Abstract

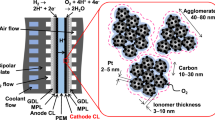

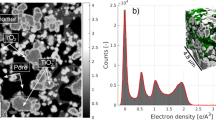

Polymer electrode fuel cells are fabricated by drying a ‘catalyst ink’, that is, a mixture of carbon, ionomers, Pt and water, and it is of particular importance to elucidate the structural evolution of the catalyst ink during its drying process. The structural evolution of catalyst ink was investigated by contrast-variation small-angle neutron scattering. The scattering functions of the catalyst ink at various concentrations were successfully decomposed to the corresponding partial structure factors SCC(q), SPP(q) and SCP(q) for all ink concentrations, where the subscripts C and P denote the carbon and polymer, respectively, and q is the magnitude of the scattering vector. The cross term SCP(q) indicates that the microscopic structure of the catalyst ink retains the carbon agglomerates surrounded by an ionomer shell during the drying process. SCC(q) and SPP(q) indicate that a catalyst ink is formed with carbon agglomerates of core radius of ~42 nm and an ionomer shell of thickness >8 nm. Both the size of the carbon agglomerates and the thickness of the ionomer shells decrease with increasing ink concentration, which is attributed to the exclusion of solvent molecules from the carbon and ionomer agglomerates during the drying process.

Similar content being viewed by others

Log in or create a free account to read this content

Gain free access to this article, as well as selected content from this journal and more on nature.com

or

References

Litster, S. & McLean, G. PEM fuel cell electrodes. J. Power Sources 130, 61–76 (2004).

Uchida, M., Aoyama, Y., Eda, N. & Ohta, A. New preparation method for polymer-electrolyte fuel cells. J. Electrochem. Soc. 142, 463–468 (1995).

Uchida, M., Fukuoka, Y., Yasushi Sugawara, Y., Ohara, H. & Ohta, A. Improved preparation process of very- low-Plati flu rn-loading electrodes for polymer electrolyte fuel cells. J. Electrochem. Soc. 145, 3708–3713 (1998).

Holdcroft, H. Fuel cell catalyst layers: a polymer science perspective. Chem. Mater. 26, 381–393 (2014).

Kim, M.-H., Glinka, C. J., Grot, S. A. & Grot, W. G. SANS study of the effects of water vapor sorption on the nanoscale structure of perfluorinated sulfonic acid (NAFION) membranes. Macromolecules 39, 4775–4787 (2006).

Iwase, H., Koizumi, S., Iikura, H., Matsubayashi, M., Yamaguchi, D., Maekawa, Y. & Hashimoto, T. A combined method of small-angle neutron scattering and neutron radiography to visualize water in an operating fuel cell over a wide length scale from nano to millimeter. Nucl. Inst. Method Phys. Res. A 605, 95–98 (2009).

Sekhon, S. S., Park, J.-S., Baek, J.-S., Yim, S.-D., Yang, T.-H. & Kim, C.-S. Small-angle X-ray scattering study of water free fuel cell membranes containing ionic liquids. Chem. Mater. 22, 803–812 (2010).

He, Q., Suraweera, N. S., Joy, D. C. & Keffer, D. J. Structure of the ionomer film in catalyst layers of proton exchange membrane fuel cells. J. Phys. Chem. C 117, 25305–25316 (2013).

Aldebert, P., Dreyfus, B. & Pineri, M. Small-angle neutron scattering of perfluorosulfonated ionomers in solution. Macromolecules 19, 265102653 (1986).

Gebel, G. Structural evolution of water swollen perfluorosulfonated ionomers from dry membrane to solution. Polymer 41, 5829–5838 (2000).

Gebel, G. & Diat, O. Neutron and X-ray scattering: suitable tools for studying ionomer membranes. Fuel Cells 5, 261–276 (2005).

Gebel, G., Lyonnard, S., Mendil-Jakani, H. & Morin, A. The kinetics of water sorption in Nafion membranes: a small-angle neutron scattering study. J. Phys. Condens. Matter 23 (2011).

Malek, K., Eikerling, M., Wang, Q. P., Navessin, T. C. & Liu, Z. S. Self-organization in catalyst layers of polymer electrolyte fuel cells. J. Phys. Chem. 111, 13627–13634 (2007).

More, K., Borup, R. & Reeves, K. Identifying contributing degradation phenomena in PEM fuel cell membrane electride assemblies via electron microscopy. ECS Trans. 3, 717–733 (2006).

Paul, D. K., Karan, K., Docoslis, A., Giorgi, J. B. & Pearce, J. Characteristics of self-assembled ultrathin Nafion films. Macromolecules 46, 3461–3475 (2013).

Berejnov, V., Susac, D., Stumper, J. & Hitchcock, A. P. 3D chemical mapping of PEM fuel cell cathodes by scanning transmission soft X-ray spectrotomography. ECS Trans. 50, 361–368 (2013).

Shibayama, M., Matsunaga, T., Kusano, T., Amemiya, K., Kobayashi, N. & Yoshida, T. SANS studies on catalyst ink of fuel cell. J. Appl. Polym. Sci. 131, 39842 (2014).

Endo, H., Schwahn, D. & Cölfen, J. On the role of block copolymer additives for calcium carbonate crystallization: Small angle neutron scattering investigation by applying contrast variation. J. Chem. Phys. 120, 9410–9423 (2004).

Miyazaki, S., Endo, H., Karino, T., Haraguchi, K. & Shibayama, M. Gelation mechanism of Poly(N-isopropylacrylamide)-clay nanocomposite gels. Macromolecules 40, 4287–4295 (2007).

Endo, H., Mihailescu, M., Monkenbusch, M., Allgaier, J., Gompper, G., Richter, D., Jakobs, B., Sottmann, T., Strey, R. & Grillo, I. Effect of amphiphilic block copolymers on the structure and phase behavior of oil–water-surfactant mixtures. J. Chem. Phys. 115, 580–600 (2001).

Borue, V. & Erukhimovich, I. A statistical theory of weakly charged polyelectrolytes: fluctuations, equation of state, and microphase separation. Macromolecules 21, 3240–3249 (1988).

Higgins, J. S. & Benoit, H. C. Polymers and Neutron Scattering, (Clarendon Press, Oxford, UK, 1994).

Lee, M., Uchida, M., Yano, H., Tryk, D. A., Uchida, H. & Watanabe, M. New evaluation method for the effectiveness of platinum/carbon electrocatalysts under operating conditions. Electrochim. Acta 55, 8504–8512 (2010).

Soboleva, T., Zhao, X. S., Mallek, K., Xie, Z., Navessin, T. & Holdcroft, S. On the micro-, meso-, and macroporous structures of polymer electrolyte membrane fuel cell catalyst layers. ACS Appl. Mater. Interfaces 2, 375–384 (2010).

Xu, F., Zhang, H. Y., Ilavsky, J., Stanciu, L., Ho, D., Justice, M. J., Petrache, H. I. & Xie, J. Investigation of a catalyst ink dispersion using both ultra-small-angle X-ray scattering and cryogenic TEM. Langmuir 26, 19199–19208 (2010).

Acknowledgements

The SANS experiment was performed by using a 40 m SANS instrument at the High-flux Advanced Neutron Application Reactor (HANARO), Korea Atomic Energy Research Institute (KAERI), Daejeon, South Korea, which was transferred from SANS-U at JRR-3 with the approval of the Institute for Solid State Physics, The University of Tokyo (proposal no. 13596), Japan Atomic Energy Agency, Tokai, Japan. We are grateful to T. W. Kim and Y. S. Han for helpful assistance in the SANS experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kusano, T., Hiroi, T., Amemiya, K. et al. Structural evolution of a catalyst ink for fuel cells during the drying process investigated by CV-SANS. Polym J 47, 546–555 (2015). https://doi.org/10.1038/pj.2015.36

Received:

Revised:

Accepted:

Published:

Issue date:

DOI: https://doi.org/10.1038/pj.2015.36

This article is cited by

-

Recent Advances on PEM Fuel Cells: From Key Materials to Membrane Electrode Assembly

Electrochemical Energy Reviews (2023)

-

Sample-efficient parameter exploration of the powder film drying process using experiment-based Bayesian optimization

Scientific Reports (2022)

-

The Controllable Design of Catalyst Inks to Enhance PEMFC Performance: A Review

Electrochemical Energy Reviews (2021)