Abstract

Functional polymers bear specified chemical groups and have specified physical, chemical, biological, pharmacological, or other uses. To adjust the properties while keeping material usage low, a method for direct synthesis of functional polymers is indispensable. Here we show that various functional polymers can be synthesized by in situ cross-linked polymerization/copolymerization. We demonstrate that the polymers synthesized by the facile method using different functional monomers own outstanding pH-sensitivity and pH-reversibility, antifouling property, antibacterial and anticoagulant property. Our study opens a route for the functionalization of commodity polymers, which lead to important advances in polymeric materials applications.

Similar content being viewed by others

Introduction

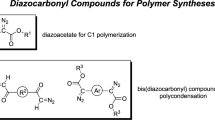

Functional polymers are macromolecules that have specific properties or uses1,2. The properties of such materials are often determined by the presence of chemical functional groups that are dissimilar to those of the backbone chains. Functional polymers can be synthesized by direct anionic, cationic, free radical and coordination polymerization, as well as the bulk and surface modification of preformed polymer backbones2. To adjust the properties while keeping material usage low, a simple method for direct synthesis of functional polymers using commodity polymers and functional monomers is indispensable. Here we provide a facile way for the synthesis of functional polymers by in situ cross-linked polymerization/copolymerization in commodity polymer solutions based on recent studies3,4, as shown in Scheme S1. Several commodity polymers, including polyethersulfone (PES), polysulfone (PSf), polyvinylidene fluoride (PVDF) and polystyrene (PS) are selected for the functionalization; and many vinyl functional monomers, including acrylic acid (AA), 4-vinyl pyridine (4-VP), sulfobetaine methacrylate (SBMA), methacrylatoethyl trimethyl ammonium chloride (DMC), N-vinylpyrrolidone (NVP) and sodium p-styrene sulfonate (NaSS) are selected in situ cross-linked polymerization/copolymerization. Then, stimuli-responsive, antifouling, antibacterial and blood compatible polymers are obtained. The polymer solutions can be directly prepared into membranes by a liquid-liquid phase separation technique5.

Results

Stimuli-responsive polymers

Stimuli-responsive (“intelligent”) materials and membranes exhibit abrupt property changes in response to small changes in external stimuli such as temperature, pH, ionic-strength and/or solvent composition of the media, concentration of specific chemical species, the electric field and photo-irradiation6,7,8,9. Compared with other external stimuli, pH-sensitivity gives more choices both for the materials and for the application environment, making it a powerful technique. Herein, we firstly prepared pH-sensitive polymers by in situ cross-linked polymerization of acrylic acid (AA) and 4-vinyl pyridine (4-VP) in PES and PVDF solutions, respectively. The polymer solutions are directly prepared into porous membranes by a liquid-liquid phase separation technique and the membranes are characterized by ATR-FTIR, 1H NMR and SEM, as shown in Fig. S1, Fig. S2 and Fig. S3 (see Supporting Information, SI). Thus, the target functional polymers were successfully synthesized according to the characterization.

Fig. 1 shows the pH-sensitivity and pH-reversibility of the as-prepared PES membranes. The flux for the PES membrane modified by the cross-linked polymerization of AA exhibits a chemical valve behavior at pH between 7.0 and 9.0 and hardly changed at the pH values lower than 7.0 or higher than 9.0. After adding methyl methacrylate (MMA) into the polymerization solution as the hydrophobic monomer, the chemical valve behavior appears at the pH between 4.0 and 7.0. The results indicated that the chemical valve behavior could be adjusted by copolymerization. The opposite changing trend of water flux for PSf/P4-VP was observed as shown in Fig. S3.

(a). Water flux for the membrane as a function of pH values. (b). Water flux for the membranes as the feed solutions are changed between pH 3.0 and pH 10.0 with 10 min equilibration flow followed by 10 min sample collection. For membranes: PES/P(AA-MMA) ( ); PES/PAA(

); PES/PAA( ). Duplicate experiments showed similar results.

). Duplicate experiments showed similar results.

Antifouling polymers

Fouling is the accumulation of unwanted molecules on solid surfaces to the detriment of function, such as membrane fouling10,11. Membrane fouling is the deposition of retained particles, colloids, macromolecules, salts, etc, at the membrane surface or inside the pore at the pore wall, which causes a higher energy use, a higher cleaning frequency and a shorter life span of the membrane11. Recently, zwitterionic polymers had been widely investigated to improve the antifouling and biocompatibility of materials12,13,14,15. Among them, poly(2-methacryloyloxyethyl phosphorylcholine) (PMPC), poly(sulfobetaine methacrylate) (PSBMA) and poly(carboxybetaine methacrylate) (PCBMA) were widely used. Herein, we prepared antifouling polymer by in situ cross-linked polymerization of sulfobetaine methacrylate (SBMA) in PES solution. Then the polymer solution was directly prepared into porous membrane. Thermogravimetric analysis (TGA) was used to investigate the chemical compositions of the modified membranes as shown in Fig. S4. It showed that the contents of PSBMA in the modified membranes were almost the same as the corresponding theoretical contents, indicating that the conversion ratios of the SBMA were nearly 100% and there was no elution of PSBMA in the membrane preparation process. The antifouling property of the membranes was evaluated by the ultrafiltration of bovine serum albumin (BSA) solution and the fluxes of BSA solution and PBS for three-cycle filtrations are shown in Fig. 2. It showed that the flux recovery ratios ((FRRs)) of the membranes prepared by PSBMA with the amount above 4 wt. % in the casting solution are nearly 100%, indicating that the PSBMA modified membranes possessed excellent antifouling property and the membranes could be used in complex media.

Antibacterial polymers

Recently, tethering of nontoxic functional polymer brush coatings has been suggested as an environmentally friendly approach to prevent the attachment of proteins, bacteria and marine organisms to surfaces16. Quaternary ammonium cations form a class of compounds which are used as biocides and corrosion inhibitors17. As biocides, quaternary ammonium cations act on the plasmic membranes of cells, disrupt the lipid bilayers and cause the release of intracellular materials18. The surfactant property of these compounds provides additional protection against the formation of polysaccharidic materials during the process of bacteria colonization19. Vinyl monomers containing tertiary amino groups, such as 2-(dimethylamino) ethyl methacrylate (DMAEMA) and 4-vinyl pyridine (4VP), have been extensively used in the synthesis of antimicrobial surfaces20,21. In this study, antibacterial polymers of poly(methacrylatoethyl trimethyl ammonium chloride) (PDMC) were prepared by in situ cross-linked polymerization of DMC in PSf solution and PS solution, respectively. The antibacterial efficiency of the PDMC modified PSf/PDMC and PS/PDMC membranes toward both gram-positive Staphylococcus aureus (S. aureus) and gram-negative Escherichia coli (E. coli) bacteria were studied. The SEM images are shown in the Fig. S6, for the membrane surfaces after bacterial fouling, a large amount of bacteria adhered on the surface of the pristine surface. After that PDMC was introduced into the membranes, the amount of the adhered bacteria was obviously reduced. In addition, the traditional surface plating method was used to quantify the antibacterial property of the PDMC membranes and the results are showed in Fig. 3. It was found that the amounts of the adhered S. aureus and E. coli bacteria were only about 8% of those of the pristine PSf and PS membranes. The results indicated that the antibacterial property of the PDMC modified membranes was obviously improved.

Blood compatible polymers

When blood is in contact with a biomaterial, plasma protein adsorption on the surface is the first event, followed by platelet adhesion and activation of coagulation pathways and then leading to thrombus formation22. To improve the blood compatibility, the current trend is to develop new materials and structures. However, alternative materials often prove more vulnerable in terms of stability and are often expensive; a good method is the modification of common polymers or membranes. There are three main approaches for the modification of polymeric membranes with improved blood compatibility23: (1) bulk modification of polymeric material and then to prepare modified membrane; (2) surface modification of prepared membrane; and (3) blending, which can also be regarded as a surface modification. Herein, the facile in situ cross-linked polymerization is used for the modification of PES membrane using different monomers of AA, VP and NaSS with the same weight ratios. The anticoagulant property of the membranes was evaluated by activated partial thromboplastin time (APTT) and thrombin time (TT) as shown in Fig. 4. The APTTs were obviously increased for the modified membranes. Furthermore, the membranes modified by AA and NaSS showed significantly improved anticoagulant property (as expressed by prolonged APTT and TT) due to the heparin-like structure24,25,26.

Discussion

We applied the in situ cross-linked polymerization/copolymerization method to adjust the properties of commodity polymers while keeping material usage low. The commodity polymers including PES, PSf, PVDF and PS were used to be functionalized with stimuli-responsive, antifouling, antibacterial and blood compatible properties by introducing PAA and P4VP, PSBMA, PDMC, PNVP and PNaSS, respectively. The advantages of our method includes (as shown in Table S1): (1). the post-processing is simple, without precipitation and dialysis; (2). the reaction solutions can be directly prepared into membranes after being cooled and degassed; (3). the miscibility between the commodity polymers and functional polymers synthesized by in situ cross-linked polymerization/copolymerization method is improved compared with conventional simple blend method; (4). the structure of the materials prepared by in situ cross-linked polymerization/copolymerization method was stable since cross-linkers were added into the reaction solution with the monomers. Thus, our study opens a practical, simple and low-cost route for the functionalization of commodity polymers, which lead to important advances in polymeric materials applications, such as separation fields and biomedical fields.

Methods

Materials

Polyethersulfone (PES, Ultrason E6020P, BASF), polysulfone (PSf, Udel P-1700, Union Carbide), polyvinylidene fluoride (PVDF, Xiya Reagent) and polystyrene (PS, Xiya Reagent) were the representative commodity polymers for the modification. Acrylic acid (AA, 99%, Aladdin), 4-vinyl pyridine (4-VP, 96%, Aladdin) and N-vinylpyrrolidone (NVP, 99%, Aladdin) were distilled under reduced pressure to remove the inhibitor. Methacrylatoethyl trimethyl ammonium chloride (DMC, 75 wt. % in H2O, Aladdin) and sodium p-styrene sulfonate (NaSS, 90%, Aladdin) were used as received. Sulfobetaine methacrylate (SBMA) was synthesized according to our previous reported procedures27. Micro BCATM protein assay reagent kits were the products of PIERCE. APTT and TT reagent kits were purchased from SIEMENS. Dimethyl sulfoxide (DMSO, 99.8%, Kelong) and N,N-dimethylacetamide (DMAc, 99.8%, Kelong) were used without further purification. Deionized water was used throughout the studies.

Preparation of functional membranes via in situ cross-linked polymerization

In this study, various commodity polymers were endowed with desired functions via in situ cross-linked polymerization, including pH-sensitivity and pH-reversibility, antifouling property, antibacterial and anticoagulant property (Table 1). To prepare functional membranes, one kind of commodity polymer was completely dissolved in the good solvent, such as DMAc and DMSO. Then, the monomers, initiator and cross-linker mixture was added into the polymer solution and the reaction time was long enough to ensure the percent conversion of the monomers. A typical procedure to prepare pH-sensitive membrane was as follows: 16 g PES (16 wt. % of the total solution) was dissolved in DMAc to get a homogeneous solution. Then a mixture of monomers, AIBN (1 ~ 4 mol% with respect to monomers), MBA (0.5 ~ 2 mol% with respect to monomers) and DMAc was added in the PES solution under nitrogen atmosphere. The polymerization was carried out at 75°C with vigorous stirring for about 24 h. The cross-linked density depends on the molecular weights of the monomers and the matrix polymers. In this study, the cross-linked density was estimated by the contents of the monomers and the cross-linking agent in the polymerization and which was ranged from 3600 to 14000 g/mol (details were shown in SI).

After that the reaction was completed, the polymer solution was directly prepared into membrane by a liquid-liquid phase separation technique after vacuum degassing. The casting solution was added on a glass plate by spin-coating and then the glass was immersed into deionized water, which was used as a nonsolvent. The solvent could exchange with deionized water and the functional membrane was then prepared. Since the synthesized functional polymer was cross-linked and the commodity polymer did not participate in the polymerization reaction, semi-interpenetrating network (semi-IPN) membrane was obtained.

Characterizations

Attenuated total reflection-Fourier transform infrared spectroscopy (ATR-FTIR) was obtained on a Nicolet 560 spectrophotometer (Nicol, America) between 4000 and 675 cm−1, with a resolution of 4 cm−1.

The cross-section morphology of the membranes was observed by using JSM-7500F field-emission scanning microscope (SEM) (JEOL, Japan) with the voltage of 5 kV. The membrane samples were dried overnight in a vacuum oven at room temperature, then quenched by liquid nitrogenous gas, attached to the sample supports and coated with a gold layer.

Thermogravimetric analysis (TGA) was performed on a TG209F1 TG instrument (Netzsch, Germany) at a heating rate of 10°C/min under N2 atmosphere. The samples were dried at 110°C to remove any moisture prior to the study.

Ultrafiltration experiments

The pH-sensitivity and pH-reversibility properties of the modified membranes were evaluated through measuring the water flux by varying the pH of the feed solution with NaOH or HCl, by using the apparatus as described in our previous study28. The test membranes were pre-compacted with pure water for 30 min to get steady filtration. Then, the water flux was determined at the pH values ranging from 3.0 to 10.0, randomly. For the pH-reversibility experiment, the feed solution was alternatively changed between 3.0 and 10.0. The flux was calculated by using the following equation:

where V is the volume of the permeated solution (mL); S is the effective membrane area (m2); P is the pressure applied to the membrane (mmHg) and t is the time (h).

The BSA solution (1 mg/mL in PBS) was applied to estimate the antifouling property of the modified membranes and the protein flux was measured as above. The BSA rejection ratio (R) was defined as follows:

where Cp and Cb (mg/mL) are the BSA concentrations of the permeated and bulk solutions, respectively, which are measured by an UV-vis spectrophotometer (UV-1750, Shimadzu, Japan) at the wavelength of 278 nm. After protein filtration, the membrane was cleaned with deionized water; the PBS flux of the cleaned membrane was measured again and the flux recovery ratio (FRR) was calculated using the following equation:

where F1 and F2 (mL/m2·h·mmHg) are the PBS flux before and after protein ultrafiltration, respectively.

Antibacterial measurement

Gram-positive Staphylococcus aureus (S. aureus) and gram-negative Escherichia coli (E. coli) are used to evaluate the antibacterial adhesion characteristics and bactericidal efficacy of the modified membranes. After incubation in beef extract peptone medium (BPDA), bacterial cells were suspended at a concentration of 106 cells/mL. Each piece of membrane was then immersed in 1 mL of bacterial suspension under static condition at 37°C for 24 h. The adhered bacterial cells were investigated under a scanning electron microscope (SEM) (JSM-7500F, JEOL, Japan) after fixing with 3% glutaraldehyde and dehydration with serial ethanol solutions (25%, 50%, 75% and 100%). To quantify the antibacterial property of the PDMC membranes, the membranes were rinsed three times with PBS after being immersed in bacterial suspension under static condition at 37°C for 24 h and then immersed in BPDA under ultrasound to make sure the adhered bacterial cells were suspended in the BPDA. The suspension was diluted and 0.1 mL of the diluted suspension was spread onto a triplicate solid agar plate. The plate was then sealed and incubated at 37°C for 24 h and the number of the viable cells was counted.

Clotting time

To evaluate the antithrombogenicity of the modified membranes, activated partial thromboplastin time (APTT) and thromboplastin time (TT) were measured by a semiautomatic blood coagulation analyzer CA-50 (Sysmex Corporation, Kobe, Japan).

The APTT test method was performed as follows. The blood was centrifuged at 1000 rpm for 15 min to obtain platelet-rich plasma (PRP) or at 4000 rpm for 15 min to obtain platelet-poor plasma (PPP). The membrane (0.5 × 0.5 cm2, three pieces) was immersed in 0.2 ml PBS buffer (pH 7.4) for 1 h. Then, the PBS was removed and 0.1 mL of fresh PPP was introduced. After incubating at 37°C for 30 min, 50 μL of the incubated PPP was added into the test cup, followed by the addition of 50 μL of APTT agent (Dade Actin Activated Cephaloplastin Reagent, Siemens; incubated 10 min before use). Thereafter, 50 μL of 0.025 M CaCl2 solution was added and then the APTT was measured. For TT test, 50 μL incubated PPP was mixed well with 100 μL of TT agent (Thromborel®S, Siemens) at 37°C for 2 min and the TT was measured. At least three measurements were averaged to get a reliable value.

References

Bergbeiter, D. E. & Martin, C. R. Functional Polymers (Plenum Press, New York, 1989).

Schulz, D. N. & Patil, A. O. Functional Polymers: An overview (ACS, Washington, DC, 1998).

Zhang, P. Y., Xu, Z. L., Yang, H., Wei, Y. M. & Wu, W. Z. Fabrication and characterization of PVDF membranes via an in situ free radical polymerization method. Chem. Eng. Sci. 97, 296–308 (2013).

Tao, M. M., Liu, F. & Xue, L. X. Hydrophilic poly (vinylidene fluoride)(PVDF) membrane by in situ polymerisation of 2-hydroxyethyl methacrylate (HEMA) and micro-phase separation. J. Mater. Chem. 22, 9131–9137 (2012).

Matsuyama, H., Nishiguchi, M. & Kitamura, Y. Phase separation mechanism during membrane formation by dry-cast process. J. Appl. Polym. Sci. 77, 776–783 (2000).

Zhao, C. S., Nie, S. Q., Tang, M. & Sun, S. D. Polymeric pH-sensitive membranes-A review. Prog. Polym. Sci. 36, 1499–1520 (2011).

Thomas, J. B., Tingsanchali, J. H., Rosales, A. M., Creecy, C. M., McGinity, J. W. & Peppas, N. A. Dynamics of poly (ethylene glycol)-tethered, pH responsive networks. Polymer 48, 5042–5048 (2007).

Dayananda, K., He, C., Park, D. K., Park, T. G. & Lee, D. S. pH-and temperature-sensitive multiblock copolymer hydrogels composed of poly (ethylene glycol) and poly (amino urethane). Polymer 49, 4968–4973 (2008).

Gil, E. S. & Hudson, S. M. Stimuli-reponsive polymers and their bioconjugates. Prog. Polym. Sci. 29, 1173–1222 (2004).

Yebra, D. M., Kiil, S. & Dam-Johansen, K. Antifouling technology-past, present and future steps towards efficient and environmentally friendly antifouling coatings. Prog. Org. Coat. 50, 75–104 (2004).

Rana, D. & Matsuura, T. Surface modifications for antifouling membranes. Chem. Rev. 110, 2448 (2010).

Huang, C. J., Li, Y. T. & Jiang, S. Y. Zwitterionic Polymer-Based Platform with Two-Layer Architecture for Ultra Low Fouling and High Protein Loading. Anal. Chem. 84, 3440–3445 (2012).

Liu, P. S., Chen, Q., Wu, S. S., Shen, J. & Lin, S. C. Surface modification of cellulose membranes with zwitterionic polymers for resistance to protein adsorption and platelet adhesion. J. Membr. Sci. 350, 387–394 (2010).

Ma, X. L., Su, Y. L., Sun, Q., Wang, Y. Q. & Jiang, Z. Y. Preparation of protein-adsorption-resistant polyethersulfone ultrafiltration membranes through surface segregation of amphiphilic comb copolymer. J. Membr. Sci. 292, 116–124 (2007).

Chang, Y., Shih, Y. J., Lai, C. J., Kung, H. H. & Jiang, S. Y. Blood-Inert Surfaces via Ion-Pair Anchoring of Zwitterionic Copolymer Brushes in Human Whole Blood. Adv. Funct. Mater. 23, 1100–1110 (2013).

Yang, W. J., Pranantyo, D., Neoh, K. G., Kang, E. T., Teo, S. L. M. & Rittschof, D. Layer-by-Layer Click Deposition of Functional Polymer Coatings for Combating Marine Biofouling. Biomacromolecules 13, 2769–2780 (2012).

Neoh, K. & Kang, E. Combating bacterial colonization on metals via polymer coatings: relevance to marine and medical applications. ACS Appl. Mater. Inter. 3, 2808–2819 (2011).

Tiller, J. C., Lee, S. B., Lewis, K. & Klibanov, A. M. Polymer surfaces derivatized with poly (vinyl-N-hexylpyridinium) kill airborne and waterborne bacteria. Biotechnol. Bioeng. 79, 465–471 (2002).

Videla, H. A. Prevention and control of biocorrosion. Int. Biodeterior. Biodegrad. 49, 259–270 (2002).

Yuan, S. J., Pehkonen, S. O., Ting, Y. P., Neoh, K. G. & Kang, E. T. Antibacterial Inorganic-Organic Hybrid Coatings on Stainless Steel via Consecutive Surface-Initiated Atom Transfer Radical Polymerization for Biocorrosion Prevention. Langmuir 26, 6728–6736 (2009).

Huang, J. et al. Nonleaching antibacterial glass surfaces via “grafting onto”: the effect of the number of quaternary ammonium groups on biocidal activity. Langmuir 24, 6785–6795 (2008).

Andrade, J. & Hlady, V. Plasma Protein Adsorption: The Big Twelvea. Ann. N.Y. Acad. Sci. 516, 158–172 (1987).

Zhao, C. S., Xue, J. M., Ran, F. & Sun, S. D. Modification of polyethersulfone membranes-A review of methods. Prog. Mater Sci. 58, 76–150 (2013).

Ran, F., Nie, S. Q., Li, J., Su, B. H., Sun, S. D. & Zhao, C. S. Heparin-Like Macromolecules for the Modification of Anticoagulant Biomaterials. Macromol. Biosci. 12, 116–125 (2012).

Tang, M., Xue, J. M., Yan, K. L., Xiang, T., Sun, S. D. & Zhao, C. S. Heparin-like surface modification of polyethersulfone membrane and its biocompatibility. J. Colloid Interface Sci. 386, 428–440 (2012).

Wang, L. R., Qin, H., Nie, S. Q., Sun, S. D., Ran, F. & Zhao, C. S. Direct synthesis of heparin-like poly (ether sulfone) polymer and its blood compatibility. Acta Biomater. 9, 8851–8863 (2013).

Yue, W. W., Xiang, T., Zhao, W. F., Sun, S. D. & Zhao, C. S. Preparation and characterization of pH-sensitive polyethersulfone membranes blended with poly (methyl methacrylate-co-maleic anhydride) copolymer. Sep. Sci. Technol. 43, 1941–1953 (2013).

Li, L. L., Yin, Z. H., Li, F. L., Xiang, T., Chen, Y. & Zhao, C. S. Preparation and characterization of poly (acrylonitrile-acrylic acid-N-vinyl pyrrolidinone) terpolymer blended polyethersulfone membranes. J. Membr. Sci. 349, 56–64 (2010).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51173119 and 51225303) and the Programme of Introducing Talents of Discipline to Universities (B13040). We should also thank our laboratory members for their generous help and gratefully acknowledge the help of Ms. Hui. Wang.

Author information

Authors and Affiliations

Contributions

T.X. and C.-S.Z. conceived and designed the study. C.-S.Z. supervised the research. T.X., L.-R.W. and L.M. performed membranes preparation and characterization experiments. Z.-Y.H., R.W., C.C., Y.X. and H.Q. performed ultrafiltration experiments, clotting time and antibacterial measurements. All authors discussed the results and contributed to the data interpretation. T.X. and C.-S.Z. wrote the manuscript and all authors commented on the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary Information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License. The images in this article are included in the article's Creative Commons license, unless indicated otherwise in the image credit; if the image is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the image. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Xiang, T., Wang, LR., Ma, L. et al. From Commodity Polymers to Functional Polymers. Sci Rep 4, 4604 (2014). https://doi.org/10.1038/srep04604

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep04604

This article is cited by

-

Functional polyethersulfone particles for the removal of bilirubin

Journal of Materials Science: Materials in Medicine (2016)

-

Hemocompatibility improvement of perfusion-decellularized clinical-scale liver scaffold through heparin immobilization

Scientific Reports (2015)

-

Antimicrobial nano-silver non-woven polyethylene terephthalate fabric via an atmospheric pressure plasma deposition process

Scientific Reports (2015)

), PES/PSBMA-2% (b,

), PES/PSBMA-2% (b,  ), PES/PSBMA-4% (c,

), PES/PSBMA-4% (c,  ) and PES/PSBMA-6% (d,

) and PES/PSBMA-6% (d,  ).

).