Abstract

Long-term remote sensing precision depends on real-time radiation calibration, challenging the stability and accuracy of spaceborne calibrators in harsh space environments. Miniature fixed points offer a solution for International System of Units traceability of space radiation values. However, traditional in-situ calibration methods face difficulties due to location mismatches between miniature fixed points and radiation surface. We demonstrated a space temperature traceability technology, which realizes continuous temperature self-calibration across all-location region is achieved through near-site transfer mechanism of phase transition characteristics. A transfer link between fixed points-blackbody-remote sensor has been established. We further provided two traceability schemes and deployed eight miniature fixed points covering 234 K to 345 K. Experiments showed repeatability and long-term stability of 6.0 mK and 3.2 mK. Additionally, we exhibited the latest spaceborne blackbody, achieving the first on-orbit replication of 7.4 mK. This technology provides an effective on-orbit traceability path for long-term remote sensing monitoring.

Similar content being viewed by others

Introduction

Accurate measurement and understanding of climate change and the establishment of climate monitoring models are important issues facing geoscience1,2,3,4,5,6. Long-term trends in the climate system are always masked by naturally occurring interannual variability7,8, and measurement uncertainties can also mask long-term trends9,10. Global temperatures vary by ~0.2 K per decade. This variation is only 1/10th of the temperature variability of a typical ENSO (El Niño-Southern Oscillation) and as low as 1/50th of the temperature variability of a weather event11,12,13. Therefore, a necessary condition for accumulating a base climate data record is the use of sufficiently stable and accurate observational instruments for climate monitoring14,15,16,17. Furthermore, to establish a unified global climate observation system, another important condition is the consistency of observations from different observation platforms18,19. The number of instruments and their spatial distribution need to be sufficient to make measurements without spatial or temporal intervals20,21. The ASIC3 (Achieving Satellite Instrument Calibration for Climate Change) report states that the radiometric temperature thresholds required for climate monitoring should have an uncertainty of better than 0.1 K and a stability of 0.04 K per decade22. This places stringent requirements on the accuracy and traceability of global observing system measurements, requiring long-term, stable and accurate measurements across decades or even longer periods.

Monitoring response decay and interpreting the degradation of potentially relevant spectra is a task. Without direct and effective traceability and calibration of the relevant quantities during orbital operation, it is difficult to ensure the long-term validity of satellite measurements14,23,24,25. Uncontrollable factors such as space noise, instrument self-heating, vibration impact, and other effects can lead to unpredictable changes in radiation gain and offset of instruments. For example, the EO-1/Hyperion payload drifted 8% in the visible-NIR spectrum and even higher in the shortwave IR spectrum (18%) during its first two years of orbital operation26. Therefore, in-orbit radiometric calibrations must be carried out under realistic satellite in-orbit operating conditions21,27,28. The availability of calibration results is maintained over the operational lifetime of the payload, the calibration uncertainties are quantified, and the calibration factors are updated as necessary to meet observational needs18,29. Blackbodies are widely used as standards for IR radiation in IR remote sensing calibrations30,31,32,33; specifically, the use of cavity or surface blackbody radiation sources with known temperature and emissivity are used to establish quantitative relationships between the output electronics of IR remote sensing payloads and the actual amount of radiation at the pupil and then quantify and calibrate bright infrared temperature parameters in space34,35,36. As the quantitative source of IR remote sensing payloads, its calibration capability is the dominant factor governing the level of quantification of IR remote sensing payloads37,38,39. American, Chinese and European scientists almost simultaneously proposed the concept of space radiation standard satellites, such as Radiometer Assessment using Climate Absolute Radiance and Refractivity Observatory (CLARREO)40, Chinese Space-Based Radiometric Benchmark Mission (CSRB)41,42 and Vertically Aligned Nanotubes43. However, the blackbody radiation source itself can only be measured back to the prelaunch laboratory stage, and it is difficult to trace the remote sensing observations back to the SI when the reference transfer link breaks with the launch of the satellite into orbit44,45,46. In the complex environment of space, the temperature of the spaceborne blackbody is measured by one or more high-precision temperature sensors47,48, which are subject to mechanical vibrations, shocks, stress release, cosmic ray irradiation, heat flow alternations, etc., over a period of years, producing a drift in the values, and their own reliability cannot be ensured 49,50,51.

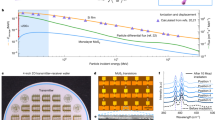

The proposed implementation of a miniaturized international temperature standard “fixed point” within NASA’s CLARREO project40,52, presents a promising solution for SI traceability of space radiation values. Serving as SI reference points, their stable freezing/melting behavior can be utilized as a benchmark for temperature traceable calibration53. However, unlike the traditional in-situ temperature calibration method (Supplementary Fig. 1), the location mismatch between the miniature fixed point (MFP) and the radiation surface poses challenges to achieving temperature transfer from the phase transition position to the radiation surface. In the CSRB project, we demonstrated a space temperature traceability technology, which utilizes the near-site transfer of the MFPs (Fig. 1a). By combining multiple miniature phase change cells (MPCCs) containing small amounts of phase change materials (PCMs) with a blackbody radiation source, we sequentially heat-drive the MFPs to reproduce the phase transition plateau. By utilizing heterogeneous interface heat conduction and diffusion, characteristic markers are transferred to temperature sensors located in close proximity to the radiation surface. The phase change plateau, which exhibits the thermal equilibrium mechanism involving conduction, convection, and radiation, serves as the temperature reference for the spectral radiance datum. This reference temperature is then transmitted to infrared remote sensors to establish a transfer chain from the International Temperature Scale-90 (ITS-90) to space infrared radiation (Fig. 1b). According to the microscale melting behavior, we developed eight MFPs with different melting temperatures for covering the observation needs from 234 K to 345 K (Fig. 1c). We further show that the technique has sufficient stability and feasibility for engineering applications. This technology can achieve self-calibration across all-location regions in continuous temperature range (Fig. 1d), establishing a transfer link between fixed points-blackbody-remote sensor. In addition, miniature phase change cells have lower load requirements and sufficient structural reliability (Fig. 1e). The technology will be applied to space-based radiometric benchmarks for infrared observations in the future.

a Schematic of space temperature traceability method. b Principle of space temperature transfer. c Multiple point calibration a Continuous phase transition curves and temperature sensor interpolation calibration from 234 K to 345 K. d Point-to-surface transfer method of the miniature fixed points (MFPs) to platinum resistance thermometers (PRTs). e Physical demonstration of the miniature phase change cells.

Results

Near-site transfer mechanism under multiphysics field coupling

In contrast to conventional in-situ temperature calibration techniques, achieving space temperature traceability necessitates the capability to quantitatively acquire blackbody radiation surface temperature. Therefore, temperature sensors should be positioned on the radiative surface instead of being surrounded in phase-change media. Supplementary Fig. 2 illustrates the heat transfer path between the phase change medium and the blackbody. The exchange heat flow can significantly accentuate the classical temperature pattern, including the metallic cavity with MPCCs. The phase change characteristics are transferred to the temperature sensor located in the blackbody cavity via a protective sleeve and a copper crucible. The main temperature differences are concentrated in the interfacial thermal resistance and the structural thermal resistance (Supplementary Fig. 3); this difference is particularly evident in the microscale cells with smaller heat transfer areas.

The thermodynamic transfer between the blackbody and the PCMs is an important issue to be considered in the temperature self-calibration. Figure 2a simulates the internal temperature evolution of the spaceborne blackbody at the Ga point during the phase transition (see Supplementary Note 1 for the methodology). The main manifestations of the local heat flow pattern are divided into three stages: solid heat transfer (stage I), latent heat exchange (stage II) and solid‒liquid heat transfer (stage III). After the external heat flow of constant power acts on the blackbody cavity (stage I), the blackbody cavity with the MPCCs slowly warms up at the same rate. When the temperature increases to 302.91 K, which is the melting point, Ga-MPCC begins to undergo a phase transition (stage II). At the beginning of the phase transition, the main heat transfer mechanism is wall heat conduction, and the convective heat exchange is weak to negligible. Afterwards, the outer layer of Ga melts preferentially and forms a liquid film to wrap the solid inside (Supplementary Fig. 4). Its ability to absorb heat from the outside during melting initially has a dramatic increase (0.03 W → 1.60 W) with increasing temperature in the blackbody cavity and then shows a slow decrease with decreasing solid-state interface (1.60 W → 1.52 W). Under the influence of the latent heat of Ga, the blackbody cavity gradually reaches thermal equilibrium with increasing heat flow exchange with the MPCCs and forms a dynamic and stable temperature plateau. The gallium within the MPCCs completes the phase transition at stage III, and the additional heat flow exchange drives an increase in the blackbody temperature. Additionally, the gallium temperature, deprived of latent heat suppression, increases together with the metal cavity and gradually converges. Notably, the transformation from II to phase III is a complex process. In a classical phase transition mechanism, the transition from the dominance of latent heat to linear heat transfer is not instantaneous but is marked by the thermodynamic propagation capacity of the moving solid clusters in the cell. Here, we define the intersection of the first order fitted lines of the blackbody temperature plateau (stage III) and the secondary warming (stage III) as the characteristic temperature, i.e., the run-off point of the latent heat rate change.

a Simulation of the temperature evolution inside the spaceborne blackbody at the gallium point during the phase transition. b Physical process and neural network of near-site heat transfer. c Phase transformation curves of spaceborne blackbody at the gallium point under different heating power increments. d Relationship between the characteristic temperature and heating power increments at the Ga point. e Relationship between the characteristic temperature and heating power increments at the Ga-In point. f Relationship between the characteristic temperature and ambient temperature increments and the platform temperature increments at the Ga point.

The heat transfer diagram is depicted in Fig. 2b, illustrating a classical multi-physical field coupling process encompassing phase transformation, radiation, and heat transfer. We used a mathematical model to describe the heat transfer process (Supplementary Note 2).

where T(x,y,z,t) is the temperature function, k is the thermal conductivity of the material, g(x,y,z,t) is the heat source function, \(\rho\) is the density, and c is the specific heat capacity. At the quasi-steady-state plateau, Tch of the blackbody can be expressed as follows:

where Tmel are the melting temperatures of PCM, Tpla and \({T}_{{\rm{amb}}}\) are the platform temperature and ambient temperature, respectively. c1, c2 and c3 are determined by the structural thermal resistance and are approximately constant when the thermal physical properties of the material tend to be stable, which can be obtained through experimental measurement. c4 tends to be equal to zero at the quasi-steady-state plateau. In summary, when extrapolated to zero external heat flux input, the characteristic temperature will tend towards the melting point eigenvalue of the PCM.

To investigate the near-site transfer mechanism under multiphysics field coupling, we tested the phase transition curves of the spaceborne blackbody at the Ga point under different external heat sources (Fig. 2c). The experimental results showed that the phase transition curves exhibited the same temperature characteristics as the Ga melting state when a sufficiently low heating power was used; however, this also indicated a long phase transition time of more than 20 h. As the heating power increased, the phase transition plateau temperature of the blackbody increased, and the duration decreased. In a typical melting process, the blackbody phase transition plateau was maintained at 303–305 K, and the phase transition duration was maintained in the range of 1–12 h. Importantly, the phase transition duration was not only related to the heating power but was also influenced by the latent heat/surface area ratio of the material, i.e., the required energy divided by the heat transfer capacity. An approximately linear relationship54 was observed between the characteristic temperature and the heating power (Fig. 2d), this relationship also applied to the carried Ga-In point (Fig. 2e), and the primary term coefficients were approximate for both: \({T}_{{\rm{ch}}}={T}_{{\rm{mel}}}+{c}_{1}\Delta P\). c1 is a constant coefficient. Similarly, we found a linear relationship between the ambient temperature and platform temperature (Fig. 2f): \({T}_{{\rm{ch}}}={T}_{{\rm{mel}}}+{c}_{2}\Delta {T}_{{\rm{pla}}}+{c}_{3}\Delta {T}_{{\rm{amb}}}\), where c2 and c3 are constant coefficients. This is consistent with the theoretical model.

Traceability link and calibration method

Based on the above mechanism, we propose two traceability links and corresponding implementation methods to address the different cases of in-orbit calibration. Figure 3a shows the space benchmark traceability link. The characteristic temperature at which the phase transition of the Hg, Ga, and H2O points can be precisely completed at low power is used as a reference, according to the ITS-90 international temperature scale definition. The temperature values are transferred to the infrared remote sensor via the temperature sensors and blackbody radiation source. This method is directly traceable to the SI. A more convenient spaceborne blackbody calibration link is shown in Fig. 3b. The characteristic temperature for a given operating condition is determined from the standard temperature sensors traceable to the national benchmark (ground-based). The temperature sensors are interpolated and calibrated to obtain the exact temperature of the blackbody radiation source, depending on good reproducibility of the MFPs, and this value is then transferred to the infrared remote sensor. This method enables a higher input heat source to be used to obtain a shorter phase change/calibration period than the previous method. Notably, here, the characteristic temperature is used as a weight after being accurately measured and not as a defined value.

The complete temperature traceability process includes a ground test and on-orbit calibration (Fig. 3c). The blackbody emissivity ε and brightness temperature L are measured before launch, the characteristic temperature Tch,i during the blackbody phase transition is determined using the high-precision temperature sensors, and the working conditions are determined. After launch, the blackbody with MPCCs is heated for the phase transition under the same thermal working conditions to reproduce the characteristic temperatures Tch,i at the known temperatures. Then, the temperature reference points g (Ti) are interpolated and assigned to the temperature sensors f (Ri) to be calibrated to achieve temperature self-calibration. Finally, the quantitative relationship between the space infrared remote sensor response signal DN and the infrared radiation energy L is determined from the temperature-traceable and emissivity known blackbody radiation source. Calibration of the thermal infrared spectrum of the remote sensor is completed. In particular, the in-orbit traceability of the blackbody emissivity can also be accomplished by the thermal loop method 55,56.

Microscale melting properties and reliability verification

An important task is to develop more continuous and denser primary (secondary) MFPs within the possible application interval. Ga and Hg have a purity of 7 N as materials of the MFP, as shown in Fig. 4a, b. In the miniature hermetic structure, a 3.2% volume expansion occurred during the transition from the liquid‒solid phase. Approximately 15% of the inert gas space was reserved during the filling process to handle the pressure change in the sealed fixed volume cavity due to the change in the material phase state. A temperature correction of 0.1 mK was obtained according to the Ga melting pressure correction equation. Experiments showed that the characteristic temperature converged to the international temperature scale defined value with reduced heating power, which are 302.92 K and 234.32 K. Figure 4c, d show the phase transition curves for the inorganic material H2O and the organic material PS as MFPs with characteristic temperature of 273.18 K and 316.01 K, respectively. However, the plateau conductivity and smoothness were relatively poor due to crystal structure constraints.

Phase transition curves and characteristic temperature of a gallium (Ga), b hydrargyrum (Hg), c water (H2O), d phenyl salicylate (PS), e gallium indium (Ga-In), f gallium stannum (Ga-Sn), g gallium zinc (Ga-Zn) and h bismuth - indium - stannum (Bi-In-Sn). i Repeatability statistics. j Long-term stability tests of miniature fixed points conducted from 2015 to 2023. k Characteristic temperature changes after the vibration test are compared with those before the vibration test at the Ga point. l Characteristic temperature changes after the vibration test are compared with those before the vibration test at the Ga-In point. m Correction of radiant brightness temperature changes with a two-year interval.

As a supplement, the low melting point of the multi-element eutectic alloy is more suitable for the temperature requirements of the earth observation, due to the good binding ability of the metal and the instability of the alloy lattice distortion. Figure 4e, f, g show the phase transition curves of a gallium-based binary eutectic alloy as MFPs. It consisted of a eutectic system of the main metal (>80%) and a small amount of dopant metal (<20%). Different melting points were shown, and sufficient stability was maintained depending on the type of dopant metal. In this work, the secondary doping ratios of Ga-In, Ga-Sn and Ga-Zn were 19.5%, 16.4% and 4.2%, respectively. The characteristic temperatures were 288.71 K, 293.66 K and 298.35 K, respectively, and their melting curves showed a single flat plateau (drift <10 mK) similar to that of the Ga metals; On this basis, we developed Bi-In-Sn ternary alloys with a melting point of 345.03 K (Fig. 4h). A 73 mK plateau shift was shown, attributed to offset the solidification, i.e., liquid ternary eutectic during solidification. Solute redistribution occurred during solidification, and the discrete, well-separated nonequilibrium lattice transformed to an equilibrium lattice structure during melting, resulting in melting point temperature segregation.

At present, we have developed eight MFPs with different melting points, including Ga, Hg, H2O, PS Ga-In, Ga-Sn, Ga-Zn and Bi-In-Sn, covering the temperature range of 234 K to 345 K (Supplementary Table 1). The repeatability of those MFPs was 2.41 mK, 3.59 mK, 5.95 mK, 1.34 mK, 1.92 mK, 2.08 mK, 1.23 mK and 4.59 mK, respectively. Depending on the observation requirements and loading conditions, the MFPs desired were selected for in-orbit calibration. Under the input of an external heat source, MPCCs with different melting points were completely and sequentially melted as the blackbody temperature increased (Fig. 1d), and the phase transition characteristics were transferred to the temperature sensors for multi-point interpolation calibration.

The reproducibility of the characteristic temperature is central to the calibration technique. A 9-year-long (2015–2024) experiment with a total of 55 phase change replications was performed on the ground using a vacuum simulation device (Supplementary Fig. 5)57, as shown in Fig. 4j. The experimental setup consisted of a 302.89 K circulating bath to provide a stable ambient temperature, a vacuum dewar chamber placed in the bath to simulate a vacuum environment, and a blackbody containing MPCCs heated with 0.008 W constant power for the phase transitions. The data showed that the MFP had good long-term stability and could be used for in-orbit calibration on large time scales. The range of variation remained within 14.0 mK with a standard deviation better than 3.2 mK over the 9-year period. A general upward bias trend of 9.0 mK from 2015–2021 was hidden in the random behavior of the characteristic transfer. After we calibrated and replaced the internal ageing components at the end of 2021, the characteristic temperature values returned to their original interval.

Vibration tests were conducted to investigate the effect of high-frequency oscillation and mechanical shock on the characteristic temperature reproduction. The characteristic temperature changes before and after vibration are shown in Fig. 4k, i. The characteristic temperature recorded at the Ga point and Ga-In point changed on average 4.8 mK and 9.6 mK, respectively, compared to those before the vibration test. The behavior could potentially originate from the mechanical shock-induced temperature sensor drift, blackbody cavity-induced thermal conductivity changes, measurement errors, or the small immobile points themselves.

Figure 4m shows the correction of radiance brightness temperature changes with a 2-year interval, where the measurements were obtained using the comparison method. The results demonstrate that, following temperature correction, the radiant brightness temperature changes were 9.9 mK, 12.4 mK, and 3.4 mK for temperatures of 281 K, 290 K, and 313 K respectively.

According to the uncertainty evaluation method, the main contributions of uncertainty sources of the Ga point were summarized as the factors of repeatability (u1), long-term stability (u2), vibration reproducibility (u3), measurement instrument (u4), and thermometer uncertainty (u5). The combined standard uncertainty was 8.1 mK (k = 1) based on the calculation method (Table 1):

Spatial replication and noise fluctuation

We designed and launched a spaceborne blackbody prototype carrying MPCCs for demonstration experiments. Figure 5a shows the in-orbit phase change reproduction test site. The spaceborne blackbody is mounted on a constant temperature platform at approximately 283.3 K via insulated housing. Here, we used an external heat source input of 4.1 W to meet a faster calibration time with a phase transition duration of ~3.1 h. The phase change curves and characteristic temperature statistics are shown in Fig. 5b, e. The three-time repeatability was better than 9.1 mK. The average variation in the characteristic temperature was 7.4 mK compared to the ground test, and the maximum temperature change was within 14.2 mK (Comparison of phase change curves is shown in Supplementary Fig. 6). This result was basically consistent with the vibration test results in order of magnitude; specifically, it mainly originated from the measurement error caused by the involvement of the temperature sensor itself in vibration attenuation.

a In-orbit phase change reproduction test site. b In-orbit reproducible results. c Phase transition curves versus experimental platform temperature. d Phase transition curve after removing the interference of orbital environment fluctuations. e Characteristic temperature statistics of in-orbit. f Characteristic temperature statistics using orbital fluctuation interference elimination method. g Characteristic temperature statistics using period mean method.

Spatial noise disturbances needed to be accounted for in the millikelvin magnitude in-orbit traceability. An anomalous fluctuation of the phase transition plateau was observed during on-orbit replication (Fig. 5c). Periodic fluctuations with consistent peak/valley positions also occurred in the experimental platform. Its temperature fluctuation period was ~1.70 h, which was the same as the orbital period, and the fluctuations ranged from 0.15 to 0.18 K. In summary, this case was potentially caused by the external heat flow variation from solar irradiation during the motion of the dawn-dusk orbital cycles. The phase change curves after stripping the space noise interference using the orbital fluctuation interference elimination method were as follows (Fig. 5d):\({T}_{{\rm{cor}}}={T}_{{\rm{bb}}}-{c}_{1}\Delta P-{c}_{2}\Delta {T}_{{\rm{amb}}}-{c}_{3}\Delta {T}_{{\rm{pla}}}\), where Tcor is the corrected phase change temperature of the spaceborne blackbody. The smoothness was significantly improved compared to the original results. The corrected characteristic temperature is shown in Fig. 5f. Its reproducibility was 10.5 mK, and the maximum variation in the characteristic temperature was 7.0 mK. Another effective approach is the periodic mean method (Supplementary Fig. 7). Specifically, the average temperature of the phase transition plateau from the phase transition inflection point to half or one orbital cycle time was used as the characteristic temperature. A reproducibility of 2.3 mK is obtained using this method (Fig. 5g).

Discussion

In summary, we demonstrated the latest generation of spaceborne blackbody calibration technology based on MFPs. The spatial metric of the radiation source temperature parameter was achieved by reproducing the known characteristic temperature during near-site transfer of the MFPs. In our study, the traceability principle was highlighted. The near-site transfer mechanism under multiphysics field coupling was determined by numerical and experimental methods, and the spaceborne blackbody calibration method traceable to SI was proposed. Depending on the melting behavior at the microscale, eight MFPs with better than 6.0 mK repeatability were developed; these included Ga, Hg, H2O, PS, Ga-In, Ga-Sn, Ga-Zn, and Bi-In-Sn, covering the temperature range of 234–345 K. The reliable characteristic temperature depended on the solid thermodynamic transfer properties with the thermodynamic stability of the solid‒liquid phase state. The 3.2 mK long-term stability tests and less than 9.6 mK vibration reproducibility demonstrated the reliability of the technique. Finally, in-orbit experiments successfully demonstrated the feasibility of the technique, with statistics showing typical consistent behavior. In particular, the external heat flow from the orbit disturbed the phase transition curve to some extent, and a method was proposed for the corresponding spatial noise suppression.

This research, as the core technology of the Chinese Space-based Radiometric Benchmark, addresses the key problem of high quantification of infrared remote sensing load and responds to the requirements of the World Meteorological Organization (WMO) for the observation accuracy and stability of climate monitoring system. This technology can provide important technical support and reference for the new generation of in-orbit radiometric calibration, which is anticipated to become the space benchmark for infrared observations in the future.

Materials and methods

Material configuration and MPCC perfusion

Prior to perfusion, the crucibles and caps were soaked in alcohol of 99% purity for ~2 h and then cleaned 2 to 3 times by an ultrasonic cleaner at 28 kHz. PCM perfusion was performed under the argon gas protection system (Supplementary Fig. 8). The mass of the high purity PCM (Supplementary Fig. 9) was initially weighed using the electronic balance scale according to the component ratio, and then the known weight of the metal particles was mixed and gradually introduced into the crucible in a heated state. Notably, for the filling of H2O points, the steam filling method was used (Supplementary Fig. 9c). Finally, the caps were sealed with a 3000 W high-power laser weld. After, bonding pads were scanned by an electron microscope and checked (Supplementary Fig. 10) for leaks by three rounds of vacuum melting to ensure the seal.

Vacuum radiance temperature standard facility

The main tests were conducted at the Vacuum Radiance Temperature Standard Facility established by the National Institute of Metrology, China (Supplementary Fig. 11)58. The system included a vacuum chamber, an optical system, and a temperature control and measurement system. The vacuum chamber was composed of a cabin body, liquid nitrogen circulating cooling system and vacuum system to simulate the space environment. The temperature control and measurement system mainly included platinum resistance thermometers, a Fluke 1595A temperature bridge, a Eurotherm EPC3004 temperature control metre, heating films, an E3633A voltage-stabilized DC source, an IT6932B power supply, a water-cooling plate and a thermostatic bath. The platinum resistance thermometers were provided by the medium-temperature standard laboratory at the National Institute of Metrology, China, and were directly traceable to the medium-temperature standard. The uncertainty was within 5.0 mK after calibration.

The test environment was as follows:

Vacuum degree: 2.5 × 10-4 ~ 5.0×10-4 Pa

Vacuum chamber temperature: 293 K ~ 294 K

Test bench temperature: 283.15 K

Vibration impact test

Vibration tests were conducted on the spaceborne blackbody to verify its mechanical and thermal reliability. The tests were conducted on a vibration shock metre (Supplementary Fig. 12), and the test scenario is shown in Supplementary Table 2 and Supplementary Table 3. It included a periodic sinusoidal sweep vibration in the range from 5 Hz to 100 Hz on the single/double axles and a random vibration from 20 to 2000 Hz on the X, Y, Z triaxial axis.

Phase change characteristic test

The phase transition experimental steps are mainly divided into three parts; by using the Ga point as an example, the parts are as follows: (1) Freeze. The liquid gallium metal has a supercooling effect. Therefore, it is necessary to control the test bench by a thermostatic bath to keep the spaceborne blackbody at a temperature well below the melting point. This state is maintained for ~10 h to ensure that the PCM is completely solidified. (2) Stable initial temperature before the phase change. First, the EPC3004 temperature control metre and IT6932B power supply are used to maintain the blackbody cavity temperature at 302 K and record the output power of the power supply when the blackbody temperature is stable. Then, the power is switched to the E3633A voltage-stabilized DC source, and the output power is kept constant. (3) Heating and phase change. After the temperature of the blackbody cavity is stabilized, a certain power is added on the basis of the original output power to complete the phase change. The data are collected and recorded by a Fluke 1595 A temperature bridge.

Radiance temperature test

Fourier transform spectrometer and standard blackbody (190–340 K) are used as a set of infrared brightness temperature standard transfer system to measure the brightness temperature of the spaceborne blackbody. In the experiment, the temperature of the spaceborne blackbody and the standard blackbody is controlled at target temperature and the actual temperature is monitored by internal temperature sensors. By adjusting the rotating mirror, Fourier transform spectrometer is used to measure the radiation signals of standard blackbody, spaceborne blackbody and liquid nitrogen blackbody (As background signal). The ratios of the two are obtained using OPUS spectral processing software. The data processing equation which is based on the Planck’s law is established to calculate the brightness temperature by ten groups of measurement results.

On-board loading and in-orbit testing

The blackbody is fixed on a metal platform by the heat insulating blocks with baffles and an infrared hyperspectral atmospheric sounder on each side. The entire system is wrapped with multiple layers of thermal insulation, with the cavity opening facing the rotating shaft mirror. The radiation calibration stage is controlled by a PID thermostat, and the self-calibration stage used a 4.1 W constant power heating mode, driving the power supply at 1000 Hz and 25% duty cycle. The metal platform is thermostatically controlled at ~283 K.

Data availability

The data that supports the findings of this study are available on Science DB (Data DOI: 10.57760/sciencedb.21286).

References

Fuldauer, L. I., Thacker, S. & Haggis, R. A. et al. Targeting climate adaptation to safeguard and advance the Sustainable Development Goals. Nat. Commun. 13, 3579 (2022).

Guy, J., Shears, E. & Meckling, J. National models of climate governance among major emitters. Nat. Clim. Chang. 13, 189–195 (2023).

Saintilan, N., Horton, B. & Törnqvist, T. E. et al. Widespread retreat of coastal habitat is likely at warming levels above 1.5 °C. Nature 621, 112–119 (2023).

Esperon-Rodriguez, M., Tjoelker, M. G. & Lenoir, J. et al. Climate change increases global risk to urban forests. Nat. Clim. Chang. 12, 950–955 (2022).

Kang, S. M., Ceppi, P. & Yu, Y. et al. Recent global climate feedback controlled by Southern Ocean cooling. Nat. Geosci. 16, 775–780 (2023).

Christian, J. I., Martin, E. R. & Basara, J. B. et al. Global projections of flash drought show increased risk in a warming climate. Commun. Earth Environ. 4, 165 (2023).

Hakuba, M. Z. et al. Earth’s energy imbalance measured from space. IEEE T. Geosci. Remote 57, 32–45 (2019).

Leroy, S., Anderson, J. G. & Ohring, G. Climate signal detection times and constraints on climate benchmark accuracy requirements. J. Climate 21, 841–8464 (2008).

Liu, X., Wu, W. & Wielicki, B. A. et al. Spectrally dependent CLARREO infrared spectrometer calibration requirement for climate change detection. J. Climate 30, 3979–3998 (2017).

Wielicki, B. A., Young, D. F. & Mlynczak, M. G. et al. Achieving climate change absolute accuracy in orbit. B. Am. Meteorol. Soc. 94, 1519–1539 (2013).

Latif, M., Sun, J. & Visbeck, M. et al. Natural variability has dominated Atlantic Meridional Overturning Circulation since 1900. Nat. Clim. Chang. 12, 455–460 (2022).

George, O., Joe, T., William E., et al. Achieving satellite instrument calibration for climate change, Eos Transactions American Geophysical Union. https://doi.org/10.1029/2007eo110015 (2007).

Power, S. et al. Decadal climate variability in the tropical Pacific: characteristics, causes, predictability, and prospects. Science 374. https://doi.org/10.1126/science.aay9165. (2021).

Fox, N., Green, P. Traceable radiometry underpinning terrestrial- and helio-studies (TRUTHS): an element of a space-based climate and calibration observatory. Remote Sens. 2400 (2020).

Mitta, J., Merchant, C. J. & Woolliams, E. R. Applying principles of metrology to historical Earth observations from satellites. Metrologia 56, 032002 (2019).

Andrew W., Michel J. Measurement Challenges for Global Observation Systems for Climate Change Monitoring (World Meteorological Organization 2010).

Seidel, D. J., Berger, F. H. & Immler, F. et al. Reference upper-air observations for climate: rationale, progress, and plan. Bull. Am. Meteorol. Soc. 90, 361–369 (2009).

Niro, F., Goryl, P. & Dransfeld, S. et al. European Space Agency (ESA) calibration/validation strategy for optical land-imaging satellites and pathway towards interoperability. Remote Sens. 13, 3003 (2021).

Sapritsky, V. I. Metrological support for climatic time series of satellite radiometric data. J. Appl. Remote Sens. 3, 033506 (2009).

Mlynczak M. G., Daniels T., Hunt L. A., et al. Radiometric stability of the SABER instrument. Earth Space. Sci. 7. https://doi.org/10.1029/2019ea001011 (2020).

Helder, D., Doelling, D. & Bhatt, R. et al. Calibrating geosynchronous and polar orbiting satellites: sharing best practices. Remote Sens. 12, 2786 (2020).

Ohring, G., Wielicki, B. & Spencer, R. et al. Satellite instrument calibration for measuring global climate change: report of a workshop. Bull. Am. Meteorol. Soc. 86, 1303–1314 (2005).

French, W. J. R. & Mulligan, F. J. Stability of temperatures from TIMED/SABER v1.07 (2002–2009) and Aura/MLS v2.2 (2004–2009) compared with OH(6-2) temperatures observed at Davis Station, Antarctica. Atmos. Chem. Phys. 10, 11439–11446 (2010).

Matthews, G. NASA CERES spurious calibration drifts corrected by lunar scans to show the sun is not increasing global warming and allow immediate CRF detection. Geophys. Res. Lett. 48. https://doi.org/10.1029/2021gl092994 (2021).

Gorroño, J., Banks, A. C., Fox, N. P. & Underwood, C. Radiometric inter-sensor cross-calibration uncertainty using a traceable high accuracy reference hyperspectral imager. ISPRS J. Photogramm. 130, 393–417 (2017).

Franks, S., Neigh, C. & Campbell, P. et al. EO-1 data quality and sensor stability with changing orbital precession at the end of a 16 year mission. Remote Sens. 9, 412 (2017).

Xiong, X. & Butler, J. J. MODIS and VIIRS calibration history and future outlook.Remote Sens. 12, 2523 (2020).

Xiong, X., Aisheng, W. & Wenny, B. N. et al. Terra and aqua MODIS thermal emissive bands on-orbit calibration and performance. IEEE Trans. Geosci. Remote 53, 5709–5721 (2015).

Dowell, M., Lecomte, P., Husband, R. et al. Strategy towards an architecture for climate monitoring from space. In Proc. the sixteenth World Meteorological Congress (2013).

Berg, W., Brown, S. T. & Lim, B. H. et al. Calibration and validation of the TEMPEST-D CubeSat radiometer. IEEE T. Geosci. Remote 59, 4904–4914 (2021).

Montanaro, M., Levy, R. & Markham, B. On-orbit radiometric performance of the Landsat 8 thermal infrared sensor. Remote Sens. 6, 11753–11769 (2014).

Wen, J., Wu, X. & Xiao, Q. et al. Full-band, multi-angle, multi-scale, and temporal dynamic field spectral measurements in China. Sci. Data 10, 353 (2023).

Xie, C., Zhang, X. & Zhuang, L. et al. Analysis of surface temperature variation of lakes in China using MODIS land surface temperature data. Sci. Rep. 12, 2415 (2022).

Peng, M., Xie, R., Wang, Z., et al. Blackbody-sensitive room-temperature infrared photodetectors based on low-dimensional tellurium grown by chemical vapor deposition. Sci. adv. 7. https://doi.org/10.1126/sciadv.abf7358 (2021).

Jiao, H., Wang, X. & Chen, Y. et al. HgCdTe/black phosphorus van der Waals heterojunction for high-performance polarization-sensitive midwave infrared photodetector. Sci. adv. 8, 1811 (2022).

Shukla, M. V. & Thapliyal, P. K. Development of a methodology to generate in-orbit electrooptical module temperature-based calibration coefficients for INSAT-3D/3DR infrared imager channels. IEEE T. Geosci. Remote 59, 240–246 (2020).

Pagano, T. S., Aumann, H. H. & Broberg, S. E. et al. SI-traceability and measurement uncertainty of the atmospheric infrared sounder version 5 level 1B radiances. Remote Sens.-Basel. 12, 1338 (2020).

Fox, N., Kaiser-Weiss, A. & Schmutz, W. et al. Accurate radiometry from space: an essential tool for climate studies. Philos. Trans. R. Soc. A: Math. Phys. Eng. Sci. Med. 369, 4028–4063 (2011).

Zhao, W. N., Fang, W. & Sun, L. W. et al. Calibration chain design based on integrating sphere transfer radiometer for SI-traceable on-orbit spectral radiometric calibration and its uncertainty analysis. Chinese Phys. B 25, 090701 (2016).

Best, F. A., Adler, D. P., Pettersen, C. et al. Results from recent vacuum testing of an on-orbit absolute radiance standard (OARS) intended for the next generation of infrared remote sensing instruments. Proc. SPIE, Multispectral, Hyperspectral, and Ultraspectral Remote Sensing Technology, Techniques and Applications V. https://doi.org/10.1117/12.2069338 (2014).

Ye, X., Yi, X. & Lin, C. et al. Instrument development: Chinese radiometric benchmark of reflected solar band based on space cryogenic absolute radiometer. Remote Sens.-Basel. 12, 2856 (2020).

Zhang, P., Lu, N. & Li, C. et al. Development of the Chinese space-based radiometric benchmark mission LIBRA. Remote Sens.-Basel. 12, 2179 (2020).

Swartz, W. H., Dyrud, L. P. Lorentz, S. R., et al. The RAVAN CubeSat mission: advancing technologies for climate observation. In Proc. IEEE International Geoscience and Remote Sensing Symposium (IGARSS) https://doi.org/10.1109/igarss.2015.7327031 (IEEE, 2015).

Immler, F. J., Dykema, J., Gardiner, T. et al. Reference quality upper-air measurements: guidance for developing GRUAN data products. Atmos. Meas. Tech. 1217–1231. https://doi.org/10.5194/amt-3-1217-2010 (2010).

Datla, R. V., Kessel, R. & Smith, A. W. et al. Review Article: Uncertainty analysis of remote sensing optical sensor data: guiding principles to achieve metrological consistency. Int. J. Remote Sens. 31, 867–880 (2010).

Madhavan, S., Xiong, X. & Wu, A. et al. Noise characterization and performance of MODIS thermal emissive bands. IEEE T. Geosci. Remote 54, 3221–3234 (2016).

Madhavan, S., Sun, J. & Xiong, X. Sensor calibration impacts on dust detection based on MODIS and VIIRS thermal emissive bands. Adv. Space Res. 67, 3059–3071 (2021).

Xiong, X., Wu, A., Chang, T., et al. On-orbit calibration and performance assessments of Terra and Aqua MODIS thermal emissive bands. J. Appl. Remote Sens. 15, https://doi.org/10.1117/1.jrs.15.014520 (2021).

Mlynczak, M. G., Daniels, T., Hunt, L. A. et al. Radiometric stability of the SABER instrument. Earth Space Sci. 7, https://doi.org/10.1029/2019ea001011 (2020).

Matthews, G. First decadal lunar results from the Moon and Earth Radiation Budget Experiment. Appl. Optics 57, 1594 (2018).

Madhavan, S., Sun, J. & Xiong, X. Sensor calibration impacts on dust detection based on MODIS and VIIRS thermal emissive bands. Adv. Space Res. 3059–3071 https://doi.org/10.1364/ao.57.001594 (2021).

Taylor, J. K., Revercomb, H. E. & Best, F. A. et al. The Infrared Absolute Radiance Interferometer (ARI) for CLARREO. Remote Sens. 12, 1915 (2020).

Hao, X. P., Sun, J. P., Xu, C. Y. et al. Miniature fixed points as temperature standards for in situ calibration of temperature sensors. Int. J. Thermophys. https://doi.org/10.1007/s10765-017-2223-9 (2017).

Sima R. H., Hao X. P., Song J. et al. Research on the temperature transfer relationship between miniature fixed-point and blackbody for on-orbit infrared remote sensor calibration. IEEE Trans. Geosci. Remote, 6266–6276 https://doi.org/10.1109/tgrs.2020.3023455 (2021).

Song, J., Hao, X. P., Yuan, Z. D. et al. Research of ultra-black coating emissivity based on a controlling the surrounding radiation method. Int. J. Thermophys. 39. https://doi.org/10.1007/s10765-018-2404-1 (2018).

Gero, P. J., Taylor, J. K. & Best, F. A. et al. On-orbit absolute blackbody emissivity determination using the heated halo method. Metrologia 49, S1–S8 (2012).

Hao X. P., Sima R. H., Liu Y. et al. Experimental research on the temperature characterization of a miniature phase change cells in the blackbody for the on-orbit radiometric calibration of thermal infrared sensors. IEEE Trans. Geosci. Remote, 1–8 (2022).

Hao, X. P., Song, J., Xu, M. et al. Vacuum radiance-temperature standard facility for infrared remote sensing at NIM. Int. J. Thermophys. 39. https://doi.org/10.1007/s10765-018-2396-x (2018).

Acknowledgements

This work was supported by National Key R & D Program of China (2023YFB3905402, 2022YFF0610800), National Natural Science Foundation of China (No. 12075229) and National Science Fund for Distinguished Young Scholars (No. 62425506).

Author information

Authors and Affiliations

Contributions

R.S., X.H., M.G., and L.D. conceived and designed research this project. R.S., J.S., L.L. and J.Z. performed experiments and collected data. R.S. wrote the manuscript. X.H. and H.Q. added selected paragraphs and corrected the content of the manuscript. All the authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Engineering thanks Dilip Shivagan, Abdallah M. Karmalawi, and the other, anonymous, reviewer for their contribution to the peer review of this work. Primary Handling Editors: [Anastasiia Vasylchenkova and Rosamund Daw]. Peer review reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sima, R., Hao, X., Song, J. et al. Space temperature traceability based on near-site transfer of miniature fixed points. Commun Eng 4, 83 (2025). https://doi.org/10.1038/s44172-025-00419-0

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44172-025-00419-0