Abstract

This study provides a comprehensive analysis of residual stress characteristics in nitinol parts fabricated via laser powder bed fusion (PBF-LB). Unlike previous works that primarily focus on qualitative assessments or single-measurement techniques, this research employs a multi-modal experimental approach, Electronic Speckle Pattern Interferometry-Hole Drilling (ESPI-HD) and X-ray Diffraction (XRD), to achieve a more precise and spatially resolved evaluation of residual stress distribution. Furthermore, the study establishes a direct correlation between residual stress evolution and in situ pyrometric melt pool temperature data, an aspect that has not been extensively explored in prior investigations. A key novel finding is the non-monotonic relationship between volumetric energy density (VED) and residual stress. In this work, laser power was kept constant, and VED was varied by adjusting scanning speed and hatch spacing. The results show that the average residual stress initially increases with decreasing scan speed and hatch spacing, plateaus at a critical threshold, and subsequently decreases. However, residual stress was also found to vary in the build direction, indicating the complex stress distributions and accommodation mechanisms within the material. Additionally, an inverse relationship was recorded between the thermal gradient and VED which challenges conventional assumptions about their relationship. These insights offer a new perspective on optimizing PBF-LB process parameters for enhanced structural performance and long-term reliability of additively manufactured nitinol.

Similar content being viewed by others

Introduction

Powder bed fusion using laser beam (PBF-LB) manufacturing technology has gained attention in the metal additive manufacturing sector over the past decade because of its ability to fabricate hard-to-machine metallic (such as Ti alloys) components into a near net shape with little or no postprocessing1,2. Nitinol (NiTi) intermetallic alloys are widely used for their shape memory capabilities caused by solid-state diffusionless phase transformations. The phase transformations between the austenite and martensite phases can be thermally induced (shape memory NiTi) or stress-induced (superelastic NiTi) based on the material composition and microstructure for specific applications. By controlling the PBF-LB parameters, these phase transformations can be controlled by altering the mechanical, physical, and thermal properties3,4,5. The PBF-LB of NiTi alloys is at a high developmental pace to produce effective complex structures for a wide range of applications in the medical, energy, and aerospace sectors.

Residual stresses (RS) are often defined as the stresses that remain at equilibrium in a material after certain material processing or treatment steps. These stresses are often exposed when the material is plastically deformed. Since manufacturing processes involve nonuniform loading, RSs are developed and modified at every stage of material processing6,7. The RS in PBF-LB originates primarily from process-induced thermal gradients (often referred to as thermal residual stress). The local differences in thermal expansion in a multiphase matrix or between neighboring grains can also cause RS8,9. Localized remelting of the powder and fused particles and subsequent rapid cooling (approximately 106 K/s) cause thermal transients, which stimulate stress formation10. In PBF-LB, these thermal mechanisms can be described via two models: the temperature gradient mechanism (TGM) and the cool-down mechanism. TGM is linked to stress formation in a single melt track, whereas the latter is linked to stress formation in an entire layer of melted powder11.

In NiTi alloys, RS can lead to localized detwinning and plastic dislocations, potentially altering phase transformation characteristics12. As a result, the formation of RS in NiTi components plays a critical role in their functional performance. Ma et al. 13 reported that increasing the hatch distance in PBF-LB samples resulted in high dislocation densities, leading to local misfits during phase transformation, which correlated with a reduction in the transformation temperatures. Conversely, RS was shown to increase the transformation temperatures, following a Clausius‒Clapeyron stress‒temperature relationship of approximately 8 MPa/K in the work of Liu et al.14. This finding indicates that both process-induced RS and high dislocation densities influence the transformation temperatures. Wang et al.15 demonstrated that reducing the scanning vector length and employing an appropriate scanning strategy can help minimize RS development in PBF-LB-produced NiTi. In another study by Lu et al.16, various martensite morphologies (variants) were attributed to RS in the samples. Additionally, both martensite and intermediate R-phase were observed in the microstructure, potentially resulting from stress accumulation and relaxation during processing. Chekotu et al.17 reported that RS from scan overlaps led to microcracks in PBF-LB-fabricated NiTi and recommended substrate preheating to mitigate these stresses. Monu et al18. used simulations to model RS in NiTi produced by PBF-LB under different bi-directional scanning patterns. Their predicted stress contours closely matched thermograms from in situ temperature data, providing insights into TGM-type RS formation.

RS can be evaluated through destructive (distortion-based), semi-destructive and nondestructive techniques (diffraction-based). The destructive measurements work on the basis of the strain‒release principle. When an RS-free material is sectioned at a plane, the total summation of stresses normal to the plane should be zero at static equilibrium. If a nonzero strain value is measured normal to the plane, then this difference caused by disturbance of the mechanical equilibrium provides an indication of the RS. The measured strain can then be processed via an analytical or finite element (FE) model to estimate the actual stress values. Common destructive methods include the hole-drilling (HD) method, contour method, and micro-ring core milling analysis19,20. A recent modification has been introduced to the traditional hole-drilling method, known as the electronic speckle-pattern interferometry (ESPI)-hole drilling method. ESPI is an innovative, noncontact optical measurement technique designed for the precise measurement of small displacements across the entire field of view. It is a semi-destructive RS measurement technique that is utilized to measure the distribution and magnitude of RS near the surface of a component. It involves drilling a small hole at small increments on the surface of the component, which is illuminated by coherent laser light. The removal of material causes surface displacements and strains as a result of stress release, while the back calculation of these strains is used to determine the original RS at each increment. The method is based on image analysis of images created by the interference of the object beam and the reference beam, where the reference beam is phase shifted and an image is taken at each shift. The ESPI method is therefore more effective in determining the stress relaxations identified by the changes in the speckle pattern. By subtracting this modified speckle pattern from a reference pattern, correlation fringes are obtained, enabling accurate quantification of RS in a highly efficient and noninvasive manner21,22.

Diffraction-based methods, such as X-ray diffraction (XRD) and neutron diffraction (ND), rely on two fundamental principles. The first is Bragg’s law presented in Eq. (1), which relates the position of the diffracted peak (\(\theta\)) to the lattice spacing (\({{\rm{d}}}_{\mathrm{hkl}}\)) and the wavelength of the incident radiation (\({\rm{\lambda }}\)). This relationship allows the measurement of the lattice spacing, which can then be compared with the unstrained lattice parameters and ray constants to determine the existing lattice strain23,24.

The second principle is based on Hooke’s law, which relates strain to stress through the material’s modulus of elasticity (\({\rm{E}}\)). In diffraction-based methods, this relationship is used to estimate stress values. The stress normal to the measured plane is assumed to be zero, allowing the lattice spacing (\({\rm{d}})\) to be directly interpreted as the strain measurement. The relationship between the stress (\({\sigma }_{\varphi }\)), Young’s modulus (\({\rm{E}}\)), Poisson’s ratio (\({\rm{\nu }}\)), and slope (\({\rm{m}}\)) of \({\rm{d}}\) vs. \({\sin }^{2}{\Psi }\) (\({\Psi}\) is the angle between the sample surface normal and the diffraction vector) is given by Eq. (2)25,26, where \({\rm{\varphi }}\) represents the orientation angle.

The primary objective of this study was to investigate the influence of VED (controlled through variations in scanning speed and hatch spacing while keeping laser power constant) on the development of RS in NiTi samples fabricated via PBF-LB. RS measurements were conducted using two complementary techniques: X-ray diffraction (XRD) for surface-level stress distribution (up to 100 μm depth) and Electronic Speckle Pattern Interferometry-Hole Drilling (ESPI-HD) for stress analysis up to 250 μm in depth. Unlike previous studies that primarily focus on qualitative residual stress assessments or single-measurement methods, this work provides a depth-resolved, multi-modal analysis, offering a more comprehensive understanding of RS distribution in additively manufactured NiTi. Furthermore, the measured residual stresses were systematically correlated with in situ pyrometric infrared (IR) melt pool temperature data—an approach that has received limited attention in the literature to date.

A key novelty of this research lies in its detailed exploration of the relationship between VED, thermal gradients, and RS evolution. While prior studies have acknowledged the role of energy input in stress formation, the findings here reveal a non-monotonic trend in average RS with increasing VED and thermal gradients, alongside depth-dependent variations in stress distribution. Additionally, the inverse relationship between thermal gradients and VED challenges conventional assumptions about their relationship. By elucidating these complex interactions, this study provides new insights into the temperature gradient mechanism of RS formation, demonstrating how precise control of PBF-LB parameters can tailor RS distributions potentially without requiring post-process heat treatments. These findings contribute valuable knowledge for optimizing PBF-LB processing strategies to manage or mitigate RS in NiTi components, ultimately enhancing their structural integrity and functional performance.

Results and Discussion

RS analysis based on the XRD and ESPI-HD results

The XRD and ESPI-HD RS analyses were conducted on the XY plane of the samples (along the z-axis or build direction). In the XRD method, the residual strain (lattice spacing) in the samples was calculated as described earlier through the peak intensities, full width at half-maximum (FWHM) and shifts in the peaks observed. To convert the measured strains into stresses, Eq. (2) was applied using material properties determined from previously conducted in-house experiments, where a Poisson’s ratio of 0.3 and a Young’s modulus of 28 GPa were measured. These values were further validated through published literature27,28 to ensure consistency and accuracy. The first stress-measurement trials indicated the presence of a mild-medium texture on the basis of the intensities recorded for 5 positive and 5 negative χ-tilts, which is expected for PBF-LB parts. This resulted in a high relative uncertainty in the results. To improve the results, the number of tilts was increased to 9 positive tilts and 9 negative tilts with a tilt (χ) oscillation of 2°. Moreover, for further improvement, the measurements were carried out on 3 different orientations (φ = 0°, 45°, 90°) with a rotation oscillation of ± 5°. The peak shifts were determined via the cross-correlation method after background removal and absorption correction. The individual stresses for each orientation were determined by fitting an ellipsoid model function to d-sin2ψ plots. After this treatment, the relative measurement uncertainties were within 25%, which is considered acceptable for mild-medium textured samples. The XRD patterns of the samples are illustrated in Fig. 1.

The stress components are detailed in Table 1, where \({\upsigma} {\_}{\rm{x}}{\rm{x}}\) and \({\upsigma}{\_}\mathrm{yy}\) represent normal stresses, \({\uptau} {\_}{\rm{x}}{\rm{y}}\) denotes shear stress, and \({\upsigma}{\_}{\rm{Max}}\) and \({\upsigma}{\_}{\mathrm{Min}}\) are principal stresses. To derive an average generalized stress value from the RS measurements, the von-Mises stress was calculated using the normal and shear stress components, as expressed in Eq. (3). The analysis revealed that the stresses exist in both the tensile and compressive regimes. Specifically, compressive stresses are predominant near the surface, whereas tensile stresses become more prevalent deeper within the material. Compressive stresses can be beneficial, as they increase the resistance of a material to crack initiation and improve its fatigue life. In contrast, tensile stresses may increase the susceptibility to crack propagation29,30.

Effect of increasing VED by reduced scanning speed and hatch spacing on RS

Figure 2a illustrates the relationship between the stress components and VED along with error bars calculated based on standard deviation of the stress values in Table 1. Our work focused on increasing the VED by decreasing the scanning speed and hatch spacing, while keeping the laser power constant. The data show that the RS behavior varies significantly with depth and VED. When examining the stress trends at different depths, distinct variations emerge. For instance, at depths less than 100 μm, the von-Mises stress consistently decreases with increasing VED. At deeper regions, specifically at 200 μm and 250 μm, a consistent increasing trend in von-Mises stress is observed with rising VED. This depth-dependent variation in RS highlights the need for a more nuanced interpretation of VED’s effects across different regions of the sample. Upon analyzing the averaged values of the stress components and von-Mises stress, it can be observed that, as VED increases, RS initially rises and then decreases. This trend suggests that at lower to intermediate VED levels, energy absorption within the material intensifies, likely causing localized heating that leads to uneven expansion and contraction, which in turn generates RS. Additionally, at these lower VED levels, rapid cooling rates can promote the formation of martensitic phases, further contributing to increased RS31. As VED continues to increase, the melt pool reaches higher temperatures and expands, resulting in a larger melt pool volume and reduced cooling rates. This mitigates the steep thermal gradients associated with high cooling and solidification rates, which are known to drive detrimental tensile RS. The elevated melt pool temperatures and slower cooling rates promote stress relaxation, as the material has more time to accommodate thermal strains during solidification. Consequently, the reduction in the RS at a higher VED is observed as the cooling rate decreases. Since scanning speed affects solidification rates, it is likely that both factors—higher thermal energy input and slower solidification—contribute to the stress relaxation observed at high VED. Materials exposed to high energy densities can adapt more effectively to thermal changes, leading to lower RS32. Furthermore, phase transformations, such as those from martensite to austenite at elevated temperatures, induce volume changes that aid in redistributing internal stresses, contributing to an overall reduction in RS levels33,34. Mugwagwa et al.35 also reported that intermediate VED resulted in higher RS than both low and high VED in PBF-LB, similar to the findings of this study. These authors attributed the higher porosity in the low- and high-VED samples as the cause for lower RS. The porosity related to VED in PBF-LB can arise from two main causes. Excessively high VED can result in overheating, leading to keyhole porosity, whereas insufficient VED can cause underheating, leading to a lack of fusion porosity. However, in addition to VED, variations in scanning speed impact solidification dynamics, further influencing both RS and defect formation. Therefore, while VED remains a key parameter in RS development, differences in solidification rates resulting from varying scanning speeds must also be considered when interpreting the observed trends in the sample stress profile.

Figure 2b shows the impact of increasing the VED on the FWHM of the diffraction peaks, as measured via XRD. A sharp increase in the FWHM is observed when the VED increases from low to intermediate levels, followed by a less significant increase from intermediate to high levels. As indicated by the Scherrer equation, the FWHM is directly related to strain within the material and inversely related to crystallite size: larger FWHM values generally signify smaller crystallites, whereas smaller FWHM values are associated with larger grains and better crystalline quality36. With increasing VED, the elevated energy input promotes atomic mobility during solidification, lowers the cooling rate, and consequently leads to grain growth. According to the Hall-Petch relationship, a reduced grain size increases the material strength. However, the greater grain boundary area in smaller grains limits dislocation movement, which in turn increases internal stress levels37,38. In our study, the grain size reduction is more pronounced from low to intermediate VED and less so from intermediate to high VED, as evidenced by the changes in the FWHM. This trend aligns with the observed RS, where the intermediate VED results in the highest RS, which is likely due to the rapid decrease in the grain size at this level. In contrast, the reduction in RS at high VED may result from a less steep overall grain size reduction, potentially due to the formation of larger grains. Lin et al.39 previously reported this unique grain size behavior in NiTi processed via PBF-LB, noting that the grain size can vary nonlinearly with VED, increasing with increasing VED in some cases and decreasing in others. Additionally, elevated VED levels during PBF-LB of NiTi have been shown to increase melt pool temperatures, which can lead to Ni evaporation and the formation of fine martensitic grains and precipitates such as Ti2Ni and Ni4Ti340,41.

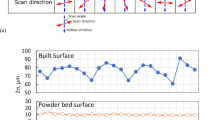

Thermal data analysis for the correlation between the RS, VED and thermal gradient

The IR thermal data collected during the PBF-LB printing process were analyzed across the XY plane for each sample, aligning with the RS measurements. The thermal profiles, which represent layer temperatures as a function of build height (z-axis), are presented in Fig. 3a. The recorded temperature can be seen to decrease with build height. This trend can be attributed to multiple factors. As more layers are deposited, the additional input energy results in a temperature rise locally. This heat conducts toward the substrate to raise the temperature toward the base of the sample. The substrate raises to a certain temperature threshold level before stabilizing. The upper layers experience more heat dissipation to their surrounding environment due to the convective gas flow42,43. These factors contribute to the observed temperature gradient with increasing build height. Another trend observed is the progressive temperature increase from samples S1 to S3 with increasing VED, indicating that higher VED levels lead to higher melt pool temperatures. The thermal gradient (TG) for each sample was calculated using Eq. (4), which assesses changes in the normalized temperature with respect to the build height:

The effect of VED (reduced scanning speed and hatch spacing) on the TG is illustrated in Fig. 3b, which shows a decrease in the TG with increasing VED. As VED increases, the larger melt pool volume and lower cooling rates promote a more uniform thermal distribution, leading to lower thermal gradients. Figure 3c shows the relationships between TG and the various stress components previously discussed along with error bars calculated based on standard deviation of the stress values in Table 1. Similar to the VED-RS trend, the average RS is highest at intermediate TG level. Owing to the inverse relationship between VED and TG, these trends mirror one another: a low TG corresponds to high VED, and vice versa. Initially, increasing TG increases RS due to disparities in thermal expansion and contraction. However, with further increases in TG, phase transformations (such as martensite-to-austenite) and increased plastic deformation contribute to reducing RS44.

Xue et al.45 investigated the effect of increasing VED in PBF-LB by reducing hatch spacing, similar to this study, and observed a reduction in RS, delamination, and cracking. Lin et al.39 also reported that a higher VED, achieved by reducing the hatch distance, improved the thermal gradient, reduced the cooling rate, and lowered the RS, resulting in a favorable <001> texture in the PBF-LB of NiTi. However, as indicated by Monu et al. 46, the relationship between VED and RS is not always straightforward. Their study showed that an increase in VED resulted in higher thermal gradients and increased RS in PBF-LB NiTi, underscoring the complex nature of RS evolution in this material. This discrepancy suggests that, while adjusting VED does influence RS, its effects are material- and process-dependent. Liu et al.47 observed a consistent increase in RS in the PBF-LB of NiTi when they increased both laser power and scanning speed while keeping hatch spacing and VED constant. This finding suggests that laser power plays a critical role in driving RS, highlighting the need for a more nuanced approach in optimizing process parameters. Furthermore, Li et al.48 reported a trend similar to ours in their study on RS-induced cracking, where RS first increased with VED and then decreased with further increases in VED.

More broadly, the effect of VED on RS is highly material-dependent49. Additional studies examined this relationship in different materials, specifically steels, and presented trends between RS and VED for these materials50,51. Simson et al.50 found that RS, that was measured on the top surface of austenitic 316 L stainless steel samples, increased considerably between low to mid VED values and remained relatively constant at higher VED values. Narvan et al.51 also examined the relationship between RS and VED on the top surface of H13 tool steel samples. This study found that compressive stresses existed on these surfaces and were observed to increase significantly from low to mid VED values and were then seen to decrease slightly moving to higher VED values. These contrasting results across different materials reinforce the need for continued research into how PBF-LB process parameters influence RS, including for NiTi specifically.

Our study’s results, particularly the observed depth-dependent variation in RS, emphasize the need for further investigation into the interaction between scanning speed, hatch spacing, and laser power in determining RS. Moreover, the stochastic nature of the PBF-LB process and practical constraints on sample characterization limit the number of specimens we can measure. The time-intensive nature of stress measurement techniques, such as XRD and ESPI-HD, restricts the dataset size. Although the results in this study provide valuable insights into the role of VED in RS development, there is much more process window space that could be investigated to provide a more detailed understanding of the relationship between the parameters and RS. Further studies could also focus on varying laser power while keeping scanning speed constant. This would allow for more of an understanding of how power influences thermal gradients and RS, independent of other parameters. Additionally, VED can be calculated based on laser spot size instead of hatch spacing, providing a different perspective on how energy is distributed across the material during processing. Expanding experimental datasets and leveraging in situ monitoring techniques in these ways could help provide a more comprehensive understanding of the complex thermal-mechanical interactions governing residual stress evolution in PBF-LB components.

Methods

PBF-LB process

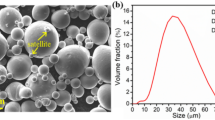

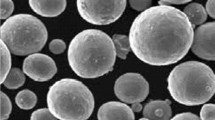

The NiTi powder used was composed of 50 at.% Ni and 50 at.% Ti. The samples were fabricated using Aconity MINI (GmbH) PBF-LB machine equipped with a Nd:YAG fiber laser system from IPG Photonics, which has a wavelength of 1068 nm and a maximum power capacity of 200 W. The build chamber was installed with a rubber-based recoater blade. The chamber was purged with argon gas (99.999%) to ensure a minimum oxygen content ( < 50 ppm) throughout the melting and solidification process. A powder supply factor of 1.8 (nearly twice the layer thickness) was used in the print process to ensure sufficient powder spread. To reduce spatter on fresh layers, the printing sequence started from the inert gas exit side of the build chamber.

Printing was performed using the laser parameter levels shown in Table 2, with a layer thickness of 40 μm and a spot size of 50 μm. The sample dimensions were 20\(\times\)10\(\times\)7.5 mm3. The layer thickness was determined on the basis of the feedstock particle size distribution to ensure good powder spread and flowability on the build platform. These parameter sets can be used to calculate the volumetric energy density (VED), which can be calculated via Eq. (5):

where \({\rm{P}}\) is the laser power (W); \({\rm{v}}\) is the scan speed (mm/s); \({\rm{h}}\) is the hatch spacing (mm); and \({\rm{t}}\) is the layer thickness (mm). The laser power was kept constant, while the scanning speed was decreased in increments of 300 mm/s, and the hatch spacing was reduced by 15 μm steps to achieve increasing VED.

The samples were arranged on the substrate plate at an in-plane angle of 30° to reduce any impact load on the re-coater assembly and to allow more gradual gas flow/fume removal over the layers in the chamber during printing. A simple stripe scanning strategy was maintained with a rotation of 90° for each subsequent layer. This prevents any unwanted overheating around the corners of the sample. The build chamber ambient temperature during the process was 20 ± 1 °C.

Thermal data monitoring

The thermal data of the molten pool were captured using two pyrometers from KLEIBER Infrared GmbH, which were employed in the Aconity PBF-LB machine. These pyrometers detect the light emitted from the area where the laser interacts, which falls within the 1500–1700 nm wavelength range. The resulting infrared (IR) data are recorded in terms of voltage (mV) units and the corresponding coordinates on the build plate (x, y, z). In this study, we generated graphical representations to visualize the temperature variations across different sections of a sample. The rate at which the data were collected was 100000 samples per second. Approximately 6 million data points were collected for a single layer, each comprising both coordinates and temperature values in mV. To depict the thermal profile, the temperature readings were transformed into a normalized scale ranging from 0 to 1.

Experimental RS measurement

XRD measurements were performed using a 3-circle portable-type stress diffractometer in modified-χ mode. Considering the fluorescence of copper with nickel and chromium with titanium, it was not possible to measure the stresses with those well-known X-ray sources. As alternatives, Mn‒Kα and Ti‒Kα radiation were used, and the best results were acquired using Ti‒Kα radiation with an average wavelength of 0.2752 nm. Using this radiation, considering the diffraction peaks above 2θ > 120°, it was possible to perform the measurements using the {1 1 0} or {2 0 0} set of planes of the austenite phase. Although a higher diffraction angle is favored for the {2 0 0} set of planes, the peaks were quite broad (reaching 10°–15°) because of the small crystallite size and high dislocation density, which resulted in the extension of the detection range. Thus, the measurements were carried out on a (2 1 1) set of planes located at approximately 134°. The tube voltage was set to 30 kV, and the tube current was 7 mA. Before the measurements, the focal distance was calibrated using both commercially pure Ti (CP-Ti) and Ti-6Al-4V powders, which are certified by the diffractometer manufacturer. In both cases, the focal distance was adjusted so that the total error in the stress calculations was lower than ±10 MPa. Figure 4a shows the XRD measurement setup.

For ESPI-hole drilling measurements, the sample surface was spray painted to reduce reflections. A drilling operation was performed precisely at the center of the sample using a Ø0.79 mm 2 flute carbide TiAlNi-coated inverted end mill. The drilling process involved incremental steps of approximately 50 μm until a depth of 250 μm was reached. A feed rate of 0.025 mm/s and a spindle speed of 30 × 1000/min were selected as the drilling conditions, according to the recommendations of the operation manual. Simultaneously, a laser beam was employed to illuminate the sample, while a camera captured the distinctive speckle pattern generated by the surface roughness. This camera image captures the interference between the object beam and the reference beam. The reference beam underwent phase shifting, and an image was acquired for each phase shift, resulting in a total of four images to characterize the surface conditions before and after each drilling increment. These four images facilitated the computation of a phase angle for every pixel. This phase angle information was subsequently translated into surface displacement. Figure 4b shows the ESPI-hole drilling setup.

Data availability

Any additional data apart from what is provided within the manuscript can be supplied upon request.

Change history

19 May 2025

In this article the equation 4 was not displayed correctly in the PDF version and this has been updated.

References

Pan, J. et al. A novel defect-related cyclic damage model driven by strain energy density for LPBF titanium alloy. Eng. Fract. Mech. 295, 109793 (2024).

Cobbinah, P. V., Nzeukou, R. A., Onawale, O. T. & Matizamhuka, W. R. Laser powder bed fusion of potential superalloys: a review. Metals11, 58 (2020).

Chekotu, J. C. et al. Control of mechanical and shape memory characteristics in martensitic NiTi by setting L-PBF parameters and build orientation. J. Mater. Res. Technol. 25, 6407–6431 (2023).

Alipour, S et al. Nitinol: from historical milestones to functional properties and biomedical applications. Proc. Inst. Mech. Eng. H236, 1595–1612 (2022).

Walker, J., Andani, M. T., Haberland, C. & Elahinia, M. in Volume 2 A: Advanced Manufacturing (American Society of Mechanical Engineers, 2014). https://doi.org/10.1115/IMECE2014-40432.

Bartlett, J. L. & Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 27, 131–149 (2019).

Singh, R. In Applied Welding Engineering 175–190 (Elsevier, 2012). https://doi.org/10.1016/B978-0-12-391916-8.00017-0.

Promoppatum, P. & Rollett, A. D. Influence of material constitutive models on thermomechanical behaviors in the laser powder bed fusion of Ti-6Al-4V. Addit. Manuf. 37, 101680 (2021).

Chua, C., Liu, Y., Williams, R. J., Chua, C. K. & Sing, S. L. In-process and post-process strategies for part quality assessment in metal powder bed fusion: a review. J. Manuf. Syst. 73, 75–105 (2024).

Paraschiv, A., Matache, G. & Vladut, M. Assessment of residual stresses in laser powder bed fusion manufactured IN 625. Materials 17, 413 (2024).

Watkins, T. R. et al. Residual stresses and microstructure within Allvac 718Plus laser powder bed fusion bars. Addit. Manuf. 47, 102334 (2021).

Zhang, Y. et al. Concentration of transformation-induced plasticity in pseudoelastic NiTi shape memory alloys: Insight from austenite–martensite interface instability. Int J. Plast. 160, 103481 (2023).

Ma, J. et al. Spatial control of functional response in 4d-printed active metallic structures. Sci. Rep. 7, 46707 (2017).

Liu, Y., Mahmud, A., Kursawe, F. & Nam, T.-H. Effect of pseudoelastic cycling on the Clausius–Clapeyron relation for stress-induced martensitic transformation in NiTi. J. Alloy. Compd. 449, 82–87 (2008).

Wang, C. et al. The effect of laser scanning strategy on NiTi shape memory alloys processed by laser powder bed fusion. Mater. Charact. 215, 114185 (2024).

Lu, H. Z. et al. Formation mechanism of heterogeneous microstructures and shape memory effect in NiTi shape memory alloy fabricated via laser powder bed fusion. Mater. Des. 232, 112107 (2023).

Chekotu, J. C., Goodall, R., Kinahan, D. & Brabazon, D. Control of Ni-Ti phase structure, solid-state transformation temperatures and enthalpies via control of L-PBF process parameters. Mater. Des. 218, 110715 (2022).

Monu, M. C. C. et al. Bi-directional scan pattern effects on residual stresses and distortion in as-built nitinol parts: a trend analysis simulation study. Integr. Mater. Manuf. Innov. 12, 52–69 (2023).

Salem, M., Le Roux, S., Hor, A. & Dour, G. A new insight on the analysis of residual stresses related distortions in selective laser melting of Ti-6Al-4V using the improved bridge curvature method. Addit. Manuf. 36, 101586 (2020).

Guo, J., Fu, H., Pan, B. & Kang, R. Recent progress of residual stress measurement methods: a review. Chin. J. Aeronautics 34, 54–78 (2021).

Díaz-Mendoza, A. E. et al. Experimental and numerical analysis of the residual stress distribution in a three-point bending test of a TRIP sheet by using ESPI. J. Braz. Soc. Mech. Sci. Eng. 42, 544 (2020).

Li, X. et al. Research progress of residual stress measurement methods. Heliyon 10, e28348 (2024).

Ao, S., Li, C., Huang, Y. & Luo, Z. Determination of residual stress in resistance spot-welded joint by a novel X-ray diffraction. Measurement 161, 107892 (2020).

Marola, S. et al. Residual stresses in additively manufactured AlSi10Mg: Raman spectroscopy and X-ray diffraction analysis. Mater. Des. 202, 109550 (2021).

Chen, S., Shen, B., Zhang, J., Wang, L. & Sun, F. Evaluation on residual stresses of silicon-doped CVD diamond films using X-ray diffraction and Raman spectroscopy. Trans. Nonferrous Met. Soc. China 22, 3021–3026 (2012).

Luo, Q. A modified X-ray diffraction method to measure residual normal and shear stresses of machined surfaces. Int. J. Adv. Manuf. Technol. 119, 3595–3606 (2022).

Muwafaq Mohmmed Ali, O., Hamid Mohammed Al-Kalali, R. & Mohamed Mahdi Mubarak, E. Vibrational analysis of composite beam embedded with nitinol shape memory alloy wires. Int. J. Eng. Technol. 7, 143 (2018).

McKenna, C. G. & Vaughan, T. J. A finite element investigation on design parameters of bare and polymer-covered self-expanding wire braided stents. J. Mech. Behav. Biomed. Mater. 115, 104305 (2021).

Braun, M. et al. Fatigue crack initiation and propagation in plain and notched PBF-LB/M, WAAM, and wrought 316L stainless steel specimens. Mater. Des. 244, 113122 (2024).

Fan, M. et al. Effect of residual stress induced by different cooling methods in heat treatment on the fatigue crack propagation behaviour of GH4169 disc. Materials 15, 5228 (2022).

Moritz, S. et al. Impact of in situ heat treatment effects during laser-based powder bed fusion of 1.3343 high-speed steel with preheating temperatures up to 700 °C. Steel Res. Int. 94 (2023).

Luu, D.N., Zhou, W. & Nai, S. M. L. Mitigation of liquation cracking in selective laser melted Inconel 718 through optimization of layer thickness and laser energy density. J. Mater. Process Technol. 299, 117374 (2022).

Praveen Kumar, V. & Vinoth Jebaraj, A. Microscale investigations on additively manufactured Inconel 718: influence of volumetric energy density on microstructure, texture evolution, defects control and residual stress. Appl. Phys. A 129, 370 (2023).

Croft, D. N. Heat Treatment of Welded Steel Structures 21–47 (Elsevier, 1996). https://doi.org/10.1533/9781845698812.21.

Mugwagwa, L., Yadroitsev, I. & Matope, S. Effect of process parameters on residual stresses, distortions, and porosity in selective laser melting of maraging steel 300. Metals9, 1042 (2019).

Sharif, A., Farid, N., Vijayaraghavan, R. K., McNally, P. J. & O’Connor, G. M. Femtosecond laser assisted crystallization of gold thin films. Nanomaterials 11, 1186 (2021).

Zhang, S. et al. Effect of laser energy density on the microstructure and texture evolution of hastelloy-x alloy fabricated by laser powder bed fusion. Materials 14, 4305 (2021).

Kumar, V. P. & Jebaraj, A. V. Attainment of favorable microstructure for residual stress reduction through high-temperature heat treatment on additive manufactured inconel 718 alloy. Int. J. Adv. Manuf. Technol. 121, 4455–4472 (2022).

Lin, Z. et al. Controlling the crystal texture and microstructure of NiTi alloy by adjusting the thermal gradient of laser powder bed melting. Mater. Sci. Eng. A 912, 146970 (2024).

Chekotu, J. C. et al. Formation of β-Ti phase during L-PBF processing of martensitic NiTi. Mater. Today Commun. 36, 106668 (2023).

Obeidi, M. A. et al. Laser beam powder bed fusion of nitinol shape memory alloy (SMA). J. Mater. Res. Technol. 14, 2554–2570 (2021).

Lee, Y. S. & Zhang, W. Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion. Addit. Manuf. 12, 178–188 (2016).

Trevisan, F. et al. Additive manufacturing of titanium alloys in the biomedical field: processes, properties and applications. J. Appl Biomater. Funct. Mater. 16, 57–67 (2018).

Ahmed, N., Barsoum, I. & Abu Al-Rub, R. K. Numerical investigation on the effect of residual stresses on the effective mechanical properties of 3d-printed TPMS lattices. Metals12, 1344 (2022).

Xue, L. et al. Laser powder bed fusion of defect-free NiTi shape memory alloy parts with superior tensile superelasticity. Acta Mater. 229, 117781 (2022).

Monu, M. C. C. et al. Resultant physical properties of as-built nitinol processed at specific volumetric energy densities and correlation with in-situ melt pool temperatures. J. Mater. Res. Technol. 21, 2757–2777 (2022).

Liu, M. et al. Deformation mechanism of defect-free Ni50Ti50 alloys via laser powder bed fusion. J. Mater. Sci. Technol. 225, 111–124 (2025).

Li, S., Hassanin, H., Attallah, M. M., Adkins, N. J. E. & Essa, K. The development of TiNi-based negative Poisson’s ratio structure using selective laser melting. Acta Mater. 105, 75–83 (2016).

Vyatskikh, A.L. et al. Residual stress mitigation in directed energy deposition. Mater. Sci. Eng. A 871, 144845 (2023).

Simson, T., Emmel, A., Dwars, A. & Böhm, J. Residual stress measurements on AISI 316 L samples manufactured by selective laser melting. Addit. Manuf. 17, 183–189 (2017).

Narvan, M., Ghasemi, A., Fereiduni, E., Kendrish, S. & Elbestawi, M. Part deflection and residual stresses in laser powder bed fusion of H13 tool steel. Mater. Des. 204, 109659 (2021).

Acknowledgements

This research was supported by I-Form, the Science Foundation Ireland Research Centre for Advanced Manufacturing, and the Advanced Metallic Systems Centre of Doctoral Training (AMSCDT), a collaboration between Dublin City University, University College Dublin, The University of Sheffield, and The University of Manchester. The project was conducted in partnership with the Advanced Forming Research Centre at the University of Strathclyde, Glasgow, Scotland and ANSYS Inc., a company based in Utah, USA. Funding for this work was provided through Science Foundation Ireland grants 18/EPSRC-CDT/3584, 16/RC/3872 and 21/RC/10295_P2, as well as the Engineering and Physical Sciences Research Council grant EP/S022635/1. For the purpose of Open Access, the author has applied a CC BY public copyright license to any Author Accepted Manuscript version arising from this submission.

Author information

Authors and Affiliations

Contributions

S.R. conceptualized the study, performed the major data analysis and wrote the manuscript. J.C.C. conceptualized the study, produced the samples and assisted with the data analysis. T.G. assisted with the data analysis and revised the manuscript. C.H. performed the analysis of the thermal data and drafted the figures. J.N. and D.E. conducted ESPI-HD measurements and associated data analysis. C.S. performed the XRD measurements and associated data analysis. D.E. conceptualized the study, acquired funding for the work and revised the manuscript. All authors read and approved the final manuscript and had final responsibility for the decision to submit it for publication.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rangaswamy, S., Chekotu, J.C., Gillick, T. et al. Evaluating residual stress in additively manufactured nitinol shape memory alloy. npj Adv. Manuf. 2, 16 (2025). https://doi.org/10.1038/s44334-025-00027-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44334-025-00027-y