Abstract

Ceramic nanofiber architectures are useful for a wide range of applications, including lightweight structures, filtration, and catalyst supports, due to their high specific surface area, chemical resistance, and thermal stability. To date, ceramic nanofibers have been predominantly fabricated by electrospinning; however, controlling nanofiber alignment within complex architectures is not possible by this technique. Here, we report the in-situ generation of aligned ceramic nanofibers that form through a combination of polymer self-assembly and additive manufacturing. Specifically, preceramic polymer and block copolymer feedstock blends were observed to phase separate during the heat treatment of printed filaments. Nanofiber alignment appears to be influenced by confinement effects imposed on the self-assembling polymers by the printed filament geometry. Following curing, the printed structures were pyrolyzed to generate complex objects composed of ceramic nanofibers. As exemplars, we have printed one-dimensional nanofibrous tows, springs, and lattices that can be manipulated by bending and twisting without mechanical failure.

Similar content being viewed by others

Introduction

Ceramic nanofibers are of growing interest for applications ranging from mechanical reinforcement1,2,3, filtration4,5, and catalyst supports6,7. These nanofibers possess high specific surface area, chemical resistance, and thermal stability. Several fabrication routes have been used to produce ceramic nanofibers, including electrospinning8,9,10, reactive sintering11,12, and rotary jet spinning13. Electrospinning is a popular and relatively inexpensive technique, making the process approachable for academic research. Electrospinning has been utilized to create a broad spectrum of ceramics14,15,16, including both oxides10 and non-oxide compositions, such as silicon carbide (SiC), silicon oxycarbide (SiOC), and silicon oxycarbide nitride (SiCON)17,18,19,20,21,22,23.

SiC, SiOC, and SiCON are materials of increasing importance due to their dual role as both functional and high-temperature structural materials (e.g., as Li ion battery anode materials24 or composite reinforcement25). The broad applicability of SiC, SiOC, and related compositions have thusly propelled these materials forward as candidates for electrospinning. The spinning dopes utilized to produce SiC-based nanofibers include preceramic polymers (PCPs)26,27, such as polycarbosilanes17,20,25,28,29,30,31,32, polysilazanes21,33,34,35, and polysiloxanes22,23. Additionally, electrospinning feedstocks commonly feature silicon-containing species (e.g., silicon tetraethoxide18,19,36 and vinyltrimethoxysilane19), transition metal compounds (e.g., Ti isopropoxide37, Zr butoxide30, or Fe acetylacetone32), or nanoparticle additions (e.g., carbon nanotubes29) to tailor the final ceramic nanofiber composition. SiC-based nanofiber feedstocks vary in their spinnability, often requiring the addition of spinning aids, such as polystyrene (PS)17, poly(methylmethacrylate) (PMMA)34, or poly (vinylpyrrolidone) (PVP)20,31,36, which may fully dissolve within the PCP/solvent spinning dope or exist as a secondary phase (i.e., micelle20) within the feedstock. The combination of polymeric feedstocks and electrospinning setups (e.g., coaxial nozzle-in-nozzle apparatuses) allows for the generation of ceramic or SiC-based nanofibers of specific geometries, including porous35, hollow17, and nanoparticulate composite28,36 morphologies. For example, Tian and colleagues fabricated hollow SiC nanofibers from a single nozzle electrospinning system where phase segregation and spinning dope elongation resulted in the PCP segregating to the fiber sheath while PS resided in the core17. Following pyrolysis, the resulting hollow SiC fibers were found to exhibit excellent thermal insulation properties17.

Though a number of unique and useful morphologies can be produced by electrospinning, the ceramic nanofibers produced via this method are typically arranged as unaligned, non-woven mats comprised of a single or several filaments21. Electrospinning of aligned nanofibers is possible but requires specialized setups (e.g., rotating drums38 or patterned electrodes15). One particularly elegant example of aligned SiC-based nanofiber production was recently reported by Denk and colleagues33. In this prior report, electrospun nanofibers composed of polyacrylonitrile (PAN) (i.e., a common carbon fiber precursor) and oligosilazane (i.e., a C-Si-N containing precursor) were collected with a rotating funnel, where the polymeric nanofibers were wound and collected as poorly aligned nanofibers33. These nanofibers were spooled off the collector, stretched, and recollected to yield highly oriented structures33. The oriented PAN/oligosilazane nanofibers were subsequently pyrolyzed to yield multi-fibrillar hybrid fibers composed of amorphous C/SiCON33. The study by Denk et al. is particularly significant as the continuous processing methodologies used throughout the study are directly applicable to industrial transition33. Though studies that demonstrate the production of aligned SiC-based nanofibers are of scientific and practical significance, the electrospinning technique is not amenable to producing architected ceramic nanofibers with controlled orientation in complex components (e.g., lattice structures, springs, or high-temperature components).

One approach that can be used to achieve nanofiber alignment is material extrusion (i.e., direct ink writing (DIW)) in which filaments containing short, discontinuous nanofibers (e.g., carbon or ceramic fibers) can be printed in a controlled manner. Material extrusion allows for the programmable alignment of fiber fillers within polymer39,40,41,42 and ceramic43,44 composite feedstocks (i.e., inks) due to the shear-induced alignment along the print path39,40,41,42,45,46. However, fiber-filled inks often induce nozzle clogging during printing, thereby limiting both the fiber loading and minimum printed filamentary feature size40. For example, Croom and colleagues utilized both in-situ X-ray radiography and ex-situ X-ray computed tomography to visualize and quantify fiber entanglement during additive manufacturing40. Due to the limitations of material extrusion with preformed nanofibers, it is desirable to develop new materials for DIW that enable the in-situ fabrication of aligned ceramic nanofiber composites (i.e., without using pre-synthesized nanofibers, as pursued by Croom et al. and others).

Here, we leverage a novel PCP/block copolymer (BCP) feedstock developed for the additive manufacturing of hierarchical ceramic architectures with nanoscale porosity47. In prior work conducted at AFRL, we found that a BCP (PMMA-b-PnBA-b-PMMA) could be used to template a PCP during additive manufacturing to produce ceramic filaments with a nanofoam-like (i.e., nanocoral) morphology47. It should be noted that the procedure followed in this prior study relied on UV-initiated PCP cross-linking to kinetically lock the co-continuous worm-like morphology of the PCP/BCP system, thereby producing ceramic nanocoral47. Without the application of UV-initiated curing and crosslinking reagents, we found that the expected nanocoral structure was not the predominant phase, but instead observed that the resulting ceramic was comprised of aligned nanofibers47. Herein, we explored this discovery to create aligned ceramic nanofibers tows, springs, and lattices via an integrated printing, self-assembly, and pyrolysis approach. Material extrusion is used to produce the desired shape, while PCP/BCP self-assembly, followed by pyrolysis, yields ceramic composites composed of SiOC nanofibers embedded in a porous ceramic matrix. Importantly, these inorganic nanofibers are aligned along the print direction, resulting in flexible architected ceramics, which can be reversibly bent, twisted, and compressed.

Results

Initial observation of nanofiber formation

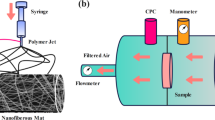

We first prepared an ink composed of a polycarbosilane PCP (SMP-10) and a BCP (PMMA-b-PnBA-b-PMMA) dissolved in a 1-butanol and acetone co-solvent mixture (Fig. 1A). The BCP ink component provides a template for the PCP, where the PCP is selectively associated with the BCP’s hydrophobic PnBA domains (Fig. 1B)47,48,49. In our prior work, PCP/BCP inks contained a multi-armed thiol molecule (i.e., pentaerythritol tetrakis(3-mercaptopropionate)) and photoinitiator to facilitate UV crosslinking, which locked in the desired worm-like micelle morphology prior to thermal treatment47. However, in the absence of UV curing, polymeric nanofibers form within the printed features (Figs. 1C–H, S1, S2). Given these observations, it is reasonable to suspect that nanofiber formation potentially arose during printing, thermal curing, and/or pyrolysis processing phases, rather than within the polymeric feedstock contained in the syringe barrel.

A Chemical composition of preceramic-block copolymer ink that contains a BCP with poly(methyl methacrylate) (PMMA) and poly(n-butyl acrylate) (PnBA) blocks and a PCP (polycarbosilane, PCS), B TEM micrograph of an as-printed filament with a representative schematic showing the worm-like PCP/BCP morphology, with particular attention given to the arrangement of the PCP/BCP chains in the rightmost cartoon. Scale bar is 2 µm. TEM micrographs (left) and corresponding EDS spectra (right) of PCP/BCP printed filaments at chosen temperatures along the curing cycle: C and F 80 °C, D and G 100 °C, and E and H 160 °C. Scale bars are 2 µm. Polar histograms for nanofiber diameter variations in I nozzle diameter, J final cure temperature, and K curing ramp rate. Radial scales are given in microns. L–N SEM micrograph of an aligned tow of ceramic nanofibers.

Nanofiber formation outside of printing processes

Based on our prior reported observations47, we know that PCP/BCP inks exhibit a worm-like morphology that can be locked into place following printing. Hence, nanofibers are likely not formed within the ink reservoir or print nozzle. The absence of nanofibers in the current printing ink was confirmed by TEM imaging of printed samples prior to thermal curing and pyrolysis, which shows the expected worm-like micellular morphology (Fig. 1B, TEM inset). In control experiments, the PCP/BCP ink was drop-cast onto a silicon wafer, then thermally cured and pyrolyzed. Surprisingly, drop-cast and processed materials took on a nanofiber morphology.

Though not widespread, there are a handful of reports featuring the production of PCP-based nanofibers, which arise due to polymer segregation effects. For example, Pillai and co-workers reported on the self-assembly of polysilazane-based BCP into nanofibrillar structures that converted to heavily agglomerated SiCN thin fibers following pyrolysis50. In another report, Choi et al. described a mechanism where PCP micelles in an aqueous PVP solution elongated under electrospinning-associated shear forces to form core/shell structures20. Interestingly, Choi and colleagues reported that a PCP fibril-core encapsulated by an outer PVP shell was obtained from the aggregation of PCP droplets in the PVP matrix20. Though the PCP/BCP solution used in the current study differs from PCP/PVP utilized by Choi, the coalescence of PCP nanomicelles into larger structures represents a plausible phenomenon for nanofiber development in our current system.

While polymer segregation is clearly playing a role in nanofiber formation within our PCP/BCP system, the nanofibers arising from drop-cast samples were not aligned (Fig. S3). This lack of observed nanofiber alignment suggests that shear forces and/or geometric confinement within printed filaments may play an important role in nanofiber organization. To test this hypothesis, we fabricated polydimethylsiloxane (PDMS) molds with narrow channels akin to the DIW-printed filament geometry featured in our study. The formulated PCP/BCP ink was drop cast into the PDMS molds, cured, released, and subsequently pyrolyzed the molded ceramics. Significantly, we observed that the pyrolyzed ceramics contained inorganic nanofibers aligned parallel to the PDMS channel long axis (Figs. S1 and S2), indicating that grapho-epitaxy may serve to template nanofiber alignment. Though shear forces cannot be entirely ruled out in these capillary casting experiments, the magnitude of these shear forces should be substantially lower than those encountered during printing. The capillary casting results indicate that nanofiber alignment results from ink confinement within PDMS molds, and by extension, may occur for the same reason in the printed filaments. Confinement of BCPs (e.g., within 2-dimensional pores) has previously been shown to impact BCP morphology and can result in structures substantially different from those native to films of the same material51. Further, the dimensions of confining 2-dimensional structures are known to influence self-assembled BCP morphology52. However, previous literature has not explored confinement on the size order as the PDMS capillary and printed filament experiments shown here.

Effect of processing parameters on nanofiber morphology

To further investigate the role of confinement in our system, we DIW-printed PCP/BCP filaments utilizing increasingly larger nozzle diameters (200–580 µm) at a constant printing speed of 20 mm/sec (Fig. 1I). Nanofiber tows printed with 200 and 250 µm nozzles generated similar distributions of nanofibers, with the 200 µm diameter nozzle creating a higher fraction of smaller nanofibers (Fig. 1I). When the DIW nozzle diameter was increased beyond 250 µm (up to 580 µm), we observed a broader distribution of nanofiber sizes coupled with reduction in their alignment (Fig. S5). Indeed, nanofiber tows within the largest diameter filaments (580 µm) possess a similar morphology to drop cast films (Fig. S3). Based on their higher degree of alignment, the nanofiber tows produced using 250 µm nozzles exhibit better mechanical performance (Figs. S4, S6, and S7). A visually striking example of nanofiber alignment present within the 250 µm nozzle-printed filaments is shown in Fig. 1L–N and Fig. S1, where ceramic nanofiber tows are seen to align with the DIW print path (long axis) closely. Though confinement appears to be a major driver in nanofiber alignment, the potential influence of shear alignment on polymer phases cannot be completely ruled out based on the experiments performed in this study.

Having investigated the influence of filament confinement on nanofiber orientation within DIW prints, we next sought to uncover the onset of nanofiber formation during post-print processing. To examine PCP morphology prior to pyrolysis, printed and thermally cured (160 °C) PCP/BCP filaments were chemically etched to selectively remove the BCP. This etching process revealed that the cured filament contained continuous PCP nanofibers (Fig. S8). To assess the evolution of nanofiber formation during the cure process, we heated printed PCP/BCP architectures to varying temperatures (80 °C–160 °C) and characterized their morphology by TEM (Fig. 1C–H). This TEM image sequence reveals that the nanofiber morphology evolves during thermal curing. The lower bound of 80 °C corresponds to the onset of SMP-10 cross-linking, as determined by differential scanning calorimetry (DSC) (Fig. S9). Samples annealed at 80 °C (Fig. 1C, F) exhibit a diffuse pattern of stratification, with layers enriched in Si or C, yet considerable intermixing of BCP (C-rich) and PCP (Si-rich) phases are still evident. Upon curing at 100 °C, the nanofibers display more defined morphology (Fig. 1D, G) but still contain Si-rich domains within the C-rich phase. However, upon curing at 160 °C, the nanofibers possess clearly identifiable phases, one enriched in C and a second enriched in Si and O (Fig. 1E, H). Si-O islands were observed within the C-enriched phase based on energy dispersive spectroscopy (EDS) mapping (Fig. 1H). The appearance of O in these samples likely results from PCP reacting with residual air within the curing oven47. Following curing at 160 °C, the PCP/BCP nanofibrous filaments were pyrolyzed (at 800 °C), resulting in aligned, continuous ceramic nanofibers (Fig. 1I) with lengths of ~300 µm (Fig. S2).

Having established an initial connection between cure temperature and nanofiber formation, we then further explored the influence of cure temperature and ramp rate on nanofiber morphology (Fig. 1J, K). First, the final PCP cure temperature (80 °C–200 °C) was examined, while holding the ramp rate (1 °C/min) constant (Fig. 1J). Once the selected temperature was reached, the samples were held at temperature in the oven overnight. As seen in Fig. 1J, increasing cure temperature (from 80 °C to 160 °C) led to a narrower distribution of nanofiber diameters; however, further increases in cure temperature (≥180 °C) led to an increase in nanofiber diameter distribution. Based on these cure temperature/nanofiber diameter distribution results, 160 °C was selected as the preferred curing condition for the remainder of the study. Next, the effects of temperature ramp rate on nanofiber diameter distribution were evaluated (Fig. 1K, S10). We found that 1 °C/min produced nanofibers with the second lowest diameter (mode) and smallest diameter distribution. Interestingly, both the higher (15 °C/min) and lower (0.5 °C/min) ramp rates increased nanofiber distributions and diameters. Further, 15 and 0.5 °C/min cure ramp rates resulted in nanofiber morphological defects, including nanofiber coalescence (Fig. S11).

Based on the results of our curing temperature and ramp rate study, it appears that PCP/BCP nanofiber formation is a non-equilibrium, kinetically controlled process. PCP/BCP nanofiber formation and morphology are influenced by both microphase PCP/BCP separation and PCP (SMP-10) cross-linking. We posit that PCP rearrangement can occur prior to full curing (i.e., consistent with the mechanism proposed by Choi et al.20), without gross coalescence of individual nanofibers. The balance between macromolecular mobility and curing kinetics is reflected in the histogram data: final curing temperatures or ramp rates that are too high or too low lead to a broader distribution of ceramic nanofiber sizes and alignments (Fig. 1J, K, S11, S12).

Small-angle x-ray scattering characterization of morphology evolution

Small-angle X-ray scattering (SAXS) was used to complement the direct observations of morphological evolution with the PCP/BCP ink during printing and thermal curing (Figs. 2, S13). Scattering experiments were carried out with the X-ray beam normal to the printing direction ‘N’ and parallel to the print direction (cross-sectional) denoted ‘P’; drop cast ink was also characterized as a benchmark. Previous analysis of PCP/BCP films with worm-like morphology exhibit a center-to-center distance of 28 nm via SAXS49. By contrast, the domain spacing of an uncured sample is smaller, having peak positions ranging from 19–22 nm, as confirmed by TEM images (Fig. S14). Figure 2A–C shows examples of 2D SAXS patterns acquired during the heating of the printed PCP/BCP structures to 160 °C at 1 °C/min. An isotropic scattering ring at q ~ 0.019 occurs at room temperature (25 °C, Fig. 2A). This scattering ring increases in intensity and exhibits anisotropic intensity distribution with increased cure temperature and time (meridional lobes in 2D pattern, Fig. 2B, C). Temperature-dependent SAXS measurements indicate that anisotropic worm-like BCP domains are oriented along the printing direction (Fig. 2A, B). Interestingly, BCP domain alignment is similar in both the normal and perpendicular direction, which is consistent with the printing-associated morphology (Fig. S14)51,52. There is strong indication of a phase transition from lamellar (two peaks, Fig. 2D, low temperatures) to hexagonal packing (three peaks, Fig. 2D, high temperatures, not commensurate with lamellar structure but with hexagonal packing) with increased cure temperature. Once the system is fully cured, no further changes are observed other than an expected small decrease due to thermal contraction after cure.

Select 2D scattering patterns from a 1 °C/min in-situ curing cycle in the with X-rays along the printing direction P: A in the uncured state (25 °C) B a midpoint temperature (75 °C), and C at 10 °C below the final cure temperature (150 °C). D A waterfall plot of intensity versus q and temperature, showing the evolution of the characteristic peak position. E The difference in peak position between samples measured along the print direction (P) and normal to the print direction (N).

We also found that the rate of change in the BCP domain dimensions is not the same when comparing dimensional changes normal or parallel to the print direction. The rate of change increases when viewed along the printed direction of the filament (Fig. 2E), indicating that the center-to-center distance increases faster between the nanofiber lateral spaces. Considering the SAXS characterization of the PCP/BCP system, in conjunction with the confined casting experiment described above (Fig. S4), it appears that the printing process (e.g., PCP/BCP system confinement in a cylindrical filament) influences macromolecular phase evolution in the printed filaments. While macromolecular conformation changes are clearly occurring in the system, it is unclear if these phase changes are a factor in nanofiber formation or a consequence of PCP/BCP segregation. Additional studies utilizing simulation tools are currently planned to further evaluate this phenomenon.

Inorganic Conversion of Printed Structures

Having characterized the printed PCP/BCP system in its polymeric state, we next investigated the inorganic structures produced via pyrolysis of these materials. Investigating the polymer-derived inorganic systems via SEM and TEM revealed the presence of ceramic nanoparticles and nanocoral (i.e., nanofoam) within the printed filaments (Figs. S16, S18). The composition of both the nanofibers and nanocoral were determined to be SiOC by EDS analysis (Fig. S15C–G) and is consistent with our prior work with ceramics derived from this PCP/BCP system47,48,49. The presence of oxygen in the polymer-derived ceramic limits the service temperature of these structures to temperatures below those where carbothermal reactions will degrade the material. Optimization of processing conditions may reduce oxygen contamination in the nanofibers and is currently being investigated. TEM characterization of the pyrolyzed materials indicates that the ceramic nanocoral had a morphology consistent with that produced in our prior studies of PCP/BCP systems47,48,49. The presence of ceramic nanocorals is consistent with the worm-like morphology of the PCP/BCP ink observed during curing. Though the worm-like phase is likely consumed during ink constituent microphase segregation during the cure process and nanofiber formation, it is evident that a portion of this phase persists through processing. Ceramic nanocoral was observed between the nanofibers, with increasing radial concentration towards the outside of the filament, which culminates as a solid shell on the filament surface. The presence of ceramic nanofiber tows embedded within a nanoporous matrix is analogous to the structure of oxide/oxide ceramic composites, where (micron sized) ceramic fibers are embedded within a porous matrix of similar composition53,54.

Mechanical behavior of nanofibrous ceramic structures

Given the morphological similarity of our printed materials to ceramic composites, we were interested in characterizing the mechanical properties of this system. Mechanical property evaluation was conducted on fully processed single filament samples (Fig. 3) and the average stress at failure and Young’s modulus were 29.63 + /− 7.5 MPa and 5.39 + /− 1 GPa, respectively. The failure stress and modulus of our ceramic nanofiber-based materials were lower than most commercially available SiC fibers (2.4–2.8 GPa and 270–390 GPa, respectively55,56). These results are not surprising, as the printed nanofiber/nanoporous ceramics are composed of amorphous SiOC rather than crystalline SiC, which is the predominant phase in high-performance commercial fibers57. The lower-than-expected strengths of our fibers are also consistent with the properties for aligned C/SiCON nanofibers reported by Denk and colleagues33; however, it should be noted in both cases that these are developmental systems, which have not benefited from the decades of optimization work implemented for commercial SiC fibers. One feature visible in the stress/strain behavior of our aligned SiOC nanofibril bundles is evidence of nanofiber pull-out (Fig. 3B, C) where the stress (load) temporarily drops, and then increases as the load is transferred, and finally drops again when that nanofiber tow fails. SEM characterization of filaments after tensile testing verified the presence of nanofiber pull-out (i.e., composite-like behavior), where nanofibers (average length of 169 µm (n = 50)) can be seen protruding from the failure site (Fig. 3B, C). In addition to nanofiber pull-out, instances of brittle fracture were also observed. Brittle fracture predominantly initiated at the printed filament glassy shell and occurred across groups of nanofibers, resulting in blunt fracture faces (Fig. 3B). To assist with visualization of filament failure, tensile testing of materials was performed within a SEM (Fig. S17, Movie S1). During this in-situ testing, pre-existing flaws (i.e., cracks on the filament surface) served as failure initialization defects and the printed filaments were then seen to fail with extensive fiber-pullout (Fig. S18).

In handling additively manufactured ceramic nanofibers, we noted that individual filaments and printed structures were quite flexible (Fig. 4A–D). Quantification of material flexibility revealed that individual filaments could be deflected by up to 40° without mechanical failure (Fig. 4A, B, Movie S2). While printed lattice structures can be deflected or twisted (Fig. 4C, D, Movie S4), the connections between filaments fractured during extreme deformation (Figs. 3, S19). In addition to the flexible characteristics of printed assemblies, we were also interested in their response to load (Fig. 4E, F). We fabricated two-layer woodpile lattice structures and loaded them with 20 and 50 g masses, representing a load ~90 and 230x greater than the structure itself, respectively (Movie S3). We found that bridging lattice structures could recover to 100 and 52% of its original position under 20 and 50 g loads, respectively.

A and B Pyrolyzed single traces can be deflected up to 40°, while C and D mesh assemblies can be deflected in positive and negative directions. E and F Two-layer woodpile elastic load response. E A two-layer lattice structure (width 1 cm) supports a 20 g mass and returns to its original position after removal of the weight (inset). F The same woodpile lattice structure can support a 50 g mass with minimal damage after weight removal (inset).

Building on the flexible nature of the printed, nanofibrous ceramics, we sought to further probe the limits of these unique materials. As a proof-of-principle demonstration, we produced a structure that is unusual due to the conflicting properties of the material and structure: a ceramic spring. Ceramic springs were fabricated by twisting a printed filament into a helical geometry around a small quartz cylinder (1.5 mm outer diameter) during the thermal curing process. Following pyrolysis, the ceramic springs demonstrate recoverable mechanical responses in both tension and compression (Fig. 5, Movie S5). Ceramic springs could be fully compressed (50%) with full recovery (Fig. 5A, B) and extended 50% (Fig. 5C) (note: 50% extension threshold was not due to spring failure, but rather a limitation of the test stage’s travel capabilities). We also examined the hysteresis response of a spring (Fig. 5D) and found that the spring could be reversibly strained to 10% for over 10,000 cycles without a change greater than 5% in the required force. Considering Hooke’s law (F = -kx), if x (spring extension) is constant, we would expect that any spring material breakdown would result in a decrease in k (spring constant) and therefore in F (force). Given that there was no significant change in the force needed to strain the spring after 105 cycles, we concluded that k remains the same. This indicates that the nanofiber-based ceramics exhibit robust toughness and flexibility, stemming from their unique architecture. The mechanical responses of our spring design (e.g., flexibility, resiliency, and toughness) are indicative of a wider possible application of these printed ceramic nanofiber structures. The combination of 3D printing and post-print molding opens up the possibility to create flexible ceramics for joints, seals, or other structural applications that would benefit from the increased toughness and flexibility43,58,59,60.

A spring made from a single printed and pyrolyzed filament was A compressed to 50%, B brought back to its origin, and C strained to 50%. D Hysteresis graph showing the change in oscillation force required to strain a spring to 10% of its original length over the course of 1 h at 3 Hz frequency. Scale bars in (A–C) represent 1 mm.

Discussion

Additive manufacturing (i.e., DIW) of PCP/BCP feedstocks, followed by curing and pyrolysis, was observed to yield filaments with aligned, internal ceramic nanofiber architectures. Systematic study of printing and pyrolysis conditions revealed that the formation of nanofibers occurs at elevated temperature during PCP curing. The microphase separation of PCPs and BCPs was influenced by the 2D confinement of the printed filament, as determined by experiments varying nozzle size and small angle x-ray scattering characterization. Though SiOC nanofibers are the most conspicuous morphology, ceramic material was also present as nanocoral (nanofoam) between fibers. The nanofibrous and composite structure of the filaments contributed to their unique flexibility and robust mechanical properties. We are encouraged by the nanofiber assembly’s mechanical performance, both in displaying substantial nanofiber pull-out during tensile testing and the robust mechanical properties of the ceramic spring. The ability to produce nanofibrous ceramics through additive manufacturing is impactful, as it presents the opportunity to print nanofiber-based structures without the use of preformed fibers, thereby mitigating nozzle clogging issues. We anticipate that the PCP/BCP inks described in this study may be utilized to create complex components through molding, additive manufacturing, and post-print manipulation. In addition to the PCP explored here (i.e., SMP-10), it is conceivable that this methodology could be applied to other precursors26,27,61,62,63,64,65,66,67,68 or PCP/BCP systems to produce ceramic or organic nanofibers of various compositions.

Methods

A PCP composed of polycarbosilane (StarPCS SMP-10, Starfire Systems, Inc., Schenectady, NY) with a molecular weight, Mw, of 7500 g/mol, and a polydispersity index (PDI) of 8.60 was stored at −20 °C and used without further modification. A BCP composed of PMMA and poly(n-butyl acrylate) (PnBA) with 25 wt% PMMA-b-50 wt% PnBA-b-25 wt% PMMA, total Mw of 64,000 g/mol and PDI of 1.1912 (Kurarity LA4285, Kurary, Japan) was dried at 80 °C overnight (~16 h) and subsequently stored in vials in vacuum sealed bags at room temperature (18 °C–25 °C), as recommended by the manufacturer. 1-butanol (Sigma-Aldrich, Burlington, MA) was used as a midblock selective solvent. Note: Maintaining the anhydrous nature of 1-butanol was found to be significant in synthesizing expected nanostructures in our previously reported work48.

The printing feedstocks (or inks) were prepared by mixing 1.8 g of BCP to 2 g of 1-butanol in a 25 mL glass vial with a stir bar and heated in an aluminum bead bath to 80 °C while stirring. Once BCP has fully dissolved (~60 min), 1.2 g of room temperature SMP-10 was added to the vial, heated to 80 °C while stirring to fully dissolve (~10 min). After all components were fully mixed, the vial was removed from the heat and allowed to cool to room temperature. Inks were prepared immediately before printing and were not utilized for more than 4 h. Immediately before printing, 1 g of acetone was added to an ink vial and the contents mixed in an orbital planetary mixer (Thinky, Laguna Hills, CA) for 12 min at 2000 RPM.

Each ink was poured into a 3 mL syringe (Nordson, Westlake, OH). Samples were printed using an Aerotech (Aerotech, Pittsburgh, PA) gantry printer. Pressure was controlled using an EFD Ultimus V (Nordson, Westlake, OH) pressure regulator. Filaments and parts were printed at a pressure of 350 psi with a print speed of 20 mm/s onto a glass substrate (Fisher Scientific, Waltham, MA) using 250 μm smooth flow tapered tip nozzles (Nordson), unless otherwise noted. For drop cast samples, a small amount (<0.1 mL) of ink was deposited using a syringe on silicon wafers (cleaned by wiping down with acetone, isopropoanol, and methanol). For the narrow channel drop cast samples, Silgard 184 PDMS molds were fabricated using capillary tubes to create narrow channels akin to the DIW-printed filament geometry featured in our study. The formulated ink was then drop-cast into the PDMS molds.

After printing/deposition, samples were placed in a vacuum desiccator (<100 torr) and dried for 15 min to remove solvent. Samples were thermally cured in a vacuum oven (<100 torr) where they were heated at 1 °C/ min to 160 °C, held at 160 °C overnight (12 h), and max cooled. Pyrolysis was carried out up to 800 °C (1 h hold) in flowing argon gas, in a tube furnace equipped with an alumina tube lined with a graphite sleeve, at a heating rate of 1 °C/min.

Scanning electron microscopy (SEM) of pyrolyzed ceramic films was performed on a Zeiss Gemini 500 field emission SEM operated at 0.5 keV (Carl Zeiss AG, Oberochen, Germany). Films were sputter coated with ~10 nm Ir before imaging. Chemical etching of thermally cured samples was performed using a 0.025 M NaOH solution comprised of 50/50 MeOH/water. Samples were soaked for 2 h at 50 °C and washed with water. Cross-section lamella of the 100 °C and 160 °C samples were prepared using a FEI (Hillsboro, OR) Helios NanoLab 600 DualBeam FIB/SEM. The 80 °C sample was prepared using cryo-ultramicrotome. High angle annular dark field (HAADF) images and EDS of the 80 °C and 100 °C samples were collected on a FEI Tecnai F20 S/TEM operating at 200 kV equipped with an EDAX TEM silicon drift detector. HAADF STEM images and EDS maps of the 160 °C sample were collected on a FEI image corrected Titan3 G2 operating at 300 kV equipped with a Bruker (Billerica, Massachusetts) 4D quad SuperX detector. All the S/TEM analysis was performed at liquid nitrogen temperature using a Gatan (Pleasanton, CA) cryogenic TEM specimen holder model 636.

Nanofiber diameter analysis was performed using Fiji69 image analysis software. Histograms were constructed using OriginPro (OriginLab Corp., Northampton, MA), with n = 129 for all samples. Modal distribution was determined by finding the most represented histogram bin for each sample.

A discovery Q400 thermal gravimetric analyzer (TA instruments, New Castle, DE) was used to determine mass gain during thermal cure of uncured 3D printed BCP/PCS parts by heating to the cure temperature at 10 °C/min and holding isothermally at 160 °C for 4 or 8 h, in air. A TA instruments discovery series differential scanning calorimeter was used to observe thermal phenomena uncured as well as cured samples. Samples with ~10 mg mass were prepared in Tzero hermetic aluminum pans and submitted to a heat-cool-heat cycle at 10 °C from −60 °C to 160 °C for cured samples or 25 °C–160 °C for uncured samples.

In-situ curing of 3D printed BCP/PCS was performed at the Cornell High Energy Synchrotron Source (CHESS) Synchrotron on the Functional Materials Beamline. Samples were printed with all filaments parallel and side by side, then allowed to dry before being cold stored and shipped to the beam line (to prevent room temperature cure). Prior to testing, samples were placed between two Kapton sheets in the center of an aluminum washer. Two experimental observation angles were examined: one with the beam incident normal to the surface of sample/printed filaments with printed filaments point up, labeled ‘N’’ and one with the beam incident parallel to the printed filaments (cross-section), labeled ‘P.” Beam energy was 9.7 keV and the beam positions was: Samples were heated at curing rates of either 1 °C, 2 °C, or 5 °C to 160 °C and held isothermally for 1 h before cooling to room temperature. Samples were collected every 1 min until the isothermal hold and then every 5 min. After quenching to room temperature, a second room temperature collection was made on the cured material. Azimuthal integration of data from 0–360° was performed in InstaPlot, being co-developed at CHESS with AFRL and plotted in Origin using the waterfall function to create plots of intensity, I (q), versus scattering vector, q (q = 4πsin(φ)/λ). 2D patterns for visualization of data were rendered in Datasqueeze using the batch processing tool. All data were calibrated to silver behenate.

A TA instruments Discovery Series Q850 Dynamic Mechanical Analyzer (DMA) was used for micromechanical tensile tests of 3D printed, cured, and pyrolyzed single tows of SiOC nanofiber. Samples were carded on heavy, textured paper with a 1 cm gauge length using high-strength epoxy. The filament diameter was measured using optical microscopy and taken as the average of three measurements. Samples were loaded into the film tension fixture of the DMA, secured, and then the carding edges were clipped before testing. The testing conditions were room temperature, 0.01 N preload and 2 mm/min uniaxial extension. Five samples were successfully tested. Engineering stress and engineering strain were calculated from the crosshead displacement and load using the DMA displacement and cross-section of the printed and pyrolyzed filament. Cyclic tests were performed with a 0.01 N preload at a frequency of 3 Hz for 1 h and a constant distance of 2.5 mm.

In-situ mechanical testing was performed on straight and spring nanofiber tows in an FEI Quanta 650 SEM with a micromechanical test frame made by MicroTesting Solutions LLC. Nanofiber samples (250 µm cross-sections) were coated with 5 nm iridium to reduce charging. The sample ends were adhered to the crossheads with epoxy and silver paint. Samples were tested in displacement control, where displacements were applied via an electromechanical stepper motor. A displacement ramp profile was applied, in which samples were displaced, held at that displacement to be imaged at 5.0 keV, and then displaced further. Three profiles were explored; 1) maximum tension, 2) maximum compression and 3) cyclic testing where samples were displaced to +/− 10% strain.

Supplementary information and videos: supplementary information, including, additional photographic, SEM, and TEM images of nanofibrous ceramics, additional SAXS and DSC data, and schematics. Supplementary videos include: S1. A single printed and pyrolyzed filament is pulled apart on an in-situ testing rig within an SEM, S2. A single printed and pyrolyzed filament is deflected by hand, S3. A bridge consisting of a two-layer woodpile geometry undergoes increasing loading with various masses, S4. A single-layer rectangle with printed filaments all touching is deflected by hand, S5. A ceramic spring is compressed and pulled on an in-situ testing rig within an SEM.

Data availability

Additional characterization data and results available upon request from corresponding authors.

Code availability

Not applicable.

References

Abdo, H. S. et al. Ceramic nanofibers versus carbon nanofibers as a reinforcement for magnesium metal matrix to improve the mechanical properties. J. King Saud. Univ. Eng. Sci. 32, 346–350 (2020).

Kobayashi, S. & Kawai, W. Development of carbon nanofiber reinforced hydroxyapatite with enhanced mechanical properties. Compos. Part Appl. Sci. Manuf. 38, 114–123 (2007).

Zhang, X. et al. Evolution from microfibers to nanofibers toward next-generation ceramic matrix composites: a review. J. Eur. Ceram. Soc. 43, 1255–1269 (2023).

Wang, H. et al. High-temperature particulate matter filtration with resilient yttria-stabilized ZrO(2) nanofiber sponge. Small Weinh. Bergstr. Ger. 14, e1800258 (2018).

Thavasi, V., Singh, G. & Ramakrishna, S. Electrospun nanofibers in energy and environmental applications. Energy Environ. Sci. 1, 205–221 (2008).

Dai, Y., Liu, W., Formo, E., Sun, Y. & Xia, Y. Ceramic nanofibers fabricated by electrospinning and their applications in catalysis, environmental science, and energy technology. Polym. Adv. Technol. 22, 326–338 (2011).

Xue, J., Xie, J., Liu, W. & Xia, Y. Electrospun nanofibers: new concepts, materials, and applications. Acc. Chem. Res. 50, 1976–1987 (2017).

Wu, H., Pan, W., Lin, D. & Li, H. Electrospinning of ceramic nanofibers: Fabrication, assembly and applications. J. Adv. Ceram. 1, 2–23 (2012).

Ramaseshan, R., Sundarrajan, S., Jose, R. & Ramakrishna, S. Nanostructured ceramics by electrospinning. J. Appl. Phys. 102, 111101 (2007).

Mercante, L. A., Andre, R. S., Mattoso, L. H. C. & Correa, D. S. Electrospun ceramic nanofibers and hybrid-nanofiber composites for gas sensing. ACS Appl. Nano Mater. 2, 4026–4042 (2019).

Huo, W. et al. In situ synthesis of three-dimensional nanofiber-knitted ceramic foams via reactive sintering silicon foams. J. Am. Ceram. Soc. 102, 2245–2250 (2019).

Chu, Y., Jing, S. & Chen, J. In situ synthesis of homogeneously dispersed SiC nanowires in reaction sintered silicon-based ceramic powders. Ceram. Int. 44, 6681–6685 (2018).

Badrossamay, M. R., McIlwee, H. A., Goss, J. A. & Parker, K. K. Nanofiber assembly by rotary jet-spinning. Nano Lett. 10, 2257–2261 (2010).

Sigmund, W. et al. Processing and structure relationships in electrospinning of ceramic fiber systems. J. Am. Ceram. Soc. 89, 395–407 (2006).

Carnell, L. S. et al. Aligned mats from electrospun single fibers. Macromolecules 41, 5345–5349 (2008).

Li, D., Wang, Y. & Xia, Y. Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays. Nano Lett. 3, 1167–1171 (2003).

Tian, Q., Wu, N., Wang, B. & Wang, Y. Fabrication of hollow SiC ultrafine fibers by single-nozzle electrospinning for high-temperature thermal insulation application. Mater. Lett. 239, 109–112 (2019).

Wang, Y., Zujovic, Z., Wu, J., Wang, H. & Gao, W. Robust and ultrafine silicon oxycarbide fiber mats prepared by a spinning-aid-free electrospinning/sol-gel method. Mater. Lett. 283, 128696 (2021).

Wang, X., Gong, C. & Fan, G. Preparation and mechanical properties of silicon oxycarbide fibers from electrospinning/sol–gel process. Mater. Res. Bull. 46, 2398–2402 (2011).

Choi, S.-H., Youn, D.-Y., Jo, S. M., Oh, S.-G. & Kim, I.-D. Micelle-mediated synthesis of single-crystalline β(3C)-sic fibers via emulsion electrospinning. ACS Appl. Mater. Interfaces 3, 1385–1389 (2011).

Ramlow, H., Ribeiro, L. F. B., Schafföner, S., Motz, G. & Machado, R. A. F. Thermo-oxidative resistance of C-rich SiCN(O) nonwovens influenced by the pretreatment of the silazane. Eng. Ceram. 2023 44, 5308–5318 (2024).

Guo, A., Roso, M., Modesti, M., Liu, J. & Colombo, P. Preceramic polymer-derived SiOC fibers by electrospinning. J. Appl. Polym. Sci. 131, 39836 (2014).

Guo, A. et al. Characterization of porosity, structure, and mechanical properties of electrospun SiOC fiber mats. J. Mater. Sci. 50, 4221–4231 (2015).

Bin Mujib, S. et al. Electrospun SiOC ceramic fiber mats as freestanding electrodes for electrochemical energy storage applications. Ceram. Int. 46, 3565–3573 (2020).

Liu, H., Pengcheng, H., Ying, S., Jianyu, C. & Jianwei, J. High thermal insulation and high strength SiBCN@SiC double network ceramic composite aerogel. Ceram. Int. 49, 38351–38359 (2023).

Ackley, B. J. et al. Advances in the synthesis of preceramic polymers for the formation of silicon-based and ultrahigh-temperature non-oxide ceramics. Chem. Rev. 123, 4188–4236 (2023).

Colombo, P., Mera, G., Riedel, R. & Sorarù, G. Polymer-derived ceramics: 40 years of research and innovation in advanced ceramics. J. Am. Ceram. Soc. 93, 1805–1837 (2010).

Ye, L., Ge, K., Qiu, W., Han, W. & Zhao, T. Fabrication and characterization of SiC/ZrC/C ultra-thin composite fibers. Mater. Lett. 141, 210–213 (2015).

Zhang, Y. et al. Flexible SiC-CNTs hybrid fiber mats for tunable and broadband microwave absorption. Ceram. Int. 47, 8123–8132 (2021).

Rui, J. et al. Preparation of C–SiC/ZrSixOyCz core-shell fibers by Coaxial electrospinning and the high-temperature performance. Ceram. Int. 48, 2625–2631 (2022).

Zhang, B. et al. Zirconium-modified hierarchical porous SiC-based nanofibrous aerogel with efficient electromagnetic waves absorption and thermal insulation properties. J. Eur. Ceram. Soc. 45, 116808 (2025).

Hou, Y. et al. Flexible Fe3Si/SiC ultrathin hybrid fiber mats with designable microwave absorption performance. RSC Adv. 8, 33574–33582 (2018).

Denk, J. et al. Novel multifibrillar carbon and oxidation-stable carbon/ceramic hybrid fibers consisting of thousands of individual nanofibers with high tensile strength. Sci. Rep. 14, 18143 (2024).

Lu, P., Huang, Q., Mukherjee, A. & Hsieh, Y.-L. Effects of polymer matrices to the formation of silicon carbide (SiC) nanoporous fibers and nanowires under carbothermal reduction. J. Mater. Chem. 21, 1005–1012 (2011).

Hou, H. et al. Electrospinning 3C-SiC mesoporous fibers with high purities and well-controlled structures. Cryst. Growth Des. 12, 536–539 (2012).

Xu, Z., Li, F., Wang, Y., Zhao, K. & Tang, Y. Microstructure and oxidation resistance of ZrB2–ZrC–SiC composite nanofibers fabricated via electrospinning combined with carbothermal reduction. Ceram. Int. 47, 20740–20744 (2021).

Joo, Y., Khishigbayar, K., Kim, C. & Cho, K. Fabrication and morphological study of converged SiC-TiC fiber mats by electrospinning. Adv. Compos. Mater. 28, 397–408 (2019).

Katta, P., Alessandro, M., Ramsier, R. D. & Chase, G. G. Continuous electrospinning of aligned polymer nanofibers onto a wire drum collector. Nano Lett. 4, 2215–2218 (2004).

Wright, W. J., Koerner, H., Rapking, D., Abbott, A. & Celik, E. Rapid fiber alignment quantification in direct write printing of short fiber reinforced composites. Compos. Part B Eng. 236, 109814 (2022).

Croom, B. P. et al. Mechanics of nozzle clogging during direct ink writing of fiber-reinforced composites. Addit. Manuf. 37, 101701 (2021).

Sydney Gladman, A., Matsumoto, E. A., Nuzzo, R. G., Mahadevan, L. & Lewis, J. A. Biomimetic 4D printing. Nat. Mater. 15, 413–418 (2016).

Compton, B. & Lewis, J. 3D-printing of lightweight cellular composites. Adv. Mater. 26, 5930-+ (2014).

Kemp, J. W. et al. Direct ink writing of ZrB2-SiC chopped fiber ceramic composites. Addit. Manuf. 44, 102049 (2021).

Clarkson, C. et al. Phenolic carbon fiber composite inks for the additive manufacturing of carbon/carbon (C/C). Addit. Manuf. 83, 104056 (2024).

Liu, Z.-Y., Zhu, J.-L., Tong, X., Niu, S. & Zhao, W.-Y. A review of CoSb3-based skutterudite thermoelectric materials. J. Adv. Ceram. 9, 647–673 (2020).

Zeng, C., Liu, L., Bian, W., Leng, J. & Liu, Y. Bending performance and failure behavior of 3D printed continuous fiber reinforced composite corrugated sandwich structures with shape memory capability. Compos. Struct. 262, 113626 (2021).

Bowen, J. J. et al. Hierarchically porous ceramics via direct writing of preceramic polymer-triblock copolymer inks. Mater. Today 58, 71–79 (2022).

Bowen, J. J. et al. Tailorable Micelle Morphology in Self-Assembling Block Copolymer Gels for Templating Nanoporous Ceramics. Macromolecules 53, 7528–7536 (2020).

Rueschhoff, L. M. et al. Fabricating Ceramic Nanostructures with Ductile-like Compression Behavior via Rapid Self-Assembly of Block Copolymer and Preceramic Polymer Blends. ACS Appl. Nano Mater. 2, 250–257 (2019).

Pillai, S. et al. SiCN nanofibers with a diameter below 100 nm synthesized via concerted block copolymer formation, microphase separation, and crosslinking. SMALL 9, 984–989 (2013).

Xiang, H. et al. Block copolymers under cylindrical confinement. Macromolecules 37, 5660–5664 (2004).

Xiang, H. et al. The influence of confinement and curvature on the morphology of block copolymers. J. Polym. Sci. PART B-Polym. Phys. 43, 3377–3383 (2005).

Kerans, R., Hay, R., Parthasarathy, T. & Cinibulk, M. Interface design for oxidation-resistant ceramic composites. J. Am. Ceram. Soc. 85, 2599–2632 (2002).

Wang, Y., Liu, H., Cheng, H. & Wang, J. Research progress on oxide/oxide ceramic matrix composites. J. Inorg. Mater. 29, 673–680 (2014).

Youngblood, G. E., Lewinsohn, C., Jones, R. H. & Kohyama, A. Tensile strength and fracture surface characterization of Hi-NicalonTM SiC fibers. Symp. Fabr. Prop. Ceram. Fusion Energy 289, 1–9 (2001).

Sauder, C., Brusson, A. & Lamon, J. Influence of interface characteristics on the mechanical properties of hi-nicalon type-S or tyranno-SA3 fiber-reinforced SiC/SiC Minicomposites. Int. J. Appl. Ceram. Technol. 7, 291–303 (2010).

Flores, O., Bordia, R., Nestler, D., Krenkel, W. & Motz, G. Ceramic fibers based on SiC and SiCN systems: current research, development, and commercial status. Adv. Eng. Mater. 16, 621–636 (2014).

Nawafleh, N. & Celik, E. Additive manufacturing of short fiber reinforced thermoset composites with unprecedented mechanical performance. Addit. Manuf. 33, 101109 (2020).

Griffini, G. et al. 3D-printable CFR polymer composites with dual-cure sequential IPNs. Polymer 91, 174–179 (2016).

Li, Z. et al. Glass fiber-reinforced phenol formaldehyde resin-based electrical insulating composites fabricated by selective laser sintering. Polymers 11, 135 (2019).

Viard, A. et al. Molecular chemistry and engineering of boron-modified polyorganosilazanes as new processable and functional SiBCN precursors. Chem. - Eur. J. 23, 9076–9090 (2017).

Hanniet, Q. et al. Activation of patternable ceramics for hydrogen evolution reaction using molybdenum-based fillers. NEW J. Chem. 49, 712–720 (2025).

Yu, Z. et al. Liquid single-source-precursor synthesis and phase evolution of SiC-HfC-C ceramics nanocomposites with core-shell structured SiC@C and HfC@C nanoparticles. OPEN Ceram. 15, 100430 (2023).

Petry, N. et al. Oxidation resistance and microstructural analysis of polymer-derived (HfxTa1-x)C/SiC ceramic nanocomposites. Adv. Eng. Mater. 26, (2024).

Reschke, V., Bordia, R., Scheffler, F. & Scheffler, M. Rheology and crosslinking of a low-viscosity SiOC preceramic polymer. Ceram. Int. 42, 7620–7625 (2016).

Ionescu, E. et al. Polymer-derived ultra-high temperature ceramics (UHTCs) and related materials. Adv. Eng. Mater. 21, 1900269 (2019).

Bernard, S., Salameh, C. & Miele, P. Boron nitride ceramics from molecular precursors: synthesis, properties and applications. DALTON Trans. 45, 861–873 (2016).

Anand, R., Lu, K., Nayak, B. & Behera, S. Structural evolution and oxidation resistance of polysilazane-derived SiCN-HfO2 ceramics. J. Am. Ceram. Soc. 107, 1657–1668 (2024).

Schindelin, J. et al. Fiji: an open-source platform for biological-image analysis. Nat. Methods 9, 676–682 (2012).

Acknowledgements

This work is based upon research conducted at the Materials Solutions Network at CHESS (MSN-C) which is supported by the Air Force Research Laboratory under award FA8650-19-2-5220. This research was conducted while Dr. Caitlyn Clarkson held an NRC Research Associateship award at the Air Force Research Laboratory. We would like to thank Dr. Lawrence Drummy and Ms. Melinda Ostendorf at the Air Force Research Laboratory for their assistance with transmission electron microscopy and Dr. Bingqian Zheng and Dr. Brian Ree for their guidance on SAXS. We would like to thank Dr. Louisa Smieska and Dr. Arthur Woll at Cornell University for their assistance at CHESS. We are grateful for the guidance and support provided by Prof. Jennifer A. Lewis at Harvard University. Distribution A: Cleared for public release; AFRL-2025-2632.

Author information

Authors and Affiliations

Contributions

J.B., C.C., and K.D.: conceptualization, investigation, formal analysis, writing - original draft, writing - review & editing, visualization. A.T., C.W., and B.R.-M.: investigation, writing - original draft, writing - review & editing. H.K. and M.D.: conceptualization, methodology, resources, formal analysis, writing - original draft, writing - review & editing, visualization, supervision, project administration, funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bowen, J.J., Clarkson, C.M., Detwiler, K.N. et al. Nanofibrous ceramics via the additive manufacturing of self-assembling preceramic polymer and block copolymer feedstocks. npj Adv. Manuf. 2, 39 (2025). https://doi.org/10.1038/s44334-025-00047-8

Received:

Accepted:

Published:

Version of record:

DOI: https://doi.org/10.1038/s44334-025-00047-8