Abstract

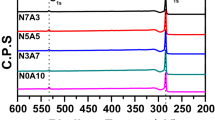

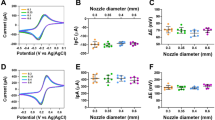

To improve the application of carbon black (CB)-filled polymer composites, we investigated the relationship between the processing parameters, microstructure and electrical properties of injection moldings made from the material. Standard tensile specimens were fabricated under different injection pressures and packing pressures. Up to five layers were removed from the surfaces of the molded specimens to observe the microstructure at different positions within the moldings. Microstructures were observed with a scanning electron microscope, and electrical properties were measured at room temperature with a standard two-terminal direct current (DC) resistor. The results showed that CB particles form the best conductive path at high packing pressures combined with high injection pressures. If the packing pressure is low, the resistivity in the skin zone when loaded by high injection pressures is less than when loaded by low injection pressures, but resistivity increases in the sub-skin zone. We found that the sub-skin zone is a high-resistivity area that can be expanded under the action of higher injection pressures along with lower packing pressures. In contrast to an injection-molded single polymer, an injection–molded, CB-filled polymer composite develops a highly oriented microstructure in the core zone rather than in the skin or sub-skin zones because of the migration of CB particles.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Jiang, X., Bin, Y., Kikyotani, N. & Matsuo, M. Thermal, electrical and mechanical properties of ultra-high molecular weight polypropylene and carbon filler composites. Polym. J. 38, 419–431 (2006).

Mohammed, H., Al-Saleh & Sundararaj, U. An innovative method to reduce percolation threshold of carbon black filled immiscible polymer blends. Composites Part A 39, 284–293 (2008).

Markov, A., Fiedler, B. & Schulte, K. Electrical conductivity of carbon black/fibers filled glass-fiber-reinforced thermoplastic composites. Composites Part A 37, 1390–1395 (2006).

Bayer, R. K., Ezquerra, T. A. & Zachmann, H. G. Conductive PE-carbon black composites by elongational flow injection moulding. J. Mater. Sci. 23, 475–480 (1988).

Konishi, Y. & Cakmak, M. Structural hierarchy developed in injection molding of nylon6/clay/carbon black nanocomposites. Polymer 46, 4811–4826 (2005).

Saleem, A., Frormann, L. & Iqbal, A. Mechanical, thermal and electrical resisitivity properties of thermoplastic composites filled with carbon fibers and carbon particles. J. Polym. Res. 14, 121–127 (2007).

Mucha, M., Marszalek, J. & Fidrych, A. Crystallization of isotactic polypropylene containing carbon black as a filler. Polymer 41, 4137–4142 (2000).

Yui, H., Wu, G., Sano, H., Sumita, M. & Kino, K. Morphology and electrical conductivity of injection-molded polypropylene/carbon black composites with addition of high-density polyethylene. Polymer 47, 3599–3608 (2006).

Li, Y., Wang, S., Zhang, Y. & Zhang, Y. Electrical properties and morphology of polypropylene/epoxy/glass fiber composites filled with carbon black. J. Appl. Polym. Sci. 98, 1142–1149 (2005).

Mather, P. J. & Thomas, K. M. Carbon black/high density polyethylene conducting composite materials. J. Mater. Sci. 32, 1711–1715 (1997).

Sumita, M., Sakata, K., Asai, S., Miyasaka, K. & Nakagawa, H. Dispersion of fillers and the electrical conductivity of polymer blends filled with carbon black. Polym. Bull. 25, 265–271 (1991).

Katada, A., Buys, Y. F., Tominaga, Y., Asai, S. & Sumita, M. Relationship between electrical resistivity and particle dispersion state for carbon black filled poly (ethylene-co-vinyl acetate)/poly (L-lactic acid) blend. Colloid Polym. Sci. 284, 134–141 (2005).

Chougule, V. A. & Zumbrunnen, D. A. In situ assembly using a continuous chaotic advection blending process of electrically conducting networks in carbon black-thermoplastic extrusions. Chem. Eng. Sci. 60, 2459–2467 (2005).

Sumita, M., Sakata, K., Hayakawa, Y., Asai, S. & Miyasaka, K. Double percolation effect on the electrical conductivity of conductive particles filled polymer blends. Colloid Polym. Sci. 270, 134–139 (1992).

Katada, A., Buys, Y. F., Tominaga, Y., Asai, S. & Sumita, M. Resistivity control in the semiconductive region for carbon black filled polymer composites. Colloid Polym. Sci. 283, 367–374 (2005).

Ponomarenko, A. T., Shevchenko, V. G. & Enikolopyan, N. S. Formation processes and properties of conducting polymer composites. Adv. Polym. Sci. 96, 125–147 (1990).

Hong, C.- M., Kim, J. & Jana, S. C. Shear-induced migration of conductive fillers in injection molding. Polym. Eng. Sci. 44, 2101–2109 (2004).

Akcora, P., Liu, H., Kumar, S. K., Moll, J., Li, Y., Benicewicz, B. C., Schadler, L. S., Acehan, D., Panagiotopoulos, A. Z., Pryamitsyn, V., Ganesan, V., Ilavsky, J., Thiyagarajan, P., Colby, R. H. & Douglas, J. F. Anisotropic self-assembly of spherical polymer-grafted nanoparticles. Nat. Mater. 8, 354–359 (2009).

Kono, A., Miyakawa, N. & Kawadai, S. Effect of cooling rate after polymer melting on electrical properties of high-density polyethylene/Ni composites. Polym. J. 42, 587–591 (2010).

Naficy, S. & Garmabi, H. Study of the effective parameters on mechanical and electrical properties of carbon black filled PP/PA6 microfibrillar composites. Compos. Sci. Tech. 67, 3233–3241 (2007).

Acknowledgements

We thank the National Natural Science Foundation of China for financial support (number: 51075120).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Wu, H., Feng, L., Jiang, A. et al. Effect of the processing of injection-molded, carbon black-filled polymer composites on resistivity. Polym J 43, 930–936 (2011). https://doi.org/10.1038/pj.2011.95

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/pj.2011.95