Abstract

Direct air capture (DAC) is widely considered as a critical negative emission technology to not only mitigate but reverse global climate change. While commercially expanding, its efficiency is limited by energy-intensive sorbent regeneration. Here, we highlight distributed DAC as a complement to centralized systems, analyzing the regeneration energy demands and carbon footprints of various sorbents. A comprehensive evaluation of distributed DAC’s impact is crucial for maximizing its potential.

Similar content being viewed by others

Introduction

According to the Paris Agreement, the mitigation of climate change aims to hold the temperature rise below 2 °C, ideally 1.5 °C, by the end of this century1. Carbon neutrality is targeted by the mid-century through the reduction in greenhouse gas emissions, and negative emission technology (NET) plays a vital role in mitigation efforts. To meet climate goals while sustaining economic growth, NET is recommended to remove approximately 10 Gt of CO2 per year by mid-century, increasing to 20 Gt CO2 per year globally by the century’s end1. Considering the annual industrial growth rate of around 20%2, the current use of non-carbon technologies and flue gas capture process can only slow the increase in atmospheric CO2 concentration. The urgency to deploy more carbon NET cannot be overemphasized3.

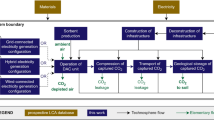

Direct air capture (DAC) is one of the critical NETs, with a noticeable deployment progress in recent years. DAC is broadly defined as the direct extraction of CO2 from ambient air4. It generally involves two steps: capture and regeneration. In the contactor, CO2 is extracted from ambient air by chemically bonding with the sorbents. The air, now depleted of CO2, leaves the carbonated sorbents. Once a sufficient loading capacity is reached, the saturated sorbents must be regenerated, predominantly by elevated temperature. The extracted atmospheric CO2 can be either sequestrated geologically5, reused in other industries such as enhanced oil recovery6, or converted to valuable chemicals7. (Fig. 1a) One prominent advantage of DAC is its efficient use of land compared to photosynthesis. Modern DAC plants require 0.4 − 66 km2 land for each ton of captured CO2, much smaller than 862 km2 required for the afforestation and reforestation to capture a similar amount of CO28. From a long-term perspective, as we decarbonize fossil fuel-driven industry, capturing CO2 through DAC will play a crucial role in achieving net-zero emissions.

a DAC plants incorporate both centralized and distributed designs for flexible deployment. Ambient air is drawn into the system via fans, where CO2 is captured using either liquid or solid sorbents. Once captured, the CO2 is released through thermal regeneration of the sorbents powered by various energy sources. The captured CO2 can subsequently be sequestered or utilized as a raw material in industrial applications. b Schematic of centralized DAC design. c Schematic of distributed DAC design.

As of 2023, twenty-seven DAC plants have been commissioned worldwide, and 130 DAC facilities are under development, according to the International Energy Agency9,10. Given the urgency of climate change mitigation, upscaling current DAC technologies is essential for gigaton-scale CO2 capture, with a target of 20 Gt CO2 per year by 2100 to meet net-zero emission1. Currently, global carbon capture capacity stands at 0.049 Gt per year11, while DAC contributes only 0.01 Mt annually9. Scaling DAC alone presents significant challenges in meeting these capture targets. Table 1 summarizes three major DAC technology providers and their projects as of 2022.

Centralized versus distributed DAC

Although atmospheric CO2 is ubiquitous and mostly uniform, current DAC deployment is nonetheless location-selective and has yet to achieve the full potential of its carbon removal. Why is this the case? To make a DAC plant carbon-negative and financially sustainable, the location must have vast and cheap land, renewable energy sources, and preferably nearby sequestration or conversion sites. To understand this bottleneck, we first break down each component of current DAC plants.

In centralized DAC systems, considerable infrastructure is typically required for CO2 capture, compression, and storage or utilization. Large air contactors are often stacked together, with electric fans drawing ambient air into the reactors. Sorbents with strong chemical affinity capture and react with the dilute CO2 in the air. Once saturated, these sorbents are directly regenerated in a central regeneration facility for subsequent capture cycles. (Fig. 1b)

Low-temperature DAC sorbent relies on two primary sorption mechanisms: physisorption and chemisorption. Physisorption involves the physical trapping of CO2 within the pores of solid sorbents without chemical reactions, whereas chemisorption involves the reaction of CO2 with basic sites functionalized on solid materials called adsorbent12. Alternatively, CO2 can be chemically absorbed into liquid sorbents, such as aqueous bases absorbent like NaOH and Ca(OH)2. Physisorbents, such as unmodified zeolites and metal-organic frameworks (MOFs), generally exhibit poorer performance in capturing CO2 compared to chemisorbents13. But excellent tunability and crystallinity of MOFs enable efficient kinetic separations of gases. Chemisorbents, on the other hand, are more effective due to their strong chemical bonding with dilute CO2 from air13. Therefore, this discussion will focus on chemisorbents, due to their critical role in enabling efficient DAC processes.

There are three factors to be evaluated when deploying DAC: cost, resource demand, and carbon footprint. First, for DAC to be economically viable, the costs must be reduced to below $100 per ton of CO21, making it competitive with other NETs like bioenergy with carbon capture and sequestration (BECCS). However, the current DAC has the costs as high as $600 per ton of CO2, so it is not among the NETs ready for large-scale deployment1. Second, the availability of energy sources and materials is critical for scaling up. Locations with existing supply chains for metals, hydroxides, calcium carbonate are advantageous for producing DAC sorbents. Energy sources and freshwater are also essential for the regeneration process. Lastly, the carbon footprint of DAC operations should not be overlooked. The selection of energy sources and sorbents can significantly impact the carbon emissions generated during operation. These three factors will be the focus of discussions in the following sections.

Thermodynamic consideration of DAC sorbent regeneration

Significant progress has been made so far in advancing the DAC capacity and selectivity. However, CO2 capture is only the first step in the DAC cycle, and the regeneration process should not be underestimated. Because of the low concentration of CO2 in ambient air, the thermodynamic driving force must be sufficiently strong to ensure high capacity. As we reverse the adsorption into desorption, the same large amount of free energy (or enthalpy for a pure thermal process) is needed. Such energy requirement is a major factor that needs to be rationally engineered to realize carbon-negative14. For example, thermal regeneration of CaO and the subsequent production of high-purity CO2 account for approximately 63% of the energy in the overall DAC process1. Therefore, controlling the energy demand and minimizing the carbon emissions during regeneration is essential. A thorough assessment of the regeneration process is critical for developing an efficient DAC system.

In the regeneration of DAC sorbents, temperature swing desorption (TSD) and temperature-vacuum swing deposition (TVSD) are among the most widely used regeneration methods. Thermal regeneration typically requires heat or electricity input from different energy sources15, and its effectiveness depends heavily on the types of sorbents and energy sources used.

To better understand the energy consumption related to the materials properties, we take a deeper look into the components of regeneration energy in detail. The total energy required for sorbent regeneration is the sum of several thermodynamic quantities. \({(Q}_{{regeneration}}={{Q}_{{desorption}}+Q}_{{sensible}}+T\Delta {S}_{{separation}}+{Q}_{{non}-{ideal}}\)) The entropy of separation (\(T\Delta {S}_{{separation}})\) and non-ideality (\({Q}_{{non}-{ideal}})\), which accounts for entropic irreversibility (e.g., mass and heat transfer inefficiencies), are included in the calculation of regeneration energy. Due to the low CO₂ concentration in the gas mixture and its rapid removal, entropic terms contribute minimally compared to other terms in the regeneration process. So we narrow the focus of discussion only into \({Q}_{{desorption}}\) and \({Q}_{{sensible}}\).

The heat of desorption (\({Q}_{{desorption}}\)) refers to the energy needed to break chemical bonds and release CO2. For DAC, \({Q}_{{desorption}}\) should be sufficiently large and should not be treated as a drawback. But if the heat of desorption is excessively high, the energy and associated costs required to desorb the captured CO₂ could become a significant challenge. Sensible heat (\({Q}_{{sensible}}\)) is the energy required to heat the sorbent to the regeneration temperature16. The sensible heat is determined by the specific heat capacity (\({{C}_{P}}_{{sorbent}}\)) of the sorbent and CO2 capacity of the sorbent in a single adsorption-desorption cycle. For solvent-based processes, it is additionally influenced by the liquid flow rate. Besides that, the latent heat from the vaporization of co-adsorbed water should also be considered, originating from ambient air or steam used for regeneration. To narrow the focus of our discussion, the specific heat capacity (\({{C}_{P}}_{{sorbent}}\)) of the sorbent is used for quantitative comparisons of the sensible heat. Minimizing the sensible heat is crucial for optimizing the full regeneration process.

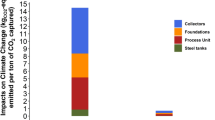

For example, CO2 capture using liquid absorbent like NaOH is thermodynamically favorable due to the formation of carbonate and bicarbonate, however, the regeneration can be energy intensive. The regeneration temperature necessary for NaOH exceeds 800 °C, with an energy consumption of around 6.57–9.9 GJ/t CO214. In contrast, solid sorbents require lower regeneration temperatures, reducing the energy demand to 5–8.3 GJ/t CO217. Consequently, sensible heat contributes significantly to the overall energy consumption during regeneration. Strategies to reduce this loss include selecting sorbent substrates with lower heat capacity, minimizing the temperature swing rate and contactor area during the regeneration1. (Fig. 2)

The components of regeneration energy include the sensible heat, heat of desorption and heat of vaporization. a Upper panel: Solid and liquid sorbents are compared based on their specific heat capacity of sorbent (\({C}_{{P\; sorbent}}\)) and enthalpy of reaction (\({\rm{\Delta }}{H}_{{reaction}}\)), measured from thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). The \({C}_{{P\; sorbent}}\) of 30 wt% MEA,3M K-SAR, mesoporous silica (SBA-15), MGBIG and CaCO3 have been reported as approximately 3.5340, 2.9218, 1.0841,42, 1.3018, 0.83443 J/(g•K) in the temperature range of 25 °C to 70 °C. The \({\rm{\Delta }}{H}_{{reaction}}\) for 30 wt% MEA,3M K-SAR, branched PEI on SBA mesoporous silica 15 (7.55 mmol/g amine loading), MGBIG and CaCO3 are reported to be 8044, 16118, 9345, 26418, 18746 kJ/mol CO2. b Lower panel: The carbon footprint and energy cost of DAC systems vary depending on the energy sources used, whether renewable or fossil-based. The reported carbon footprints for solar, nuclear, natural gas, and coal are 0.0084–0.018, 0.006–0.009, 0.29–0.44, 0.47–0.74Mt CO2 for 1Mt CO2 captured per year1. The corresponding energy costs of CO2 removal in calcium looping using solar, nuclear, natural gas, and wind are reported to be $430–690, $400–620, $220–390, and $360–570/t CO2 captured23.

For the commonly used liquid amine-based sorbent, monoethanolamine (MEA) aqueous solution, the heat loss from water evaporation (\({Q}_{{vaporization}}\)) must be considered besides the substantial \({Q}_{{sensible}}\) from water (4.2 J/g•K)16. During regeneration, the CO2 at the top of the regenerator becomes saturated with water18. While sorbents with low \({Q}_{{desorption}}\) may reduce the direct energy consumption from desorption, sorbent with high \({Q}_{{desorption}}\) can reduce the water vapor loss by increasing the partial equilibrium pressure of CO2, and the need for excess water vapor can be minimized. Therefore, the choice of sorbent should balance the regeneration temperature and \({Q}_{{vaporization}}\) for optimal efficiency19. The upper panel of DAC regeneration in Fig. 2 outlines the thermodynamic quantities and corresponding heat components for several DAC sorbents.

Another important property is the sorbent longevity. The replacement of sorbents leads to increased energy consumption and carbon emissions if the sorbents have a short lifetime after adsorption-regeneration cycles. This aspect is often overlooked by those prioritizing higher sorption capacity and mild regeneration conditions. First, deterioration occurs over repetitive capture and regeneration cycles, where poorer sorbent quality compromises the effectiveness of capture by lowering the adsorption capacity17. The causes of degradation include moisture effect20, air oxidation21 and low tolerance to impurities22. Last but not least, rapid sorption/desorption kinetics is also crucial to enhance the turnover frequency of DAC. Besides the intrinsic chemical reaction rate constants, kinetics is also influenced by pore structure, surface area, and specific heat capacity.

Carbon footprint and cost consideration of energy sources

From the previous discussion, different sorbents require different energy inputs for regeneration, which determines the weighting of this step among the entire life cycle of DAC. Accordingly, the choice of energy sources for regeneration significantly impacts overall energy efficiency and carbon emissions. One can picture an extreme case that fossil fuel is used to regenerate the sorbents, then it is likely that the emitted CO2 could approach the amount captured, making the overall DAC process less effective. Renewable energy sources can result in carbon negativity but still vary drastically among different types and locations. For example, when solar energy is used for both heat and electricity in solid sorbent, carbon emission is around 0.0084 to 0.018 Mt CO2 for 1 Mt CO2 captured per year in the mid-range, whereas natural gas can produce 0.29 to 0.44 Mt carbon emission per year1. The numbers show that natural gas in regeneration can additionally contribute nearly half of the captured 1 Mt CO2, proving to be very counterproductive.

On the other hand, the financial cost of natural gas is lower than that of solar energy. For gross capture cost per ton of CO2 removal using liquid solvent sorbent, natural gas costs $220–390, while solar energy costs $430–69023. A more accurate cost estimate must consider net CO2 removal, as burning natural gas for regeneration produces additional carbon emissions. While renewable energy sources achieve a similar removal rate, they come at much higher costs than fossil fuels. Achieving a balance between effectiveness and low cost remains challenging in fostering clean alternatives. In Fig. 2, the lower panel of DAC regeneration outlines the carbon footprint and energy cost of DAC systems using different energy sources.

Additionally, the optimization of flow configuration can reduce both capture costs and energy demand. In the capture process, electricity is required to operate fans and pumps, highlighting its role as a key component of energy consumption alongside the thermal energy needed for regeneration. Traditional CO2 absorption methods in industry employ towers filled with packing materials. However, DAC contactor has a different dimension compared to traditional tower. To minimize the pressure drop caused by the dilute concentration of CO2 and the large volume of gas intake, shallow contactors with a large contacting surface area are more effective24,25.

Distributed DAC

From previous discussions, careful location selection is crucial for a centralized DAC plant to be carbon-negative and financially sustainable upon scaling up due to land occupation, energy requirements for ventilation, and post-regeneration CO2 collection. The limited land available in dense cities relative to nonurban global areas might imply priority of the deployment of the less land-intensive DAC1. These stringent conditions suggest that centralized DAC may not always be a flexible and efficient option for large-scale deployment. To expand the overall carbon removal potential, rather than piling up large contactors in DAC plants as single-point sources for CO2 capture, a distributed deployment model within urban areas complementary to the centralized DAC could overcome these limitations.

Distributed DAC systems in urban areas can offer significant benefits by leveraging existing infrastructure and serving large populations. Placing these systems in cities takes advantage of the growth of carbon economy, especially in areas where CO2 emission sources and the carbon industry are easily accessible. Using captured CO2 as a feedstock for producing sustainable fuels has the potential to replace fossil-based inputs in industrial processes (Fig. 1a) Our analysis indicates that clean energy can greatly reduce carbon emissions. With cities increasingly advocating for clean energy sources, including wind, solar, and nuclear, the availability of renewable low-carbon electricity will enhance the efficiency of DAC systems26. Both the capture and utilization of CO2 can be effectively implemented in urban areas. (Fig. 2, lower panel)

The distributed design for CO2 removal in urban areas significantly enhances the potential for carbon capture and storage. By integrating DAC with existing urban building infrastructure, this approach reduces location dependency and lowers energy costs associated with ventilation and transportation, making it both environmentally and financially sustainable1. A major contributor to operational costs in centralized DAC is the contactor. For instance, in the case of CO2 regeneration with liquid-based sorbents, air contactors contribute 20% of the capital costs and 30% of the operating and maintenance costs of the entire direct air capture (DAC) plant1. To optimize DAC design and minimize costs, systems-level strategies may include adopting more integrated designs, such as utilizing existing hardware and infrastructure (e.g., heating, ventilation, and air conditioning(HVAC) systems in buildings or combined heat and power systems) and integrating with industrial systems (e.g., steel and cement production) that generate significant quantities of low- to high-quality waste heat1. Additionally, urban areas offer access to various transportation methods, including rail, pipelines, and commercial trucks, further enhancing the feasibility of DAC deployment in such settings. (Fig. 1c)

Large-scale and flexible deployment

Recirculating air through a building’s HVAC system offers great potential for implementing indoor DAC. Capturing CO2 from indoor environments, where concentrations are about two to three times higher than the atmospheric level of 420 ppm, represents a thermodynamic advantage over conventional centralized DAC27. The estimated capacity for carbon storage from indoor spaces ranges from 0.02 to 0.13 Gt CO₂ per year28. Moreover, the utilization of urban vegetation, soil, and construction materials such as wood and biochar within built environments can estimated to contribute to 0.2–1.1 Gt CO₂ per year28. Currently, the scale of distributed DAC, though still in its early stages, is estimated to reach approximately 9 kt CO₂ per year in Germany10.

A typical volumetric exchange rate in office buildings is about 5–10 times per hour29. Despite the low concentration of CO2 in the air, the absolute amount of CO₂ passing through the HVAC system is substantial29. For example, the Willis Tower, a landmark building in Chicago, U.S., provides 418,000 m2 of office space. Assuming an average ceiling height of 4 m, this results in a total air volume of around 1,670,000 m3 30. Based on the recommended ventilation rate for office buildings, the estimated airflow is 8–17 Mm3 h−1. With a CO2 concentration of 400 ppm in air, this translates to 6–14 tCO2 h−1 available for capture in a single building. Implementing additional distributed DAC filters in buildings is expected to significantly enhance CO₂ capture efforts.

Building sector energy efficiency and improved public health

By integrating building HVAC systems with DAC units, energy use by air contactors is minimized as the system takes advantage of the existing airflow for CO₂ capture. CO2-lean air can be supplied to indoor occupants without the need for additional fans and pumps, by retrofitting distributed DAC filters downstream of conventional air filters in buildings. Filtering the air post-capture reduces indoor air pollutants and enables air to be recirculated within the building, avoiding the frequent intake of fresh outdoor air, which is typically energy-intensive and inefficient31.

Moreover, distributed DAC systems can directly benefit the large population living in the urban area, helping to decrease indoor CO2 concentration and improve public health. According to the ASHRAE 62.2-2022 standard, buildings require a minimum circulation rate of 15 cubic feet per minute to maintain air quality and occupant comfort32. Average indoor CO2 levels in offices and homes typically range from 600 to 1,000 ppm, but can exceed 2,000 ppm with higher occupancy and lower building ventilation33. The elevated CO2 level can adversely impact both work productivity and sleep quality34. For instance, high CO₂ levels are associated with increased headaches, higher student absenteeism, as well as reduced cognitive performance35.

Efficient low-carbon-footprint regeneration with optimal transportation modes

Minimizing capture costs, energy demand, and carbon emissions are essential for developing the most efficient CO2 capture system. A comprehensive life-cycle analysis (LCA) must account for the carbon emissions to accurately evaluate the overall CO2 removal. A low-carbon-footprint heat source is essential to ensure positive carbon capture efficiency. Current centralized DAC plants are typically situated near renewable energy sources such as geothermal or other renewable energy options. To implement distributed DAC effectively, the regeneration energy source also needs be decentralized.

The availability of renewable low-carbon electricity and heat sources near urban areas can remove location constraints, making them ideal for regeneration. Low-carbon electricity and heat sources, such as wind, solar, biomass, nuclear, and geothermal energy, can all contribute to the energy supply. According to the map of low-carbon heat sources26, biomass and nuclear energy are more readily accessible around urban areas in the U.S. Additionally, rural areas with abundant renewable energy sources are often located not far away from urban centers. The efficient transport and regeneration of sorbents can be supported by urban transportation infrastructure, while the use of electric vehicles can further reduce capital costs and carbon emissions. This enables large-scale deployment of distributed DAC systems.

Reflecting on the example of CO2 capture using air filters at Willis Tower, the energy demand for regenerating CO2 with solid sorbents is estimated to be 5–8.3 GJ/t CO₂. Consequently, the additional power requirement for regenerating saturated sorbents will range from 8–33 MWh. Integrating the HVAC system with the DAC system does not require energy to facilitate gas intake, assuming the pressure drop is negligible. It is anticipated that sorbents will be regenerated using onsite renewable solar energy or electricity. Given the substantial energy required for regeneration and the collection of carbon products, CO2 must be processed and transported to collection sites. The subsequent deployment involves selecting optimal transport modes to collection sites around urban areas for short-term storage or geological chambers for long-term storage, eventually leading to geological sequestration at specific locations28.

Additional consideration

The rapid scaling of DAC technology can greatly benefit from its distributed design, along with public acceptance and political support. However, the discrepancies in technological and social feasibility of distributed DAC across different regions pose additional challenges case by case, such as the availability of renewable energy supply for regeneration and integration into existing hardware and infrastructure, including ventilation systems in buildings and industrial settings1,10. Further justification and evaluation are required to address these challenges effectively.

Additional energy costs and carbon emission associated with transportation to collection sites for storage must also be considered in the full analysis. For example, utilizing existing urban transportation infrastructure, including water pipelines, railways, and other systems, can reduce capital costs. The widespread adoption of electric vehicles can further minimize carbon footprints, making transportation in distributed DAC systems more sustainable. According to transportation model36, a less frequent pickup is preferred to reduce the transportation’s impact on the overall CO2 removal efficiency, while daily pickups reduce net CO2 removal efficiency by 40%. The efficiency approaches nearly 100% if transportation occurs as infrequently as bimonthly. However, less frequent pickups could cause issues if the saturated sorbent filters are not shipped promptly for regeneration. Once the sorbent reaches its capture capacity, it will no longer capture CO2 effectively, decreasing system efficiency. While waiting for sorbent replacement, prolonged storage of saturated sorbents requires additional space, increases operational costs, and pose safety and maintenance concerns. It is important to determine how frequent pickups remain advantageous for overall CO2 removal efficiency.

Conclusions and future perspectives

Developing energy-efficient and cost-effective DAC systems is essential for reducing the global carbon emissions upon scaling up15. Efforts to advance energy-demanding thermal regeneration of sorbents in DAC is crucial for achieving efficient operations. As improvement and innovation of DAC technology mostly focus on the sorption capacity, limitation exists in evaluating the effectiveness of the regeneration process.

To optimize DAC effectiveness, it is important to assess the energy demands and carbon footprints associated with different sorbents and energy sources. Ideal sorbents exhibit low heat capacity, high durability, and efficient sorption/desorption kinetics to maximize both the energy efficiency and longevity. Despite their high energy costs, renewable energy sources with minimal carbon emissions are preferred for regeneration. Additionally, system optimizations that increase mass-transfer efficiency can also reduce overall operational expenses and energy demands.

Centralized DAC plants may face limitations in scaling up due to challenges such as land requirements, energy source availability, and CO2 collection post-regeneration. A distributed deployment within urban areas can address these limitations, by integrating DAC with existing urban building infrastructure. This approach expands the capture scale, minimizes location constraints, and improves public health.

Several emerging technologies have the potential for further reducing carbon emissions in the full life-cycle analysis, including passive-air contactors and natural sorbents17. Passive air contactors help minimize energy and freshwater consumption, while natural sorbents, such as biomass and biochar, contribute to a reduced carbon footprint during production.

The National Academies’ report emphasizes the development of low-cost solid sorbents with enhanced CO2 sorption capacity and kinetics1. These solid sorbents, which require less energy for regeneration, can be supported in various solid forms with amine functionalization. Chemical functional groups are introduced onto the surface or within pore structures of the sorbent materials through impregnation procedure37, combining the advantages of the host materials with enhanced chemical functionality to improve both the sorption capacity and efficiency. Additionally, identifying and recycling degradation products from sorbents is crucial for maintaining long-term efficiency.

Finally, besides the modular designs and collaborative efforts between academia and industry, the scale-up rate of DAC will largely depend on public acceptance and political support. This could be driven by strategies such as incentives (e.g., subsidies, tax rebates) and mandates (e.g., regulations, policy initiatives) that encourage widespread adoption28,38. Mandating the progressive deployment of DAC drives market investment, which sustains political backing from a feedback loop of incentives and mandates in turn38. In summary, for DAC to be truly sustainable and effectively contribute to meaningful global carbon reductions, it is essential to prioritize the efficient regeneration of sorbents after capture, especially as the technology scales.

Data availability

Data sharing is not applicable to this article as no datasets were generated or analysed during the current study.

References

National Academies of Sciences Engineering, and M. et al. Negative Emissions Technologies and Reliable Sequestration. (National Academies Press, Washington, D.C., 2018). https://doi.org/10.17226/25259.

Hanna, R., Abdulla, A., Xu, Y. & Victor, D. G. Emergency deployment of direct air capture as a response to the climate crisis. Nat. Commun. 12, 368 (2021).

Division on Earth and Life Studies, Ocean Studies Board, Board on Atmospheric Sciences and Climate & Committee on Geoengineering Climate: Technical Evaluation and Discussion of Impacts. Climate Intervention. Climate Intervention: Carbon Dioxide Removal and Reliable Sequestration (National Academies Press, Washington, D.C., 2015). https://doi.org/10.17226/18805.

Lackner, K., Ziock, H.-J. & Grimes, P. Carbon Dioxide Extraction from Air: Is It An Option? https://www.osti.gov/servlets/purl/770509 (1999).

Ehlig-Economides, C. A. Geologic carbon dioxide sequestration methods, opportunities, and impacts. Curr. Opin. Chem. Eng. 42, 100957 (2023).

Al-Shargabi, M., Davoodi, S., Wood, D. A., Rukavishnikov, V. S. & Minaev, K. M. Carbon dioxide applications for enhanced oil recovery assisted by nanoparticles: recent developments. ACS Omega 7, 9984–9994 (2022).

Olah, G. A. Beyond oil and gas: the methanol economy. Angew. Chem. Int. Ed. 44, 2636–2639 (2005).

K. Lebling, H. Leslie-Bole, Z. Byrum & L. Bridgwater. 6 Things to Know About Direct Air Capture. World Resources Institute https://www.wri.org/insights/direct-air-capture-resource-considerations-and-costs-carbon-removal (2022).

Direct Air Capture. Internation Energy Agency https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage/direct-air-capture (2023).

Borchers, M. et al. Scoping carbon dioxide removal options for Germany–What is their potential contribution to Net-Zero CO2? Frontiers in Climate 4, https://www.frontiersin.org/journals/climate/articles/10.3389/fclim.2022.810343/full (2022).

Global CCS Institute. Global Status of CCS 2023 – Report & Executive Summary https://www.globalccsinstitute.com/resources/publications-reports-research/global-status-of-ccs-2023-executive-summary (2023).

Abdullatif, Y. et al. Emerging trends in direct air capture of CO2: a review of technology options targeting net-zero emissions. RSC Adv 13, 5687–5722 (2023).

Jones, C. W. CO2 capture from dilute gases as a component of modern global carbon management. Annu Rev. Chem. Biomol. Eng. 2, 31–52 (2011).

Chatterjee, S. & Huang, K.-W. Unrealistic energy and materials requirement for direct air capture in deep mitigation pathways. Nat. Commun. 11, 3287 (2020).

An, K., Li, K., Yang, C. M., Brechtl, J. & Nawaz, K. A comprehensive review on regeneration strategies for direct air capture. J. CO2 Utilization 76, 102587 (2023).

Van Straelen, J. & Geuzebroek, F. The thermodynamic minimumregeneration energy required for post-combustion CO2 capture. Energy Procedia 4, 1500–1507 (2011).

Ozkan, M., Nayak, S. P., Ruiz, A. D. & Jiang, W. Current status and pillars of direct air capture technologies. iScience 25, 103990 (2022).

Kasturi, A. et al. Determination of the Regeneration Energy of Direct Air Capture Solvents/Sorbents Using Calorimetric Methods. Sep. Purif. Technol. 310, 123154 (2023).

Oexmann, J. & Kather, A. Minimising the regeneration heat duty of post-combustion CO2 capture by wet chemical absorption: The misguided focus on low heat of absorption solvents. Int. J. Greenh. Gas. Control 4, 36–43 (2010).

Fayaz, M. & Sayari, A. Long-term effect of steam exposure on CO 2 capture performance of amine-grafted silica. ACS Appl Mater. Interfaces 9, 43747–43754 (2017).

Ahmadalinezhad, A. & Sayari, A. Oxidative degradation of silica-supported polyethylenimine for CO 2 adsorption: insights into the nature of deactivated species. Phys. Chem. Chem. Phys. 16, 1529–1535 (2014).

Uyanga, I. J. & Idem, R. O. Studies of SO 2 - and O 2 -induced degradation of aqueous MEA during CO 2 capture from power plant flue gas streams. Ind. Eng. Chem. Res 46, 2558–2566 (2007).

McQueen, N., Desmond, M. J., Socolow, R. H., Psarras, P. & Wilcox, J. Natural gas vs. electricity for solvent-based direct air capture. Frontiers in Climate 2, https://doi.org/10.3389/fclim.2020.618644 (2021).

Keith, D. W., Ha-Duong, M. & Stolaroff, J. K. Climate strategy with Co2 capture from the air. Clim. Change 74, 17–45 (2006).

Zhao, X., Wang, S., Yin, X., Yu, J. & Ding, B. Slip-effect functional air filter for efficient purification of PM2.5. Sci. Rep. 6, 35472 (2016).

Great Plans Institute. An Atlas of Direct Air Capture: Opportunities for Negative Emissions in the United States. https://carboncaptureready.betterenergy.org/wp-content/uploads/2023/03/DAC-Hubs-Atlas-2023.pdf (2023).

López, L. R. et al. CO2 in indoor environments: From environmental and health risk to potential renewable carbon source. Sci. Total Environ. 856, 159088 (2023).

Rodriguez Mendez, Q., Fuss, S., Lück, S. & Creutzig, F. Assessing global urban CO2 removal. Nat. Cities 1, 413–423 (2024).

Dittmeyer, R., Klumpp, M., Kant, P. & Ozin, G. Crowd oil not crude oil. Nat. Commun. 10, 1818 (2019).

Willis Tower. https://en.wikipedia.org/wiki/Willis_Tower.

Baus, L. & Nehr, S. Potentials and limitations of direct air capturing in the built environment. Build Environ. 208, 108629 (2022).

ASHRAE. Standard 62.2-2022 -- Ventilation and Acceptable Indoor Air Quality in Residential Buildings (ANSI Approved) https://store.accuristech.com/ashrae/standards/ashrae-62-2-2022?product_id=2501064 (2022).

Jacobson, T. A. et al. Direct human health risks of increased atmospheric carbon dioxide. Nat. Sustain 2, 691–701 (2019).

Kang, M. et al. Ventilation causing an average CO2 concentration of 1,000 ppm negatively affects sleep: A field-lab study on healthy young people. Build Environ. 249, 111118 (2024).

Seppänen, O. A., Fisk, W. J. & Mendell, M. J. Association of Ventilation Rates and CO2 Concentrations with Health andOther Responses in Commercial and Institutional Buildings. Indoor Air 9, 226–252 (1999).

Kobayashi-Carvalhaes, T. & Ahmad, N. Initial Systems-Level Assessment of a Distributed Direct Air Capture System Concept at the Urban-Scale (UrbanDAC). www.osti.gov (2023).

Sanz-Pérez, E. S., Murdock, C. R., Didas, S. A. & Jones, C. W. Direct Capture of CO2 from Ambient Air. Chem. Rev. 116, 11840–11876 (2016).

Meckling, J. & Biber, E. A policy roadmap for negative emissions using direct air capture. Nat Commun 12, (2021).

Callum Hunt. DAC Unpacked – a Guide to the Direct Air Capture Market. https://abatable.com/blog/dac-unpacked-direct-air-capture-guide/ (2023).

Weiland, R. H., Dingman, J. C. & Cronin, D. B. Heat Capacity of Aqueous Monoethanolamine, Diethanolamine, N-Methyldiethanolamine, and N-Methyldiethanolamine-Based Blends with Carbon Dioxide. https://pubs.acs.org/sharingguidelines (1997).

Surkatti, R. et al. Comparative analysis of amine-functionalized silica for direct air capture (DAC): Material characterization, performance, and thermodynamic efficiency. Sep Purif Technol 354, (2025).

Ghedini, E. et al. Multifunctional and environmentally friendly TiO2-SiO2 mesoporous materials for sustainable green buildings. Molecules 24, (2019).

Materials Property Data. Calcium Carbonate, Calcite (CaCO3). https://www.matweb.com/search/datasheet_print.aspx?matguid=bea4bfa9c8bd462093d50da5eebe78ac.

Song, H. J. et al. Simplified estimation of regeneration energy of 30 wt % sodium glycinate solution for carbon dioxide absorption. Ind. Eng. Chem. Res 47, 9925–9930 (2008).

Potter, M. E., Pang, S. H. & Jones, C. W. Adsorption microcalorimetry of CO2 in confined aminopolymers. Langmuir 33, 117–124 (2017).

Criado, J. M., González, M., Málek, J. & Ortega, A. The effect of the CO2 pressure on the thermal decomposition kinetics of calcium carbonate. Thermochim. Acta 254, 121–127 (1995).

Acknowledgements

The project is sponsored by the startup fund by Pritzker School of Molecular Engineering, University of Chicago and the ACS Petroleum Research Fund (PRF) 67770-ND10.

Author information

Authors and Affiliations

Contributions

P. C. H. and Y. C. conceived the perspective. Y. C. wrote the manuscript under the supervision of P. C. H., and R.W. contributed to manuscript revisions.

Corresponding author

Ethics declarations

Competing interests

All authors declare no financial or non-financial competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Chen, Y., Wu, R. & Hsu, PC. Perspective on distributed direct air capture: what, why, and how?. npj Mater. Sustain. 3, 12 (2025). https://doi.org/10.1038/s44296-025-00056-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44296-025-00056-w