Abstract

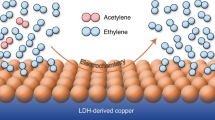

Acetylene, produced from coal or natural gas, was a cornerstone of the chemical industry until the 1960s. However, the long-term global availability of inexpensive petroleum before 1973 accelerated the production of olefins, diminishing acetylene’s market prominence because of their similar downstream applications. As petroleum prices fluctuate, acetylene has regained economic viability in certain regions, notably accounting for approximately one-third of the global vinyl chloride production, despite its high carbon footprint. Environmental and economic assessments show that replacing coal with biochar in acetylene-derived vinyl chloride production not only lowers the carbon footprint but also could remain economically viable compared with the ethylene route. Despite this potential, research on acetylene has been largely overlooked for decades. Here we provide an analysis of acetylene production technologies, propose sustainable production initiatives and quantify their economic and environmental performance, and explore potential applications. By showcasing this promising trajectory, we seek to rekindle interest and foster collaborative efforts in advancing sustainable acetylene production and broadening its use as a building block.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on SpringerLink

- Instant access to the full article PDF.

USD 39.95

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Davy, E. Notice of carburet of potassium, and of a new gaseous bi-carburet of hydrogen. J. Frankl. Inst. 19, 216 (1837).

Rasmussen, S. C. Acetylene and Its Polymers: 150+ Years of History (Springer, 2018).

Carolina, N. Discovery of the Commercial Processes for Making Calcium Carbide and Acetylene (American Chemical Society, 1998).

Trotus, I. T., Zimmermann, T. & Schüth, F. Catalytic reactions of acetylene: a feedstock for the chemical industry revisited. Chem. Rev. 114, 1761–1782 (2014). Systematic review of catalytic C2H2 applications.

Jiang, C. & Hu, J. Conversion of Methane to Acetylene 93–116 (Royal Society of Chemistry, 2023). The most comprehensive book chapter on CH4-to-C2H2 routes, covering calcium carbide, partial combustion, hot plasma, warm/cold plasma and thermal pyrolysis.

Bixler, G. H. & Coberly, C. W. Wulff process acetylene. Ind. Eng. Chem. 45, 2596–2606 (1953).

Weissermel, K. & Arpe, H.-J. Industrial Organic Chemistry (Wiley, 2008).

Crafts, J. M. A lecture upon acetylene. Science 3, 377–392 (1896).

Schobert, H. Production of acetylene and acetylene-based chemicals from coal. Chem. Rev. 114, 1743–1760 (2014). Systematic review of coal-based C2H2 synthesis, encompassing commercial calcium carbide route and all related attempts.

Crynes, B. L., Albright, L. F. & Tan, L. F. in Encyclopedia of Physical Science and Technology 3rd edn (ed. Meyers, R.) 613–626 (Academic Press, 2003).

Shlyapin, D. A., Afonasenko, T. N., Glyzdova, D. V., Leont’eva, N. N. & Lavrenov, A. V. Acetylene production technologies in the 21st century: main trends of their development in the paradigm of low-carbon economy of the future. Catal. Ind. 14, 251–267 (2022).

Chauhan, R., Sartape, R., Minocha, N., Goyal, I. & Singh, M. R. Advancements in environmentally sustainable technologies for ethylene production. Energy Fuels 37, 12589–12622 (2023).

Zhang, S. et al. Life cycle assessment of acetylene production from calcium carbide and methane in China. J. Clean. Prod. 322, 129055 (2021). Comparison of three commercial C2H2 synthesis routes—calcium carbide, partial combustion and hot plasma—via life cycle assessment.

Jiang, P. et al. Towards carbon neutrality of calcium carbide-based acetylene production with sustainable biomass resources. Green Energy Environ. 9, 1068–1078 (2024).

Huo, H. et al. Case study of a novel low rank coal to calcium carbide process based on techno-economic assessment. Energy 228, 120566 (2021).

Saeki, Y. & Emura, T. Technical progresses for PVC production. Prog. Polym. Sci. 27, 2055–2131 (2002).

Jiang, M. et al. Tracing fossil-based plastics, chemicals and fertilizers production in China. Nat. Commun. 15, 3854 (2024).

Liu, Y. et al. Life cycle assessment of beneficial use of calcium carbide sludge in cement clinker production: a case study in China. J. Clean. Prod. 418, 138003 (2023).

Stournaras, Y. A. Are Oil Price Movements Perverse? A Critical Explanation of Oil Price Levels 1950–1985 (Oxford Institute for Energy Studies, 1985).

Gadea, M. D., Gómez-Loscos, A. & Montañés, A. Oil price and economic growth: a long story? Econometrics 4, 41 (2016).

Yan, B., Lu, W. & Cheng, Y. China goes green: cleaner production of chemicals. Green Process. Synth 1, 33–47 (2012).

Singh, R. P., Kumar, S., Dubey, S. & Singh, A. A review on working and applications of oxy-acetylene gas welding. Mater. Today Proc. 38, 34–39 (2021).

Khodabakhshi, S., Fulvio, P. F. & Andreoli, E. Carbon black reborn: structure and chemistry for renewable energy harnessing. Carbon 162, 604–649 (2020).

Zhu, Y., Yang, J., Mei, F., Li, X. & Zhao, C. Bio-based 1,4-butanediol and tetrahydrofuran synthesis: perspective. Green Chem. 24, 6450–6466 (2022).

Chiang, C. K. et al. Electrical conductivity in doped polyacetylene. Phys. Rev. Lett. 39, 1098–1101 (1977).

Zimmermann, H. & Walzl, R. in Ullmann’s Encyclopedia of Industrial Chemistry Vol. 13, 466–529 (Wiley, 2009).

Pässler, P. et al. in Ullmann’s Encyclopedia of Industrial Chemistry Vol. 13, 466–529 (Wiley, 2011). The most comprehensive introduction of C2H2, covering its physical and chemical properties, industrial applications, synthesis routes, safety precautions, transportation and storage.

Bilera, I. V. & Lebedev, Y. A. Plasma-chemical production of acetylene from hydrocarbons: history and current status (a review). Pet. Chem. 62, 329–351 (2022).

Bowker, M. et al. Advancing critical chemical processes for a sustainable future: challenges for industry and the Max Planck-Cardiff centre on the fundamentals of heterogeneous catalysis (FUNCAT). Angew. Chem. Int. Ed. 61, e202209016 (2022). Review pointing out the importance of C2H2 production derived from biomethane.

Ma, H., Wang, Y., Qi, Y., Rout, K. R. & Chen, D. Critical review of catalysis for ethylene oxychlorination. ACS Catal. 10, 9299–9319 (2020).

Faust Akl, D. et al. Reaction-induced formation of stable mononuclear Cu(I)Cl species on carbon for low-footprint vinyl chloride production. Adv. Mater. 35, 2211464 (2023).

Cannon, S., Levine, S. & Ritter, A. Natural Gas Conversion into Clean Hydrogen and Carbon for Li-Ion Battery Electrodes Using Renewable Energy (Penn Collection, 2022).

Satam, C. C. & Realff, M. J. Comparison of two routes for the bio-based production of economically important C4 streams. J. Adv. Manuf. Process. 2, e10054 (2020).

De Bari, I. et al. From cardoon lignocellulosic biomass to bio-1,4 butanediol: an integrated biorefinery model. Processes 8, 1585 (2020).

Zhang, N., Wang, S., Gibril, M. E. & Kong, F. The copolymer of polyvinyl acetate containing lignin-vinyl acetate monomer: synthesis and characterization. Eur. Polym. J. 123, 109411 (2020).

Swathy, K. K., Verma, R. & Kumar, L. in Polymeric Foams: Fundamentals and Types of Foams Vol. 1 (ed. Gupta R. K.) 205–221 (American Chemical Society, 2023).

Okoro, O. V., Nie, L., Alimoradi, H. & Shavandi, A. Waste apple pomace conversion to acrylic acid: economic and potential environmental impact assessments. Fermentation 8, 21 (2022).

Zhang, J. et al. Advances in the catalytic production of acrylonitrile. Chem. Catal. 4, 100825 (2024).

Reesh Abu, M. I. Acrylonitrile process enhancement through waste minimization: effect of reaction conditions and degree of backmixing. Sustainability 13, 7923 (2021).

Pal, P. & Nayak, J. Acetic acid production and purification: critical review towards process intensification. Sep. Purif. Rev. 46, 44–61 (2017).

Sarchami, T., Batta, N. & Berruti, F. Production and separation of acetic acid from pyrolysis oil of lignocellulosic biomass: a review. Biofuels Bioprod. Bioref. 15, 1912–1937 (2021).

Wang, H. et al. Carbon-calcium composite conversion of calcium carbide-acetylene system: on the imperative roles of carbon capture and solid waste recycling. Appl. Energy 327, 120139 (2022).

Guo, J. & Zheng, D. Thermodynamic analysis of low-rank-coal-based oxygen-thermal acetylene manufacturing process system. Ind. Eng. Chem. Res. 51, 13414–13422 (2012).

Ma, S. et al. Energy and exergy analysis of a new calcium carbide production process. Fuel Process. Technol. 226, 107070 (2022).

Radoiu, M. T., Chen, Y. & Depew, M. C. Catalytic conversion of methane to acetylene induced by microwave irradiation. Appl. Catal. B 43, 187–193 (2003).

Holmen, A., Olsvik, O. & Rokstad, O. A. Pyrolysis of natural gas: chemistry and process concepts. Fuel Process. Technol. 42, 249–267 (1995).

Gyrdymova, Y., Lebedev, A., Du, Y.-J. & Rodygin, K. Production of acetylene from viable feedstock: promising recent approaches. ChemPlusChem 89, e202400247 (2024).

Fincke, J. R. et al. Plasma thermal conversion of methane to acetylene. Plasma Chem. Plasma Process. 22, 105–136 (2002).

Yan, B., Xu, P., Guo, C. Y., Jin, Y. & Cheng, Y. Experimental study on coal pyrolysis to acetylene in thermal plasma reactors. Chem. Eng. J. 207–208, 109–116 (2012).

Xia, W. et al. The plasma energy route to industrial carbon neutrality in China. Chin. J. Theor. Appl. Mech. 55, 2779–2795 (2023).

Guo, X. et al. Analysis and prospect on plasma pyrolysis technology for coal-to-acetylene production. Environ. Prot. Chem. Ind. 41, 229–234 (2021).

Scapinello, M., Delikonstantis, E. & Stefanidis, G. D. The panorama of plasma-assisted non-oxidative methane reforming. Chem. Eng. Process. Process Intensif. 117, 120–140 (2017). The most comprehensive introduction of non-oxidative methane coupling via plasma methods.

Kado, S., Sekine, Y. & Fujimoto, K. Direct synthesis of acetylene from methane by direct current pulse discharge. Chem. Commun. 24, 2485–2486 (1999).

Han, Q. et al. Conversion of methane to C2 and C3 hydrocarbons over TiO2/ZSM-5 core-shell particles in an electric field. RSC Adv. 9, 34793–34803 (2019).

Wnukowski, M., van de Steeg, A. W., Hrycak, B., Jasiński, M. & van Rooij, G. J. Influence of hydrogen addition on methane coupling in a moderate pressure microwave plasma. Fuel 288, 119674 (2021).

Zhang, X., Dai, B., Zhu, A., Gong, W. & Liu, C. The simultaneous activation of methane and carbon dioxide to C2 hydrocarbons under pulse corona plasma over La2O3/γ-Al2O3 catalyst. Catal. Today 72, 223–227 (2002).

Ma, Y. et al. Direct conversion of methane to ethylene and acetylene over an iron-based metal-organic framework. J. Am. Chem. Soc. 145, 20792–20800 (2023).

Julian, I., Ramirez, H., Hueso, J. L., Mallada, R. & Santamaria, J. Non-oxidative methane conversion in microwave-assisted structured reactors. Chem. Eng. J. 377, 119764 (2019).

Suib, S. L. & Zerger, R. P. A direct, continuous, low-power catalytic conversion of methane to higher hydrocarbons via microwave plasmas. J. Catal. 139, 383–391 (1993).

Ortiz-Bravo, C. A., Chagas, C. A. & Toniolo, F. S. Oxidative coupling of methane (OCM): an overview of the challenges and opportunities for developing new technologies. J. Nat. Gas Sci. Eng. 96, 104254 (2021).

Sakbodin, M., Wu, Y., Oh, S. C., Wachsman, E. D. & Liu, D. Hydrogen-permeable tubular membrane reactor: promoting conversion and product selectivity for non-oxidative activation of methane over an Fe©SiO2 catalyst. Angew. Chem. Int. Ed. 55, 16149–16152 (2016).

Oh, S. C. et al. Direct non-oxidative methane conversion in a millisecond catalytic wall reactor. Angew. Chem. Int. Ed. 58, 7083–7086 (2019).

Xie, P. et al. Nanoceria-supported single-atom platinum catalysts for direct methane conversion. ACS Catal. 8, 4044–4048 (2018). The highest C2H2 selectivity from non-oxidative methane coupling via catalytic thermal pyrolysis.

Zhang, H. et al. Pt/CeO2 as catalyst for nonoxidative coupling of methane: oxidative regeneration. J. Phys. Chem. Lett. 14, 6778–6783 (2023).

Talpade, A. D. et al. Catalytic reactivity of Pt sites for non-oxidative coupling of methane (NOCM). Chem. Eng. J. 481, 148675 (2024).

Eggart, D. et al. Operando XAS study of Pt-doped CeO2 for the nonoxidative conversion of methane. ACS Catal. 12, 3897–3908 (2022).

Hohn, K. L., Witt, P. M., Davis, M. B. & Schmidt, L. D. Methane coupling to acetylene over Pt-coated monoliths at millisecond contact times. Catal. Lett. 54, 113–118 (1998).

Zhang, S. B. X. Y. et al. Role and dynamics of transition metal carbides in methane coupling. Chem. Sci. 14, 5899–5905 (2023).

Han, S. J., Lee, S. W., Kim, H. W., Kim, S. K. & Kim, Y. T. Nonoxidative direct conversion of methane on silica-based iron catalysts: effect of catalytic surface. ACS Catal. 9, 7984–7997 (2019).

Guo, X. et al. Direct, nonoxidative conversion of methane to ethylene, aromatics and hydrogen. Science 344, 616–619 (2014). The breakthrough of non-oxidative methane coupling.

Teh, W. J. et al. Selective electroreduction of acetylene to 1,3-butadiene on iodide-induced Cuẟ+–Cu0 sites. Nat. Catal 7, 1382–1393 (2024). The new acetylene application.

Zhao, B. H. et al. Economically viable electrocatalytic ethylene production with high yield and selectivity. Nat. Sustain. 6, 827–837 (2023).

Shi, R. et al. Room-temperature electrochemical acetylene reduction to ethylene with high conversion and selectivity. Nat. Catal. 4, 565–574 (2021).

Zhao, Z. H. et al. Photocatalytic acetylene hydrochlorination by pairing proton reduction and chlorine oxidation over g-C3N4/BiOCl catalysts. J. Am. Chem. Soc. 146, 29441–29449 (2024).

Wang, A., Cao, H., Zhang, L. & Wang, A. Co/SiO2 catalyst for methoxycarbonylation of acetylene: on catalytic performance and active species. Molecules 29, 1987 (2024).

Li, X. et al. Palladium and ruthenium dual‐single‐atom sites on porous ionic polymers for acetylene dialkoxycarbonylation: synergetic effects stabilize the active site and increase CO adsorption. Angew. Chem. Int. Ed. 62, e202307570 (2023).

Li, G. et al. Production of calcium carbide from fine biochars. Angew. Chem. Int. Ed. 49, 8480–8483 (2010). Systematic study of the biochar to CaC2 process.

Dimitrakellis, P., Delikonstantis, E., Stefanidis, G. D. & Vlachos, D. G. Plasma technology for lignocellulosic biomass conversion toward an electrified biorefinery. Green Chem. 24, 2680–2721 (2022).

Zhang, M. et al. Pyrolysis of polyolefins using rotating arc plasma technology for production of acetylene. Energies 10, 513 (2017).

Zhang, M. et al. Gas production from polyethylene terephthalate using rotating arc plasma. Chem. Eng. Process. Process Intensif. 128, 257–262 (2018).

Kolb, T., Kroker, T. & Gericke, K.-H. Conversion of biogas like mixtures to C2 hydrocarbon in a plug flow reactor supported by a DBD at atmospheric pressure. Vacuum 88, 144–148 (2013).

Zeng, Y. et al. Biogas reforming for hydrogen-rich syngas production over a Ni-K/Al2O3 catalyst using a temperature-controlled plasma reactor. Int. J. Hydrog. Energy 48, 6192–6203 (2023).

Li, M. et al. Reengineering of the carbon-to-acetylene process featuring negative carbon emission. Green Chem. 25, 8584–8592 (2023).

McEnaney, M. J. et al. A cyclic electrochemical strategy to produce acetylene from CO2, CH4, or alternative carbon sources. Sustain. Energy Fuels 4, 2752–2759 (2020). The CO2–C2H2 cycles.

Fawzy, S., Osman, A. I., Yang, H., Doran, J. & Rooney, D. W. Industrial biochar systems for atmospheric carbon removal: a review. Environ. Chem. Lett. 19, 3023–3055 (2021).

Alberici, S., Grimme, W. & Toop, G. Biomethane Production Potentials in the EU (European Biogas Association, 2022).

Mitchell, S., Martín, A. J., Guillén-Gosálbez, G. & Pérez-Ramírez, J. The future of chemical sciences is sustainable. Angew. Chem. Int. Ed. 63, e202318676 (2024).

Rodin, V., Lindorfer, J., Böhm, H. & Vieira, L. Assessing the potential of carbon dioxide valorisation in Europe with focus on biogenic CO2. J. CO2 Util. 41, 101219 (2020).

Glaser, B., Parr, M., Braun, C. & Kopolo, G. Biochar is carbon negative. Nat. Geosci. 2, 2 (2009).

Nabera, A., Martín, A. J., Istrate, R., Pérez-Ramírez, J. & Guillén-Gosálbez, G. Integrating climate policies in the sustainability analysis of green chemicals. Green Chem. 26, 6461–6469 (2024).

Sacchi, R. et al. PRospective EnvironMental Impact asSEment (premise): a streamlined approach to producing databases for prospective life cycle assessment using integrated assessment models. Renew. Sustain. Energy Rev. 160, 112311 (2022).

Johnston, P., Carthey, N. & Hutchings, G. J. Discovery, development and commercialization of gold catalysts for acetylene hydrochlorination. J. Am. Chem. Soc. 137, 14548–14557 (2015).

Malta, G. et al. Identification of single-site gold catalysis in acetylene hydrochlorination. Science 355, 1399–1403 (2017).

Acknowledgements

This publication was created as part of NCCR Catalysis (grant number 180544), a National Centre of Competence in Research funded by the Swiss National Science Foundation.

Author information

Authors and Affiliations

Contributions

Z.Z. and J.P.-R. conceived this Perspective. Z.Z. and A.N. produced figures. A.N. and G.G.-G. completed the life cycle assessment and techno-economic study. Z.Z. and A.N. co-wrote the paper. G.G.-G. and J.P.-R. revised the paper. J.P.-R. supervised the project. All authors reviewed, edited and enriched each section of the Perspective.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Chemical Engineering thanks Yi Cheng, Jian Zhang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Notes 1–3,Tables 1–8 and References.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Z., Nabera, A., Guillén-Gosálbez, G. et al. Rekindling the use of acetylene as a chemical building block. Nat Chem Eng 2, 99–109 (2025). https://doi.org/10.1038/s44286-025-00185-y

Received:

Accepted:

Published:

Version of record:

Issue date:

DOI: https://doi.org/10.1038/s44286-025-00185-y