Abstract

The structures and properties of rhenium nitrides are studied with density function based first principle method. New candidate ground states or high-pressure phases at Re:N ratios of 3:2, 1:3 and 1:4 are identified via a series of evolutionary structure searches. We find that the 3D polyhedral stacking with strong covalent N-N and Re-N bonding could stabilize Re nitrides to form nitrogen rich phases, meanwhile, remarkably improve the mechanical performance than that of sub-nitrides, as Re3N, Re2N and Re3N2. By evaluating the trends of the crystal configuration, electronic structure, elastic properties and hardness as a function of the N concentration, we proves that the N content is the key factor affecting the metallicity and hardness of Re nitrides.

Similar content being viewed by others

Introduction

The combination of electron-rich 4d and 5d transition metals (TM) with light covalent-bond forming elements (LE) like B, C, N and O has been proved to be an effective way to design novel superhard material over the past decade1,2,3. The idea is that the collaboration of TM's high electron concentration (EC) and the directional bonding formed by strong hybridizations between TM d electrons and LE s, p electrons can effectively withstand both elastic and plastic deformations. With this philosophy, compounds such as OsB24, ReB25, PtN26,7, IrN27,8, OsN28 and PdN29 were successfully designed. All of them are promising candidates for superhard and fracture-resistant materials with the elastic modulus comparable to diamond and c-BN. Recently, two Re sub-nitrides Re3N (SG P-6m2) and Re2N (SG P63/mmc) were synthesized by Friedrich et al.10 at moderate pressures (13–20 GPa) and temperatures (1600–2400 K). The ultra-high bulk modulus of > 400 GPa made them novel ultra-incompressible materials10,11,12,13,14,15,16,17. However, independent theoretical works by Zhang et al.18 and Zang et al.19 proved that the relatively lower ideal tensile strengths inherently limit the application of Re3N and Re2N as superhard material. This discrepancy tells that the small compressibility is not equal to high hardness20 and the high EC of Re sub-nitrides which is responsible for their low compressibility should actually go against the directional bonding. The Re:N stoichiometry may be the key to understand the competition between the EC and the directional bonding. And recent experimental and theoretical attempts to design N-rich Re nitrides are the subjects of intensive interest. Zhao et al.21 and Wang et al.22 proposed that Re mononitride forms in wurtzite-type, NbO-type and NiAs-type structures, respectively. Besides, orthorhombic (SG Pbcn) and tetragonal (SG P4/mmm) Re dinitrides (denoted as orth-ReN2 and tetr-ReN2) with high bulk and shear modulus has been predicted theoretically23,24,25. Recently, Kawamura et al.26 synthesized the MoS2-type ReN2 with metathesis reaction. However, the MoS2-type ReN2 with a weak bulk modulus is less stable according to the calculations of Wang et al.27 and a monoclinic structure (SG C2/m) was proposed. In addition, the hypothetical ReP4-type ReN4 with high computational hardness has also been predicted by Zhao et al.28 and Aydin et al.29.

Despite the substantial amount of works focused on Re nitrides. There are still two questions to be answered. Firstly, the multiple oxidation states of Re promise the emergence of Re-N phases at wide stoichiometries and pressures. Therefore a comprehensive study to update the Re-N phase diagram toward different Re/N ratios and pressures, especially in the N-rich side, is necessary. Secondly, the effect of the N concentration on the mechanical behavior of Re nitrides and relevant mechanism are still unclear. To address these issues, we employ a series of evolutionary structure searches to reconstruct the low-T Re-N phase diagram at moderate pressures of 0–100 GPa. New stable phases for the known Re:N ratios and new stoichiometries were updated and established. The trends of the crystal structure, electronic transition and mechanical performance of Re nitrides as a function of N concentration are compared based on the updated full-scale Re-N phase diagram. The results show that the metallicity and hardness of Re nitrides can be correlated to the N content and N-rich Re nitrides are better candidates for superhard materials due to the strong 3D covalent structural networks.

Results and discussion

The global stability of Re nitrides can be quantified by constructing the thermodynamic convex hull within considered pressures, which is defined as the average atom formation enthalpy of the most stable phases at each composition: ΔH = H(RexNy) – xH(Re) – yH(N2)/2. Any structure with the enthalpy lies on the convex hull is considered to be thermodynamically stable and synthesizable experimentally30,31,32. To give a more realistic prediction, both the experimental33 and computational34,35 high-P (low-T) phase orders of nitrogen were adopted (the ζ-N2 was replaced by ε-N2 in the calculations due to its structural uncertainty). The formation energy Ef of predicted Re nitrides can be calculated in the same way, listed in Table 1. The high-pressure convex hull and pressure-composition phase diagram of Re nitrides are depicted in Figure 1 and Figure 2. We present a rich phase content of Re nitrides toward different Re:N ratios and pressures. Particularly, three stable phases denoted as P-6m2-Re3N2, Imm2-ReN3 and Cmmm-ReN4, beside the well-known Re3N, Re2N sub-nitrides and N-rich ReN2, are proposed here as the complements to the Re-N phase diagram. It follows that the formation of Re nitrides, especially in the N-rich side, will be endothermic processes at absolute 0 K and 0 GPa due to their positive formation energies toward the thermodynamic summation of Re and α-N2. For Re sub-nitrides, Re3N is stable at whole considered pressures while Re2N is thermodynamically stable only at high pressures, which is accord with the experimental results of Friedrich et al.10 and make our thermodynamic calculations reliable. In addition to the experimental sub-nitrides, our structure searches establish the ground state of new Re3N2 stoichiometry for the first time (denoted as P-6m2-Re3N2), which is thermodynamically stable up to 40.0 GPa as shown in Figure 1 and Figure 2. For the N-rich side, structure searching confirms that the C2/m-ReN2 proposed by Wang et al.27 is the most stable phase and can be synthesized at the pressures of above 7.4 GPa. The previous orth-ReN2, tetr-ReN2 and MoS2-type ReN226 become metastable phases during the considered pressures. With further increasing the N concentration, a new stable structure (denoted as Imm2-ReN3) with extended Re:N ratio of 1:3 can be synthesized at wide pressures of 38.3–100 GPa (see Figure 2 (a)). And for Re tetranitrides, the proposed Cmmm-ReN4 is stable at elevated pressures of above 68.2 GPa, which can be viewed as the limit of high N content phase of the predicted 0–100 GPa Re-N phase diagram. Note that the hypothetical ReP4-ReN4 predicted by Zhao et al.28 and Aydin et al.29 should also be a metastable phase and can hardly be synthesized (see Figure 1 (c)). The adoption of the computational high-P phase order of nitrogen34,35 gives consistent phase diagram of Re nitrides, displayed in Figure 2 (b), except that the stable pressures of Imm2-ReN3 and Cmmm-ReN4 have been raised to 39.5 and 89.8 GPa, respectively.

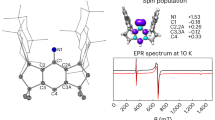

The crystal structures of Re nitrides are schematically showed in Figure 3. The mechanical and dynamical stabilities are examined by calculating the elastic constants (see Supplementary Table S1 online) and phonon dispersions (see Supplementary Figure S1 online), all proposed phases are mechanically stable at 0 GPa with the elastic constants meet the Born-Huang stability criteria36. Besides, the P-6m2-Re3N2 is dynamically stable at 0 GPa. And N-rich C2/m-ReN2 and Imm2-ReN3 are tested to be dynamically stable from 0 GPa to their synthetic pressures, which means that they are quenchable to the ambient condition. The Cmmm-ReN4 is dynamically stable at high pressures (50–100 GPa). According to Figure 3, a unique structural transition induced by increasing N content can be clearly revealed. The Re-Re-N-Re, Re-N-Re and Re-Re-N-N-Re lamellar stacking orders of Re3N, Re2N and Re3N2 sub-nitrides has been broken and transformed into intriguing polyhedral stacking configurations as in C2/m-ReN2, Imm2-ReN3 and Cmmm-ReN4. Among them, the structure of Re3N2 is special since it can be viewed as the substitution of the isolated N with N2 dimer in the configuration of Re3N. This reveals that the segregation of Re layers by N bilayer can stabilize Re nitride to low energy and also weak metallicity (see the following electronic structure discussions). With this idea, an analogous structure can be built for ReN that is by substituting the N with N2 dimer in Re2N along the c-axes. Along with slightly stagger of the neighbouring two Re layers, it results in R-3m-ReN, which is more stable than the wurtzite-ReN, NbO-ReN and NiAs-ReN proposed by Zhao et al.21 and Wang et al.22 (see Figure 1 (a)) and can easily be obtained by the 1:1 fixed Re:N ratio evolutionary structure searches. However, the lamellar order with a growing number of the vertical N2 dimers destabilize Re nitride. The R-3m-ReN is metastable and will decompose into Re3N2 and ReN2 as shown in Figure 1. Besides, the introduction of N2 dimer can lower the crystal density and results in large volume phases. The PV works will sacrifice the enthalpies markedly, which is responsible for the instability of Re3N2 at high pressures. The polyhedral stacking configuration can be an effective way to stable Re nitride and forms in dense N-rich phases. For C2/m-ReN2, the stacking consists of the corner or edge shared ReN7 decahedrons and also bonded with N-N connections according to Figure 3 (e). With an additional N into the lattice, the stacking for Imm2-ReN3 consists of more regular ReN7 octahedrons with the connections of the special tri-nitrogen units (see Figure 3 (f)). As to the high-pressure phase Cmmm-ReN4, the novel ReN8 cubic box can actually be formed due to the coordination number of Re changing from 7 to 8. The parallel ~1.40 Å N-N bonds (0 GPa) in C2/m-ReN2, Imm2-ReN3 and Cmmm-ReN4 represent the typical single N-N bond lengths in PM nitrides, e.g., 1.41 Å for PtN2, 1.43 Å for OsN2 and 1.42 Å for IrN2, therefore we can draw the conclusion that N-N forms in single bond since the bond-length similarity within a related bonding scheme37. The common polyhedral stacking configurations of N-rich Re nitrides is a prerequisite for superhard since it can avoid the direct Re-Re interactions and the structural networks can be constructed primarily by Re-N and N-N covalent bonds. The space group, calculated equilibrium lattice parameters and the unit cell volumes of rhenium nitrides with various stoichiometries are listed in Table 1. Our calculated lattice parameters of Re, Re3N, Re2N and C2/m-ReN2 are all in good accordance with previous studies10,18,27,38.

Crystal structures of Re nitrides.

(a) Re; (b) Re3N; (c) Re2N; (d) P-6m2-Re3N2: Re1 atoms occupy the 1f (0.6667, 0.3333, 0.5), Re2 atoms occupy the 2h (0.3333, 0.6667, 0.2361) and N atoms occupy the 2i (0.6667, 0.3333, 0.0841) positions; (e) C2/m-ReN2; (f) Imm2-ReN3: Re atoms occupy the 2b (0.5, 0, 0.3466), N1 atoms occupy the 4c (0.21, 0.5, 0.2455) and N2 atoms occupy the 2b (0, 0.5, 0.4123) positions; and (g) Cmmm-ReN4 (at 50 GPa): Re atoms occupy the 2b (0, 0.5, 0), while N atoms occupy the 8q (0.8401, 0.1927, 0.5) positions. Large and small balls denote Re and N atoms, respectively.

The updated full-scale Re-N phase diagram allows us to evaluate the trend of the mechanical performance of Re nitrides as the function of N concentration and correlate it with the structural and electronic transitions. The calculated bulk modulus (B), shear modulus (G), Young's modulus (E), Poisson's ratios (ν), densities (ρ) and hardness (HV) of Re nitrides at different N concentrations are depicted in Figure 4 and Table 2 (for comparability, the elastic data of the high-P phase Cmmm-ReN4 in Figure 4 are achieved at 0 GPa), while the electronic density of states (DOS) are showed in Figure 5. Re nitrides have similar metallic bonding features owing to the finite DOS at the Fermi level (EF), which originate mostly from 5d electrons of Re. According to Figure 4 (a) and (e), the high N content in the crystal can decline the bulk modulus and densities markedly, which heralds the decrease of the incompressibility and EC of N-rich Re nitrides. This is accords with the reducing of the metallicity, i.e., the DOS at the Fermi level (N(EF)), of Re nitrides at elevated N concentrations. Here, we should note that the Imm2-ReN3 with the lowest B possess the N(EF) minimum of ~0.11 eV/atom (see Figure 5). On the other hand, a parallel increasement of shear modulus, Young's modulus and a reduction of Poisson's ratios can be clearly revealed with increasing N contents, as shown in Figure 5 (b), (c) and (d). The unsmooth change of the G, E and ν between the Re3N, Re2N and Re3N2 sub-nitrides can be attributed to the discontinuity of the C12 and C13 elastic constants (see Supplementary Table S1 online), which relate to the Poisson effect in the hexagonal structures. According to Table 2, the calculated mean value of the G and E for N-rich C2/m-ReN2, Imm2-ReN3 and Cmmm-ReN4 are about 46 and 86 GPa respectively higher than that of Re and sub-nitrides. In addition, the Poisson's ratios of Imm2-ReN3 and Cmmm-ReN4 have been dropped down from the typically delocalized metals (~0.3) to the level of strong directional covalent materials (~0.2). The reinforcement of the N-rich Re nitrides has its own origin and can be attributed to the enhanced hybridizations between N 2p and Re 5d electronic states (i.e., in the bonding states of −5 to 0 eV below the Fermi level) as shown in Figure 5. Therefore, we can conclude that the primary contribution of the high N content to N-rich Re nitrides is that it facilitates more p electrons involved in bonding, thus can translate the material from high EC strong metal sub-nitrides to the strong covalent N-rich nitrides with enhanced directional bondings. These results suggest that the N content is a key factor to influence the hardness of Re nitrides and the hardness of C2/m-ReN2, Imm2-ReN3 and Cmmm-ReN4 should be far higher than that of Re3N, Re2N and Re3N2 sub-nitrides.

Elastic properties of Re nitrides at 0 GPa.

Calculated (a) bulk modulus B (GPa), (b) shear modulus G (GPa), (c) Young's modulus E (GPa), (d) Poisson's ratio ν, (e) density ρ (g/cm3) and (f) Vickers hardness HV (GPa) of Re nitrides as a function of N concentration. The neighboring data points were connected by B-Spline to evaluate the changing trends. N-rich stoichiometries are highlighted by cyan shadows.

The hardness of Re nitrides as a function of N concentration is estimated by recently proposed empirical model39 with the formula HV = 2.0(k2G)0.585-3.0, as shown in Figure 4 (f). It can be seen that the high N content promote the hardness of Re nitrides according with the changes of G, E and ν as discussed above. On the other hand, the strong covalency of the bonding in N-rich Re nitrides allows us to evaluate their intrinsic hardness by microscopic hardness models40,41,42,43. Here we use the method proposed by Gao et al.40 and its further development which includes a small metallic component of chemical bond and considering the orbital form of s-p or s-p-d44. The hardness of the μ-type particular bond in metallic and s-p-d hybridized crystals is written as40,44,45:

where A0 is the proportionality coefficient takes 350 and 1051 for the pure covalent N-N and polar covalent Re-N bonds, respectively. Ne is the valence electron density of the bond, d is the bond length. The Phillips iconicity fi of chemical bond is calculated by the Mulliken population46. The fm in Equation (1) is a factor introduced to account for the metallicity effect on hardness and can be calculated as fm = kBTDF/ne, where ne is the total number of valence electrons in the unit cell, DF is the density of electronic states at the Fermi level44. The total hardness can be expressed as the average of all bond hardnesses:

where nμ is the number of bond of type μ composing the actual complex crystal. The detailed bond parameters of hardness calculations can be found as Supplementary Table S2 online. The hardness of C2/m-ReN2 and Imm2-ReN3 at ambient condition are evaluated as 38.4 and 44.4 GPa respectively, which could be potential candidates to be superhard materials.

Conclusion

In summary, we have systematically explored the structures and properties of Re nitrides at wide stoichiometries and pressures with ab initio evolutionary method. We corrected the stable structure of ReN4 to the phase with the Cmmm symmetry and new stoichiometries of P-6m2-Re3N2 and Imm2-ReN3 are established for possible synthesis. It is found that high-pressure can be an effective approach to stable Re nitrides. The C2/m-ReN2, Imm2-ReN3 and Cmmm-ReN4 can be synthesized at pressures above 7.4, 38.3 and 68.2 GPa, respectively. And C2/m-ReN2 and Imm2-ReN3 are retainable to ambient condition. A good relation between the mechanical behavior and N concentration of Re nitrides was established by detailed evaluating the variations of the crystal configurations, electronic structures, elastic properties and computational hardness. Our results show that the high N content benefits the formation of the covalent 3D polyhedral stacking structure and can effectively avoid the weak Re-Re metal interactions, which result in the reinforcement of the Re nitrides from ultra-incompressible sub-nitrides to superhard N-rich materials. These results are expected to stimulate the exploration and discovery of new material and the approach of harden Re nitride by high LE content may also applicable to other TM compounds.

Methods

Evolutionary structure searches are performed with USPEX code47,48,49. Structure cells with Re:N ratios of 3:1, 2:1, 1.5:1, 1:1, 1:1.5, 1:2, 1:2.5, 1:3, 1:4, 1:5 and 1:6 within 2 and 4 formula units (f.u.) are implemented at 0, 30, 60 and 100 GPa, respectively. To update a full-scale Re-N phase diagram, moreover, variable-composition structure predictions50 are also performed at 0, 50 and 100 GPa, respectively. The first generation of structures was produced randomly and the succeeding generations were obtained by applying heredity (60%), atom transmutation (10%) and lattice mutation (30%) operations. Each structure was fully relaxed to an energy minimum at different pressures with the Vienna ab initio simulation package (VASP)51. The projector augmented waves (PAW) method52 within the generalized gradient approximation (GGA) of Perdew-Burke-Ernzerhof (PBE)53 was adopted. By performing accurate convergence tests, we choose a cutoff of 520 eV for the wave function expansion into plane waves and a k-mesh of 0.03 × 2π Å−1 within the Monkhorst-Pack scheme for sample the Brillouin zone, which ensures the error bars of total energies are less than 1 meV/atom. Besides, all forces on atoms were converged to less than 1 meV/Å and the total stress tensor was reduced to the order of 0.01 GPa. Phonon curves were calculated by the direct supercell method with the forces obtained by the Hellmann-Feynman theorem54,55. Elastic constants were calculated by the strain-stress method, while bulk modulus B, shear modulus G, Young's modulus E and Poisson's ratio ν are derived from the Voigt-Reuss-Hill averaging scheme56. The theoretical Vickers hardness was estimated by using the Chen's model39 and the Gao's model40, respectively. For the latter, the Mulliken bond population is calculated with the CASTEP code57,58. The ultra-soft Vanderbilt pseudopotential (USPP)59 with PBE-GGA is chosen. The cutoff energy and k-mesh are same as the setting in VASP calculations.

References

Brazhkin, V. V., Lyapin, A. G. & Hemley, R. J. Harder than diamond: Dreams and reality. Philos. Mag. A 82, 231–253 (2002).

Kaner, R. B., Gilman, J. J. & Tolbert, S. H. Designing Superhard Materials. Science 308, 1268–1269 (2005).

Chung, H.-Y. et al. Synthesis of Ultra-Incompressible Superhard Rhenium Diboride at Ambient Pressure. Science 316, 436–439 (20076).

Cumberland, R. W. et al. Osmium diboride, an ultra-incompressible, hard material. J. Am. Chem. Soc. 127, 7264–7265 (2005).

Chung, H. Y. et al. Synthesis of ultra-incompressible superhard rhenium diboride at ambient pressure. Science 316, 436–439 (2007).

Gregoryanz, E. et al. Synthesis and characterization of a binary noble metal nitride. Nat. Mater. 3, 294–297 (2004).

Crowhurst, J. C. et al. Synthesis and Characterization of the Nitrides of Platinum and Iridium. Science 311, 1275–1278 (2006).

Young, A. F. et al. Synthesis of Novel Transition Metal Nitrides IrN2 and OsN2 . Phys. Rev. Lett. 96, 155501 (2006).

Crowhurst, J. C. et al. Synthesis and characterization of nitrides of iridium and palladium. J. Mater. Res. 23, 1–5 (2008).

Friedrich, A. et al. Novel Rhenium Nitrides. Phys. Rev. Lett. 105, 085504 (2010).

Friedrich, A., Winkler, B., Refson, K. & Milman, V. Vibrational properties of Re3N from experiment and theory. Phys. Rev. B 82, 224106 (2010).

Bannikov, V. V., Shein, I. R. & Ivanovskii, A. L. Elastic and electronic properties of hexagonal rhenium sub-nitrides Re3N and Re2N in comparison with hcp-Re and wurtzite-like rhenium mononitride ReN. Phys. Status. Solidi. B 248, 1369–1374 (2011).

Hao, X. F. et al. Elastic properties of novel rhenium nitrides from first principles. Phys. Status. Solidi. B 248, 2107–2111 (2011).

Deligoz, E., Colakoglu, K., Ozisik, H. B. & Ciftci, Y. O. Vibrational properties of Re2N and Re3N compounds. Solid State Commun. 151, 1122–1127 (2011).

Liang, Y. C., Yuan, X. & Zhang, W. Q. Ultrastiffness and metallicity of rhenium nitrides. J. Appl. Phys. 109, 053501 (2011).

Miao, N. H., Sa, B. S., Zhou, J., Sun, Z. M. & Ahuja, R. Mechanical properties and electronic structure of the incompressible rhenium carbides and nitrides: A first-principles study. Solid State Commun. 151, 1842–1845 (2011).

Du, X. P., Lo, V. C. & Wang, Y. X. The Effect of Structure and Phase Transformation on the Mechanical Properties of Re2N and the Stability of Mn2N. J. Comput. Chem. 33, 18–24 (2012).

Zhang, R. F., Lin, Z. J., Mao, H. K. & Zhao, Y. S. Thermodynamic stability and unusual strength of ultra-incompressible rhenium nitrides. Phys. Rev. B 83, 060101 (2011).

Zang, C., Sun, H., Tse, J. S. & Chen, C. Indentation strength of ultraincompressible rhenium boride, carbide and nitride from first-principles calculations. Phys. Rev. B 86, 014108 (2012).

Gu, Q., Krauss, G. & Steurer, W. Transition Metal Borides: Superhard versus Ultra-incompressible. Adv. Mater. 20, 3620–3626 (2008).

Zhao, E. J. & Wu, Z. J. Electronic and mechanical properties of 5d transition metal mononitrides via first principles. J. Solid State Chem. 181, 2814–2827 (2008).

Wang, Y. et al. Structural stability, phase transition and mechanical and electronic properties of transition metal nitrides MN (M = Tc, Re, Os and Ir): First-principles calculations. Comput. Mater. Sci. 56, 116–121 (2012).

Zhao, E. & Wu, Z. J. Structural, electronic and mechanical properties of ReN2 from first principles. Comput. Mater. Sci. 44, 531–535 (2008).

Li, Y. L. & Zeng, Z. New potential super-incompressible phase of ReN2 . Chem. Phys. Lett. 474, 93–96 (2009).

Du, X. P., Wang, Y. X. & Lo, V. C. Investigation of tetragonal ReN2 and WN2 with high shear moduli from first-principles calculations. Phys. Lett. A 374, 2569–2574 (2010).

Kawamura, F., Yusa, H. & Taniguchi, T. Synthesis of rhenium nitride crystals with MoS2 structure. Appl. Phys. Lett. 100, 251910 (2012).

Wang, Y. C., Yao, T. K., Yao, J. L., Zhang, J. W. & Gou, H. Y. Does the real ReN2 have the MoS2 structure? Phys. Chem. Chem. Phys. 15, 183–187 (2013).

Zhao, W. J., Xu, H. B. & Wang, Y. X. Prediction of a superhard material of ReN4 with a high shear modulus. Chin. Phys. B. 19 (2010).

Aydin, S., Ciftci, Y. O. & Tatar, A. Superhard transition metal tetranitrides: XN4 (X = Re, Os, W). J. Mater. Res. 27, 1705–1715 (2012).

Ghosh, G., van de Walle, A. & Asta, M. First-principles calculations of the structural and thermodynamic properties of bcc, fcc and hcp solid solutions in the Al-TM (TM = Ti, Zr and Hf) systems: A comparison of cluster expansion and supercell methods. Acta Mater. 56, 3202–3221 (2008).

Zhang, X. W., Trimarchi, G. & Zunger, A. Possible pitfalls in theoretical determination of ground-state crystal structures: The case of platinum nitride. Phys. Rev. B 79, 092102 (2009).

Zhang, M. G., Wang, H., Wang, H. B., Cui, T. & Ma, Y. M. Structural Modifications and Mechanical Properties of Molybdenum Borides from First Principles. J. Phys. Chem. C 114, 6722–6725 (2010).

Gregoryanz, E. et al. High P-T transformations of nitrogen to 170GPa. J. Chem. Phys. 126, 184505 (2007).

Pickard, C. J. & Needs, R. J. High-Pressure Phases of Nitrogen. Phys. Rev. Lett. 102, 125702 (2009).

Wang, X. et al. Cagelike Diamondoid Nitrogen at High Pressures. Phys. Rev. Lett. 109, 175502 (2012).

Wu, Z. J. et al. Crystal structures and elastic properties of superhard IrN2 and IrN3 from first principles. Phys. Rev. B 76, 054115 (2007).

Wessel, M. & Dronskowski, R. Nature of N-N Bonding within High-Pressure Noble-Metal Pernitrides and the Prediction of Lanthanum Pernitride. J. Am. Chem. Soc. 132, 2421–2429 (2010).

Kittel, C. Introduction to solid state physics. 4th edn, (Wiley, 1971).

Chen, X. Q., Niu, H., Li, D. & Li, Y. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics 19, 1275–1281 (2011).

Gao, F. M. et al. Hardness of covalent crystals. Phys. Rev. Lett. 91, 015502 (2003).

Šimůnek, A. & Vackář, J. Hardness of Covalent and Ionic Crystals: First-Principle Calculations. Phys. Rev. Lett. 96, 085501 (2006).

Li, K., Wang, X., Zhang, F. & Xue, D. Electronegativity Identification of Novel Superhard Materials. Phys. Rev. Lett. 100, 235504 (2008).

Lyakhov, A. O. & Oganov, A. R. Evolutionary search for superhard materials: Methodology and applications to forms of carbon and TiO2 . Phys. Rev. B 84, 092103 (2011).

Guo, X. et al. Hardness of covalent compounds: Roles of metallic component and d valence electrons. J. Appl. Phys. 104, 023503–023507 (2008).

Tian, Y., Xu, B. & Zhao, Z. Microscopic theory of hardness and design of novel superhard crystals. Int. J. Refract. Met. Hard Mater. 33, 93–106 (2012).

He, J., Wu, E., Wang, H., Liu, R. & Tian, Y. Ionicities of Boron-Boron Bonds in B12 Icosahedra. Phys. Rev. Lett. 94, 015504 (2005).

Oganov, A. R. & Glass, C. W. Crystal structure prediction using ab initio evolutionary techniques: Principles and applications. J. Chem. Phys. 124, 244704 (2006).

Oganov, A. R., Lyakhov, A. O. & Valle, M. How Evolutionary Crystal Structure Prediction Works—and Why. Acc. Chem. Res. 44, 227–237 (2011).

Lyakhov, A. O., Oganov, A. R., Stokes, H. T. & Zhu, Q. New developments in evolutionary structure prediction algorithm USPEX. Comput. Phys. Commun. 184, 1172–1182 (2013).

Oganov, A. R., Ma, Y. M., Lyakhov, A. O., Valle, M. & Gatti, C. Evolutionary Crystal Structure Prediction as a Method for the Discovery of Minerals and Materials. Rev. Mineral. Geochem. 71, 271–298 (2010).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59, 1758–1775 (1999).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Togo, A., Oba, F. & Tanaka, I. First-principles calculations of the ferroelastic transition between rutile-type and CaCl2-type SiO2 at high pressures. Phys. Rev. B 78, 134106 (2008).

Togo, A., Oba, F. & Tanaka, I. Transition pathway of CO2 crystals under high pressures. Phys. Rev. B 77, 184101 (2008).

Hill, R. The Elastic Behaviour of a Crystalline Aggregate. Proc. Phys. Soc. London, Sect. A 65, 349 (1952).

Segall, M. D. et al. First-principles simulation: ideas, illustrations and the CASTEP code. J. Phys-Condens. Mat. 14, 2717–2744 (2002).

Segall, M. D., Shah, R., Pickard, C. J. & Payne, M. C. Population analysis of plane-wave electronic structure calculations of bulk materials. Phys. Rev. B 54, 16317–16320 (1996).

Vanderbilt, D. Soft self-consistent pseudopotentials in a generalized eigenvalue formalism. Phys. Rev. B 41, 7892 (1990).

Acknowledgements

This work was supported by the National Basic Research Program of China (No. 2011CB808200), Program for Changjiang Scholars and Innovative Research Team in University (No. IRT1132), National Natural Science Foundation of China (Nos. 51032001, 11074090, 10979001, 51025206) and National Found for Fostering Talents of basic Science (No. J1103202). Parts of calculations were performed in the High Performance Computing Center (HPCC) of Jilin University.

Author information

Authors and Affiliations

Contributions

T.C. initiated the project. Z.Z. performed the first principle calculations and prepared all figures. Z.Z., K.B. and T.C. analyzed the data and wrote the manuscript text. D.L., D.D., F.T., X.J., C.C., X.H. and B.L. reviewed the manuscript.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Electronic supplementary material

Supplementary Information

Supplementary information

Rights and permissions

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License. The images in this article are included in the article's Creative Commons license, unless indicated otherwise in the image credit; if the image is not included under the Creative Commons license, users will need to obtain permission from the license holder in order to reproduce the image. To view a copy of this license, visit http://creativecommons.org/licenses/by-nc-sa/3.0/

About this article

Cite this article

Zhao, Z., Bao, K., Li, D. et al. Nitrogen concentration driving the hardness of rhenium nitrides. Sci Rep 4, 4797 (2014). https://doi.org/10.1038/srep04797

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep04797

This article is cited by

-

Materials synthesis at terapascal static pressures

Nature (2022)

-

Ultra-incompressibility and high energy density of ReN8 with infinite nitrogen chains

Journal of Materials Science (2021)

-

High-pressure synthesis of ultraincompressible hard rhenium nitride pernitride Re2(N2)(N)2 stable at ambient conditions

Nature Communications (2019)

-

Fe-N system at high pressure reveals a compound featuring polymeric nitrogen chains

Nature Communications (2018)

-

Diverse ruthenium nitrides stabilized under pressure: a theoretical prediction

Scientific Reports (2016)