Abstract

Soft robotic fish have garnered attention for their compliance and adaptability. However, they remain vulnerable to mechanical damage, which limits their reliability. To address this vulnerability, we introduce a bio-inspired rigid–flexible coupled skin–scales system (BIS). The BIS integrates rigid scales with a flexible silicone substrate through a multi-stage molding process to enhance protection. Static compression tests demonstrate across five elastomers that the BIS enhances energy absorption capacity by at least 2.1 times compared to the purely flexible structure (PFS, silicone skin without scales). In robotic fish underwater experiments, BIS exhibits a tail-beat amplitude deviation of <10% relative to PFS and achieves 12.8 cm/s, retaining 87% of PFS’s peak speed. In addition, fluid dynamics simulations show BIS incurs only a minor drag in low-speed flow. By balancing protection and amplitude response, this research provides a practical approach for enhancing soft robotic fish in demanding aquatic environments.

Similar content being viewed by others

Introduction

Soft robotics has emerged as a significant field in robot research, recognized for its intrinsic compliance, adaptability, and capacity to interact safely with complex environments1,2,3,4,5,6. These qualities make soft robotics particularly suited for underwater applications such as exploration, environmental monitoring, and search-and-rescue missions7,8,9, where silent operation and the ability to passively deform in response to hydrodynamic forces are critical. In contrast to rigid robots, soft robots excel in navigating unstructured terrains. They are capable of executing complex maneuvers while minimizing environmental disturbances10,11,12,13,14,15. However, despite their advantages, soft robots often lack adequate mechanical protection, leaving them vulnerable to damage from abrasions, punctures, and underwater predators. Such vulnerability restricts their use in challenging aquatic environments, highlighting the urgent need for innovative design strategies that improve durability without compromising flexibility16,17,18.

Bio-inspired design principles offer effective solutions to these challenges. Fish scale-skin systems are particularly notable for their ability to balance flexibility with mechanical protection among natural protective mechanisms19. The hierarchical arrangement of interlocked rigid scales and soft tissues allows for efficient stress distribution20, energy dissipation21, and resistance to mechanical damage22. These natural mechanisms enable fish to endure abrasive conditions and predator attacks while maintaining mobility. These features, including crack deflection23, strain hardening24, and microcracking25, underpin their protective capabilities. Recent studies have demonstrated the utility of fish scale-inspired designs in applications ranging from body armor to static protective materials26,27,28,29,30,31. However, integrating rigid elements into soft, deformable structures without compromising amplitude response remains challenging. As a result, these designs have primarily focused on planar surfaces or static systems, leaving their potential for dynamic, mobile robotic platforms largely unexplored.

Bridging the gap between compliance and mechanical protection in soft robotic fish requires overcoming challenges, particularly in embedding rigid protective elements into flexible substrates on curved surfaces, without sacrificing amplitude response32,33,34,35. Existing strategies for planar surfaces are inadequate for soft robots, which often feature complex geometries and require seamless integration of protective and flexible components36,37,38. To address these challenges, we propose a bio-inspired rigid-flexible coupled skin-scales system tailored for underwater soft robotic fish. This system combines rigid polypropylene (PP) scales and a soft silicone rubber substrate, emulating the hierarchical protection observed in fish scales while maintaining structural compliance with curved geometries. Integrating this system into a tendon-driven robotic fish creates a functional platform to evaluate its effectiveness in underwater locomotion, we aim to achieve the balance between structural integrity and flexibility observed in natural fish locomotion.

In this work, we introduce the design, fabrication, and evaluation of the proposed bio-inspired rigid-flexible coupled skin-scales system. Advanced manufacturing techniques, including laser cutting and multi-stage molding, were employed to achieve precise embedding and alignment of rigid scales within the flexible substrate. Experimental assessments demonstrated significant improvements in mechanical protection while preserving mobility and maintaining minimal changes in fluid resistance during underwater locomotion, thereby confirming the effectiveness of the hierarchical design. These findings provide a scalable framework for developing durable and adaptive underwater soft robots, enabling the integration of protection, flexibility, and functionality in harsh aquatic environments.

Results

Bio-inspired skin-scales system for robotic fish

The bio-inspired skin-scales system (BIS) was developed to emulate the hierarchical protective mechanisms found in common carp (Cyprinus carpio). These fish possess a multi-layered system. It consists of a protective scale layer, an underlying epidermis, and a dermis. This system protects the deeper muscle structures and other internal organs. At the outermost layer, the scales act as a primary shield against external forces. These thin, overlapping scales are partially exposed to balance flexibility and protection. Beneath the scales, the epidermis and dermis function as barriers that minimize damage, maintain homeostasis, and regulate environmental interactions. The dermis contains fibrous tissue that anchors the scales and prevents excessive detachment, while the underlying muscles generate oscillatory motion for swimming (Fig. 1a).

a Fish structure and the construction of the skin-scales system. The skin-scales system in fish typically consists of scales, epidermis, and dermis. This system covers the muscle and provides protection to the fish. b Fish scale’s shape and bionic designed scale (see Supplementary Fig. S2 for the detailed dimensions). c The coupling methodology of bio-inspired skin-scales system with/without pre-drilled holes. d The bio-inspired (BI) design in robotic fish. It includes a BI tendon inspired by muscle to drive the robotic fish, BI scales inspired by both the arrangement and shapes of natural fish scales, and BI skin inspired by the functional properties of epidermis and dermis in fish.

Drawing upon the hierarchical protective mechanisms of common carp, our bio-inspired skin-scales system (BIS) incorporates rigid PP (MSPP-006) scales, which replicate the morphology of fish scales, into a soft silicone rubber substrate (Ecoflex 00-10, Smooth-On). This substrate provides flexibility and surface protection, resembling the functions of the epidermis and dermis. To enhance mechanical interlocking between the rigid scales and the flexible substrate, each scale features two pre-drilled holes at the proximal end. This design facilitates strong mechanical coupling during molding and curing, ensuring stability under dynamic loading conditions. To validate this approach, we integrated the BIS into a tendon-driven robotic fish, which simulates muscle layers through tension-driven motion. Figure 1c illustrates the assembly of the BIS on the robotic platform.

Each scale was designed based on the geometric characteristics of fish scales and simplified to facilitate fabrication. The slightly curved shape of the scales further enhances mechanical interlocking with the silicone rubber matrix during molding (Fig. 1b). Upon pouring and curing of the silicone rubber, strong mechanical interlocks are formed, securely embedding the rigid scales within the soft substrate. This design ensures stability and functionality under dynamic loading conditions (Fig. 1d).

The BIS is composed of two materials: laser-cut PP scales and a molded silicone rubber substrate (see Methods for the detailed materials selection, design, and fabrication). The flexible fish body is 3D-printed using thermoplastic polyurethane elastomer (TPU 95A-HF, BambuLab; see Supplementary Fig. S4 for structure). The scale arrangement of BIS is inspired by the stacking pattern of cycloid scales on the surface of Cyprinus carpio (as depicted in Fig. 1a). By modulating the thickness of TPU at selected points, flexible hinges are introduced at points requiring rotational motion, while wider sections provide structural stability for the BIS. Laser-cut PP is also used for the tail fin, while additional components, including the pectoral fins, dorsal fin, and head shell, are 3D-printed using polylactic acid (PLA Basic, BambuLab). Both TPU and PLA were printed by a 3D printer (P1S, BambuLab).

Mechanical protective performance of the skin-scales system

To evaluate the mechanical protective performance of the bio-inspired skin-scales system (BIS) compared to a purely flexible structure (PFS) (the PFS uses the same substrate as the BIS but lacks scales, with its structure provided in Supplementary Fig. S4), we conducted static compression tests using a 3 mm cylindrical impactor mounted on a universal testing machine (ZQ-990A, Zhiqu), operated at a constant crosshead speed of 1 mm/s. All tests were performed at room temperature, with five repetitions for both BIS and PFS to ensure data reliability.

To characterize the mechanical response comprehensively, deformation-applied force curves were acquired by recording applied force-deformation data starting at initial specimen-impactor contact (i.e., when the applied force exceeded zero), with data collection focused on the 0.5–4.5 s interval to mitigate transient effects from the impactor’s approach (results depicted in Fig. 2b). As for deformation-applied force data collecting, due to mechanical constraints imposed by the robotic fish’s internal skeleton (detailed in Supplementary Fig. S4), tests were terminated at a maximum deformation of 11 mm to prevent structural interference with underlying components. Preliminary trials revealed that a deformation of 11 mm corresponded to an applied force of ~1 N, prompting us to restrict the force range to 0.2–0.9 N (results depicted in Fig. 2c).

a Experimental setup for mechanical protection performance test. b Applied forces required to achieve the same level of deformation in BIS and PFS, with deformation ranging from 0.5 mm to 4.5 mm. c Deformation response of BIS and PFS under the same applied force ranging from 0.2 N to 0.9 N. All experimental data were collected in multiple sets, and the average value of these data was taken as the final experimental result. To assess the data reliability, error analysis was conducted using the standard deviation, and the error bars in the figures represent the standard deviation values, providing a visual indication of the data variability. This approach of data processing was consistently applied to all subsequent experiments.

Figure 2b, c demonstrates that the BIS significantly reduces deformation and enhances load-bearing capacity compared to the PFS (all relevant data are provided in Supplementary Tables S2, S3). To further validate the mechanical protective performance of the BIS across different materials, we extracted small specimens from the mid-body sections of the robotic fish equipped with BIS and PFS (as shown in Fig. 3a), extending our analysis beyond the initial Ecoflex 00-10 substrate to include four additional materials: Ecoflex 00-30, Ecoflex 00-50, Dragon Skin 20, and Dragon Skin 30. For each material, one BIS specimen and one PFS specimen were fabricated. The specimens were clamped using custom-designed supports and fixtures without internal hinge structures (specimen and auxiliary structures shown in Fig. 3b), ensuring uniform mechanical boundary conditions.

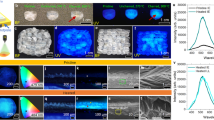

a Sections cut from the mid-body of robotic fish, retaining the mounts and distribution of scales. b The structure of specimen used in this test, including a supporter, two side clampers and one bottom clamper (these parts are prepared by using PLA). The specimen is placed on the supporter and then clamped by three clamps to ensure its fixation. c The range of load applied on specimen (both 3 mm and 10 mm impactor on BIS and PFS). The Deformation-applied force curves of PFS and BIS made from Ecoflex 00-10 (d), Ecoflex 00-30 (e), Ecoflex 00-50 (f), Dragon Skin 20 (g), and Dragon Skin 30 (h) with 3 mm and 10 mm impactors. i Comparative analysis of energy absorption capacity for BIS and PFS across all materials.

Static compression tests were conducted at room temperature using 3 mm and 10 mm cylindrical impactors (load range depicted in Fig. 3c). For each specimen, five repeated tests were performed at the same central position, measuring deformation from 0 to 5 mm under incremental loading as previous test. The force-deformation curves for all five materials (BIS and PFS) are presented in Fig. 3d–h, with 3 mm impactor and 10 mm impactor data integrated into the same plots for direct comparison.

To quantify the mechanical protective performance of BIS, we evaluated their energy absorption capacities (calculated by Eq. (1) in Methods) across different materials and impactor sizes. For the robotic fish with BIS and PFS (Fig. 2b, c), energy absorption was calculated by integrating force-displacement curves at specific body positions. Results showed that the BIS absorbed 241% more energy than the PFS under identical loading conditions, reflecting its superior damage resistance. For the five tested materials (Fig. 3d–h), energy absorption was compared using 3 mm and 10 mm impactors. As shown in Fig. 3i, the BIS exhibited at least 130% higher energy absorption than the PFS with the 3 mm impactor, with a slightly reduced but still significant improvement of 110% under the 10 mm impactor. These findings validate the hierarchical mechanical protective performance of the BIS, demonstrating that scale structures most effectively enhance mechanical protection under localized loading, a behavior aligned with the force-dispersing mechanism of biological scales38,39. Specifically, the strategic embedding of rigid scales within the compliant substrate enables efficient distribution of external forces, mitigating stress concentrations and thereby enhancing both energy absorption capacity and overall load-bearing capability, as evident from the superior performance of BIS across tested materials and impactor sizes.

Amplitude response of the bio-inspired system

To assess the amplitude response of BIS relative to PFS, an experimental platform was used to evaluate their undulation amplitude under oscillatory motion in both aerial and aquatic environments (the experimental setup is detailed in the Methods section). For each frequency (f = 0.5–4 Hz, corresponding to 0.5–4 oscillations per second), 20 continuous undulation cycles were performed for both BIS and PFS during a single test session. Three representative cycles were selected from the 20 for statistical analysis: upward and downward undulation angles were recorded for each selected cycle, and the average value of these two angles was calculated as the characteristic undulation angle. Figure 4b, c demonstrate the system’s ability to retain amplitude response across various undulation frequencies while maintaining protective functionality (all data are available in Supplementary Tables S2, S3).

a Experimental setup for amplitude response test. b Amplitude of undulation of BIS and PFS under the same undulation frequency in an aerial environment. c Amplitude of undulation of BIS and PFS under the same undulation frequency in an aquatic environment. d BIS amplitude deviation rate relative to PFS in both aerial and aquatic environments.

As illustrated in Fig. 4b (also presented in Movie S1), in the aerial environment, at lower undulation frequencies (0.5 and 1 Hz), the oscillation amplitudes of the BIS and PFS were quite close. The amplitude deviation rate (defined and calculated by Eq. (2) in Methods) of the BIS relative to the PFS was approximately 5%. When the frequency increased (2 Hz and 4 Hz), this rate rose to around 17%. A comparable trend was observed in aquatic experiments (Fig. 4c, Movie S2). At lower frequencies (0.5 and 1 Hz), the deviation rate was below 3%, and at higher frequencies (2 and 4 Hz), it was less than 10%. All the BIS amplitude deviation rates relative to PFS are presented in Fig. 4d.

Experimental findings suggest that the strategic placement of rigid scales preserves a high degree of amplitude response while maintaining protective effectiveness. By optimizing the balance between dynamic response and mechanical reinforcement, the design is well-suited for oscillatory applications, particularly underwater locomotion.

Swimming performance test

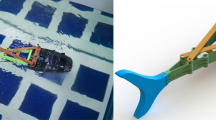

We further assessed the integration of the BIS into soft robotic platforms using a robotic fish (Fig. 5a). The primary objective was to evaluate the effect of BIS incorporation on the robot’s swimming velocity, stability, and thrust efficiency across driving frequencies. Swimming trials were conducted in a glass tank (same as the tank used in the amplitude response test) equipped with two high-speed cameras (M120M-16G, Revealer) to record motion over a 40 cm distance between reference lines (test setup shown in Fig. 5a, robotic fish structure detailed in Fig. 5b), with tests performed at tail beat frequencies from 2 to 5 Hz (lower frequencies, such as 0.5 and 1 Hz, were excluded as excessive body undulation prevented stable swimming) and five repetitions per frequency to ensure reliability. The swimming posture of the BIS robotic fish during experiments is shown in Fig. 5c (also in Movie S3).

a Experimental setup of swimming performance test, including two high-speed cameras secured on an adjustable mounting camera stand. b The structure of the robotic fish, including its fins, skeleton, and drive mechanism. c Swimming posture of the BIS robotic fish during trials, demonstrating stable undulatory motion (see Movie S3 for dynamic visualization). d Forward swimming velocity of BIS and PFS robotic fish across tail beat frequencies (f = 2–5 Hz). e BIS-to-PFS speed ratio and body-length-normalized velocity (BL/s).

As illustrated in Fig. 5d, e, the PFS robotic fish achieved a maximum forward swimming velocity of 14.8 cm/s (0.63 BL/s, body-length per second) at its optimal frequency of 3 Hz, while the BIS robotic fish peaked at 12.8 cm/s (0.55 BL/s) at 3 Hz, reflecting a shift in optimal frequency due to scale-mediated structural dynamics. At 3 Hz, when PFS reached its highest velocity, the BIS retained 87% of the PFS’s velocity, and at 4 Hz, it maintained 90% of the PFS’s performance, as shown in the BIS/PFS speed ratio analysis (Fig. 5e).

These results confirm that while the BIS introduces a minor reduction in peak velocity, it sustains high swimming efficiency across frequencies (with a maximum of 90% speed retention at 4 Hz and a minimum of 73% at 2 Hz) and expands the operational frequency range without compromising thrust stability or trajectory control. Comparative analyses demonstrate that the BIS achieves functionally neutral locomotion performance, validating its integration as a protective enhancement for soft underwater robots.

Fluid drag characteristics of the bio-inspired skin-scales system

To investigate the impact of the BIS on the drag of robotic fish, we numerically simulated the flow field characteristics of these surfaces using computational fluid dynamics (CFD) methods with ANSYS Fluent software (simulation settings are detailed in Supplementary Table S4). The robotic fish with BIS and PFS were simulated in a fluid domain measuring 400 × 400 × 800 mm, which was implemented in a computational model that has undergone grid independence test (details in Methods and Supplementary Tables S5, S6), with fluid velocities ranging from 5 cm/s to 20 cm/s.

Viscous drag refers to the resistance encountered by a body moving through a fluid due to the friction between the fluid and the surface of the object, while pressure drag is caused by the difference in pressure between the front and rear of the object as it moves through the fluid. Figure 6a compares the pressure drag, viscous drag, and total drag forces between the BIS and PFS as a function of fluid velocity. The results show that within the tested velocity range, the total drag curves of the two systems were closely aligned. This alignment is attributed to the fact that the viscous drag of the BIS was lower than that of the PFS, peaking at 7.6%, while the pressure drag exhibited the opposite trend, with the PFS consistently having lower pressure drag than the BIS. These opposing trends in viscous and pressure drag contributed to the minimal variation in total fluid drag. Figure 6b further elucidates the variations in drag reduction rates for the three types of drag, providing a clearer understanding of the specific reasons for the changes in fluid drag and the underlying causes of the initial drag reduction followed by an increase. These results demonstrate that integrating rigid scales into a flexible surface does not increase fluid drag at specific velocities.

a Pressure drag, viscous drag, and total drag of the streamline surface and skin-scales system surface in the liquid velocity from 5 cm/s to 20 cm/s (all the data are available in Supplementary Table S7). b Pressure drag reduction rate, viscous drag reduction rate and total drag reduction rate of skin-scales system surface in the liquid velocity from 5 cm/s to 20 cm/s.

Discussion

This study introduces a bio-inspired rigid-flexible coupled skin-scale system that addresses key challenges in soft robots, including structural durability, impact resistance, and constraints on amplitude response in underwater environments. Inspired by the hierarchical structure of fish scales, our design integrates rigid polypropylene scales with a flexible silicone rubber substrate, optimizing the trade-off between mechanical protection and locomotion efficiency.

Experimental results confirm the effectiveness of this approach in enhancing load-bearing capacity and stress distribution. Compared to a purely flexible silicone rubber surface (PFS), the bio-inspired skin-scales system (BIS) achieved an approximately 3.6-fold enhancement in load-bearing capability, validating the hierarchical principle observed in natural fish scales, where rigid elements work synergistically with flexible substrates to distribute stress and reduce localized strain.

Based on the amplitude deviation rate metric, in the aerial environment, the deviation rate of BIS’s amplitude relative to PFS was below 5% at 0.5 and 1 Hz, rising to around 17% at 2 and 4 Hz. In water, this deviation rate was below 3% at lower frequencies and less than 10% at higher frequencies. This suggests that while rigid scales introduce some resistance, they have a small impact on overall swimming performance, as evidenced by the robot achieving stable forward locomotion at 12.8 cm/s (0.55 BL/s), under a tail beat frequency of 3 Hz, retaining 87% of the performance observed in PFS configuration. Furthermore, we compared the swimming speed of the robotic fish using the bio-inspired skin-scales system (BIS) in this study with that of other existing robotic fish40 in Fig. 7.

Fluid dynamics simulations confirmed that BIS induced only a modest change in overall drag. Although the independence of the computational mesh has been verified, CFD results are also influenced by factors such as the selection of turbulence models, computational methods, and solver choices. In comparison with actual underwater experiments, CFD results have certain limitations; therefore, the maximum −0.95% drag reduction effect can be considered within the range of numerical error. However, despite the modest overall drag change, both pressure drag and viscous drag exhibit relatively significant alterations, confirming that BIS does alter the hydrodynamic characteristics of the robotic fish’s surface. Additionally, localized drag reduction was observed in certain configurations, likely due to boundary-layer stabilization effects. These findings indicate that there is potential to further optimize pressure drag to reduce overall drag through customized scale arrangements. Since these simulations are based on static models, they cannot simulate the local vortex shedding, time-varying body undulations, and transient fluid-structure interactions during BIS movement. In our future work, dynamic fluid-structure coupling effects should be incorporated to comprehensively evaluate hydrodynamic performance, and actual underwater experiments with physical prototypes will be conducted to measure the drag reduction performance of BIS in practice.

While this study establishes a robust foundation, several avenues for further research remain. These include exploring the impact of more parameters of the scales, including scales’ dimensional parameters and scales’ layout parameters, on strength, mobility, and hydrodynamic capabilities, as well as structural refinements through adaptive scale configurations. Additionally, further research should involve conducting deeper fluid-structure interaction studies incorporating tail oscillations and advancements in scalable manufacturing techniques such as multi-material 3D printing. Moving forward, we plan to optimize scale layout to reduce pressure drag and incorporate dynamic motion simulations to better capture real swimming dynamics. Furthermore, expanding the platform’s functionality, such as integrating sensors, actuators, or camouflage mechanisms, could pave the way for multifunctional robotic systems suitable for environmental monitoring, object manipulation, or interactive behaviors in dynamic aquatic environments.

In conclusion, this study demonstrates that a bio-inspired rigid-flexible coupled skin-scales system can effectively enhance mechanical protection while preserving amplitude response in underwater soft robots. By integrating biological design principles with engineering innovation, this system provides a scalable and functional approach to improving underwater soft robot durability and adaptability in challenging aquatic environments. The results highlight the potential of this design for applications where both robustness and efficiency are critical, laying the groundwork for future advancements in bio-inspired soft robotic fish.

Methods

Design process of bio-inspired skin-scales system

The design process of the BIS aimed to optimize mechanical protection and structural flexibility on a 3D curved surface. In contrast to planar surfaces, the varying curvature introduced challenges in aligning and distributing the scales effectively. To address this, a computational model was developed in MATLAB R2024b, enabling precise scale placement based on key parameters such as scale overlap ratio and surface curvature.

The surface geometry was approximated as a series of elliptical cross-sections along the longitudinal axis, simplifying the fish’s complex morphology while providing a functional framework for scale placement. To streamline design and fabrication, all scales were standardized both in size and shape. Additionally, to reduce computational complexity, scales were approximated as rectangles during the initial modeling phase. Their vertex placement was constrained by two primary factors: the overlap ratio between adjacent scales and the local curvature of the surface.

The design process began by determining the spacing between successive scale layers along the z-axis, calculated based on the overlap ratio and scale dimensions. By iteratively applying these parameters, the relative positioning of each layer was established, forming elliptical cross-sections that approximate the target surface. Within each elliptical layer, the initial vertex distribution was determined by the overlap ratio and scale dimensions, followed by refinement based on local curvature. This curvature analysis ensured that adjacent scales remained properly aligned, eliminating overlaps or gaps that could compromise structural integrity. The process was repeated layer by layer until the scales uniformly covered the curved surface.

Once the vertex locations were generated, the scale placements were compared against the modeled surface geometry to verify parameter accuracy. Any misalignments or inconsistencies were iteratively corrected to ensure a smooth, structurally robust arrangement. The finalized design, comprising the surface vertex locations and scale positions, was then visually analyzed to confirm alignment accuracy and validate the feasibility of the selected geometric constraints and scale distribution parameters. This refined process ensures consistent alignment and robust protection across the entire curved surface (Fig. 8).

Fabrication process of skin-scales system

Typical silicone rubber molding methods often lead to detachment of rigid embedded elements during demolding, as the peeling process induces stress on these components. To address this challenge, we introduced a multi-stage molding process utilizing low-melting-point wax (Paraffin 58#, Kunlun), enabling clean demolding without damaging the scales or compromising their alignment. The wax, with a melting point of 58 °C, was specifically chosen to avoid thermal distortion of the embedded scales during demolding (Fig. 9).

A positive mold, consisting of a wax mold and a wax container made from acrylonitrile butadiene styrene (ABS, BambuLab), which was chosen for its high thermal resistance and structural rigidity to withstand wax melting processes, was first fabricated using a 3D printer (P1S, BambuLab). Rigid scales (made from PP, selected for its high stiffness and durability to maintain scale shape during molding), laser-cut to a thickness of 0.2 mm with tolerances of ±0.05 mm, were arranged onto the mold. To create a removable support structure, a layer of low-melting-point wax was poured into the positive mold, forming an intermediate wax mold upon cooling. This method addressed the limitations of traditional approaches, as the wax could be melted and removed without applying excessive force. The mold was composed of one positive mold made from PLA, which was selected for its 3D printability and moderate rigidity to form the mold framework, and two negative molds made from wax (detailed structures are shown in Supplementary Fig. S3).

Ecoflex 00-10 (Smooth-On) silicone rubber, selected for its flexibility and strong adhesion to the embedded scales, was mixed in a 1:1 ratio and degassed under vacuum for 5 minutes to eliminate entrapped air. The silicone rubber was then poured into the mold, filling the perforations in the rigid scales and forming mechanical interlocks that enhanced bonding strength. After curing at 23 °C for four hours, the wax mold was placed in a 60 °C oven (101-0 A, Shangcheng) for two hours to melt the wax and release the BIS. This process maintained the alignment and structural integrity of the skin-scale system. For comparative analysis, a control group featuring a smooth silicone rubber surface without scales was fabricated using the same molding technique and curved substrate.

Mechanical protection performance measurement

To compare the mechanical protection efficiency between the BIS and the PFS, a compression testing machine (ZQ-990A, Zhiqu) was employed to apply incremental external forces to both structures. The deformation was quantified through direct readings from the machine’s built-in sensors, providing precise force-displacement data along with real-time line charts. To ensure consistency, a 3 mm steel pin was used as the impactor, centrally aligned with the midpoint between two skeleton-supporting regions. The machine operated at a constant speed and momentarily paused upon reaching the target force or displacement. A custom PLA (PLA Basic, BambuLab) support fixture was fabricated for each test group to stabilize the surface during testing and minimize extraneous displacement. Given the differences in surface geometry between the BIS and PFS, two specifically designed support fixtures were used to eliminate geometric bias. Figure 2a illustrates the experimental setup.

To quantify the mechanical protective performance of BIS and PFS, we employed energy absorption capacity as a key metric. This parameter measures the total energy a material or structure can absorb through deformation under applied loads, reflecting its resistance to damage and ability to dissipate mechanical energy without catastrophic failure. The energy absorption capacity (E) was determined via numerical integration of the force-deformation response, described by the equation,

where h0 denotes initial contact displacement (m), hmax is the maximum allowable deformation (m), and F(h) is the contact force (N) exerted by the impactor as a function of its vertical displacement.

Amplitude response performance measurement

To evaluate the amplitude response of the BIS, we established a tendon-driven amplitude response testing frame. A flexible skeleton, fabricated from thermoplastic polyurethane (TPU; TPU 95A HF, BambuLab), formed the core of the frame and provided the necessary elasticity for oscillatory motion. This skeleton was produced as a single part, with thicker sections supporting BIS as well as PFS and thinner sections facilitating rotational movement to mimic fishtail undulation (the dimensions of robotic fish are provided in the Supplementary Fig. S1). TPU was selected for its suitability for 3D printing complex spatial geometries and its unique balance of rigidity and localized flexibility, TPU 95 A was specifically chosen among flexible 3D printing materials for its higher rigidity, ensuring structural support in non-articulating regions while allowing controlled deformation at joints. To enhance the visibility of the amplitude of undulation, a caudal fin (fabricated using PP via laser cutting) was installed at the end of this skeleton. A tendon-driven actuation system comprised a servo motor (TR4 K-5, Nangu) and a bobbin winding mechanism (fabricated using PLA) was employed to drive the flexible skeleton. The servo motor was controlled by servo tester (ST8, ToolkitRC) and powered by a DC power supply (UTP1305S, LINI-T), transmitting motion along the skeleton, inducing body bending, and tail oscillation. Dyneema cables (UHMWPE 01, Jinai), chosen for their high durability and high tensile strength, were routed through the internal skeleton. One end of the tendons was secured to the bobbin winding system, while the other was connected to the caudal fin, enabling precise oscillatory motion.

This structure was mounted within an aluminum frame, which was submerged in a glass tank measuring 400 × 400 × 800 mm (W×H×L). Motion data, including amplitude of undulation, were captured using a camera (EOS 90D, Canon) positioned above the tank. The amplitude of undulation was measured by analyzing video frames at different points in the motion cycle. Although the experiments were conducted under unregulated hydrodynamic conditions, multiple trials were performed to ensure consistency and eliminate bias. Figure 4a illustrates the experimental setup.

To quantify the amplitude response performance of BIS relative to PFS, we used the deviation rate of amplitude as metric. This parameter measures the relative difference between the oscillation amplitude of BIS and that of PFS, reflecting how well the BIS adheres to the motion profile of PFS under oscillatory motion in both aerial and aquatic environments, which is a critical indicator for evaluating the dynamic performance of BIS in different frequency and environmental conditions. The deviation rate of amplitude (D) was calculated using the formula,

where APFS and ABIS stand for the undulation amplitude of the PFS and BIS respectively.

Swimming performance measurement

The experiment was conducted in the same glass tank used for the amplitude response testing, with a water depth of 300 mm. Two high-speed (HS) cameras (M120M-16G, Revealer) were positioned on a camera stand at the front of the tank. After installation, the camera stand was leveled. Two reference lines were marked on each side of the tank at the same position, with a distance of 400 mm between the lines on each side (shown in Fig. 5a). To ensure the HS cameras were directly facing the tank, they were adjusted using an image acquisition software as a reference. Alignment was confirmed when the reference lines on both sides overlapped, and the reference lines coincided with the composition auxiliary lines in the image acquisition software. Two HS cameras were set at a sampling frame rate of 100 frames per second. Pre-experiments showed that the robotic fish could swim normally at a driving frequency of 2 Hz, with a maximum swimming time of no more than 6 seconds. Considering the minimum swimming speed, the sampling time was set to 7 seconds.

The experimental procedure was as follows: Once the robotic fish was powered on and started swimming, two HS cameras began shooting simultaneously and continued until the set sampling time of 7 seconds was completed. The synchronized cameras recorded a total of 700 frames of motion image sequences each. To calculate the swimming velocity, the first frame in each sequence where the frontmost part of the robotic fish’s head reached the reference line was identified. The time difference between the two frames, divided by the frame rate, was taken as the time for the robotic fish to travel the distance between the reference lines. The swimming velocity was then calculated by dividing the distance between the reference lines by this time. Each type of robotic fish was tested five times at different driving frequencies, ranging from 2 to 5 Hz.

Structure of robotic fish

The BIS was integrated into a robotic fish to evaluate its applicability in soft robots. The robotic platform consisted of three primary components: a hydrodynamically optimized fish head, a tendon-driven actuation system (same as the system used in previous experiment), and a flexible caudal fin. The fish head was structured to occupy one-third of the total robot length. It featured a dorsal fin and two pectoral fins (fabricated using PLA) to enhance postural stability during swimming. A tether cable extended from the head of the robotic fish to provide power and control. The robotic platform was also tested in the same glass tank as the amplitude response experiments. Swimming speed and motion stability were recorded to evaluate the system’s structural integration and operational effectiveness in dynamic robotic applications. Figure 5b illustrates the structure of the robotic fish.

CFD simulation methodology

The steady-state flow around both the PFS and BIS was modeled in ANSYS Fluent within a rectangular domain (400 × 400 × 800 mm) using incompressible, Newtonian water at inlet velocities ranging from 5 to 20 cm/s. A no-slip boundary condition was imposed on all solid walls, the inlet was specified as a uniform velocity profile, and the outlet was held at atmospheric pressure. To resolve the intricate geometry of the scales, unstructured meshes of approximately 5.11 million cells for BIS and 5.98 million cells for PFS were generated; successive mesh refinements altered the computed drag by less than 0.8% (Supplementary Tables S5, S6), confirming grid independence. Turbulence was treated with the SST k–ω model, selected for its proven accuracy in transitional and near-wall flows at Reynolds numbers on the order of 10⁴–10⁵, and all residuals were driven below 10⁻⁵ prior to recording drag forces. In addition to drag coefficients, we extracted contours of turbulent kinetic energy (k) and specific dissipation rate (ω) in the viscous sublayer to assess whether the BIS texture imparts measurable stabilization to the boundary layer (Supplementary Table S8).

Data availability

The corresponding data, including the mechanical protection performance test, amplitude of undulation, and CFD setup are supplied in the supplementary information file.

References

Kim, S., Laschi, C. & Trimmer, B. Soft robotics: A bioinspired evolution in robotics. Trends Biotechnol. 31, 287–294 (2013).

Rus, D. & Tolley, M. T. Design, fabrication and control of soft robots. Nature 521, 467–475 (2015).

Laschi, C., Mazzolai, B. & Cianchetti, M. Soft robotics: Technologies and systems pushing the boundaries of robot abilities. Sci. Robot 1, eaah3690 (2016).

Polygerinos, P. et al. Soft robotics: Review of fluid-driven intrinsically soft devices; manufacturing, sensing, control, and applications in human-robot interaction. Adv. Eng. Mater. 19, 1700016 (2017).

Majidi, C. Soft-matter engineering for soft robotics. Adv. Mater. Technol. 4, 1800477 (2019).

Ren, Z., Hu, W., Dong, X. & Sitti, M. Multi-functional soft-bodied jellyfish-like swimming. Nat. Commun. 10, 2703 (2019).

Yamada, H. & Hirose, S. Development of practical 3-dimensional active cord mechanism ACM-R4. J. Robot. Mechatron. 18, 305–311 (2006).

Katzschmann, R. K., DelPreto, J., MacCurdy, R. & Rus, D. Exploration of underwater life with an acoustically controlled soft robotic fish. Sci. Robot. 3, eaar3449 (2018).

Kurumaya, S. et al. A modular soft robotic wrist for underwater manipulation. Soft Robot 5, 399–409 (2018).

Galloway, K. C. et al. Soft robotic grippers for biological sampling on deep reefs. Soft Robot 3, 23–33 (2016).

Zhong, Y., Li, Z. & Du, R. A novel robot fish with wire-driven active body and compliant tail. IEEE-ASME T Mech. 22, 1633–1643 (2017).

Chen, T., Bilal, O. R., Shea, K. & Daraio, C. Harnessing bistability for directional propulsion of soft, untethered robots. PNAS 115, 5698–5702 (2018).

Sinatra, N. R. et al. Ultragentle manipulation of delicate structures using a soft robotic gripper. Sci. Robot 4, eaax5425 (2019).

Zhu, J. et al. Tuna robotics: A high-frequency experimental platform exploring the performance space of swimming fishes. Sci. Robot. 4, eaax4615 (2019).

Li, G. et al. Self-powered soft robot in the Mariana Trench. Nature 591, 66–71 (2021).

Trivedi, D., Rahn, C. D., Kier, W. M. & Walker, I. D. Soft robotics: Biological inspiration, state of the art, and future research. Appl Bionics Biomech. 5, 99–117 (2008).

Iida, F. & Laschi, C. Soft robotics: Challenges and perspectives. Procedia Comput Sci. 7, 99–102 (2011).

Qu, J. et al. Recent advances on underwater soft robots. Adv. Intell. Syst. 6, 2300299 (2024).

Ikoma, T., Kobayashi, H., Tanaka, J., Walsh, D. & Mann, S. Microstructure, mechanical, and biomimetic properties of fish scales from Pagrus major. J. Struct. Biol. 142, 327–333 (2003).

Meyers, M. A., Lin, Y. S., Olevsky, E. A. & Chen, P. Y. Battle in the Amazon: Arapaima versus piranha. Adv. Eng. Mater. 14, B279–B288 (2012).

Ghods, S., Murcia, S., Ossa, E. A. & Arola, D. Designed for resistance to puncture: The dynamic response of fish scales. J. Mech. Behav. Biomed. Mater. 90, 451–459 (2019).

Wegst, U. G., Bai, H., Saiz, E., Tomsia, A. P. & Ritchie, R. O. Bioinspired structural materials. Nat. Mater. 14, 23–36 (2015).

Bruet, B. J., Song, J., Boyce, M. C. & Ortiz, C. Materials design principles of ancient fish armour. Nat. Mater. 7, 748–756 (2008).

Vernerey, F. J. & Barthelat, F. On the mechanics of fishscale structures. Int J. Solids Struct. 47, 2268–2275 (2010).

Allison, P. G. et al. Mechanical properties and structure of the biological multilayered material system, Atractosteus spatula scales. Acta Biomater. 9, 5289–5296 (2013).

Duro-Royo, J. et al. MetaMesh: A hierarchical computational model for design and fabrication of biomimetic armored surfaces. Comput-Aided Des. 60, 14–27 (2015).

Rudykh, S., Ortiz, C. & Boyce, M. C. Flexibility and protection by design: imbricated hybrid microstructures of bio-inspired armor. Soft Matter 11, 2547–2554 (2015).

Funk, N. et al. Bioinspired fabrication and characterization of a synthetic fish skin for the protection of soft materials. ACS Appl Mater. Inter 7, 5972–5983 (2015).

Martini, R. & Barthelat, F. Stretch-and-release fabrication, testing and optimization of a flexible ceramic armor inspired from fish scales. Bioinspir. Biomim. 11, 066001 (2016).

Sherman, V. R., Quan, H., Yang, W., Ritchie, R. O. & Meyers, M. A. A comparative study of piscine defense: the scales of Arapaima gigas, Latimeria chalumnae and Atractosteus spatula. J. Mech. Behav. Biomed. 73, 1–16 (2017).

Yang, W. et al. Natural flexible dermal armor. Adv. Mater. 25, 31–48 (2013).

Ghosh, R., Ebrahimi, H. & Vaziri, A. Contact kinematics of biomimetic scales. Appl Phys. Lett. 105, 233701 (2014).

Martini, R., Balit, Y. & Barthelat, F. A comparative study of bio-inspired protective scales using 3D printing and mechanical testing. Acta Biomater. 55, 360–372 (2017).

Mirkhalaf, M., Zhou, T. & Barthelat, F. Simultaneous improvements of strength and toughness in topologically interlocked ceramics. PNAS 115, 9128–9133 (2018).

Wang, J. & Xi, F. Robotic fish scales driven by a skin muscle mechanism. Mech. Mach. Theor. 172, 104797 (2022).

Ali, H., Ebrahimi, H. & Ghosh, R. Frictional damping from biomimetic scales. Sci. Rep. 9, 14628 (2019).

Vernerey, F. J. & Barthelat, F. Skin and scales of teleost fish: Simple structure but high performance and multiple functions. J. Mech. Phys. Solids 68, 66–76 (2014).

Liu, P., Zhu, D., Yao, Y., Wang, J. & Bui, T. Q. Numerical simulation of ballistic impact behavior of bio-inspired scale-like protection system. Mater. Des. 99, 201–210 (2016).

Vernerey, F. J., Musiket, K. & Barthelat, F. Mechanics of fish skin: A computational approach for bio-inspired flexible composites. Int J. Solids Struct. 51, 274–283 (2014).

White, C. H., Lauder, G. V. & Bart-Smith, H. Tunabot Flex: a tuna-inspired robot with body flexibility improves high-performance swimming. Bioinspir. Biomim. 16, 026019 (2021).

Acknowledgements

The authors acknowledge the funding support from the Shanghai Natural Science Foundation (No. 25ZR1402165), the National Natural Science Foundation of China (52105002, 52505030) and the Shanghai Pujiang Programme (23PJD069).

Author information

Authors and Affiliations

Contributions

J.W. and F.X. conceived the idea. J.W. and S.T. supervised the project. F.X. and Y.Z. helped supervise the project. Y.L. and G.R. designed the experiments, and conducted the experiments. Y.Z. and Y.L. conducted the computational fluid dynamics. Y.L. analyzed the data and wrote the manuscript with support from J.W. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Wang, J., Li, Y., Tian, S. et al. Bio-inspired rigid-flexible coupled skin-scales system for enhanced protection in soft robotic fish. npj Robot 3, 35 (2025). https://doi.org/10.1038/s44182-025-00052-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44182-025-00052-1