieve flat foldability, where the folded origami can be pressed flat, the following conditions must be met: αAOB + αDOC = αBOD + αCOA = π. The kinematic motion of this origami can be represented by a spherical 4 R linkage. Given its one-DOF and the plane-symmetry of the triangular origami, the analytical relationship among the four dihedral angles φAO, φBO, φDO, and φCO can be derived:

The kinematic relationship of n-layer rigid OriSTPs is derived as follows:

where \(i=2,3\cdots {n}\). The specific kinematic relationships of zero-thickness one- and n-layer rigid OriSTPs are analyzed as shown in Supplementary Text S2A.

Origami-based STTPUs (OriSTTPUs)

For one-layer four-crease origami, the introduction of the spatial four-bar Bennett over-constraint linkage41,42 enables the creation of thick-panel forms, achieving kinematic equivalence between thick-panel units and zero-thickness rigid origami32. Accordingly, n-layer OriSTTPUs for n-layer rigid OriSTPs are constructed based on the principle of the spatial Bennett over-constraint linkage. Examples include one-layer OriSTTPUs (Fig. 1A), two-layer OriSTTPUs (Fig. 1B), and three-layer OriSTTPUs (Fig. 1C). The corresponding 3D printed prototypes proved the feasibility of flat-folding, as shown in Fig. 1G-I and Movie S1.

The distances between adjacent folding lines are represented as hAOB, aBOD, aDOC, and hCOA, respectively. Specifically, hAOB and hCOA represent the boss height of panel AOB and panel COA, respectively, while aBOD and aDOC represent the thicknesses of panel BOD and panel DOC, respectively. The existence of mobility is attributed to the special geometry conditions of the Bennett linkage42,43, defined by the following conditions: hAOB = aBOD = aDOC = hCOA. Similarly, for n-layer rigid OriSTPs, the condition for the existence of mobility is derived as follows:

where \(i=2,3\cdots {n}-1;k=i,i+1\cdots {n}-1\). The specific kinematic relationships of one- and n-layer OriSTTPUs are analyzed as shown in Supplementary Text S2B.

Symmetrical triangular origami-kirigami patterns (KiriSTPs)

Building on the one-layer four-crease OriSTPs, an additional four-crease vertex is introduced along with kirigami techniques to create a one-layer, two-slit, seven-crease symmetrical triangular origami-kirigami pattern (KiriSTP). This transformation maintains the kinematic equivalence of the original one-layer four-crease OriSTPs, as shown in Fig. 1A. The essence of KiriSTPs lies in two one-layer four-crease origami patterns sharing a common axis. The kinematic motion of KiriSTPs can be represented as two spherical 4 R linkages sharing two links and the rotational joint between the two links, thereby providing a single DOF and inward-flat-folding capability.

Similarly, n-layer KiriSTPs are constructed by using the one-layer, two-slit and seven-crease KiriSTPs (Fig. 1A and S1D), including two-layer KiriSTPs (Fig. 1B and Figure S1E), and three-layer KiriSTPs (Fig. 1C and Fig. S1F). Movie S2 shows the folding processes of their origami sheets. The kinematic relationships of for n-layer rigid KiriSTPs are analyzed as follows:

where \(i=2,3\cdots {n}\). The specific kinematic relationships of zero-thickness one- and n-layer rigid KiriSTPs are analyzed as shown in Supplementary Text S2C.

Origami-kirigami-based STTPUs (KiriSTTPUs)

For one-layer OriSTTPUs, the structure does not lie completely flat on both planes when fully unfolded. Instead, two bosses are introduced on the plane to accommodate the placement of rotational joints, which are designed based on the unique geometric conditions of the Bennett linkage. In the case of one-layer KiriSTPs, the thick-panel transformation is achieved by directly employing two coaxial Bennett linkages. These two coaxial Bennett linkages can be further simplified into a spatial six-bar Bricard over-constrained linkage44,45, preserving the single-DOF characteristic. Consequently, we can further modify the one-layer KiriSTPs by introducing additional slits, transforming the minimum loop in each layer from a four-revolute-joint configuration to a six-revolute-joint configuration. By leveraging the principle of the spatial six-bar Bricard over-constrained linkage, we constructed one-DOF flat-foldable one-layer KiriSTTPUs, as illustrated in Fig. 1A. This design ensures kinematic equivalence to zero-thickness rigid KiriSTPs, enabling the KiriSTTPUs to inward-fold and unfold with both planes lying completely flat.

A one-layer KiriSTTPU is shown in Fig. 1A, wherein the panel is divided into six subpanels using the identical set of sector angles of zero-thickness KiriSTPs. The existence of mobility is due to the special geometry conditions of the Bricard linkage, defined by the following conditions: aBOD = aFEI = aDOC = aHEI. Similarly, n-layer KiriSTTPUs are constructed by using the one-layer KiriSTTPUs (Fig. 1A), including two-layer KiriSTTPUs (Fig. 1B), and three-layer KiriSTTPUs (Fig. 1C). The corresponding 3D printed prototypes proved the feasibility of flat folding, as shown in Fig. 1J-O and Movie S2.

Therefore, for n-layer KiriSTTPUs, the condition for the existence of mobility is derived as follows:

where \(i=2,3\cdots {n}-1;k=i,i+1\cdots {n}-1\). The specific kinematic relationships of one- and n-layer KiriSTTPUs are analyzed as shown in Supplementary Text S2D.

For both n-layer origami-based and KiriSTTPUs, the thickness ratios of the folded to unfolded configurations are identical, both being 2 + 2n. However, the ratios of the highest boss height to the panel thickness are n and n-1, respectively. Consequently, the highest boss height of KiriSTTPUs is always lower than that of OriSTTPUs, as shown in Fig. 1D. The base angle (\(\theta\)) and the ratio (\(\lambda\)) of the base length to panel thickness are critical parameters in the design of these STTPUs. The ratio of change in main surface area of n-layer STTPUs, derived from Equation S24, is shown in Fig. 1E. This ratio increases with the number of layers. For layer counts lower than four, the ratio of change in main surface area (the projected area of the configuration on the frontal plane of the largest panel) exhibits minimal variation with increasing base angle. Conversely, for layer counts greater than four, this ratio increases with the base angle. Figure 1F illustrates the ratio of change in total surface area (the entire surface area of the configuration) of n-layer STTPUs, based on Equation S26. This ratio increases with the increasing \(\lambda\). For \(\lambda\) less than 40, the ratio of change in total surface area increases with the number of layers. However, for \(\lambda\) greater than 40, the ratio initially decreases and then increases with the number of layers. Hence, the STTPUs can achieve an optimized folding rate by appropriately setting the structural parameters.

Origami-kirigami-based thick-panel modular scalable arrays (TPMSAs)

Modular origami involves the assembly of multiple origami units, folded from paper sheets, into two- or three-dimensional composite structures9,27. Inspired by this approach, we propose a novel method for designing multi-crease multi-vertex origami patterns. Built on symmetrical triangular origami-kirigami patterns and thick-panel units as the basic origami units, we can construct m-unit thick-panel modular scalable arrays. This modular assembly technique allows for the expansion of thick-panel units in two orthogonal dimensions of the array’s plane.

To maintain the one-DOF characteristic of n-layer m-unit origami patterns and TPMSAs, it is crucial to assemble the n-layer origami units into multiple loops. Within each loop, the adjacent triangular base subpanels from different units are combined to form a parallelogram subpanel. This assembly process requires a minimum of four origami units, as shown in Fig. 2A-C and Fig. 3A-C, which illustrate the construction of one- and two-layer four-unit origami patterns, respectively. By offsetting the axes of n-layer m-unit origami patterns, we can create n-layer m-unit TPMSAs, thereby generating spatial linkage mechanisms that maintain kinematic equivalence with zero-thickness origami patterns.

A The process of constructing a one-layer four-unit origami pattern with a mixture of both four- and six-crease vertices; The blue solid lines represent mountain creases and the red dashed lines represent valley creases. B, C The folding sequences of a 3D model and 3D printed prototype of one-layer four-unit origami-kirigami-based TPMSAs, where the apex angles are 60 degrees. D The modular assembly of one-layer fourteen-unit origami patterns with a mixture of both four- and six-crease vertices; E The folding sequence of a paper sheet of one-layer fourteen-unit origami patterns. F The folding sequence of a 3D model of one-layer fourteen-unit origami-kirigami-based TPMSAs, where the apex angles are 60 degrees. G Ratio of change in main surface area of n-layer four-unit TPMSAs when the values of \({\theta }\) are taken as 60°, 75°, and 90°.

A The process of constructing a two-layer four-unit origami pattern with a mixture of both four- and eight-crease vertices; The blue solid lines represent mountain creases and the red dashed lines represent valley creases. B, C The folding sequences of a 3D model and 3D printed prototype of two-layer four-unit origami-based TPMSAs, where the apex angles are 75 degrees. D The modular assembly of two-layer fourteen-unit origami patterns with a mixture of both four- and eight-crease vertices; E The folding sequence of a paper sheet of two-layer fourteen-unit origami patterns, where the apex angles are 60 degrees. F The folding sequence of a 3D model of one-layer fourteen-unit origami-based TPMSAs, where the apex angles are 75 degrees. G Ratio of change in main surface area of n-layer fourteen-unit TPMSA when the values of \(\theta\) are taken as 60°, 75°, and 90°.

One-layer TPMSAs

Figure 2A (left) illustrates an origami pattern composed of four one-layer, four-crease origami units. In this configuration, the A4 triangular sheet of unit A is in contact with the D3 triangular sheet of unit D, while the C3 triangular sheet of unit C contacts the D4 triangular sheet of unit D. These adjacent triangular sheets merge to form two parallelogram sheets, creating a one-layer four-unit origami pattern as shown in Fig. 2A (right). The motion characteristics and folding behavior of this pattern indicate that units B and D move synchronously but in opposition to units A and C. Furthermore, since each of the four units exhibits one-DOF motion, the loops formed by these origami units preserve the one-DOF property. This origami pattern integrates both four- crease and six-crease vertices. Figure 2D show the modular assembly of a one-layer, fourteen-unit origami pattern with a combination of four- and six-crease vertices. Figure 2E and Movie S3 demonstrates the folding process of its origami sheets.

When thickening the one-layer, four-unit origami pattern to construct origami-kirigami-based TPMSAs, a challenge emerges due to the thickness of the panels. In the fully folded state, the A4 triangular subpanel of unit A cannot directly connect with the D3 triangular subpanel of unit D, and similarly, the C3 triangular subpanel of unit C cannot directly connect with the D4 triangular subpanel of unit D. To resolve this, we introduce connecting parts and grooves. Specifically, connecting parts are added to the two sets of triangular panels, and grooves are integrated into the middle subpanels between the connected triangular panels (Fig. 2B). This modification prevents interference between panels during movement. The connecting parts have a thickness twice that of the subpanels, i.e., hcpart = 2hpanel.

By offsetting the axes of the one-layer four-unit origami patterns, we successfully create one-layer four-unit origami-kirigami-based TPMSAs. Despite the addition of these components, the loops within the four-unit TPMSAs maintain their one-DOF motion, as all four units exhibit one-DOF behavior. The folding sequences of a 3D model and 3D printed prototype of the four-unit origami-kirigami-based TPMSAs is illustrated in Fig. 2B, C, with Movie S3 providing a view of the folding process of its 3D printed prototype.

Two-layer TPMSAs

Figure 3A (left) illustrates an origami pattern composed of four two-layer, seven-crease origami units. In this configuration, the A6 triangular sheet of unit A contacts the D5 triangular sheet of unit D, while the C5 triangular sheet of unit C contacts the D6 triangular sheet of unit D. These adjacent triangular sheets merge to form two parallelogram sheets, resulting in a two-layer, four-unit origami pattern as depicted in Fig. 3A (right). The motion characteristics and folding behavior of this two-layer, four-unit origami pattern reveal that units B and D move synchronously but in opposition to units A and C. Since each of the four units exhibits one-DOF motion, the loops formed by these origami units preserve the one-DOF property. Consequently, this pattern features a combination of four- and eight-crease vertices. Figure 3D demonstrates the modular assembly process of a two-layer, fourteen-unit origami pattern with both four- and eight-crease vertices, while Fig. 3E and Movie S3 demonstrates the folding process of its origami sheets.

To thicken the two-layer, four-unit origami pattern for constructing the two-layer TPMSAs, we also introduce connecting parts and grooves. Specifically, connecting parts are added to the two sets of triangular panels, and grooves are incorporated into the middle subpanels between connected triangular panels (Fig. 3B). This design prevents interference between panels during movement. The thickness of the connecting parts is four times that of the subpanels, i.e., hcpart = 4hpanel. To avoid folding interference and maintain structural integrity, the top section of the folded unit B must not extend beyond the bottom section of the folded unit A. Therefore, the apex angle of the two-layer units must be less than one-third of the base angle, i.e., \(\theta \le 67.5{^{\circ }}\).

By offsetting the axes of the two-layer, four-unit origami patterns, we effectively form two-layer, four-unit origami-based TPMSAs. These TPMSAs retain one-DOF motion as all four units exhibit one-DOF behavior. The folding sequences of a 3D model and 3D printed prototype of the four-unit origami-kirigami-based TPMSAs is illustrated in Fig. 3B, C, with Movie S3 providing a view of the folding process of its 3D printed prototype.

We have demonstrated the construction of n-layer, m-unit origami patterns featuring a combination of four- and (2n + 4)-crease vertices through modular assembly method. For instance, a three-layer, fourteen-unit origami pattern incorporating both four- and ten-crease vertices is depicted in Figure S2, while a four-layer, fourteen-unit origami pattern with both four- and twelve-crease vertices is shown in Figure S3. The offset axis technology, which involves offsetting the axes of n-layer, m-unit origami patterns, facilitates the formation of n-layer, m-unit TPMSAs.

In these TPMSAs, the thickness of the connecting parts is 2n times that of the subpanels, i.e., hcpart = 2nhpanel. For odd n, where Units A and C connect to Unit D at non-long edges, the top section of the folded unit B should not extend beyond the bottom section of the folded unit A to prevent folding interference with Unit D. Consequently, the base angle of the units must satisfy \(\theta \ge 90{^{\circ }} \,(n+1)/(n+2)\). In contrast, for even n, where Units A and C connect to Unit D at the long edges, no such restrictions apply. Despite these constraints, the loops of m-unit TPMSAs formed by the units preserve one-DOF motion.

Figures 2G and 3G illustrate the ratio of change in main surface area of n-layer four- and fourteen-unit TPMSAs, as described by Equation S27 and S28, respectively. This ratio increases with the increasing \(\lambda\). However, it decreases as the number of layers and \(\theta\) increase. Therefore, the TPMSAs can achieve an effective folding rate by appropriately setting the structural parameters based on these patterns.

The novel multi-crease, multi-layer modular scalable arrays, characterized by their high folding/unfolding ratio and flatness, show promising potential for advanced applications in space deployable structures, such as ultra-large solar arrays, solar sails, sunshades, large-aperture antennas, and versatile aircraft. For instance, two-layer, four-unit origami-based TPMSAs with a ratio of base length to panel thickness is 150, can achieve up to 555.6% elongation change and 422.4% variation in wing area, substantially enhancing aerodynamic performance across diverse flight profiles. Detailed performance metrics are provided in Supplementary Text S4C.

Origami-kirigami-based thick-panel closed polyhedral structures

Mathematicians have proven that closed polyhedral structures cannot achieve rigid folding while remaining closed, highlighting the complexity of the problem in achieving flat folding for closed polyhedral forms. However, kirigami technologies offer a promising solution to this challenge. By leveraging the principles of STTPUs, we investigate the design of various one-DOF inward-flat-foldable closed polyhedral structures by origami-kirigami principles. These include configurations such as tetrahedrons, square pyramids, and triangular prisms. These novel thick-panel closed polyhedral structures that offer both functionality and feasibility for engineering applications.

Origami-kirigami-based thick-panel regular tetrahedral structures

We start with a zero-thickness two-dimensional origami-kirigami pattern for regular tetrahedrons, illustrated in Fig. 4A. This pattern consists of two one-layer four-crease OriSTPs and two auxiliary triangular sections. When folded into three dimensions and with edges hinged, it forms an origami-kirigami pattern of regular tetrahedron, as shown in Fig. 4B. The two OriSTPs share vertices B and C, i.e., \({\varphi }_{OA}={\varphi }_{OD}={\varphi }_{RE}={\varphi }_{RD{\prime} }\), resulting in synchronous movement of the entire pattern. Consequently, the zero-thickness origami-kirigami pattern of regular tetrahedron exhibits only one DOF.

A, B Zero-thickness 2D and 3D origami-kirigami patterns of regular tetrahedrons, respectively; the blue solid lines represent mountain creases, the red dashed lines represent valley creases, and the green dotted line represents slit creases. C, D The 3D models of TPRTS−1 and TPRTS-2, respectively; E Rates of change in volume and surface area of TPRTSs. F, G The folding sequences of TPRTS-1 and TPRTS-2, respectively. H The folding sequence of a metal prototype of TPRTS-2.

By utilizing single-layer OriSTTPUs and KiriSTTPUs, we successfully transformed the zero-thickness origami-kirigami pattern of the regular tetrahedron into thick-panel regular tetrahedral structures (TPRTSs), designated as TPRTS-1 and TPRTS-2 (Fig. 4C, D). Since these TPRTSs preserve the kinematic properties of their zero-thickness counterparts (\({\varphi }_{OA}={\varphi }_{OD}={\varphi }_{RE}={\varphi }_{RD{\prime} }\)), they maintain a single DOF, as demonstrated by their 3D-printed prototypes in Fig. 4F, G. To further validate the practical applicability of this design, we fabricated a functional metal prototype of the origami-kirigami-based TPRTS-2 using aluminum hinges and panels (Fig. 4H). The folding sequences of both the 3D-printed and metal prototypes are comprehensively illustrated in Fig. 4F-H and Movie S4, confirming the kinematic performance of the developed TPRTSs.

For flat folding in TPRTSs, it is essential that the panel thicknesses of the two STTPUs be identical, i.e., \({a}_{ABC}={a}_{EBC}\). In contrast, the panel thicknesses of the auxiliary triangular panels can vary. Consequently, in the unfolded state, the TPRTS-1 features a boss on each plane of its two OriSTTPUs, while all four triangular planes of the TPRTS-2 are flat, allowing for equal thicknesses across all four planes.

To achieve inward folding of TPRTSs, the sum of the divided base angles of the two STTPUs must be less than or equal to the apex angle of the auxiliary triangular panel in the folded state. Given that the apex angle of the auxiliary triangular panel in the tetrahedron is 60 degrees, the divided base angles of the two STTPUs, which each are 30 degrees, sum to 60 degrees, satisfying the requirement for inward folding.

The ratio of change in volume and surface area of TPRTSs, derived from Equations S31 and S32, is illustrated in Fig. 4E. It is observed that the ratio of change in volume increases nearly linearly with the increase in \(\lambda\). The ratio of change in surface area also increases when \(\lambda\) is less than 40. However, when \(\lambda\) exceeds 40, the ratio of change in surface area increases only slightly with further increases in \(\lambda\). Hence, the TPRTSs can achieve a favorable folding rate by appropriately setting the structural parameters.

Origami-kirigami-based thick-panel regular triangular prismatic structures

A zero-thickness two-dimensional origami-kirigami pattern of regular triangular prisms is created as shown in Fig. 5A. This pattern includes two one-layer four-crease OriSTPs, one two-vertex seven-crease symmetrical rectangular origami pattern, and two auxiliary rectangular sections. By folding this pattern into three dimensions and hinging the edges, it transforms into an origami-kirigami pattern of regular triangular prism, as depicted in Fig. 5B. The pattern reveals that the two-layer seven-crease symmetrical rectangular origami pattern shares vertices B, C, F and G with the two OriSTPs. Thus, the three origami pattern units move synchronously, i.e., \({\varphi }_{PQ}={\varphi }_{PD}={\varphi }_{QD^{\prime} }={\varphi }_{OD}={\varphi }_{O^{\prime} D}={\varphi }_{OA}={\varphi }_{O^{\prime} A}\), with the two auxiliary rectangular sections moving accordingly. Therefore, the zero-thickness origami-kirigami pattern of regular triangular prism maintains only one DOF.

A, B Zero-thickness 2D and 3D origami-kirigami patterns of regular triangular prisms, respectively. The blue solid lines represent mountain creases, the red dashed lines represent valley creases, and the green dotted line represents slit creases. C, D The 3D models of TPRTPS-1 and TPRTPS-2, respectively; E Ratio of change in volume of TPRTPSs. F, G The folding sequences of TPRTPS-1 and TPRTPS-2, respectively. H Ratio of change in surface area of TPRTPSs. I The folding sequence of a metal prototype of TPRTPS-2.

By utilizing single-layer OriSTTPUs and KiriSTTPUs, we successfully transformed the zero-thickness origami-kirigami pattern of regular triangular prism into thick-panel regular triangular prismatic structures (TPRTPSs), designated as TPRTPS-1 and TPRTPS-2 (Fig. 5C-D). Since these TPRTPSs preserve the kinematic properties of their zero-thickness counterparts (\({\varphi }_{PQ}={\varphi }_{PD}={\varphi }_{QD^{\prime} }={\varphi }_{OD}={\varphi }_{O^{\prime} D}={\varphi }_{OA}={\varphi }_{O^{\prime} A}\)), they maintain a single DOF, as demonstrated by their 3D-printed prototypes in Fig. 5F-G. Furthermore, to validate the practical applicability of this design, we fabricated functional metal prototypes of TPRTPS-2 and a thick-panel inclined triangular prismatic structure (TPITPS) using aluminum hinges and panels, as shown in Fig. 5I and Figure S8. The folding processes of both the 3D-printed and metal prototypes are comprehensively demonstrated in Movie S5, confirming the kinematic performance of the proposed TPRTPSs and TPITPS.

For flat folding in TPRTPSs, identical panel thicknesses must be maintained for both STTPUs and the two-vertex seven-crease symmetrical rectangular thick-panel unit, i.e., \({a}_{BCFG}={a}_{ABC}={a}_{EFG}\). Consequently, in the unfolded state, while the TPRTPS-1 exhibits bosses on each plane of its OriSTTPUs, the TPRTPS-2 can have all five planes flat and of equal thickness.

For inward folding, the sum of the divided base angles of the STTPUs and the symmetrical rectangular thick-panel unit must be less than or equal to the apex angle of the auxiliary rectangular panel. In TPRTPSs, with an apex angle of 90 degrees, the divided base angles become 30 and 45 degrees after folding, summing to 75 degrees, thereby satisfying the inward folding requirement.

The ratio (µ) of prismatic length to panel thickness is a critical parameter in the design of the TPRTPSs. The ratios of change in volume and surface area of TPRTPSs are examined: The ratio of change in volume increases nearly linearly with \(\lambda\), as shown in Fig. 5E (Equation S33), while it remains nearly constant with changes in µ. The ratio of change in surface area increases with \(\lambda\), as shown in Fig. 5H (Equation S34). For \(\lambda\) less than 40, the surface area change ratio increases slightly with µ. For \(\lambda\) greater than 40, the increase is more pronounced. Hence, the TPRTPSs can achieve a favorable folding rate by appropriately setting the structural parameters.

Origami-kirigami-based thick-panel regular quadrangular pyramidal structures

A zero-thickness two-dimensional origami-kirigami pattern of regular quadrangular pyramids is created by using two three-layer OriSTPs, a one-vertex six-crease symmetrical square origami pattern, and two auxiliary triangular sections. When folded in three dimensions and with hinged edges, the origami-kirigami pattern forms an origami-kirigami pattern of regular quadrangular pyramids, as shown in Fig. 6B. The one-vertex six-crease symmetrical square origami pattern shares vertices B, C, E and F with the two three-layer OriSTPs, i.e., \({\varphi }_{PD}={\varphi }_{PD^{\prime} }={\varphi }_{OD}={\varphi }_{O^{\prime} D}={\varphi }_{OA}={\varphi }_{O^{\prime} A}\). Thus, three two-dimensional origami patterns and two auxiliary triangular sections move synchronously, resulting in a zero-thickness origami-kirigami pattern of regular quadrangular pyramids with only one DOF.

A, B Zero-thickness 2D and 3D origami-kirigami patterns of regular quadrangular pyramids, respectively. The blue solid lines represent mountain creases, the red dashed lines represent valley creases, and the green dotted line represents slit creases. C, D The 3D models of TPRQPS-1 and TPRQPS-2, respectively; E Ratios of change in volume and surface area of TPRQPSs. F, G The folding sequences of TPRQPS-1 and TPRQPS-2, respectively. H The folding sequence of a metal prototype of TPRQPS-2.

By utilizing single-layer OriSTTPUs and KiriSTTPUs, we successfully transformed the zero-thickness origami-kirigami pattern of regular quadrangular pyramids into thick-panel regular quadrangular pyramidal structures (TPRQPSs), designated as TPRQPS-1 and TPRQPS-2 (Fig. 6C-D). Since these TPRQPSs preserve the kinematic properties of their zero-thickness counterparts (\({\varphi }_{PD}={\varphi }_{PD^{\prime} }={\varphi }_{OD}={\varphi }_{O^{\prime} D}={\varphi }_{OA}={\varphi }_{O^{\prime} A}\)), they maintain a single DOF, as demonstrated by their 3D-printed prototypes in Fig. 6F, G. To further demonstrate the practical applicability of this design, a functional metal prototype of TPRQPS-2 was fabricated using aluminum hinges and panels (Fig. 6H). The folding processes and structural characteristics of both the 3D-printed and metal prototypes are systematically illustrated in Fig. 6F-H and Movie S6, confirming the kinematic performance of the proposed TPRQPSs.

For flat-folding, equal panel thicknesses must be maintained for the two STTPUs, with the thickness of the symmetrical square thick-panel unit being double that of the STTPUs, i.e., \({a}_{BCEF}=2{a}_{ABC}=2{a}_{A^{\prime} EF}\). The panel thicknesses of the auxiliary triangular panels can be arbitrary. In the unfolded state, the TPRQPS-1 shows three bosses on each plane of its OriSTTPUs, while the TPRQPS-2 exhibits two lower bosses on each of its KiriSTTPUs.

For inward folding, the sum of the divided base angles of the STTPU and the symmetrical square thick-panel unit must be less than or equal to the apex angle of the auxiliary triangular panels. In the TPRQPSs, with an apex angle of 60 degrees, the divided base angles are 15 and 45 degrees, respectively, summing to 60 degrees, thereby meeting the inward folding requirement.

The ratio of change in volume and surface area is depicted in Fig. 6E (Eqs. S35 and S36). The volume change ratio increases nearly linearly with \(\lambda\). The change ratio of the surface area increases when \(\lambda\) is less than 40, and shows a slight increase when \(\lambda\) exceeds 40. Hence, the TPRQPSs can achieve a favorable folding rate by appropriately setting the structural parameters.

The design methodology for origami-kirigami-based thick-panel closed polyhedral structures enables the creation of both regular and irregular closed configurations, scalable from centimeter to meter dimensions. With the increasing focus on space exploration and the development of future space stations and extraterrestrial bases, these innovative origami-kirigami structures offer exceptional advantages. Their high folding/unfolding ratio, flatness, and ability to achieve structural closure after unfolding make them particularly well-suited for large-scale deployable space stations and modular foldable buildings for extraterrestrial environments.

Discussion

In this study, we propose a design methodology for one-DOF flat-foldable thick-panel origami-kirigami structures. This methodology facilitates the creation of modular scalable arrays and closed polyhedral structures ranging from centimeters to meters. We introduce the concept of inward-flat-foldable OriSTTPUs and KiriSTTPUs by thickening OriSTPs and KiriSTPs using the Bennett and Bricard linkages. The origami-kirigami units synergistically integrate the principles of origami and kirigami, providing lower bosses on the plane. We rigorously derive the kinematic conditions necessary to realize one-DOF motion within these STTPUs. Additionally, we introduced one-DOF flat-foldable multi-crease multi-vertex origami patterns and thick-panel arrays featuring various vertex types, including four- and six-crease vertices, four- and eight-crease vertices, and even four-vertices with (2n + 4)-crease vertices. The modular assembly method allows for scalable expansion in two directions of STTPUs in two directions, offering robust adaptability and versatility. The resulting TPMSAs are characterized by their high folding/unfolding ratio and flatness, as confirmed by folding ratio analysis and experiments. These arrays show promising potential for advanced applications in space-deployable ultra-large structures. Using the STTPUs, we investigated various configurations of one-DOF flat-foldable origami-kirigami-based thick-panel closed polyhedral structures, including TPRTSs, TPRTPSs, and TPRQPSs. Folding experiments conducted on 3D-printed and metal prototypes validate their high folding/unfolding ratio, flatness, and effective structural closure after unfolding. These polyhedral structures hold great promise for future aerospace applications, particularly in the design of large-scale deployable space stations, and extra-terrestrial modular foldable buildings. This methodology provides a solid theoretical and technical foundation for novel origami-kirigami structures in engineering applications.

Methods

For all paper sheets of origami-kirigami patterns, we used a printer to print out the creases, then used scissors to cut them, and finally followed the creases to complete the folding. For all 3D models of origami-kirigami structures, we used SolidWorks software for modeling and motion simulation. For all 3D printed prototypes of origami-kirigami structures, we used 3D printing technology to fabricate all thick panels in photosensitive resin. The thick panels were then bonded together using adhesive tape corresponding to the 3D models. The construction procedures of one-, two-, and three-layer OriSTPs are described in Supplementary Text S1. The kinematic modeling of symmetrical triangular origami-kirigami patterns and thick-panel units is described in Supplementary Text S2. The assembly of metal prototypes of thick-panel polyhedral structures is described in Supplementary Text S5.

Data availability

All data are available in the main text or the supplementary information.

References

Wang, C. et al. Reconfigurable origami-inspired multistable metamorphous structures. Sci. Adv. 10, eadk8662 (2024).

Zirbel, S. A. et al. Accommodating thickness in origami-based deployable arrays. J. Mech. Des. 135, 111005 (2013).

Wang, S., Yan, P., Huang, H., Zhang, N. & Li, B. Inflatable metamorphic origami. Research 6, 0133 (2023).

Novelino, L. S., Ze, Q., Wu, S., Paulino, G. H. & Zhao, R. Untethered control of functional origami microrobots with distributed actuation. Proc. Natl Acad. Sci. 117, 24096–24101 (2020).

Felton, S., Tolley, M., Demaine, E., Rus, D. & Wood, R. A method for building self-folding machines. Science 345, 644–646 (2014).

Beatini, V. et al. Integration of origami and deployable concept in volumetric modular units. Sci. Rep. 12, 19180 (2022).

Melancon, D., Gorissen, B., García-Mora, C. J., Hoberman, C. & Bertoldi, K. Multistable inflatable origami structures at the metre scale. Nature 592, 545–550 (2021).

Filipov, E. T., Tachi, T. & Paulino, G. H. Origami tubes assembled into stiff, yet reconfigurable structures and metamaterials. Proc. Natl Acad. Sci. 112, 12321–12326 (2015).

Hu, X., Tan, T., Wang, B. & Yan, Z. A reprogrammable mechanical metamaterial with origami functional-group transformation and ring reconfiguration. Nat. Commun. 14, 6709 (2023).

Schenk, M. & Guest, S. D. Geometry of Miura-folded metamaterials. Proc. Natl Acad. Sci. 110, 3276–3281 (2013).

Dai, J. S., & Rees Jones, J. Mobility in metamorphic mechanisms of foldable/erectable kinds. J. Mech. Design. 375–382. (1999)

Tachi, T. Rigid-foldable thick origami. Origami 5, 253–264 (2011).

Miura, K. & Lang, R. J. The science of Miura-ori: A review. Origami 4, 87 (2009).

Schenk, M. & Guest, S. D. Origami folding: A structural engineering approach. Origami 5, 291–304 (2011).

Chen, Y., Lv, W., Peng, R. & Wei, G. Mobile assemblies of four-spherical-4R-integrated linkages and the associated four-crease-integrated rigid origami patterns. Mech. Mach. Theory 142, 103613 (2019).

Hull, T. C. Counting mountain-valley assignments for flat folds. arXiv preprint arXiv:1410.5022.(2014)

Kumar, P. & Pellegrino, S. Computation of kinematic paths and bifurcation points. Int. J. Solids Struct. 37, 7003–7027 (2000).

Lang, R. J., Magleby, S. & Howell, L. Single degree-of-freedom rigidly foldable cut origami flashers. J. Mech. Robot. 8, 031005 (2016).

Tachi, T. Designing freeform origami tessellations by generalizing Resch’s patterns. J. Mech. Des. 135, 111006 (2013).

Resch, R. D. The topological design of sculptural and architectural systems. In Proceedings of the June 4-8, 1973, national computer conference and exposition (pp. 643–650) (1973).

Chen, Y., Feng, H., Ma, J., Peng, R. & You, Z. Symmetric waterbomb origami. Proc. R. Soc. A: Math., Phys. Eng. Sci. 472, 20150846 (2016).

Lee, D. Y., Kim, J. K., Sohn, C. Y., Heo, J. M. & Cho, K. J. High–load capacity origami transformable wheel. Sci. Robot. 6, eabe0201 (2021).

Yoshimura, Y. On the mechanism of buckling of a circular cylindrical shell under axial compression (No. NACA-TM-1390).(1955).

Zhang, X. & Chen, Y. Vertex-splitting on a diamond origami pattern. J. Mech. Robot. 11, 031014 (2019).

Yasuda, H. et al. Origami-based impact mitigation via rarefaction solitary wave creation. Sci. Adv. 5, eaau2835 (2019).

Zhai, Z., Wang, Y. & Jiang, H. Origami-inspired, on-demand deployable and collapsible mechanical metamaterials with tunable stiffness. Proc. Natl Acad. Sci. 115, 2032–2037 (2018).

Li, Y., Zhang, Q., Hong, Y. & Yin, J. 3D transformable modular Kirigami based programmable metamaterials. Adv. Funct. Mater. 31, 2105641 (2021).

Sun, H. et al. Shape editing of kirigami-inspired thick-panel deployable structure. Mechanism Mach. Theory 191, 105471 (2024).

Edmondson, B. J., Lang, R. J., Morgan, M. R., Magleby, S. P. & Howell, L. L. Thick rigidly foldable structures realized by an offset panel. Origami6: I. Math. 149 (2015)

Morgan, M. R., Lang, R. J., Magleby, S. P. & Howell, L. L. Towards developing product applications of thick origami using the offset panel technique. Mech. Sci. 7, 69–77 (2016).

Tolman, K. A., Lang, R. J., Magleby, S. P., & Howell, L. L. Split-vertex technique for thickness-accommodation in origami-based mechanisms. In International Design Engineering Technical Conferences and Computers and Information in Engineering Conference (Vol. 58189, p. V05BT08A054). American Society of Mechanical Engineers. (2017).

Chen, Y., Peng, R. & You, Z. Origami of thick panels. Science 349, 396–400 (2015).

Yang, J., Zhang, X., Chen, Y. & You, Z. Folding arrays of uniform-thickness panels to compact bundles with a single degree of freedom. Proc. R. Soc. A 478, 20220043 (2022).

Connelly, R., Sabitov, I. & Walz, A. The bellows conjecture. Beitr. Algebra Geom. 38, 1–10 (1997).

Gu, Y. & Chen, Y. Origami cubes with one-DOF rigid and flat foldability. Int. J. Solids Struct. 207, 250–261 (2020).

Gu, Y., Wei, G. & Chen, Y. Thick-panel origami cube. Mech. Mach. Theory 164, 104411 (2021).

Zhang, X. et al. Kirigami-based metastructures with programmable multistability. Proc. Natl Acad. Sci. 119, e2117649119 (2022).

Xiao, L., Hong, Y., Wang, K. & Zhao, H. Folding of sealed origami-inspired capsule with rigid panels and hyperelastic hinges. Thin-Walled Struct. 190, 111003 (2023).

Zhang, Y., Gu, Y., Chen, Y., Li, M. & Zhang, X. One-DOF rigid and flat-foldable origami Polyhedra with slits. Acta Mech. Solid. Sin. 36, 479–490 (2023).

Liu, F., Terakawa, T., Long, S. & Komori, M. Rigid-foldable cylindrical origami with tunable mechanical behaviors. Sci. Rep. 14, 145 (2024).

Bennett, G. T. The skew isogram mechanism. Proc. Lond. Math. Soc. 1, 151–173 (1903).

Baker, J. E. On the motion geometry of Bennett’s mechanism. Mech. Mach. Theory 15, 267–286 (1980).

Denavit, J. & Hartenberg, R. S. A kinematic notation for lower-pair mechanisms based on matrices. J. Appl. Mech. 22, 215–221 (1955).

Bricard, R. Leçons de cinématique. (Gauthier-Villars, 1927).

Goldberg, M. New five-bar and six-bar linkages in three dimensions. Trans. ASME, J. Appl. Mech. 65, A49–A52 (1943).

Acknowledgements

The authors acknowledge the support from National Natural Science Foundation of China (Grant No. 52205039), in part from China Manned Space Engineering Program and the Director’s Foundation of Technology and Engineering Center for Space Utilization, Chinese Academy of Sciences (Grant No. CSU-JJKT-2024-8).

Author information

Authors and Affiliations

Contributions

Conceptualization: C.Z., E.C., S.Z., H.Z. Methodology: C.Z., E.C., S.Z., Q.S. Investigation: C.Z., E.C., S.Z., G.Y. Visualization: C.Z., E.C., S.Z., L.Z. Supervision: H.Z., R.L., G.Z., K.W. Writing—original draft: C.Z., G.Y. Writing—review & editing: H.Z., H.G., K.W.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Engineering thanks Larry Howell, Fabien Royer, Yang Li, and Ivy Running a for their contribution to the peer review of this work. Primary Handling Editors: [Maria Sakovsky] and [Rosamund Daw].

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Zhao, C., Cui, E., Zou, S. et al. One-degree-of-freedom flat-foldable thick-panel origami-kirigami structures: modular arrays and closed polyhedra. Commun Eng 4, 62 (2025). https://doi.org/10.1038/s44172-025-00397-3

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44172-025-00397-3