Abstract

Metal Additive Manufacturing (AM) is a rapidly growing technology that enables the production of parts with complex geometries. However, accurate cost estimation remains a critical challenge, preventing the industry from fully capitalizing on AM’s capabilities. While conventional cost models provide a solid analysis of the build process, none consider the full process chain in sufficient detail. This paper presents, for the first time, a new approach based on Discrete Event Simulation to develop a rigorous dynamic model for analyzing manufacturing costs in laser powder bed fusion (L-PBF) of metal components. The analysis shows that post-processing activities in AM significantly impact overall costs. Part geometry and production rate also influence key cost drivers. The model provides a flexible and adaptable tool for identifying and optimizing major cost and time drivers across the entire AM process chain, enabling comprehensive analysis for decision-makers in the manufacturing industry.

Similar content being viewed by others

Introduction

In the past two decades, Additive Manufacturing (AM) has emerged as a disruptive manufacturing technology, which typically builds up material in layers to form a part, as an alternative to traditional subtractive methods. Both additive and traditional manufacturing methods have their respective benefits and drawbacks1. Choosing the appropriate manufacturing route may be dictated by technical requirements, manufacturing costs, production rate and/or the availability of the technology. The choice is often based on the intuition of a manufacturing expert. For producing a functional part, conventional manufacturing processes require multiple stages which may increase in number as the design becomes more complex. In contrast, the AM build is generally performed in a single step with design flexibility, which may allow for shorter lead times, improved supply chains and reduced inventory2. In conventional techniques, machine tools are limited by axis and line of sight constraints, so part features such as complex internal geometries, undercuts or sharp edges are difficult or impossible to be achieved. If complex internal features are required, multiple parts may need to be produced and assembled, increasing process time3. However, conventional methods are typically more economical at higher production volumes where the high costs of fixtures, moulds and/or tooling are amortised over many parts. In contrast, AM is generally considered to be more suitable for low to mid-volume production, eliminating the need for costly tooling4,5. Where technical feasibility is not a determining factor and a part can be manufactured using multiple routes, cost modelling can help to make a comparison by determining the overall costs of a manufacturing process and whether it is suitable for a particular industry.

In industries using high-performance difficult-to-cut metal alloys, AM can provide great advantages since it can produce parts with lower buy-to-fly ratios, the ratio between the material purchased to the weight of the final product, limiting the need for costly machining to finishing operations6. Powder Bed Fusion (PBF) and Directed Energy Deposition (DED) are the most common AM processes for metals7. PBF is widely used where intricate and complex geometries are required. Generally, parts produced using PBF have better surface finish than DED and thus require fewer finishing operations. However, PBF is typically limited by production speed and workpiece size. Parts produced by PBF are commonly used in aerospace and medical applications8. However, it is important to acknowledge that metal additive manufacturing currently does not produce the same high-quality finish that can be obtained with conventional processes such as machining and forming. Whilst the structure of AM parts can be somewhat controlled through heat treatments, voids and impurities may appear depending on part orientation or production sequence9. Even though the build is in a single step, many post-processing operations may be required to improve mechanical properties and surface finish, which must be considered in costing for AM.

Cost modelling of advanced manufacturing processes is crucial to enable manufacturers to make informed decisions as to which manufacturing route is more economical. While the benefits of AM have resulted in an uptake of this method in industry as the technology has matured, current availability of costing models for AM is limited. Several researchers have focused on costing of AM using different approaches10,11,12. Activity Based Costing (ABC) is one of the popular techniques used for costing of AM since it focuses on the actual activities and their main cost drivers. Traditional costing methods are not as beneficial as ABC at presenting data for operation-related decisions13. ABC offers a more precise and consistent way of calculating manufacturing costs as it distributes the overhead costs in proportion to the actual activities carried out in a particular job14. This approach enhances the rationality of decision-making and does not distort considerations related to cost reduction, pricing, and performance evaluation15,16.

There have been many attempts to develop a cost estimation model for additive manufacturing processes, employing either the ABC approach or other cost estimation techniques. The earlier models were focused on processing polymers typically using fused deposition modelling and stereolithography17,18,19. This was later followed with models for various metal AM processes with the major focus on laser powder bed processes20. The overarching approach amongst these models is the division of the total AM costs (\({C}_{{tot}}\)) into pre-processing (\({C}_{{pre}}\)), processing (\({C}_{{build}}\)) and post-processing (\({C}_{{post}}\)) stages assuming a finished component is manufactured17,19. This is formulated mathematically as shown below:

The cost driver for each stage is then identified and classified into labour, energy, material, etc. and the costs for each stage are calculated. The duration for each activity determines the amount of resources used such as energy and labour21.

Initial investigations emphasised a correlation between the quantity of parts within a single build and the production cost per unit22. Subsequent analysis involving builds with multiple part geometries demonstrated that optimising the building space through effective packing of the build volume with parts of similar heights can significantly reduce the unit cost12. Piili et al.23 revealed that in a laser PBF (L-PBF) process for stainless steel parts, producing a single part at a time is highly inefficient. However, manufacturing multiple parts simultaneously reduced costs by 81% to 92% compared to building individual parts separately. The primary factor within the control is optimising the utilisation of the AM build volume.

With the progress on costing of AM, additional cost drivers were integrated. Ruffo et al.18 identified energy consumption as a major cost driver in AM. Building upon this, researchers extended their approach by incorporating a detailed energy estimate directly as a cost factor in their models20. Barclift et al.24 extended an existing cost model on PBF and highlighted the need for taking metal powder degradation into consideration. They noted that taking metal powder expense as a fixed cost underestimates the value of parts built with virgin powder24.

Existing cost models for AM often fail to adequately consider the consequential effect of post-processing activities on the overall cost. Certain models do not even include the pre-processing costs20. While attempts have been previously made to incorporate the post-processing activities in cost models by including support removal, surface treatment and quality control measures, the considered post-process parameters remained limited25. Earlier models neglect a full analysis of the post-processing costs, overlooking critical elements like the cost of tools used, heat treatment, material removal and finish machining. According to Schröder et al.26, characteristics such as calculation of the build time and post-processing are necessary for a complete ABC model. Although detailed information is limited, studies have shown that post-processing is one of the major cost drivers in part production using AM26. For a direct economical comparison with conventional processes, an AM metal part must be finished to meet the engineering requirements, and therefore detailed post-processing activities must be included in the costing. This added complexity necessitates developing cost models for other pre- and post-processing operations in addition to costing for the AM build.

Despite the number of AM cost models identified in the literature, none provide a comprehensive, dynamic, activity-based approach for the full process. Existing models require accurate data on material and energy consumption and the time necessary for performing specific activities. As such, they are generally suitable for post-manufacturing analysis. As a prognosis tool, they fail to capture the stochastic and dynamic changes during manufacturing. The static and deterministic cost estimation models can be extended to include stochastic and dynamic parameters. However, the complexity of dynamic modelling can hinder wide adoption and applicability of such cost models.

In this study, a cost estimation model for L-PBF additive manufacturing is proposed for the first time by integrating cost models within a discrete event simulation. The model provides a comprehensive analysis of the costs involved in L-PBF with the ABC approach by simulating the individual activities performed during the AM of a part. The costs for a number of test parts with a variety of part size, herein named as joint, pyramid lattice, and a modified NAS979 part, have been investigated. The model is capable of providing a detailed breakdown of the costs.

Results

The results of three case studies for low, medium and high-volume parts chosen were calculated following the discrete event simulation in Simio and ABC analysis. Analysis and comparison of processing time, part cost, resource cost and production volume are presented in the next sections.

Processing time

Figure 1 demonstrates the total processing time for manufacturing a batch of parts in three scenarios of low, medium and high production rates. Here, a maximum of one NAS979 test piece can be produced in one build representing a low volume production. In contrast a maximum of 25 pyramids and 100 joints can be packed into a build representing medium and high production volume scenarios. For comparison, the time for producing only one part per build is also provided.

In the case of a joint, increasing the production volume per build from one part to 100 reduces the time for producing a part from 11.7 h to 15 min. In this case, whilst the laser scanning and finish machining times are individual to each part, the remaining drivers such as setup times, removal time, etc. are shared between the parts in a build, resulting in an overall reduction in processing time per part. The overall processing time from a build for one joint was 11.7 h which was increased to 24.3 h when processing 100 joints in a single build representing only a 2 times increase. This is reflected by a 7 times increase in AM processing time and 1.5 times increase in post processing time.

Pyramid lattice part processing represents a scenario with a medium production rate where only 25 pyramids can be packed into a build. The higher volume (~2.5 times) and surface area (2.8 times) of the pyramid lattice compared to a joint resulted in a 56% increased processing time compared to the joint when considering a single part. The part removal time is also higher as more powder requires removing from the machine due to the increased part height. A similar effect is seen in packing the build, with a rise in total build and post-processing time. The addition of 24 parts to the single part increased the total processing time by only about 8 h, which means the efficiency of production is improved by reducing the time from 18 h per part to 1 h per part.

The processing time for a single NAS979 part is 49.91 h, of which build contributes 75.7%. Scanning takes 82% of the build time since such a high-volume part requires many more layers to be scanned. However, the post-processing time is only 1 h longer than the post-processing time of joint and pyramid lattice since the impact of increased volume (329 times larger than the joint) and surface area (42 times larger than the joint) is more profound on the build time.

Part cost

Figure 2 shows the cost comparison and cost breakdown of each type of part for single and packed build. It can be seen that the part cost rises with the increase in the part size from joint part to NAS979. While the setup activity is the dominant factor influencing the final cost at the low and medium volume single part production, build activity takes over most of the share in the full capacity production due to scanning time and material cost attributed to each part. In contrast, for the larger NAS979 component, the costs associated with the AM build is the dominant factor for production, irrespective of the production rate.

The cost per part for a joint is reduced by 98% from £640.23 to £15.07 by packing the build since the constant time activities are split between the 100 parts. Similarly, 93% cost improvement can be observed for pyramid lattice part production by increasing the number of parts in the build.

Figure 3 shows a more detailed analysis of NAS979 component. The AM250 has a build volume of dimension of 250 mm × 250 mm × 300 mm that can only accommodate one NAS979 part. Therefore, the costs cannot be shared over parts. As a result, the build activity takes 75.5% of the total cost, which shows that inert gas, energy, machine and material consumption are the main drivers for components with a large volume. Although cost elements such as setup and post-processing could potentially be shared in multiple builds, the geometric constraints of the NAS979 part prevent such optimisation in this case. Therefore, the high per-part cost is largely unavoidable under current build capacity limitations.

In L-PBF process, all parts required anchoring support structures to secure them to the build plate. The density and thickness of these support structures vary depending on part geometry and weight, typically ranging between 4 mm and 6 mm in thickness. These supports are fabricated from the same metal powder as the part itself, and can therefore be considered as additional layers in the cost model. Their presence directly affects the build time, material consumption and part removal costs. For example, in the case of the joint part, adding a 5 mm-thick support structure resulted in an increase in the cost per part from £640.23 to £647.61 for a single build. In the case of the pyramid lattice, the addition of a 5 mm-thick support structure increased the cost per part 2.13% for a single build and 1.69% for a packed build. This cost rise was primarily due to longer build time and increased part removal effort. As post-processing costs are calculated based on the contact surface area with the build plate, the support structure did not impact that part of the cost.

Resource cost

Figure 4 shows the resource cost breakdown for a single part and packed build for the joint. For a single part, the build plate makes up most of the cost by 55%. For a part in a packed build, the build plate cost is split between all the parts so makes up less of the total, reducing to 23%. Cost for resources such as materials and finish machining is negligible in the single-part production, whereas they have a 24% and 14% share, respectively, for the packed build production since these resources are used separately for each part.

The cost breakdown for pyramid lattice production is given in Fig. 5 for a single part and packed build, respectively. It can be seen that the use of resources such as gas and AM machine increased compared to joint manufacturing due to the increased part volume and height. Similar to the packed build for joint production, the build plate cost is spread over multiple parts and material and finish machining resources make up a great proportion.

In the case of NAS979 manufacturing, the cost drivers associated with the build operation, such as material, AM machine, and gas make the highest contribution to the total cost, as shown in Fig. 6.

Production volume

Figure 7a shows how the cost per part varies with production volume for the Joint and Pyramid Lattice. As can be seen, the cost per part decreases very quickly as the build is packed up to full capacity. At this point, a new build must be introduced, causing a slight increase in cost, as seen in every 100 parts for the joint and every 25 parts for the pyramid lattice. This follows the trend identified in the Ruffo et al.18 model, which was the first to assert that cost would not be completely constant for AM production. The effect of a new build is greater on the pyramid lattice since the extra cost is split between fewer parts. There is a slightly larger increase when a new build plate is required after 5 builds. This is seen at 500 parts for the joint and 125 parts for the pyramid lattice. The lowest cost per part identified is £11.99 for the joint (500 parts) and £41.87 for the pyramid lattice (125 parts) at which point the build plate has reached its maximum use. As build volumes increase further, there will be less oscillation and the cost per part will settle around these low values and will approach to the cost of powder used for producing the part. However, it remains above the material costs (£3.64 and £8.83 for joint and pyramid lattice, respectively) even at its lowest point.

Figure 7b shows the cost variation with production volume for the NAS979 test part. This is vastly different to the trends observed in (a), as there is only room for 1 part in each build. As a result, the cost is only reduced over multiple builds by amortisation of build plate costs from £2906 to around £2598. Additionally, small rises in cost are observed every 5 builds due to the introduction of a new build plate. In this case, the cost of powder required for producing the NAS979 part remains substantially lower than the lowest recorded cost per part, as the total manufacturing cost cannot be distributed across multiple parts.

Time focused optimisation

An additional use for an ABC model may be to take advantage of the detailed time and cost breakdowns to target areas in the process for improvement. As identified previously, build and post-processing are the major contributors to process time regardless of production volume for the pyramid lattice part. Based on this model, the processing time was 18 h for one part and 26 h for a build of 25 parts.

Build optimisation

The model is based on the Renishaw AM250, which uses a single laser for scanning and has a scanning area of 250 mm × 250 mm. AM technology is still improving and has led to machines with faster warm-up, cool-down and recoating time for each layer, and multiple lasers allowing faster scanning and a reduced total build time. For instance, Renishaw’s RenAM500Q model with 4 lasers has a scan rate around 7.5 times faster than that of the AM250.

Figure 8a shows the comparison of AM250 and RenAM500Q for the pyramid lattice part manufacturing. The increased machine speed results in a 24% process time reduction for one part and a 35% reduction for the packed build. The RenAM500Q has an estimated purchase cost 4 times that of the AM250, so improved process time comes with an increased capital cost. However, Fig. 8b shows that the reduced build time and consequential cost-saving results in a slightly lower total cost per part despite that increased initial capital cost.

Post-processing optimisation

Technologies used for post-processing are highly capable and increasing cutting speeds could easily lead to a reduction in quality. A consideration may be to introduce a specific operator for post-processing activities, allowing AM builds and post-processing to take place simultaneously. This will only be beneficial over multiple builds.

Assigning one more operator results in a 29% reduction in total processing time for the manufacture of 125 pyramid lattice parts. This minimises the bottle neck for performing different tasks simultaneously. However, for costing, the model only charges hourly rates when the operator is being used and unproductive times are not accounted for.

Multiple regression model

With the current lack of cost models, quotes for AM parts are uninformed estimates. Providing a simple Rough Order of Magnitude (ROM) cost regression model accounting for all the variables in this model is not feasible due to the number of parameters. However, a good model can be created if the major inputs affecting process times and therefore costs are considered. For the same material and AM machine these are the part volume, surface area, build height, and manufacturing volume.

The regression analysis involved testing 28 parts builds with random build quantities ranging from 1 to 2000 parts, covering low to medium volume. The build height was excluded from the analysis as it remained constant regardless of the number of parts in the build. The Simio model was employed to calculate the estimated cost of the 28 builds. A regression model was then created, using the total volume and surface area of the parts to be manufactured as the independent variables, incorporating the manufacturing volume. The total cost was used as the dependent variable, with the objective of establishing a Cost Estimating Relationship (CER) between these variables. Both cost drivers showed a strong correlation with the total cost and had a low correlation with each other (0.678), making them suitable independent variables for the CER. The regression output indicated a high \({R}^{2}\) value, demonstrating a strong correlation between the variables and the predicted cost. Furthermore, the F-statistic was found to be significant, validating the prediction model. The statistics are shown in Table 1.

The regression output is shown in Fig. 9 for total volume as the primary cost driver. The 28 Simio model output values used to create the regression model are displayed. The regression model also uses the output standard error, t-statistic and calculated Z-values to create upper and lower prediction limits and confidence limits based on a 90% confidence interval, and an optimistic, most likely and pessimistic prediction of the total part cost.

Using the output coefficients and intercepts, the estimated likely cost value for AM of a titanium part using a standard machine can be expressed as the following:

Where:

-

CTotal Total Cost to Manufacture (£)

-

VTotal Total Volume of Parts to Build (\({{mm}}^{3}\))

-

STotal Total Surface Area of Parts to Build (\({{mm}}^{2}\))

Discussion

Accurate cost modelling and estimation for new and emerging manufacturing processes is a vital step in widespread adoption of new technologies in industry. Despite technological advances in different additive manufacturing processes, its integration in routine manufacturing is limited and cost estimation for AM in industry is commonly based on past experience. In this study, a dynamic activity-based cost model using discrete event simulation has been presented for the metal laser powder bed fusion (L-PBF) process for the first time. The model was designed and tested through a comprehensive examination of a typical L-PBF AM process to ensure the inclusion of all relevant activities and the assignment of appropriate cost drivers. It incorporates a dynamic simulation capability that enables the modelling of costs associated with any component, material, machine, and production volume. This capability supports process optimisation and serves as a comprehensive tool for evaluating the cost comparison between AM and traditional manufacturing methods.

The newly proposed cost model addresses the shortcomings of previous models by including the impact of post-processing activities such as heat treatment, Wire EDM, and finish machining, which were previously disregarded. The recent AM models developed by Rickenbacher et al.12 and Fera et al.27 were found to be robust, encompassing most of the required activities and costs for various part geometries. However, both models were found to have underestimated the post-processing costs. The study highlights the importance of post-processing in achieving the dimensional accuracy of final parts in AM, even though the technology can produce near-net shape parts without subtractive machining. The findings indicate that post-processing operations in AM have a substantial effect on the overall cost, and they must be thoroughly accounted for designing manufacturing value streams. The model also captures variations in cost drivers as the part geometry (volume/surface area) changes. Additional considerations include cost related to the costs of build plates and PPE, along with the ability to model the production of multiple parts in a single build by using a packing algorithm. Furthermore, the build time estimator is taken from Fera et al.27 and enhanced by adding the costs for energy, material waste and inert gas in the build chamber. This makes the model more comprehensive and accurate compared to previous models in the analysis of the costs of Additive Manufacturing (AM) production.

For single-part production, setup costs, particularly build plate costs, were the major contributor to overall costs. As the number of parts in a build increases, setup costs and removal costs become a smaller proportion of the overall costs as they are largely fixed-time activities. On the other hand, activities dependent on the total build volume, such as build scanning and finish machining, have a higher cost contribution along with the resources they utilise, such as the AM machine, finish machining and tooling, and argon gas. The optimisation aimed at reducing process times and costs in the build stage was successful, resulting in a 35% decrease in process time due to an improved scan rate with the AM500Q and lower overall costs. This resulted in not only a boost to the investment through shorter lead time but also an immediate reduction in the cost of parts.

The analysis of production volume revealed the impact of cost distribution over an increase in production volume as well as slight fluctuations at instances where new builds or build plates are necessary. This concept was originally established by Ruffo et al.18. For low-volume parts, costs rapidly decline with the increase in production volume while for high-volume NAS979 parts, costs only slightly reduce as the cost of build plates is shared. Figure 10 presents a comparison of the cost per part between typical conventional manufacturing and Additive Manufacturing (AM) for different parts. The cost-production volume relationship can differ greatly depending on the methodology and parameters employed, however, it illustrates that AM can be suitable for prototypes and one-time production of any parts, where the low initial costs of AM are advantageous. AM may also be feasible for low/medium volume production of smaller parts as costs can be decreased through build packing. Results from packing the build showed that the cost of a low-volume joint was reduced by 98%, while the cost of a medium-volume pyramid lattice was reduced by 93%. For larger parts, AM is only appropriate for very low-volume production as conventional methods become more cost-efficient in a short period.

In L-PBF AM build, failures can significantly affect cost, as defects are typically not detectable until after the build is completed and the part is removed from the build plate. As a result, setup and build-related costs including machine time, energy and consumables are still incurred even for failed parts. In many cases, unless a defect is visually evident, post-processing may also proceed which compounds the wasted resources. Build success rate would highly depend on part geometry, design and process parameters. For example, an 80% build success rate would mean that out of every 10 parts produced, two is likely to fail which effectively increases the cost per part. In the case of the joint scenario, the cost per part would increase from £15.07 to £18.83 considering 80% build success rate.

The regression model was formed with the goal of simplifying the Simio model and improving its cost predictions for different parts. The results of the regression were compared to the actual cost output of the Simio model for a random number of parts. Although the regression output was within the range of the 3-point estimate, it still showed some deviations from the actual cost, with the likely regression value for the pyramid lattice being 27.5% outside the actual value as given in Table 2. This indicates that the cost predictions can be highly dependent on various factors and that the full model should be used for more accurate results. Additionally, it’s important to note that the linear regression assumption may not be suitable for low volumes of small parts.

The accuracy of the model output is contingent on the quality of the input data. The output of the model will be precise only when the data related to machine and material specifications, costs, and activity times are accurate and appropriate for the production of a specific part. However, if it is not feasible to obtain all the required data, the accuracy of the output will be diminished. The machine parameters will vary based on the specific machinery utilised. Material costs and thickness can fluctuate depending on the supplier, and other costs may fluctuate based on factors such as location, machinery, and suppliers. The activity times will also differ based on the operator and machinery. Despite collecting accurate data, there may still be errors in activity time calculations, such as longer powder removal times for complex parts or additional machining moves required. Build time is the largest contributor to overall time and cost, thus the build time estimator is likely to be the main source of error and have a significant impact on the final cost. For instance, Baumers et al.20 conducted a comparison of their estimated build times with real data and found that their calculated time was up to 8% lower than the actual build time. Therefore, it is important to consider these fluctuations in the decision-making process.

Additionally, a number of assumptions were made which need to be taken into account. The cost analysis excludes the overheads associated with the space rental, lighting, heating, etc. as well as the design and process planning activities, software maintenance, etc. were not included in this investigation and should be considered in future studies. Another source of uncertainty in the cost estimation arises from the assumption of a zero residual value for the AM machine at the end of its life. While this is a conservative simplification commonly used in early-stage costing, it does not reflect potential resale or reuse value at the end of the equipment life. In the long-term financial assessments, salvage value should not be ignored to avoid overestimation of the machine cost rate.

Another point to consider would be the inclusion of overhang support structures, their angles and impact of their density on the cost per part. In this study, all parts included anchoring support structures that secure the part to the build plate, and an analysis was conducted to show their cost impact. However, a detailed analysis of overhang supports would require evaluation of a wider range of geometries, support angles, and packing orientations, significantly increasing the number of combinations to be simulated. These supports could further influence material consumption, build duration, and post-processing effort. Expanding the model to include such variations would improve its comprehensiveness and practical applicability in more complex manufacturing scenarios.

Finally, the build success rate should not be overlooked and should be specified based on the process parameters, part geometries and material. While specific failure rates are not standardised, industry observations and certain studies provide insights into common causes. Some metals can have failures such as physical distortion as a result of thermal stresses and inadequate support structures. Incorporating a process-specific build success rate into cost models for batch and mass production is crucial for accurately estimating economic feasibility of AM. It is straightforward to integrate the success rate as the total cost of AM can simply be divided by the number of successfully produced parts which allows the impact of failures to be easily reflected in per-part cost estimations.

Methodology

A new approach is presented for cost modelling incorporating discrete event simulation. In ABC, a cost is associated with each activity and material consumed. As a result, there is a synergy with discrete event simulation, where all activities for a system are modelled at discrete points in time for the purpose of understanding the systems behaviour. In the proposed method, a cost is assigned to each activity and material consumed in a discrete event simulation for L-PBF. A discrete event simulation model of a typical L-PBF AM process was developed. For the purpose of this paper, the model was implemented in Simio discrete event simulation software. However, the proposed method is independent of the simulation platform and other discrete event simulation methods can be used. The model formed the basis for the ABC approach and includes the detailed activities performed and consumables used for producing a part using L-PBF. For modelling purposes, only deterministic values have been used for the simulation and costing unless specified.

In order to accurately represent the manufacturing process within the simulation environment, it is crucial to have a comprehensive understanding of the process. This requires the correct identification of the cost drivers, which is accomplished through the initial identification of the inputs for the manufacturing process. This is followed by the mapping of the process steps and relevant resources and activity times as well as the assumptions made for the modelling. Cost functions are determined using activity-based costing approach.

Input analysis

Part, material and equipment

The three important elements of user input for manufacturing are (I) the specification of the part geometry, (II) its material, and (III) the AM machine used.

I) For the part geometry, the volume, surface area, maximum dimensions, and the total number of parts to be manufactured are required. The part height is used to determine the average cross section area of the part, and the number of powder layers needed to build the part. Rickenbacher et al.12 tested and validated the manufacturing costs for three test parts, (i) pyramid, (ii) pyramid lattice and (iii) joint made from Ti-6Al-4V titanium alloy. The Rickenbacher et al.12 cost estimation model was identified as a suitable candidate for comparison since it included the inert gas costs, material change factors and some post-processing activities.

For this investigation, the pyramid lattice and joint test parts proposed by Rickenbacher et al.12 were selected. In addition, the National Aerospace Standard test piece (NAS979) has been included, as shown in Fig. 11. The parts selected were assumed to be made from Ti-6Al-4V titanium alloy. The analysis investigates low, medium and high volume production comparing process costs and timescales as well as a breakdown of the cost drivers for each part. For low and medium volume parts, joint and pyramid lattice were used. For high volume part, the NAS979 test piece that is commonly used for machine tool verification has been selected.

The volume and dimensions of the parts used in the model can be seen from Table 3.

For the purpose of this study, a simple two dimensional packing algorithm has been used to determine the number of parts in each build, ignoring potential part orientations in three dimensions. The algorithm takes the geometry of each part as its maximum length, depth, and height, and determines the maximum number of parts that can be fitted into the length and depth of a build chamber. The algorithm spreads parts equally between multiple builds. This packing algorithm is demonstrated in Fig. 12. As per the assumptions, builds are not packed height-wise as this may impact the build quality. As a result, a maximum of 100 joints, 25 pyramid lattices and one NAS979 test piece can be packed into a build. It is acknowledged that more complex algorithms for packing may exist. However, the simple two dimensional algorithm used is deemed sufficient for the purpose of this study.

II) The workpiece material as a model input determines the part cost and the layer thickness of the powder, directly affecting the build time. The material properties and cost depend on the supplier and order quantity and can be updated in the cost model. In this study, Titanium Alloy Ti-6AI-4V was considered since it is widely used in aerospace and medical implant industries and is commonly available for L-PBF. Material inputs were based on the data sheets available in ref. 28.

III) A range of machine data can be prepared as an input for the model, which allows the AM machines with different performance capabilities to be selected. Factors that vary with machine include scan rates, warm-up, cool-down and recoat times within the build process, energy and Argon gas consumption, build chamber dimensions, and capital cost. Data for Renishaw’s range of machines is provided, either estimated or obtained from machine specifications28. In this study, a Renishaw AM250 L-PBF machine was selected for the cost analysis. Renishaw AM500Q was also used to compare the build capabilities of the machines.

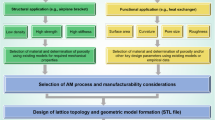

Manufacturing process and cost drivers

The manufacturing chain of producing an L-PBF part is demonstrated in Fig. 13 and formed the basis for developing the discrete event simulation model. A typical PBF process starts with a CAD preparation process, known as Design for Additive Manufacturing. The parts can be optimised by reducing material consumption and weight. Then, the designs are imported into a slicing software where they can be positioned and oriented on a build plate. A full build simulation is run to ensure there are no issues during printing. Next, the operator sets up the machine by placing a build plate and adding powder material. The machine is flushed with an inert gas, typically argon or nitrogen29 to ensure a controlled atmosphere suitable for reactive materials. A thin layer of metal powder is spread across the build plate and a fibre laser selectively fuses areas of the powder bed. The build platform moves down and is coated with a new powder layer. This process repeats until all layers have been scanned. After the machine and part have cooled, powder around the part is brushed or vacuumed away. The part and build plate are removed for post-processing, where excess powder is removed by mechanical and/or air brushing. The build is heat-treated in a vacuum furnace to relieve internal stresses and improve the microstructure. The cooled build plate and parts are separated using Wire Electrical Discharge Machining (EDM). The build plate is face milled for re-use depending on its thickness and condition. For the purpose of this study, it has been assumed that the build plate can be machined up to 5 times before a new one is required. The parts are finish machined (CNC) and then inspected for dimensional accuracy, structural properties, and surface finish. If the part is not suitable, it may be returned for additional work or discarded.

Based on the AM process identified, the major activities for costing of the AM process to allow comparison with conventional methods are determined as setup, build, removal and post-processing. Figure 14 summarises these major process steps and their associated cost drivers for the L-PBF process.

Setup activities are to completely prepare the machine for build. This involves ensuring a build plate is in place, that there is sufficient powder in the machine, and warming up the machine for use. Most metal AM methods use an inert gas within the build chamber to avoid contamination of the part and ensure that there is no oxygen in the chamber thus eliminating a combustion risk. Handling of the AM powder with micrometre dimensions, loading/unloading of build plates, or changing the powder require suitable personal protective equipment (PPE).

The build step can be split into the material warm-up time, scanning (sintering/melting) time, cool-down time, and powder recoating time for each layer. Since these are all part of the same build process, they are shared between the parts in a single build. One of the major cost drivers here is the direct material cost. This will be dependent on the overall part volume and will include waste when excess powder is removed from the machine along with the part. A material waste factor of 10% is applied to the material cost to reflect this.

The removal step involves allowing the part to cool in the machine, manually removing surrounding powder from the part using a brush or vacuum, and finally physically removing the part and build plate from the machine. Cooling time is assumed constant for all builds. During removal, the machine is still ‘in-use’ and therefore machine costs are applied. PPE costs are also included again as operators will have to deal with the micron-size powder.

Post processing operation involves six activities which are part cooling, airbrushing for full powder removal, heat treatment, build plate removal via Wire EDM, milling and CNC machining. The first four activities are operated to the whole build plate, so the cost of each activity will be split between all parts in the build. Part cooling after being removed from the machine has a minimal effect on the overall cost since it has no associated cost drivers. Milling of the build plate is also split between all parts but does not physically involve the parts. Lastly, each part is processed individually during the CNC machining activity.

Activity times

Machine setup

The first and last steps of machine set-up; positioning the build plate and machine warm-up, have a constant activity time of ~1 h. However, the activity time for powder setup may vary. For some builds, there will be enough powder in the machine to start immediately whilst for others, the powder may require topping up or changing completely. Therefore, a triangular distribution is used with minimum 5, most likely 10 and maximum 30 min activity time.

Build

For a dynamic model, to be able to predict costs of any part, a build time estimator must be used. This model uses the build time estimator devised by Fera et al.27. The total build time for all parts is the sum of the individual build activity times:

Warm-up (\({T}_{{warm}-{up}}\)) and cool-down (\({T}_{{cool}-{down}}\)) time for each layer will be consistent, hence the total warm-up and cool-down times for the build are given by that of one layer (\({t}_{{wu},{layer}}\) / \({t}_{{cd},{layer}}\)) multiplied by the number of layers (\({N}_{L}\)). The delay time between the warm-up, scan, cool-down and recoat activities for each layer is also included in cool-down time for increased accuracy of the estimator.

The recoating time (\({T}_{{re}-{coat}}\)) is dependent on the number of layers in the build and can be estimated using the following equation:

where:

\({t}_{{recoat},{layer}}\) Time to recoat one layer of powder

\({N}_{L}\) Number of layers

Scanning time (\({T}_{{scan}}\)) is dependent on the build geometry and given by the sum of the scan time required for each layer. An estimate for this can be provided by taking the average cross section of the whole part and using the scan time per unit area to calculate the estimated overall scan time.

and:

where:

\({N}_{P}\) Number of parts in build

\({{cs}}_{{av}}\) Average cross section of layer

\({N}_{L}\) Number of layers

t Scan time per unit area

V Part Volume

h Part height

It Material layer thickness

Based on the calculations above, AM250 build operations such as warm-up, cool down and recoating would take 8500 s for 1700 layers, whereas scanning would take 817 s per part for a part which again consists of 1700 layers. It should be noted that the build time will vary depending on the number of layers and other process parameters as determined in the equation.

Removal

Once the build finishes, the build plate is left to cool in the machine. The cooling time for all builds is assumed to be about an hour. The excess powder in the build chamber is then removed using a brush and/or vacuum, to be recycled back into the machine vats. The activity time for this is given by:

PRR Powder Removal Rate (\({{mm}}^{3}\)/s)

VRemoval Volume of Powder to be removed (\({{mm}}^{3}\)), given by:

\({V}_{{Removal}}=({l}_{c}* {w}_{c}* h)-({V}_{p}* {N}_{p})\)

lc Length of build chamber (mm)

wc Width of build chamber (mm)

h Part height (mm)

Vp Volume of part (\({{mm}}^{3}\))

Np Number of parts per build

Based on the equations above, the powder removal process takes around 2500 s with a 1000 \({{mm}}^{3}\)/s PRR and 2458450 \({{mm}}^{3}\) of \({V}_{{Removal}}\) in the case of NAS979 part.

The part together with the build plate is removed from the machine, which is the final operation in the build process, and it is assumed to take a constant time of 600 s in this study. This assumption is made because the time required for part removal is generally independent of build parameters and involves removing the part from the machine, which is a relatively standardised procedure.

Post-processing

Post-processing activities start with a cooling down process of the build after being removed from the machines, which takes an hour on average. The activity time for the second operation, which is air brushing, is dependent on the total area of the build requiring brushing. It is assumed that the full surface area of each part will be treated, and therefore air blast time (\({T}_{{AB}}\)) is given by:

SP Part surface area (mm2)

ABR Air Blast Rate (mm2/s)

Thirdly, heat treatment time is constant for all builds, independent of build parameters. The furnace must be heated for 1 h, followed by 2 h of treatment and a further hour of cooling down time.

Moving on to the fourth operation, the speed of the wire EDM process is dependent on factors including the type of equipment, machine parameters and the cut dimensions. The effect of cutting speed on EDM accuracy has been investigated and a cutting speed of 500 \({{mm}}^{2}\)/min (8.33 \({{mm}}^{2}\)/s) has been identified as optimal speed30. Given the dimensions of the build plate for AM250, the EDM time can be estimated to be 7503 s following the equation below.

ABP Area of build plate (\({{mm}}^{2}\))

CREDM EDM cut rate (\({{mm}}^{2}\)/s)

The fifth operation in post-processing process is milling, which is necessary to be able to re-use the build plate. The activity time can be estimated following the equations below:

Vr Volume to remove (mm3)

MRR Material removal rate (mm3/s)

And:

vf Feed rate (mm/s), dr Radial depth of cut (mm), da Axial depth of cut (mm)and:

fz Feed per tooth (mm), n Spindle speed (rpm), Z Number of teeth/flutesand:

Vc Tool cutting speed (m/min), D Tool diameter (mm)

Finally, the activity time of the last operation in post-processing step which is CNC finish machining is calculated using the same equations above. The removal volume here \({V}_{r}\) will be the surface area of the part, multiplied by the machining depth. This is assumed to be 1 mm across the entire surface to produce a quality finish. A 10% additional time was included to account for none-material cutting moves during machining i.e. rapid moves and tool change. Overall machining time calculation is therefore as follows:

Table 4 shows the parameters that are used to calculate the activity times of milling and CNC operations.

Costing

Costs will be applied in the model either as a single direct cost each time a resource is utilised, or as a rate-based cost, which are applied per unit of time that the resource is in use. A cost breakdown is shown in Fig. 15.

Material cost

Using the selected material properties, and the input part data, a material cost per part can be calculated, therefore providing a material cost per build to use in the model. A waste factor is used to model extra material removed from the machine post-build, which was assumed to be 10%. The total material cost per build is calculated using the number of parts in the build (\({N}_{p}\)), the waste factor (\({F}_{{waste}}\)), the material cost per kg (\({C}_{{mat},{kg}}\)) and the mass of one part (\({M}_{{part}}\)) as follows:

In this study, the material cost of Titanium Alloy Ti6AI4V was calculated as £3.64/part, £8.83/part, and £1200/part for joint, pyramid lattice and NAS979 respectively.

Electricity and gas cost

Electricity consumption is different for each machine and part. According to International Energy Agency statistics published by the Department for Business, Energy and Industrial Strategy31, the cost of industrial energy in the UK was 25.46p per kWh in 2024, which was the latest data shared. Mognol et al.32 studied the power consumption of three different AM techniques, reporting that mean consumption for metal methods was 2 kW when the machine was idle, and 4 kW when the machine was operating.

High purity argon gas is used in most machines, which comes at a high cost. Industrial prices are £0.32 per litre refill. Machine gas consumption rate has been assumed at 50 l per hour for all machines. This conservative assumption is made to maintain consistency when comparing the results for AM250 and AM500Q, however the flow rate in AM250 can be as low as 30 l per hour. This results in a cost rate of £16 per hour, similar to the €20 per hour estimated in the Rickenbacher et al.12 model. Therefore, energy cost rates for idle and busy are determined as £0.50 and £1 per hour, whereas gas cost rate is £15 per hour.

Consumables

PPE must be used when handling the powder and using the AM machine which contains inert gas. A £5.00 usage cost has been applied for each activity where PPE is required to cover the cost of equipment and cost of cleaning.

Each build plate is milled down and re-used after a build. Eventually, it can no longer be used, and a new build plate is required which comes with an associated cost. This will depend on the build material (since the build plate material must match), the build chamber area, and the build plate thickness. For the purpose of this model, a fixed price of £350 per build plate has been assumed. The number of build plates required is given below, where \({N}_{b}\) is the number of builds (from the packing algorithm), and \({n}_{{bp},\max }\) is the maximum number of times each build plate can be used, which is typically five times.

Operator costs

According to the Office for National Statistics (ONS), the average labour wage in manufacturing in November 2024 is £706 per week (£36,712 per year)33. With an average of 37.5 working hours per week in the UK, the operator cost translates to £18.38/h.

AM machine cost rate

The machine cost needs to consider the capital purchase cost, the expected lifetime (or depreciation each year) and the yearly maintenance costs. These can be applied to produce a yearly machine cost, converted into a rate using the expected machine uptime per year.

where:

Crate, mach Machine hourly cost rate (£/hr)

Ccap,mach Machine capital purchase cost (£)

Cmaint,mach Machine yearly maintenance cost (£)

d Machine lifetime in years

upt Yearly uptime (hr)

AM machine rate is determined £10 per hour considering machine uptime, machine purchase cost, machine life, machine depreciation and maintenance cost which are 5000 h/year, £300,000 per year, 10 years, £30,000 per year and £20,000 per year, respectively. It should be noted that no residual value was assumed for the machine at the end of its life however, this can be taken into account by deducting the residual value at the end of life from the machine capital purchase cost.

Post-processing machine cost rates

Similar to the AM machine, post processing machine costs are applied as an hourly rate calculated using capital purchase cost and depreciation, as well as maintenance and consumables (such as lubricants and filters).

Post processing machines (CNC milling and Wire EDM) will also have additional tooling costs. Each tool has an expected life and set replacement cost and therefore is also modelled using an hourly cost rate. Usually, tool life can be measured and estimated experimentally34,35, however this is not possible for this model and therefore a set replacement cost and tool life have been assumed. Table 5 shows the machine cost rates for each post-processing equipment.

Model development

The model is based on the following assumptions:

-

CAD preparation and build job preparation are excluded from this model. These activities are carried out on the design side, and times and costs are widely varied depending on the engineer and software used. There are also software preparation activities required for conventional CNC machining (Design optimisation, orientation and build simulations), and these can therefore be discounted when comparing the two.

-

Inspection/quality checks have been excluded for the same reason, these take place in both AM and conventional processes.

-

General overheads costs (rent, administration etc.) are also excluded. However, space has been left in the model for their consideration, since overall additive manufacturing footprint including post-processing machines may be larger those required for conventional manufacturing.

-

Initially, the model will only encompass the production of multiple instances of a single part geometry. This approach has been adopted for the purposes of simplifying the development of the model.

-

In this study, the builds are not stacked vertically, which is a common practice. This approach is often associated with the need for additional support structures and can result in reduced structural integrity for parts located higher up in the build and increased material/powder consumption for building the support structures.

-

Parts in the build have been orientated to minimise the support structures required. As such the cost of support structures will not be considered.

-

All post-processing treatments require an operator.

-

All activity time values are deterministic unless stated.

Based on the listed assumptions and exclusions, a detailed simulation model was built in Simio36. Specific tools are used to provide detailed logic to the model. Manufacturing activities are represented by servers, each of which can be assigned process times, work schedules, resources and workers.

Implementation in Simio

An overview of the L-PBF manufacturing system for discrete event simulation is shown in Fig. 16. The building blocks in Simio were used for including the data that encompass all the process steps, resources and operators as well as the associated times for each activity. The model is integrated with a dataset where input data is given for each specific part and manufacturing scenario. After performing the simulation, the discrete event simulation model exports specific activity times and resources used for cost analysis.

Data availability

The data that supports the findings of this study are available within the article. Any additional data apart from what is provided within the manuscript can be supplied upon reasonable request.

References

Prashar, G., Vasudev, H. & Bhuddhi, D. Additive manufacturing: expanding 3D printing horizon in industry 4.0. Int. J. Interact. Des. Manuf. 17, 2221–2235 (2023).

Holmström, J., Partanen, J., Tuomi, J. & Walter, M. Rapid manufacturing in the spare parts supply chain: alternative approaches to capacity deployment. J. Manuf. Technol. Manag. 21, 687–697 (2010).

Babu, S. & Goodridge, R. Additive manufacturing. Mater. Sci. Technol. 32, 615–616 (2016).

Gibson, I., Rosen, D. & Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing (Springer, 2010).

Mellor, S., Hao, L. & Zhang, D. Additive manufacturing: a framework for implementation. Int. J. Prod. Econ. 149, 194–201 (2014).

Shokrani, A., Arrazola, P. J., Biermann, D., Mativenga, P. & Jawahir, I. S. Sustainable machining: recent technological advances. CIRP Ann. 73, 483–508 (2024).

ASTM/ISO 52900. Additive Manufacturing—General Principles—Terminology. ASTM Int. 2021, 1–14 (2021).

Joshua, R. J. N. et al. Powder bed fusion 3D printing in precision manufacturing for biomedical applications: a comprehensive review. Materials17, 1–30 (2024).

Das, S., Wohlert, M., Beaman, J. J. & Bourell, D. L. Processing of titanium net shapes by SLSrHIP. Mater. Des. 20, 115–121 (1999).

Busachi, A. et al. A review of additive manufacturing technology and cost estimation techniques for the defence sector. CIRP J. Manuf. Sci. Technol. 19, 117–128 (2017).

Kokare, S., Oliveira, J. P., Santos, T. G. & Godina, R. Environmental and economic assessment of a steel wall fabricated by wire-based directed energy deposition. Addit. Manuf. 61, 103316 (2023).

Rickenbacher, L., Spierings, A. & Wegener, K. An integrated cost-model for selective laser melting (SLM). Rapid Prototyp. J. 19, 208–214 (2013).

Calvi, K., Halawa, F., Economou, M., Kulkarni, R. & Chung, S. H. Simulation study integrated with activity-based costing for an electronic device re-manufacturing system. Int. J. Adv. Manuf. Technol. 103, 127–140 (2019).

Khanna, N., Salvi, H., Karaş, B., Fairoz, I. & Shokrani, A. Cost Modelling for Powder Bed Fusion and Directed Energy Deposition Additive Manufacturing. J. Manuf. Mater. Process. 8, 142 (2024).

Haroun, A. E. Maintenance cost estimation: application of activity-based costing as a fair estimate method. J. Qual. Maint. Eng. 21, 258–270 (2015).

Özbayrak, M., Akgün, M. & Türker, A. K. Activity-based cost estimation in a push/pull advanced manufacturing system. Int. J. Prod. Econ. 87, 49–65 (2004).

Alexander, P., Allen, S. & Dutta, D. Part orientation and build cost determination in layered manufacturing. Comput. Aided Des 30, 343–356 (1998).

Ruffo, M., Tuck, C. & Hague, R. Cost estimation for rapid manufacturing—laser sintering production for low to medium volumes. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 220, 1417–1427 (2006).

Hopkinson, N. & Dickens, P. Analysis of rapid manufacturing-using layer manufacturing processes for production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 217, 31–39 (2003).

Baumers, M., Tuck, C. J., Wildman, R. & Ashcroft, I. Combined build-time, energy consumption and cost estimation for direct metal laser sintering. https://doi.org/10.26153/tsw/15401 (University of Texas at Austin, 2012).

Wiese, M., Kwauka, A., Thiede, S. & Herrmann, C. Economic assessment for additive manufacturing of automotive end-use parts through digital light processing (DLP). CIRP J. Manuf. Sci. Technol. 35, 268–280 (2021).

Costabile, G., Fera, M., Fruggiero, F., Lambiase, A. & Pham, D. Cost models of additive manufacturing: A literature review. Int. J. Ind. Eng. Comput. 8, 263–282 (2016).

Piili, H. et al. Cost estimation of laser additive manufacturing of stainless steel. Phys. Procedia 78, 388–396 (2015).

Barclift, M., Joshi, S., Simpson, T. & Dickman, C. Cost modeling and depreciation for reused powder feedstocks in powder bed fusion additive manufacturing. in 2016 International Solid Freeform Fabrication Symposium (University of Texas at Austin, 2016).

Lindemann, C., Jahnke, U., Moi, M. & Koch, R. Analyzing product lifecycle costs for a better understanding of cost drivers in additive manufacturing. in 23rd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, University of Texas at Austin SFF 2012 177–188 (2012).

Schröder, M., Falk, B. & Schmitt, R. Evaluation of cost structures of additive manufacturing processes using a new business model. Procedia CIRP 30, 311–316 (2015).

Fera, M., Fruggiero, F., Costabile, G., Lambiase, A. & Pham, D. T. A new mixed production cost allocation model for additive manufacturing (MiProCAMAM). Int. J. Adv. Manuf. Technol. 92, 4275–4291 (2017).

Renishaw. Data sheets—additive manufacturing. https://www.renishaw.com/en/data-sheets-additive-manufacturing-17862 (2022).

Chen, C. et al. Microstructure evolution and mechanical properties of laser additive manufactured Ti6Al4V alloy under nitrogen-argon reactive atmosphere. Mater. Sci. Eng. A 841, 143076 (2022).

Sanchez, J. A., Rodil, J. L., Herrero, A., de Lacalle, L. N. L. & Lamikiz, A. On the influence of cutting speed limitation on the accuracy of wire-EDM corner-cutting. J. Mater. Process. Technol. 182, 574–579 (2007).

UK Government Department for Business, E. and I. S. International industrial energy prices. https://www.gov.uk/government/statistical-data-sets/international-industrial-energy-prices (2013).

Mognol, P., Lepicart, D. & Perry, N. Rapid prototyping: energy and environment in the spotlight. Rapid Prototyp. J. 12, 26–34 (2006).

Trading Economics. United Kingdom Average Weekly Wages in Manufacturing. https://tradingeconomics.com/united-kingdom/wages-in-manufacturing (2022).

Fernández-Robles, L., Sánchez-González, L., Díez-González, J., Castejón-Limas, M. & Pérez, H. Use of image processing to monitor tool wear in micro milling. Neurocomputing 452, 333–340 (2021).

Omole, S., Dogan, H., Lunt, A. J. G., Kirk, S. & Shokrani, A. Using machine learning for cutting tool condition monitoring and prediction during machining of tungsten. Int. J. Comput. Integr. Manuf. 37, 747–771 (2024).

Simio LLC. No Title. Simio Software, Acad. Des. Ed. (2025).

Author information

Authors and Affiliations

Contributions

B.K.—methodology, data curation, investigation, validation, formal analysis, software, visualisation, writing original draft. A.S.—conceptualisation, methodology, investigation, validation, writing review and editing, resources, supervision, project administration.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Karaş, B., Shokrani, A. Activity-based costing of laser powder-bed additive manufacturing incorporating discrete event simulation. npj Adv. Manuf. 2, 24 (2025). https://doi.org/10.1038/s44334-025-00036-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44334-025-00036-x