Abstract

Directed Energy Deposition (DED) was used to deposit Inconel 625 (IN625) onto 316L stainless steel (SS316L) substrates fabricated by Laser Powder Bed Fusion. Tensile properties of the resulting multi-material specimens were compared to those of the individual alloys. Two bonding approaches were evaluated: a direct transition and a 50/50 intermediate layer formed by blending equal parts of each alloy during deposition. The multi-material specimens demonstrated higher yield strength than the single alloys. However, samples with the 50/50 transition exhibited brittle failure at the joint, whereas the direct transition behaved more ductile. Scanning Electron Microscopy revealed microcracks at the interface of the 50/50 transition, and Energy Dispersive Spectroscopy detected aluminum oxide particles in the DED-IN625 samples. These results underscore the importance of transition design in multi-material components and provide guidance for optimizing mechanical performance in demanding applications such as in extreme conditions, particularly where structural integrity and high-performance bonding are critical.

Similar content being viewed by others

Introduction

Additive manufacturing (AM) has been an increasingly popular method for producing multi-materials by enabling spatially controlled deposition of dissimilar alloys 1. This capability opens the doors to fabricating parts with optimized mechanical properties for their intended applications which is especially useful in harsh environments of high temperature and high load 2,3. The ability to locally tailor composition and microstructure provides new opportunities for multifunctional components in aerospace, energy, and defense applications. Among the AM techniques, Directed Energy Deposition (DED), also known as laser metal deposition, direct laser deposition, or laser engineered net shaping, is widely used for fabricating multimaterial components and repair 3. DED is advantageous in relation to other techniques due to the size of the components that can be manufactured, the in-situ multi-powder deposition capability, availability of a wide range of materials suitable for the method, and the ability to bond materials with high-strength interfaces. The disadvantages of this process include the low dimensional accuracy of the printed parts, residual thermal stress, requirement of atmospheric control and machining processes which are necessary for quality surface finish4,5. In contrast, laser powder-bed fusion (LPBF) can produce high-precision small and medium-sized multi-metal parts, but with limitations on the location and orientation where different materials can be added due to the powder distribution system 3. For multi-material manufacturing, the powders must be premixed in the hopper or the system must be upgraded to include in-layer material changes, though advancements in selective deposition are ongoing. This makes LPBF less ideal for printing with multi-materials, or at least more expensive, when compared with DED.

Many properties are of interest when testing the bonding of two alloys together. One of the more popular properties is tensile strength of the dissimilar metals which provides valuable insights into the bond strength of a multi-material. In the case of Stainless Steel (SS) and Inconel (IN), a number of efforts focused on evaluating the strength of the bond between the materials while focusing on the effect of the inter-boundary layer transition and the deposition order. The literature available for both DED and LPBF methods is presented next and focuses on the approaches that were used in attempting to improve the multimaterial strength in SS and IN material systems.

The DED technique is most popular in fabricating multimaterial components given the advantages presented earlier, mainly the ease of switching between materials to achieve a multi-material interface. Zhang et al.6 fabricated IN625 onto SS316L with intermediate layers of 50% SS and 50% IN for 2 mm via DED with pre-mixed powders. Tensile results were compared to the single alloy counterparts. The Ultimate Tensile Strength (UTS) of the multi-material was slightly higher than SS316L fabricated by DED at a value of 606 MPa. The yield strength (YS) approached that of single alloy DED IN625 at 406 MPa, but the % elongation (El) was not recorded. In an effort to characterize the effect of deposition order, Chen et al.7 manufactured two types of multi-material samples through DED where the first type was IN625 onto SS316L and the second type was SS316L onto IN625. They found that IN on SS exhibited less cracks and no sudden-change compositional zone in contrast to the samples where SS was deposited onto IN. No tensile results were provided to compare to other literature values.

Grading is another technique that was tested for improving the strength of the multi-materials, but exhibited defects at the inter-boundary layer. Yang et al.8 studied three samples of SS316L deposited onto IN718 through DED. The first sample was non-graded (a direct transition from SS to IN), the second was graded with 25 wt% change, and the third was a graded sample with 10 wt% change. Cracks were observed in both graded samples and were attributed to differences in cooling rate and differences in coefficients of thermal expansion of the two materials. Cracks were observed in the non-graded sample at the interface between the two materials, and silicon oxide inclusions were revealed and analyzed near the crack surfaces. The tensile results showed slightly higher performance for the 25 wt% graded sample when compared to the 10 wt% graded and non-graded samples. None of the multi-materials achieved tensile values above that of single alloy SS316L, and did not elongate beyond 10% with the direct transition elongating at only 9%. Similarly, Shah et al.9 produced a thin wall structure through a type of DED process composed of IN718 deposited onto SS316L where the transition gradually changed in composition every 3 layers by 25% IN718. Tensile results revealed that the UTS decreased with laser power and increased with powder mass flow rate. High powder flow rate resulted in UTS between 531 and 596 MPa. Beyond the mechanical behavior, efforts have been made to evaluate the residual stresses in similar direct transitions and graded multimaterials 10. The results reveal a jump in the residual stress at the interfaces in the direct transition materials fabricated via DED. The work revealed maximum tensile residual stress at the two free ends and the accumulation of compressive residual stress at the mid-length of the structure-substrate interface.

In a more recent study and an effort to optimize DED processing parameters for multi-material SS and IN, Stair et al.11 investigated the bonding of IN625 to SS304L using DED. The study also identified processing conditions that yield crack-free, high-strength joints without resorting to functionally graded materials, which can be complex to manufacture. The tensile strength of specimens fabricated using DED without application of surface machining revealed that failures occurred exclusively within the SS304L region, not at the interface. This indicates that the joint strength exceeds 650 MPa, demonstrating the effectiveness of the optimized bonding approach presented.

Due to the hardware limitation in fabricating multi-material components using LPBF, fewer studies focused on the material behavior using this technique. Ghanavati et al.12 fabricated 4 types of samples using LPBF: A bimetal sample with direct transition from SS316L to IN718, a 50/50 intermediate transition between the two single alloys (one using the SS process parameters and another using the IN parameters), and finally a sample with a graded step composition of 25 wt%. The latter sample exhibited the highest YS, but the lowest elongation and broke prematurely at just 10% El compared to the other samples that fractured at elongations between 30 and 35%. Using the same material systems, some promising results were presented by Singh et al.13, who analyzed a bimetallic (Direct Transition) composed of SS316L that transitioned directly to IN718 through LPBF. The tensile results showed that the bimetallic structure exhibited a higher UTS than that of the monolithic alloy SS316L. The elongation at break was 21% which was slightly higher than the IN718 fabricated using LPBF.

Despite the successful fabrication of multi-materials with high strength using DED and LPBF solely, a combination of the two techniques to fabricate SS and IN components with a comparable strength to the monolithic materials is crucial. A hybrid approach combining DED and LPBF draws the advantages of each technique to manufacture a component that benefits from high dimensional accuracy on the LPBF side with a high cost material and a lower dimensional accuracy side where a lesser costly material is deposited. In a scenario where a LPBF part has failed and needs repair, DED can be used to not only restore the part, but enable higher strength through a multi-material that can withstand extreme environments. Another application could be when a multi-material part is needed and might only require high-resolution features in one section, but less precision at another (e.g., a heat exchanger for high-temperature applications).

This article aims to document the tensile properties of a multi-material fabricated through both LPBF and DED, specifically, depositing IN625 using powder-fed DED onto a LPBF SS316L. The authors draw from the presented literature and chose the higher strength deposition order while the transition is evaluated. Two joining interfaces are tested, namely, direct transition and 50/50 intermediate transition (where 50% SS316L powder is blended with 50% IN625 during the DED process). As AM technology continues to become more popular, LPBF combined with DED will likely be employed to leverage the advantages of both methods. Documenting the bonding of SS316L and IN625 is paramount to enable evidence for quick decision-making in the applications mentioned above, or in other scenarios not yet explored.

Results

Monolithic materials

The stress-strain responses comparing the single alloy wrought and LPBF SS316L samples are recorded in Fig. 1. It is observed that the LPBF SS316L has higher YS (average value of 438 MPa), lower % El (average of 74 compared to 106), and a slightly lower UTS (average 626 MPa) compared to the wrought SS316L. The fractography images reveal ductile characteristics with localized plastic deformation.

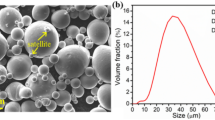

For DED IN625, Fig. 2 demonstrates the tensile behaviors of single material wrought IN625 compared to DED IN625. The DED IN625 was extracted from a bulk material to ensure testing of anisotropic characteristics. Wrought IN625 has a higher elongation until fracture (average 74%) that leads to increased toughness compared to the DED IN625. Anisotropy is demonstrated where the Z-oriented samples had lower YS and UTS (averages 367 and 707 MPa, respectively) compared to the XY-oriented samples (averages 433 and 780 MPa, respectively). The elongation to fracture was not affected by the print orientations (averages of 57 and 56, respectively). There were several notable samples that fractured at lower elongations than the rest of the samples and are denoted in Fig. 2 with the letters a, b, and c. Upon examination of the fracture surfaces, dark particles were observed. The particles were analyzed through EDS, and the results can be seen in the inset of Fig. 3.

The particles have the right chemical proportions of aluminum and oxygen to be considered aluminum oxide powder, also known as alumina, and are suspected to have contaminated the build from the powder feeding system during the transition of the system from a prior material system.

Multi-materials

The tensile behavior of the multi-material samples, both direct transition and 50/50 intermediate transition, are shown in Fig. 4.

Observations when comparing the tensile behavior of the multi-material samples include better elongation until fracture for the direct transition samples when compared to the 50/50 intermediate joint samples (average of 37 versus 14). Striations are prominent in the fractography images for two of the samples that had a brittle fracture and are referred to as samples a and b in Fig. 4. The more brittle fracture is attributed to brittle carbides and Laves phases present in the 50/50 samples as previously presented by Aydogan et al.14 when mixed SS and IN powders are deposited using DED. The striation is attributed to the scan strategy that was used during deposition.

A box plot summarizing the tensile properties of the multi-material samples and single-alloy samples is illustrated in Fig. 5. The percent elongation until fracture was lower for both multi-materials compared to the single alloy AM and wrought samples. The UTS of the Direct Transition (average 684 MPa) samples exceeded that of the wrought SS316L (average 681 MPa) and approached that of IN625 printed in the Z orientation (average 707 MPa). Most remarkably, the YS of the multi-materials is higher than that of any of the single alloy counterparts. One explanation for this behavior could be the choice not to stress relieve the parts, and residual thermal stresses remained. As presented in the literature, residual compressive stresses are expected to build up in the multi-material, especially close to the transition zone 10 which results in the increase in yield strength. Moreover, the heating cycles in the SS side of the multi-material can result in strengthening in the heat affected zone, resulting in a local heat-treatment of the base material (namely, IN625).

Upon examining the samples post-mortem in Fig. 6, the 50/50 samples exhibited brittle fracture, while the direct transition samples were more ductile. The plastic deformation appears to have only affected the stainless steel regions of the samples with fracture occurring within the 50/50 intermediate region for the 50/50 samples, while fracture occurring within the stainless steel region of the direct transition samples. This was confirmed using an EDS line scan across the fractured specimens, and results can be seen in Fig. 7. Figure 7 shows the EDS line scans across the two fracture sides of the multi-material samples. The Fe and Ni content can be seen closing the gap while moving from left to right in the 50/50 sample (Fig. 7 left). It then shows a transition to complete IN625 as the Ni content increases while the Fe content drops to a range of 10-20 wt%. In contrast, the fracture in the direct transition sample (Fig. 7 right) is evidently located on the SS316L side, as indicated by the constant levels of Fe and Ni throughout the scan.

Further analysis of the 50/50 transition region revealed microcracks at the transition from SS316L to the 50/50 intermediate zone that are highlighted in the high-resolution image on the left side of Figure 8. The authors postulate that the microcracks present in the transition region drove the brittle failure as the cracks would introduce a crack-initiation site for propagation. Another crack was observed inside the SS316L side ~500 μm from the transition (See the lower right-hand high-resolution image in Fig. 8). The mechanism for crack formation is related to the remelting of the SS316 during the deposition of the 50/50 intermediate layers which results in growth of a crack during solidification. The intergranular crack formation is also connected to ductility dip cracking as explained by Caruso and Frame 15. Cracks develop in austenitic stainless steels during LPBF due to the presence of liquid films. The combination of these liquid films and thermal stresses resulting from LPBF and remelting during the deposition leads to the formation of solidification cracks 16. This means that both process parameters and the solidification sequence can influence cracking. Consequently, optimizing the chemical composition of the alloy can reduce the susceptibility of austenitic stainless steels to solidification cracking. In contrast to nickel superalloys, which are prone to various types of cracking like liquation and environmentally-assisted cracking, solidification cracking is the type observed during LPBF of austenitic stainless steels 11.

The low resolution image (upper right corner) allows to identify areas of interest at the single material side (SS316L at the right hand side) and the transition zone. Higher resolution images highlight the presence of a microcrack in the SS316L side, and microporosity at the inter-boundary layer. A further analysis of the underlying microstructure is available by Bettencourt and Kouraytem17.

Discussion

The direct comparison of the tensile values to literature is challenging as there has been no work on combining LPBF SS316L to IN625 via DED. However, others have used both techniques to combine similar alloys together with the same additive technique. Figure 9 shows the comparison of median values of UTS, YS, and % El of the multi-materials in this work to that of similar research.

Direct transition joining is shown where Yang and Singh produced a direct transition sample with SS316L onto IN718 (left), and 50/50 transition joining is shown where Zhang deposited IN625 onto SS316L with a 2 mm transition zone, and Ghanavati combined IN718 onto SS316L with a 4 mm intermediate zone (right).

The trend in tensile values compared to literature for the direct transition samples shows the current work outperformed the literature values substantially. This was likely due to the fact that the current work deposited IN625 onto SS316L, whereas Yang et al.8 and Singh et al.13 both deposited SS316L onto IN718. Chen et al.7 showed that printing sequence affects crack formation during fabrication of multi-material made with DED IN625 and SS316L 7. When SS316L was deposited onto IN625, it had a higher susceptibility to cracking than if the sequence were opposite and IN625 was deposited onto SS316L. Further work could prove that the increased tensile values are purely due to printing sequence, or if it is an unforeseen benefit of combining DED and LPBF. The trend in the 50/50 transition values between the literature values and the current work is nearly identical; however, elongation values appear much lower than that of the literature values. The results for the current work are median value with the % El values for two of the four samples around 20 and 30% which is in closer agreement to literature values; however, the other two values were approximately 3% which lowered the median value.

The novel combination of powder-fed DED with LPBF base material was successfully demonstrated. Multi-material LPBF-SS316L/DED-IN625 samples with a direct transition outperformed the intermediate 600 μm layer of 50% SS316L and 50% IN625 transition samples. Cracks were present in the 50/50 transition samples and were the cause for the brittle failure observed. Comparing the multi-material samples to single alloy counterparts, it is clear that the multi-material samples have an increased yield strength, less ductility, and UTS approaching that of DED-IN625 which presents a promising approach for the design and repair of multimaterials produced via hybrid AM techniques, especially for applications in extreme environments.

Methods

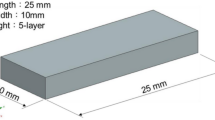

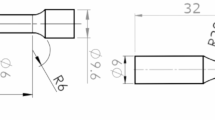

Three types of samples were prepared following the ASTM E8 subsize specimen standards dimensions provided in Fig. 10 for tensile testing: (1) AM monolithic alloy samples, (2) AM multi-material samples, and (3) wrought samples. The preparation of each will be detailed.

Sample preparation: AM single alloy

The AM samples were produced through LPBF (SS316) and DED (IN625). The SS316L was produced using gas-atomized Praxair TruForm316-3 powder on an Additive Industries MetalFAB1. See Table 1 for the chemical composition of the powder and Table 2 for the processing parameters. The system uses four SPI Red Power (500-Watt, 1,070 nm wavelength) lasers, a nominal spot size of 120 μm, and a meander scan strategy. The samples were stress relieved at 450circ C for 4 h, furnace cooled to 200circ C then air cooled. Wire Electrical Discharge Machining (EDM) was used to detach the rectangular bars from the build plate as oriented in Fig. 1. The samples were then machined to geometry.

The single alloy IN625 was fabricated using powder-fed DED with gas atomized Praxair Ni-328-17 powder. The chemical composition can be seen in Table 3. The DED system used was a FormAlloy L5 machine equipped with a 1 kW fiber laser. A proprietary software was used to maintain the optimal meltpool geometry by varying parameters with a closed-loop feedback control. Set points are seen in Table 4. A block sample in an L-shape was printed and cut off the build plate with wire EDM. Keeping in mind the ultimate application of depositing IN625 onto the LPBF SS316L, the DED blocks were not stress relieved as it would not be possible to subject the final multi-material component (SS316L and IN625) to it in a real life scenario.

Using a waterjet, samples were extracted from the block in three orientations. The XY orientation refers to the sample having the build direction in the same direction as the thickness of the sample. The YZ orientation refers to the samples extracted with the build direction in the same direction of the width of the sample. Finally, the Z orientation was when samples were extracted having the length of the specimen in the same direction as the build direction. This can be seen in the images overlayed onto the stress strain graphs in Fig. 2.

Sample preparation: LPBF-SS316L/DED-IN625 multi-materials

The multi-material samples were fabricated by producing SS316L half blocks via LPBF using the same parameters and powder as the single alloy samples. The blocks were stress relieved and detached from the build plate through wire EDM and sent to the DED manufacturer. IN625 was deposited onto the half blocks using DED with the same powder and parameters as the AM single alloy samples. One of the blocks had a direct transition with only IN625 powder deposited onto the LPBF SS316L half block, while the other half block had an intermediate zone that was two layers thick (600 μm total) of an in-situ mix of 50% SS316L powder and 50% IN625 powder.

The full builds were removed from the build plate with wire EDM. Four (4) subsize ASTM E8 specimens were extracted via waterjet and then machined to thickness in each transition approach (for a total of eight multi-material samples) then tested as detailed below in the mechanical testing section. All sides of the tested specimens were machined to eliminate the surface effects and isolate the material behavior.

Sample preparation: wrought materials

The wrought samples were extracted from commercially available bulk material using a waterjet. The SS316L samples were extracted from SS316L 11 gauge cold rolled coil, with chemical composition provided in Table 5. It was solution annealed at 1040circ C then air and water quenched. The IN625 samples were extracted using EAF-AOD-electroslag remelted IN625 coil that was pickled and annealed. The composition of the wrought IN625 is provided in Table 6.

Mechanical testing

Uniaxial tensile testing was performed on an MTS Bionix 370 tabletop load frame. The test was quasi-static and displacement controlled using a rate of 1 mm/min. In total, 6 groups of samples were tested: wrought samples (SS316L and IN625), AM single alloy samples (LPBF SS316L and DED IN625), and finally, the two types of multi-materials (direct transition and an intermediate zone transition).

Post-processing of the tensile data was performed using MATLAB. Strain was calculated by dividing the crosshead displacement by the gauge length of 25.4 mm. The yield strength was calculated using a linear fit of data between an upper and lower limit selected by the user from the elastic portion of the stress strain curve. The 0.2% rule was used where the fit was offset to find the intersection with the stress strain curve.

For Scanning Electron Microscopy (SEM), an FEI Quanta FEG 650 scanning electron microscope was used. It was equipped with an Oxford X-Max detector for Energy Dispersive Spectroscopy (EDS) capability. EDS and post-processing were accomplished via AZtec software. The accelerating voltage was 15 kV with a spot size of 2 μm and a dwell time of 15 μs in an approach similar to that used by the authors in 17.

Data availability

Data will be made available upon reasonable request to the corresponding author.

Code availability

Data will be made available upon reasonable request to the corresponding author.

References

Saleh, B. et al. 30 Years of functionally graded materials: an overview of manufacturing methods, applications and future challenges. Compos. Part B. Eng. 201, 108376 (2020).

Vaezi, M., Chianrabutra, S., Mellor, B. & Yang, S. Multiple material additive manufacturing—part 1: a review: this review paper covers a decade of research on multiple material additive manufacturing technologies which can produce complex geometry parts with different materials. Virtual Phys. Prototyp. 8, 19–50 (2013).

Wei, C. et al. An overview of laser-based multiple metallic material additive manufacturing: from macro- to micro-scales. Int. J. Extrem. Manuf. 3, 012003 (2020).

Hasanov, S. et al. Review on additive manufacturing of multi-material parts: progress and challenges. J. Manuf. Mater. Process. 6, 4 (2022).

Tan, C. et al. Ultra-strong bond interface in additively manufactured iron-based multi-materials. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 802, 140642 (2021).

Zhang, X., Chen, Y. & Liou, F. Fabrication of SS316L-IN625 functionally graded materials by powder-fed directed energy deposition. Sci. Technol. Weld. Join. 24, 504–516 (2019).

Chen, N. et al. Microstructural characteristics and crack formation in additively manufactured bimetal material of 316L stainless steel and Inconel 625. Addit. Manuf. 32, 101037 (2020).

Yang, S. W., Yoon, J., Lee, H. & Shim, D. S. Defect of functionally graded material of inconel 718 and STS 316L fabricated by directed energy deposition and its effect on mechanical properties. J. Mater. Res. Technol. 17, 478–497 (2022).

Shah, K. et al. Parametric study of development of Inconel-steel functionally graded materials by laser direct metal deposition. Mater. Des. (1980-2015) 54, 531–538 (2014).

Ghanavati, R., Naffakh-Moosavy, H., Moradi, M., Gadalińska, E. & Saboori, A. Residual stresses and distortion in additively-manufactured ss316l-in718 multi-material by laser-directed energy deposition: a validated numerical-statistical approach. J. Manuf. Process. 108, 292–309 (2023).

Stair, A., Webler, B. A., Beuth, J. L. & de Boer, M. P. Demonstration and analysis of conditions to obtain a high strength inconel 625 to stainless steel 304l interface by directed energy deposition. Metall. Mater. Trans. A 55, 2186–2199 (2024).

Ghanavati, R. et al. Design and development of SS316L-IN718 functionally graded materials via laser powder bed fusion. Mater. Lett. 349, 134793 (2023).

Singh, S. P., Aggarwal, A., Upadhyay, R. K. & Kumar, A. Processing of IN718-SS316L bimetallic-structure using laser powder bed fusion technique. Mater. Manuf. Process. 36, 1028–1039 (2021).

Aydogan, B., O’Neil, A. & Sahasrabudhe, H. Microstructural and mechanical characterization of stainless steel 420 and Inconel 718 multi-material structures fabricated using laser directed energy deposition. J. Manuf. Process. 68, 1224–1235 (2021).

Caruso, M. & Frame, L. Ductility dip cracking mechanisms and characterization: a review. J. Mater. Sci. 59, 16789–16814 (2024).

Sabzi, H. E. et al. Controlling crack formation and porosity in laser powder bed fusion: Alloy design and process optimisation. Addit. Manuf. 34, 101360 (2020).

Bettencourt, C. J. & Kouraytem, N. Microstructural characterization of the transition in SS316L and IN625 bimetallic fabricated using hybrid additive manufacturing. JOM https://doi.org/10.1007/s11837-023-06119-4 (2023).

Acknowledgements

This material is based upon work supported by the U.S. Department of Energy, Office of Science, Office of Energy and Renewable Energy, Solar Energy Technologies Office (SETO) under Award Number DE-EE0009381. N. K. would like to acknowledge the support by the U.S. Nuclear Regulatory Commission under award number 31310024M0039. The authors acknowledge startup funding from Utah State University and the support from the Microscopy Core Facility at Utah State University for the SEM results. Material fabrication performed by ADDMAN and FormAlloy is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Christopher Bettencourt: Methodology, Formal analysis, Investigation, Data Curation, Writing—Original Draft, Writing—Review & Editing, Visualization. Nadia Kouraytem: Conceptualization, Methodology, Resources, Data Curation, Writing—Review & Editing, Visualization, Supervision, Project administration, Funding acquisition.

Corresponding author

Ethics declarations

Competing interests

All authors declare no financial or non-financial competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bettencourt, C.J., Kouraytem, N. Bonding SS316L and IN625 through laser powder bed fusion and directed energy deposition: a comparative tensile analysis. npj Adv. Manuf. 2, 30 (2025). https://doi.org/10.1038/s44334-025-00044-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44334-025-00044-x